Pearly lustre pigment coded polymer micro ball and its preparing method

A pearlescent pigment and polymer technology, which is applied to the field of polymer microspheres encoded by pearlescent pigments and the preparation thereof, can solve the problems of high production equipment requirements, uneven particle size and high production cost, and achieves reduction of application cost and preparation. Simple installation and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of green pearlescent pigment-encoded carboxyl-modified polystyrene microspheres

[0026] ① dissolving the carboxy-modified polystyrene solid in a mixed solvent of ethylene dichloride and benzene, so that the concentration of the carboxyl-modified polystyrene solid in the mixed solvent of ethylene dichloride and benzene is 7%, and dichloroethane and benzene The mixing ratio of benzene is 1:1;

[0027] ②Add green pearlescent pigment to the polystyrene solution at a ratio of 0.5mg pearlescent pigment / ml polymer solution, and stir evenly;

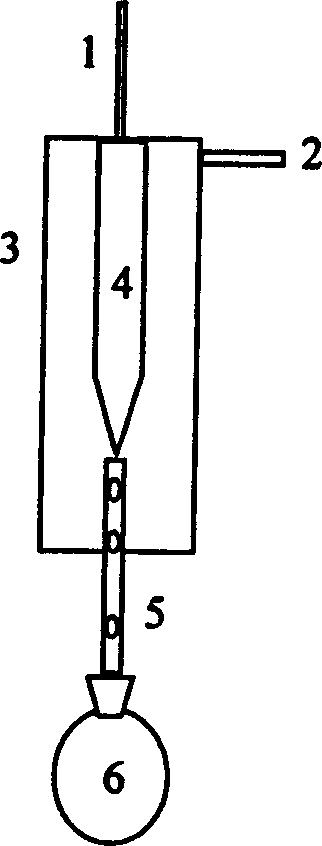

[0028] ③The diameter of the tip of the tip glass tube 4 is set to 200 μm, and the distance between the upper port of the glass conduit 5 and the tip of the tip glass tube is 1 mm;

[0029] ④ Inject 5% polyvinyl alcohol solution into the glass cylinder through the interface 2 of the electromagnetic pump. When the glass cylinder 3 is filled with the polyvinyl alcohol solution, control the injection speed of the poly...

Embodiment 2

[0033]Example 2: Preparation of purple pearlescent pigment-coded polymethyl methacrylate microspheres

[0034] ① Dissolve polymethyl methacrylate in a mixed solvent of ethylene dichloride and benzene, so that the concentration of polymethyl methacrylate in the mixed solvent of ethylene dichloride and benzene is 5%, and ethyl chloride and benzene The mixing ratio is 2:3;

[0035] ②Add green pearlescent pigment to the polystyrene solution at a ratio of 0.7mg pearlescent pigment / ml polymer solution, and stir evenly;

[0036] ③Set the diameter of the tip of the tip glass tube 4 to be 200 μm, and the distance between the upper port of the glass conduit 5 and the tip of the tip glass tube is 1.5 mm;

[0037] ④ Inject 5% polyvinyl alcohol solution into the glass cylinder through the electromagnetic pump interface 2, and when the glass cylinder (3) polyvinyl alcohol solution is filled, control the injection speed of the polyvinyl alcohol solution to 20ml / min;

[0038] ⑤Inject the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com