Normal-temperature yoghurt containing complete fruit granules and preparation method thereof

A fruit and yoghurt technology, applied in the direction of milk preparations, dairy products, applications, etc., to achieve the effect of high uniformity, moderate viscosity and fluidity, and good flavor release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

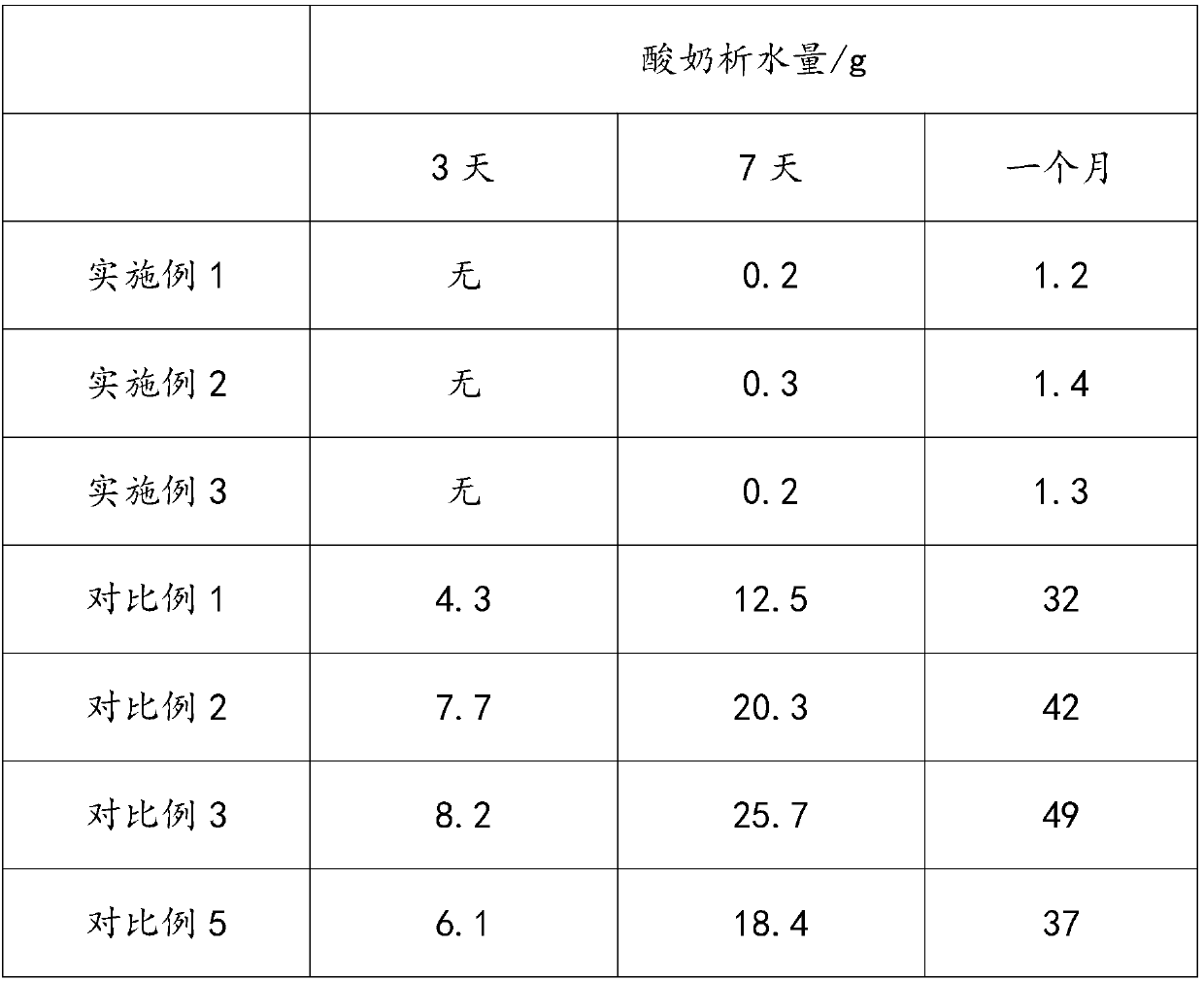

Examples

Embodiment 1

[0060] (1) Evenly mix non-antibiotic milk with sucrose, starch, agar and sodium alginate after sterilizing at 135°C for 5s to obtain a mixed solution. The ratio is as follows:

[0061] ingredients

Non-antibiotic milk after sterilization

sodium alginate

Addition wt%

90

6.3

1.5

2

0.2

[0062] In the above ingredients, the protein content in the raw milk is 2.8wt%, the fat is 2.8wt%, the lactose content is 3.0wt%, the mineral substance is 0.5wt%, the non-fat milk solid is 6.3wt%, and the titrated acidity is ≤18°T. The modified starch in the above ingredients is made from corn or waxy corn and denatured by heat treatment.

[0063] The mixing temperature of the above ingredients is 45°C, and the vacuum cycle time is 30 min.

[0064] (2) Homogenize the mixed solution obtained in step (1) at 45° C., with a pressure of 150 bar;

[0065] (3) The homogenized liquid is pasteurized at a temperature of 9...

Embodiment 2

[0075] (1) Evenly mix non-antibiotic milk with sucrose, starch, agar and sodium alginate after sterilizing at 137°C for 3 seconds to obtain a mixed solution. The mixing ratio is as follows:

[0076] ingredients

Non-antibiotic milk after sterilization

sucrose

modified starch

agar

Addition wt%

94.7

4

1.0

0.2

0.1

[0077] The protein content in the raw milk in the above ingredients is 3.1wt%, the fat is 3.1wt%, the lactose content is 4wt%, the mineral matter is 0.8wt%, the non-fat milk solid is 7.9wt%, and the titrated acidity is ≤18°T. The modified starch in the above ingredients is made from cassava starch, which is denatured by heat treatment.

[0078] The mixing temperature of the above-mentioned ingredients is 65° C., and the vacuum cycle time is 20 min.

[0079] (2) Homogenize the mixed solution obtained in step (1) at 65° C., with a pressure of 200 bar;

[0080] (3) The homogenized liquid is pasteuri...

Embodiment 3

[0090] (1) Evenly mix non-antibiotic milk with sucrose, starch, agar and sodium alginate after sterilizing at 136°C for 4s to obtain a mixed solution. The ratio is as follows:

[0091] ingredients

Non-antibiotic milk after sterilization

sucrose

modified starch

agar

Addition wt%

91.45

8

1.2

0.25

0.1

[0092] The protein content in the raw milk in the above ingredients is 2.95wt%, the fat is 2.95wt%, the lactose content is 3.5wt%, the mineral matter is 0.65wt%, the non-fat milk solid is 7.1wt%, and the titrated acidity is ≤18°T. The modified starch in the above ingredients is made from potato starch and denatured by heat treatment.

[0093] The mixing temperature of the above ingredients was 55°C, and the vacuum cycle time was 25 min.

[0094] (2) Homogenize the mixed solution obtained in step (1) at 55° C., with a pressure of 180 bar;

[0095] (3) The homogenized liquid is pasteurized at a temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com