Patents

Literature

181results about How to "Moderate fluidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

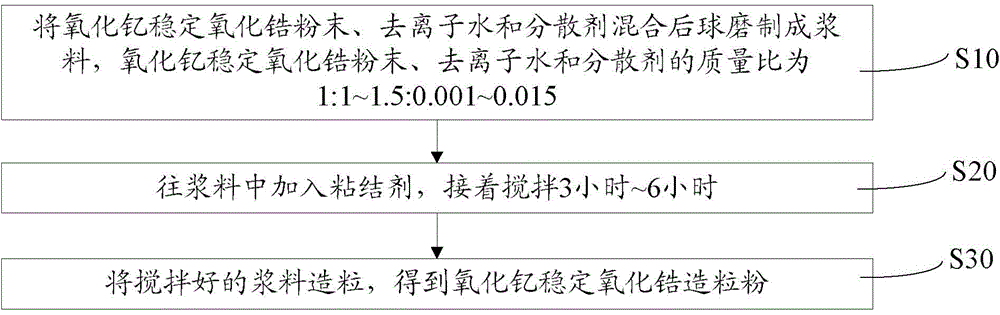

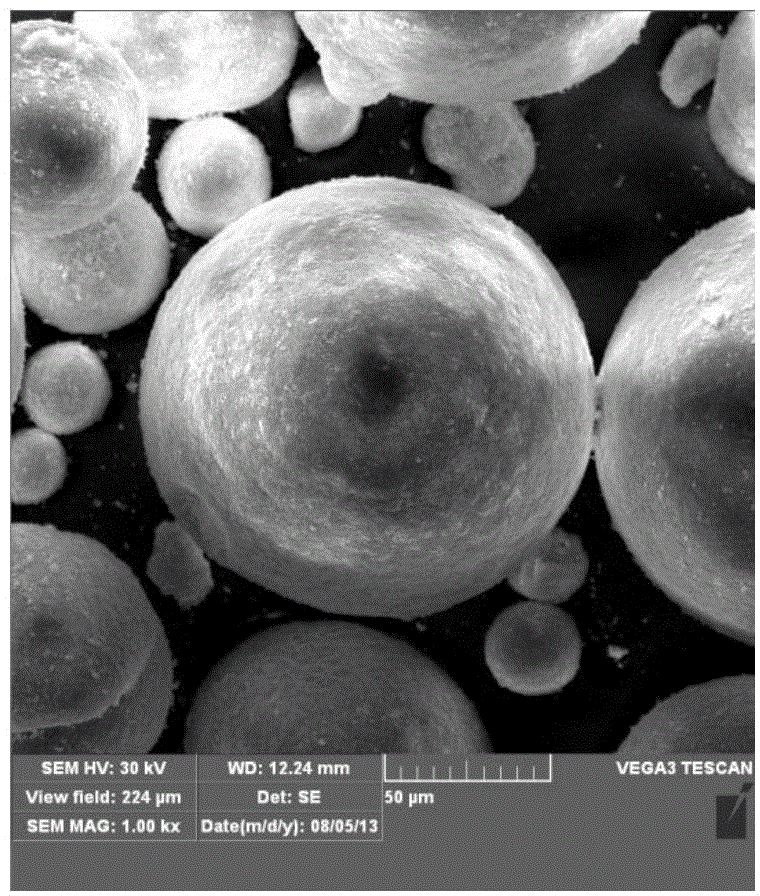

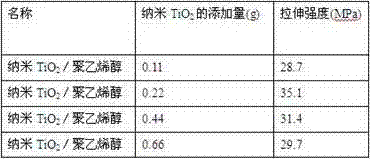

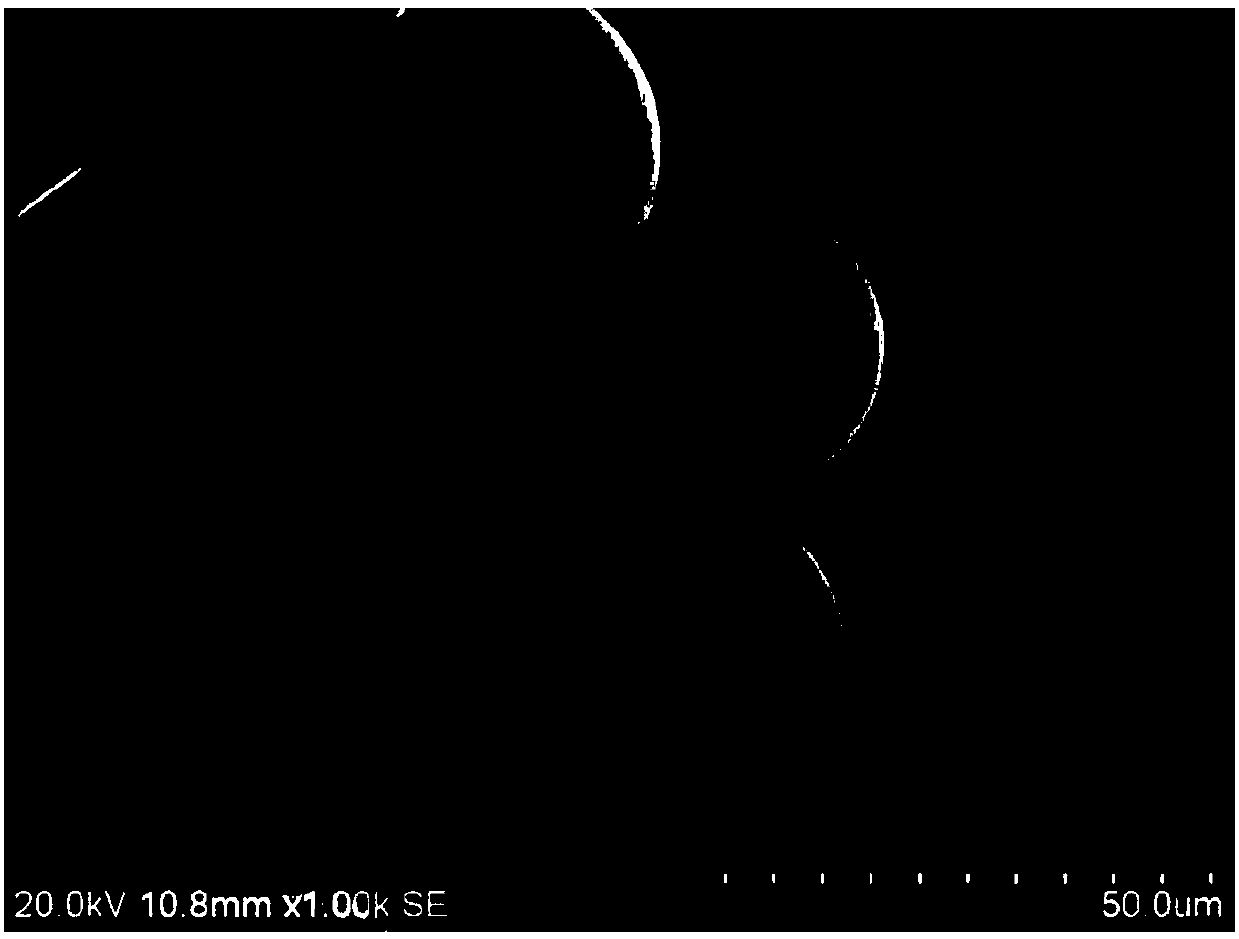

Preparation method of yttrium oxide-stabilized zirconia pelletized powder

The invention discloses a preparation method of yttrium oxide-stabilized zirconia pelletized powder. The method comprises the following steps: mixing yttrium oxide-stabilized zirconia powder, deionized water and a dispersing agent in a mass ratio 1:(1-1.5):(0.001-0.015), and performing ball milling on the mixture to obtain a sizing agent; adding a bonding agent into the sizing agent, and stirringthe mixture for 3-6 hours; and pelletizing the stirred sizing agent to obtain the yttrium oxide-stabilized zirconia pelletized powder. According to the preparation method of the yttrium oxide-stabilized zirconia pelletized powder, the ratio of the yttrium oxide-stabilized zirconia powder to the deionized water to the dispersing agent is adjusted appropriately, so that the sizing agent obtained bymeans of ball milling has appropriate solid content; and meanwhile, after the bonding agent is added and stirring is performed, the fluidity and viscosity of the sizing agent are moderate, so that the sizing agent is prevented from being stuck to a feeding tube in a pelletizing feeding process and can be effectively used for pelletizing, and the yield of the pelletized powder is over 94 percent.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

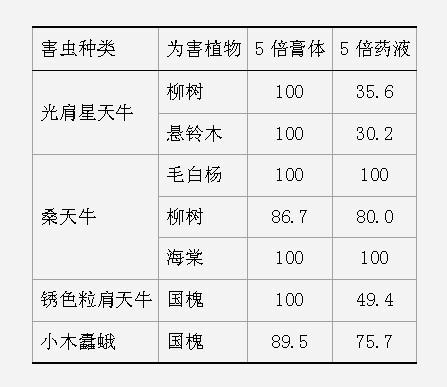

Paste for preventing and curing stem borer

The invention relates to a paste for preventing and curing stem borers, which is prepared by mixing the following raw materials based on the weigh ratio: 0.1-4 parts of botanical pesticide, 4-6 parts of kaolin, 0.5-1.5 parts of glycerol, 0.3-1 part of thickening agent and 10-13 parts of water. The paste has the advantages of certain stickiness, moderate mobility and long moisturizing period and pesticide effect period and has small possibility of drying and volatilizing. The paste is neutral and nontoxic, is safe to plants and does not pollute environment. The prevention and cure effect of the paste on Anoplophora glabripennis is improved by 64.4-69.8%, the prevention and cure effect on the Apriona swainsoni is improved by 50.6%, and the prevention and cure effect on small carpenter moths is improved by 13.8%. Meanwhile, the use amount and the loss amount of pesticides are lowered, thereby lightening environmental pollution.

Owner:乔建国

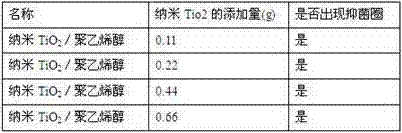

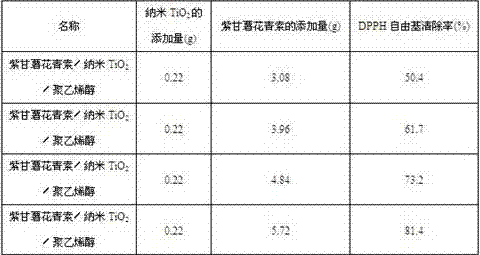

Preparation method for intelligent chromogenic antibiosis antioxidant freshness-retaining film

InactiveCN107082896AModerate fluidityModerate viscosityPhysical/chemical process catalystsAntioxidantOxidation resistant

The invention provides a preparation method for intelligent chromogenic antibiosis antioxidant freshness-retaining film. The method comprises the following steps: firstly preparing a mother solution of polyvinyl alcohol, adding nanometer titanium dioxide to prepare a PVA-nano TiO2 mixed solution, stirring fully, curtain coating on a glass plate through the solution, drying to form a film in an oven, measuring the mechanical properties and antibacterial properties of the film, screening out an optimum adding ratio of nano TiO2, preparing a purple sweet potato anthocyanin solution separately, added the purple sweet potato anthocyanin solution to a solution with an optimum mixing ratio, after stirring fully, curtain coating on the glass plate through the solution, and drying to form the film in the oven. Compared with other saccharides and protein-like films, the film has good mechanical properties, the combination of antibacterial properties and antioxidant properties can better extend the shelf life of food, the films can exhibit different color changes in different pH environments, and the film combines chromogenic, antibacterial, and antioxidant properties and has a wide range of uses in food packaging.

Owner:SHANGHAI OCEAN UNIV

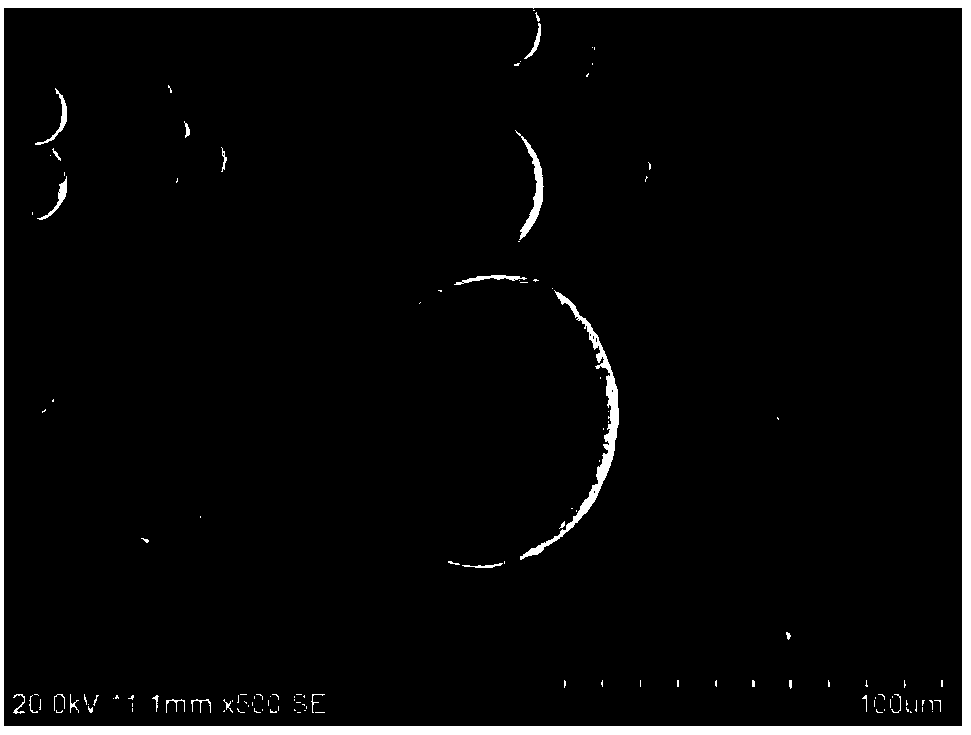

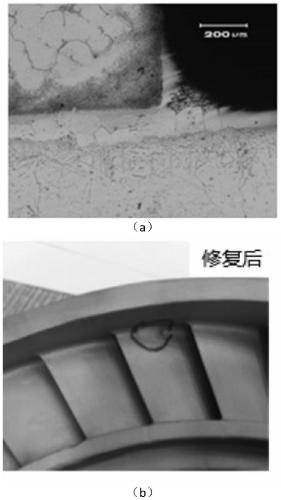

Nickel-based single-crystal high-temperature alloy connecting powder brazing filler metal as well as preparation method and application thereof

ActiveCN109420862AImprove mechanical propertiesSmall corrosionWelding/cutting media/materialsSoldering mediaChemical compositionSingle crystal superalloy

The invention discloses a nickel-based single-crystal high-temperature alloy connecting powder brazing filler metal as well as a preparation method and an application thereof, and belongs to the technical field of high-temperature alloy brazing materials. The brazing filler metal comprises the following chemical components (wt.%) of 10.0%-15.0% of Cr, 7.5%-13.5% of Co, 3.0%-8.5% of W, 0-4.5% of Al, 2.5%-5.5% of Mo, 2.5%-6.5% of Ti, 0-5.0% of Si, 0-2.0% of B, 0-3.0% of Fe and the balance Ni. The powder brazing filler metal is prepared by an atomization powder spraying method and is used for high-temperature alloy brazing connection. The brazing temperature is 1220-1320 DEG C, and the brazing time is 10-360 minutes. According to the powder brazing filler metal, the high-temperature performance brazing connection problem of a single crystal high-temperature alloy is solved and the important application value is achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

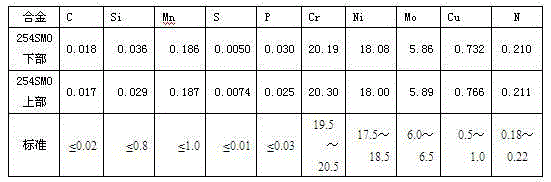

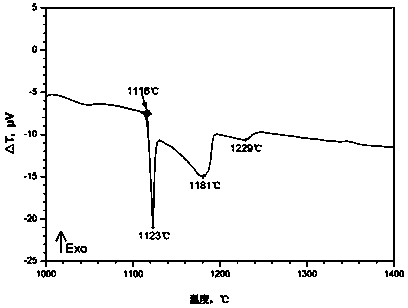

Slag system for ingot drawing electroslag remelting superaustenitic stainless steel

The invention belongs to the technical field of special alloy refining, and discloses a slag system for ingot drawing electroslag remelting superaustenitic stainless steel. The slag system for ingot drawing electroslag remelting superaustenitic stainless steel adopts a five-element slag system and is characterized in that the five-element slag system comprises the following components in percentage by weight: 40-55% of CaF2, 15-25% of Al2O3, 20-30% of CaO, 2-3% of MgO and 5-8% of SiO2. The slag system overcomes the defects of the prior art, solves the problems that slag is doped inside steel ingots and steel and slag are leaked in the ingot drawing process, and the steel ingots with good surface and internal quality are smelted.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Method for producing crystallized polyester

ActiveUS20120065342A1Improved melt processabilitySatisfactory crystallization propertyPolyesterCrystallinity

A method for producing a crystallized polyester comprises the crystallization step of applying a shear and / or a pressure to a polyester selected from an aliphatic polyester and a polyalkylene terephthalate at a temperature of (Tm−70° C.) to (Tm+20° C.), where Tm is a melting point of the polyester, thereby converting the polyester into a state having a crystallinity of 10% or more and fluidity.

Owner:NATUREWORKS LLC

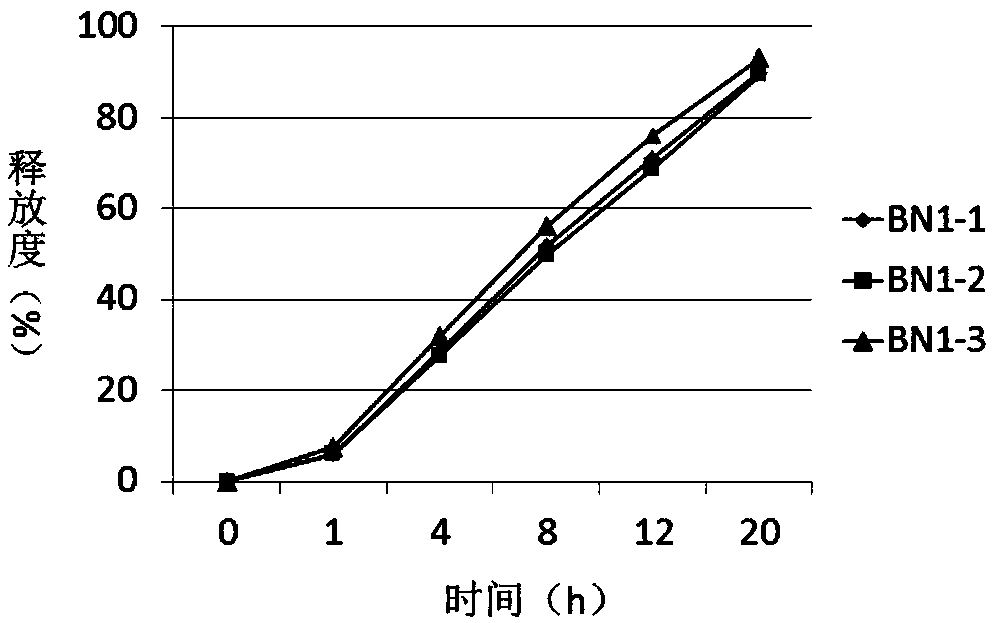

Metroprolol succinate sustained release tablet and preparation method thereof

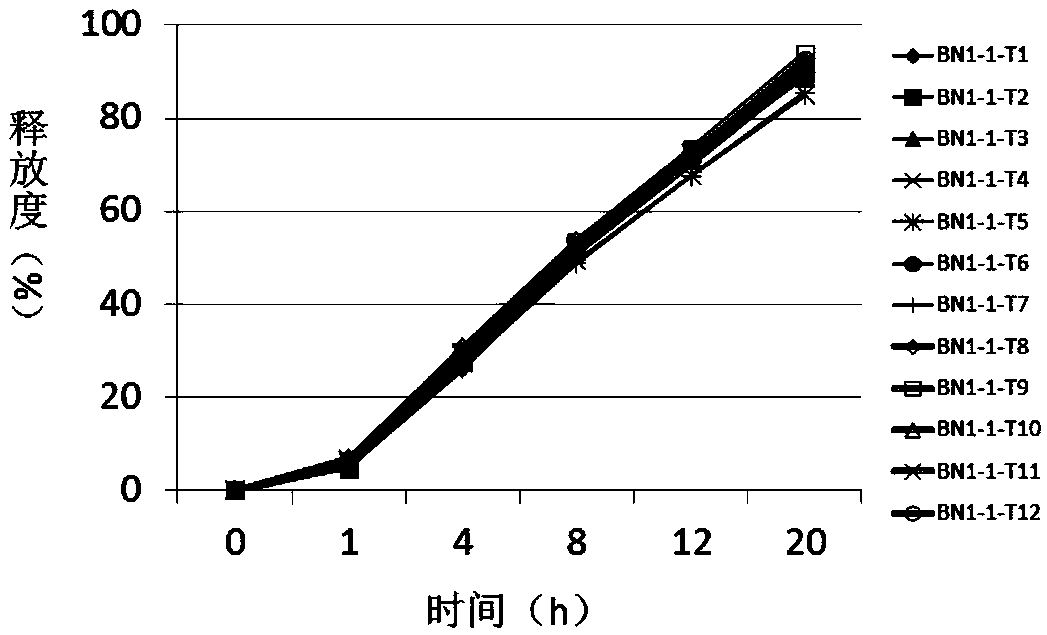

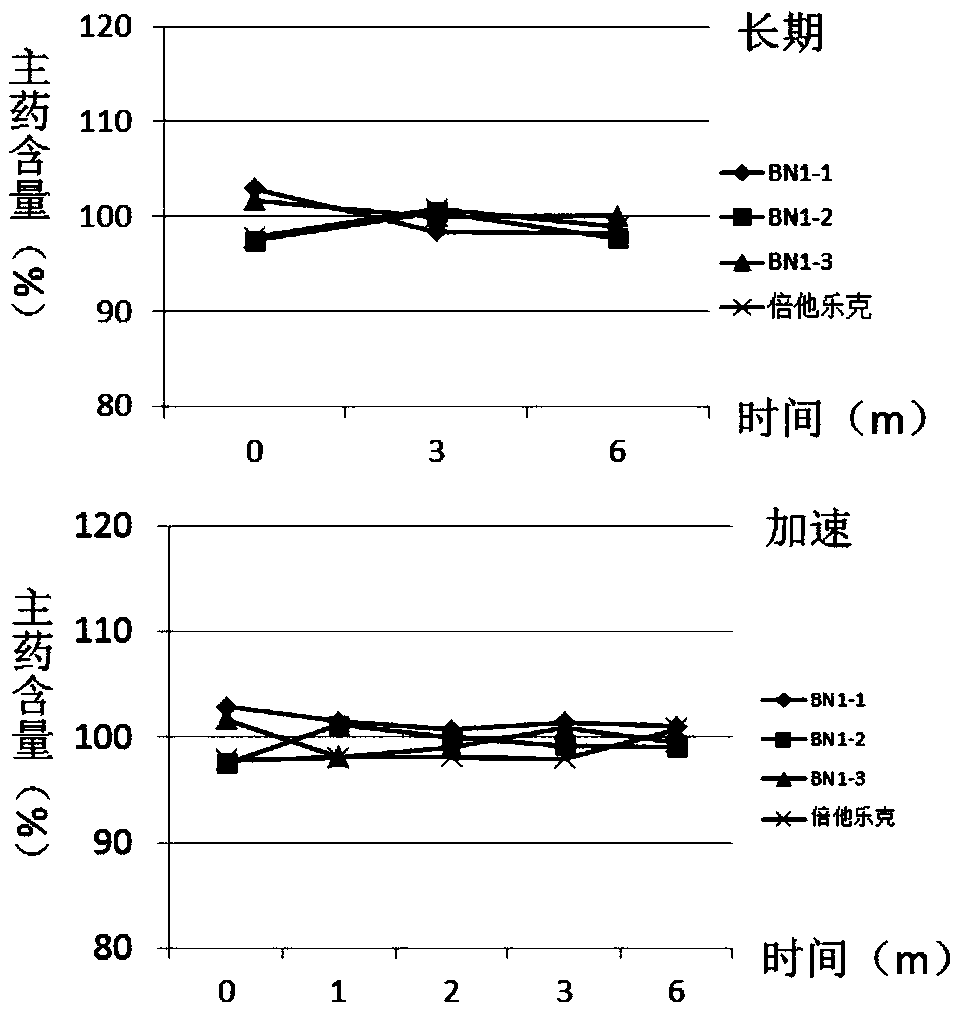

InactiveCN107595795AModerate fluidityStable release rateOrganic active ingredientsPharmaceutical delivery mechanismSustained release pelletsSustained Release Tablet

The invention belongs to the technical field of drug preparations, and relates to a Metoprolol succinate sustained release tablet and a preparation method thereof. The sustained release tablet includes a tablet film coating material and a tablet core coated with the coating, the tablet core comprises a pellet and accessories, the pellet comprises, from the inside to the outside, a blank pill core,a drug-loading coating layer, a sustained release coating layer and a protective coating layer, the drug-loading coating layer comprises Metoprolol succinate and a drug-loading pellet coating adhesive, the sustained release coating layer comprises a sustained release pellet coating layer coating material, a pore forming agent, a plasticizer and an anti adhesion agent, the protective coating layerincludes a protection pellet coating adhesive, the accessories include a filler, a disintegrating agent and a lubricating agent. The sustained layer of the release tablet is externally wrapped with the protective layer, and the problems of slow release ability reduction and unqualified content uniformity caused by excess fluidity and the like due to the damage of the sustained release layer can be solved.

Owner:北京华素制药股份有限公司

Jun red glaze and preparation method thereof

The invention relates to a Jun red glaze and a preparation method thereof, wherein the Jun red glaze comprises, by weight, 28-35 parts of quartz, 16-20 parts of albite, 12-16 parts of potassium feldspar, 4-8 parts of clay, 13-18 parts of calcium carbonate, 1-3 parts of boron oxide, 1-2 parts of lithium carbonate, 1-3 parts of zinc oxide, 2-4 parts of iron oxide, 1-2 parts of cupric carbonate, 1-2 parts of manganese carbonate, and 1-2 parts of cobalt oxide. According to the present invention, the glaze surface of the prepared ceramic product has characteristics of uniform deep red color, good glossiness, bright color, moderate fluidity and fine lines, the high-temperature firing process has the suitable viscosity so as to avoid the defects of glaze flowing and foot setoff due to the excessive high temperature fluidity, the yield is high, and the cost is low.

Owner:温书强

Cobalt-based powder brazing filler metal for high-temperature alloy connecting as well as preparation method and application of cobalt-based powder brazing filler metal

ActiveCN109909641AImprove mechanical propertiesWide brazing temperature rangeWelding/cutting media/materialsSoldering mediaChemical compositionSuperalloy

The invention discloses cobalt-based powder brazing filler metal for high-temperature alloy connecting as well as a preparation method and application of the cobalt-based powder brazing filler metal,and belongs to the technical field of high-temperature alloy brazing materials. The brazing filler metal comprises the following chemical components of, in percentage by weight, 12.0-22.0% of Cr, 15.0-30.0% of Ni, 4.0-17.0% of W, 0.5-6.5% of Al, 0.5-8.5% of Mo, 0-8.0% of Ti, 0-3.0% of Si, 0-3.0% of B, 0-7.5% of Fe, 0.2-5.0% of Nb, and the balance Co. The powder brazing filler metal is prepared bya gas atomization method and is used for high-temperature alloy brazing connection. The brazing temperature is 1170-1270 DEG C, and the brazing time is 10-150 minutes. The cobalt-based powder brazingfiller metal solves the high-performance brazing connection problem of the high-temperature alloy, and has important application value.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Producing method for solar energy photovoltaic component used for photovoltaic-building integration

ActiveCN101419998AAvoid breakingImprove yieldFinal product manufactureSemiconductor devicesPneumatic pressureEngineering

The invention discloses a fabrication method of a building integrated photovoltaics solar photovoltaic module. The fabrication method comprises the following steps: folding and putting glass sheet-PVB film-solar cell-PVB film-glass sheet in a flexible air bag, depressuizing the gas bag, pressurizing the outside of the folded module after heating, and cooling slowly to obtain the solar photovoltaic module. In the fabrication method, air in the module is removed by vacuumizing the air bag, a fusion temperature is selected to cause the PVB film to have proper fluidity, the module is moderately pressed by virtue of atmospheric pressure and dead weight of the glass to prevent the solar cell from breakage and obtain higher yield, and an obtained product meets the requirements of the building safety glass specification and can be used in enclosures of a building including curtain walls, roofs, sunshades, doors, windows, guard fences and floors, thus realizing the building integrated photovoltaics.

Owner:甘肃金刚玻璃科技股份有限公司

Making method of color solar photovoltaic assembly

The invention provides a making method of a color solar photovoltaic assembly, which satisfies the specification requirements of building safety glass and can be used for making enclosures at the outer side of a building, including a curtain wall, a roof, a sunshade, a door window, a barrier and a floor i.e. used for making a building integrated photovoltaic color solar photovoltaic assembly. In the making method, operation steps such as laminating pavement, assembly fixing, laminating curing, annealing treatment and the like are utilized. A product produced by the method has stronger peel strength without a frame for reinforcement, satisfies the shock resistance and the safety performance of the building safety glass and has elegant appearance.

Owner:赵枫

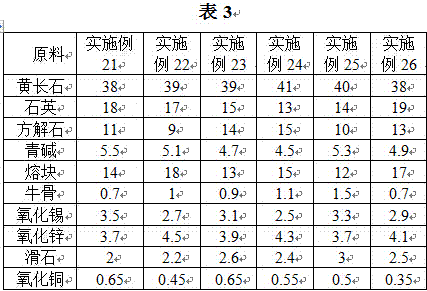

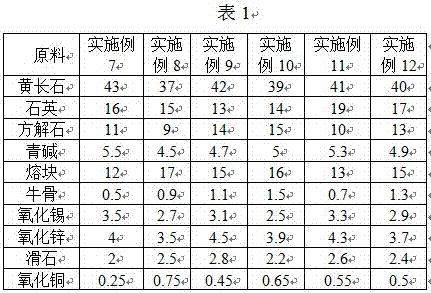

Jun red glaze

Jun red glaze is prepared from the following raw materials in parts by weight: 37 to 43 parts of melilite, 13 to 19 parts of quartz, 10 to 16 parts of calcite, 4.5 to 5.5 parts of sodium metasilicate, 12 to 18 parts of frit, 0.5 to 1.5 parts of bovine-derived power, 2.5 to 3.5 parts of stannic oxide, 3.5 to 4.5 parts of zinc oxide, 2 to 3 parts of talc, and 0.25 to 0.75 part of copper oxide. Compared with the prior art, through scientific and reasonable raw material matching and control on the firing process, the prepared jun red glaze is bright in color, good in glossiness, and moderate in flowability, and has fine cracks, the glazing colors are rich, on the basis of jun red, the colors including yellow, blue, purple and the like exist, the color transition is clear, distinct and natural, the rate of finished products is high, reaching 75% or above, the blank of no colorful graze exists in jun red glaze is filled, and a new variety is provided for jun red glaze.

Owner:禹州市神器钧窑有限公司

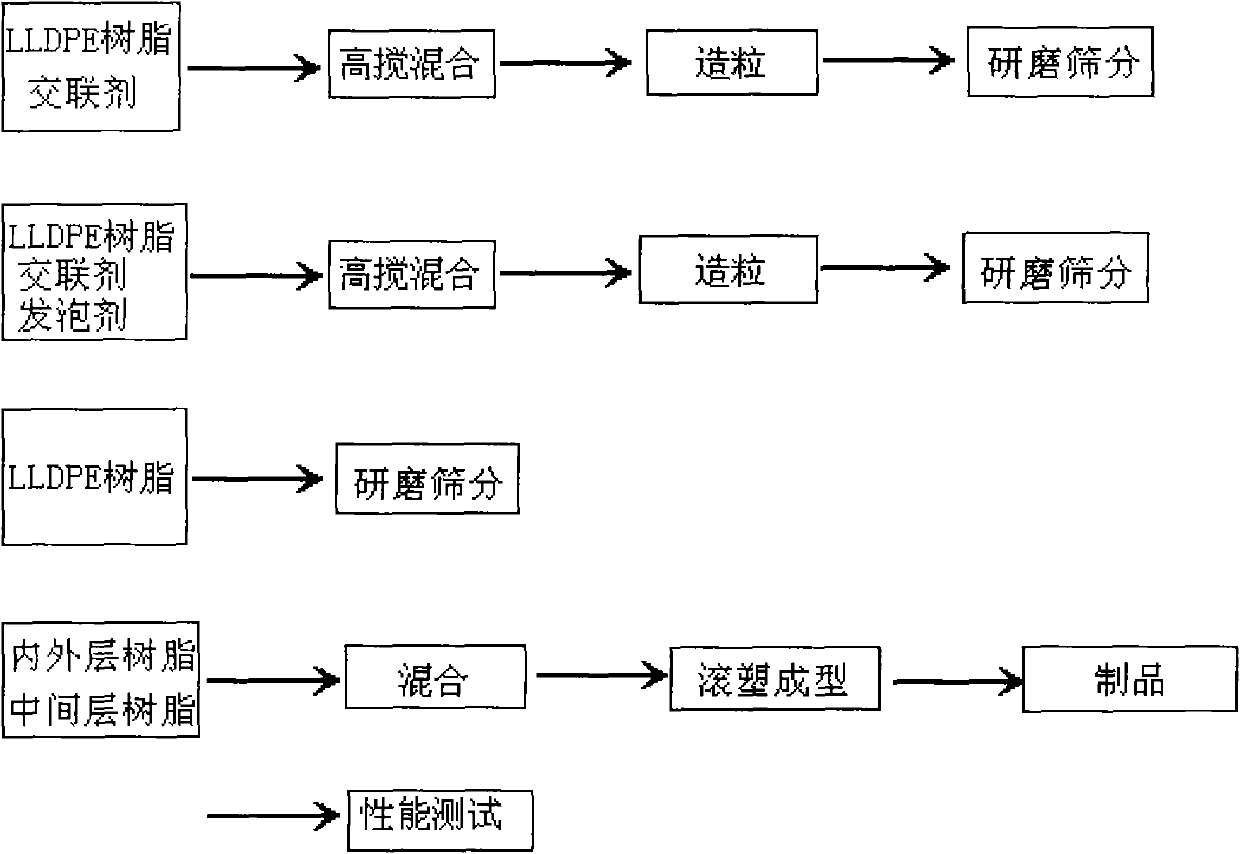

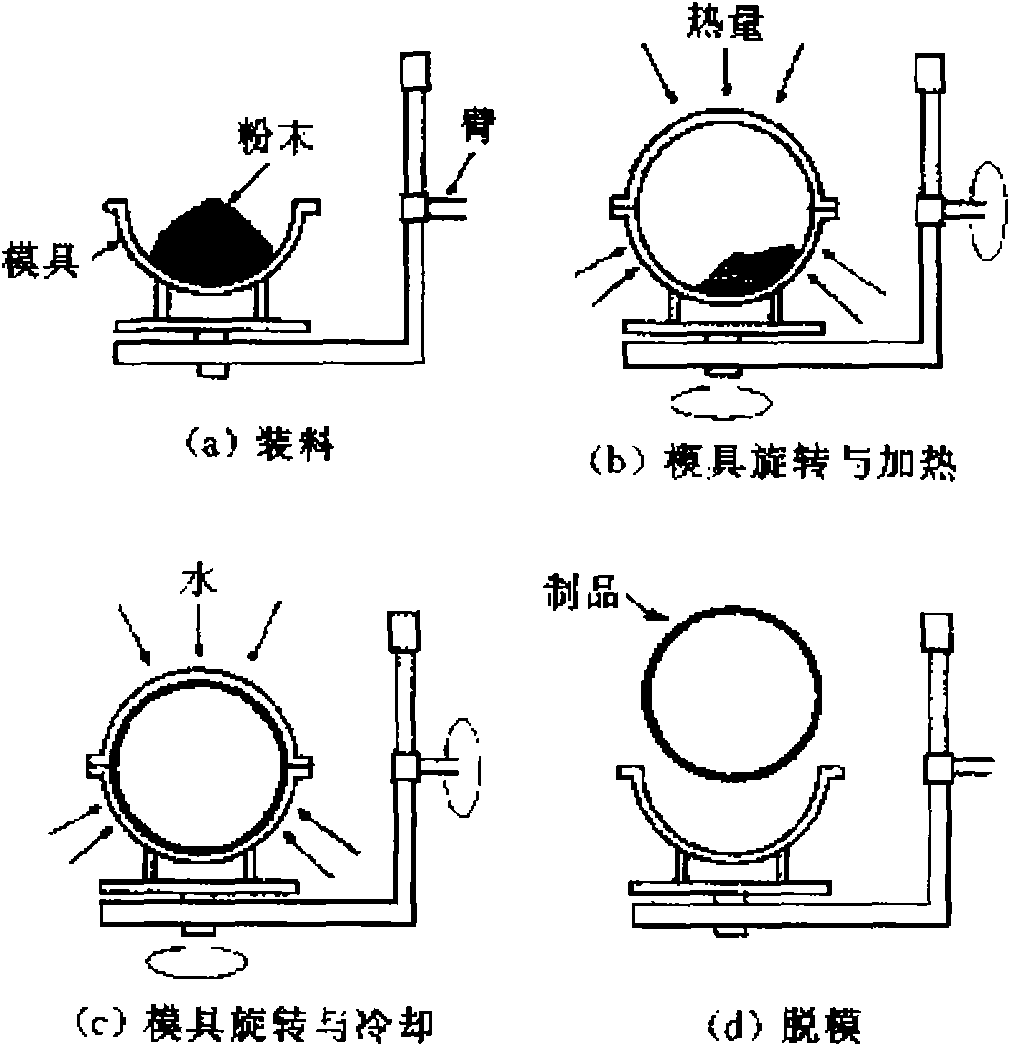

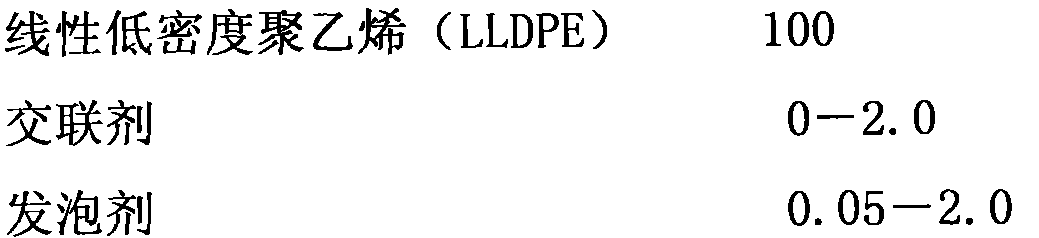

Raw material composition special for rotational molding foamed product, and preparation method and application method thereof

ActiveCN102020799AHighlight substantiveSignificant progressCoatingsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a raw material composition special for a rotational molding foamed product, and a preparation method and an application method thereof, and belongs to the composition comprising an organic high molecular compound as a basic material. The composition is characterized in that: a, an intermediate foamed layer resin comprises the following raw material components in part by weight: 100 parts of linear low-density polyethylene, 0 to 2.0 parts of cross-linking agent, 0.05 to 2.0 parts of foaming agent and 0.1 to 2.0 parts of nucleating agent; and b, a surface layer resin comprises the following raw material components: the surface layer 1 comprising 100 weight parts of the linear low-density polyethylene, and the surface layer 2 comprising 100 weight parts of the linear low-density polyethylene, 1.0 to 2.0 weight parts of cross-linking agent and 0 to 4.0 weight parts of lubricating agent. The invention provides the raw material composition special for the rotational molding foamed product, which is suitable for a one-step rotational molding process, endows the rotational molding foamed product with a perfect appearance and superior mechanical properties, has moderate fluidity, is low in cost and is easy to machine, and the preparation method and the application method thereof. The invention can be widely applied to machining of plastic products.

Owner:CHINA PETROLEUM & CHEM CORP

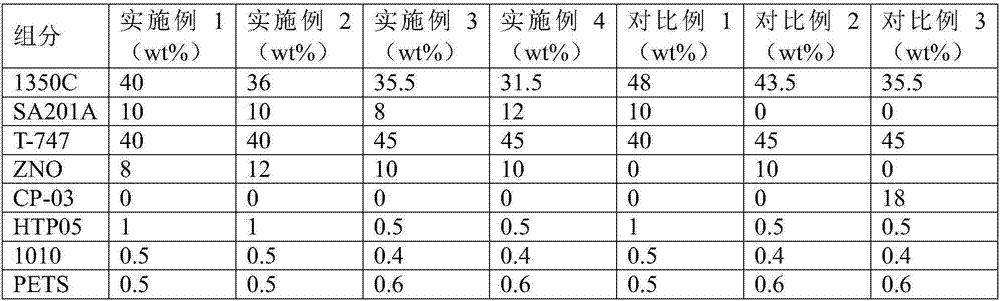

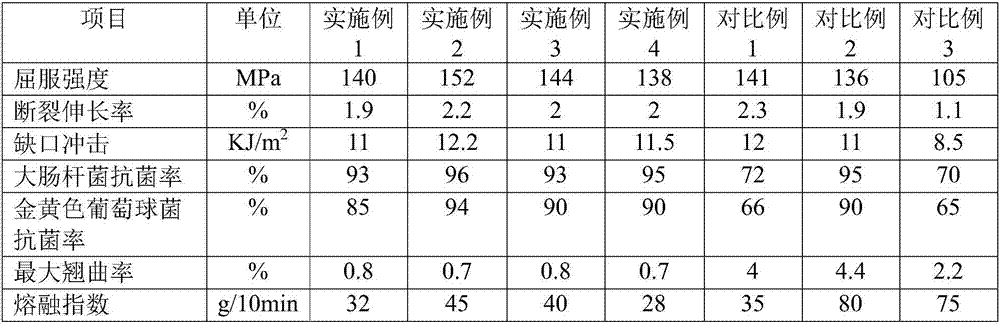

Antimicrobial low-warpage low-flash PPS composite material and preparation method thereof

The invention discloses an antimicrobial low-warpage low-flash PPS composite material and a preparation method thereof. The material is prepared from, by weight, 31.5-48% of PPS resin, 6-12% of PPE resin, 40-45% of glass fibers, 8-12% of antimicrobial agent, 0.5-1% of nucleating agent, 0.4-0.5% of antioxidant and 0.5-0.6% of lubricating agent. An engineering plastic, namely PPS, serves as a main body, the PPE resin, the glass fibers, the antimicrobial agent, the nucleating agent the antioxidant and the lubricating agent are added, the raw materials are mixed together and melted through a double-screw extruder, and then the antimicrobial low-warpage low-flash PPS composite material which is capable of meeting the antimicrobial requirements of household appliances is prepared. The material has the advantages of being antimicrobial, low in warpage and low in flash on the basis of ensuring the original excellent mechanical performance, heat resistance, fire resistance and electrical performance of PPS.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

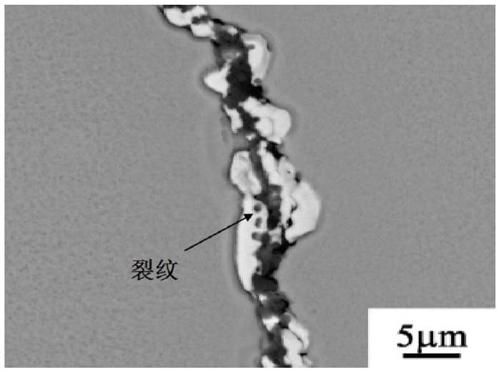

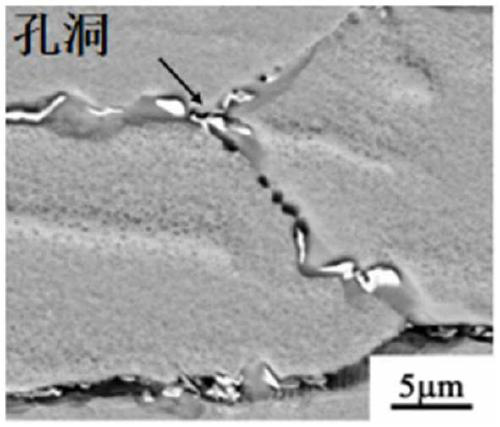

Nickel base alloy welding wire for high-temperature alloy fusion welding and preparation method and application thereof

ActiveCN111318835ASmall corrosionHigh melting temperatureWelding/cutting media/materialsSoldering mediaDirectional solidificationCasting defect

The invention discloses a nickel base alloy welding wire for high-temperature alloy fusion welding and a preparation method and application thereof, and belongs to the technical field of high-temperature alloy fusion welding materials. The nickel base alloy welding wire is prepared from the chemical components in percentage by weight: 0-1% of C, 5.0-25.0% of Cr, 1.5-25.5% of Co, 1-12.5% of Al, 0.5-20.5% of W, 1.5-10.5% of Mo, 0.8-12.5% of Nb, 0-1.0% of Y, 0-1.0% of Fe, 0-2.0% of Si, and the balance of Ni. The nickel base alloy welding wire is prepared by a directional solidification method, and is used for high-temperature alloy fusion welding connection. A welding current is 20-35A, and a voltage is 10-12V. The casting defect repairing problem of a precipitation strengthening nickel basehigh-temperature alloy is solved, the current situation that the nickel base high-temperature alloy welding wire is difficult to prepare due to the fact that the deformation resistance of the nickel base high-temperature alloy is high is changed, and important application value is achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

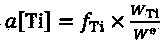

Ti element control method for Ti-contained corrosion resistant alloy ingot extracting electroslag remelting slab

The invention relates to a Ti element control method for a Ti-contained corrosion resistant alloy ingot extracting electroslag remelting slab. The control method comprises the following steps: a proper slag system is designed; according to each of melt electrodes with different chemical components, the TiO2 content of the slag system when the Ti element burning loss is balanced is obtained through a thermodynamic calculation method; the matched slag system is selected to control the Ti element burning loss; when the electroslag remelting begins, 3% of SiO2 is added; after the electroslag remelting is performed for 2-3 hours, 1-3% of remainder SiO2 is added in a slag pool; in the electroslag remelting process, Al particles are added for deoxidizing molten slag; and the content sum of the Al particles and Al in the electrode is controlled at 0.2% which is the upper limit of Al content in a UNSN08825 alloy. The Ti element control method solves the problem of synchronous control of surface quality, internal quality and Ti element content of the electroslag remelting slab in the ingot extracting electroslag remelting process of a Ti-contained iron nickel-based corrosion resistant alloy UNSN08825 slab in the atmospheric environment.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

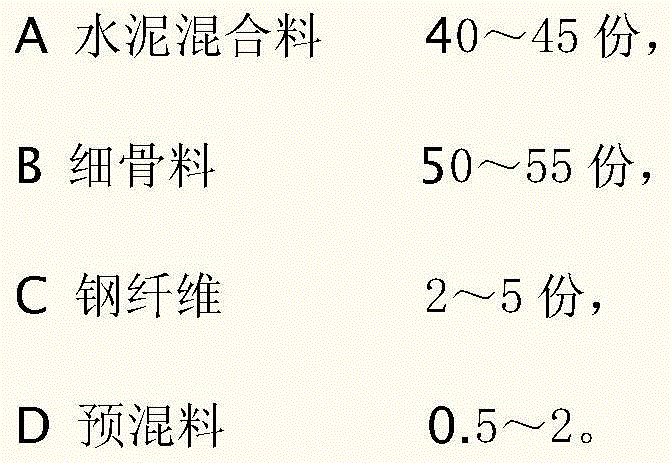

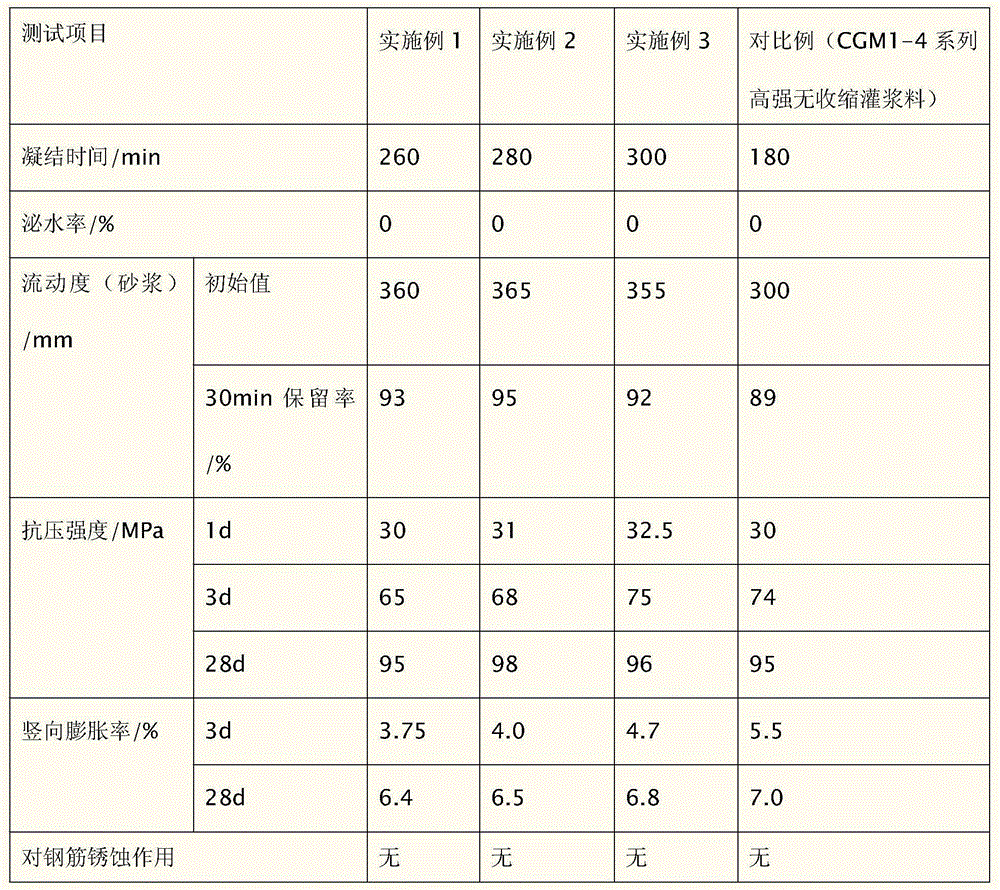

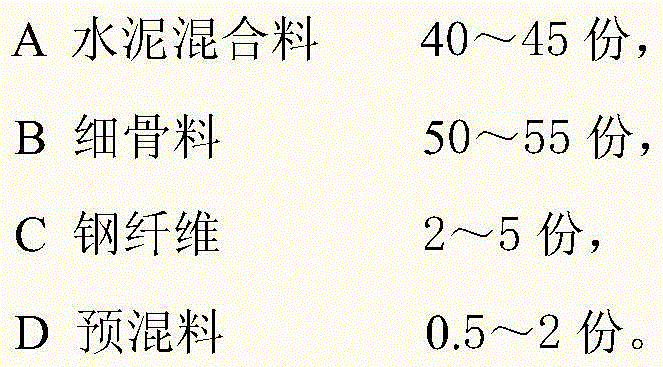

High-strength non-shrinkage grouting material with early strength and autogenous curing function and preparation method of grouting material

The invention discloses a high-strength non-shrinkage grouting material with early strength and an autogenous curing function and a preparation method of the grouting material. The grouting material is prepared from components in parts by weight as follows: 40-45 parts of cement admixture, 50-55 parts of fine aggregate, 2-5 parts of steel fiber and 0.5-2 parts of a premix. The prepared grouting material has moderate flow property, can neither cause segregation and layering phenomena due to too sparse slurry nor poor flow property and filling difficulty due to too dense slurry, and the grouting material has the advantages of high strength and low probability of cracking.

Owner:JIANGXI PINGXIANG CITY LIANYOU BUILDING MATERIAL

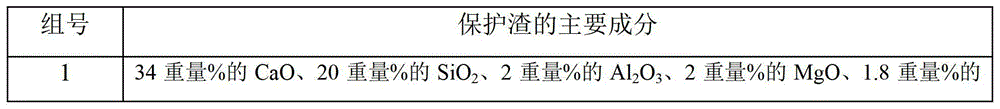

Special mold powder for all-headless high-efficiency continuous casting ESP low-carbon steel and preparation method thereof

The invention discloses special mold powder for all-headless high-efficiency continuous casting ESP low-carbon steel and a preparation method thereof. The preparation method of the mold powder comprises the steps of preparation of raw materials, homogenization of the raw materials, electronic proportioning, mixing of dry materials, levigation slurrying, spray granulation, sorting and detection ofparticle sizes of finished products, online analysis and detection of X fluorescence spectra, packaging and warehousing of qualified products and the like. The raw materials of the mold powder comprise, by weight part, 30-35 parts of electro-fused calcium silicate, 10-15 parts of 97 fluorite powder, 3-5 parts of sodium fluoride, 10-15 parts of sodium carbonate, 20-25 parts of pre-fusing additives,5-8 parts of cryolite, 2-4 parts of N oil carbon black, 1-2 parts of natural gas carbon black, 3-5 parts of battery grade lithium carbonate and 2-5 parts of carboxymethyl cellulose sodium. The binarybasicity of the mold powder is 1.13-1.23, and the viscosity at 1300 DEG C is 0.08-0.22 Pa.s; and the fusing point is 965 DEG C-1025 DEG C. The special mold powder for the all-headless high-efficiencycontinuous casting ESP low-carbon steel has the excellent characteristics of stable powder consumption, stable heat flow, reduction of the bonding alarm number, novel formula, high rate of continuouscasting finished products, significant reduction of cost compared with the cost of imported powder, etc.

Owner:洛阳科丰冶金新材料有限公司

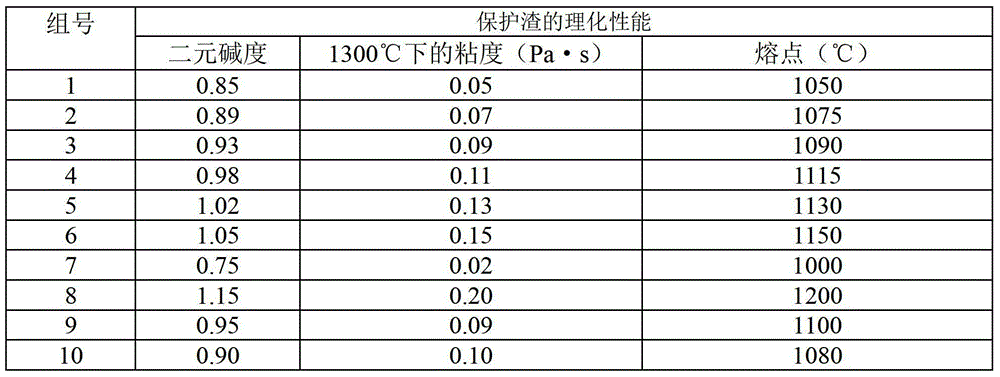

Continuous casting method for low-alloy steel wide and thick slabs

The invention discloses a continuous casting method for low-alloy steel wide and thick slabs. The continuous casting method comprises the following steps: pouring molten steel from a tundish into a crystallizer; in the crystallizer, adding casting powder on the liquid level of molten steel; cooling in the crystallizer, so that the molten steel is solidified into casting blanks with liquid cores, and then continuously pulling out the casting blanks with the liquid cores from the outlet of the crystallizer at a pulling speed Vc to pass through a secondary cooling zone so as to obtain completely solidified casting blanks, wherein the pulling speed Vc is controlled at 1.2-1.8 m / min, the binary basicity of the casting powder is 0.85-1.05, the viscosity of the casting powder is 0.05-0.15 Pa.s at 1300 DEG C, and the melting point of the casting powder is 1050-1150 DEG C. As the physical and chemical properties of the casting powder are reasonably controlled, the continuous casting method can effectively reduce the steel leakage alarm rate and that the continuity of production and the product quality are ensured is facilitated.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

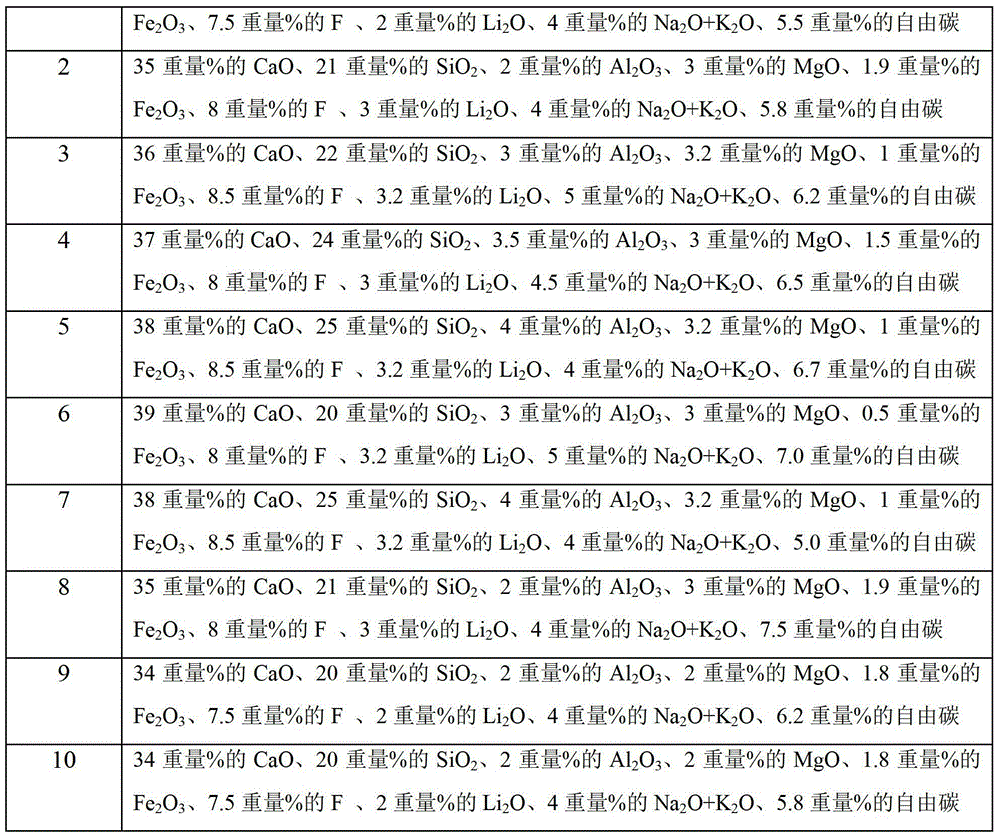

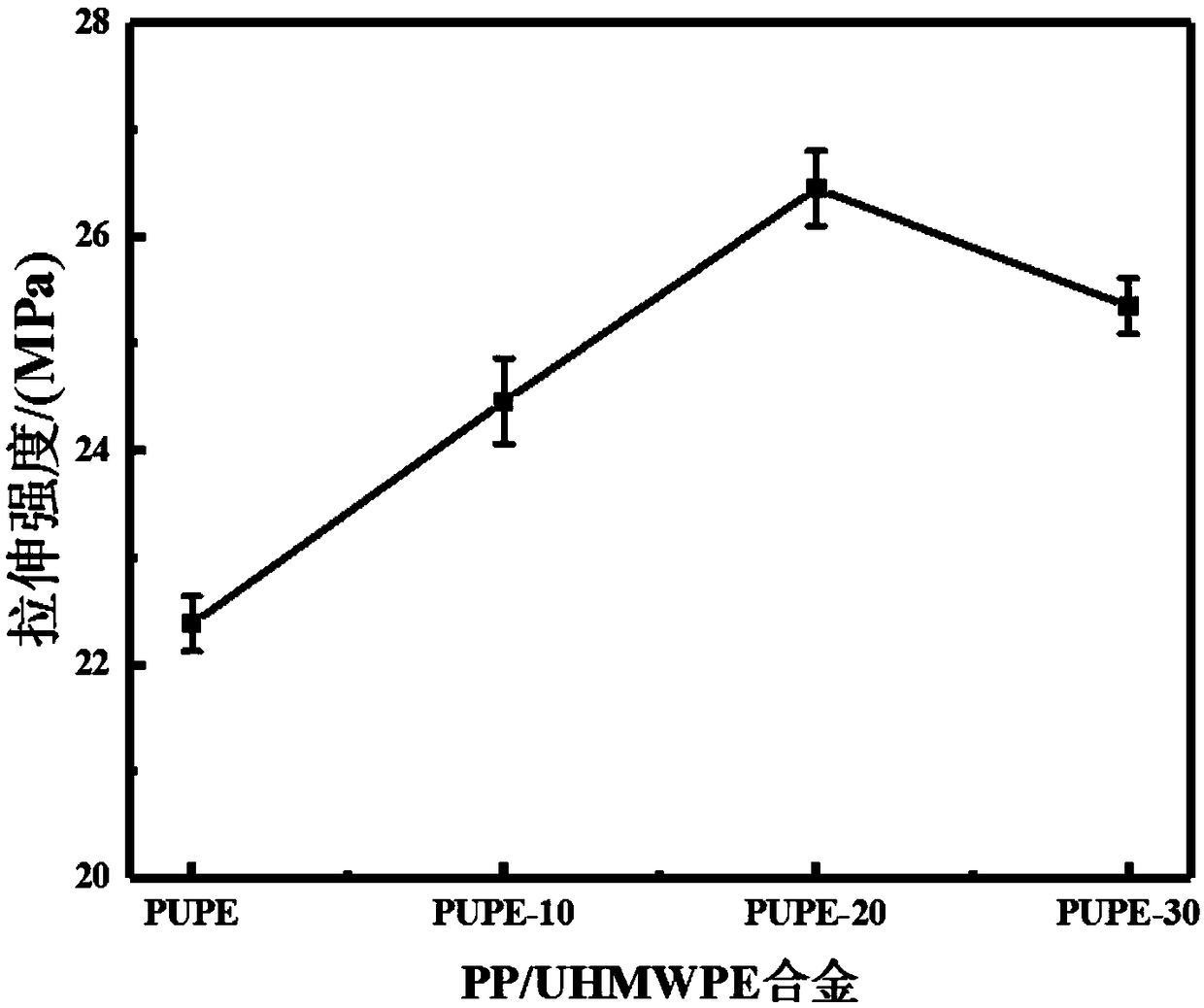

Special material for UHMWPE (Ultrahigh molecular weight polyethylene) alloy capacity increasing and toughening modified polypropylene corrugated pipe and preparation method of special material

The invention discloses a special material for an UHMWPE (Ultrahigh molecular weight polyethylene) alloy capacity increasing and toughening modified polypropylene corrugated pipe and a preparation method of the special material. The special material comprises, by weight, 60-85 parts of block co-polypropylene granules, 5-10 parts of fillers, 5-30 parts of capacity increasing and toughening agents and 1-5 parts of flowability modifiers. The corrugated pipe produced by the special material has the advantages of good mechanical properties, better low-temperature impact resistance, high heat distortion temperature, high heat conductivity coefficient, good flame resistance, good surface glossiness, good production stability and the like.

Owner:FUJIAN NORMAL UNIV

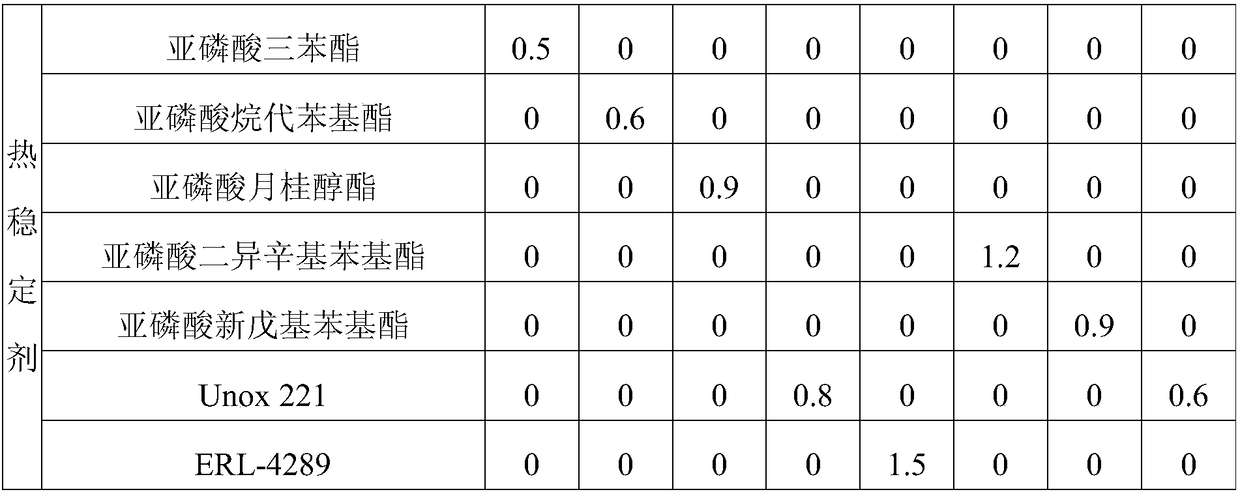

High-transparency flame-retarding polycarbonate thin film/sheet material as well as preparation method and application thereof

InactiveCN108059810ARealize and meet process technical requirementsModerate fluidityFiberCarbon fibers

The invention discloses a high-transparency flame-retarding polycarbonate thin film / sheet material as well as a preparation method and application thereof. The high-transparency flame-retarding polycarbonate thin film / sheet material is characterized by being prepared by melting and extruding a mixture of 100 parts of bisphenol A type polycarbonate by mass, 2 to 15 parts of long-chain branched polycarbonate by mass, 0.1 to 10 parts of a flame retardant A by mass, 3 to 20 parts of a flame retardant B by mass, 0.2 to 2 parts of a chain extender by mass, 0.5 to 1 part of an antioxidant by mass and0.2 to 2 parts of a thermal stabilizer by mass through a casting extruder at 240 DEG C to 320 DEG C, and casting, pouring and cooling on a cold roller at 80 to 110 DEG C; the light transmittance of the thin film / sheet material is 86 percent to 95 percent; the flame-retarding performance of different thicknesses can reach UL94VTM-0 or UL94V-0 respectively; the thin film / sheet material can be compounded with carbon fibers and glass fibers to manufacture composite materials of household appliance / computer shells, automobile interior and exterior trimmings and the like; the high-transparency flame-retarding polycarbonate thin film / sheet material has the advantages of good heat dissipation, light weight, good wear resistance and easiness for coloring.

Owner:四川东方绝缘材料股份有限公司

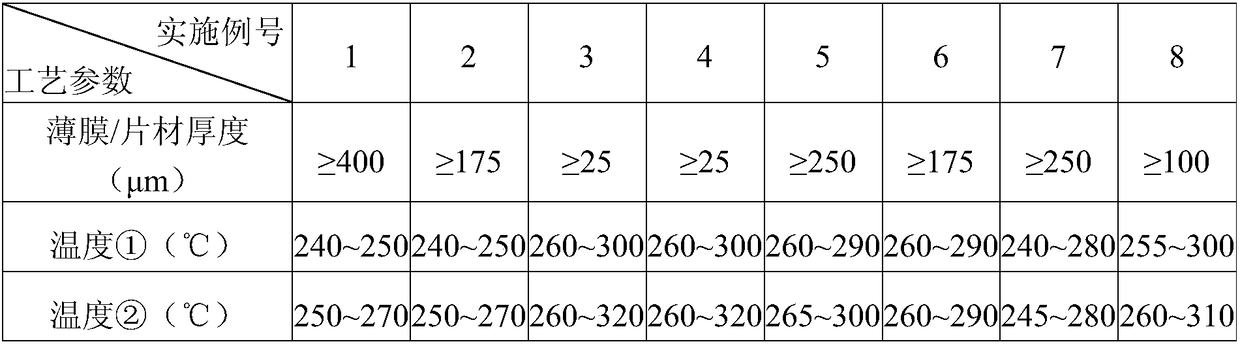

Normal-temperature yoghurt containing complete fruit granules and preparation method thereof

PendingCN108029766AImprove uniformityGood flavor releaseMilk preparationMass ratioAdditive ingredient

The invention discloses a preparation method of normal-temperature yoghurt containing complete fruit granules. The preparation method comprises the following steps: evenly mixing 90% to 95% pre-sterilized antibiotics-free milk, 4% to 8% of sweetening agent, 1.0% to 1.5% of modified starch and 0.2% to 0.6% of stabilizer in a vacuum material mixing mode, homogenizing and performing pasteurization onhomogenized liquid; adding 0.003% to 0.009% fermenting agent to perform fermentation and performing demulsification and sterilization when acidity reaches 70 to 90 thorner degrees to obtain a yoghurtbase material with a viscosity as 300 to 500cP; mixing 30% to 40% of white granulated sugar, 50% to 60% of mixed berry fruit granules, 0% to 1% of edible essence and 0.5% to 2% of PH modifier to obtain a mixture and storing the mixture under 4 to 10 DEG C, wherein the percents are mass percents of all the ingredients in the mixture; sterilizing and filling to obtain mixed berry fruit granules with a viscosity as 300 to 500cP; setting a mass ratio of the yoghurt base material adding amount to the mixed berry fruit granule adding amount as (9 to 8) to (1 to 2), mixing under a static state at first, then stirring to be mixed under a dynamic state and filling after being mixed. By means of a conveying and mixing mode of the yoghurt, the fruit granules can be evenly distributed in the yoghurt;furthermore, the mixing mode cannot affect system stability and granule completeness of products in the expiration date.

Owner:BRIGHT DAIRY & FOOD

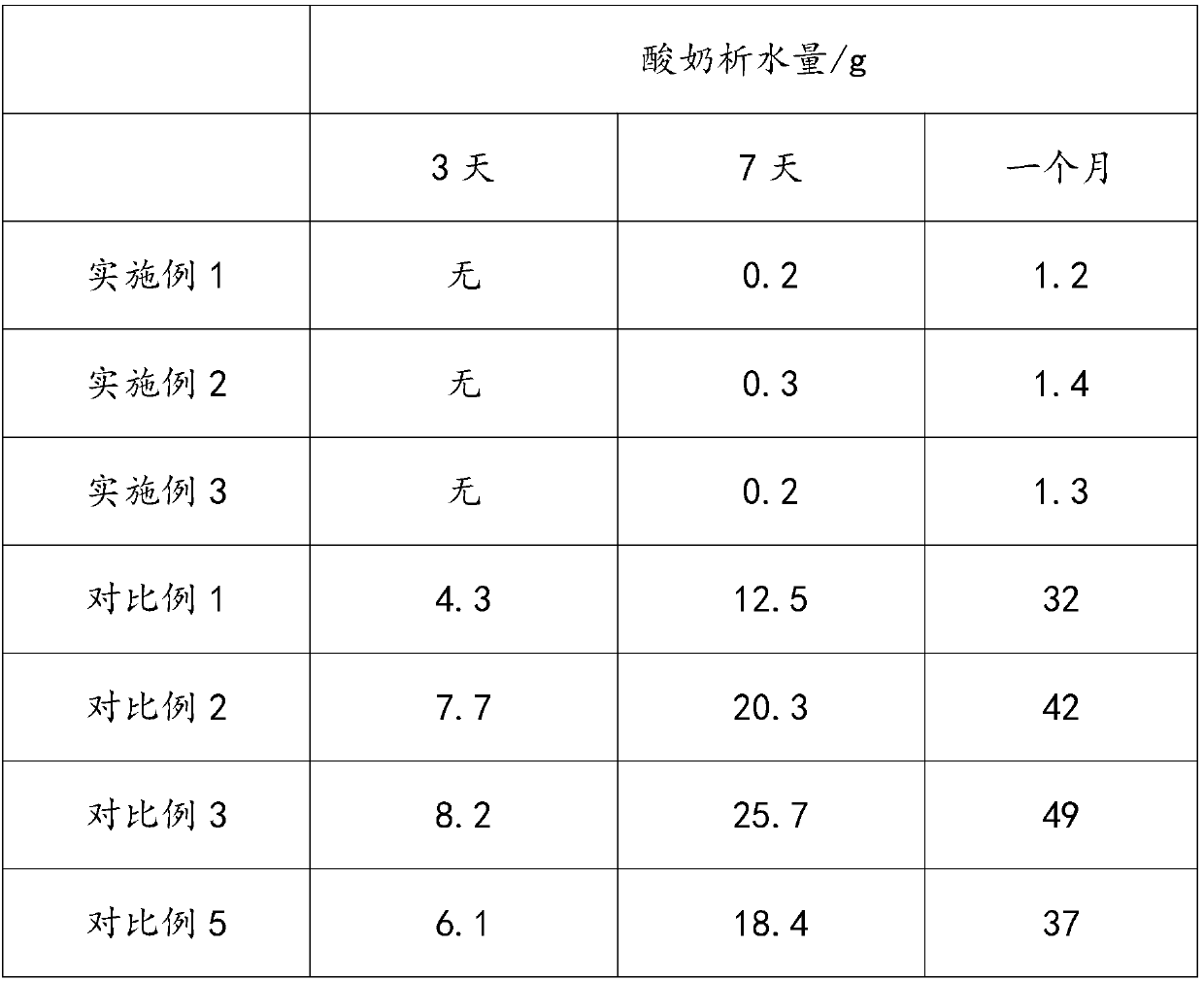

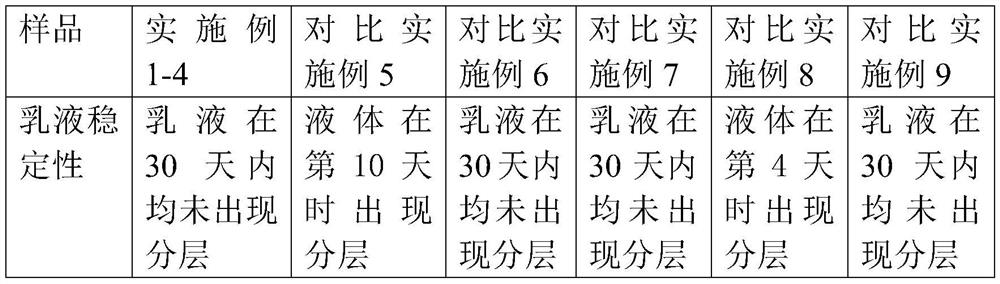

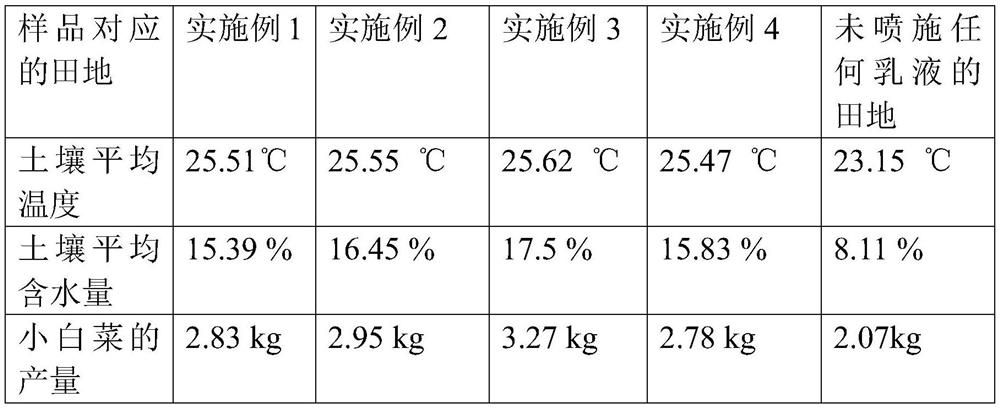

Garlic residue-based liquid mulching film and preparation method thereof

ActiveCN113563517ARealize the effect of turning waste into treasureThermal insulationBio-packagingPlant protective coveringsEmulsionPlastic mulch

The invention provides a garlic residue-based liquid mulching film and a preparation method thereof, the mulching film is prepared by using garlic residue slurry, pre-gelatinized starch and an acrylic monomer mixture as main raw materials, and the reaction process relates to a pre-oxidation process, a pre-emulsification process and an emulsion free radical polymerization process under the action of an initiator; the emulsion obtained after the reaction is not easy to layer and has stability, proper viscosity and sprayability; and compared with bare soil which is not covered with the mulching film, the garlic residue-based mulching film can improve the water content in the soil and the soil temperature, and can also improve the yield of the pakchoi. The garlic residue-based liquid mulching film also can resist the invasion of plutella xylostella to pakchoi. The crop waste resource, namely the garlic residues, is fully utilized, so that the method is low in cost, few in related production links, easy to operate and suitable for popularization and application.

Owner:NANJING FORESTRY UNIV

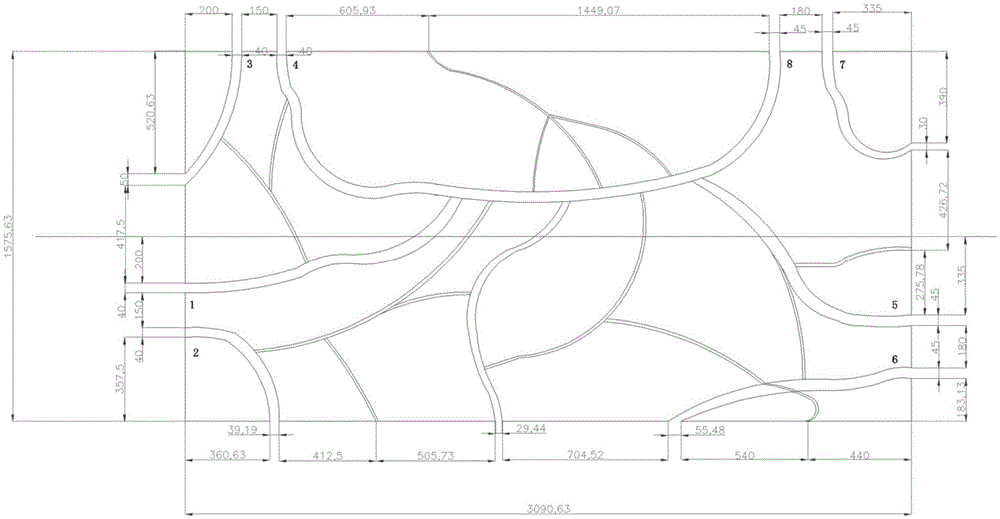

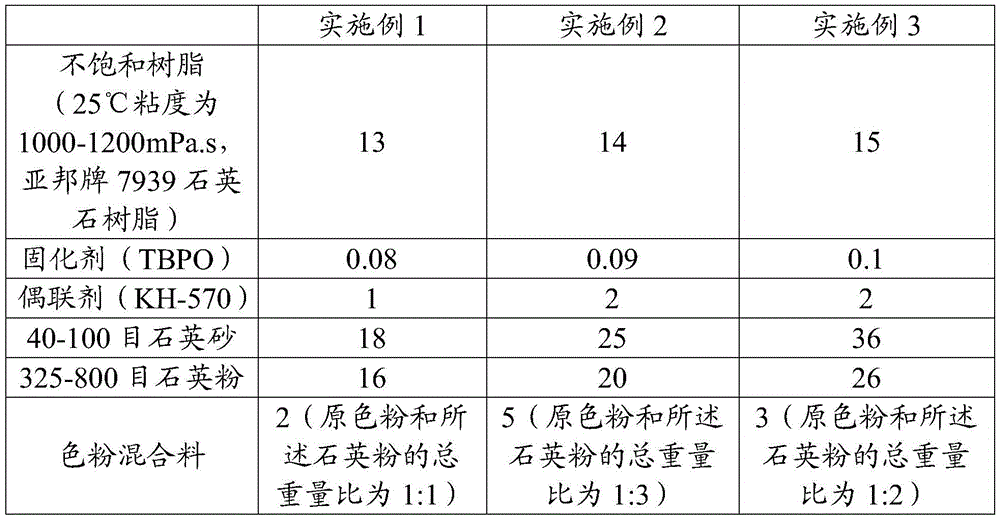

Quartz-stone board and preparation method thereof

The invention relates to a quartz-stone board and a preparation method thereof. The preparation method comprises the following steps: (1) designing a pre-pressing die, namely, arranging a bulge on a pre-pressing plate, and extending the bulge to the side edge of the pre-pressing plate to form a splicing station, so as to obtain the pre-pressing die; (2) mixing unsaturated resin, a curing agent, a coupling agent, quartz sand, quartz powder and a toner mixture to obtain a plurality of mixture groups with different color, and then rolling one group to obtain wet materials; (3) pre-pressing the wet materials through the pre-pressing die, and forming concave grooves in the surfaces of the wet materials, then removing the pre-pressing die, and filling the concave grooves with the rest mixture groups and color paste; (4) performing the subsequent forming processes to obtain the quartz-stone board. According to the method, the position of the splicing station can be flexibly designed according to the requirement of actual engineering, so that the quartz-stone boards can be spliced at random; the textures on the spliced boards are continuous and in natural transition; in addition, the preparation process is stable, and batch production can be achieved.

Owner:OPPEIN HOME GRP

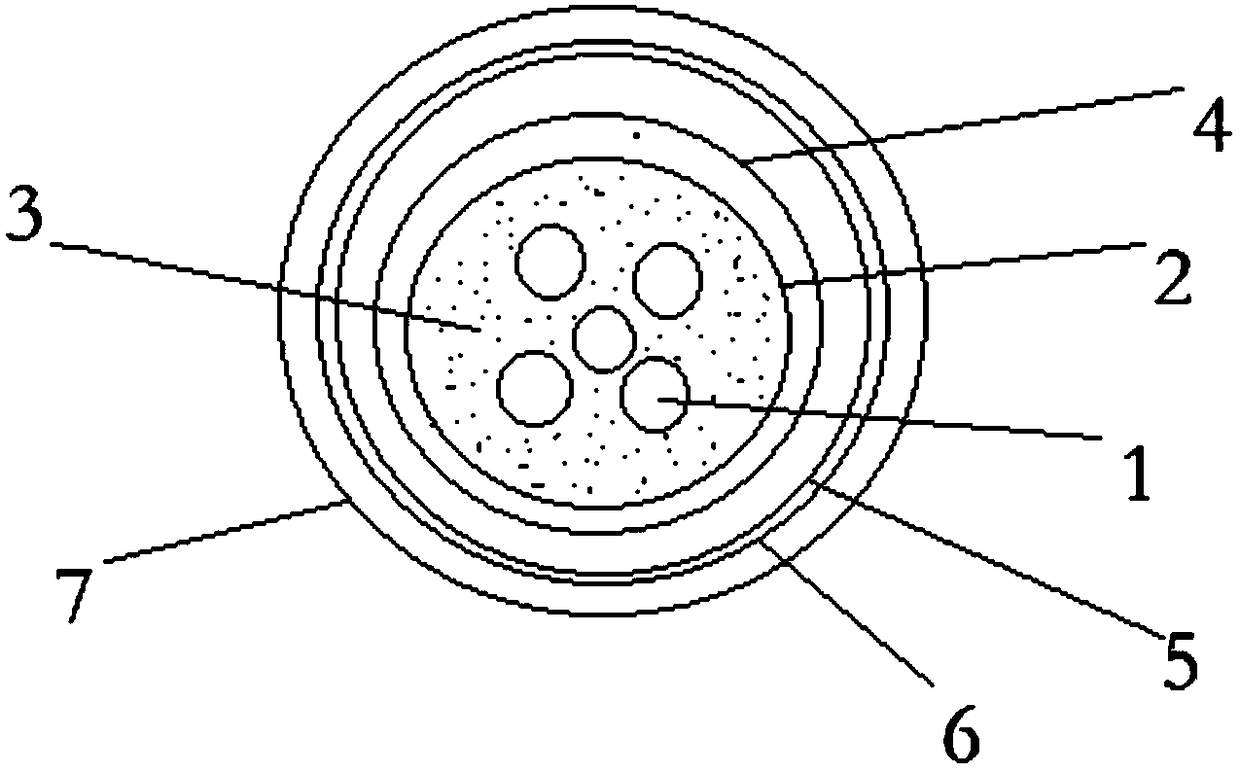

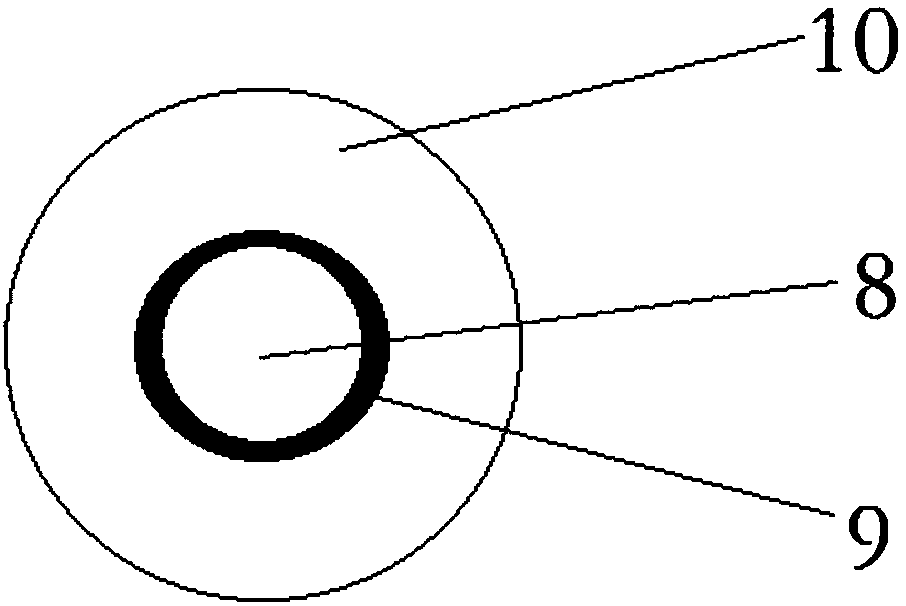

Longitudinal watertight cable

ActiveCN108172330AImprove sealingImprove flame retardant performanceNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesWater blockEngineering

The invention discloses a longitudinal watertight cable for vessel in the technical field of watertight cables. A first waterproof sealant is arranged outside a plurality of cables, a gap between thefirst waterproof sealant and a cable is filled with a water blocking filler, an inner sheath is arranged outside the first waterproof sealant, a shielding layer is arranged outside the inner sheath, asecond waterproof sealant is arranged outside the shielding layer, and an outer sheath is arranged outside the second waterproof sealant. The longitudinal watertight cable is good in sealing performance, and can bear capability of high-pressure water moving along a longitudinal direction of the cable, and the cable has the advantages of high flame retardance, no halogen, low toxicity, moderate mobility of the filler and high pressure resistance and is applicable to the development requirement of the vessel and deep-water equipment.

Owner:扬州市金鑫电缆有限公司

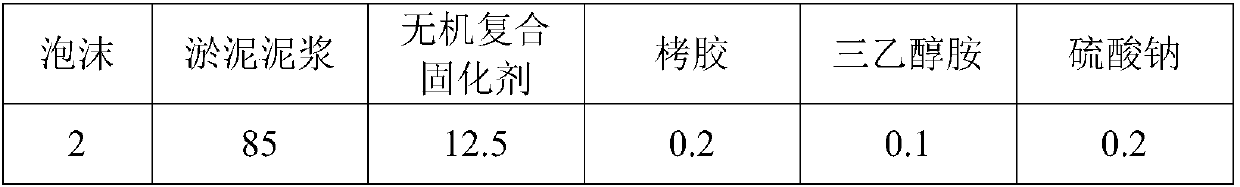

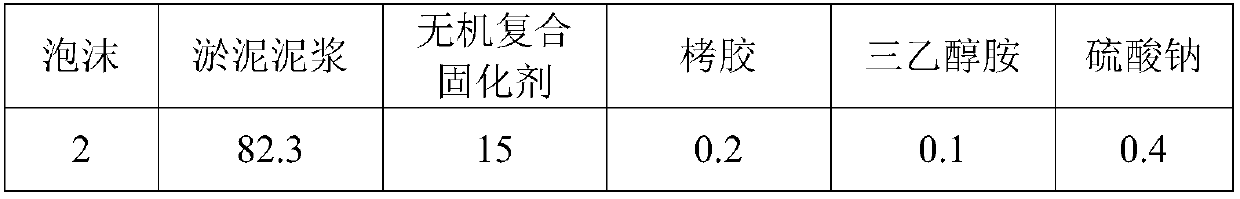

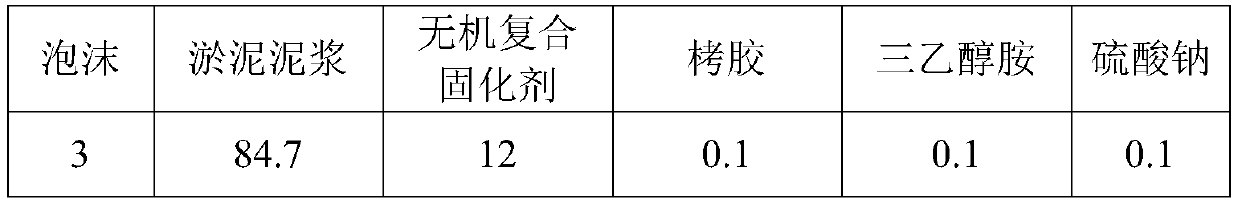

Physical-foaming silty lightweight solidified soil and preparation method thereof

The invention discloses physical-foaming silty lightweight solidified soil. The physical-foaming silty lightweight solidified soil comprises, by mass, 2-3.5% of foam, 80-85% of sludge slurry, 12-16% of inorganic composite curing agents, 0.1-0.2% of viscosity reducer and 0.2-0.5% of early strength agent. The invention further discloses a preparation method of the solidified soil. The lightweight solidified soil has the advantages of light weight, high strength, high stability, easiness in pumping, and the like; sludge is regarded as an important component of the lightweight solidified soil, theresource utilization of the sludge is realized, and the environmental protection advantage is prominent; the lightweight solidified soil can be used as filling soil to be backfilled for highway subgrades and abutments, retaining wall backs, underground projects and pipeline projects; the physical-foaming silty lightweight solidified soil is an environment-friendly building material.

Owner:JIANGSU NATURE WAY TECH

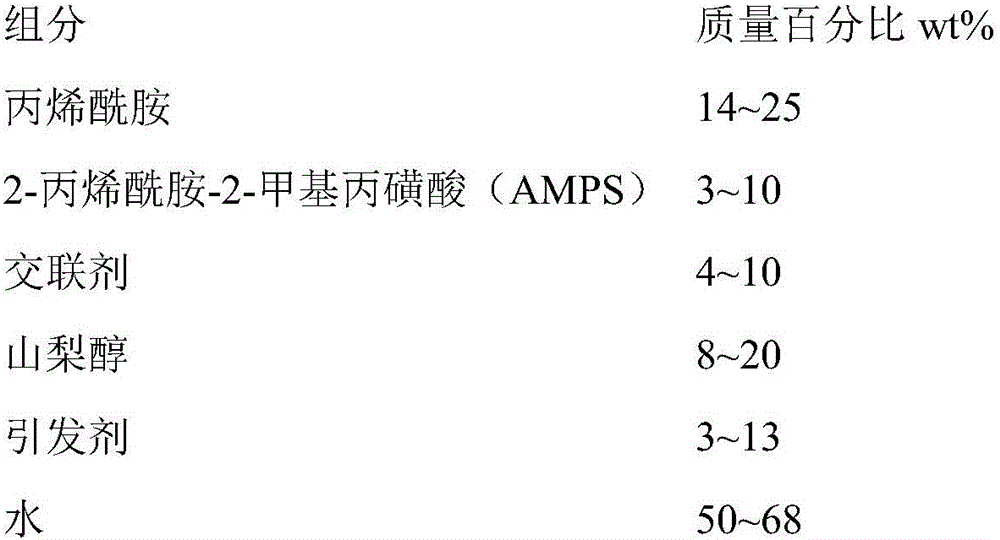

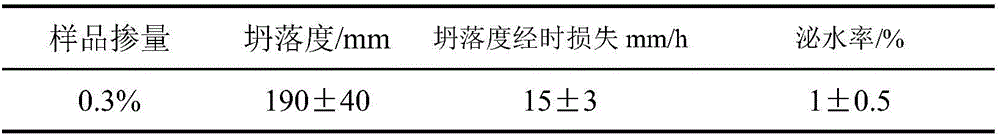

Concrete performance regulator and preparation method thereof

The invention discloses a concrete performance regulator. The concrete performance regulator is prepared from the following components by mass percent: 14 to 25 percent of acrylamide, 3 to 10 percent of AMPS, 4 to 10 percent of cross-linking agent, 8 to 20 percent of sorbitol, 3 to 10 percent of initiator, and 50 to 68 percent of water, wherein the initiator is an oxidization reduction system and consists of a reducing agent and an oxidant, the reducing agent accounts for 1 to 5 percent of the total mass of the formula, and the oxidant accounts for 2 to 8 percent of the total mass of the oxidant. The concrete performance regulator contains a three-dimensional netted structure, so that the dispersity of a binding material can be improved, the mixability of the concrete is improved, the compatibility with polycarboxylate superplasticizer is good, and the concrete performance regulator is suitable for various sand aggregates.

Owner:JIANGXI PINGXIANG CITY LIANYOU BUILDING MATERIAL

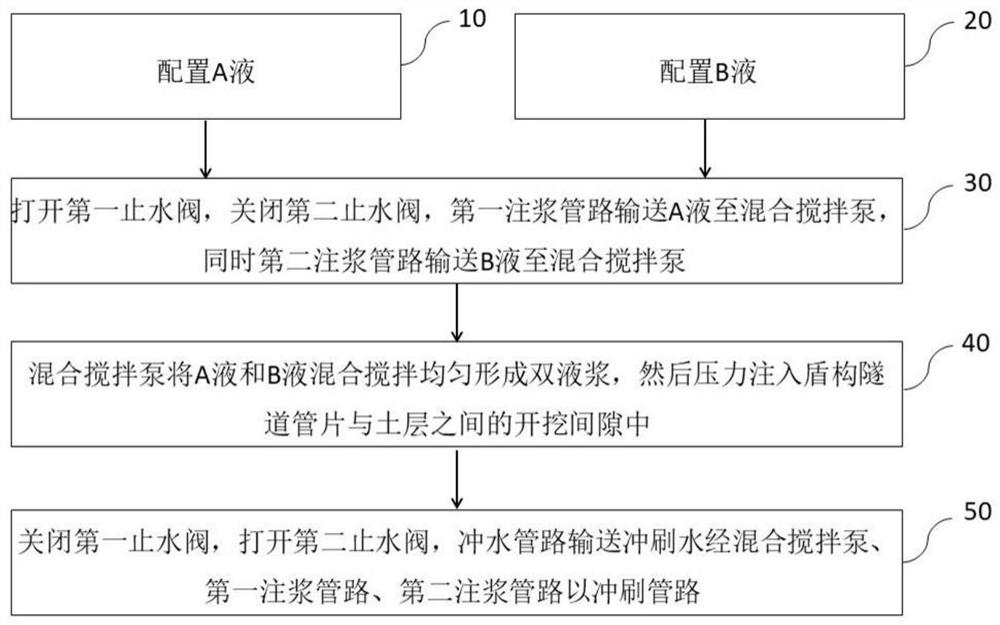

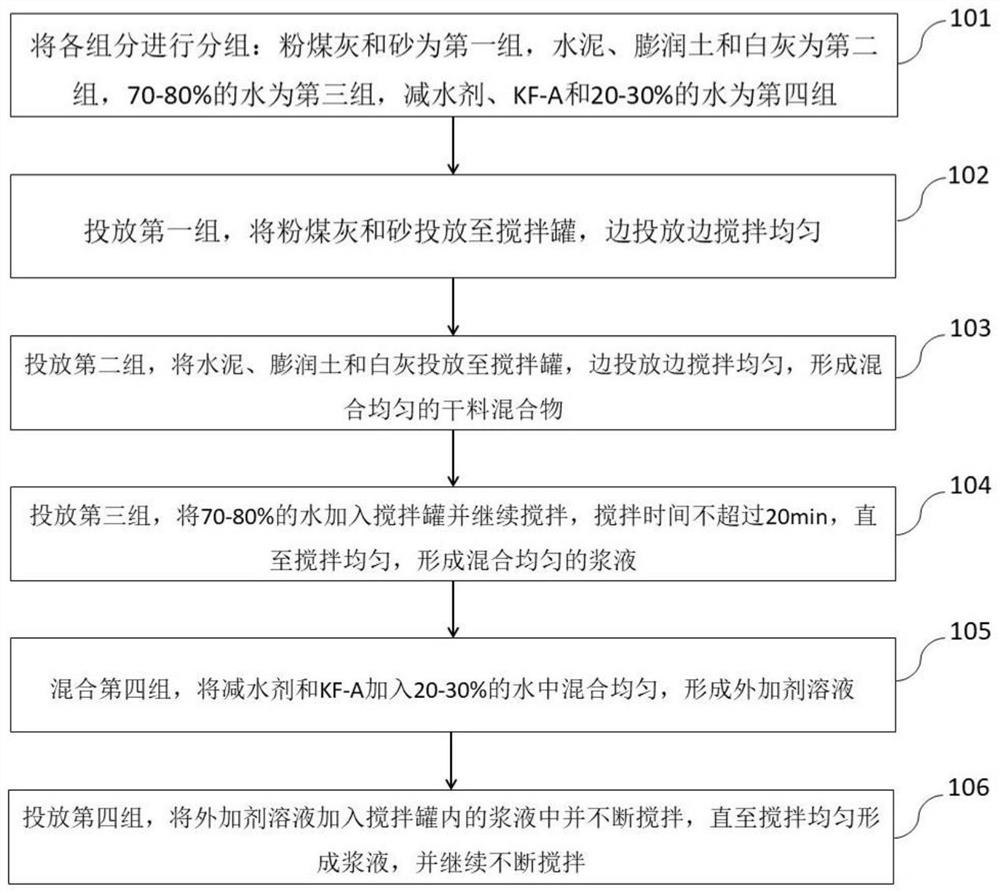

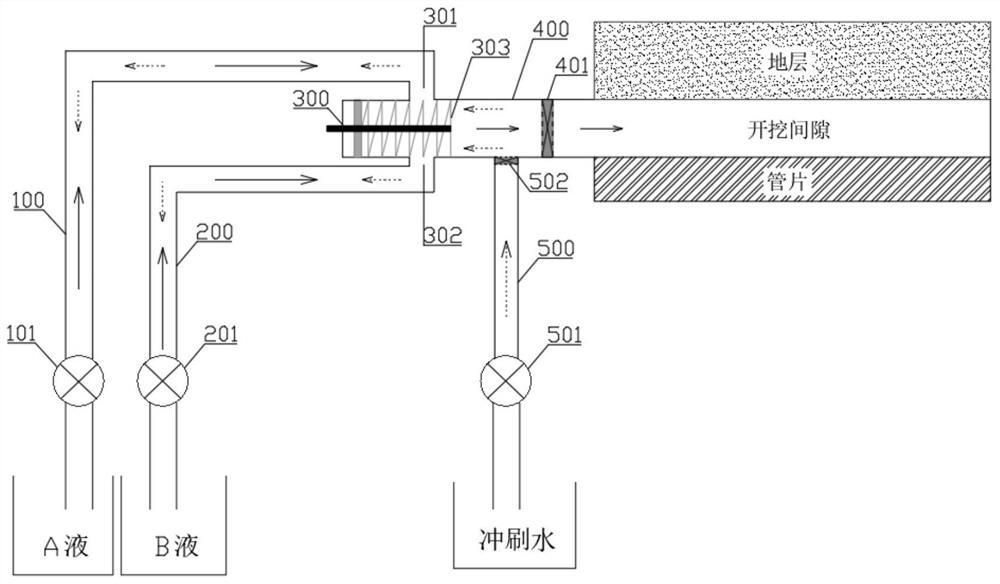

Shield excavation gap synchronous grouting slurry for water-rich powdery soil layer

The invention relates to a shield excavation gap synchronous grouting slurry for a water-rich powdery soil layer, the synchronous grouting slurry is a double-liquid slurry formed by mixing and stirring a liquid A and a liquid B. The liquid A comprises the following concrete components in terms of per cubic meter: 100 to 200 kg of cement; 400 to 600 kg of fly ash; 40 to 80 kg of bentonite; 600 to 800 kg of sand; 20 to 70 kg of lime; 400 to 550 kg of water; 6-9 kg of a water reducing agent; and 10 to 20 kg of KFA (potassium fluosilicate); wherein the solution B is a water glass solution, and the volume ratio of water glass to water is (3-4): 1; the liquid A and the liquid B are mixed and stirred according to the volume ratio of 10: 1. The synchronous grouting slurry disclosed by the invention can be widely applied to a powdery soil layer and is not limited to a pure sandy cobble layer and a pure clay layer, and double slurries can be gelled in an extremely short time, so a reinforcing effect of filling and solidifying is rapidly achieved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

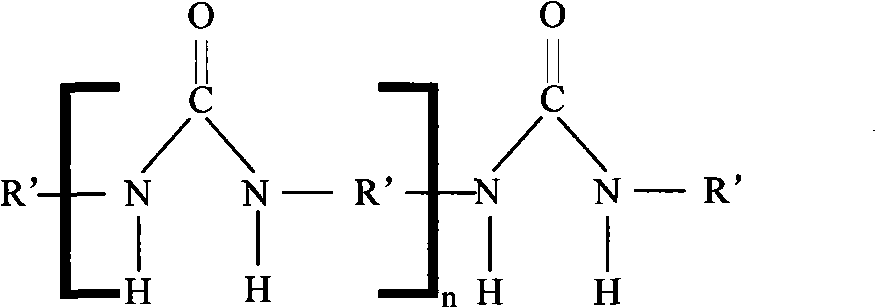

High-defoaming epoxy resin packaging material and preparation method thereof

The invention relates to a high-defoaming epoxy resin packaging material which is characterized by comprising the following components in portions by weight:100 portions of liquid epoxy resin, 5-9 portions of dicyandiamide, 0.05-0.5 portion of N-methyl pyrrolidone solution of carbamate compounds, 1-5 portions of modified imidazole accelerant, 0.1-1 portion of non-conducting carbon black, 0-5 portions of aphyl glycidol ether, 0.05-0.5 portion of organosilane defoaming agent, 40-80 portions of silicon dioxide and 40-80 portions of aluminium hydroxide. The invention also provides a preparation method of the high-defoaming epoxy resin packaging material. The high-defoaming epoxy resin packaging material has the advantages of moderate flowability and high defoaming capacity in the application process, smooth surface and no bubble or pit after curing, and compact inside and no pore residue in the cured material; and the curing temperature is moderate, and the cured material has the advantages of high heat resistance, electric insulating property and strong binding power.

Owner:NICHE TECH KAISER SHANTOU

Chinese torreya essential oil soap

InactiveCN106883959AMild ingredientsRich and fine foamSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsChemistryWool

The invention discloses Chinese torreya essential oil soap. The soap contains the following components in percentage by weight: 7 to 10% of water, 13 to 18% of sorbitol, 8 to 10% of propylene glycol, 15 to 18% of stearic acid, 8 to 12% of lauric acid, 3 to 6% of glycerinum, 6 to 8% of AES, 20 to 25% of saccharose, 0.6 to 1.5% of wool fat, 0.2 to 0.5% of sodium hydroxide, 1 to 3% of alkyl glycoside, 1 to 2% of potassium cocoyl glycinate, 1 to 2% of Chinese torreya essential oil, 0.4 to 0.7% of daily chemical fragrance compound and 0.3 to 0.6% of a Curasao Aloe extract. The Chinese torreya essential oil soap can solve the detects in the prior art, and is a good skin care product capable of moistening skin, delaying senescence and promoting cell metabolism when used at home or during travel.

Owner:浙江如美日化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com