Carrier type titanium dioxide ultrafiltration membrane and preparation method and application thereof

A titanium dioxide and ultrafiltration membrane technology, applied in the field of environmental pollution control, can solve the problems of providing the slightest help in the process of the reaction, unfavorable to the practical application of ceramic membranes, and small catalyst loading, so as to achieve optimal operation and improve membrane pollution. , the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

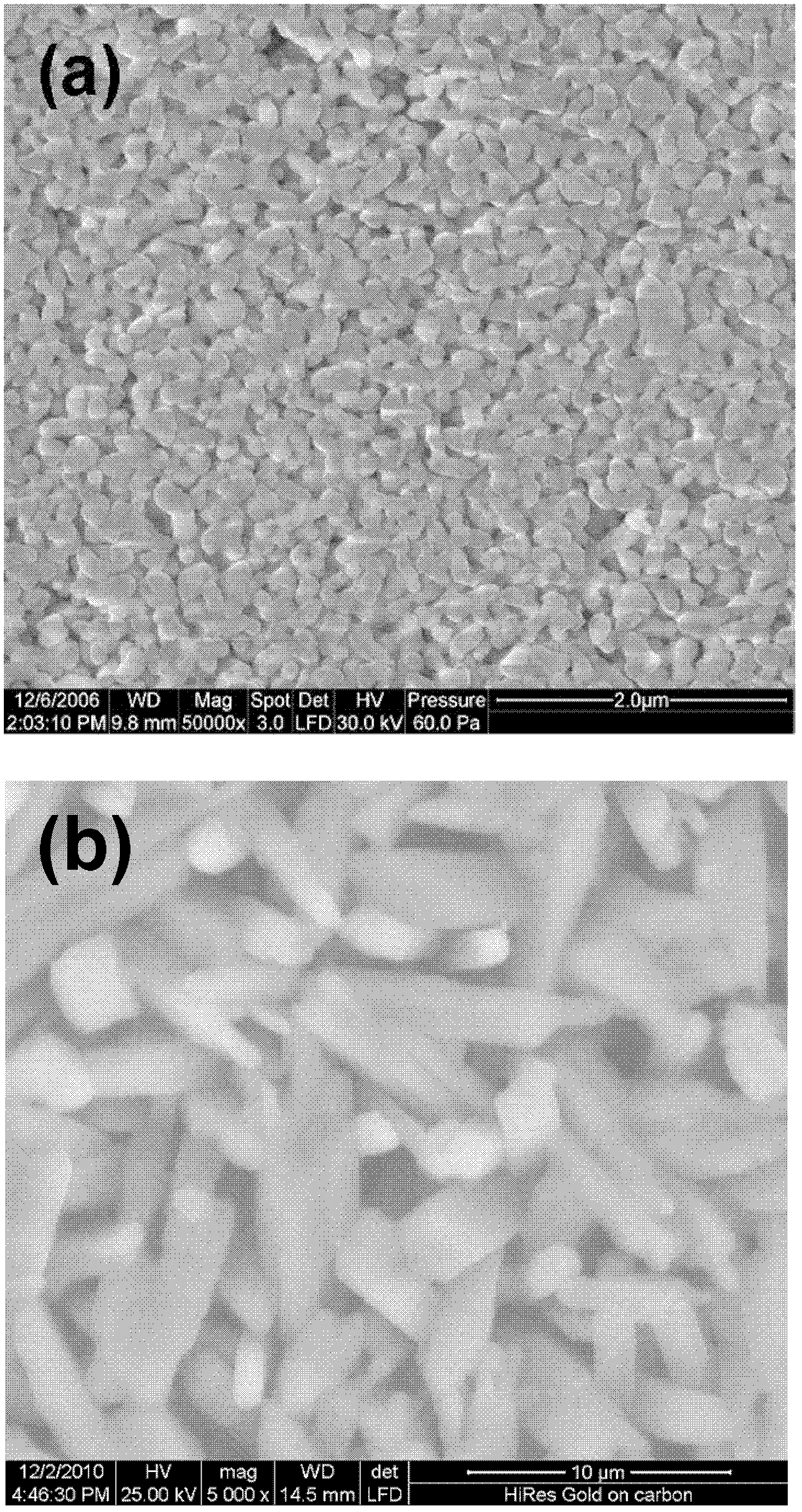

[0036] (1) Preparation of supported titanium dioxide ultrafiltration membrane

[0037] (1) The alumina ceramic membrane support made in the laboratory (plate type, prepared according to the method described in Document 1, with a pore size of 2 μm and a porosity of 45%) was ultrasonically cleaned in ether, methanol and water for 15 minutes, then dried, and dried at 300 After calcination at ℃ for 4 hours, store it in a dust-free laboratory bench for future use;

[0038] (2) Add titanium dioxide into the ball mill tank, and add ethanol according to 25% of its mass, and ball mill for 24 hours. After ball milling, the particle size reaches 100-200nm, and dry at 70°C for later use;

[0039] (3) Dissolve polyvinyl alcohol in water at a ratio of 0.75 wt%, and under vigorous stirring, add 10 wt% of the titanium dioxide prepared in step (2), stir for 4 hours, and ultrasonically seal and store for 30 minutes for later use;

[0040] (4) Coating by dipping and pulling method: fix the cera...

Embodiment 2

[0050] (1) Preparation of supported titanium dioxide ultrafiltration membrane

[0051] (1) The alumina ceramic membrane support made in the laboratory (plate type, prepared according to the method described in Document 1, with a pore size of 2 μm and a porosity of 45%) was ultrasonically cleaned in ether, methanol and water for 15 minutes, then dried, and dried at 300 After calcination at ℃ for 4 hours, store it in a dust-free laboratory bench for future use;

[0052] (2) adding titanium dioxide into the ball milling tank, adding ethanol according to 25% of its mass, ball milling for 24 hours, and drying at 70°C to prepare titanium dioxide with a particle size of 100-200nm for subsequent use;

[0053] (3) Dissolve polyvinyl alcohol in water at a ratio of 0.5 wt%, and under vigorous stirring, add 8 wt% of the titanium dioxide prepared in step (2), stir for 4 hours, ultrasonicate for 30 minutes and seal and store for later use;

Embodiment 3

[0060] (1) Preparation of supported titanium dioxide ultrafiltration membrane

[0061] (1) The alumina ceramic membrane support made in the laboratory (plate type, prepared according to the method described in Document 1, with a pore size of 2 μm and a porosity of 45%) was ultrasonically cleaned in ether, methanol and water for 15 minutes, then dried, and dried at 300 After calcination at ℃ for 4 hours, store it in a dust-free laboratory bench for future use;

[0062] (2) adding titanium dioxide into the ball milling tank, adding ethanol according to 25% of its mass, ball milling for 24 hours, and drying at 70°C to prepare titanium dioxide with a particle size of 100-200nm for subsequent use;

[0063] (3) Dissolve polyvinyl alcohol in water at a ratio of 0.5 wt%, and under vigorous stirring, add 8 wt% of the titanium dioxide prepared in step (2), stir for 4 hours, ultrasonicate for 30 minutes and seal and store for later use;

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com