Grouting construction process using GIN grouting method

A construction technology and grouting pump technology, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of water seepage in filling holes and affect construction quality, and achieve low water separation rate, good anti-seepage effect, and construction technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

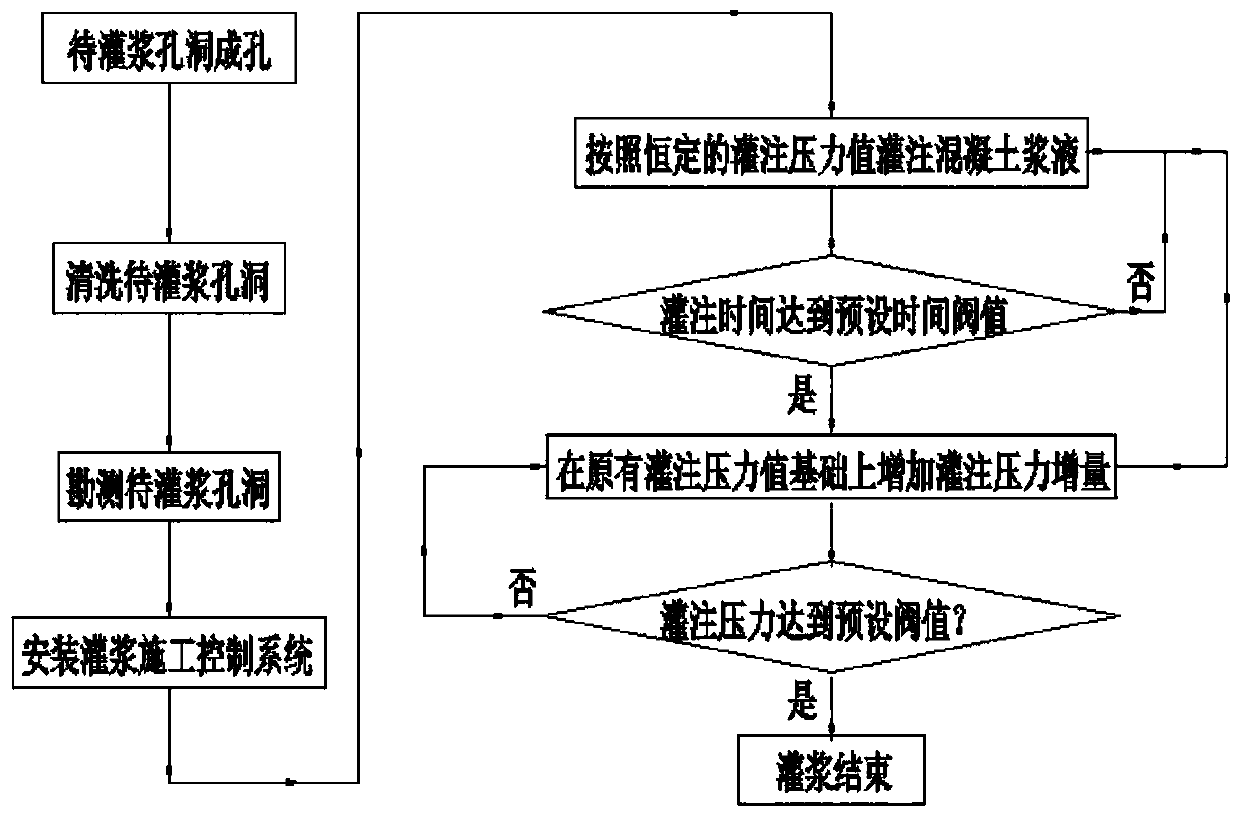

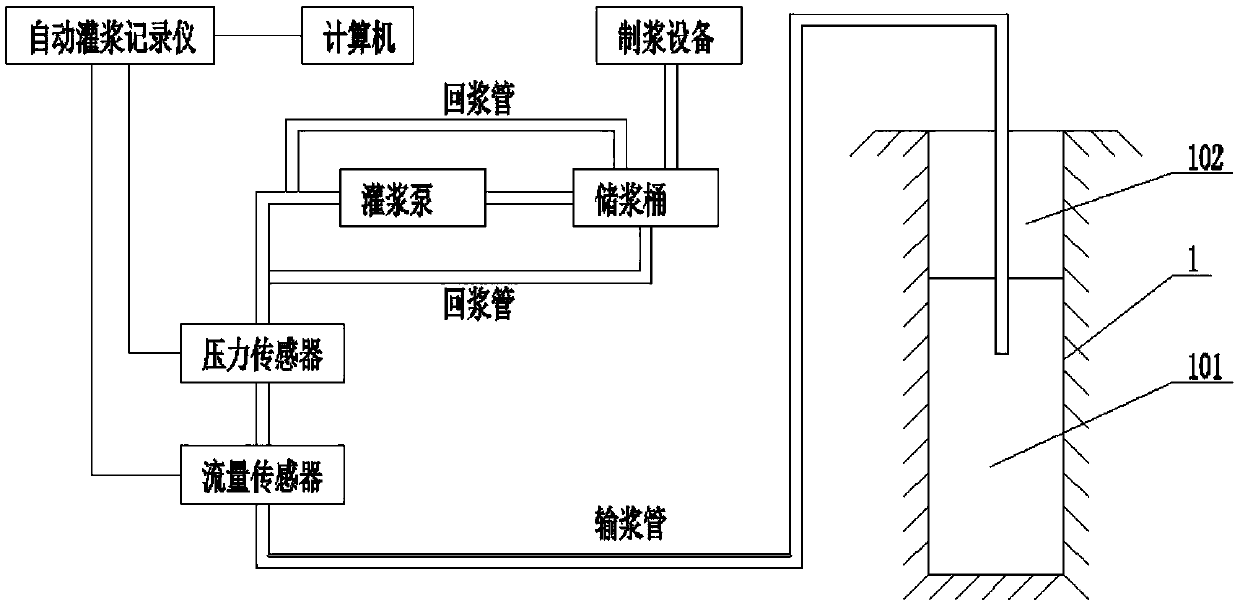

[0029] Such as figure 1 , figure 2 Shown, the present invention provides a kind of grouting construction technology that uses GIN grouting method, comprises the following steps:

[0030] Step 1: Forming the hole to be grouted: On the ground or the building object, use a drilling rig to drill into the building object to obtain the hole to be grouted; further, the nominal diameter of the drill bit of the drilling rig is 75mm to 90mm.

[0031] Step 2: Clean the hole to be grouted: wash the hole to be grouted, and remove the impurities on the inner wall and bottom of the hole to be grouted;

[0032] Step 3: Investigate the hole to be grouted: survey the hole to be grouted, measure the depth of the hole to be grouted, use the lower part of the hole to be grouted as the grouting section, and the upper part of the hole to be grouted as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com