Garlic residue-based liquid mulching film and preparation method thereof

A liquid mulch, garlic residue-based technology, applied in the field of agricultural mulch, can solve the problems of agricultural soil ecological environment destruction, water retention, weakened thermal insulation, non-biodegradability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

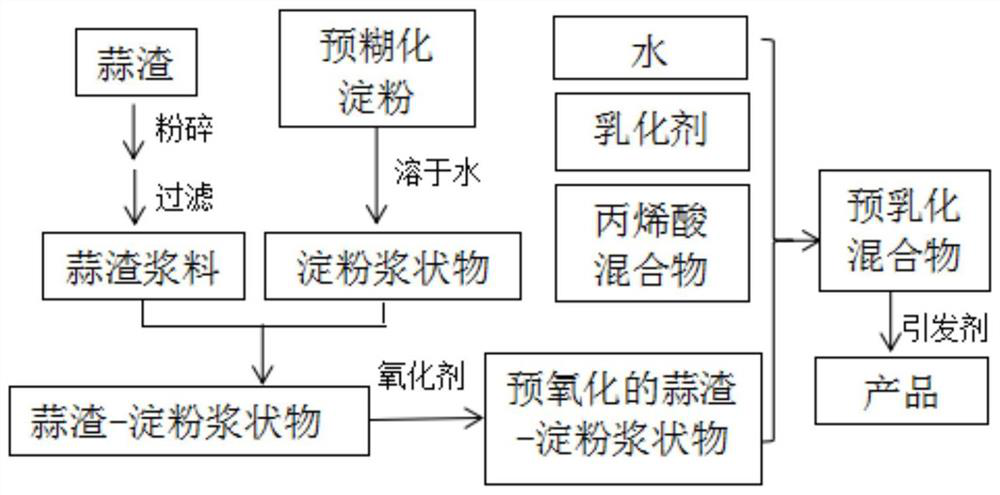

Method used

Image

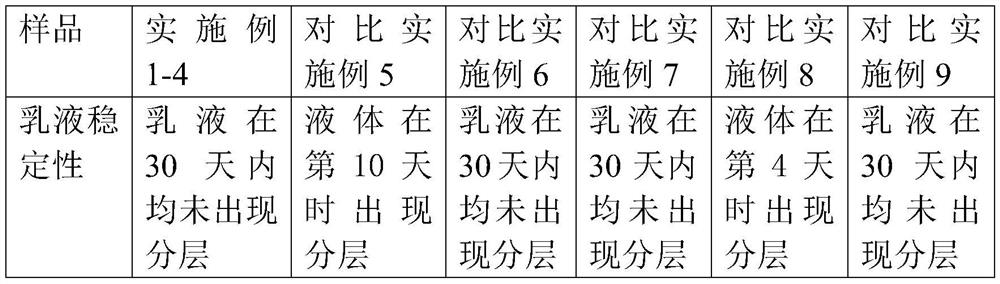

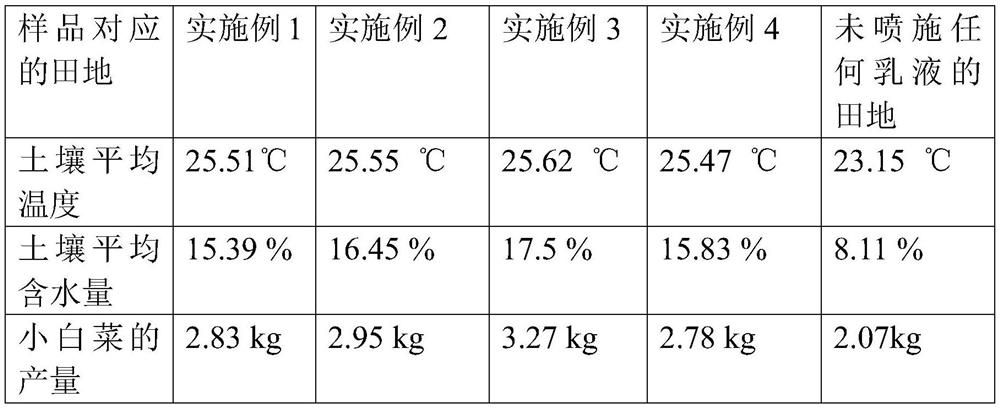

Examples

Embodiment 1

[0040] (1) Crushing the garlic residues into a garlic residue slurry with a pulverizer, and filtering the obtained garlic residue slurry with a sieve, so that the particle size of the garlic residue in the filtered garlic residue slurry is less than 10 mesh;

[0041] (2) Mix pregelatinized starch and water at 28°C to form a starch slurry, wherein the mass ratio between pregelatinized starch and water is 0.15:1;

[0042] (3) Mix the garlic residue slurry obtained in step (1) with the starch slurry obtained in step (2), and stir at 35°C for 1 hour at a stirring speed of 200r / min to obtain garlic residue-starch slurry , wherein the mass ratio between the garlic residue slurry and the starch slurry is 0.09:1;

[0043] (4) the garlic dregs-starch slurry that step (3) obtains is joined in the there-necked flask that is equipped with agitator, thermometer and condenser, then adds oxidant aqueous solution while stirring at 80 DEG C, stirring speed is 1500r / min, the stirring time is 1...

Embodiment 2

[0049] (1) Crushing the garlic residues into a garlic residue slurry with a pulverizer, and filtering the obtained garlic residue slurry with a sieve, so that the particle size of the garlic residue in the filtered garlic residue slurry is less than 10 mesh;

[0050] (2) Mix pregelatinized starch and water at 32°C to form a starch slurry, wherein the mass ratio of pregelatinized starch and water is 0.2:1;

[0051] (3) Mix the garlic residue slurry obtained in step (1) with the starch slurry obtained in step (2), and stir at 28°C for 2 hours at a stirring speed of 1000r / min to obtain garlic residue-starch slurry , wherein the mass ratio between the garlic residue slurry and the starch slurry is 0.5:1;

[0052] (4) the garlic dregs-starch slurry that step (3) obtains is joined in the there-necked flask that is equipped with agitator, thermometer and condenser, then adds oxidant aqueous solution while stirring at 88 ℃, stirring speed is 1000r / min, the stirring time is 3h, and th...

Embodiment 3

[0058] (1) Crushing the garlic residues into a garlic residue slurry with a pulverizer, and filtering the obtained garlic residue slurry with a sieve, so that the particle size of the garlic residue in the filtered garlic residue slurry is less than 10 mesh;

[0059] (2) Mix the pregelatinized starch and water at 25°C to form a starch slurry, wherein the mass ratio between the pregelatinized starch and water is 0.18:1;

[0060] (3) Mix the garlic residue slurry obtained in step (1) with the starch slurry obtained in step (2), and stir at 25°C for 3 hours at a stirring speed of 2000r / min to obtain garlic residue-starch slurry , wherein the mass ratio between the garlic residue slurry and the starch slurry is 0.3:1;

[0061] (4) the garlic dregs-starch slurry that step (3) obtains is joined in the there-necked flask that is equipped with agitator, thermometer and condenser, then adds oxidant aqueous solution while stirring at 85 ℃, stirring speed is 500r / min, the stirring time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com