Door seal and preparation method thereof as well as refrigeration equipment

A technology for refrigeration equipment and door seals, which is applied in the field of door seals and their preparation, can solve the problems of lack of elasticity, corrosion of side panels and door bodies, cracking, etc., and achieve good low-temperature characteristics and increased wear resistance and deformation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

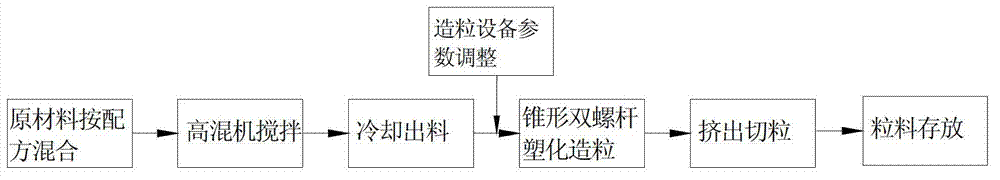

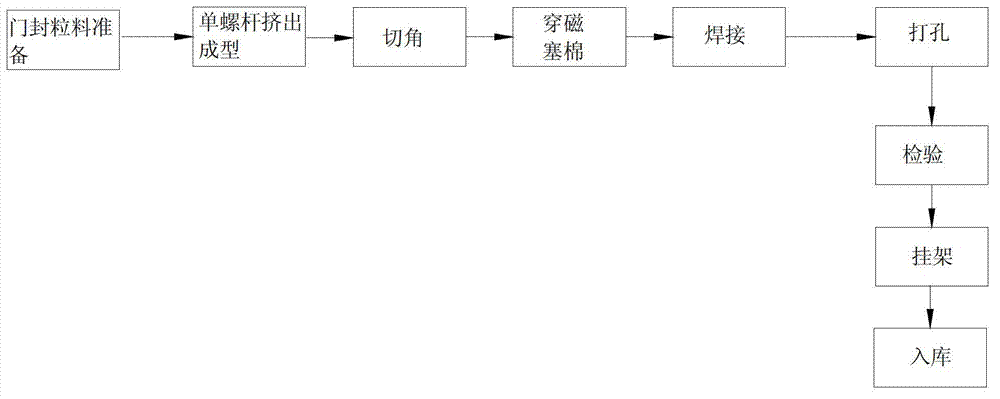

[0054] 100 parts by weight of PVC (Qilu Petrochemical S1300), 40 parts by weight of polyester plasticizer (PPA-2500), 10 parts by weight of auxiliary plasticizer (ESO), 2 parts by weight of organotin, 15 parts by weight of light calcium, 15 parts by weight of heavy calcium parts by weight, 0.35 parts by weight of foaming agent (OBSH), and 8 parts by weight of antifungal agent. Main process: Foaming agent, plasticizer and organotin are firstly mixed and ground together according to the ratio, then the PVC resin powder is put into the high-mixer, and stirred at a low speed (400-600r / min, the same below), while stirring slowly Add plasticizer evenly, turn to high speed (800r ~ 1200r) after adding, when the temperature rises to about 100°C, turn to low speed, alternate between low and high speed, control the material temperature between 90°C and 110°C for about 15 minutes. Turn to low speed and add anti-fungal agent, finally add calcium powder, continue to stir for 3-5 minutes, ta...

Embodiment 2

[0056] 40 parts by weight of PVC resin powder (SGⅡ type), 8 parts by weight of powdered nitrile (P83), 25 parts by weight of TOTM, 5 parts by weight of ESO, 1.5 parts by weight of rare earth composite stabilizer, 18 parts by weight of calcium powder, 0.75 parts by weight of AC foaming agent , ZnSt1.25 parts by weight, antibacterial agent 0.5 parts by weight. According to conventional mixing, granulation, extrusion, welding and hanging, the required door seal can be obtained.

Embodiment 3

[0058] 35 parts by weight of PVC (SGⅢ), 15 parts by weight of EVA powder (EVA30 / 10+EVA30 / 30), 15 parts by weight of DOTP+10 parts by weight of TOTM+5 parts by weight of ESO, 2 parts by weight of Ca-Zn stabilizer, 15 parts by weight of calcium powder , 1.25 parts by weight of AC blowing agent, 0.75 parts by weight of antibacterial agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com