Antimicrobial low-warpage low-flash PPS composite material and preparation method thereof

A composite material, low warpage technology, applied in the field of polymer functional composite materials, can solve the problems of affecting antibacterial properties and mechanical properties, very high processing technology requirements, easy oxidation and discoloration of silver, etc., to achieve highly ordered atomic arrangement, antibacterial Significant effect, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

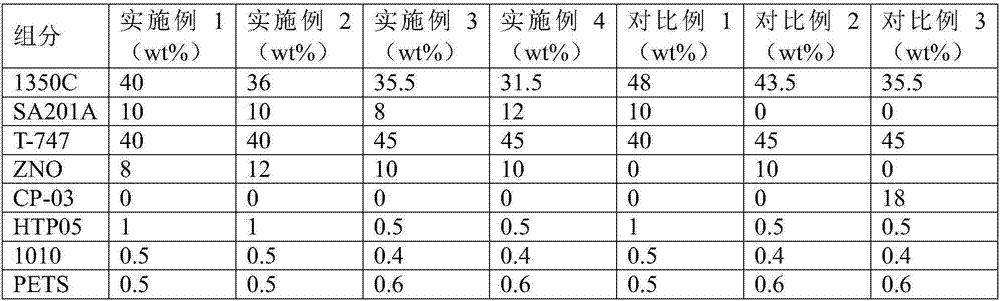

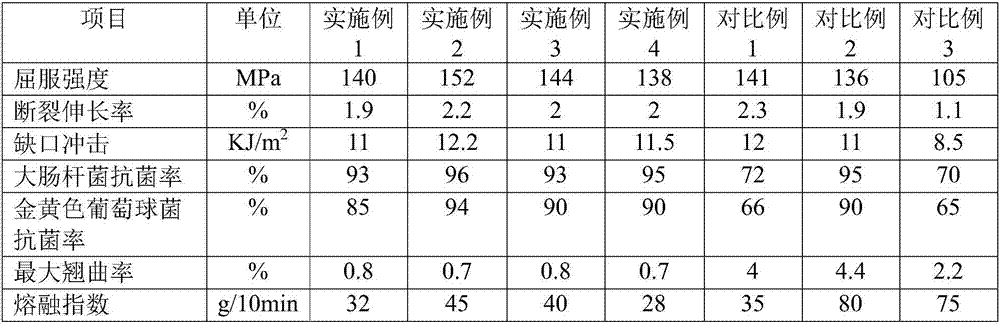

Embodiment 1

[0039] Weigh the raw materials except glass fiber according to the weight ratio in Table 1, mix them evenly and add them to the hopper of the twin-screw extruder, and at the same time feed the glass fiber from the side of the extruder, and then melt extrusion, water cooling, and air knife cooling , granulation and homogenization to obtain an antibacterial PPS composite material with low warpage and low flash. The processing technology is as follows: the temperature of the first zone of the twin-screw extruder is 250-260°C, the temperature of the second zone is 275-285°C, the temperature of the third zone is 280-290°C, the temperature of the fourth zone is 280-290°C, the temperature of the fifth zone is 265-275°C, and the temperature of the sixth zone is 265-275°C. Zone temperature 265~275℃, zone 7 temperature 255~265℃, zone 8 temperature 245~255℃, head temperature 285~295℃; screw speed 400~450r / min, vacuum: ≥600mmHg, cooling water temperature: 40~ 60°C, drying time 2~4h, dryin...

Embodiment 2

[0041] Weigh the raw materials except glass fiber according to the weight ratio in Table 1, mix them evenly and add them to the hopper of the twin-screw extruder, and at the same time feed the glass fiber from the side of the extruder, and then melt extrusion, water cooling, and air knife cooling , granulation and homogenization to obtain an antibacterial PPS composite material with low warpage and low flash. The processing technology is as follows: the temperature of the first zone of the twin-screw extruder is 250-260°C, the temperature of the second zone is 275-285°C, the temperature of the third zone is 280-290°C, the temperature of the fourth zone is 280-290°C, the temperature of the fifth zone is 265-275°C, and the temperature of the sixth zone is 265-275°C. Zone temperature 265~275℃, zone 7 temperature 255~265℃, zone 8 temperature 245~255℃, head temperature 285~295℃; screw speed 400~450r / min, vacuum: ≥600mmHg, cooling water temperature: 40~ 60°C, drying time 2~4h, dryin...

Embodiment 3

[0043] Weigh the raw materials except glass fiber according to the weight ratio in Table 1, mix them evenly and add them to the hopper of the twin-screw extruder, and at the same time feed the glass fiber from the side of the extruder, and then melt extrusion, water cooling, and air knife cooling , granulation and homogenization to obtain an antibacterial PPS composite material with low warpage and low flash. The processing technology is as follows: the temperature of the first zone of the twin-screw extruder is 250-260°C, the temperature of the second zone is 275-285°C, the temperature of the third zone is 280-290°C, the temperature of the fourth zone is 280-290°C, the temperature of the fifth zone is 265-275°C, and the temperature of the sixth zone is 265-275°C. Zone temperature 265~275℃, zone 7 temperature 255~265℃, zone 8 temperature 245~255℃, head temperature 285~295℃; screw speed 400~450r / min, vacuum: ≥600mmHg, cooling water temperature: 40~ 60°C, drying time 2~4h, dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com