Patents

Literature

211results about How to "Achieve functionalization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

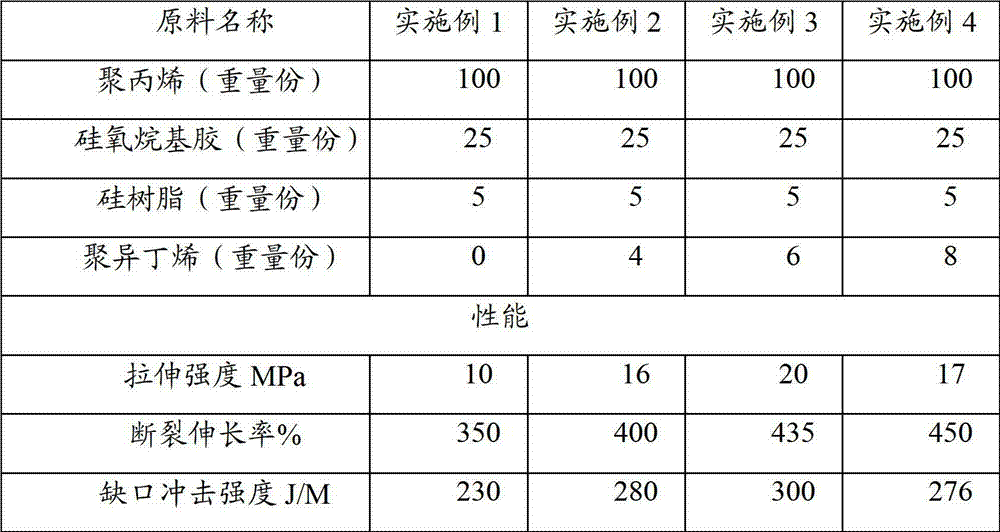

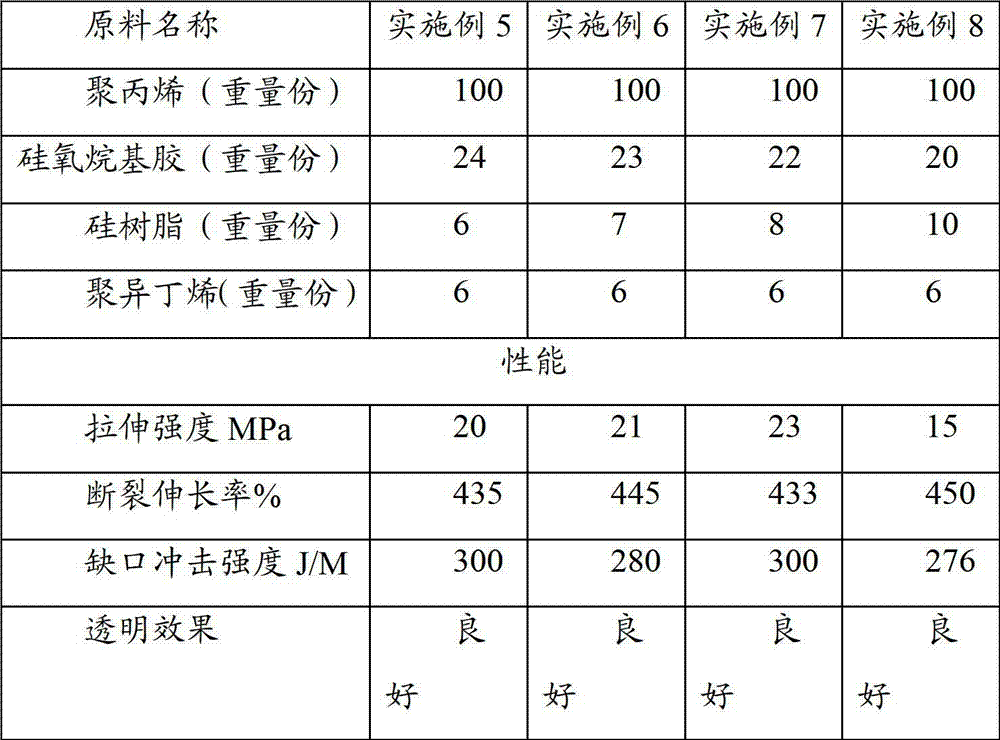

Siloxane-modified thermoplastic material and preparation method thereof

The invention relates to a method for preparing siloxane-modified thermoplastic material, which comprises the following steps: adding 100 weight parts of thermoplastic resin, 40-80 parts of high molecular weight siloxane, 20-40 parts of silicon resin, and 5-10 parts of compatibilizer into a blender, blending for 3-4min, then adding 10-25 weight parts of cross-linking agent and 0.01 -0.5 parts of hydrosilation catalyst, reacting and blending for 3-5min, discharging, cooling to the room temperature and obtaining a base stock; taking 100 weight parts of the base stock in the step one and 50-150 weight parts of thermoplastic resin for mixing uniformly, blending through an internal mixer or a double screw extruder and obtaining the siloxane-modified thermoplastic material. The cross-linking siloxane-modified thermoplastic material made by the invention has the advantages of higher heat resistance, excellent weather resistance, lower friction factor changing along with time, smooth surface, silk touch feeling and the like.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

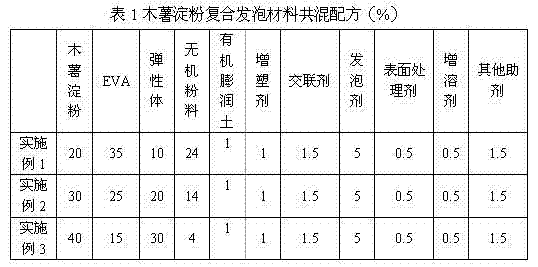

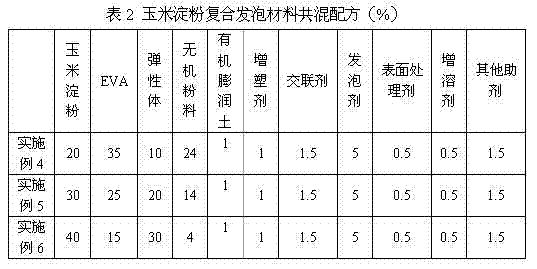

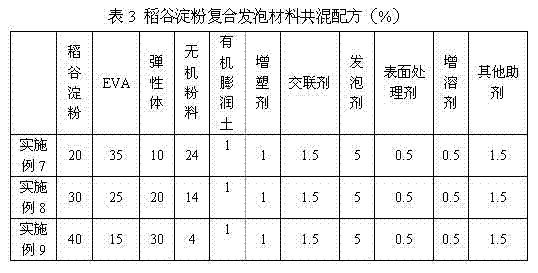

Starch composite foamed material and its production method

The invention provides a starch composite foamed material and its production method, which comprises the following components by mass fraction: 1% to 50% of starch; 10% to 60% of EVA; 1% to 50% of elastomer; 0 to 5% of organic bentonite; 0 to 50% of inorganic powder; 0.1% to 15% of plasticizer; 0.5 to 2% of cross-linking agent, 2 to 11% of composite foamed agent, 0 to 3% of surface conditioning agent, 0 to 5% of compatibilizer and 0 to 5% of other auxiliary agents. The production process is also disclosed. The starch composite foamed material can be widely used for manufacturing beach shoes, slippers, sports shoes and the like, and can be used for producing children picture mosaic, foam floor, and also can be used for package materials of precision electronic instruments, electric appliances and medical apparatus. The production of material is beneficial to environmental protection, and shortage phenomenon of plastic raw material can be alleviated. The production method is scientific and reasonable, the process is simple and strong operationality, and substantially improves degradability of a traditional EVA foamed material, realizes functionalization of EVA foamed material and enhances the added value of the products, the starch composite foamed material has wide application market prospects, obvious social benefit and economic benefit.

Owner:JINJIANG CHENGCHANG SHOES

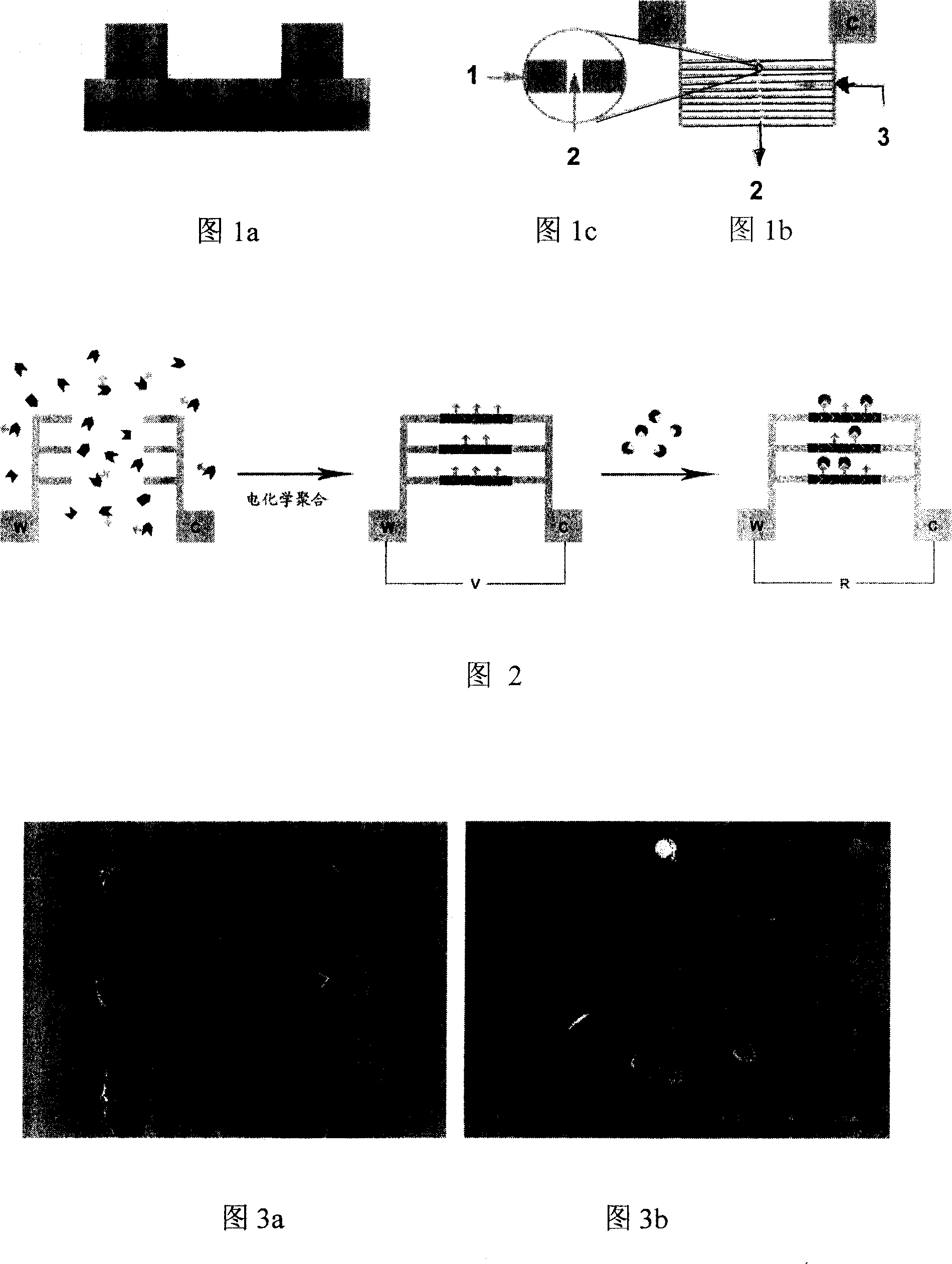

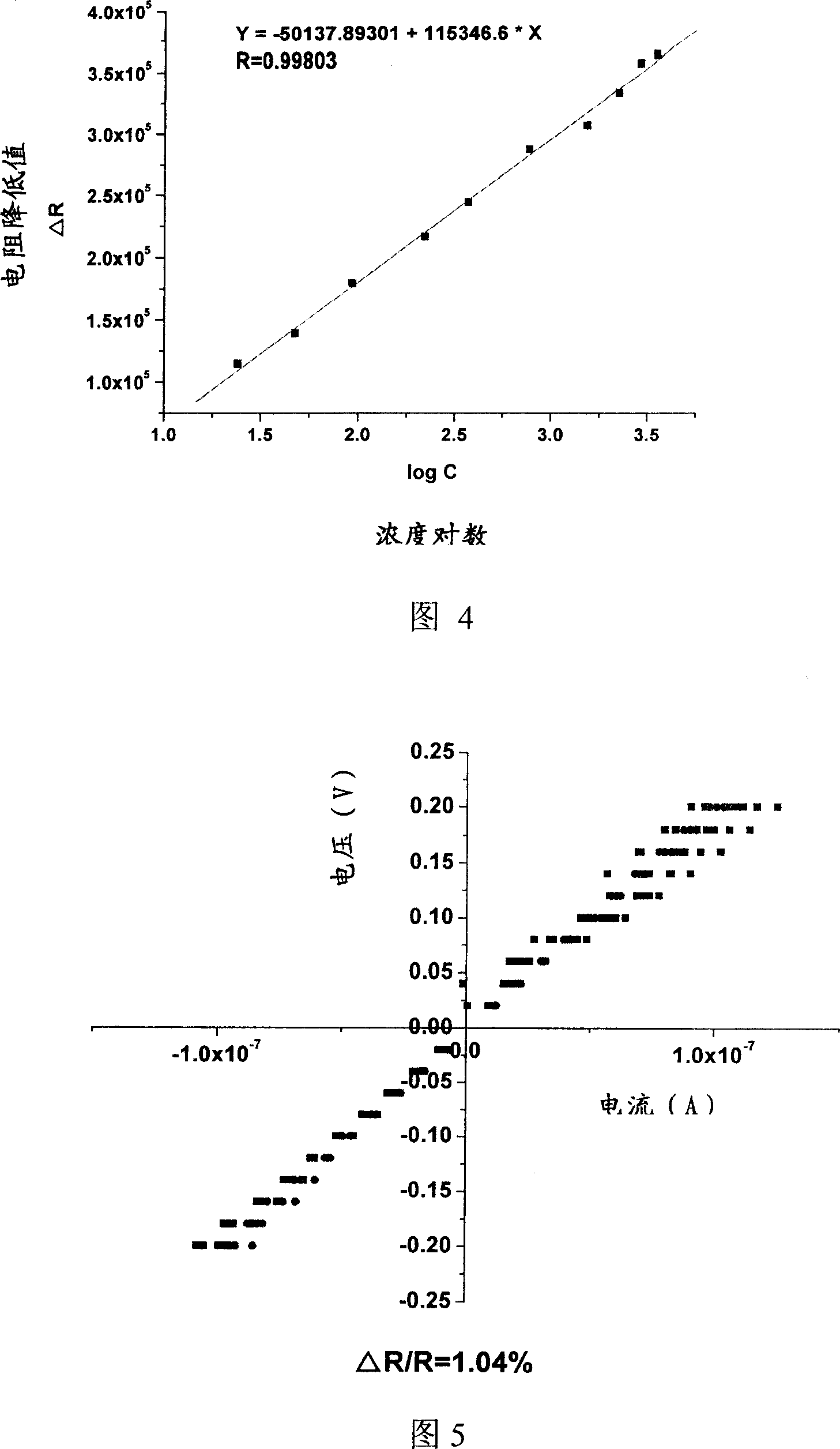

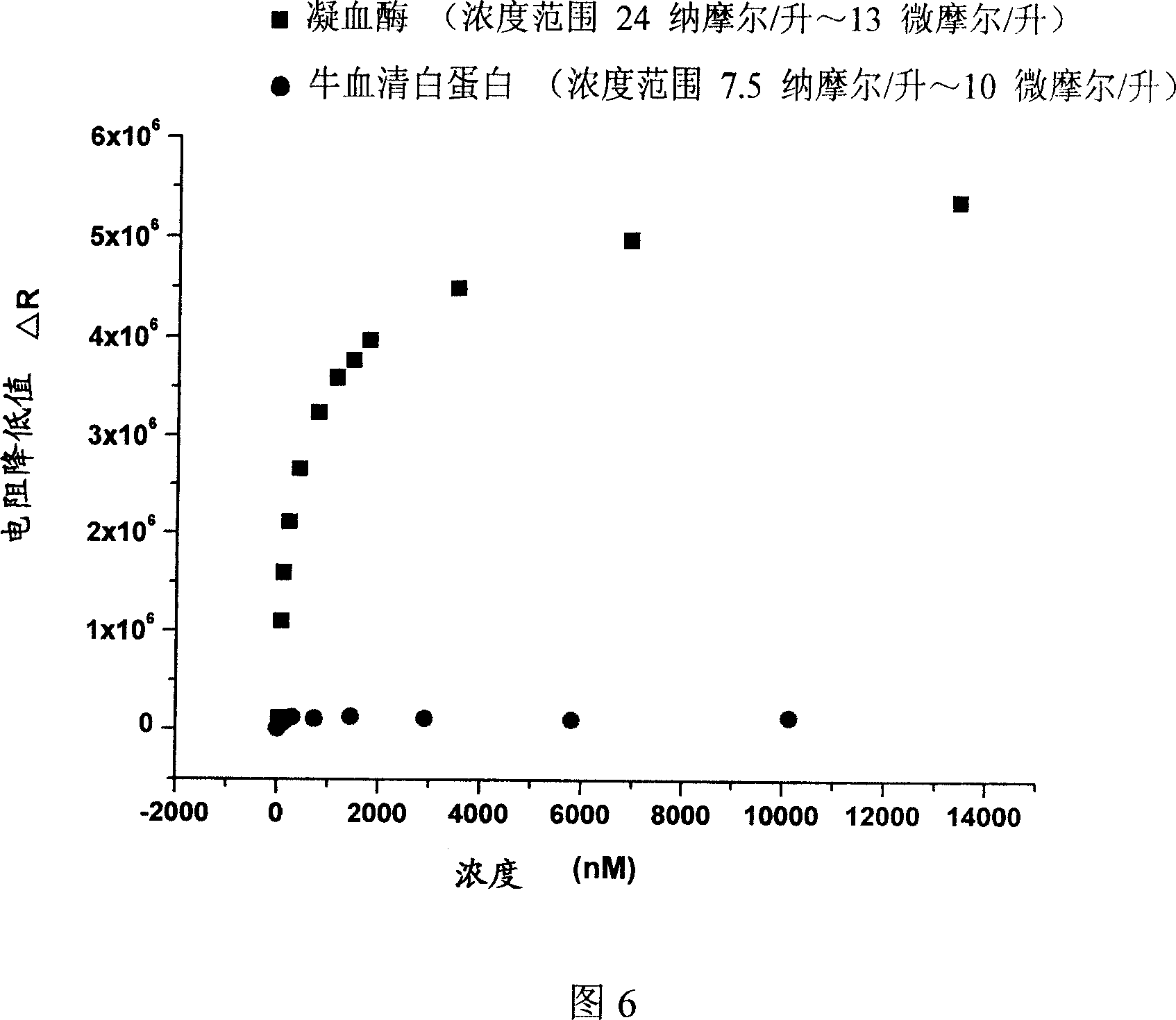

Biosensor based on aptamer modified conducting polymer and its preparation method and uses

InactiveCN101126734AHigh detection sensitivityHigh selectivityMicrobiological testing/measurementMaterial electrochemical variablesAptamerProtein target

The utility model relates to a biosensor, which utilizes the specific identification of the aptamer on target biomolecule and the changes in the electric conductance property of organic productive polymerization caused by the aptamer to do detection on the biological target quantitatively. The microelectrode of the biosensor comprises a working electrode and a counter electrode; wherein, the working electrode or the counter electrode respectively comprises a plurality of electrode wires, which are the same in number and in relative array, an in situ synthesized aptamer decorated organic conductive polymerization film or nano-wire is connected between the electrode wires of the working electrode and the electrode wires of the counter electrode, and the working electrode and the counter electrode are connected with a conductor respectively. By detecting changes in the electric conductance property of the organic productive polymerization caused by the specific combination of the target biomolecule and the aptamer on the organic conductive polymerization which is fixed between the microelectrode pairs, the utility model gets the quantitative response to the bio-macromolecules, such as the target protein, directly and fast, and avoids the complex and time consuming marking and incubation in the traditional method.

Owner:INST OF CHEM CHINESE ACAD OF SCI

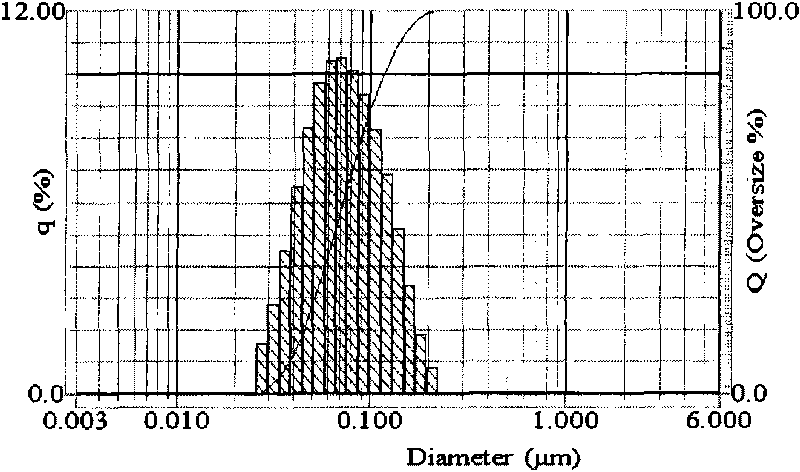

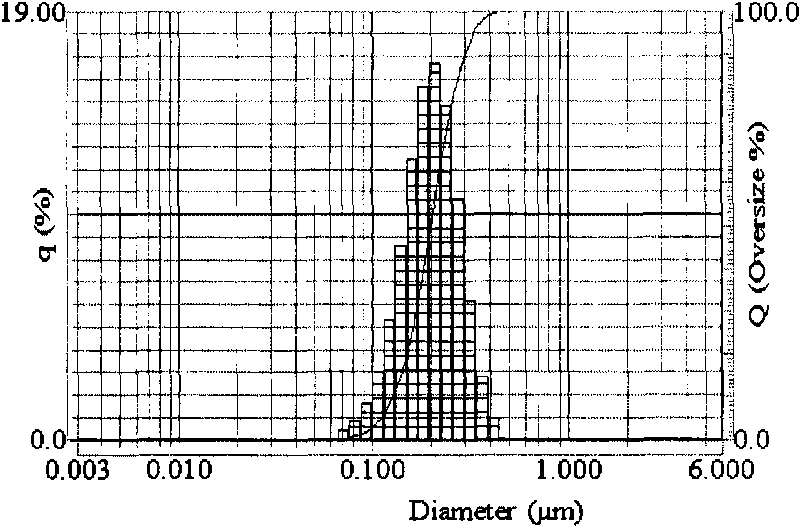

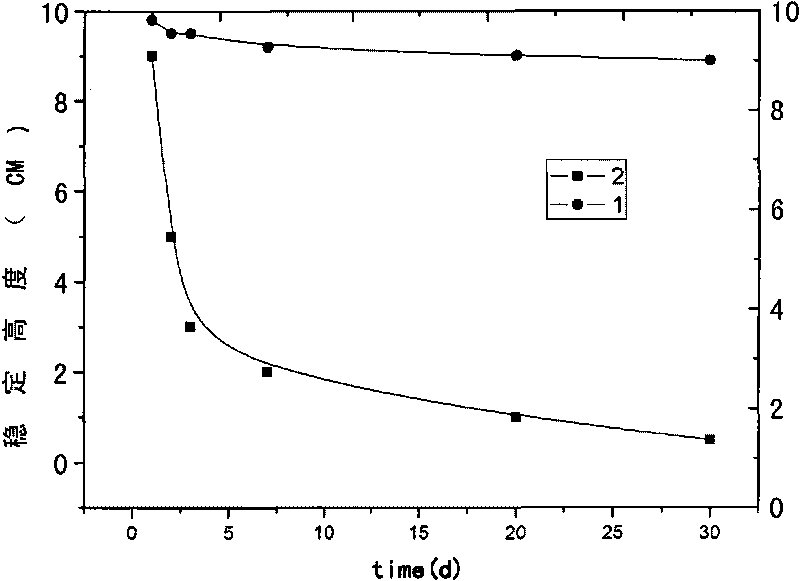

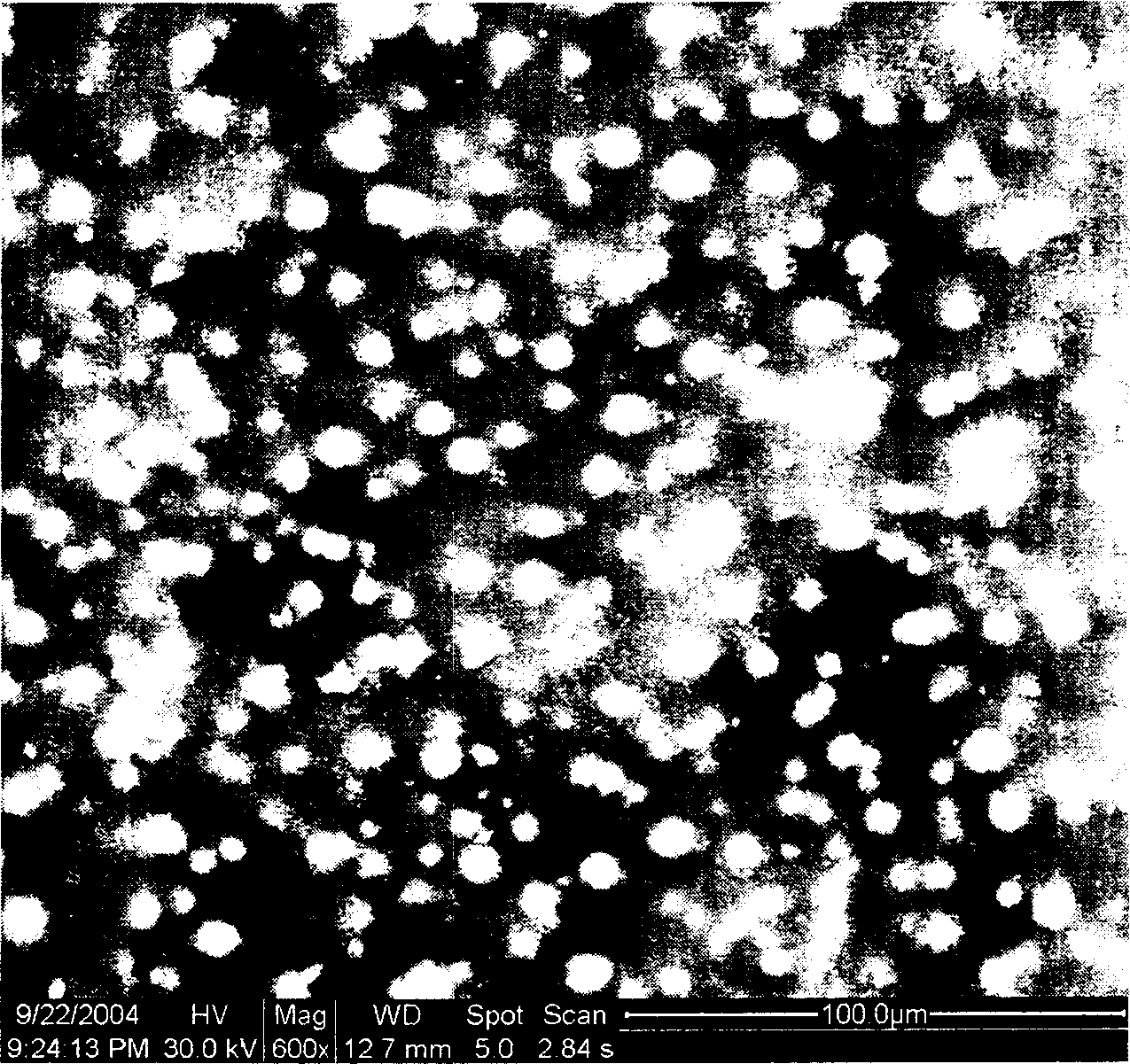

Inorganic heat-insulation nano material aqueous slurry, building glass heat-insulation coating and preparation method

InactiveCN101708958AImprove insulation performanceImprove stabilityDispersion stabilitySilicon oxygen

The invention provides a coating for building glass heat insulation which can release negative ions and a preparation method; the coating comprises inorganic heat-insulation nano material, siloxane polymer, inorganic heat-insulation nano material aqueous slurry of solvent, negative ion powder material aqueous slurry, aqueous resin, assistant and diluent; the inorganic heat-insulation nano material adopts siloxane polymer with discrete and exquisite structure as a template, selective adsorption and grafting hybridization reaction are carried out on the surface of the inorganic heat-insulation nano material, silicon-oxygen bond and hydrogen bond coordination self-assembly action is formed on the surface of the heat-insulation nano material to control the interface performance of the heat-insulation nano material, improve the compatibility and the system dispersion stability among the heat-insulation nano materials and obtain special optical and heat-insulation performances; in addition, the synergistic effect among the negative ion material, the inorganic heat-insulation nano material and the aqueous resin can improve the heat-insulation effect and the capacity of releasing the negative ions, so as to realize multi-functionalization of the building glass heat-insulation coating.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

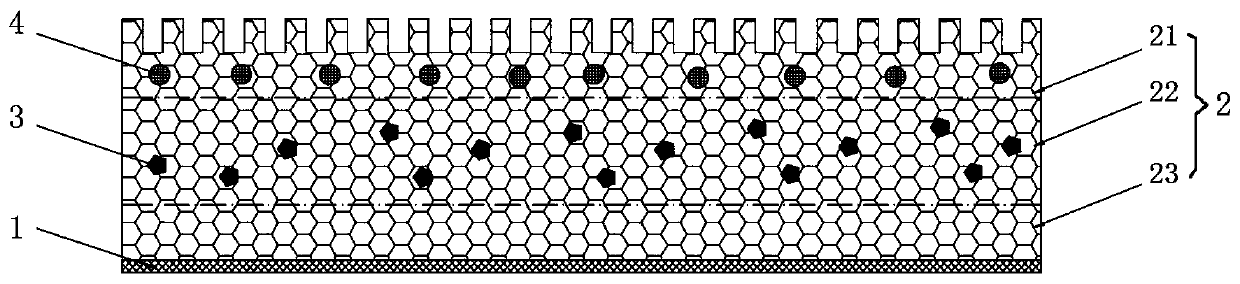

Production method of ecotypic sintering ceramic colored permeable brick

InactiveCN105948707AEnsure porosityGood water permeabilityCeramic materials productionClaywaresBrickPrill

The invention belongs to the technical field of inorganic nonmetallic material, and relates to an ecotypic sintering ceramic colored permeable brick and a production method thereof. The method is characterized by including using the waste ceramic particles as a basic skeleton material, using the coarse particle size gradation as an internal layer skeleton material, using the fine particle size gradation as a surface layer skeleton material, adding proper amount of colorless and colored clear glaze fine powder, organic binder CMC, and water, and preparing the qualified ecotypic sintering ceramic colored permeable brick by performing the technologies such as preparation of materials, mixing, aging, secondary material distribution and pressing, drying, sintering and testing. The production method disclosed by the invention is suitable for industrial production of the permeable brick, and the prepared permeable brick has high water permeability, high compressive strength, rich colors, and good practical durability, and is widely used for ground laying of the outdoor public places such as large parking lot, square and city road, and artistic landscape.

Owner:宜兴友邦陶瓷有限公司

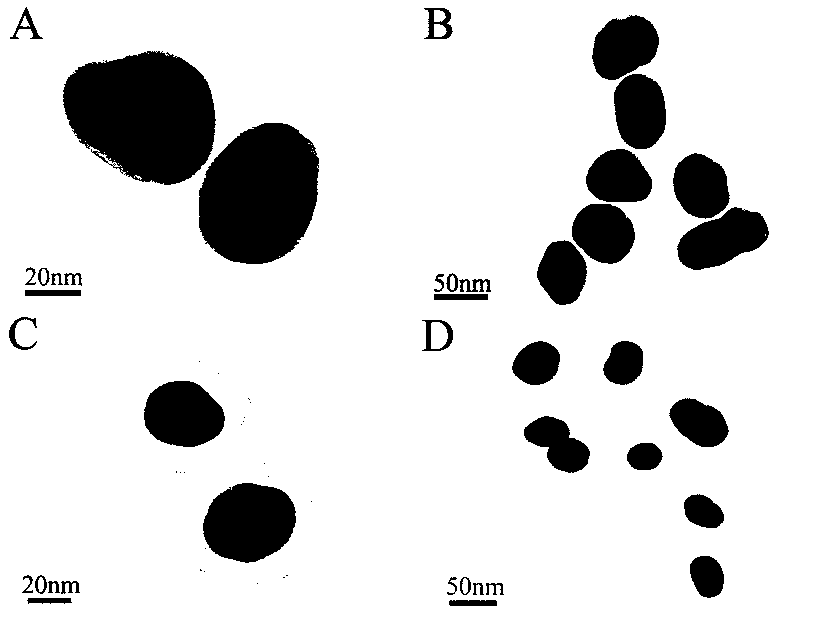

Organic-inorganic substances compound membrane and its preparation method

ActiveCN1698938AAchieve functionalizationNo pollution in the processSemi-permeable membranesElectricityPolyelectrolyte

This invention relates to an organic mineral complex film used for osmotic evaporating and separating the near or constant boiling point mixture. Said film comprises montmorillonite anion and ammonium salt or ammonium polyelectrolyte cation which alternating deposit on the sheet or pipe type surface of the supporting. The preparing method comprises the following steps: immersing the supporting body with minus electricity alternatively in the polyelectrolyte cation solution and the montmorillonite anion solution, and the electrolyte with opposite charge alternatively deposit in the liquor-solid interface through the electrostatic action; flushing the ion and small molecule electrolyte ion sticking in the surface after each immersion. It can control the number of the plies through controlling the number of immersion, then to control the film thickness.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

Carrier type titanium dioxide ultrafiltration membrane and preparation method and application thereof

ActiveCN102489172AImprove throughputGuaranteed interception effectSemi-permeable membranesCatalyst carriersUltrafiltrationTortuosity

The invention relates to a preparation method and applications in supported catalysts of a carrier type titanium dioxide ultrafiltration membrane. According to the preparation method, a ceramic membrane is used as the support body, the self-growing phenomenon of titanium dioxide particles at high temperature is utilized, a titanium dioxide ultrafiltration membrane layer with high flux and tortuosity is formed on the surface of the ceramic membrane support body through the interweaving of titanium dioxide nanorods and calcining, thus the tortuosity and loose degree of the membrane layer can be effectively increased; an enough space is provided for supporting catalysts on the basis of ensuring the retention capacity of the original ceramic membrane; and the overall functionalization of the ceramic membrane is realized, namely the ceramic membrane supporting of multiple catalysts is realized and the product can be used in the fields such as photocatalysis, catalytic ozonation, catalytic hydrogen peroxide oxidation and catalytic wet oxidation.

Owner:DALIAN UNIV OF TECH

Preparation method of flame-retardant cellulose fiber through metal ion grafting modification

The invention discloses a preparation method of flame-retardant cellulose fiber through metal ion grafting modification, and belongs to the technical field of flame-retardant textile products. The preparation method comprises the following steps: at first, grafting maleic anhydride to the cellulose fiber macromolecular chain, then modifying the grafted cellulose fiber by metal ion compounds, wherein the introduced carboxyl group can carry out grafting modification with a plurality of metal ions, and finally preparing the flame-retardant cellulose fiber through a common treatment method. The prepared flame-retardant cellulose fiber has an inherent flame-retardant property, an ideal flame-retardant effect can be achieved by using only a little amount of added flame retardant namely the metal ions for grafting, because the flame-retardant cellulose fiber has an inherent flame-retardant property, the conventional flame retardants such as phosphorus flame retardant, nitrogen flame retardant, halogen flame retardant, and the like are not needed, the cellulose fiber will not give off toxic gas during the application process, and the environment pollution generated during the production process and application process of cellulose fiber and the pollution caused by the waste cellulose fiber are reduced.

Owner:青岛大学股权投资管理有限公司

Method for compounding functional nanoparticles on surfaces of polymer filaments

ActiveCN103556451ADoes not affect mechanical propertiesRetain mechanical propertiesVegetal fibresFiberPolymer science

The invention relates to a method for compounding functional nanoparticles on surfaces of polymer filaments, belonging to the technical field of new fiber materials. The method comprises the steps of protein-based modification on surfaces of functional nanoparticles, preparation of a blended solution, formation of polymer filaments with surfaces compounded with the blended solution and control of thickness, phase inversion primary formation of the polymer filaments with surfaces compounded with the blended solution and thermosetting formation of the polymer filaments with surfaces compounded with the blended solution, thus obtaining the polymer filaments with surfaces compounded with the functional nanoparticles. In the preparation method, carbon nano tubes, graphene, carbon black, titanium dioxide, zinc dioxide, iron particles, iron oxide, aluminium oxide, silver particles and other nanoparticles can be compounded on the surfaces of the polymer filaments. The polymer filaments after compounding have good mechanical properties and functionality. The preparation method is simple to operate, dispenses with special equipment and achieves industrial production easily.

Owner:JIANGSU YIMAO FILTER MEDIA CO LTD

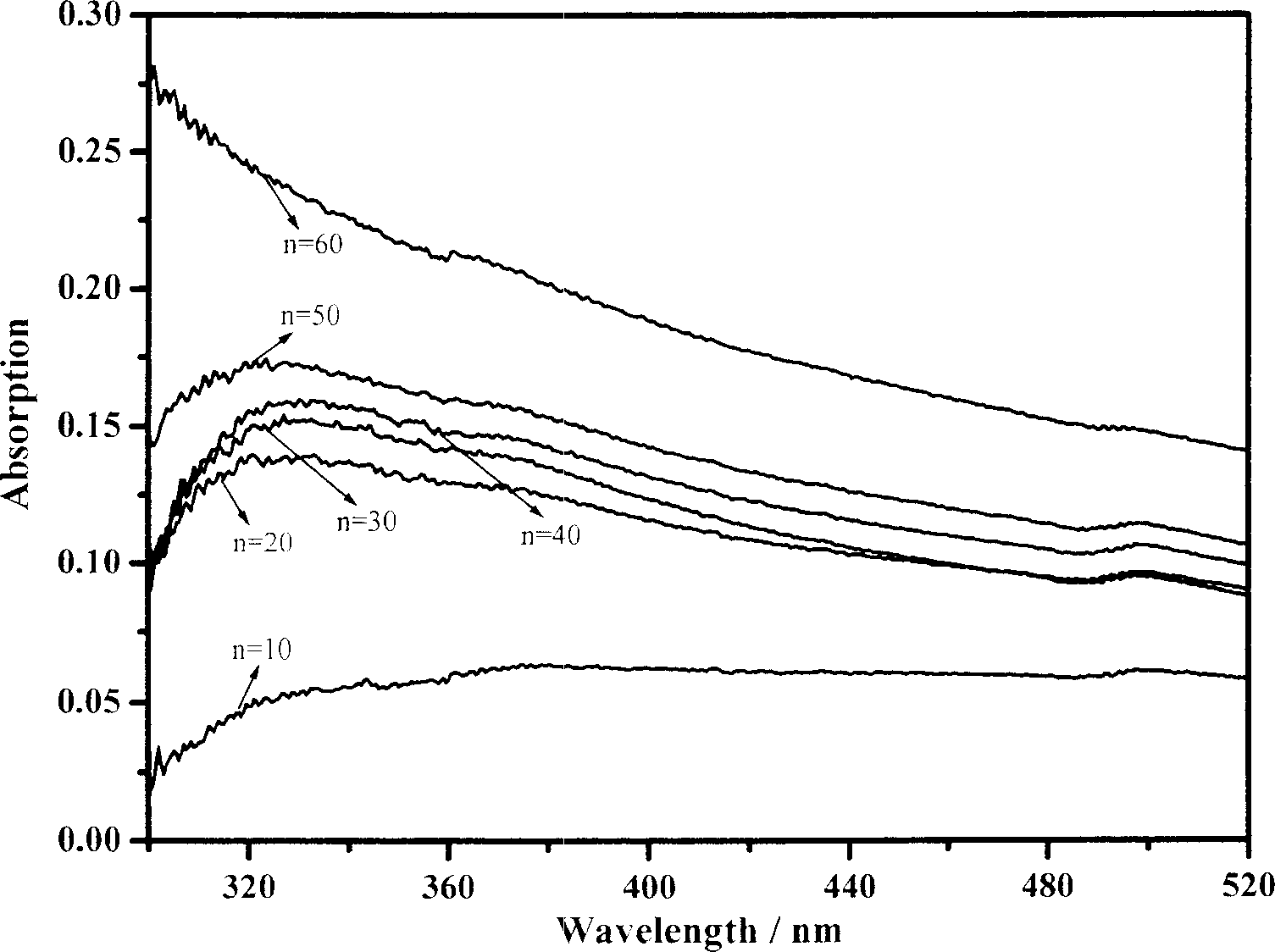

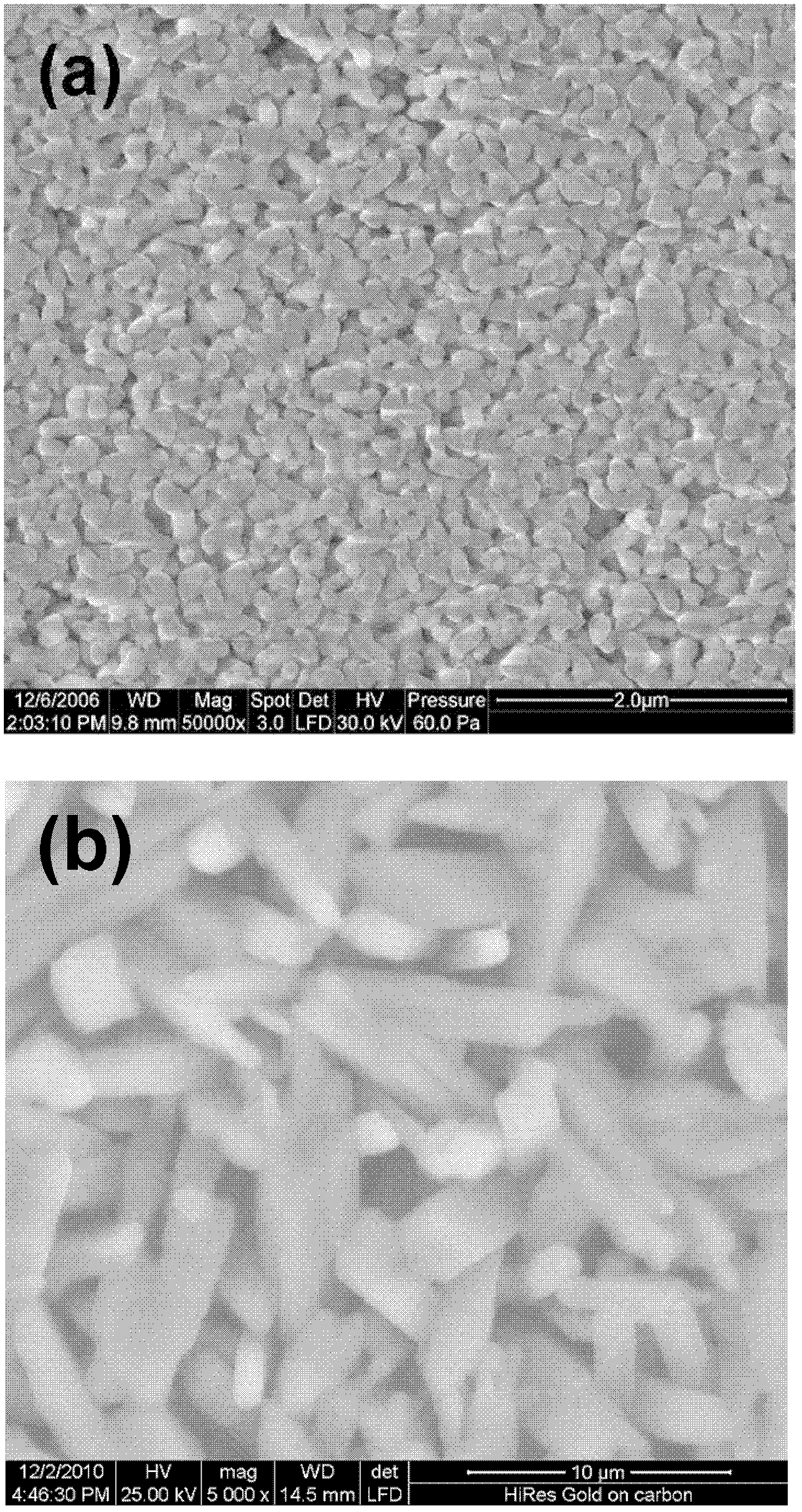

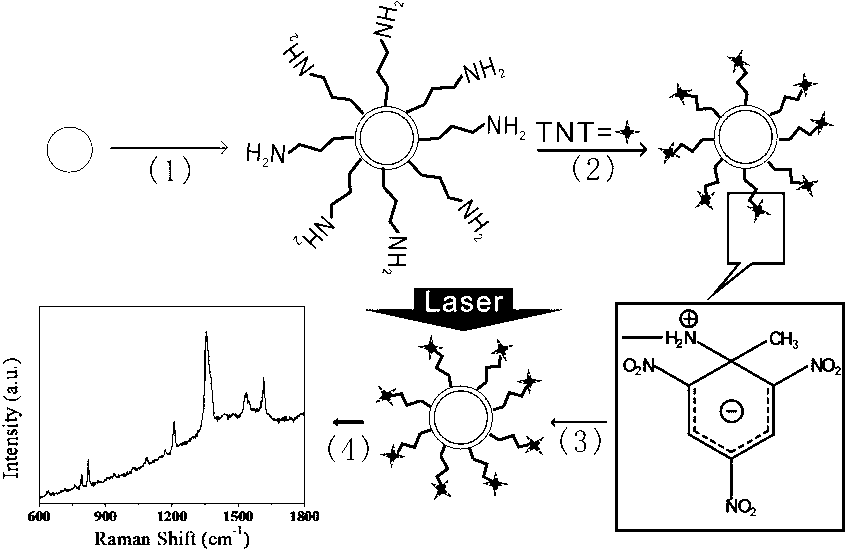

Selective detection method for TNT (trinitrotoluene) by enhanced Raman spectrometry of functionalized shell isolated nanoparticles

InactiveCN102706858AAchieve functionalizationImplement selective detectionRaman scatteringFunctionalized nanoparticlesOptical spectrometer

The invention provides a selective detection method for TNT (trinitrotoluene) by enhanced Raman spectrometry of functionalized shell isolated nanoparticles. The detection method comprises the steps of: (1) synthetizing functionalized nanoparticles by regarding gold nanoparticles as nucleus and poly(o-aminothiophnol) as a shell in one step by a solution method, and forming substrate solution; (2) fully mixing the substrate solution with TNT solution of a matter to be detected, and carrying out selective enrichment on TNT by utilizing an amino functional group on the functionalized nanoparticle shell combined with specificity of TNT; (3) dripping the solution fully mixed in the step (2) on a silicon wafer, and (4) carrying out detection analysis on the matter to be detected on the silicon wafer under a raman spectrometer. According to the selective detection method disclosed by the invention, the substrate is simple in preparation, low in cost and strong in universality, and has functionalization characteristics, so selective detection on low-concentration TNT can be achieved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

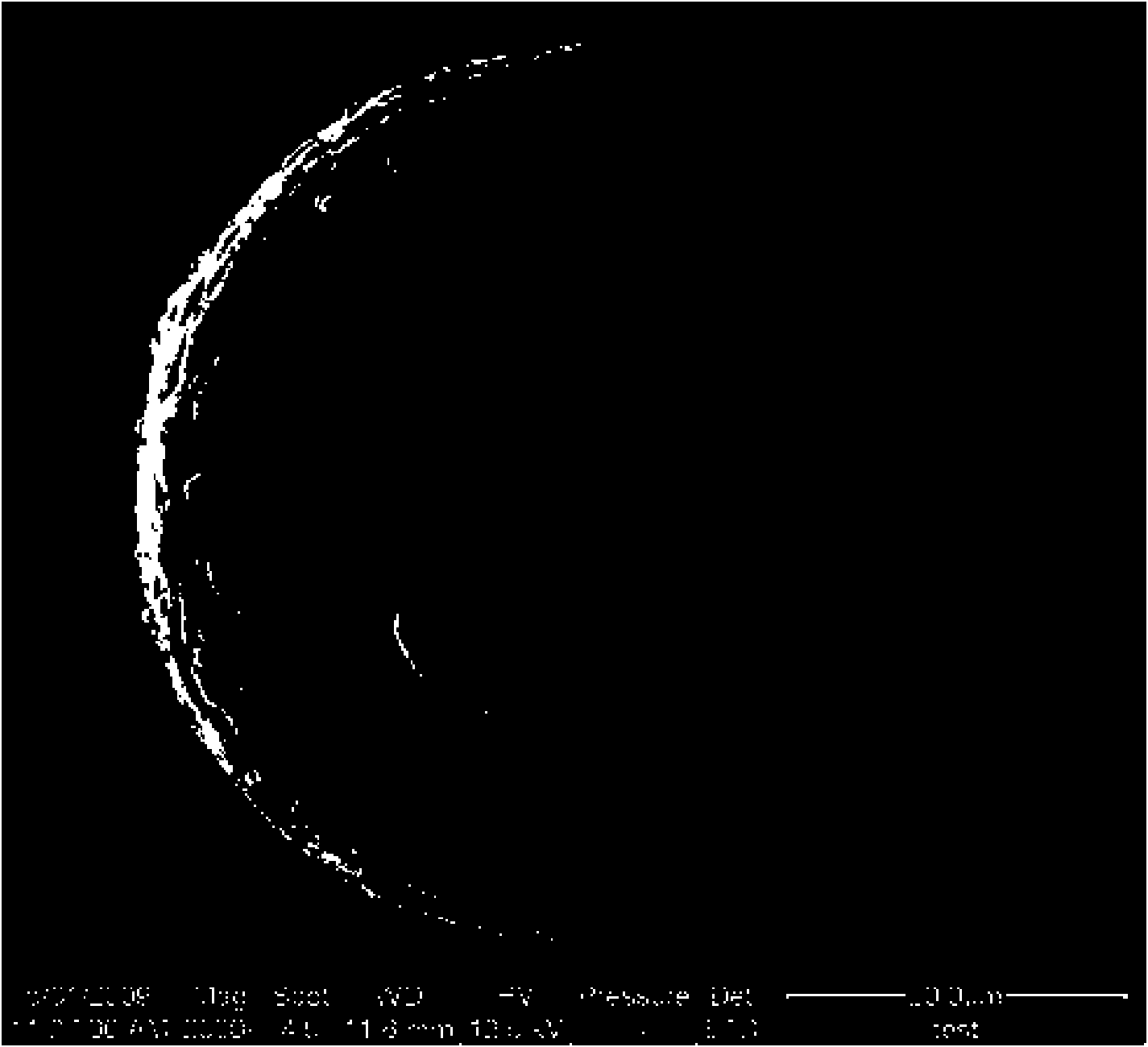

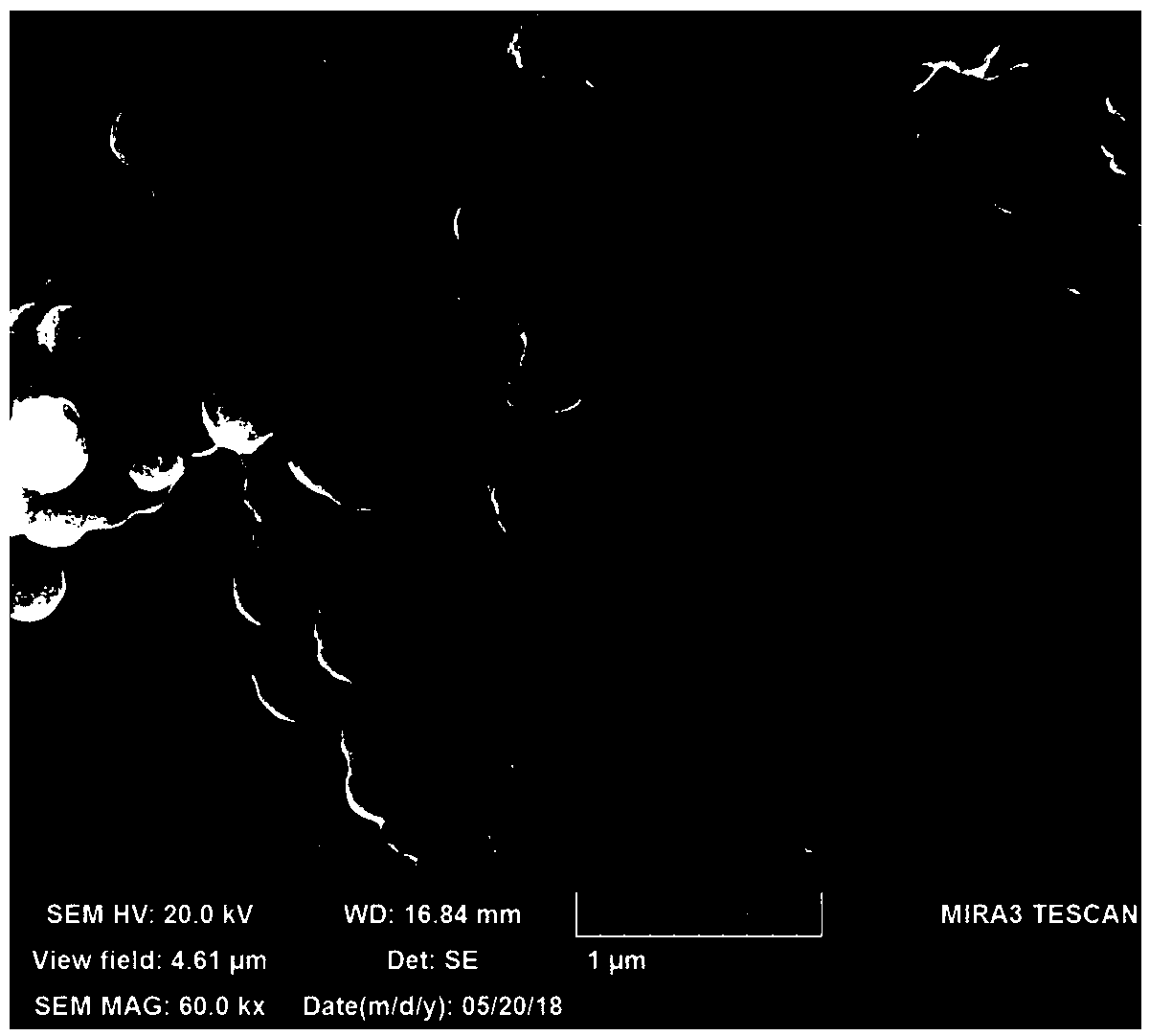

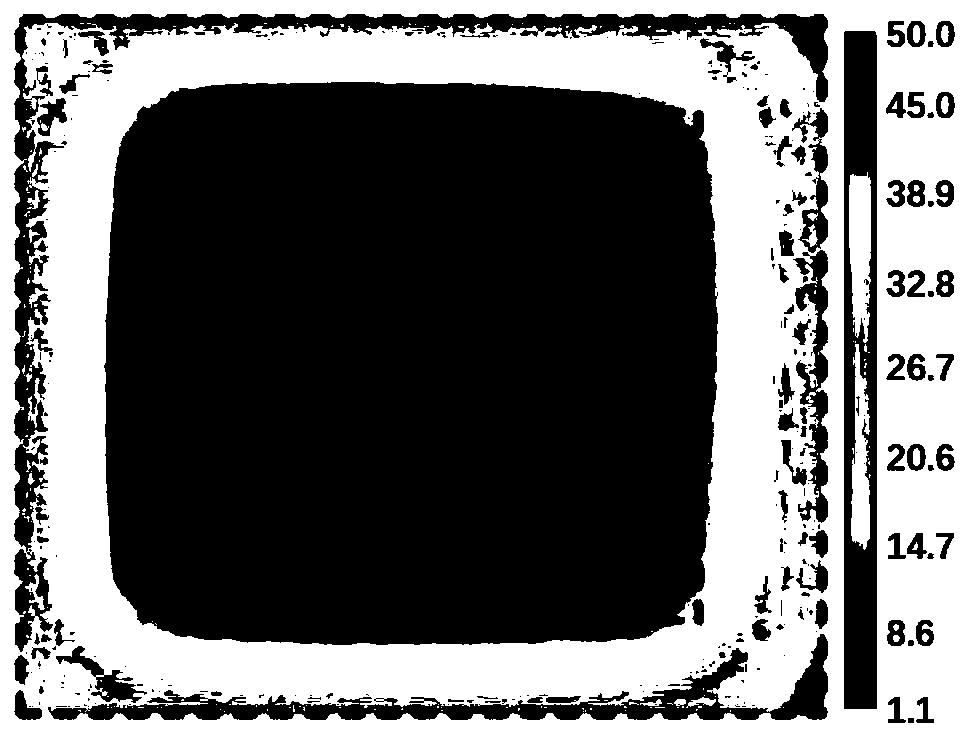

Polymer porous microsphere, carbon sphere and ultra-black material prepared from the same, and applications

ActiveCN109280209AAchieve functionalizationHigh crystallinityOther chemical processesDispersed particle separationPolymer scienceHalogen

The invention discloses a polymer porous microsphere, and a preparation method and applications thereof. A carbon sphere, and a preparation method and applications thereof are also disclosed. The carbon sphere is prepared from the polymer porous microsphere. An ultra-black material composition, and a ultra-black material prepared from the same and applications are disclosed as well. The ultra-black material composition includes the carbon sphere. As a linear polymer containing groups like halogen and hydroxy and having no heteroatom on a main chain has high degree of crystallinity and abundantcrystal types, the morphology of the obtained microsphere is also special, and a composition structure can include a sheet structure, a bicontinuous structure and a fibrous structure. The morphologyof the polymer porous microsphere can maintain unchanged through carbonization, so that the prepared carbon sphere can well maintain the morphology structure and porosity of the polymer porous microsphere; and a graphite structure with multiple defects can be formed during carbonization, so that the pore canal structure can be more abundant, and especially, the volumes of micropores can be greatlyenhanced.

Owner:INST OF CHEM CHINESE ACAD OF SCI

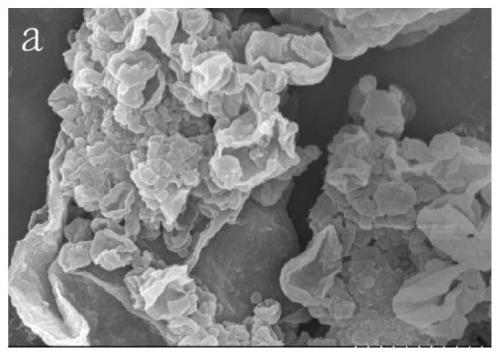

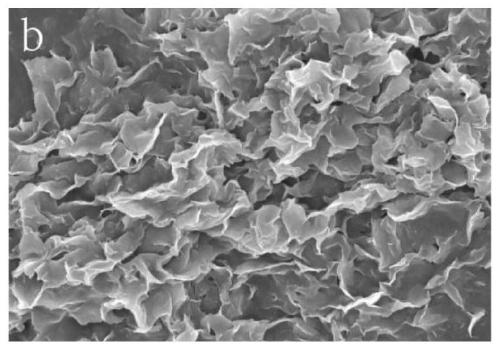

Ultrasonic-assisted method for preparing polymer functionalized graphene

InactiveCN102516829AGood dispersionGood dispersion stabilityPigment treatment with macromolecular organic compoundsPigment physical treatmentSolventCvd graphene

The invention discloses an ultrasonic-assisted method for preparing polymer functionalized graphene. According to the method, high-intensity ultrasonic equipment is adopted to carry out ultrasonic irradiation on a mixed solution of a polymer and graphene. By high-intensity ultrasound, on one hand, graphene layers are broken to induce the generation of a lot of reaction sites; on the other hand, a reactive macromolecular chain is generated by ultrasonic degradation of the polymer, and the reactive macromolecular chain is rapidly grafted on the graphene reaction sites, thus realizing in situ polymer functionalization of graphene. It is proved through experiments that the polymer functionalized graphene obtained by the method has high grafted polymer content and has good dispersibility and stability in a solvent and a polymer matrix. A polymer / functionalized graphene nanocomposite material prepared by the utilization of the polymer functionalized graphene has excellent mechanical properties. Therefore, in comparison with the prior art, the method is an ideal method for realizing polymer functionalization of graphene and has latent application values.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

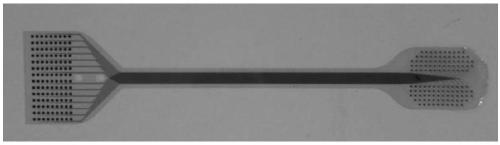

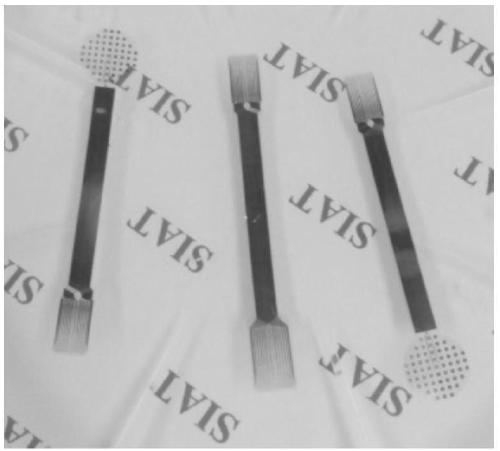

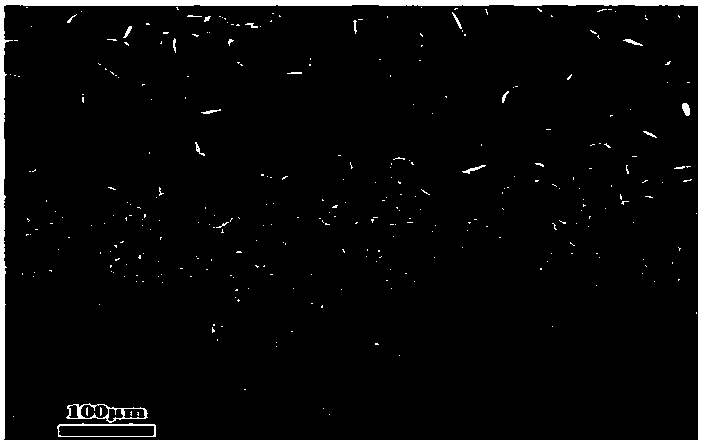

Functionalized wide-width implanted microelectrode array, manufacturing method and application thereof

PendingCN109350846AHigh resolutionReduce process complexityHead electrodesEpicardial electrodesElectrode arrayMicroelectrode

The invention relates to a functionalized wide-width implanted microelectrode array, a manufacturing method and an application thereof. The functionalized wide-width microelectrode array comprises a functional layer, a base layer, a conducting layer and an insulating layer which are successively arranged. The functional layer is a monomolecular layer, a polymer material layer and / or a polymer compound layer, and has the thickness of 1 nm to 1000 micron. The invention also provides the manufacturing method of the functionalized wide-width implanted microelectrode array. By using the functionalized wide-width microelectrode array, through increasing the size of a microelectrode, a microelectrode bit point, a line, a spacing and other correlation parameters can be effectively adjusted so as to reduce a technology complexity during a microelectrode micro-machining process and greatly increase the yield of a high-cost microelectrode array, and the design problem of a high-density microelectrode array is solved; and through a functionalized wide-width design, a microelectrode array folding or curling function can be realized so as to realize minimally invasive implantation and greatly reduce an operation risk.

Owner:SHENZHEN INST OF ADVANCED TECH

Polypropylene foam material with gradient pore structure and preparation method thereof

InactiveCN108164814AGuaranteed temperature resistanceGuaranteed mechanical propertiesPolymer sciencePolypropylene

The invention discloses a polypropylene foam material with a gradient pore structure and a preparation method thereof, belongs to the technical field of foam materials, and solves the problem to provide a preparation method of a foam material, which has the advantages of being simple in process, low in equipment requirement, and capable of realizing gradient change of foam pores in the foam material. According to the preparation method, polypropylenes with different melt strengths and a nucleating agent are firstly mixed; polypropylene resin particles having multi-layer distribution can be obtained by multi-layer co-extruding, drawing and pelletizing, or polypropylene resin particles having various components can be obtained by extrusion by an extruder, drawing and pelletizing, and a multi-layered polypropylene resin sheet can be obtained by mould pressing into sheets and superimposing and melting-molding; and finally the multi-layered particles or the multi-layered sheet are foamed toobtain the polypropylene foam material with the gradient pore structure. The polypropylene foam material has the characteristics of gradual change of the foam pore structure, the functionalization ofthe polypropylene foam material can be effectively achieved, the cost is reduced, and application methods of the material in the automotive, food, medical and other fields can be broadened.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

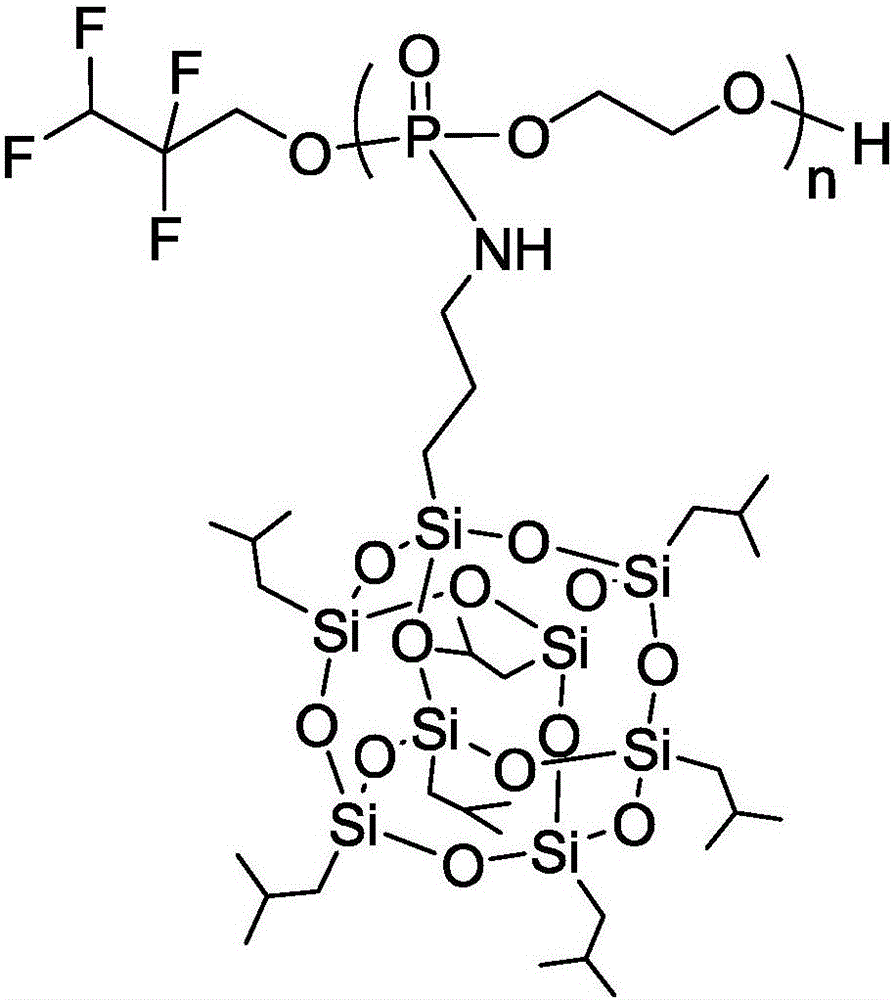

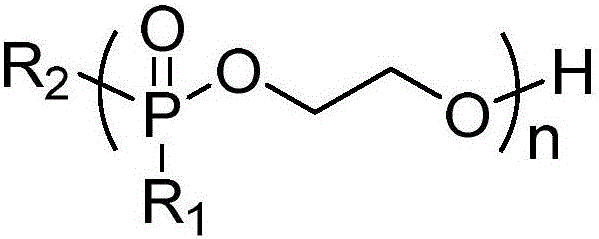

Polyphosphoester containing fluorine and silicon as well as preparation method and application thereof

ActiveCN106750328AHigh in phosphorusImprove flame retardant performanceGroup 5/15 element organic compoundsEpoxyCarbon layer

The invention discloses a polyphosphoester containing fluorine and silicon as well as a preparation method and an application thereof. The chemical formula structure of the polyphosphoester containing fluorine and silicon is expressed as a formula which is shown in description, wherein R1 is selected from a chemical formula which is shown in description, a chemical formula which is shown in description or a chemical formula which is shown in description; R2 is selected from a chemical formula which is shown in description or a chemical formula which is shown in description; n is 10-100. According to the polyphosphoester containing fluorine and silicon, phosphorus, fluorine and silicon elements are used for resisting flame; the phosphorus element is capable of catalyzing a system to form a phosphorus-enriched carbon layer, so that the effect of a protection layer is achieved, and thus the further decomposition of epoxy resin is prevented; silicon-containing epoxy resin can form a carbon layer containing silicon dioxide in the combustion process, so that the carbon layer structure is enhanced, and thus the protection effect of the carbon layer is further improved; through introduction of the fluorine element, the heat stability of the epoxy resin can be improved, so that the flame resistance of the system is improved.

Owner:XIAMEN UNIV

Chitosan-urea resin microcapsule and synthesis method thereof

InactiveCN101671440AImprove stabilityProtection Mechanical PropertiesMicroballoon preparationMicrocapsule preparationMicrosphereSynthesis methods

The invention provides chitosan-urea resin microcapsule and a synthesis method thereof, belonging to the field of microcapsule, in particular to the chitosan-urea resin microcapsule for self repairingpolymer-matrix composite materials and the synthesis method thereof. The invention solves the problem of affecting the effect for repairing the microcapsule because microcrack expands around the microcapsule to lead the microcapsule not to be cracked when in use due to the week interface binding force between the microcapsule and the matrix resin. The microcapsule is made from urea resin prepolymer, chitosan solution, DCPD, lauryl sodium sulfate, resorcinol, normal butanol and deionized water. The synthesis method comprises the steps of: 1. synthesizing urea prepolymer; 2. preparing gelatin microspheric latex system; 3. washing, filtering and drying after polymerization reaction. The microcapsule is white grain, wherein grain diameter is 10-160mu m. The microcapsule is embedded into the resin matrix to be capable of repairing the microcrack in the resin matrix and prolonging the service life of materials.

Owner:HARBIN INST OF TECH

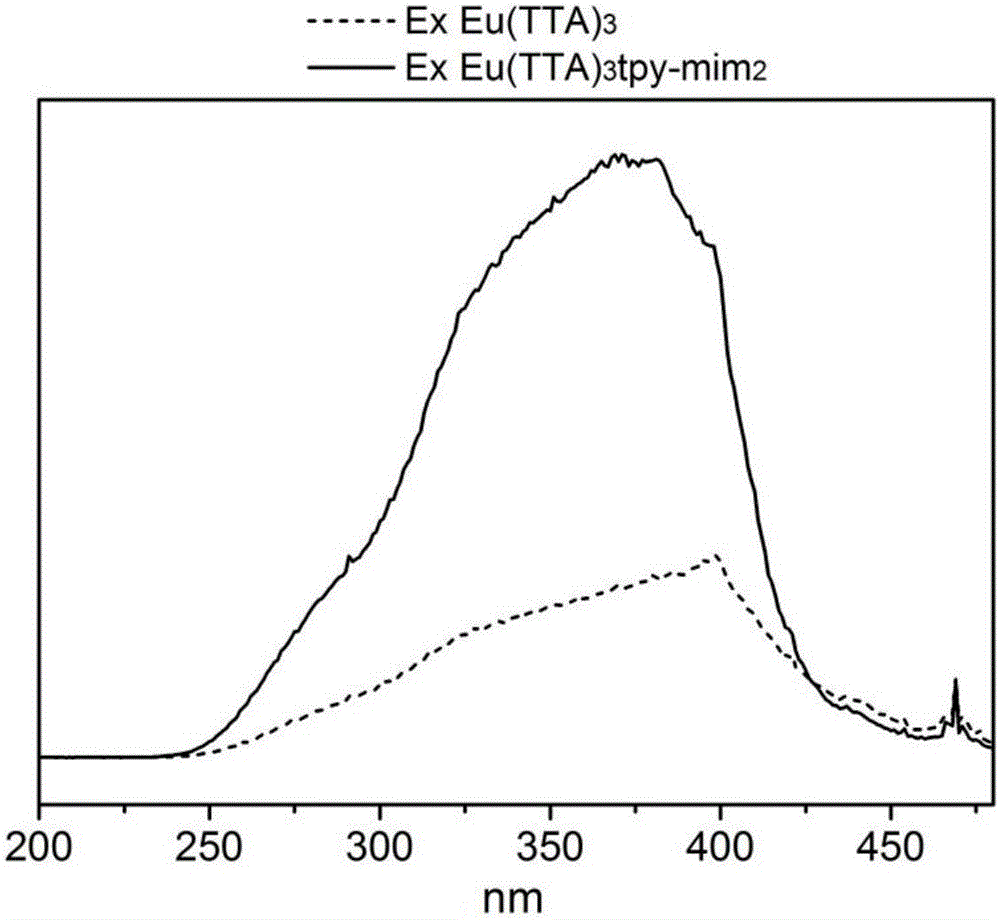

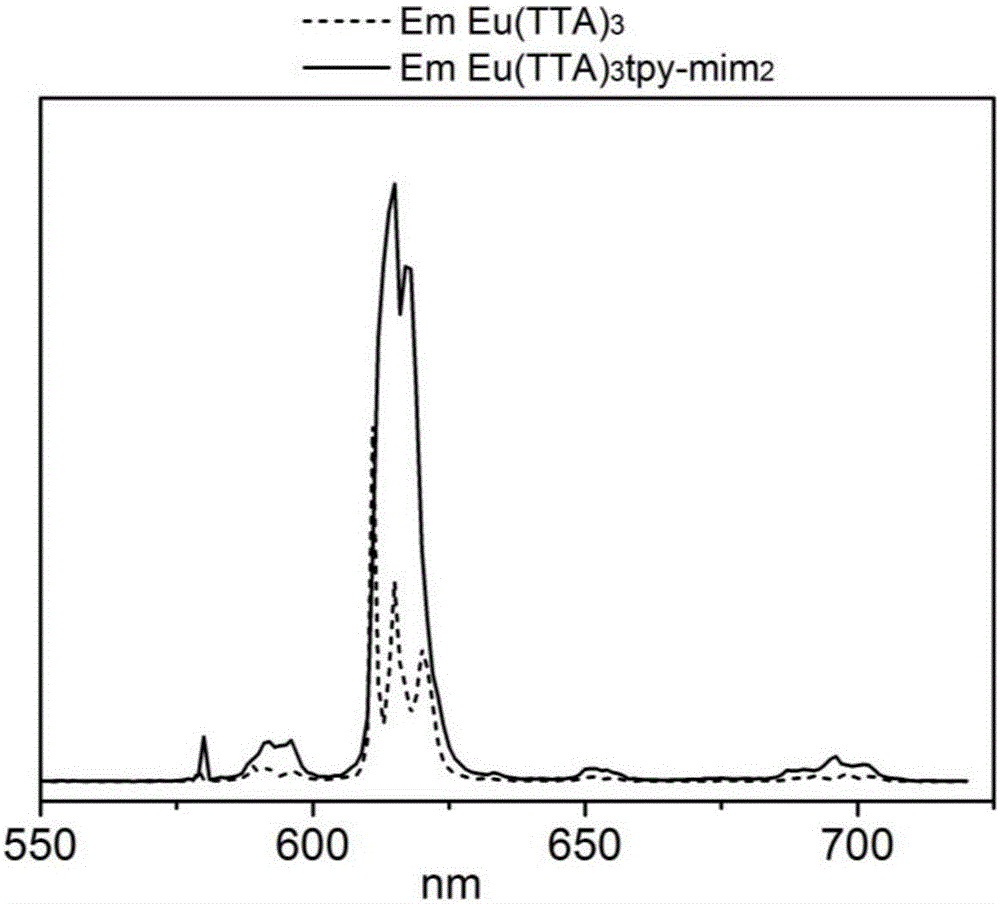

Ternary rare earth complex and application of complex in preparing high-strength hybrid luminous hydrogel

ActiveCN106432297AHigh transparencyHigh mechanical strengthGroup 3/13 organic compounds without C-metal linkagesLuminescent compositionsEnvironmental resistanceStructural formula

The invention provides a ternary rare earth complex and application of the complex in preparing high-strength hybrid luminous hydrogel. The chemical structural formula of the ternary rare earth complex is shown as follows. First terpyridyl bridged imidazolium salt is used for being combined with a rare earth beta-diketone complex to form a ternary complex, the ternary complex can be self-assembled in water to form a micellar structure, and then rare earth ions and ASPA are isolated through the collaborative protection on the rare earth ions by the ternary complex and the micellar structure, so that the aim of preparing a hydrogel which is good in luminescence property and high in mechanical strength is achieved. The hydrogel uses water as a medium, the preparation method is simple, easy and environmentally friendly, and a volatile organic solvent is avoided from being used. Please see the formula in the description.

Owner:HEBEI UNIV OF TECH

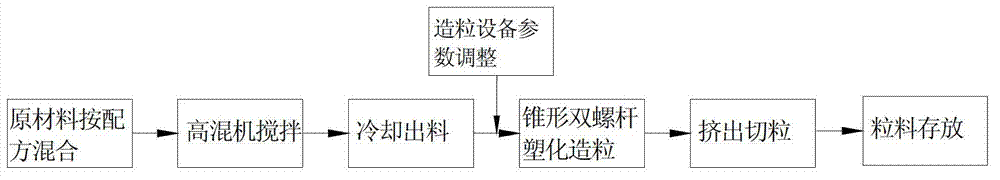

Door seal and preparation method thereof as well as refrigeration equipment

ActiveCN103087446AImprove thermal insulationReduce energy consumptionDomestic cooling apparatusLighting and heating apparatusElastomerFoaming agent

The invention discloses a door seal and a preparation method thereof as well as refrigeration equipment, wherein the door seal comprises the following components in parts by weight: 35-50 parts of PVC (polyvinyl chloride) resins, 5-15 parts of elastomer, 20-40 parts of plasticizer, 0-20 parts of inorganic filler, 1-3 parts of heat stabilizer, 0.5-2 parts of lubricating agent and 0.1-2 parts of foaming agent. The door seal disclosed by the invention has a micro-foaming structure, and has the advantages of better elasticity and tenacity, low mobility, less possibility of being adhered to side plates and a door body, low corrosivity for the side plates and the door body, and the like.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

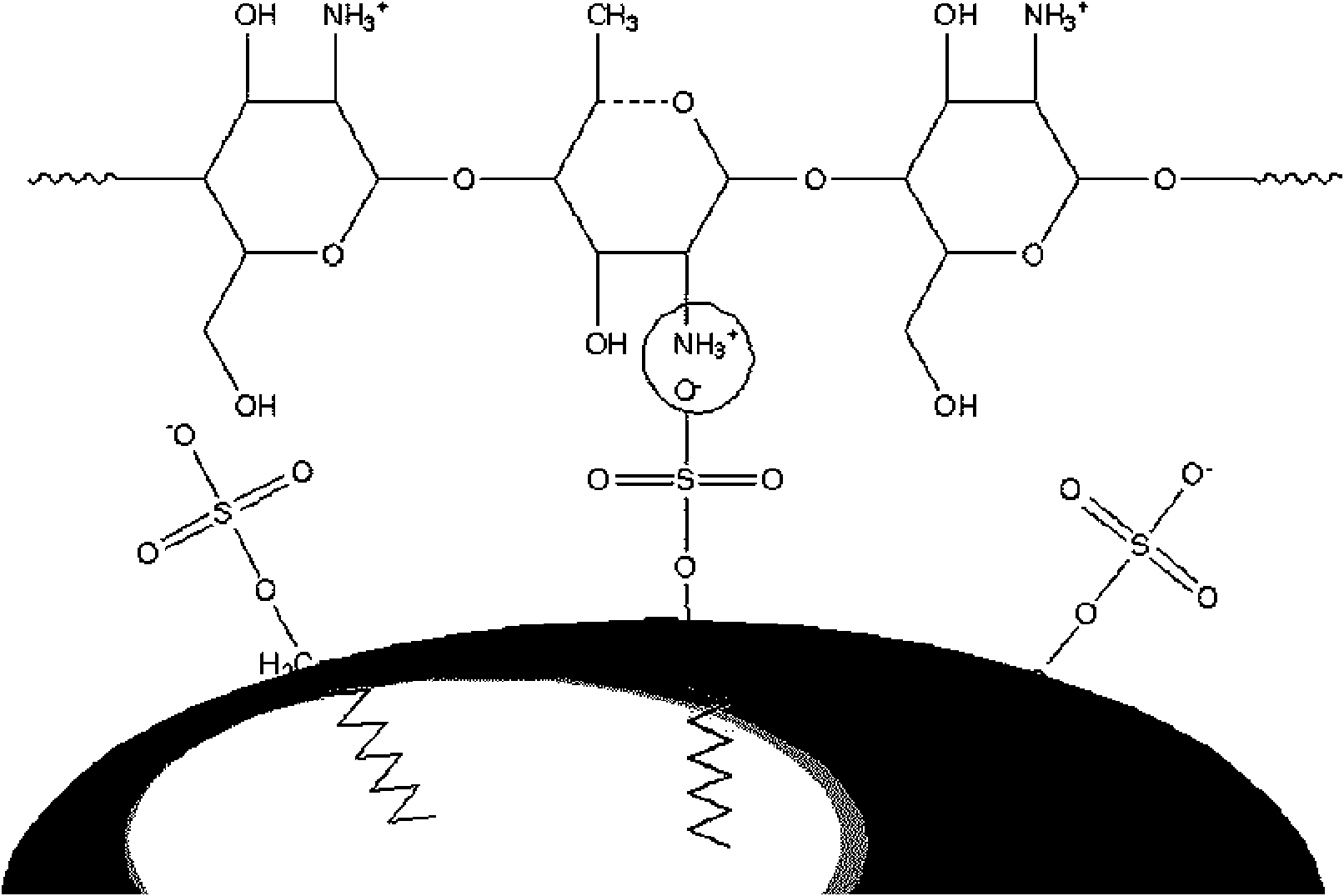

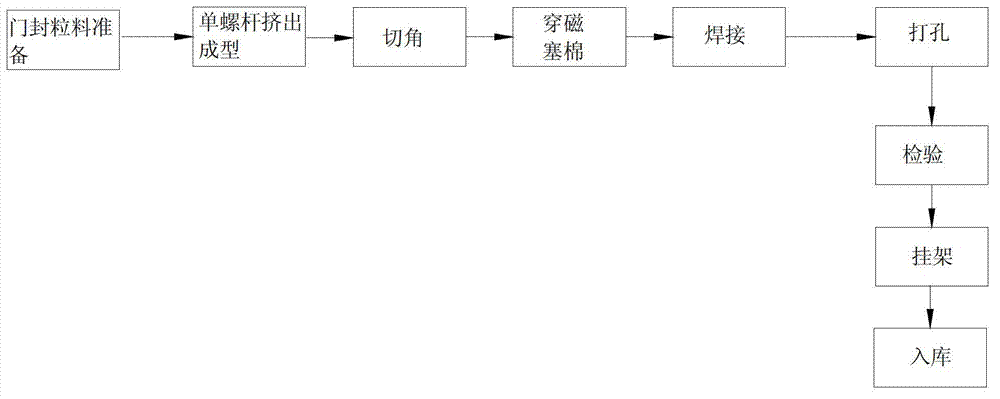

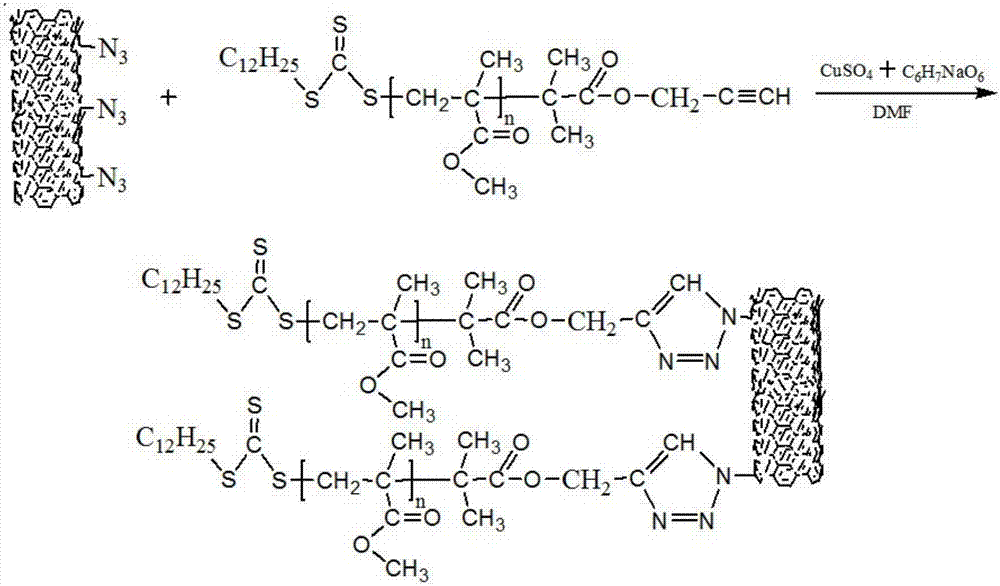

Amphiphilic polymer brush carbon nanotube/PVDF (polyvinylidene fluoride) nanofiltration membrane and preparation method thereof

ActiveCN107051215AAchieve functionalizationImprove performanceMembranesWater/sewage treatment bu osmosis/dialysisChemical reactionClick chemistry

The invention belongs to the field of preparation of nanofiltration membranes, and particularly relates to a click-chemistry-synthesized amphiphilic polymer brush carbon nanotube / PVDF (polyvinylidene fluoride) nanofiltration membrane and a preparation method thereof. The method comprises the following steps: synthesizing a novel macromolecule initiator capable of performing click chemistry reaction and initiating azido reaction, grafting the clickable macromolecule initiator onto the surface of the single-wall carbon nanotubes by click chemistry reaction, selecting an appropriate hydrophilic modifier monomer, and preparing amphiphilic polymer brush carbon nanotubes; carrying out blending, extrusion and casting on the click-chemistry-synthesized amphiphilic polymer brush carbon nanotubes and PVDF according to a certain proportion, wherein a biaxial orientation technique is adjusted to control the biaxial orientation temperature and speed and adjust the pore size of the microporous membrane; and compounding and coating a nano-pore-size ultrathin thin layer on the obtained microporous membrane, thereby obtaining the amphiphilic polymer brush carbon nanotube / PVDF nanofiltration membrane.

Owner:CHANGZHOU UNIV

Multifunctional wall cloth and manufacturing method thereof

InactiveCN102747816AAchieve functionalizationPurifyingCovering/liningsLaminationAntistatic agentMolding machine

The invention relates to a multifunctional wall cloth and a manufacturing method thereof. The multifunctional wall cloth is mainly used for solving the technical problems that the present decorative material only has a decorative effect and does not have functionality. The multifunctional wall cloth is characterized by comprising a decorative layer and a heat-insulating layer, wherein a bonding layer is arranged between the decorative layer and the heat-insulating layer; the decorative layer and the heat-insulating layer are integrally bound through the bonding layer; and the decorative layer is spun by using chemical fibers, cotton, flax and viscose. When the decorative layer is dyed, the following materials by weight percent are added into a dyestuff: 1-5% of nanometer silver antibiotic finishing agent, 3-10% of three-proofing additives, 25-35% of halogen-free fire retardants, 0.5-2% of antistatic agents and 1-8% of nanometer titanium dioxides; the materials are dried by using a 30 yards / hour molding machine and the drying temperature is at 180-230 DEG C; the heat-insulating layer is formed by spinning polypropylene fibers, viscose and three-dimensional crimp hollow fibers and 10-15g / m<2> cannabinol is sprayed on the surface of the heat-insulating layer; and then the decorative layer and the heat-insulating layer are fixedly bound through adhesive agents.

Owner:王华

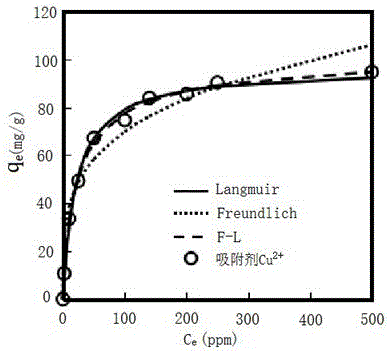

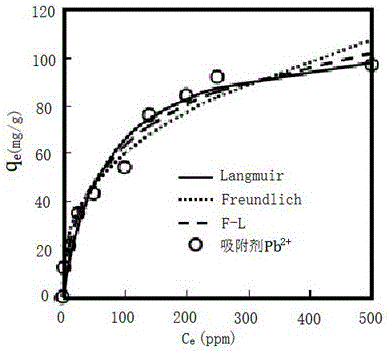

Polyvinyl alcohol/amino silanized graphene oxide macroporous compound spheres as well as preparation method and application of compound spheres

ActiveCN106311185AAchieve functionalizationImprove adsorption capacityOther chemical processesWater contaminantsSolubilityPolyvinyl alcohol

The invention discloses polyvinyl alcohol / amino silanized graphene oxide macroporous compound spheres as well as a preparation method and an application of the compound spheres. Firstly, graphite oxide is prepared with an improved Hummers method, graphene oxide is obtained through ultrasonic stripping and is silanized by 3-aminopropyltriethoxysilane, silanized graphene oxide is embedded in polyvinyl alcohol, and a target product is prepared and used for adsorbing heavy metal ions in a water body. Through silanization of graphene oxide, the water solubility of the product is reduced, and solid-liquid separation is easy to realize; introduced amino groups improve the adsorption capability of graphene oxide to pollutants, amino silanized graphene oxide is embedded in polyvinyl alcohol, the use amount of amino silanized graphene oxide is reduced, and the defect of difficulty in solid-liquid separation is further overcome; the macroporous compound spherical structure of the product has good quality transmission; besides, the mechanical strength of the material is improved due to introduction of polyvinyl alcohol, and separation after adsorption is facilitated.

Owner:WUHAN UNIV

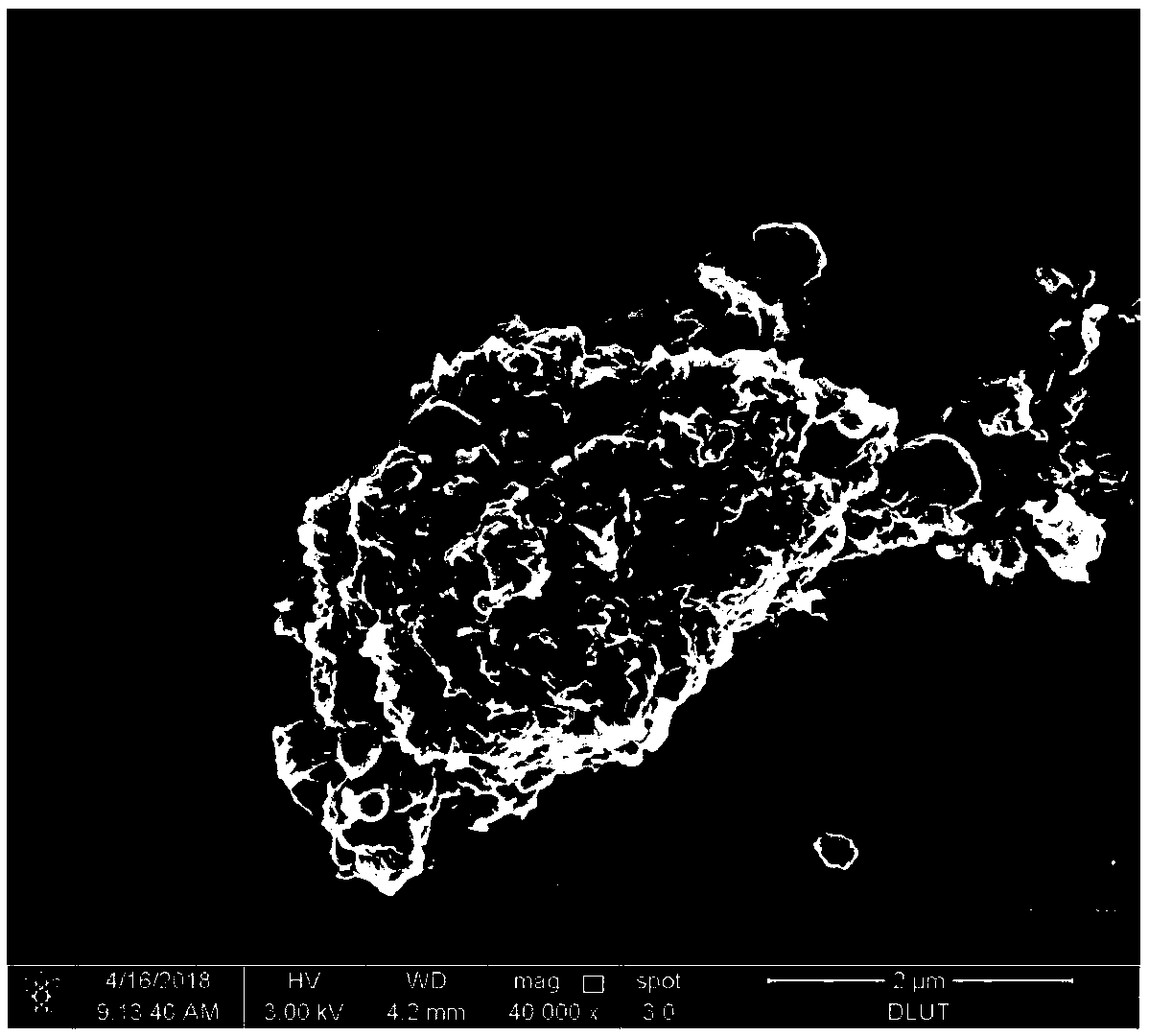

A three-dimensional graphene sponge/Fe2O3 composite wave absorbing material and a preparation method thereof

ActiveCN108774491AImprove absorbing performanceImprove operating conditionsOther chemical processesMagnetic/electric field screeningReaction temperatureCvd graphene

A three-dimensional graphene sponge / Fe2O3 composite wave absorbing material and a preparation method thereof are disclosed and belong to the technical field of wave absorbing materials. Firstly, three-dimensional graphene is prepared through a template process and is then added into deionized water, the mixture is subjected to ultrasonic treatment to obtain a uniformly dispersed three-dimensionalgraphene sponge suspension, then an aqueous Fe<3+> solution is added into the suspension dropwise, and a reaction occurs at 70-95 DEG C after the pH value is adjusted with ammonia water. The structureand wave absorbing performance of the composite wave absorbing material are adjusted through controlling the using amount of FeCl3, the pH value, the reaction temperature and the reaction time. A graphene matrix of the composite wave absorbing material in which the graphene sponge is loaded with magnetic nanometer Fe2O3 particles has a mesoporous sponge structure, and the Fe2O3 particles are uniformly anchored and grow on the graphene sponge. The prepared composite wave absorbing material has characteristics of high wave absorbing intensity, effective absorption frequency bandwidth, low density, low thickness, and the like, and has important application value in the field of developing efficient and light-weight electromagnetic wave absorbing materials.

Owner:DALIAN UNIV OF TECH

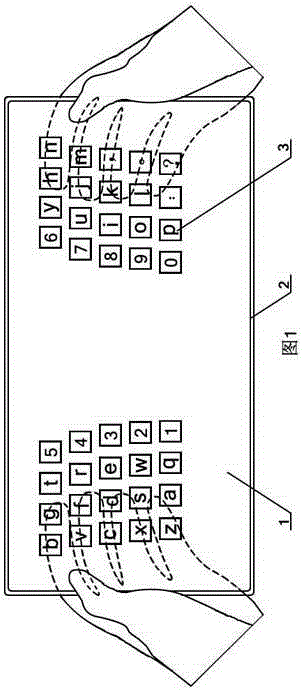

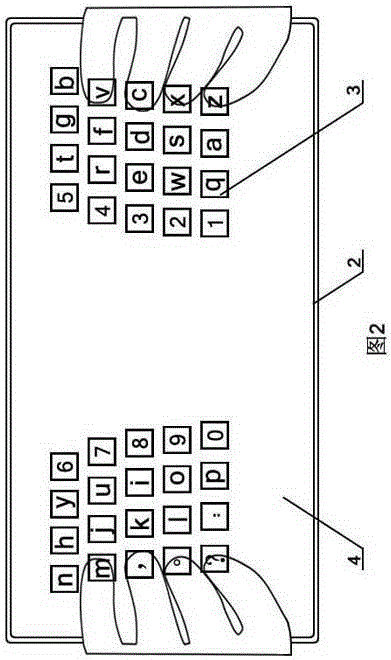

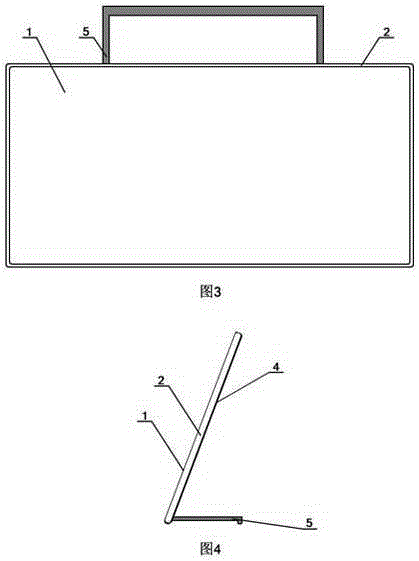

Smart tablet provided with U-shaped touch screens and holding posture input self-setting keyboard

InactiveCN105094237AAchieve functionalizationInput multi-channelDigital data processing detailsInput/output processes for data processingHand heldHuman–computer interaction

The invention discloses a smart tablet provided with U-shaped touch screens and a holding posture input self-setting keyboard. The input keyboard is arranged on the smart tablet, and in the two-hand holding posture, ten fingers of the two hands touch the surface naturally. Thumbs of the two hands touch space input keys on edges of a front touch display screen of the smart tablet as well as other function keys and a mouse, or the space input keys touched by the thumbs of the two hands are arranged on the frame of the smart tablet, and other function keys and the mouse are arranged on the edge of the front touch display screen. The rest fingers of the two hands touch a back touch display screen of the tablet as well as input keys corresponding to a conventional computer keyboard or a specific input keyboard. Functionalization of the backs of a smart phone and the smart tablet is realized.

Owner:ZIBO ENVIRONMENTAL PROTECTION TECH CO LTD +1

Polymer/inorganic nanoparticle composite material and preparation method thereof

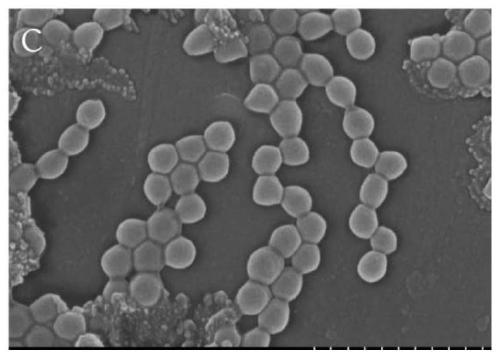

The invention discloses a polymer / inorganic nanoparticle composite material and a preparation method thereof, and belongs to the field of composite materials. The preparation method comprises the following steps: (1) uniformly mixing silica sol or inorganic nanoparticles, dopamine, tris (hydroxymethyl) aminomethane hydrochloride and water for reaction to obtain a polydopamine modified inorganic nanoparticle aqueous solution; (2) adding a monomer and water into the polydopamine modified inorganic nanoparticle aqueous solution, uniformly mixing, and introducing nitrogen to remove oxygen; and (3)adding an initiator solution into the reaction solution obtained in the step (2), bubbling to remove oxygen, and carrying out soap-free emulsion polymerization reaction under the protection of nitrogen gas to obtain the polymer / inorganic nanoparticle composite material. No surfactant needs to be added during polymerization, so that the cost is saved, and the environmental pollution is reduced. Bychanging the type of the initiator and the types of the monomer and the inorganic particles in the reaction liquid, the formation and the particle size change of the polymer / inorganic nano compositeparticles can be effectively regulated and controlled.

Owner:SOUTH CHINA UNIV OF TECH

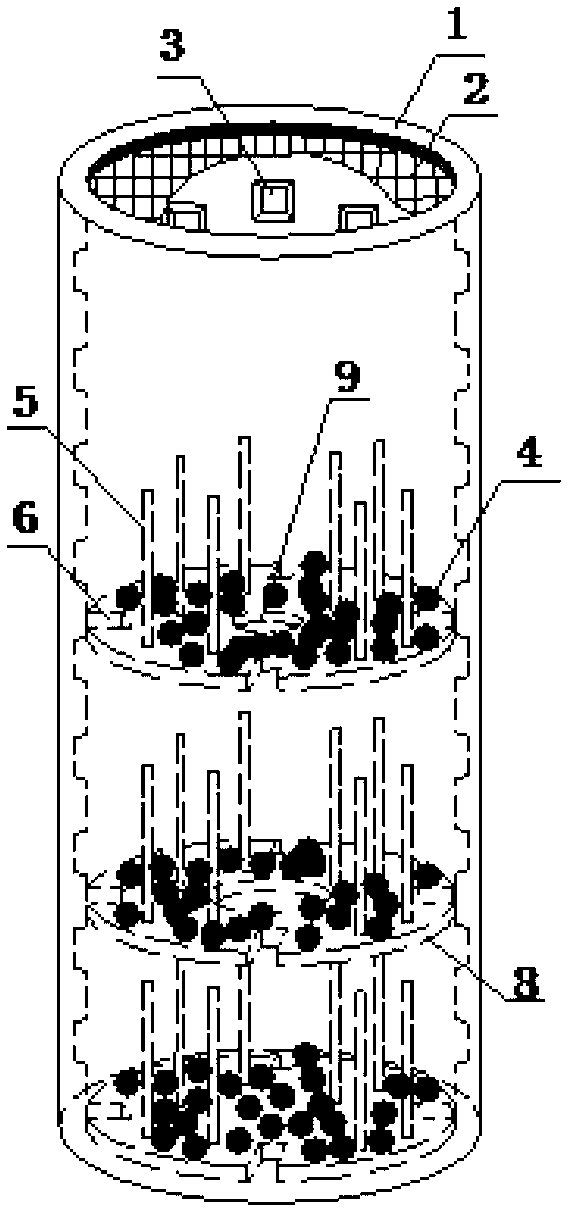

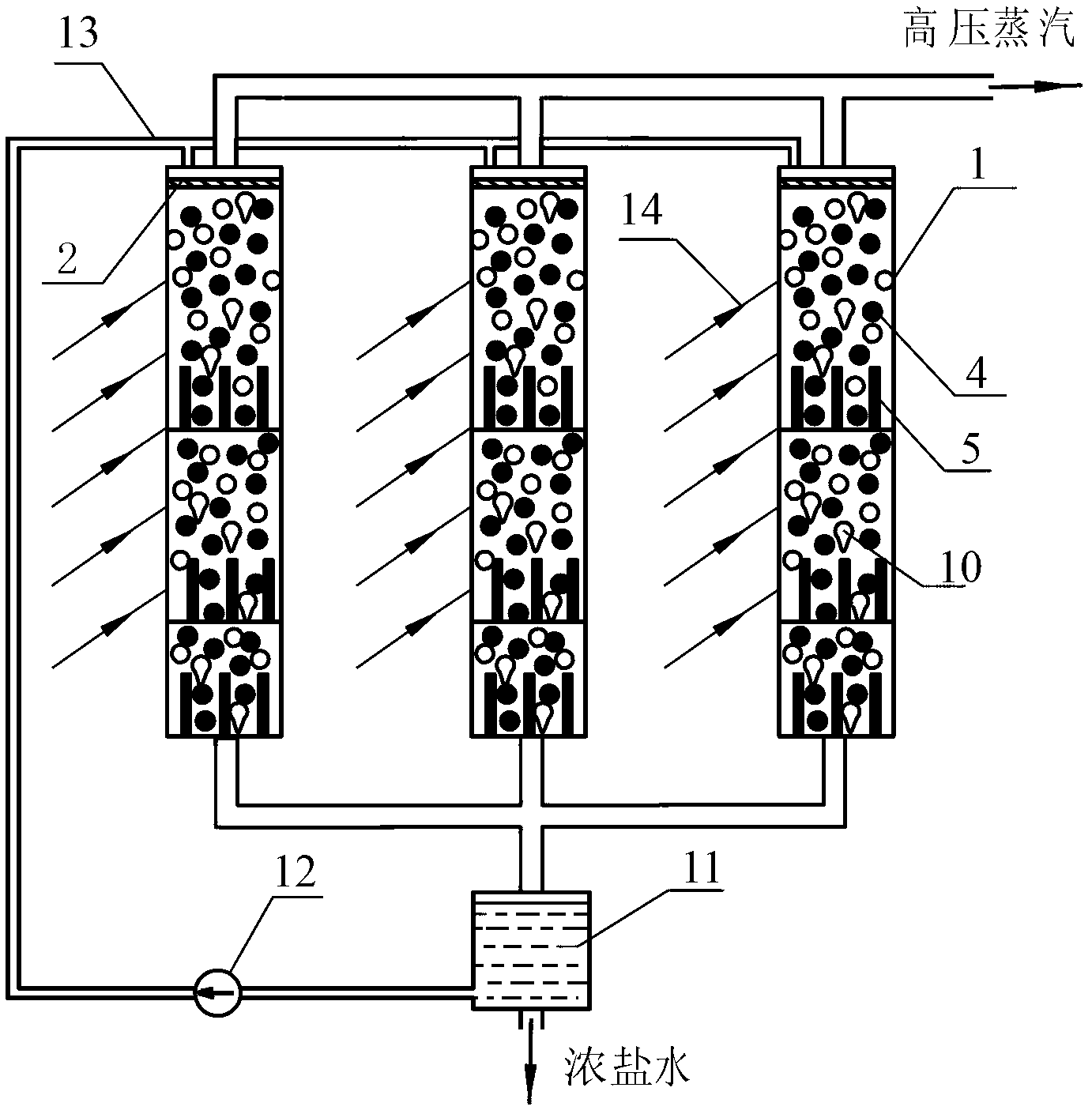

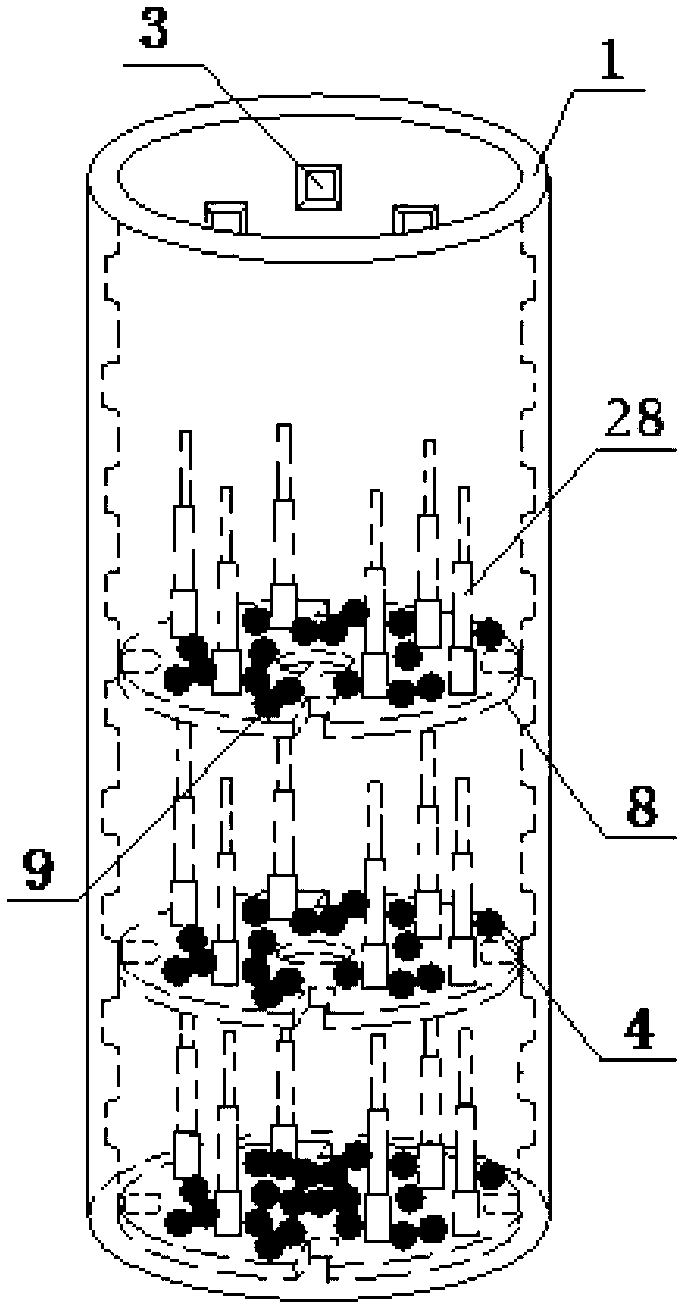

Seawater evaporator for light collecting solar seawater desalination device

InactiveCN102701304AImprove absorption performanceIncrease the optical pathGeneral water supply conservationSeawater treatmentSeawaterEvaporator

The invention provides a seawater evaporator for a light collecting solar seawater desalination device. The seawater evaporator comprises a transparent tube, a spill net, ceramic grains, fins and partition baffles; openings are respectively formed in the upper end and the lower end of the transparent tube; grooves are distributed in the inner surface of the transparent tube; the external diameterof each partition baffle is identical to the internal diameter of the transparent tube; a through hole is formed in the center of the partition baffle; a deflector hole is formed in the edge of the partition baffle; the spill net is mounted at the opening at the upper end of the transparent tube; the partition baffle is arranged in the inner chamber of the transparent tube; two adjacent layers ofpartition baffles, the upper layer of partition baffle and the spill net form a chamber; the volume of the chamber is decreased progressively in sequence from the top down; the fin is arranged on theupper end surface of each layer of partition baffle; and the ceramic grain is arranged on the upper end surface of each layer of partition baffle and put between the fins. The seawater evaporator achieves the seawater functionalization, also enhances the seawater light absorption function and the scale removal and inhibition function, can also be applied to the solar seawater desalination device,and improves the efficiency of using heat energy by the solar seawater desalination device.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Functional transparent graphene heating film

PendingCN109600868AAchieve functionalizationHigh sensitivityElectrotherapyTransparent/reflecting heating arrangementsPolymer thin filmsCvd graphene

The invention discloses a functional transparent graphene heating film. The functional transparent graphene heating film comprises a heating layer, a temperature detection layer, a pressure sensing layer and a base layer, wherein the heating layer, the temperature detection layer and the pressure sensing layer are arranged on the base layer in a lamination way, the heating layer comprises a graphene transparent heating film, the temperature detection layer comprises a thin film temperature sensor, the pressure sensing layer comprises a thin film pressure sensor, the base layer comprises a fourth transparent polymer thin film, an electrode plate and a fourth electrode, the fourth electrode is connected with the electrode plate, a hole is formed in the fourth transparent polymer thin film, and the electrode plate is arranged in the hole. By a mode of combining multiple film layers, the multifunctional graphene flexible heating thin film which integrates current output, temperature detection and pressure detection is achieved, and the functional transparent graphene heating film can be applicable to the field of health care.

Owner:CHENGDU GRAPHENE APPL INST FOR IND TECH CO LTD

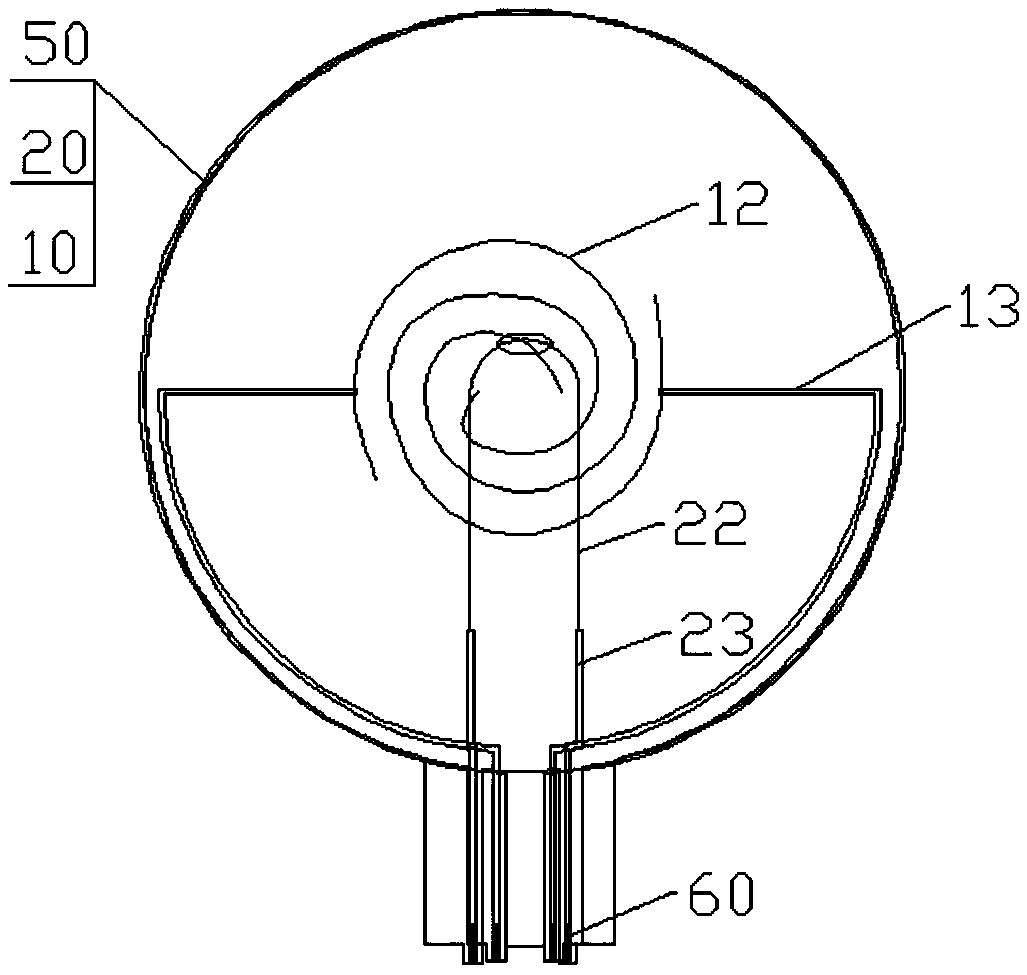

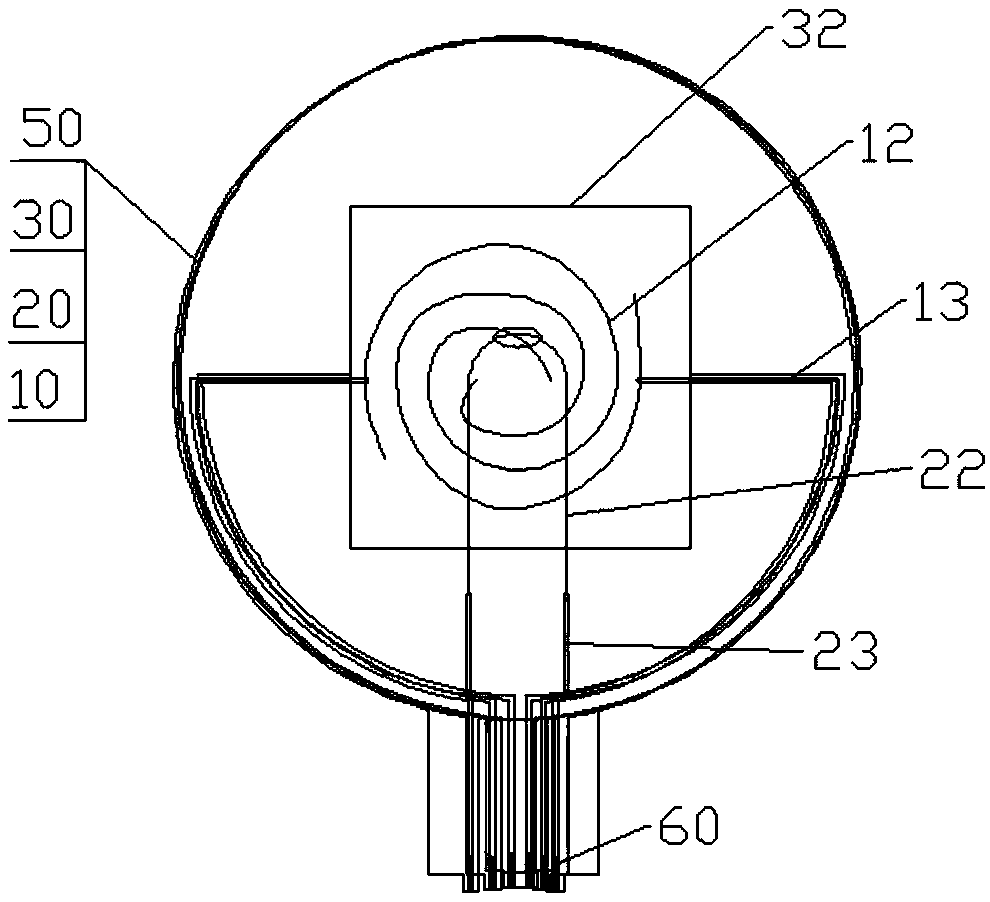

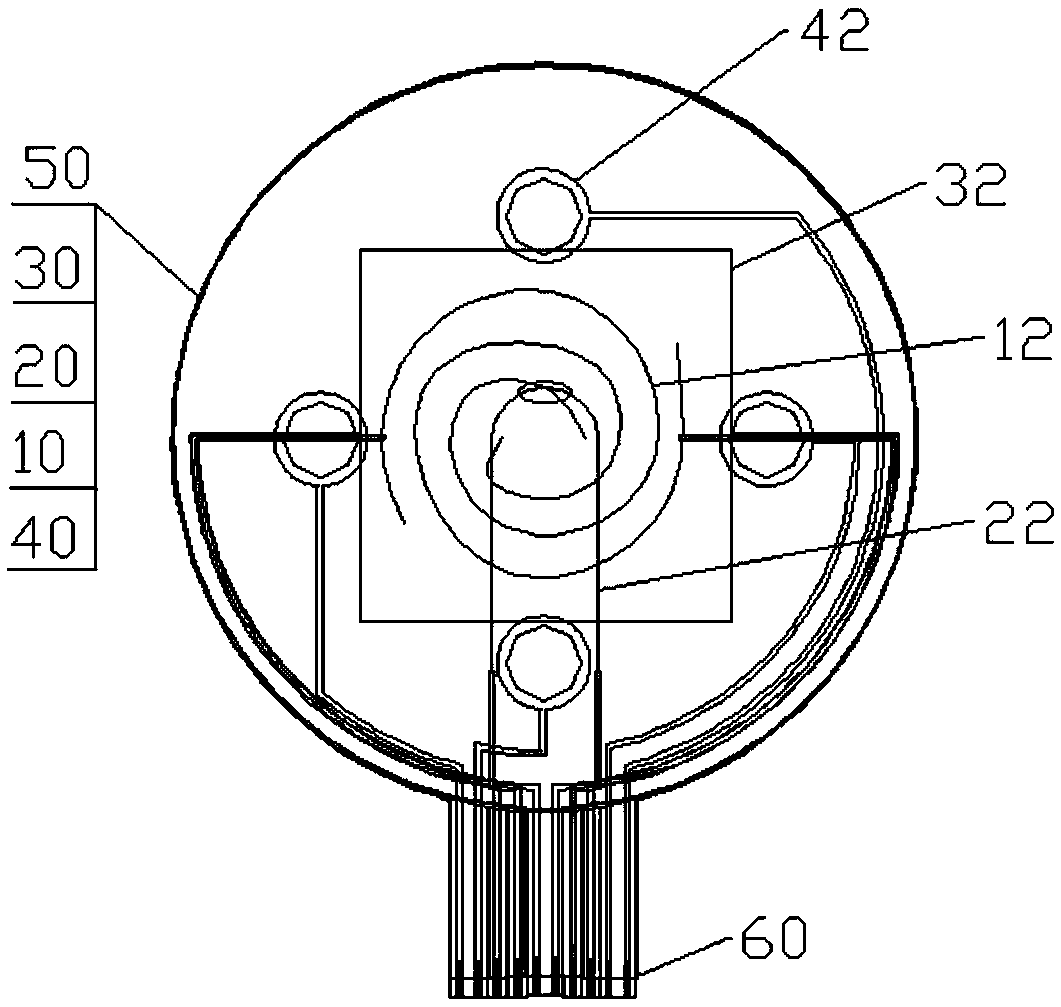

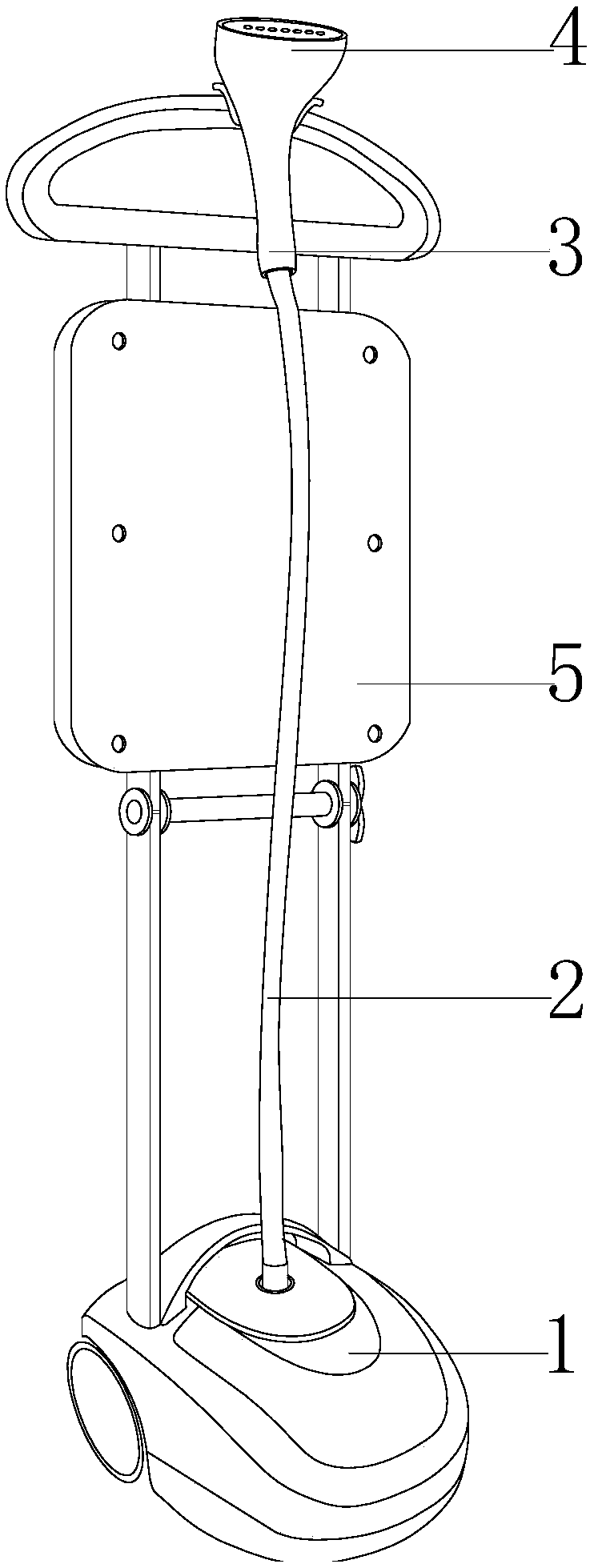

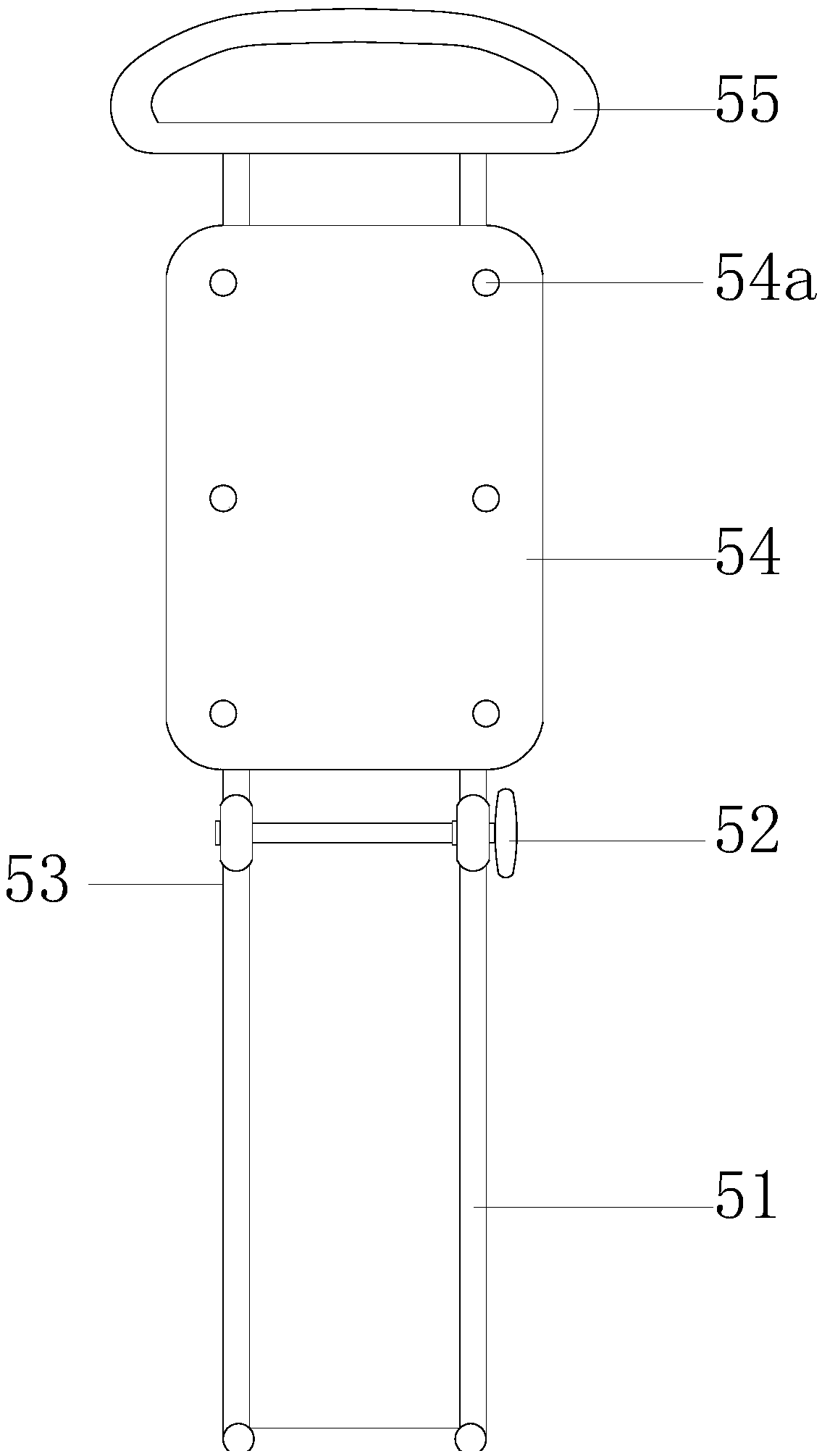

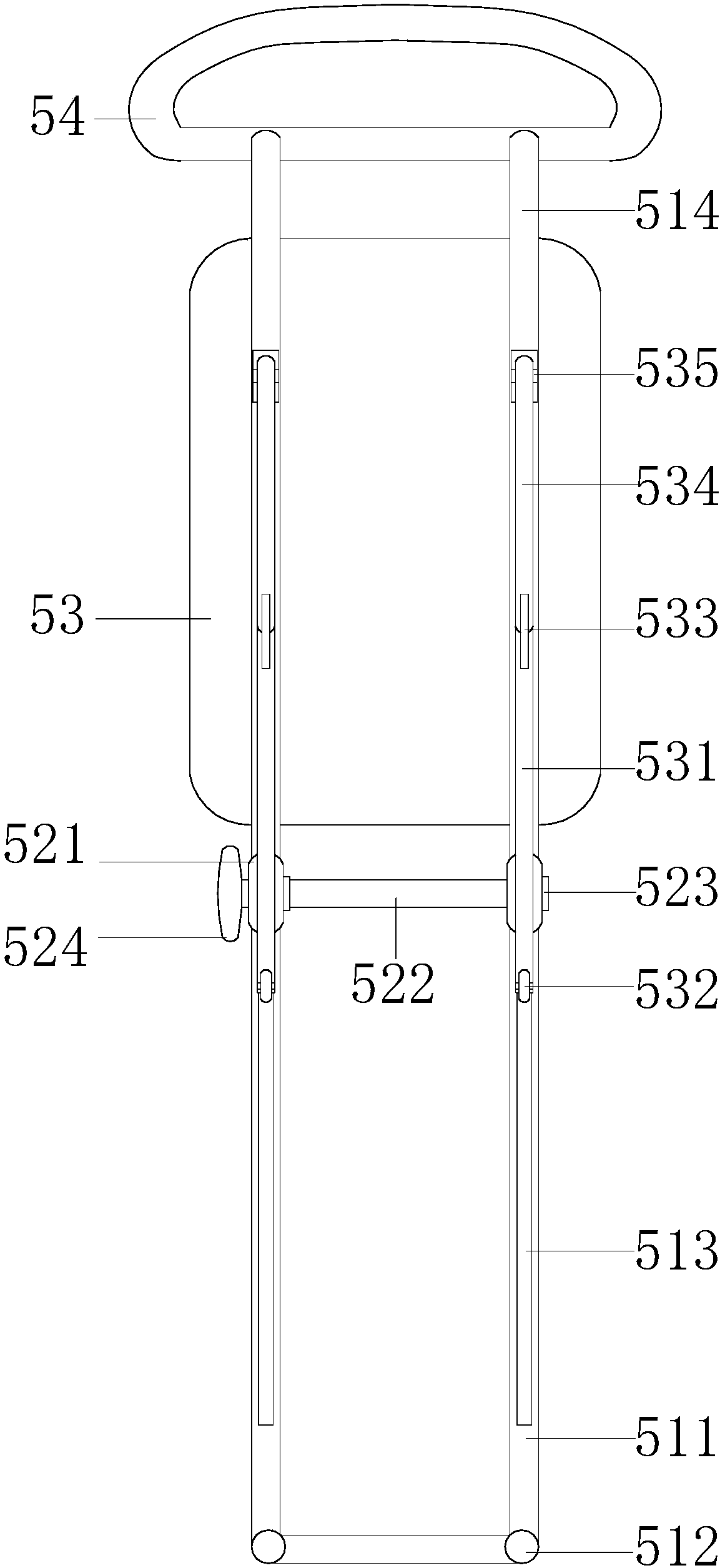

Hanging ironing and flat ironing integrated ironing device capable of pulling and fixing clothes under negative pressure

ActiveCN109322126AHanging iron is convenientHanging ironing smoothlyIroning boardsHand ironEngineering

The invention discloses a hanging ironing and flat ironing integrated ironing device capable of pulling and fixing clothes under negative pressure. The ironing device structurally comprises a steam generating machine body, a steam conveying pipe, a handle, an ironing brush, and a hanging ironing and ironing auxiliary device. One end of the steam conveying pipe is communicated with the steam generating machine body. The other end of the steam conveying pipe is communicated with the ironing brush through the handle. The handle and the ironing brush are of an integrally formed structure. The hanging ironing and ironing auxiliary device is arranged on the upper rear side of the steam generating machine body and perpendicularly and fixedly connected with the steam generating machine body. The hanging ironing and ironing auxiliary device can assist in the hanging ironing work and ensures the smoothness of the hanging ironing work so that hanging ironing can be easily achieved; hanging ironing and flat ironing can be freely switched, and the ironing modes are freely changed through rotation according to the different materials of the clothes; the ironing device can be folded to be placed,and the storage space is reduced.

Owner:浙江茗盛时装股份有限公司

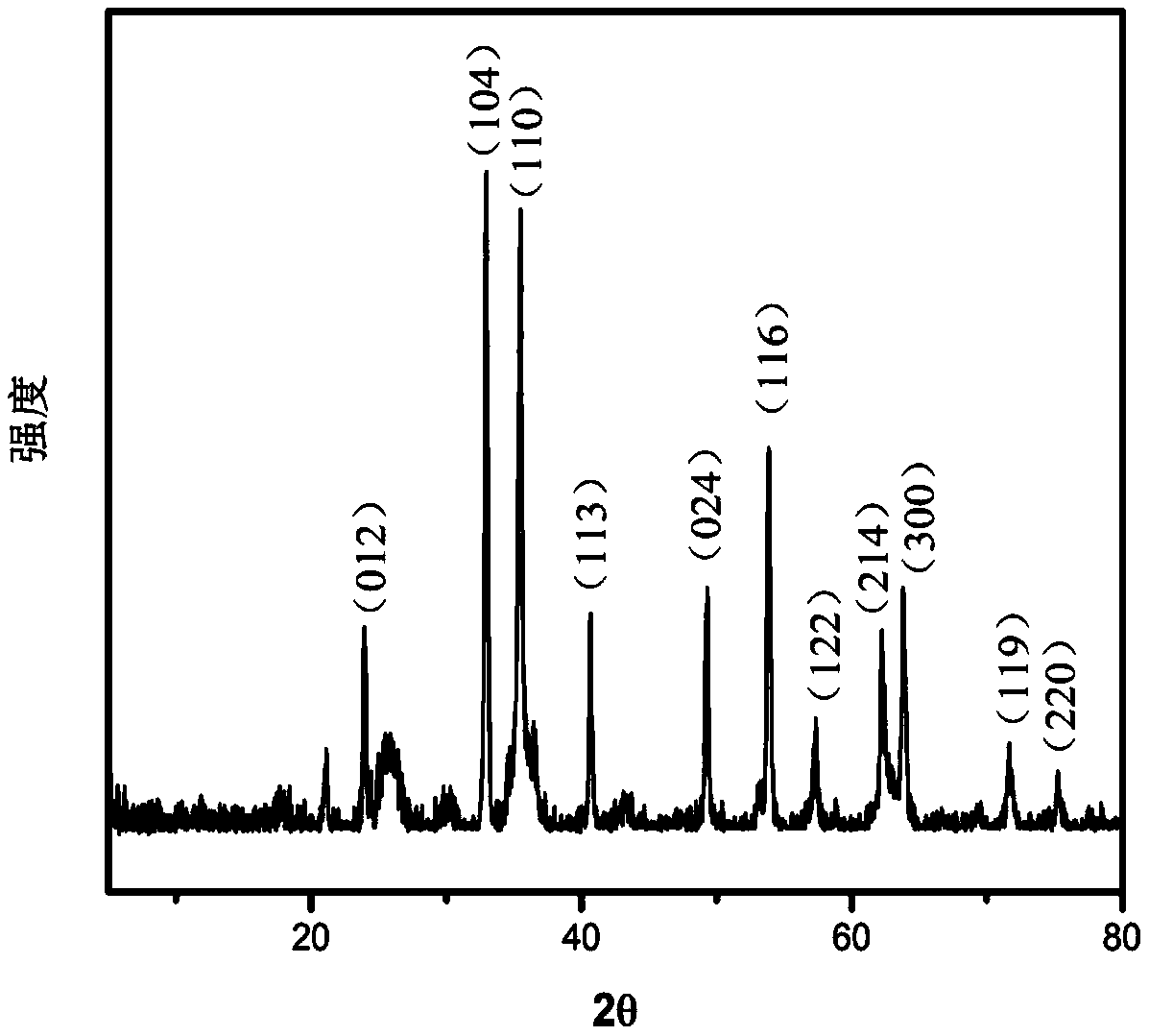

High-purity ultra-fine titanium dioxide prepared from industrial metatitanic acid and preparation method of titanium dioxide

ActiveCN106365200ABroad application prospectsAdd new varietiesNanotechnologyTitanium dioxideChemistryTitanium dioxide

The invention relates to a preparation method of titanium dioxide, in particular to a method for preparing high-purity ultra-fine titanium dioxide by industrial metatitanic acid. The method includes the steps: a, beating dispersion: washing and bleaching hydrolyzed metatitanic acid, adding water for dilution, performing beating and ultrasonic dispersion to obtain slurry, adding dispersing agents into the slurry and performing dispersion to obtain metatitanic acid slurry; b, curing: curing the metatitanic acid slurry, cooling the metatitanic acid slurry to 60-70 DEG C, and filtering and washing the metatitanic acid slurry until ferrous ions are removed to obtain a purified metatitanic acid filter cake; c, calcining: adding water to the metatitanic acid filter cake, performing ultrasonic dispersion and calcining, cooling the filter cake to room temperature, and crushing and grinding the filter cake to obtain the titanium dioxide. By the aid of an impurity ion occurrence form in hydrolyzed metatitanic acid particles and composition and structural characteristics of the metatitanic acid, the high-purity ultra-fine titanium dioxide is directly prepared by dispersion, washing, curing, calcining and the like, new varieties of the titanium dioxide can be increased, product application can be functionalized, and the method has a wide application prospect.

Owner:天津金玺科技发展有限公司

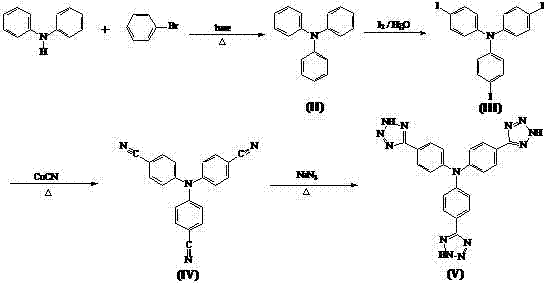

Synthesis method of tris-(4-tetrazolyl-phenyl)amine

The invention relates to a synthesis method of tris-(4-tetrazolyl-phenyl)amine, belonging to the field of material chemistry. The technical scheme of the invention is as follows: reacting diphenylamine with halo-benzene under a basic condition to obtain triphenylamine, carrying out substitution reaction on triphenylamine with iodine to generate tris-(4-iodophenyl)amine, then reacting tris-(4-iodophenyl)amine with CuCN to generate tris-(4-cyanophenyl)amine, and finally reacting tris-(4-cyanophenyl)amine with sodium azide to generate tris-(4-tetrazolyl-phenyl)amine. The porous material built by reacting obtained tris-(4-tetrazolyl-phenyl)amine with a metal has the stability of carboxylic acid porous frames, achieves intra-pore functionalization, and has pores in a mesoporous size. The adsorption capacity with respect to specific sulfur-containing small molecules shows that the porous material has potential application value in developing high-performance petrochemical products.

Owner:扬州三友合成化工有限公司

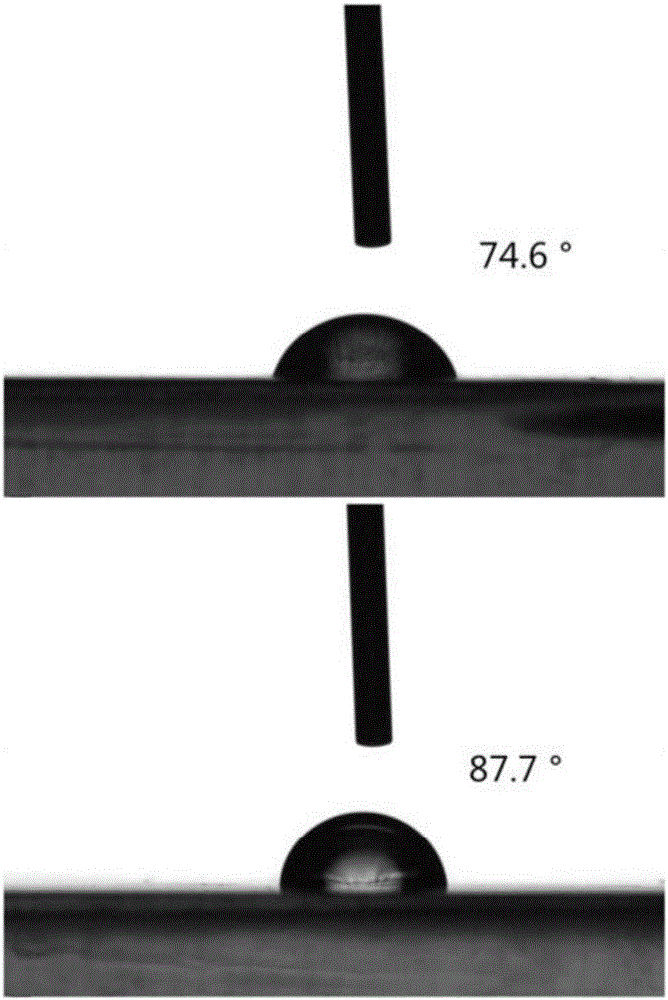

Adhesive self-resistance heating/super-hydrophobic integrated gradient thin film material

ActiveCN110510102AAchieve functionalizationImprove mechanical propertiesNon-macromolecular adhesive additivesFilm/foil adhesivesInter layerMechanical property

The invention discloses an adhesive self-resistance heating / super-hydrophobic integrated gradient thin film material. The thin film material is made of adhesive resin, insulating resin, thermally andelectrically conductive filler and thermally conductive and insulating filler, wherein the adhesive resin and the insulating resin separately form a bonding layer and a substrate which are bonded together; and the thermally and electrically conductive filler and the thermally conductive and insulating filler are added to a middle layer and an upper layer of the substrate correspondingly to dividethe substrate into three gradient regions from top to bottom, wherein the surface of the uppermost region is constructed with a super-hydrophobic structure. The adhesive self-resistance heating / super-hydrophobic integrated gradient thin film material has the beneficial effects that (1) only the insulating resin is used in a main part, the functionalization of different regions is realized while ensuring that the interface influence between layers of different materials does not exist in a structure, mechanical properties are significantly improved, and stratification is not prone to occurring;and (2) anti-icing and de-icing are integrated into one, the icing time can be effectively delayed, low-energy electric heating de-icing can be achieved, and the energy utilization efficiency of aircrafts can be ultimately improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com