High-transparency flame-retarding polycarbonate thin film/sheet material as well as preparation method and application thereof

A technology of flame-retardant polycarbonate and polycarbonate, which is applied in the field of high-transparency flame-retardant polycarbonate film/sheet and its preparation, can solve the problem of unfavorable compounding and the influence of blended phosphorus-based flame-retardant polycarbonate on transparency, Problems such as linear increase of melt index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 9

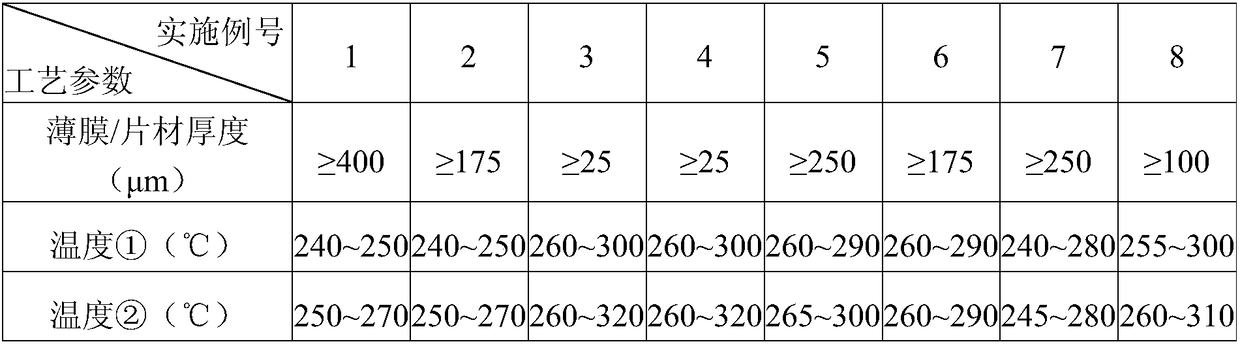

[0067] A highly transparent flame-retardant polycarbonate film / sheet is: 100 parts by mass of bisphenol A polycarbonate, 2 parts by mass of long-chain branched polycarbonate, 0.1 parts by mass of flame retardant A, A mixture of 3 parts by mass of agent B, 0.2 parts by mass of chain extender, 0.5 parts by mass of antioxidant and 0.2 parts by mass of heat stabilizer is melted and extruded by a salivating extruder at a temperature of 240°C, and cast on a cold roll at a temperature of 80°C Casting and cooling to obtain highly transparent flame-retardant polycarbonate film / sheet.

Embodiment 10

[0069] A highly transparent flame-retardant polycarbonate film / sheet is: 100 parts by mass of bisphenol A polycarbonate, 15 parts by mass of long-chain branched polycarbonate, 10 parts by mass of flame retardant A, and 10 parts by mass of flame retardant B A mixture of 20 parts by mass, 2 parts by mass of chain extender, 1 part by mass of antioxidant and 2 parts by mass of heat stabilizer is melted and extruded by a salivating extruder at a temperature of 320°C, and cast on a cold roll at a temperature of 110°C , cooling to obtain highly transparent flame-retardant polycarbonate film / sheet.

Embodiment 11

[0071] A highly transparent flame-retardant polycarbonate film / sheet is: 100 mass parts of bisphenol A polycarbonate, 8.5 mass parts of long-chain branched polycarbonate, 5 mass parts of flame retardant A, flame retardant The mixture of 11.5 parts by mass of B, 1.1 parts by mass of chain extender, 0.75 parts by mass of antioxidant and 1.1 parts by mass of heat stabilizer is melted and extruded by a salivating extruder at a temperature of 280°C, and cast on a cold roll at a temperature of 95°C Casting and cooling to obtain a highly transparent flame-retardant polycarbonate film / sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com