Nickel-based single-crystal high-temperature alloy connecting powder brazing filler metal as well as preparation method and application thereof

A nickel-based superalloy and alloy powder technology, applied in welding equipment, metal processing equipment, welding/cutting medium/material, etc., can solve the problems of inability to meet the use requirements, low high temperature performance, etc. The effect of high temperature and small dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The base material to be welded in this embodiment is a nickel-based superalloy CMSX-4, and the chemical composition of the alloy is (wt.%): Ni-9Co-6.5Cr-6W-6.5Ta-5.6Al-3Re-1Ti-0.6Mo.

[0032] The chemical composition of the solder is (wt.%): Ni-14Cr-9.5Co-4Al-4W-4Mo-5Ti-0.1Si-0.8B.

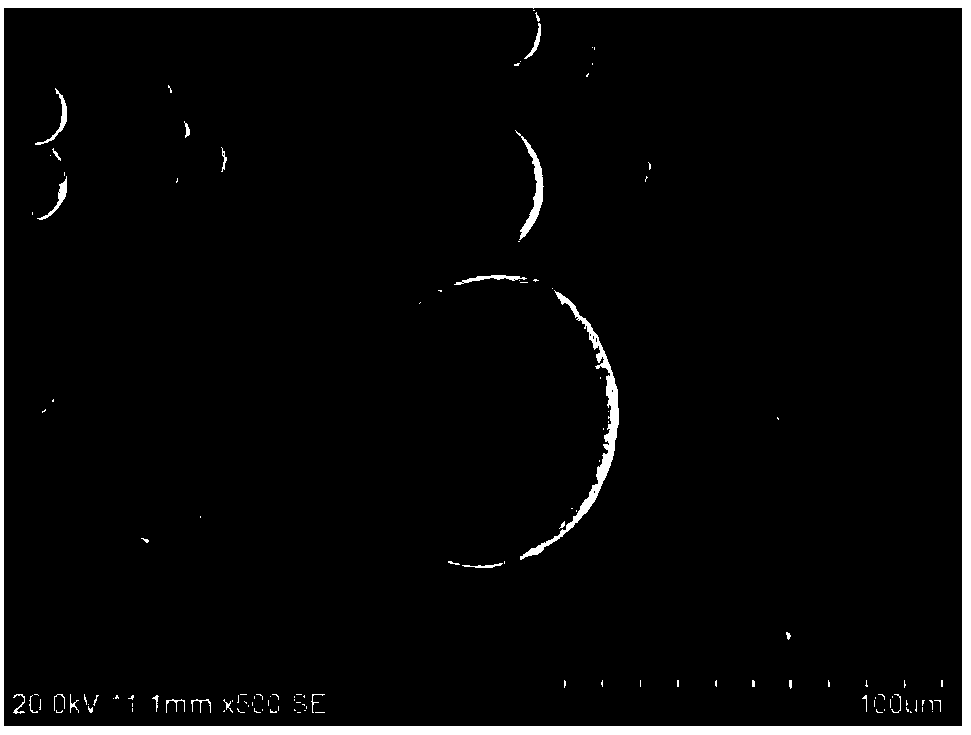

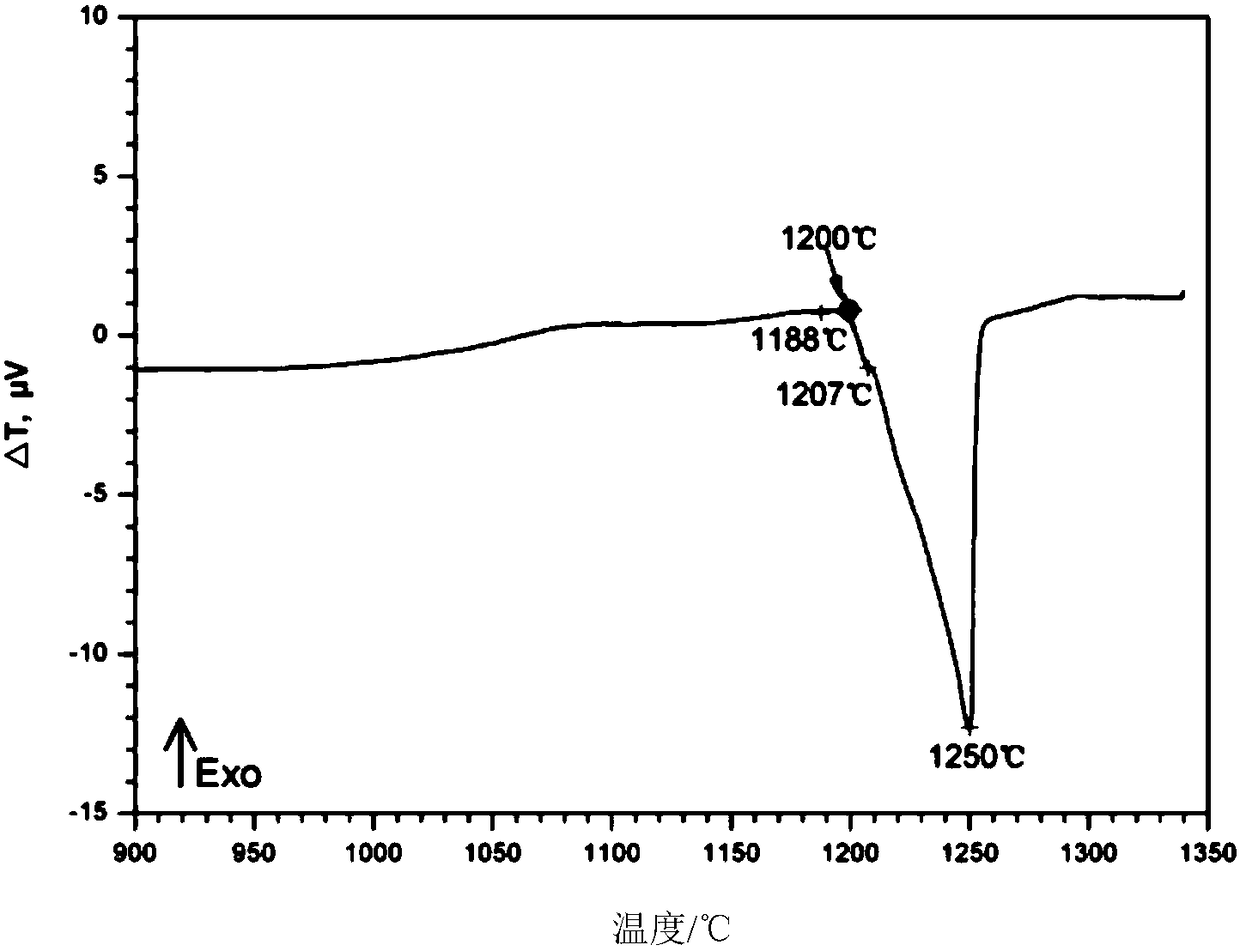

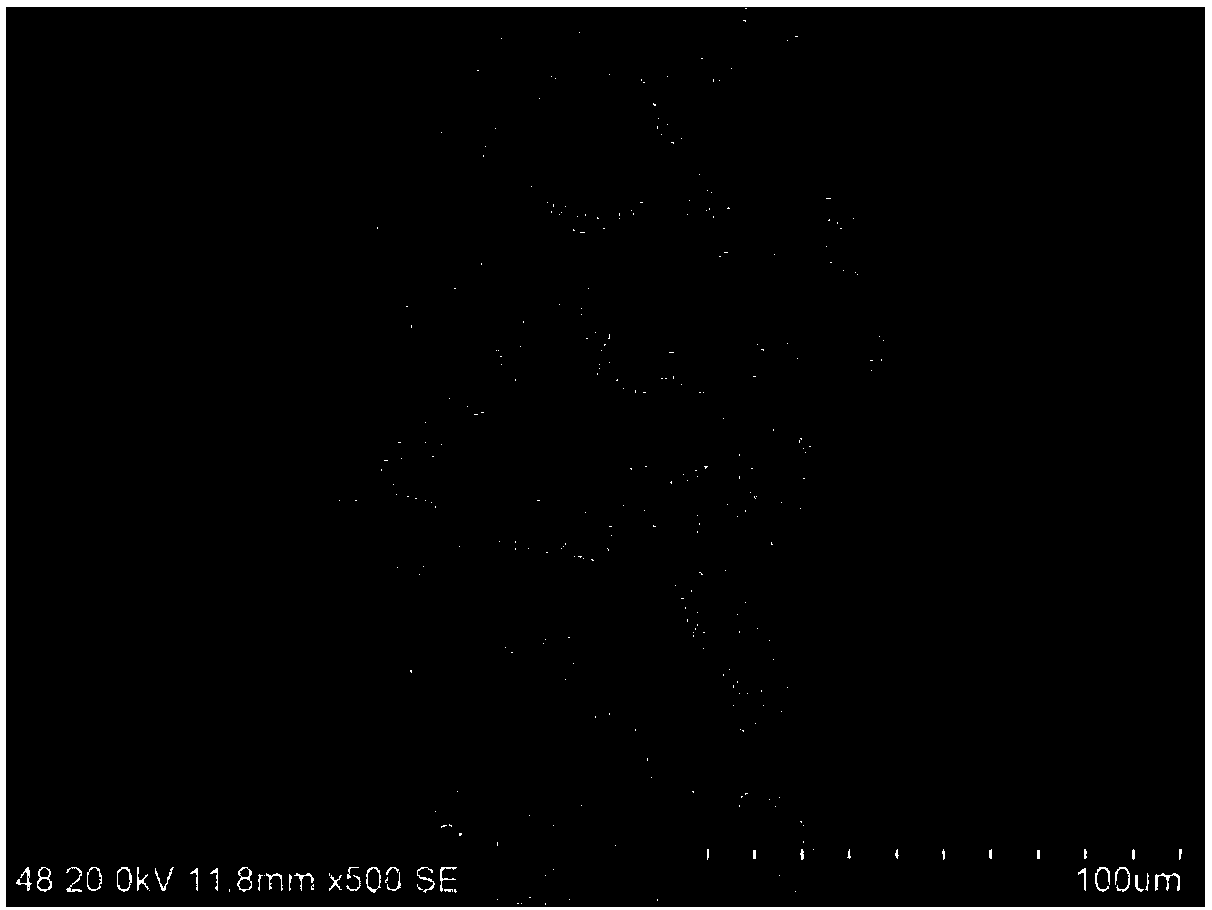

[0033] Brazing filler metal preparation method: mix the raw materials with a purity greater than 99.99% in proportion and put them into a vacuum arc melting furnace to melt them into alloy ingots. The melting process is: 1590°C / 1min→1550°C / 10min→1350°C / 10min→1450°C Pouring; after that, the smelted alloy ingot is melted into a metal liquid flow with a temperature higher than 1400 °C, and the metal liquid flow is impacted with argon gas to atomize it into fine droplets, which form alloy powder after rapid cooling, and sieve out no more than 200 mesh powder.

[0034] Before welding, the solid solution nickel-based superalloy CMSX-4 is processed into Use No. 800 sandpaper to grind the surfac...

Embodiment 2

[0037] The base material to be welded in this embodiment is a nickel-based superalloy CMSX-4, and the chemical composition of the alloy is (wt.%): Ni-9Co-6.5Cr-6W-6.5Ta-5.6Al-3Re-1Ti-0.6Mo.

[0038] The chemical composition of the solder is (wt.%): Ni-14Cr-9.5Co-4Al-4W-4Mo-5Ti-0.1Si-1B.

[0039] Brazing filler metal preparation method: mix the raw materials with a purity greater than 99.99% in proportion and put them into a vacuum arc melting furnace to melt them into alloy ingots. The melting process is: 1590°C / 1min→1550°C / 10min→1350°C / 10min→1450°C Pouring; after that, the smelted alloy ingot is melted into a metal liquid flow with a temperature higher than 1400 °C, and the metal liquid flow is impacted with argon gas to atomize it into fine droplets, which form alloy powder after rapid cooling, and sieve out no more than 200 mesh powder.

[0040] Before welding, the solid solution nickel-based superalloy CMSX-4 is processed into Use No. 800 sandpaper to grind the surface t...

Embodiment 3

[0043] The base material to be welded in this embodiment is a nickel-based superalloy CMSX-4, and the chemical composition of the alloy is (wt.%): Ni-9Co-6.5Cr-6W-6.5Ta-5.6Al-3Re-1Ti-0.6Mo.

[0044] The solder composition is (wt.%): Ni-12Cr-9.5Co-3.5Al-4.5W-3.5Mo-3Ti-3Si-0.8B.

[0045] Brazing filler metal preparation method: mix the raw materials with a purity greater than 99.99% in proportion and put them into a vacuum arc melting furnace to melt them into alloy ingots. The melting process is: 1590°C / 1min→1550°C / 10min→1350°C / 10min→1450°C Pouring; after that, the smelted alloy ingot is melted into a metal liquid flow with a temperature higher than 1400 °C, and the metal liquid flow is impacted with argon gas to atomize it into fine droplets, which form alloy powder after rapid cooling, and sieve out no more than 200 mesh powder.

[0046] Before welding, the solid solution nickel-based superalloy CMSX-4 is processed into Use No. 800 sandpaper to grind the surface to be weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com