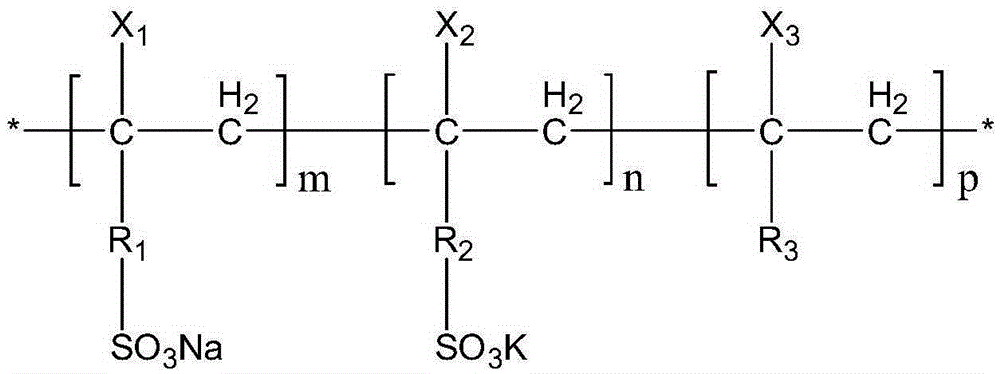

Polymer sulfonate fire retardant, and preparation method as well as application thereof

A polymer and sulfonate technology, applied in the field of sulfonate flame retardants, can solve the problems of poor water solubility and compatibility affecting light transmittance and haze, difficult to disperse uniformly, easy migration of components, etc., to achieve excellent High light transmittance and low haze, strong hydrophobicity, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

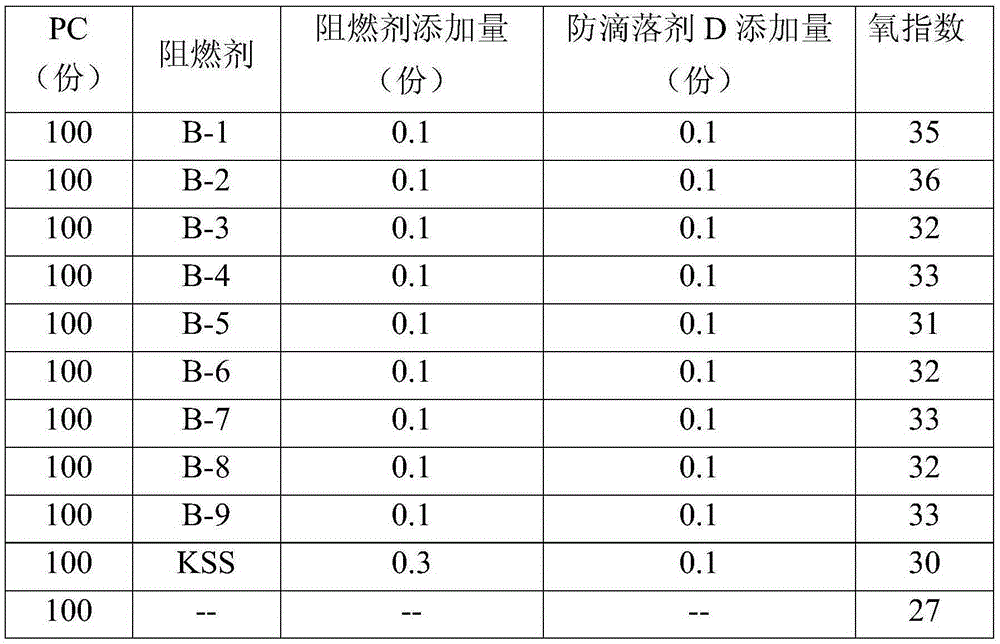

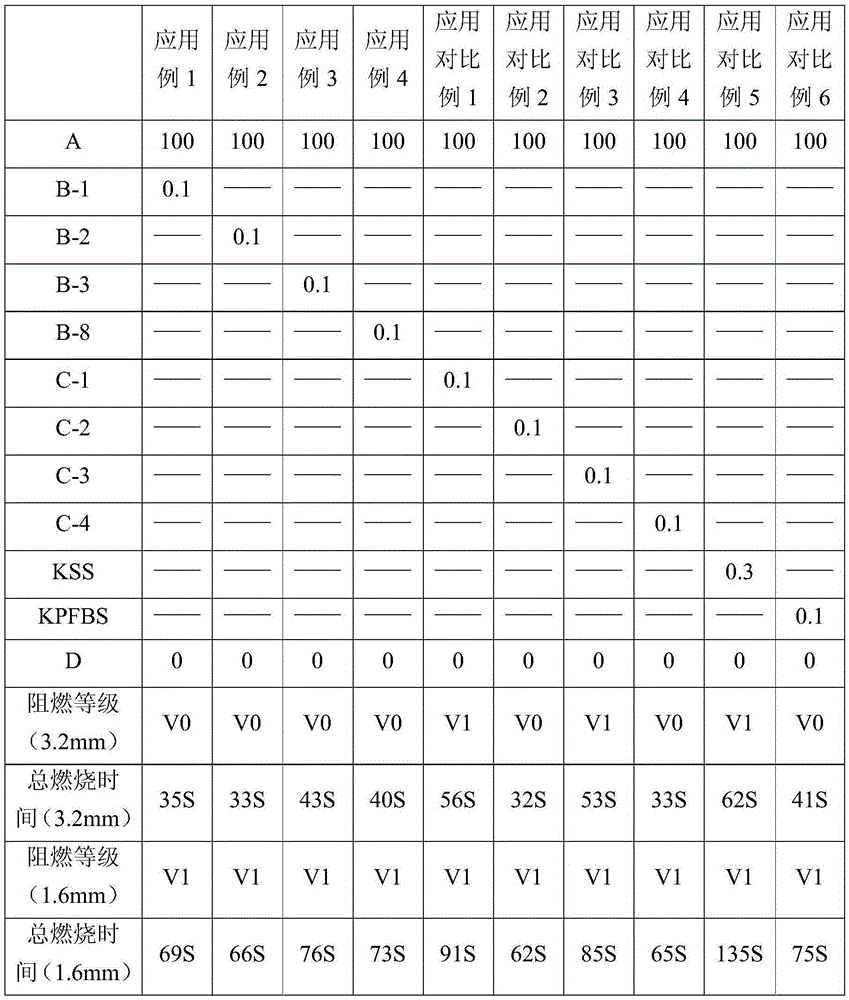

preparation example 1

[0038] Add 100g deionized water, 1.2g sodium lauryl sulfate, 1.3g sodium dodecyl diphenyl ether disulfonate into a 500ml reactor, stir and heat up to 75°C under nitrogen protection, and mix 70g styrene (0.6731 mol), 1.5g dodecyl mercaptan mixed solution, 125g25% sodium allyl sulfonate solution (0.2170mol), and 25g25% potassium allyl sulfonate solution (0.0391mol) are respectively placed in three constant pressure dropping funnels , add 35g of 3% ammonium persulfate solution to start the reaction, and at the same time start to add the monomer evenly, control the temperature at 75-80°C, stir at a constant speed, add dropwise for 3h, keep at 80°C for 1h, then cool down, discharge, dry the emulsion, and pulverize Then get the product. According to the GPC method, the number average molecular weight of the product is about 11000, and it is named as B-1. The molar ratio of the sum of allyl sulfonate monomer and allyl potassium sulfonate monomer to styrene monomer is 0.38:1; the mol...

preparation example 2

[0040] Add 100g of deionized water, 1.0g of sodium lauryl sulfate, 1.0g of octylphenol polyoxyethylene ether-10 into a 500ml reactor, stir and raise the temperature to 75°C under nitrogen protection, and dissolve 79g of methyl methacrylate (0.7900mol), 75g25% sodium styrene sulfonate solution (0.0911mol), 75g25% potassium styrene sulfonate solution (0.0845mol) are placed in three constant pressure dropping funnels respectively, add 30g3% ammonium persulfate solution to start the reaction At the same time, start to drop the monomer evenly, control the temperature at 74-78°C, stir at a constant speed, add dropwise for 3 hours, keep at 80°C for 1 hour, then cool down, discharge, dry the emulsion, and crush to obtain the product. According to the GPC method, the number average molecular weight of the product is about 82000, named as B-2. The molar ratio of the sum of sodium styrene sulfonate monomer and potassium styrene sulfonate monomer to methyl methacrylate monomer is 0.22:1; ...

preparation example 3

[0042] Add 100g deionized water, 1.0g sodium lauryl sulfate, 1.0g sodium lauryl polyoxyethylene ether sulfate in a 500ml reactor, stir and heat up to 75°C under nitrogen protection, and 30g methyl methacrylate (0.3000 mol), 25g styrene (0.2404mol) mixed solution, 88g25% sodium vinylsulfonate solution (0.1692mol), 11g25% potassium vinylsulfonate solution (0.0188mol) were respectively placed in three constant-pressure dropping funnels, adding Start the reaction with 25g of 3% ammonium persulfate solution, and at the same time start to add the monomer evenly, control the temperature at 74-78°C, stir at a constant speed, add dropwise for 3 hours, keep at 80°C for 1 hour, then lower the temperature, discharge the material, dry the emulsion, and crush it. get the product. According to the GPC method, the number average molecular weight of the product is about 78900, named as B-3. The mol ratio of the sum of sodium vinyl sulfonate monomer, potassium vinyl sulfonate monomer and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com