Preparation method of yttrium oxide-stabilized zirconia pelletized powder

A technology for stabilizing zirconia and yttrium oxide, which is applied in the field of preparation of yttria-stabilized zirconia granulation powder, and can solve the problems of low output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

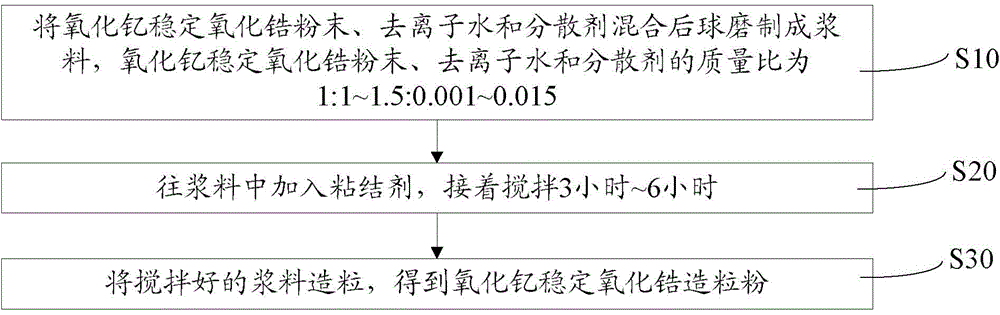

[0022] Such as figure 1 Shown, the preparation method of the yttria stabilized zirconia granulated powder of one embodiment, comprises the steps:

[0023] S10. Mix the yttria-stabilized zirconia powder, deionized water and dispersant and then ball mill to make a slurry. The mass ratio of yttria-stabilized zirconia powder, deionized water and dispersant is 1:1~1.5:0.001~0.015 .

[0024] In this embodiment, the yttria-stabilized zirconia powder includes zirconia and yttrium oxide, wherein the mass ratio of zirconia to yttrium oxide may be 94-95.2:4.8-6.

[0025] In other embodiments, the yttria-stabilized zirconia powder includes zirconia, yttrium oxide and alumina, wherein the mass ratio of zirconia, yttrium oxide and alumina may be 94-95.2:4.8-6:0.1-0.6.

[0026] The specific surface area of yttria stabilized zirconia powder can be 7m 2 / g~16m 2 / g. The yttria-stabilized zirconia powder may be yttria-stabilized zirconia calcined powder.

[0027] The yttria in the yttri...

Embodiment 1

[0044] Select the specific surface area as 9±2m 2 / g, the self-made yttria-stabilized zirconia calcined powder with an alumina addition of 0.25wt% and a yttrium oxide content of 5.4wt%.

[0045] Put 100kg of the selected yttria-stabilized zirconia calcined powder into a ball mill, add 120kg of deionized water, add 0.5kg of ammonium polyacrylate, and grind for 24 hours. The particle size D50 of the slurry after grinding is 0.5 μm to 0.7 μm.

[0046]The slurry is pumped into the stirring tank, then add 4kg of dissolved 5wt% sodium carboxymethylcellulose solution and 10kg of dissolved 10wt% PVA (polymerization degree: 1750, about 70000 molecular weight) solution, stir in the stirring tank for 4 Hour.

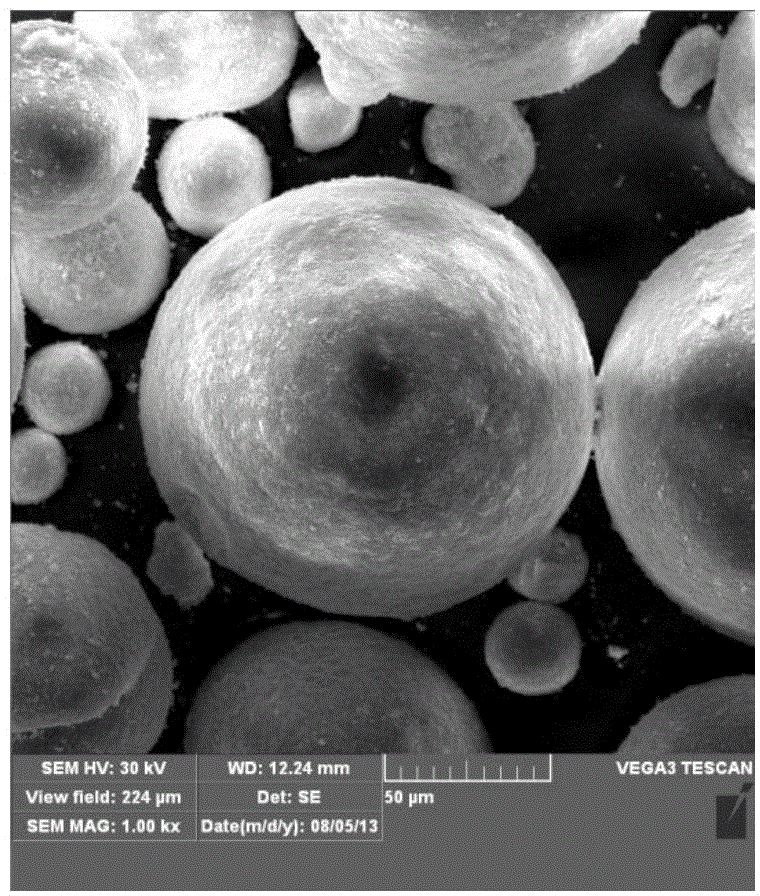

[0047] Use the feeding pump to pump the stirred slurry into the spray granulator for spray granulation, adjust the parameters of the spray granulator so that the inlet air temperature is controlled at 200°C and the outlet air temperature is controlled at 100°C, and the frequency o...

Embodiment 2

[0054] Select the specific surface area as 14±2m 2 / g, the homemade yttria-stabilized zirconia calcined powder with yttrium oxide content of 4.8wt%.

[0055] Put 100kg of the selected yttria-stabilized zirconia calcined powder into a ball mill, add 100kg of deionized water, add 0.1kg of CE-64, and grind for 24 hours. The particle size D50 of the slurry after grinding is 0.4 μm to 0.6 μm.

[0056] The slurry was pumped into a stirring tank, then 5 kg of dissolved 10 wt % PVA solution and 5 kg of dissolved 10 wt % B-1022 solution were added, and stirred in the stirring tank for 3 hours.

[0057] Use the feeding pump to pump the stirred slurry into the spray granulator for spray granulation, adjust the parameters of the spray granulator so that the inlet air temperature is controlled at 250°C and the outlet air temperature is controlled at 120°C, and the frequency of the feed pump is adjusted. 40Hz, atomizer speed 7000 rpm, and then spray granulation.

[0058] Pass the granulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com