Ti element control method for Ti-contained corrosion resistant alloy ingot extracting electroslag remelting slab

A corrosion-resistant alloy and electroslag remelting technology, which is applied in the field of special alloy refining, can solve problems such as poor fluidity, achieve the effects of reducing production costs, reducing energy consumption, and saving forging blanking processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Adopting the "Ti element control method for electroslag remelting slabs of Ti-containing iron-nickel-based corrosion-resistant alloys" of the present invention to produce UNS N08825 ingot-drawing electroslag remelting slabs with specifications of 200mm×1250mm×4000mm and weighing about 8000Kg, Include the following steps.

[0065] In the first step, the consumable electrode is smelted by the "medium frequency induction furnace + AOD" process. The electrode size is 270mm×1370mm×2800mm. The chemical composition of the electrode is shown in Table 1.

[0066] Table 1 UNS N08825 electrode chemical composition (weight %)

[0067]

[0068] The second step is to polish the surface of the consumable electrode and weld it on the dummy electrode.

[0069] The third step is to calculate the TiO required in the slag discharge system when the Ti burning loss reaction reaches equilibrium through the chemical reaction equilibrium formula and thermodynamic principles. 2 content, the...

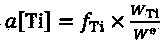

Embodiment 2

[0125] Adopting the "Ti element control method for electroslag remelting slabs of Ti-containing iron-nickel-based corrosion-resistant alloys" of the present invention to produce UNS N08825 ingot-drawing electroslag remelting slabs with specifications of 200mm×1250mm×4000mm and weighing about 8000Kg, Include the following steps.

[0126] The first step is to use the "medium frequency induction furnace + AOD" process to smelt the consumable electrode. The electrode size is 270mm×1370mm×2800mm, and the chemical composition of the electrode is shown in Table 3;

[0127] Table 3 UNS N08825 electrode chemical composition (weight %)

[0128]

[0129] The second step is to polish the surface of the consumable electrode and weld it on the dummy electrode;

[0130] The 3rd step, repeat the 3rd step in the embodiment 1, obtain the activity of Al a [Al]=1.67, the activity of Ti a [Ti]=21.29, TiO 2 Theoretical concentration 0.036, Al 2 o 3 Theoretical concentration 0.42;

[0131]...

Embodiment 3

[0142] The "Ti element control method for electroslag remelting slabs of Ti-containing iron-nickel-based corrosion-resistant alloys" of the present invention is used to produce UNS N08825 ingot-drawing electroslag remelting slabs with a size of 200mm×1250mm×4000mm and a weight of about 8000Kg.

[0143] The first step is to use the "medium frequency induction furnace + AOD" process to smelt the consumable electrode. The electrode specification is 270mm×1370mm×2800mm, and the chemical composition of the electrode is shown in Table 5;

[0144] Table 5 UNS N08825 electrode chemical composition (weight %)

[0145]

[0146] The second step is to polish the surface of the consumable electrode and weld it on the dummy electrode;

[0147] The 3rd step, repeat the 3rd step of embodiment 1, obtain the activity of Al a [Al]=1.46, the activity of Ti a [Ti]=21.59, TiO 2 Theoretical concentration 0.037, Al 2 o 3 The theoretical concentration is 0.356;

[0148] In the fourth step, ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com