Preparation method for intelligent chromogenic antibiosis antioxidant freshness-retaining film

A film preparation and anti-oxidation technology, applied in the field of food packaging materials, to achieve the effects of easy control of film making process, promotion of full mixing, and prolongation of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] (1) Preparation of polyvinyl alcohol mother liquor:

[0029] Accurately weigh 22g of PVA into a beaker, add 200ml of deionized water, and heat it in a high-temperature cooking pot at 121°C for 40 minutes. After the temperature in the cooking pot drops to 90°C, take out the beaker and place it in a heat collecting In the constant temperature heating magnetic stirrer, adjust the rotation speed to 50rpm, use a pipette gun to add 1ml glycerin as a plasticizer while magnetically stirring in a water bath, and finally obtain the PVA mother liquor;

[0030] (2)PVA-TiO 2 Preparation of mixed solution:

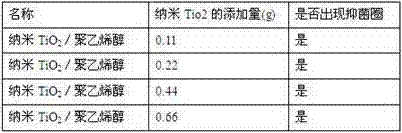

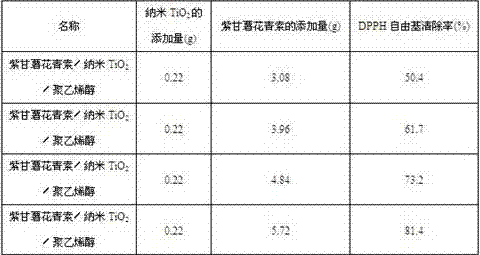

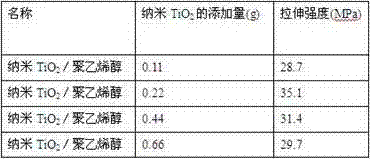

[0031] Put the PVA mother liquor in a collector-type constant temperature heating magnetic stirrer at 40°C, adjust the rotation speed to 50rpm, and add a certain proportion of nano-TiO to the PVA mother liquor while magnetically stirring in a water bath 2 , the amount added is 0.5%~3% of the PVA amount, and the water bath is magnetically stirred for 2 hours to avoid the aggrega...

Embodiment 1

[0056] Accurately weigh 22g of PVA into a beaker, add 200ml of deionized water, and heat it in a high-temperature cooking pot at 121°C for 40 minutes. After the temperature in the cooking pot drops to 90°C, take out the beaker and place it in a heat collecting In the constant temperature heating magnetic stirrer, adjust the rotation speed to 50rpm, use a pipette gun to add 1ml glycerin as a plasticizer while magnetically stirring in a water bath, and finally obtain the PVA mother liquor;

[0057] Put the PVA mother liquor in a collector-type constant temperature heating magnetic stirrer at 40°C, adjust the rotation speed to 50rpm, and add a certain proportion of nano-TiO to the PVA mother liquor while magnetically stirring in a water bath 2 , the addition amount is 0.5% of the PVA dosage, and the water bath is magnetically stirred for 2h to avoid the aggregation of nanoparticles. The blended solution was sonicated for 10 minutes to remove the air bubbles in the solution, and f...

Embodiment 2

[0061] Accurately weigh 22g of PVA into a beaker, add 200ml of deionized water, and heat it in a high-temperature cooking pot at 121°C for 40 minutes. After the temperature in the cooking pot drops to 90°C, take out the beaker and place it in a heat collecting In the constant temperature heating magnetic stirrer, adjust the rotation speed to 50rpm, use a pipette gun to add 1ml glycerin as a plasticizer while magnetically stirring in a water bath, and finally obtain the PVA mother liquor;

[0062] Put the PVA mother liquor in a collector-type constant temperature heating magnetic stirrer at 40°C, adjust the rotation speed to 50rpm, and add a certain proportion of nano-TiO to the PVA mother liquor while magnetically stirring in a water bath 2 , the addition amount is 1% of the PVA dosage, and the water bath is magnetically stirred for 2h to avoid the aggregation of nanoparticles. The blended solution was sonicated for 10 minutes to remove the air bubbles in the solution, and fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com