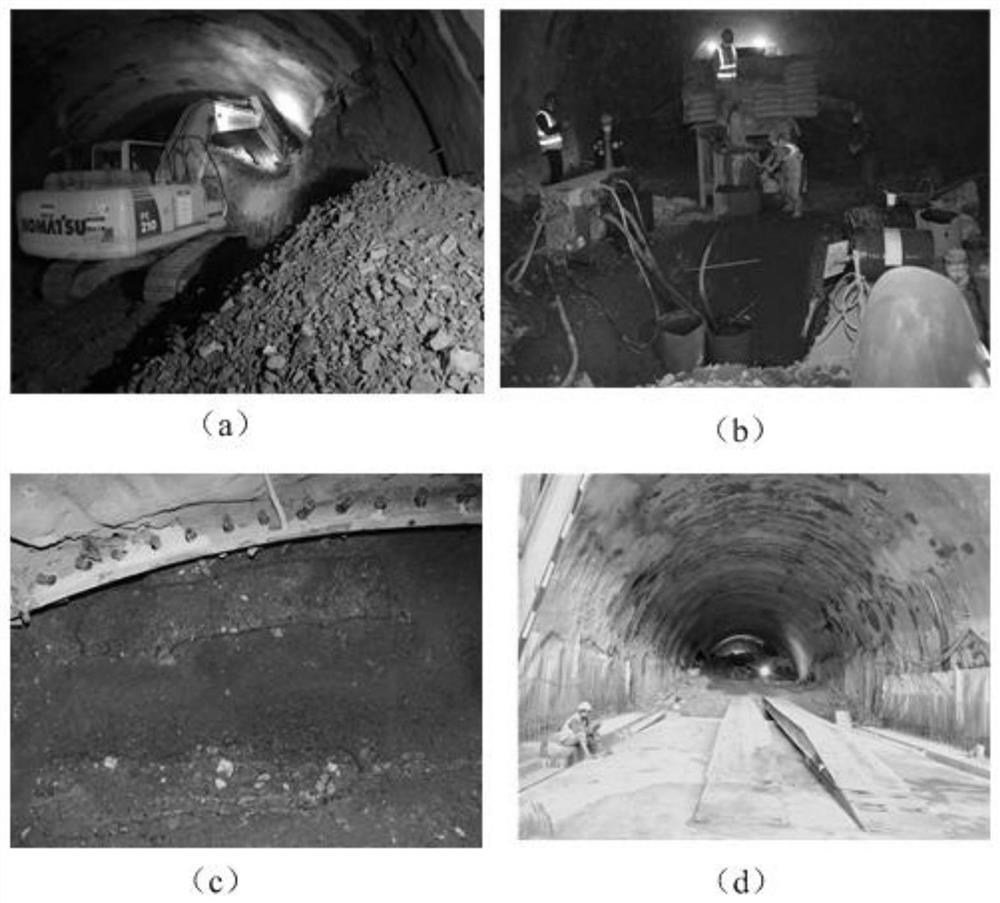

Controllable grouting material for advanced small pipe for water-rich accumulation body stratum tunnel and preparation method thereof

A technology of advanced small conduit and grouting material, which is applied in the field of advanced small conduit grouting material and its preparation in water-rich accumulation formation tunnels, which can solve the problems of slow setting time, poor slurry stability, and uncontrollable grouting diffusion range, etc. Achieve the effects of increasing strength and yield stress, increasing the degree of crosslinking, and shortening the initial setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A controllable grouting material for the advanced small conduit of the water-rich deposit formation tunnel of the present invention, the grouting material is composed of cement slurry and additives, the cement slurry is made of cement (42.5# ordinary Portland cement, and the cement passes through 80 μm square holes The sieve residue of the sieve is not more than 5%) and ordinary engineering water according to the water-cement ratio of 1:1, wherein the additives are polyethylene glycol PEG-800 solid, sodium hydroxide (100-200 mesh), Silica sand (silicon dioxide content ≥ 99.5) and calcium lignosulfonate, polyethylene glycol PEG-800 in an amount of 3% of the cement mass, sodium hydroxide in an amount of 2% of the cement mass, silica sand The addition amount is 6.5% of the cement mass, and the addition amount of calcium lignosulfonate is 0.3% of the cement mass.

[0038] The preparation method of the advanced small conduit controllable grouting material of the water-rich a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com