Patents

Literature

74results about How to "Increased tortuosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

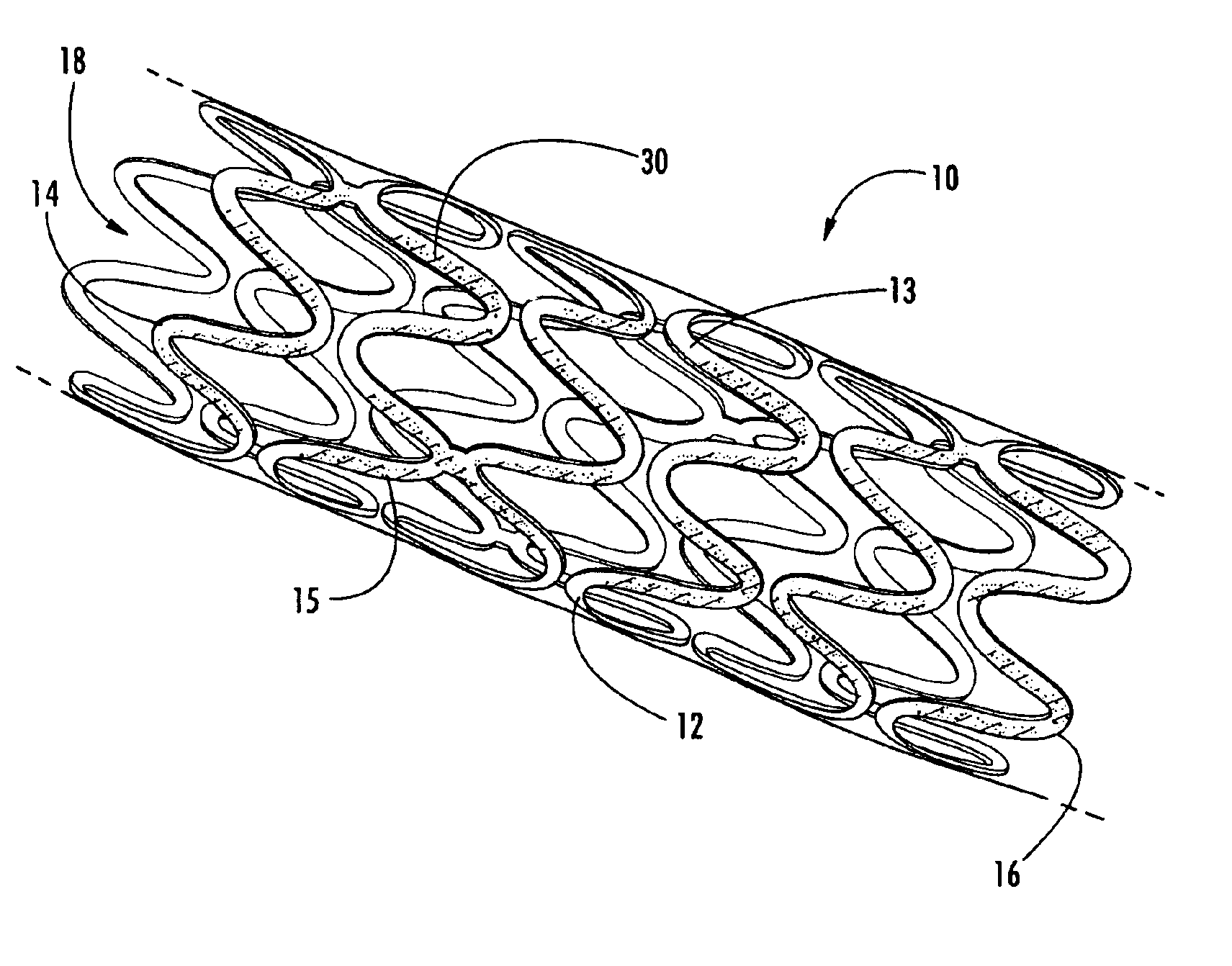

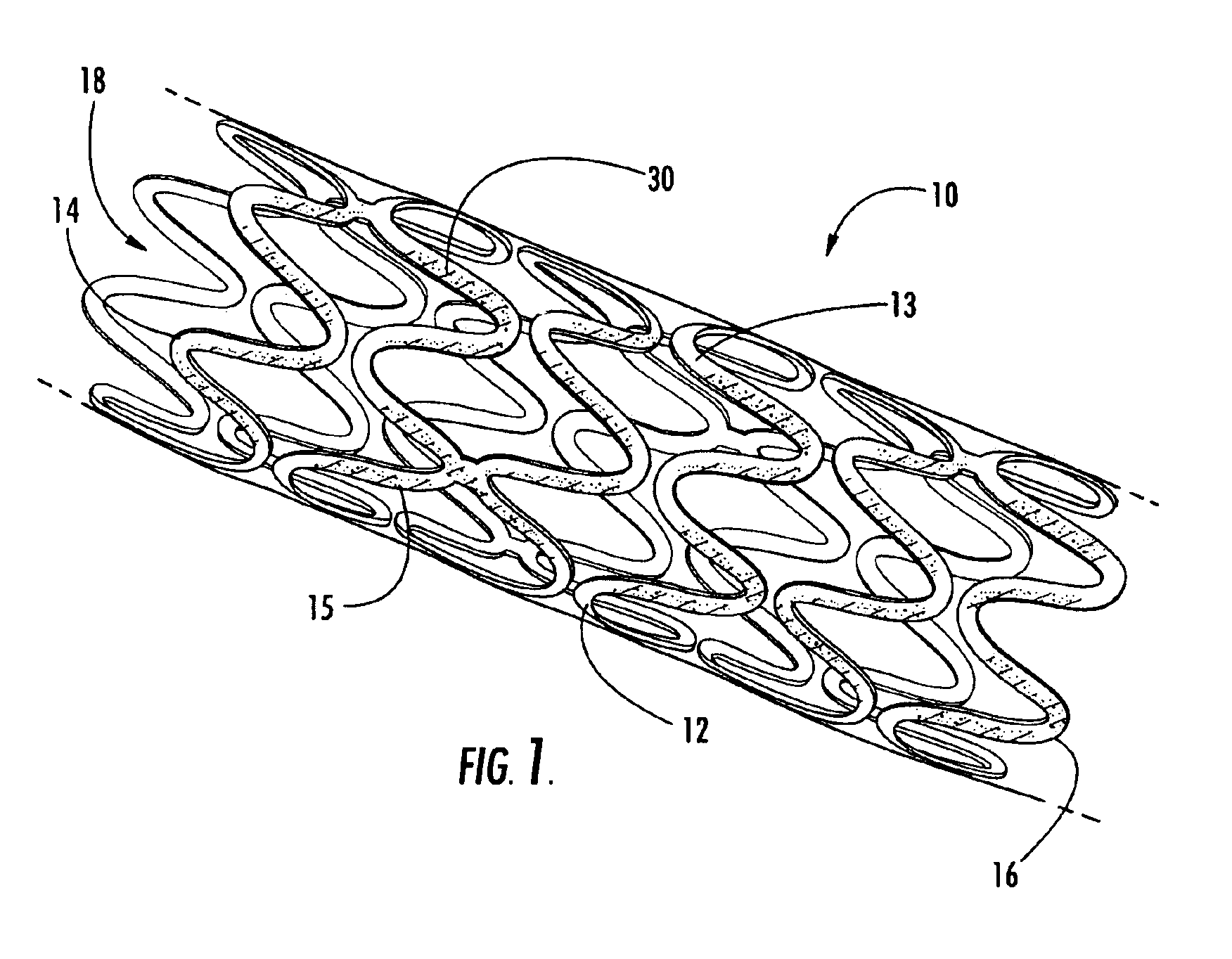

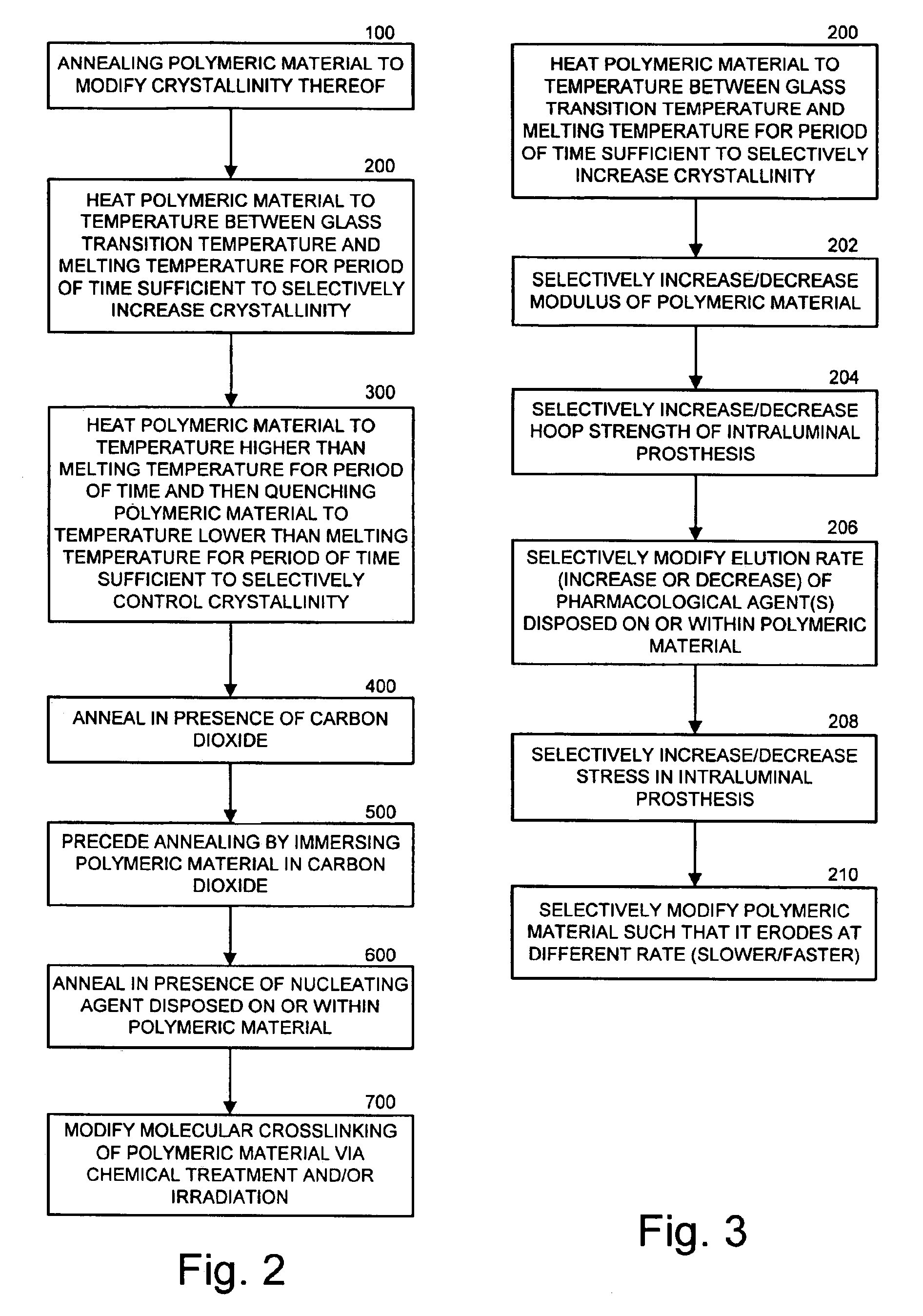

Intraluminal prostheses having polymeric material with selectively modified crystallinity and methods of making same

Methods of manufacturing polymeric intraluminal prostheses include annealing the polymeric material to selectively modify the crystallinity thereof. Annealing may be utilized to selectively modify various properties of the polymeric material of an intraluminal prosthesis, including: selectively increasing the modulus of the polymeric material; selectively increasing the hoop strength of the intraluminal prosthesis; selectively modifying the elution rate (increase or decrease) of a pharmacological agent subsequently disposed on or within the annealed polymeric material; selectively increasing / decreasing stress in the intraluminal prosthesis; and selectively modifying the polymeric material such that it erodes at a different rate.

Owner:SYNECOR LLC

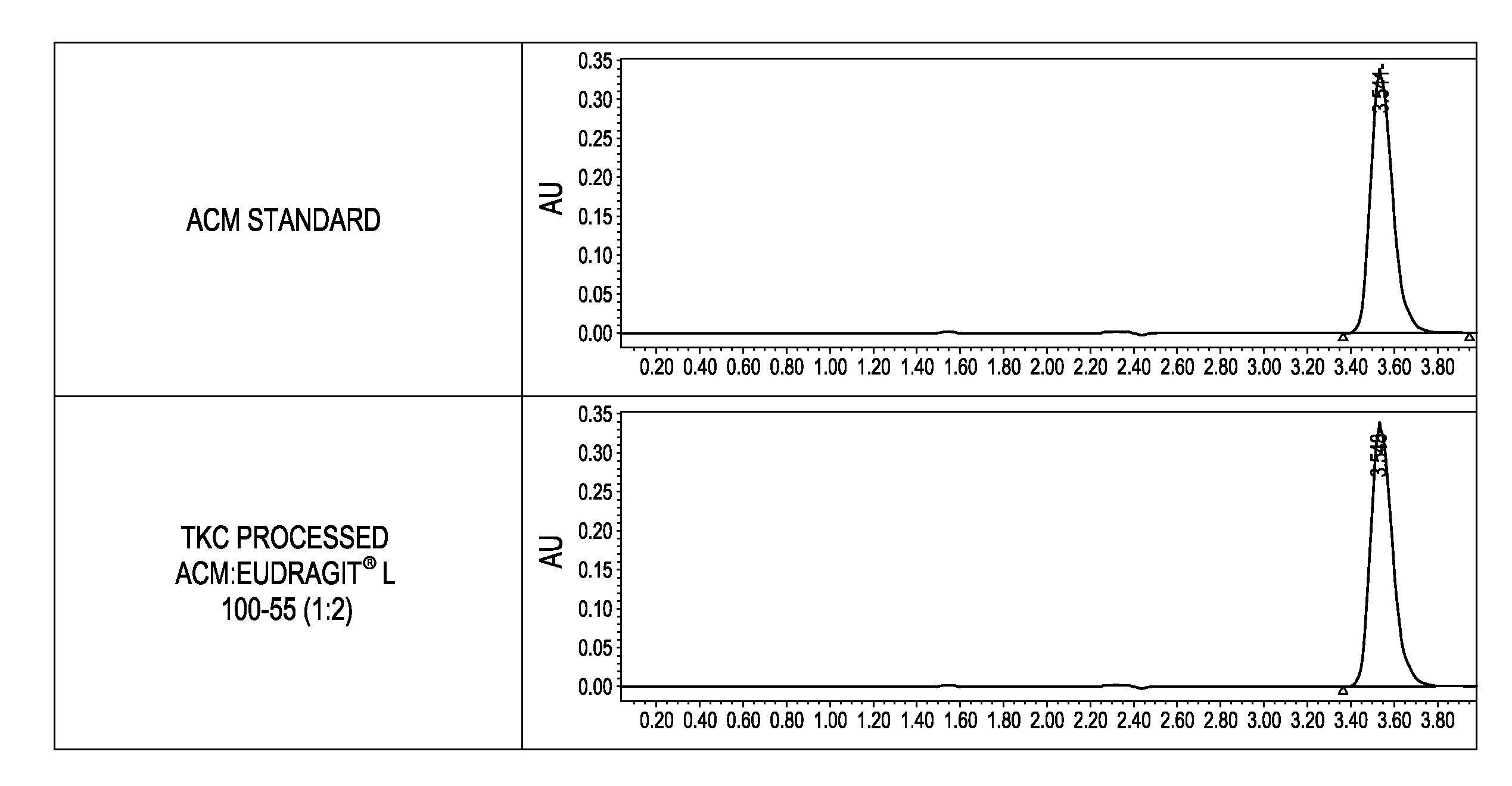

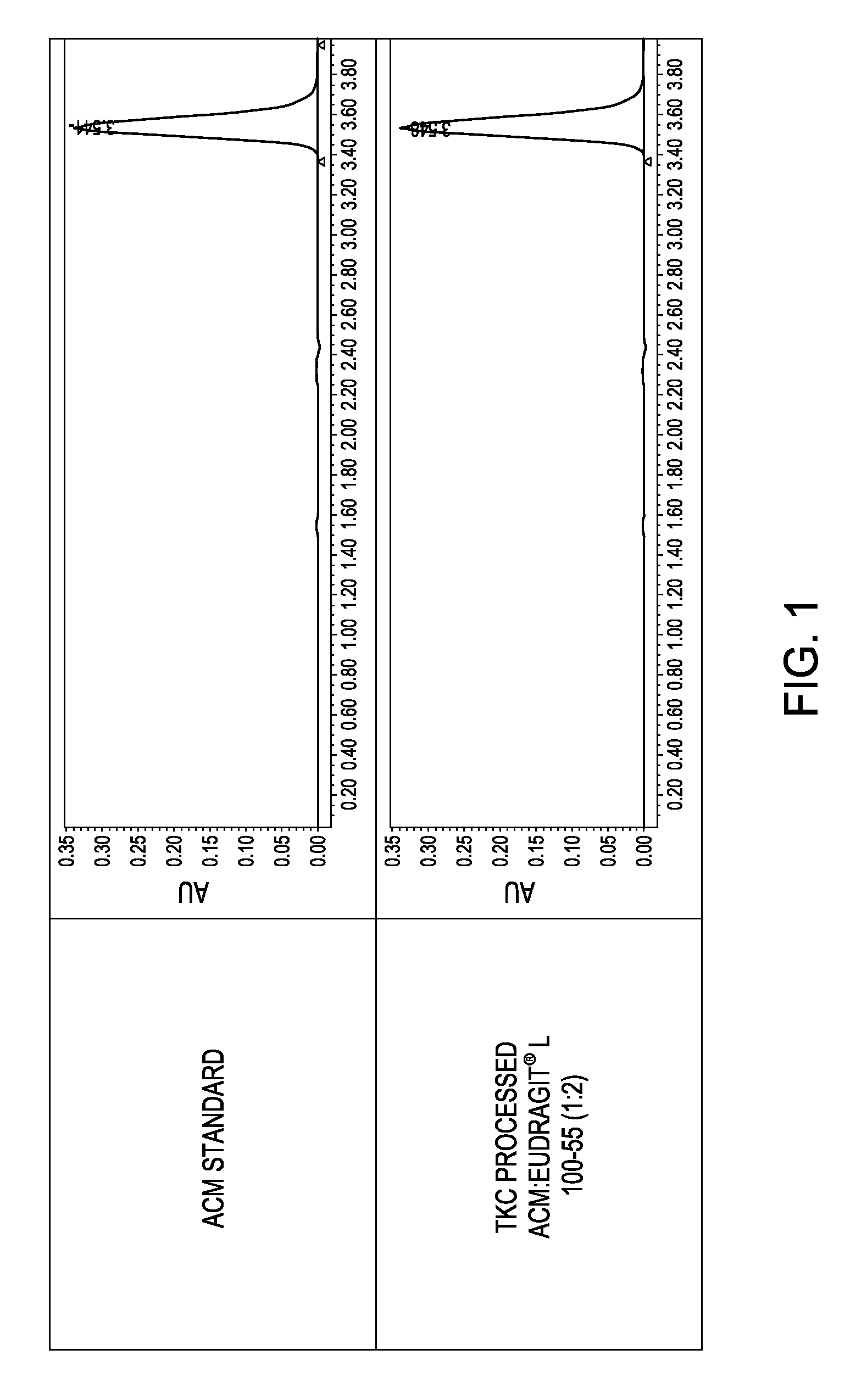

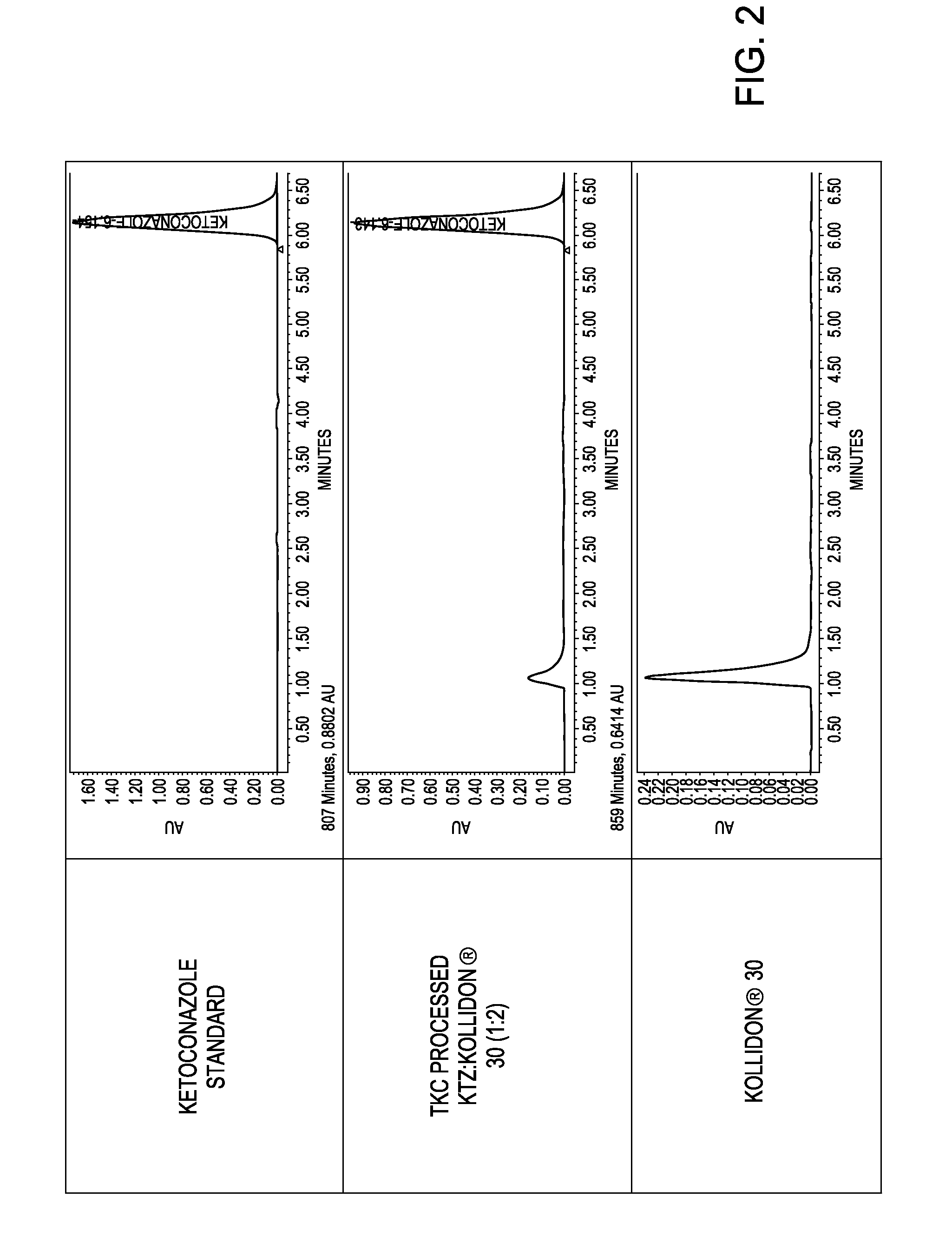

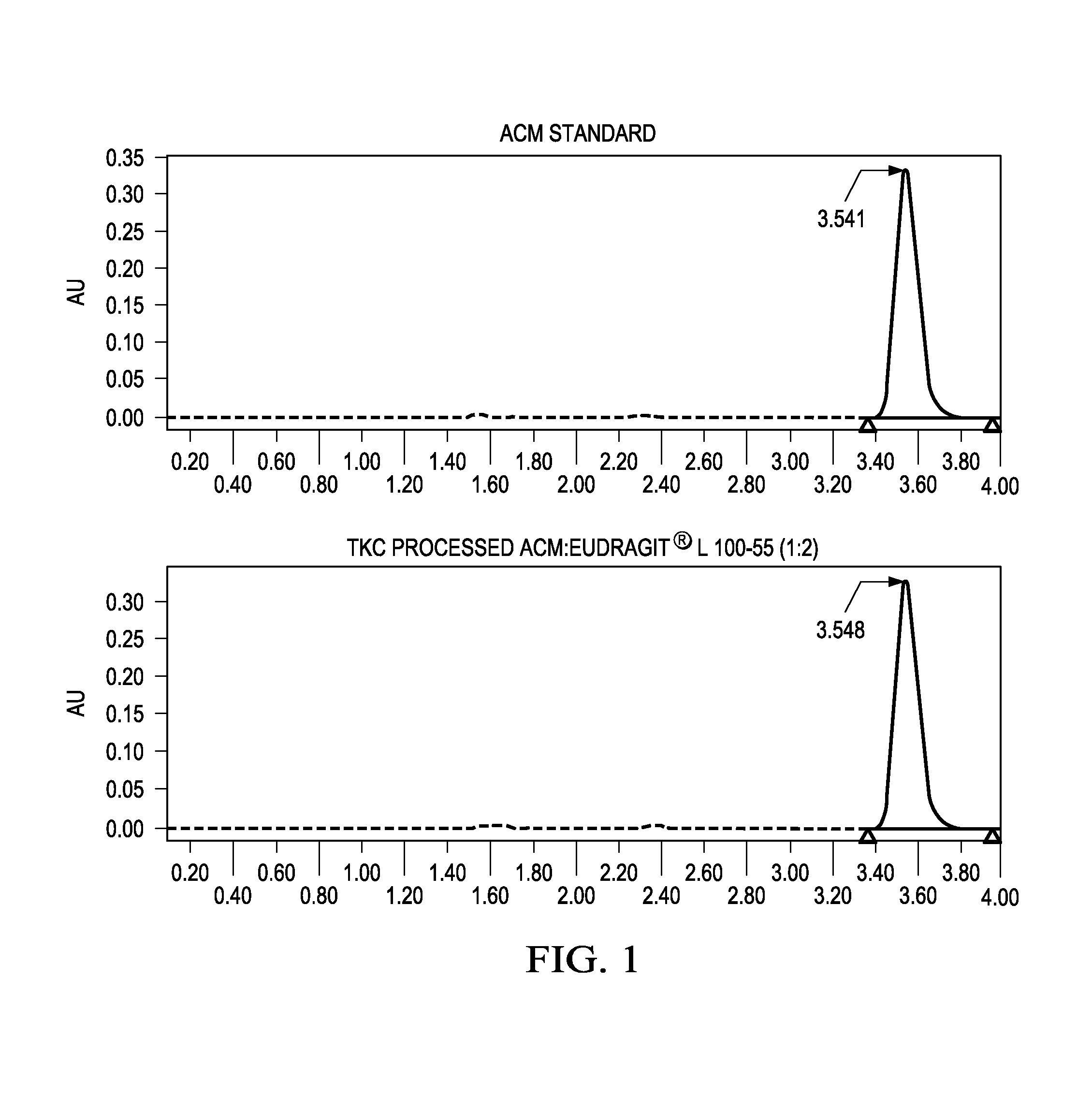

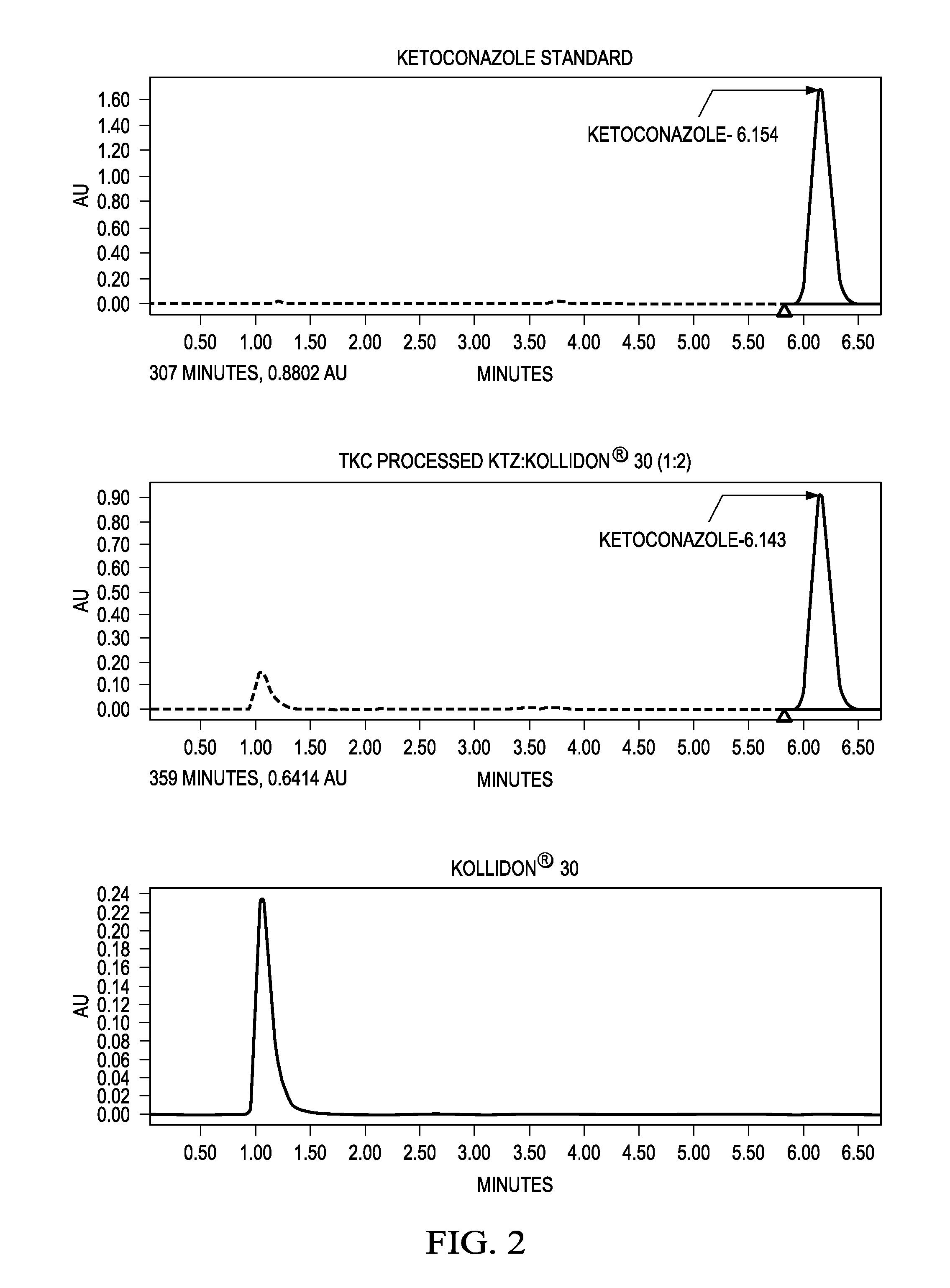

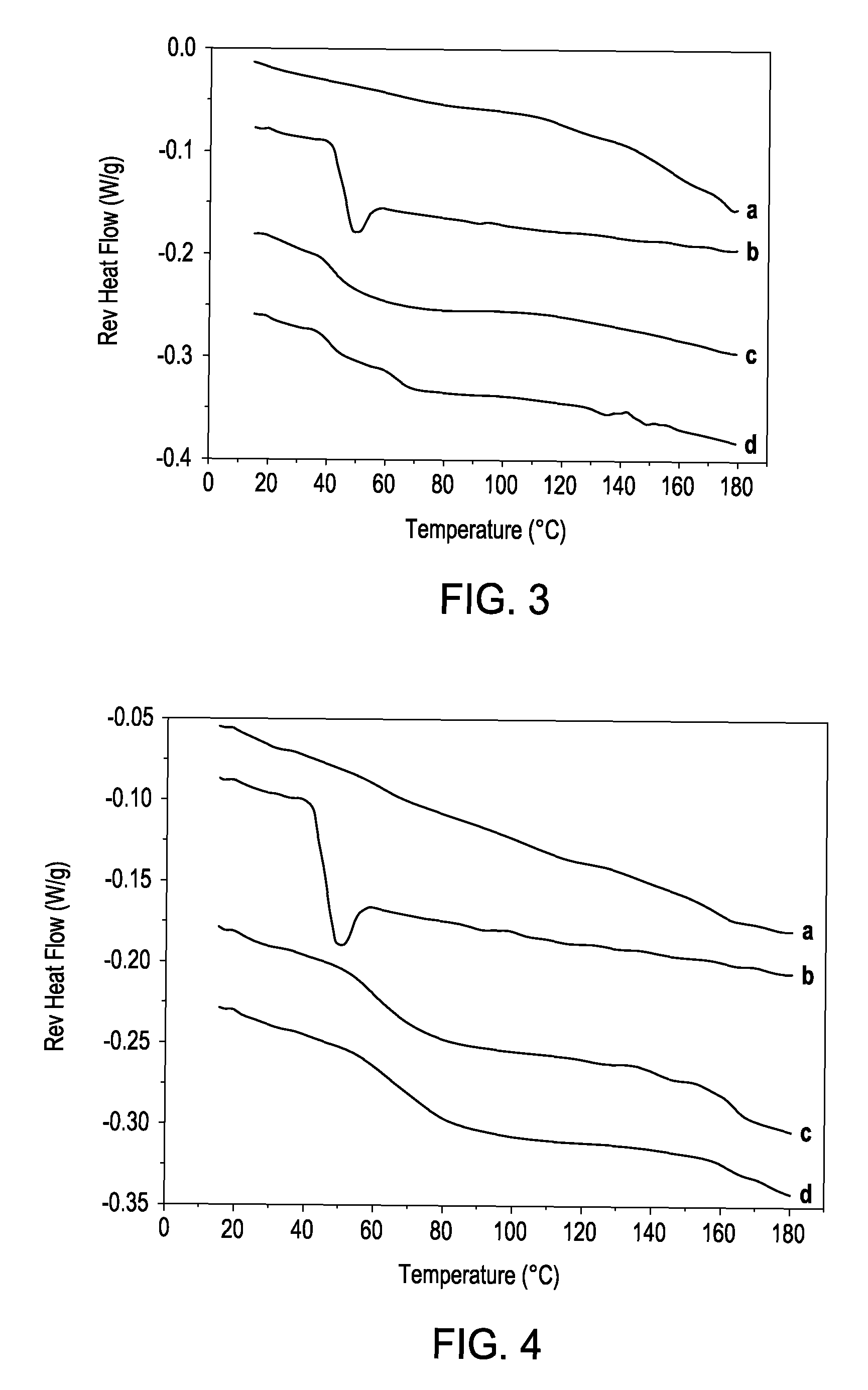

Thermo-Kinetic Mixing for Pharmaceutical Applications

ActiveUS20090053315A1Low process temperatureIncrease shear ratePowder deliveryOrganic active ingredientsCompression moldingAdditive ingredient

Compositions and methods for making a pharmaceutical dosage form include making a pharmaceutical composition that includes one or more active pharmaceutical ingredients (API) with one or more pharmaceutically acceptable excipients by thermokinetic compounding into a composite. Compositions and methods of preprocessing a composite comprising one or more APIs with one or more excipients include thermokinetic compounding, comprising thermokinetic processing the APIs with the excipients into a composite, wherein the composite can be further processed by conventional methods known in the art, such as hot melt extrusion, melt granulation, compression molding, tablet compression, capsule filling, film-coating, or injection molding.

Owner:AUSTINPX LLC +1

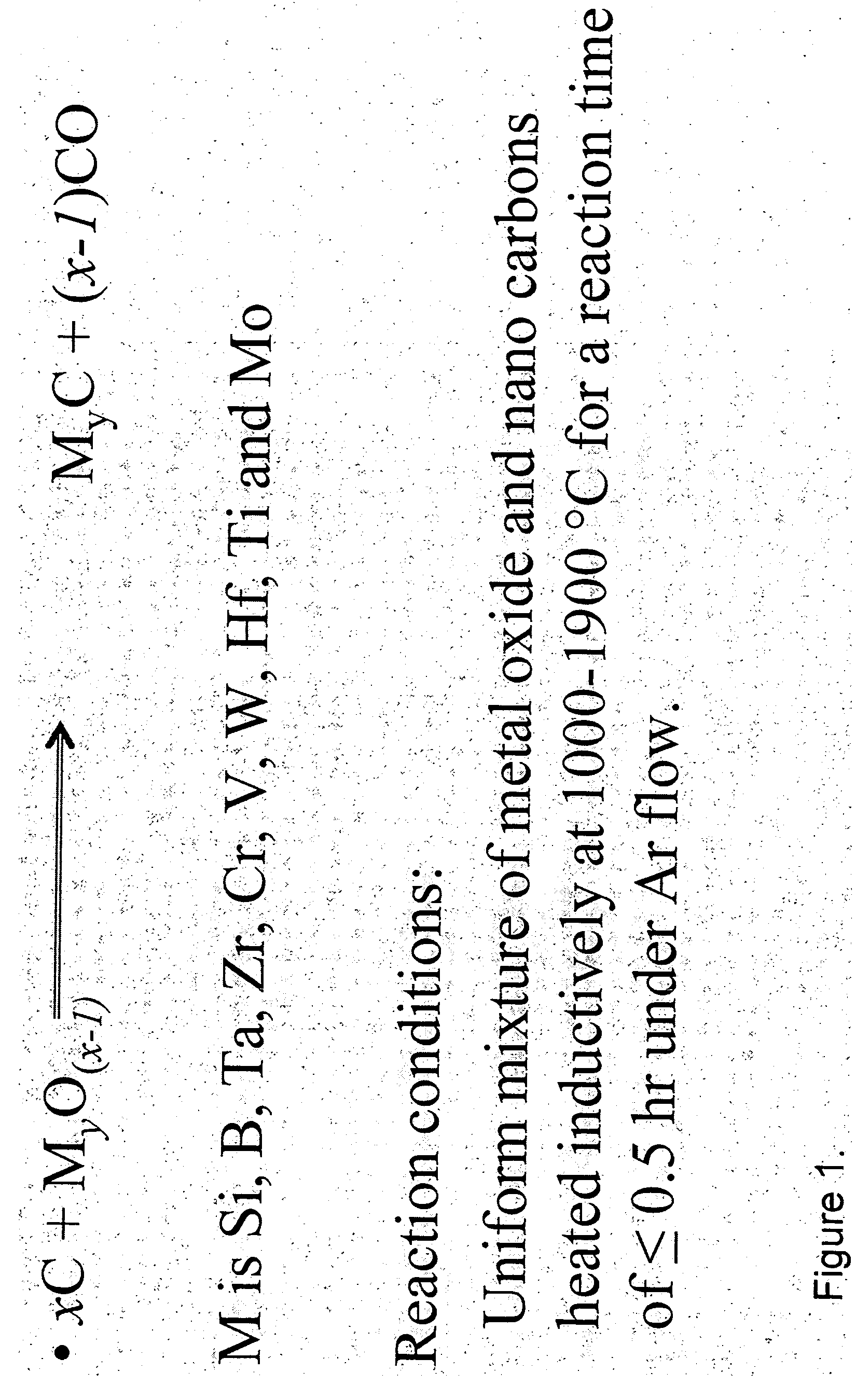

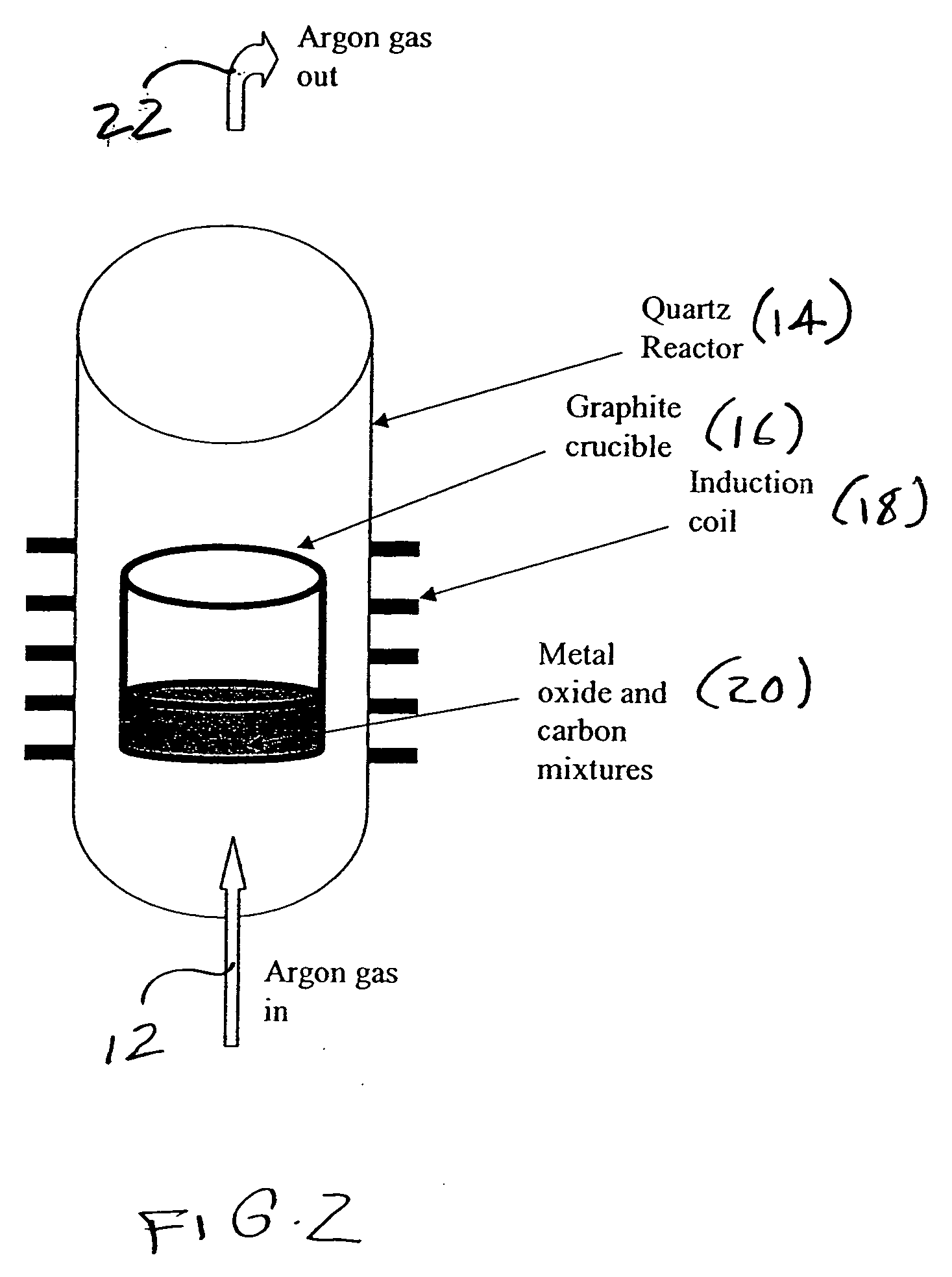

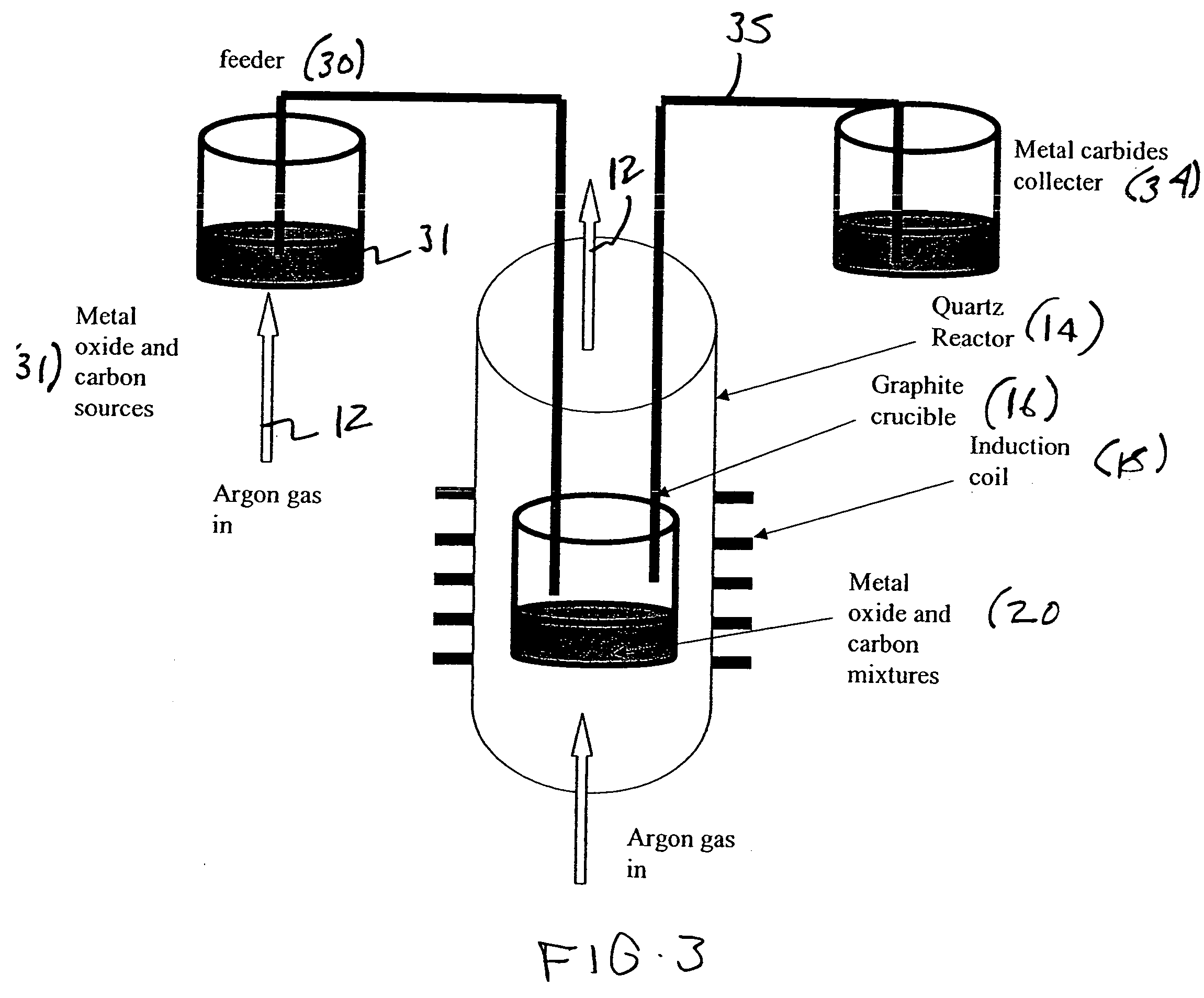

Metal carbides and process for producing same

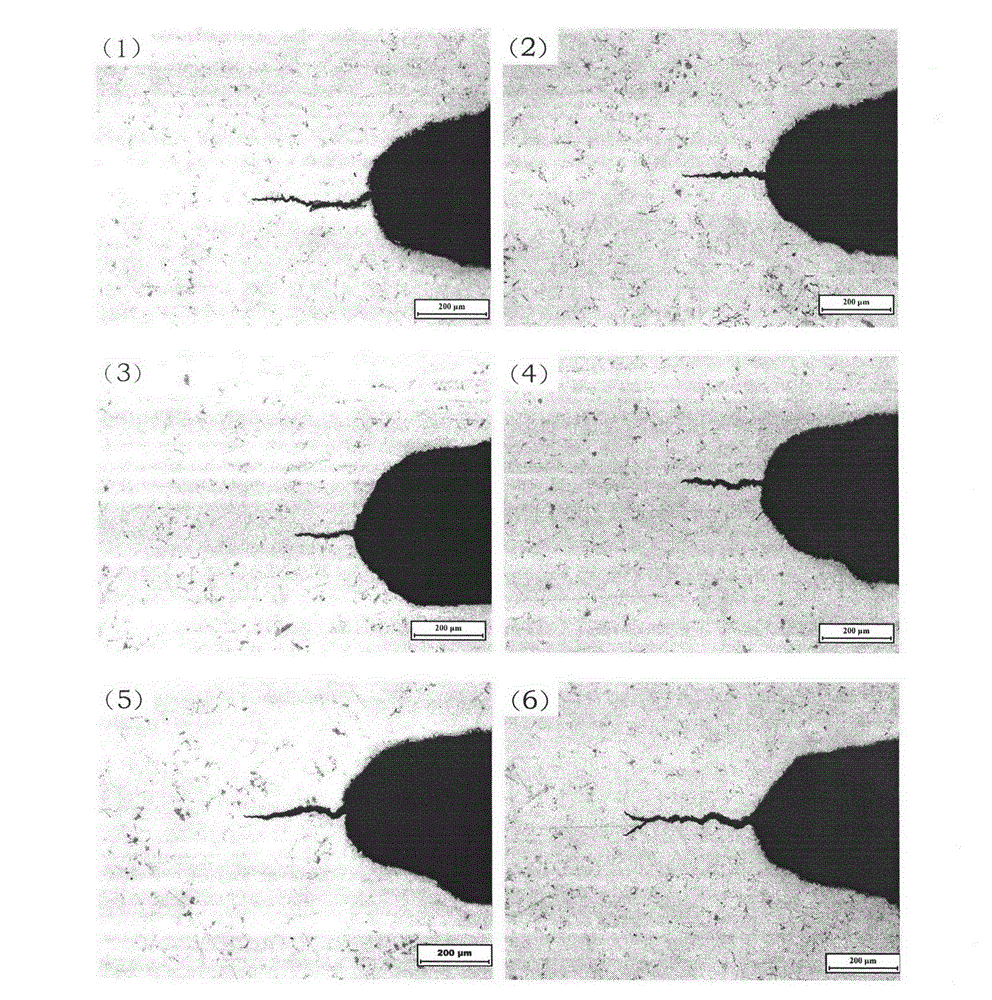

InactiveUS20060051281A1Minimize stress concentrationIncreased tortuosityMaterial nanotechnologyInorganic material artificial filamentsQuantum wellCarbide

A metal carbide composition and a process for synthesizing metal carbides, through a single step process, wherein oxides of different metals, including, but not limited to Si, Ti, W, Hf, Zr, V, Cr, Ta, B, Nb, Al, Mn, Ni, Fe, Co, and Mo were physically mixed with spherical or filamentateous nano structured carbon, and inductively heated to a certain temperature range (900-1900° C.) where the metal oxide reacts with carbon to form different metal carbides. The process retains the original morphology of the starting carbon precursor in the resultant metal carbides. This method also produces highly crystalline metal nano-carbides. The metal carbide products would have applications in high temperature thermoelectric devices, quantum wells, optoelectronic devices, semi-conductors, body armour, vehicle armour, catalysts, and as discontinuous reinforced agents in metal such as aluminum and other alloys.

Owner:COLUMBIAN CHEM CO

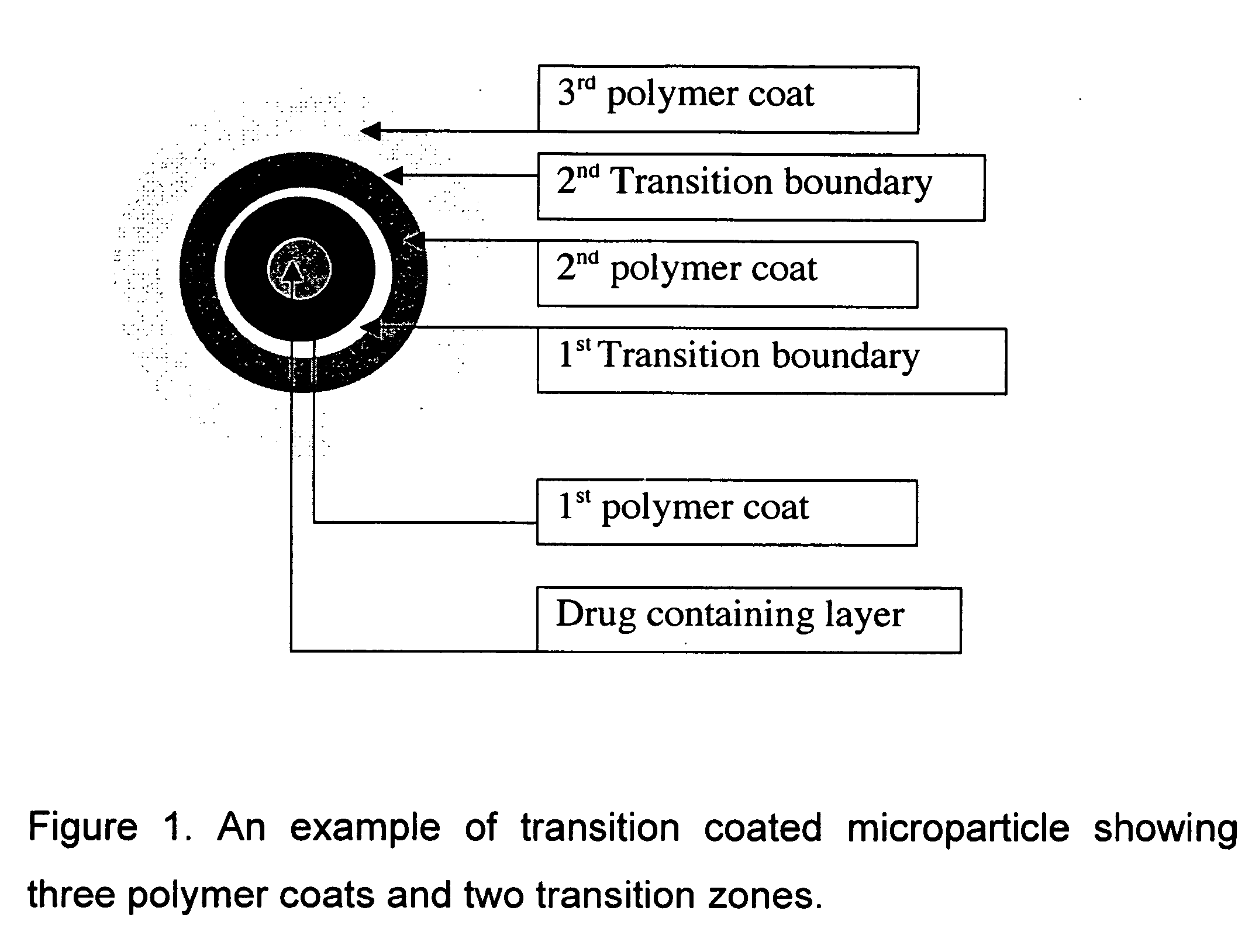

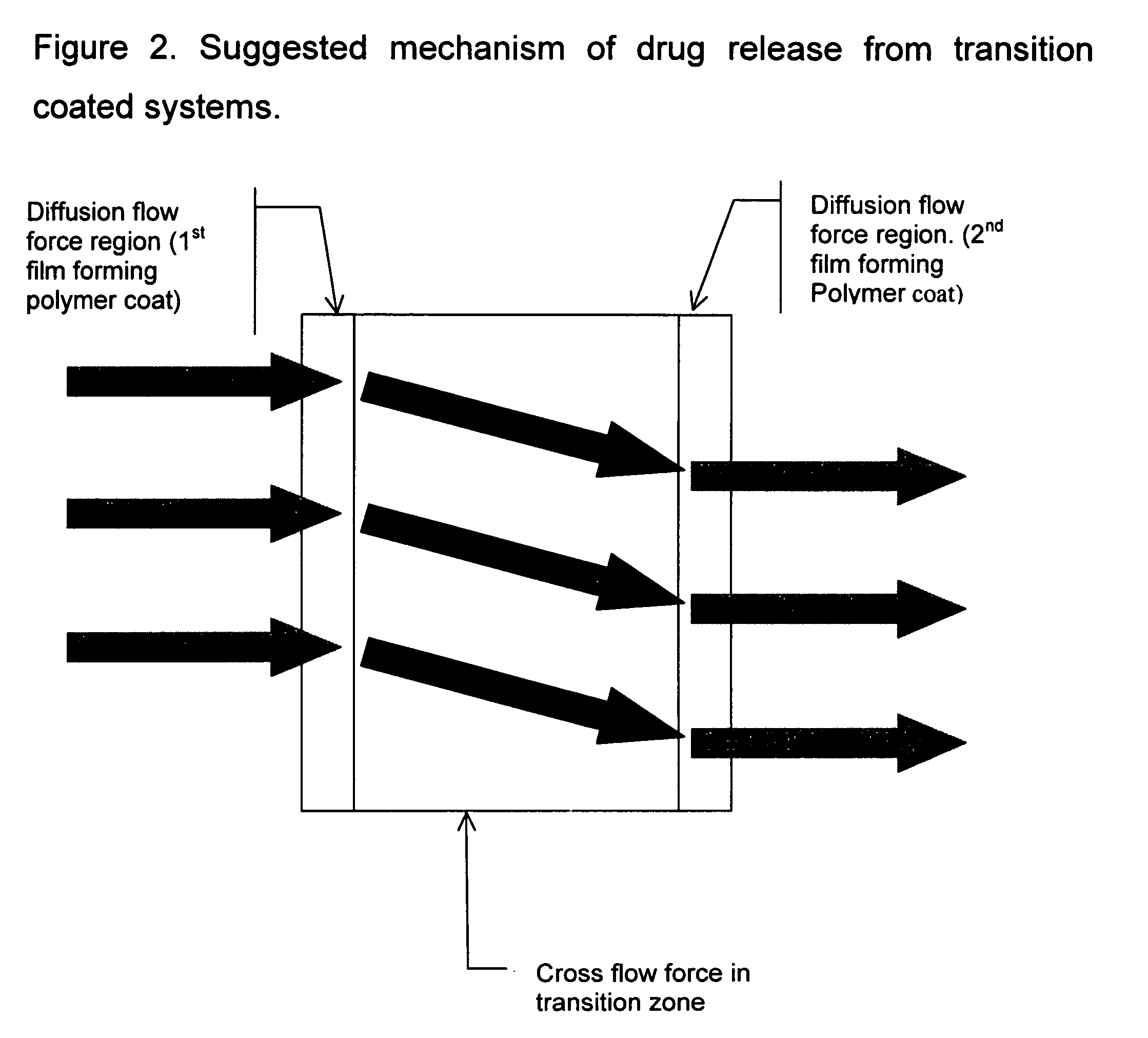

Controlled release composition using transition coating, and method of preparing same

ActiveUS20060039976A1Increased tortuosityConvenient and efficient controlPretreated surfacesCoatingsControlled releaseAdditive ingredient

The present invention is concerned with the use of transition coating and transition coating composition to control and or target the release of active pharmaceutical ingredients, and biological, chemical, neutraceutical, agricultural and nutritional materials and a method of preparing controlled release systems utilizing these components.

Owner:INTELLIPHARMACEUTICS

Thermo-kinetic mixing for pharmaceutical applications

ActiveUS8486423B2Low process temperatureIncrease shear rateBiocidePowder deliveryCompression moldingAdditive ingredient

Compositions and methods for making a pharmaceutical dosage form include making a pharmaceutical composition that includes one or more active pharmaceutical ingredients (API) with one or more pharmaceutically acceptable excipients by thermokinetic compounding into a composite. Compositions and methods of preprocessing a composite comprising one or more APIs with one or more excipients include thermokinetic compounding, comprising thermokinetic processing the APIs with the excipients into a composite, wherein the composite can be further processed by conventional methods known in the art, such as hot melt extrusion, melt granulation, compression molding, tablet compression, capsule filling, film-coating, or injection molding.

Owner:AUSTINPX LLC +1

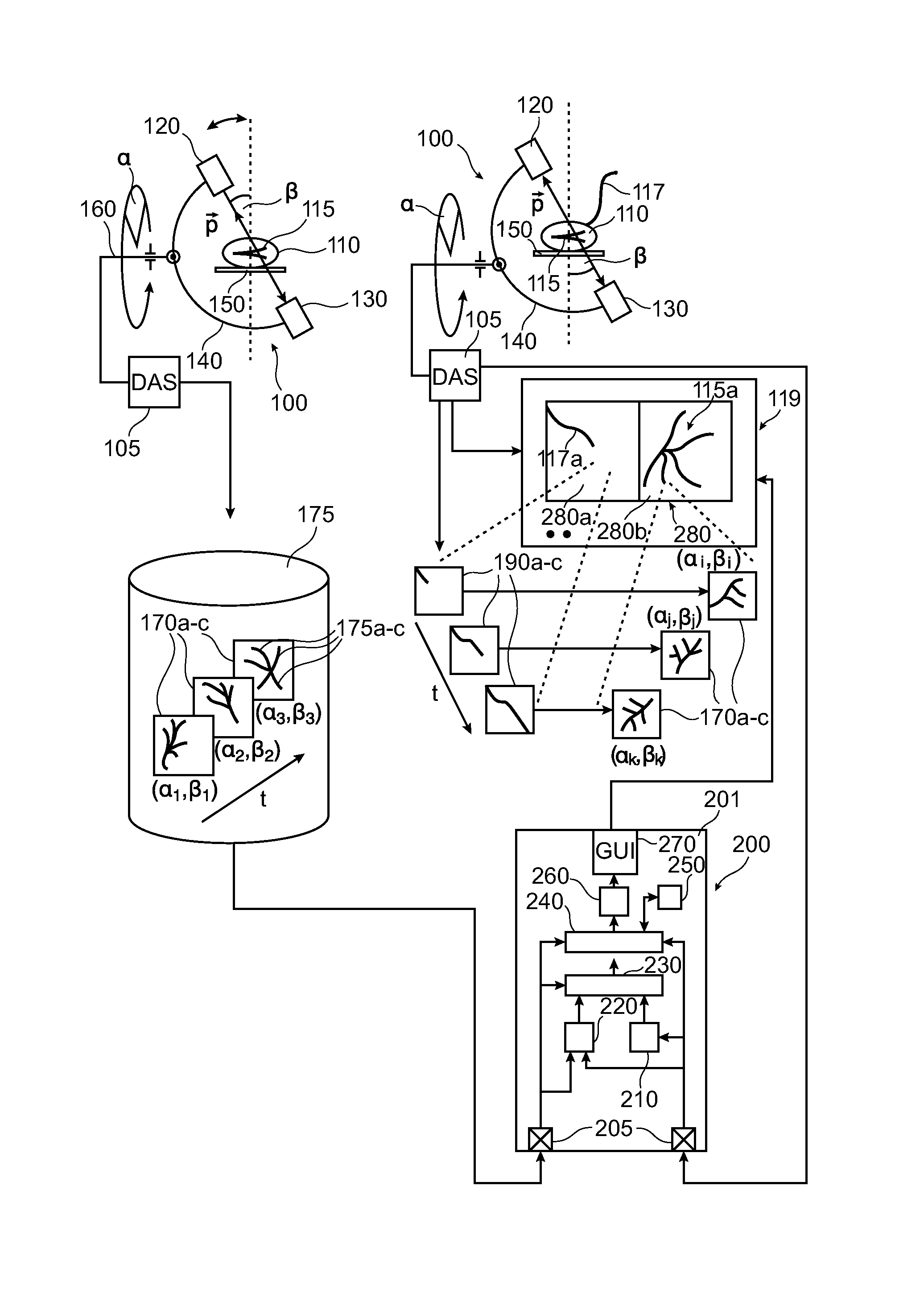

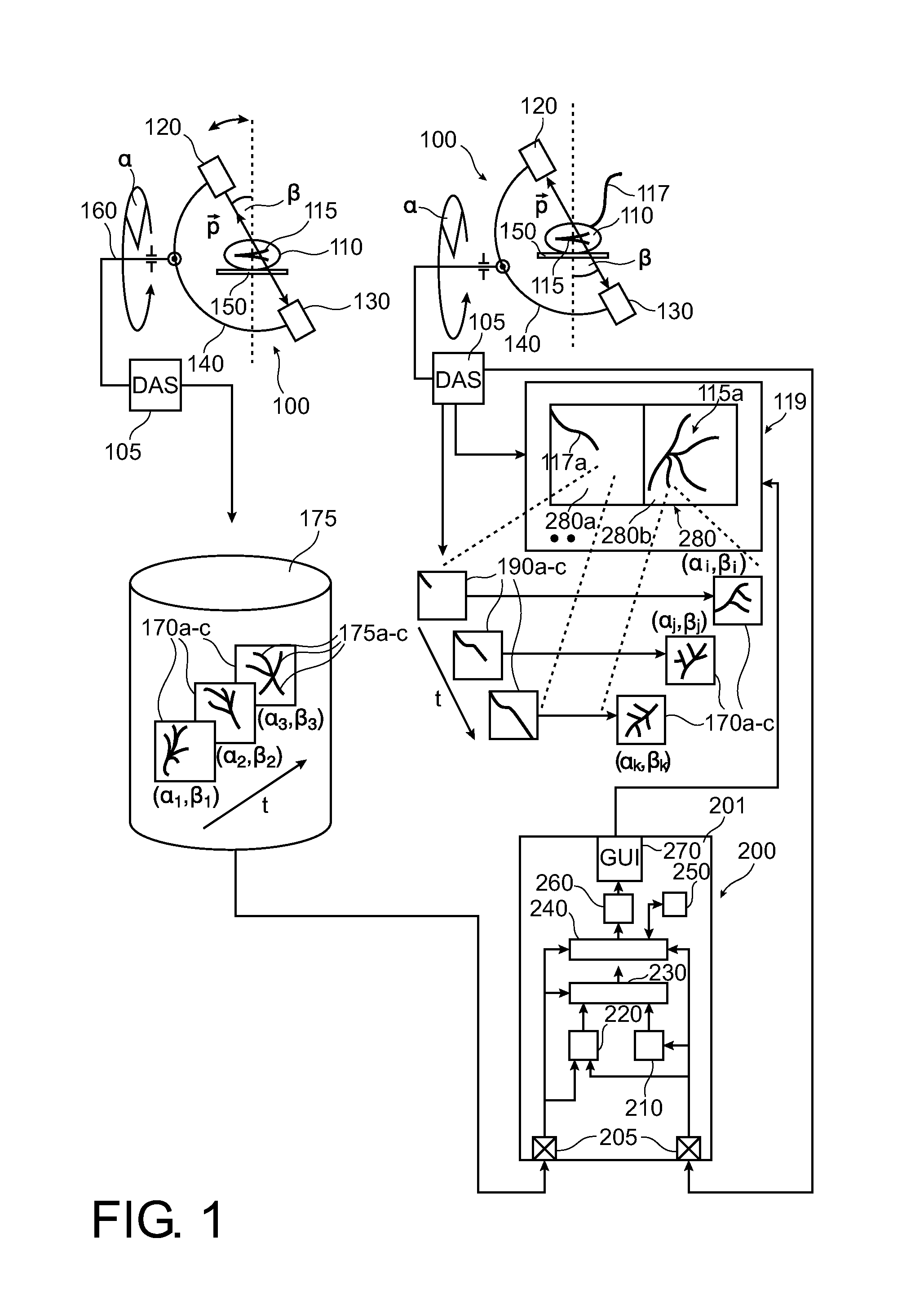

Real-time display of vasculature views for optimal device navigation

ActiveUS20140371578A1Easy to understandWell definedSurgical navigation systemsDiagnostic recording/measuringReal time displayMarine navigation

An apparatus configured to generate for display a plurality of vasculature (115) views (170a-c) alongside a live fluoroscopy image (190a). The views are selected in such a way that they allow visualizing the 3D structure of the vasculature segment in which the device (117) is currently navigating. The view is best relative to one or a weighted average of a plurality of goodness of view standards. As the device progresses and new fluoroscopy images (190b-c) are acquired, the views (170i-k) are updated accordingly.

Owner:KONINKLJIJKE PHILIPS NV

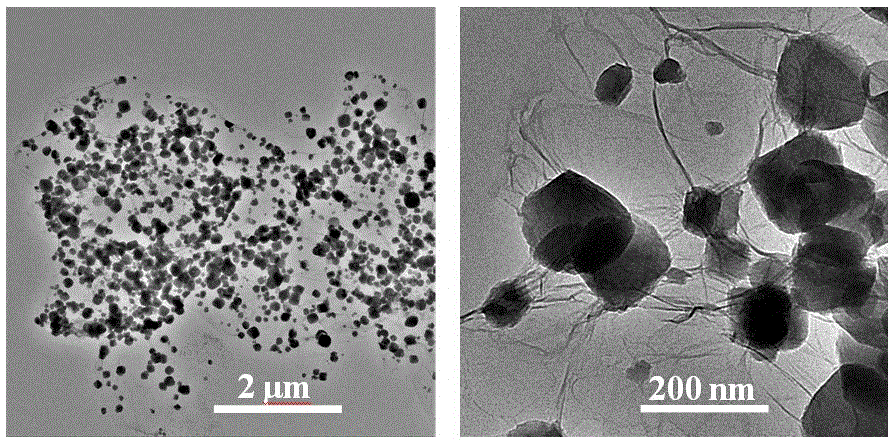

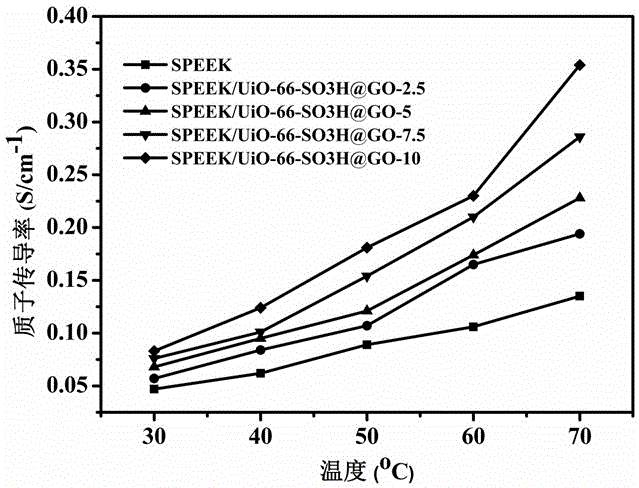

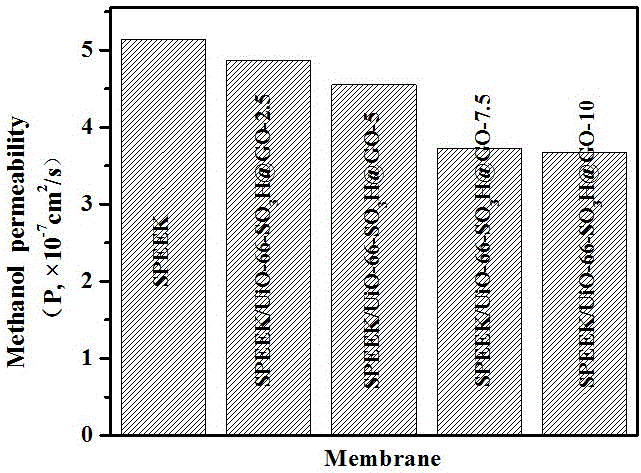

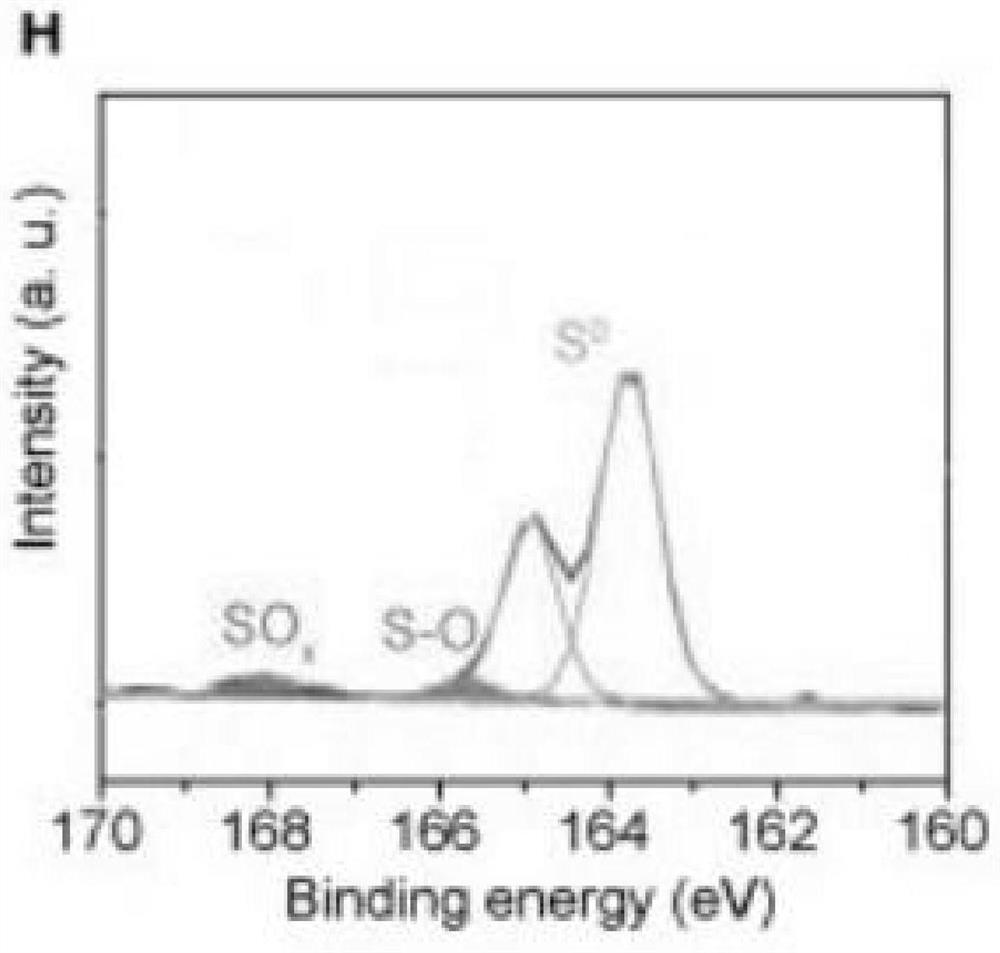

MOF-SO3H@GO modified polymer hybrid proton exchange membrane and preparation method thereof

InactiveCN106543461AImprove stabilityGood dispersionFinal product manufactureFuel cellsSulfonateProton

The invention belongs to the technical field of membranes, and in particular relates to a sulfonate functionalized metal-organic framework and graphene oxide compound modified polymer hybrid proton exchange membrane and a preparation method thereof. According to the invention, a compound(MOF-SO3H@GO) of the sulfonate functionalized metal-organic framework(MOF-SO3H) and graphene oxide(GO) is prepared first and then doped into a polymer to obtain the sulfonate functionalized metal-organic framework and graphene oxide compound particles hybridized polymer hybrid proton exchange membrane. The proton exchange membrane has excellent proton conductivity under a high dampness condition, and simultaneously improves the fuel obstructive capability of the hybrid proton exchange membrane. Therefore, the (MOF-SO3H@GO) modified polymer hybrid proton exchange membrane has more superior selectivity. The method has a simple operational process, mild preparation conditions, relatively low production cost, convenience for batch and large-scale production, good industrial production basis and wide application prospects.

Owner:FUDAN UNIV

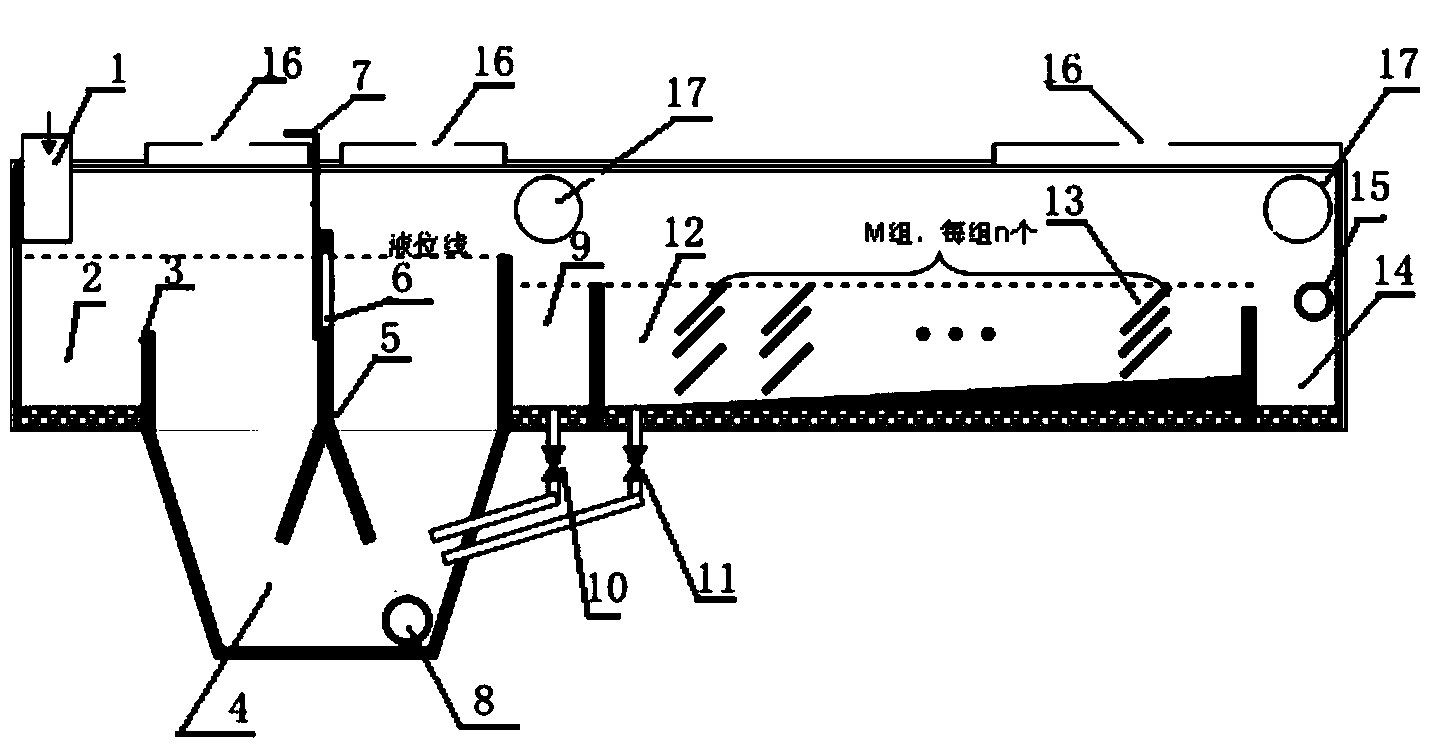

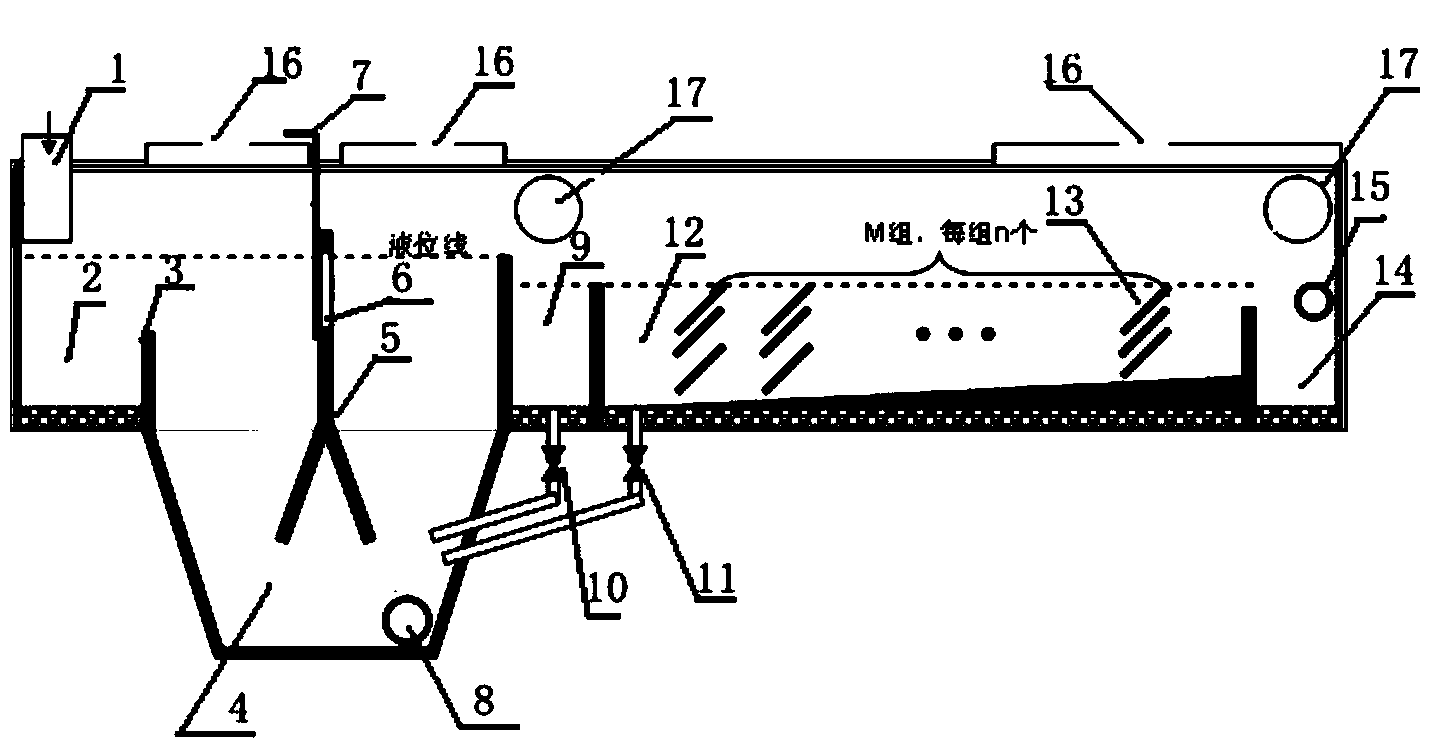

Channel type thickener with simple structure

InactiveCN104307219ASimple structureSave spaceSedimentation settling tanksElectricityPulp and paper industry

The invention relates to a channel type thickener with a simple structure. The channel type thickener is characterized by comprising a thickening pool with a channel type structure, a sedimentation tank and a clean water tank which are sequentially arranged in a linear way, wherein the thickening pool, the sedimentation tank and the clean water tank are arranged underground, and a top cover is arranged at the upper parts of the thickening pool, the sedimentation tank and the clean water tank; the depth of the thickening pool is larger than the depths of the sedimentation tank and the clean water tank; the bottom of the thickening pool is provided with a discharge hole; the bottom of the sedimentation tank is provided with a mud cleaning valve; one end of the mud cleaning valve is communicated with the front end of the bottom of the sedimentation tank, and the other end of the mud cleaning valve is communicated with the lower part of the thickening pool and is led to the discharge hole; the liquid at the upper part of the tail end of the sedimentation tank is led to a drainage hole; the top cover is provided with a feeding hole at the position close to the initial end of the thickening pool. According to the channel type thickener, the thickening pool, the sedimentation tank and the clean water tank are sequentially arranged in a linear way; the channel type thickener is arranged underground, has a channel type structure, and is capable of carrying out concentration treatment on tailings and discharging and recycling the separated clear water in situ; the channel type thickener is simple in structure and space-saving, and the aims of saving electricity and water can be realized.

Owner:曾承旺

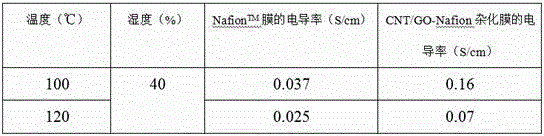

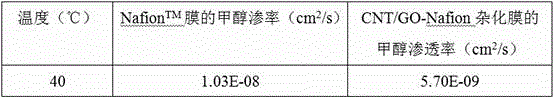

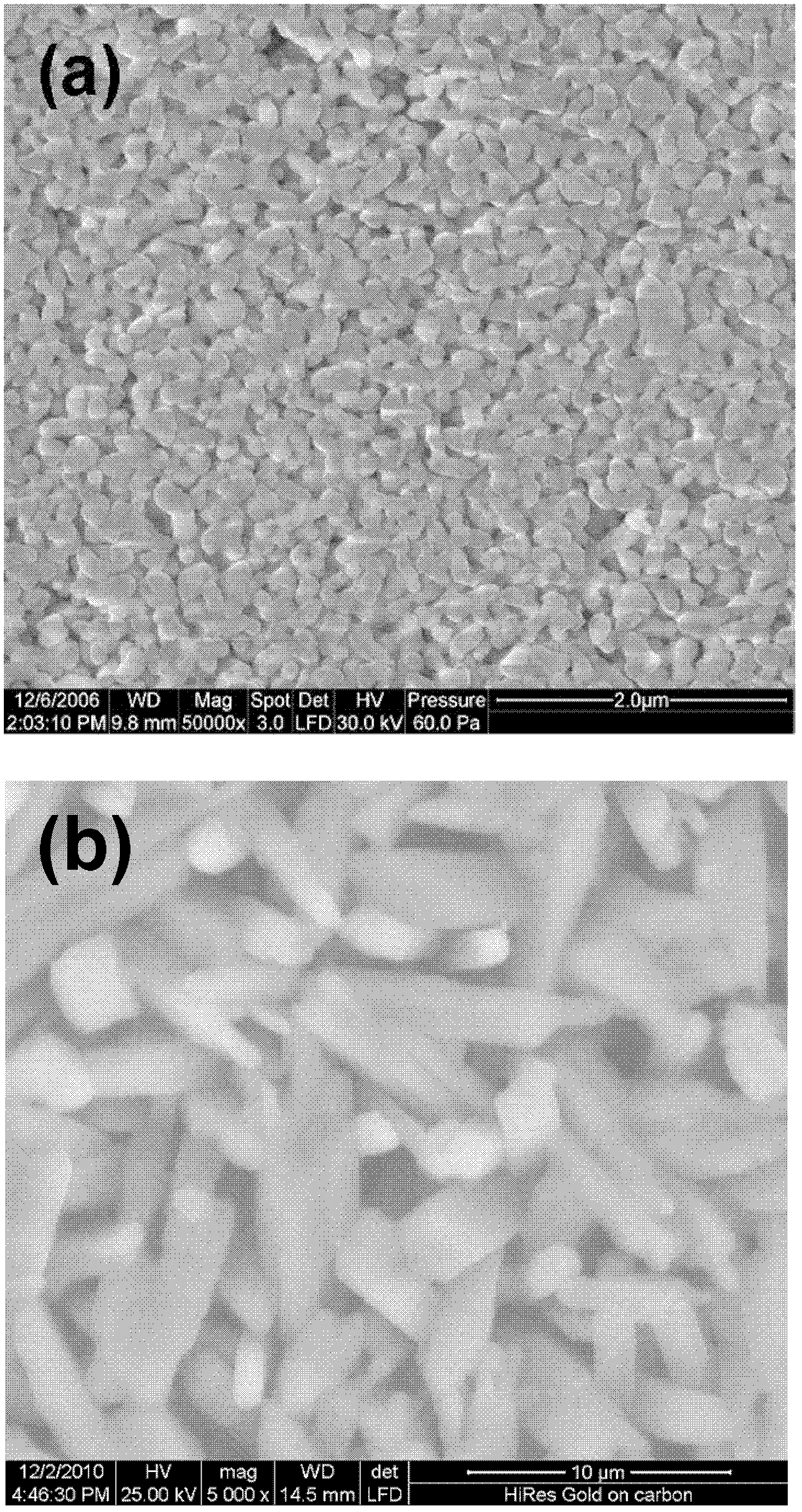

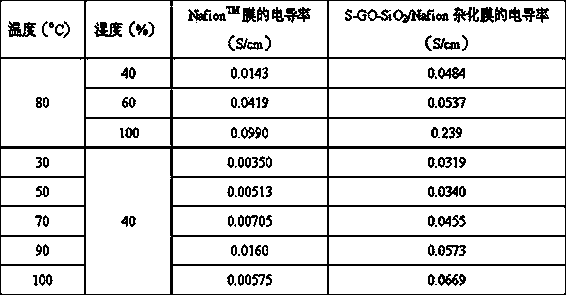

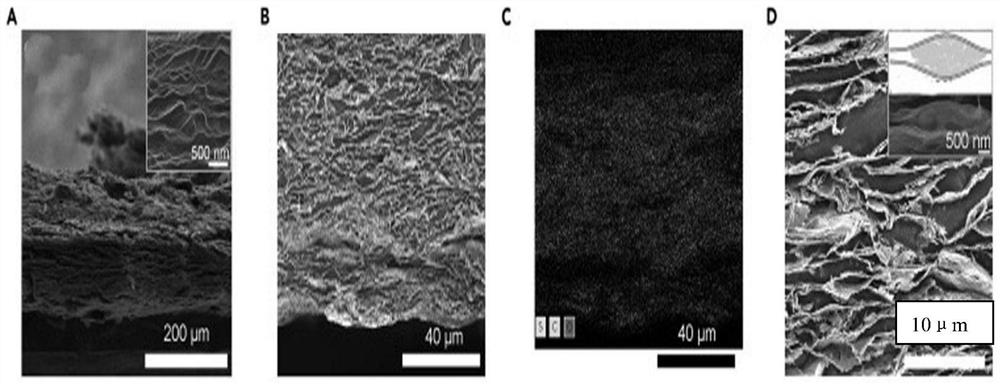

Carbon nanotube/graphene oxide nanoribbon-polymer hybrid proton exchange membrane and preparation method thereof

The invention belongs to the technical field of membranes and particularly relates to a carbon nanotube / graphene oxide nanoribbon-polymer hybrid proton exchange membrane and a preparation method thereof. The proton exchange membrane is prepared by: preparing multi-wall carbon nanotubes into carbon nanotube / graphene oxide nanoribbon composite; blending the carbon nanotube / graphene oxide nanoribbon composite with a polymer solution. The proton exchange membrane prepared herein is introduced with one-dimensional and two-dimensional composite (carbon nanotube / graphene oxide nanoribbons) and thereby has good dispersity and has proton conductivity greatly improved as compared to that of pure-polymer proton exchange membranes and multiply improved particularly in high-temperature low-humidity environment; meanwhile, the invention is low in production cost, easy for batch large-scale production and has good industrial production basis and promising application prospect.

Owner:FUDAN UNIV

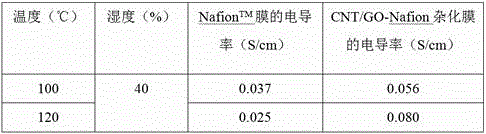

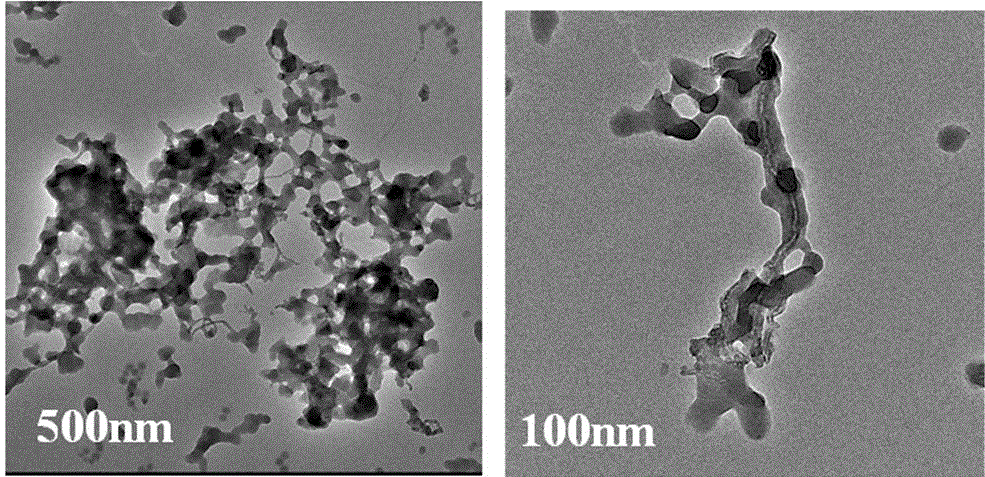

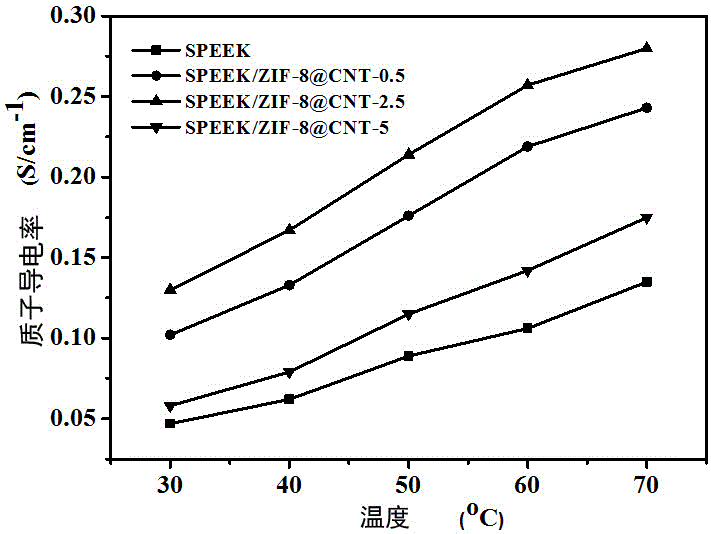

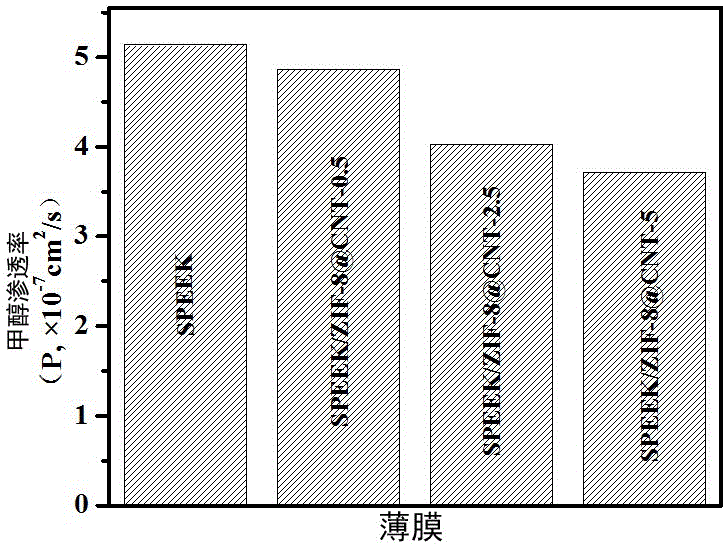

ZIF@CNT modified polymer hybrid proton exchange membrane and preparation method thereof

ActiveCN106750440AEasy to operateMild preparation conditionsFinal product manufactureFuel cellsPolymer scienceProton

The invention belongs to the technical field of membranes, and particularly discloses a zeolite imidazate skeleton coated carbon nanotube composite material modified polymer hybrid proton exchange membrane and a preparation method thereof. Composite particles (ZIF@CNT) of a zeolite imidazate skeleton (ZIF) fully-coated carbon nano tube (CNT) are firstly prepared and are uniformly dispersed in a polymer base body, the proton conduction rate of the prepared ZIF@CNT modified polymer hybrid proton exchange membrane, compared with a relatively pure polymer proton exchange membrane, is obviously improved, and is also higher than that of a CNT modified polymer hybrid proton exchange membrane. Besides, through strong mutual effect between imidazole and polymer in ZIF@CNT, the fuel obstructing capacity of the hybrid proton exchange membrane is further improved. Therefore, the ZIF@CNT modified polymer hybrid proton exchange membrane has higher selectivity. The method disclosed by the invention is simple in operation process, mild in operation condition, relatively low in production cost and easy for batch and large-scale production, and has a wide application prospect.

Owner:FUDAN UNIV

Carrier type titanium dioxide ultrafiltration membrane and preparation method and application thereof

ActiveCN102489172AImprove throughputGuaranteed interception effectSemi-permeable membranesCatalyst carriersUltrafiltrationTortuosity

The invention relates to a preparation method and applications in supported catalysts of a carrier type titanium dioxide ultrafiltration membrane. According to the preparation method, a ceramic membrane is used as the support body, the self-growing phenomenon of titanium dioxide particles at high temperature is utilized, a titanium dioxide ultrafiltration membrane layer with high flux and tortuosity is formed on the surface of the ceramic membrane support body through the interweaving of titanium dioxide nanorods and calcining, thus the tortuosity and loose degree of the membrane layer can be effectively increased; an enough space is provided for supporting catalysts on the basis of ensuring the retention capacity of the original ceramic membrane; and the overall functionalization of the ceramic membrane is realized, namely the ceramic membrane supporting of multiple catalysts is realized and the product can be used in the fields such as photocatalysis, catalytic ozonation, catalytic hydrogen peroxide oxidation and catalytic wet oxidation.

Owner:DALIAN UNIV OF TECH

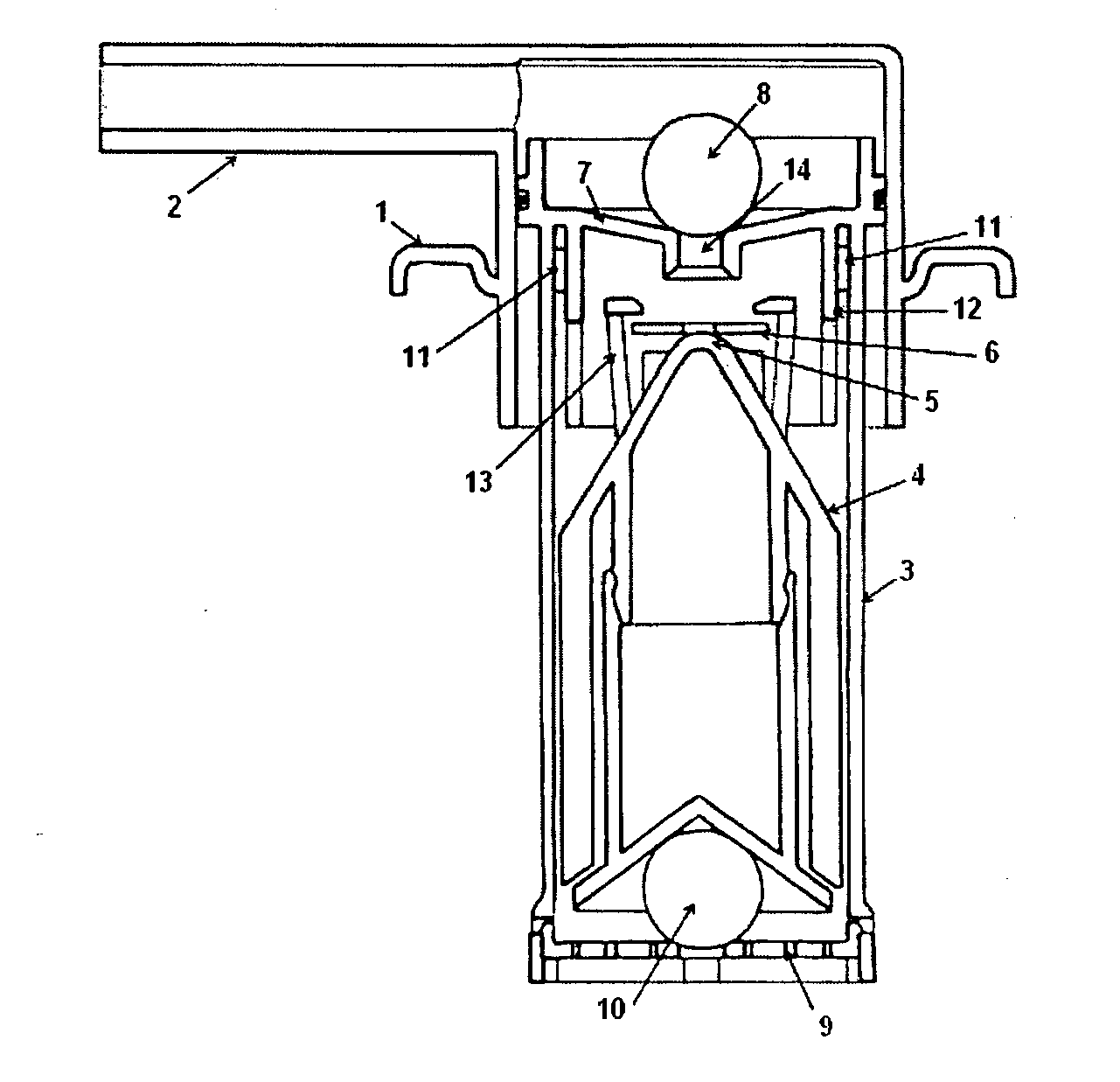

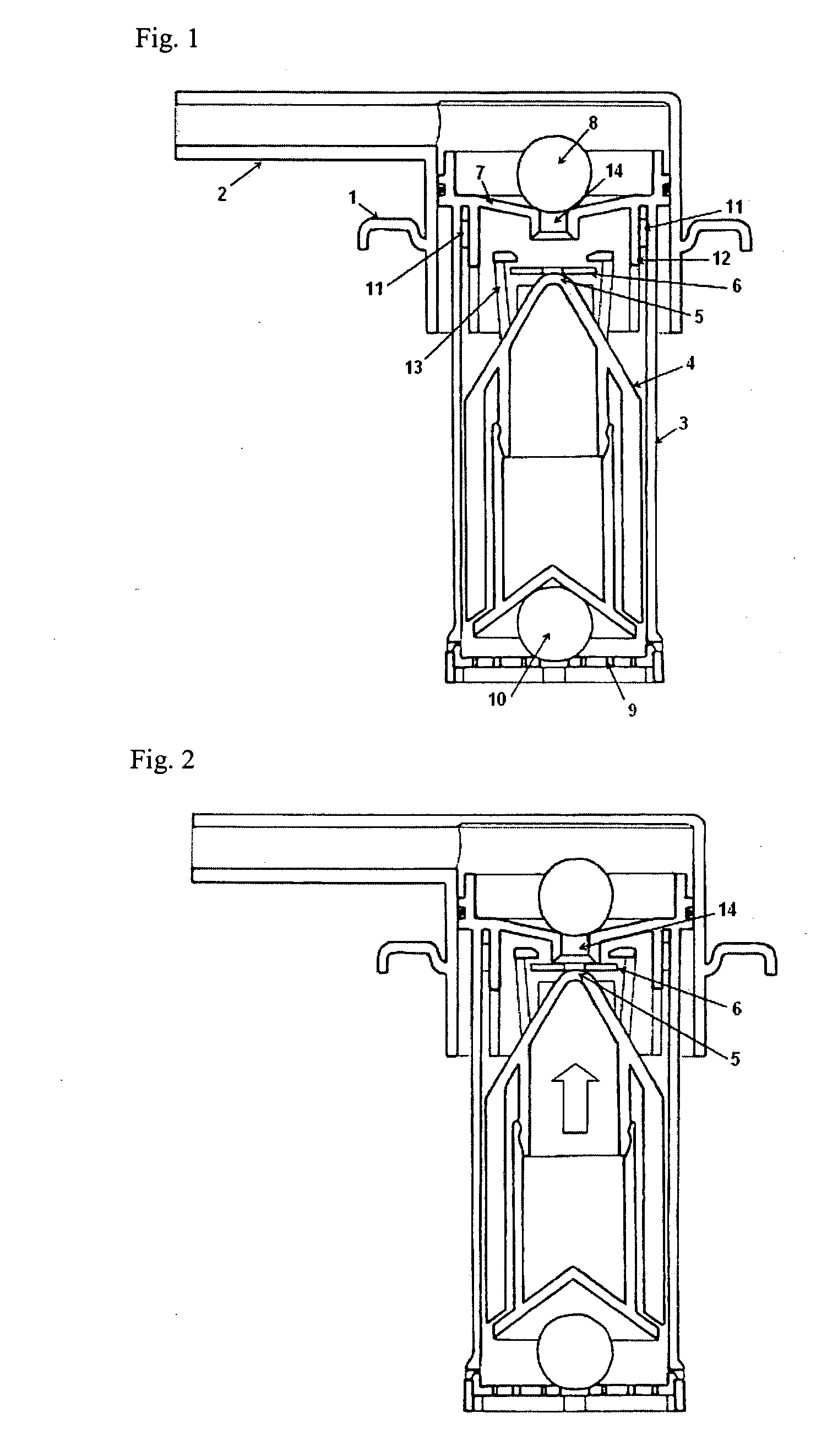

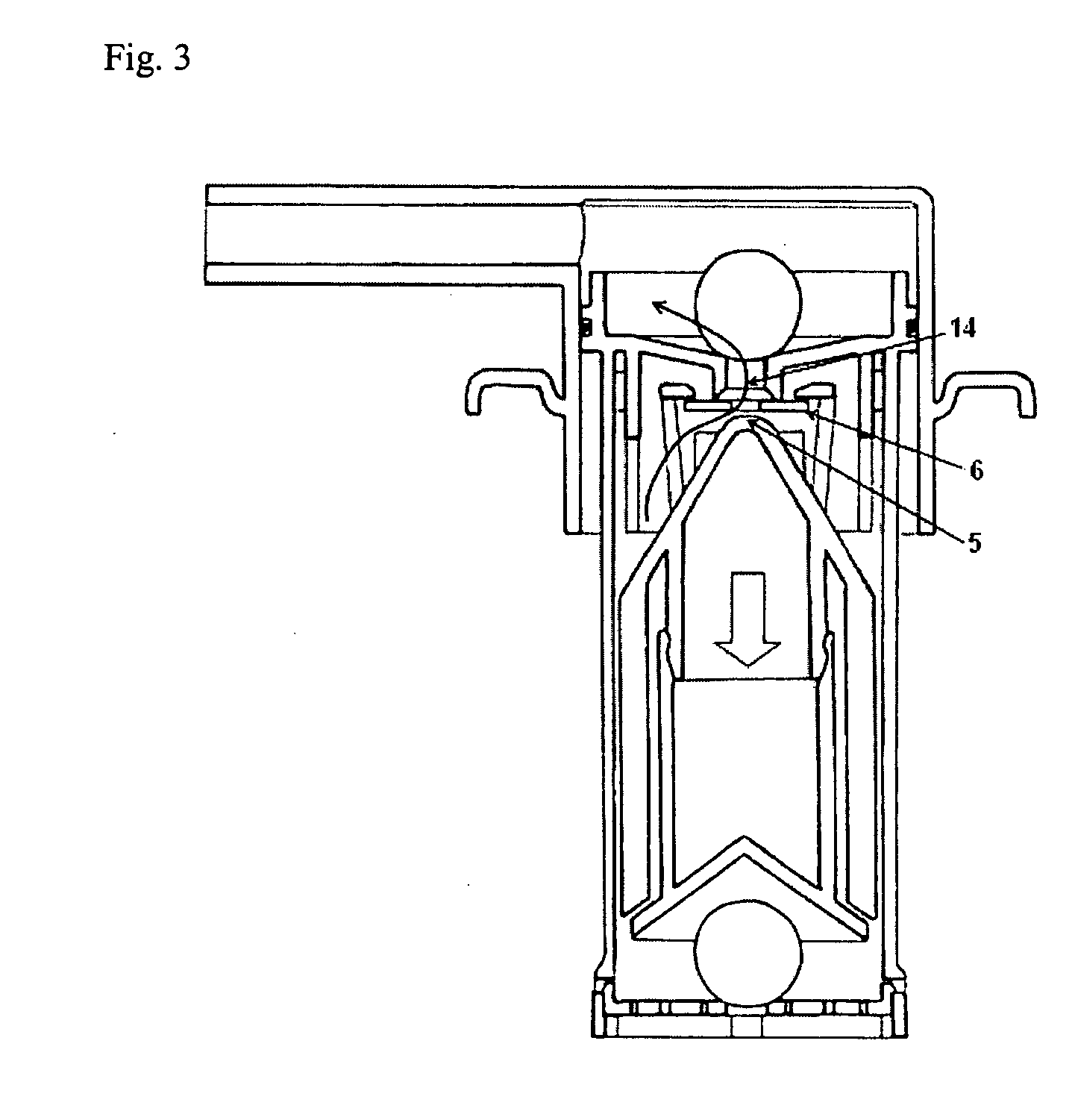

Valve for the venting circuit of a liquid tank

InactiveUS20060266415A1Increased tortuosityReduce riskEqualizing valvesSafety valvesEngineeringLiquid tank

Valve for the venting circuit of a liquid tank, said valve containing: a) a chamber (3) which opens into the tank and is connected via an aperture to the venting circuit; b) a float containing a head provided with a needle and able to slide vertically inside the chamber; and c) a closure member for closing off the venting aperture and itself having an aperture that can be closed off by the needle of the float, the closure member having a flexible seal which is capable of moving substantially vertically relative to the head of the float, said head being provided with a device for limiting the movement of the seal

Owner:INERGY AUTOMOTIVE SYST RES (SA)

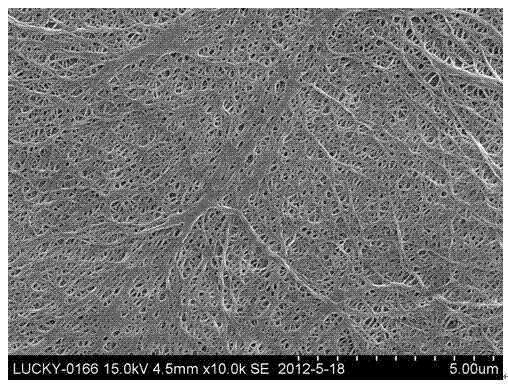

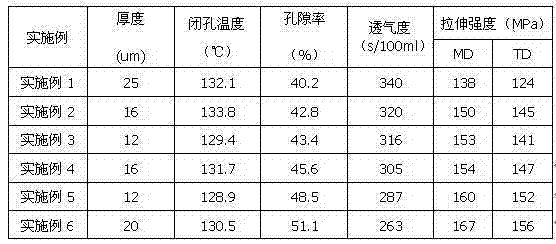

Method for preparation of polyolefin microporous membrane by wet process

ActiveCN102850573ADelay thermo-oxidative degradationPrevent thermal breakageCell component detailsFlat articlesPolyolefinOxidative degradation

The invention relates to a method for preparation of a polyolefin microporous membrane by a wet process. According to the method, polyolefin resin, an antioxidant and liquid paraffin are adopted as raw materials for preparation of the microporous membrane through a thermally induced phase separation method. Employment of the preparation method provided in the invention can effectively prevent thermal oxidative degradation and carbonization phenomena in a high temperature processing process of polyolefin resin. The antioxidant and the polyolefin resin are mixed and dispersed more uniformly, and the antioxidant can be removed during liquid paraffin extraction, so that the pure and high performance polyolefin microporous membrane can be obtained.

Owner:乐凯胶片股份有限公司

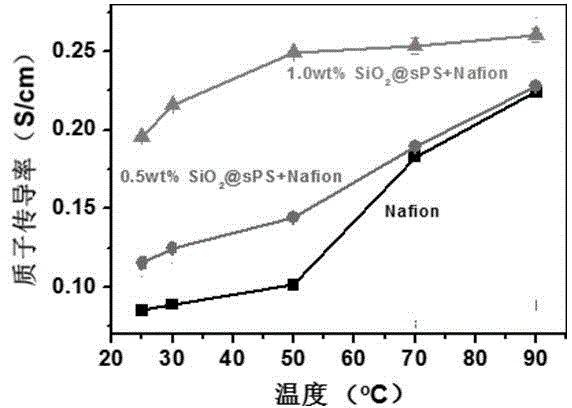

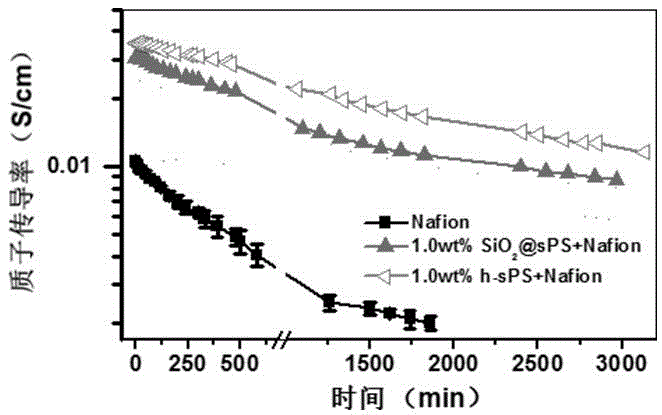

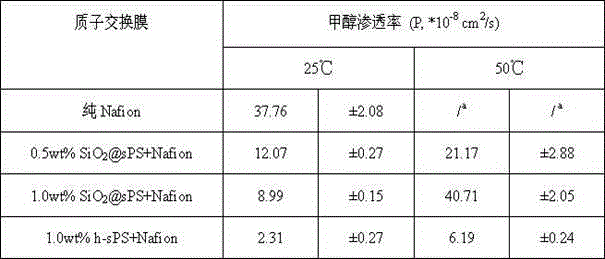

SiO2@sPS-modified polymer hybrid proton exchange membrane and preparation method thereof

InactiveCN104945644AImprove water retentionImprove proton conductivityFinal product manufactureFuel cell detailsPhysical chemistryPolystyrene

The invention belongs to the technical field of membranes, and particularly relates to a SiO2@sPS-modified polymer hybrid proton exchange membrane and a preparation method thereof. The proton conductivity of the SiO2@sPS-modified polymer hybrid proton exchange membrane prepared by uniformly dispersing SiO2@sPS in a polymer matrix is greatly higher than that of the pore polymer proton exchange membrane. Besides, the silicon sphere kernel is etched to obtain the sulfonated hollow polystyrene (h-sPS) / polymer hybrid proton exchange membrane to further enhance the water retaining capacity of the hybrid proton exchange membrane, so that the proton conductivity of the h-sPS / polymer hybrid proton exchange membrane is further enhanced; and meanwhile, the fuel permeability of the hybrid proton exchange membrane is further inhibited. Therefore, the h-sPS / polymer hybrid proton exchange membrane has higher selectivity. The method has the advantages of simple operational process, mild preparation conditions and lower production cost, can easily implement mass large-scale production, and has wide application prospects.

Owner:FUDAN UNIV

Soundproofing assembly, use for soundproofing enclosed spaces, and method for making same

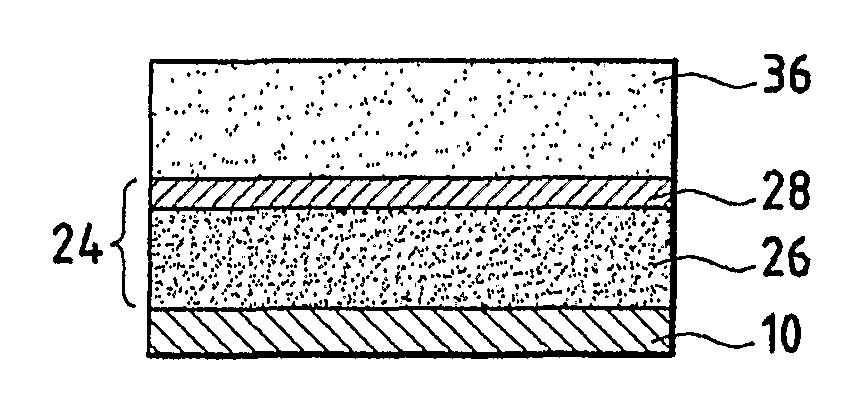

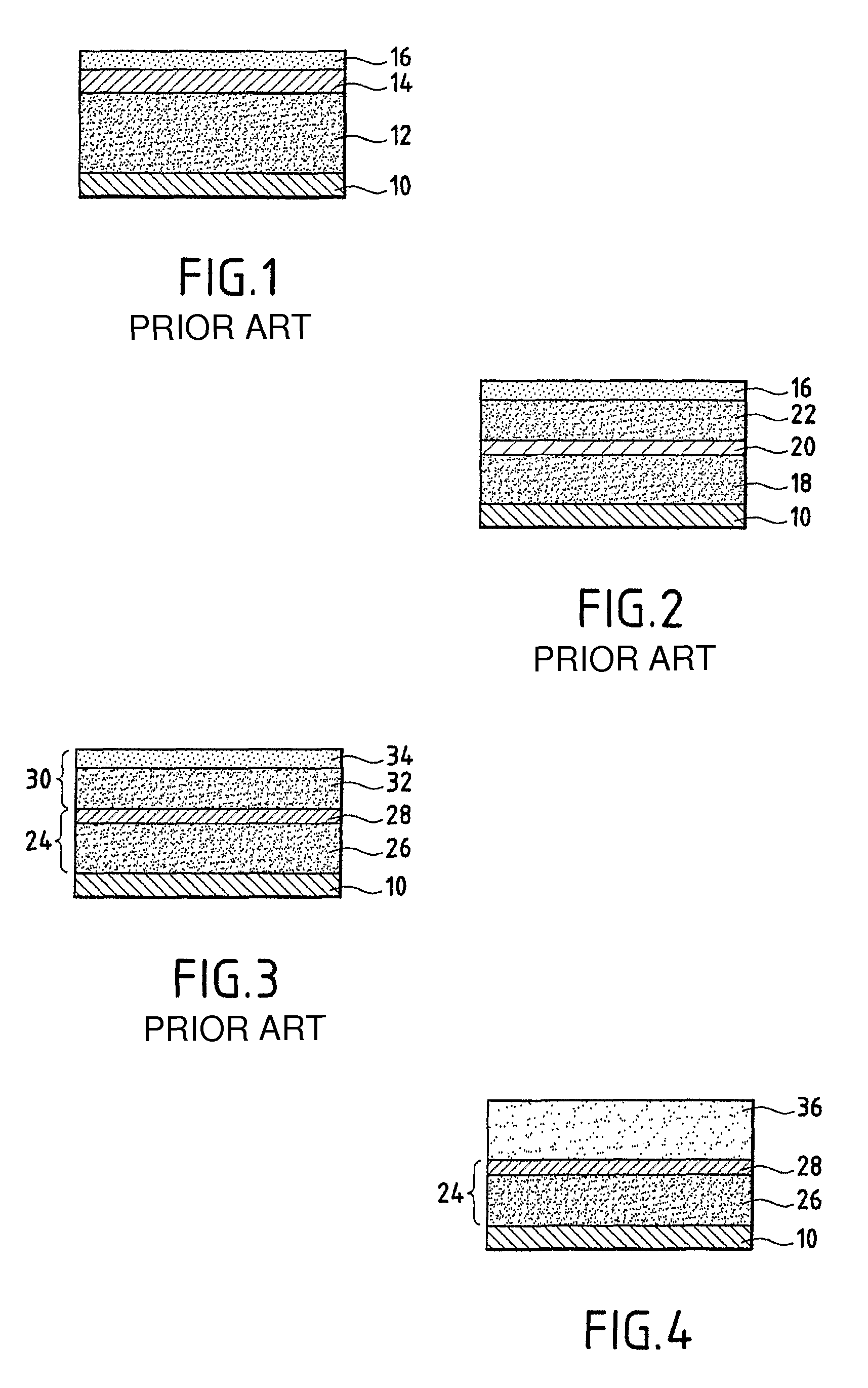

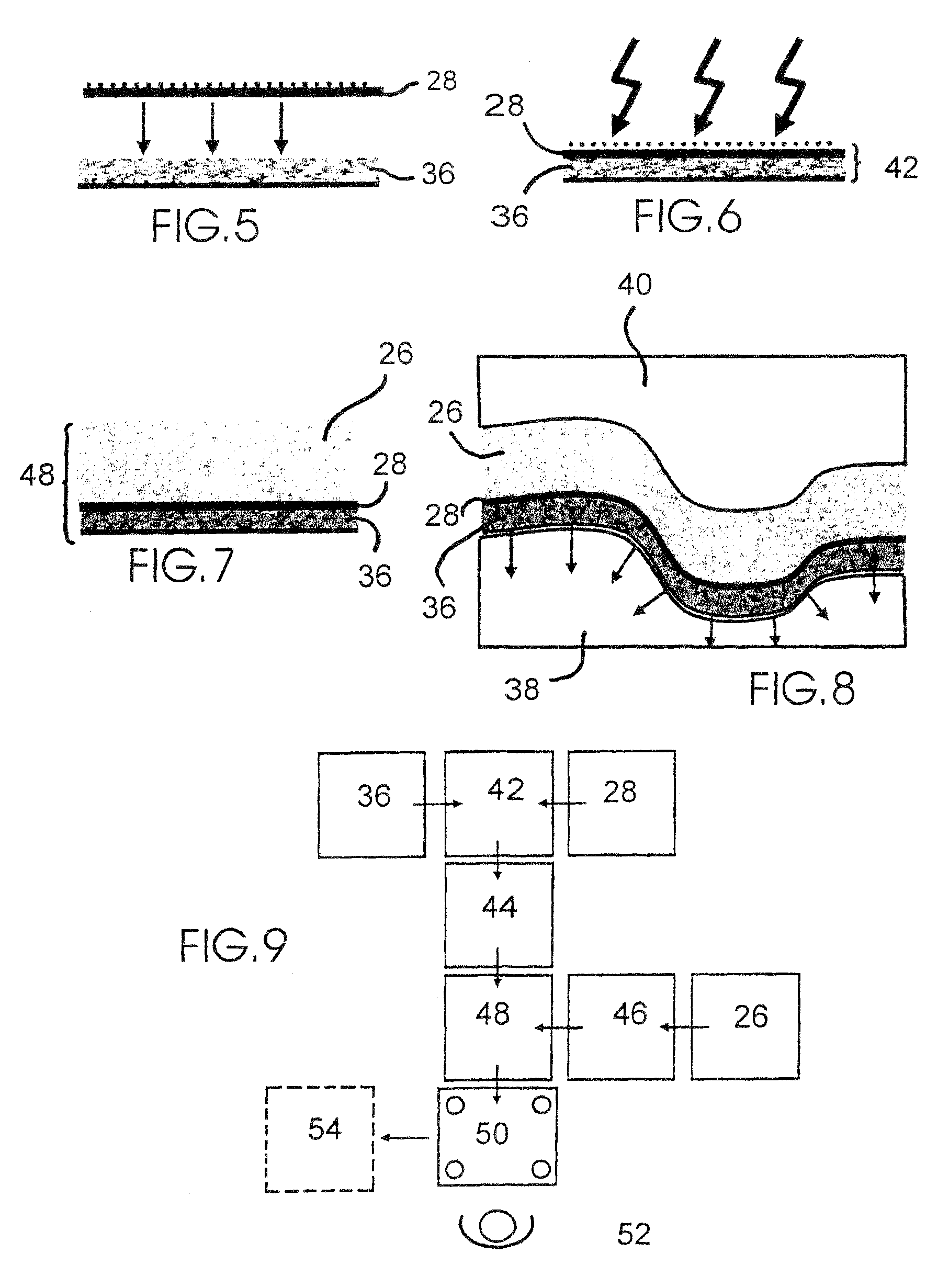

ActiveUS7789197B2Improve sound insulationIncreased tortuosityLamination ancillary operationsWallsEngineeringAcoustic wave

A soundproofing assembly includes stacked layers in the form of a first set of layers (36) having good resistance to the passage of air, and a second set of layers (24) with mass-spring function including a layer (28) having a heavy viscoelastic mass and a spring type layer (26); the first set of layers includes a layer (36) of a foam with open cells of high porosity, high tortuosity and good resistance to the passage of air, the layer (36) having, owing to its high tortuosity, excellent sonic absorption properties at medium and high frequencies. The invention is useful for soundproofing motor car passenger compartments.

Owner:FAURECIA AUTOMOTIVE IND

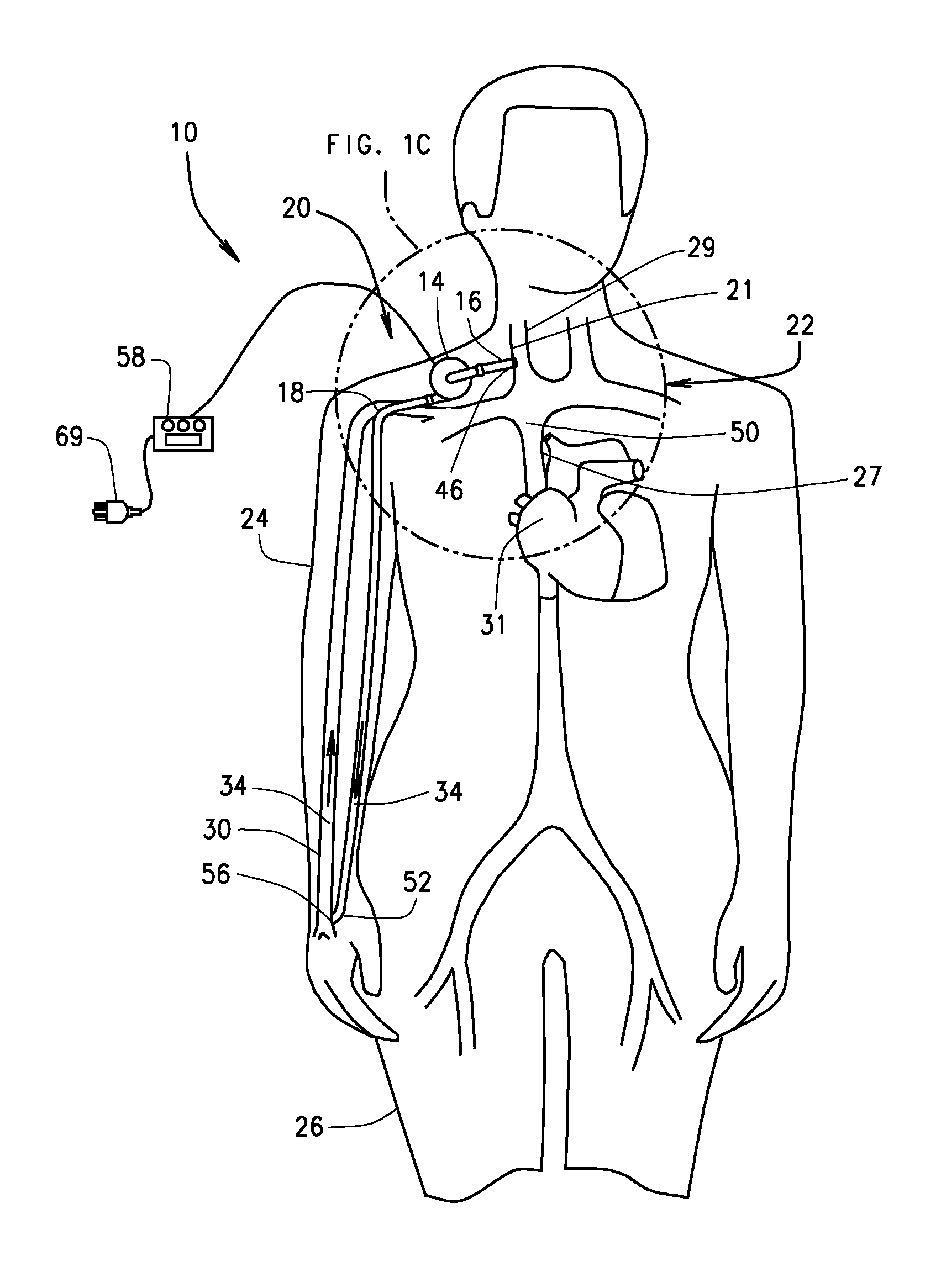

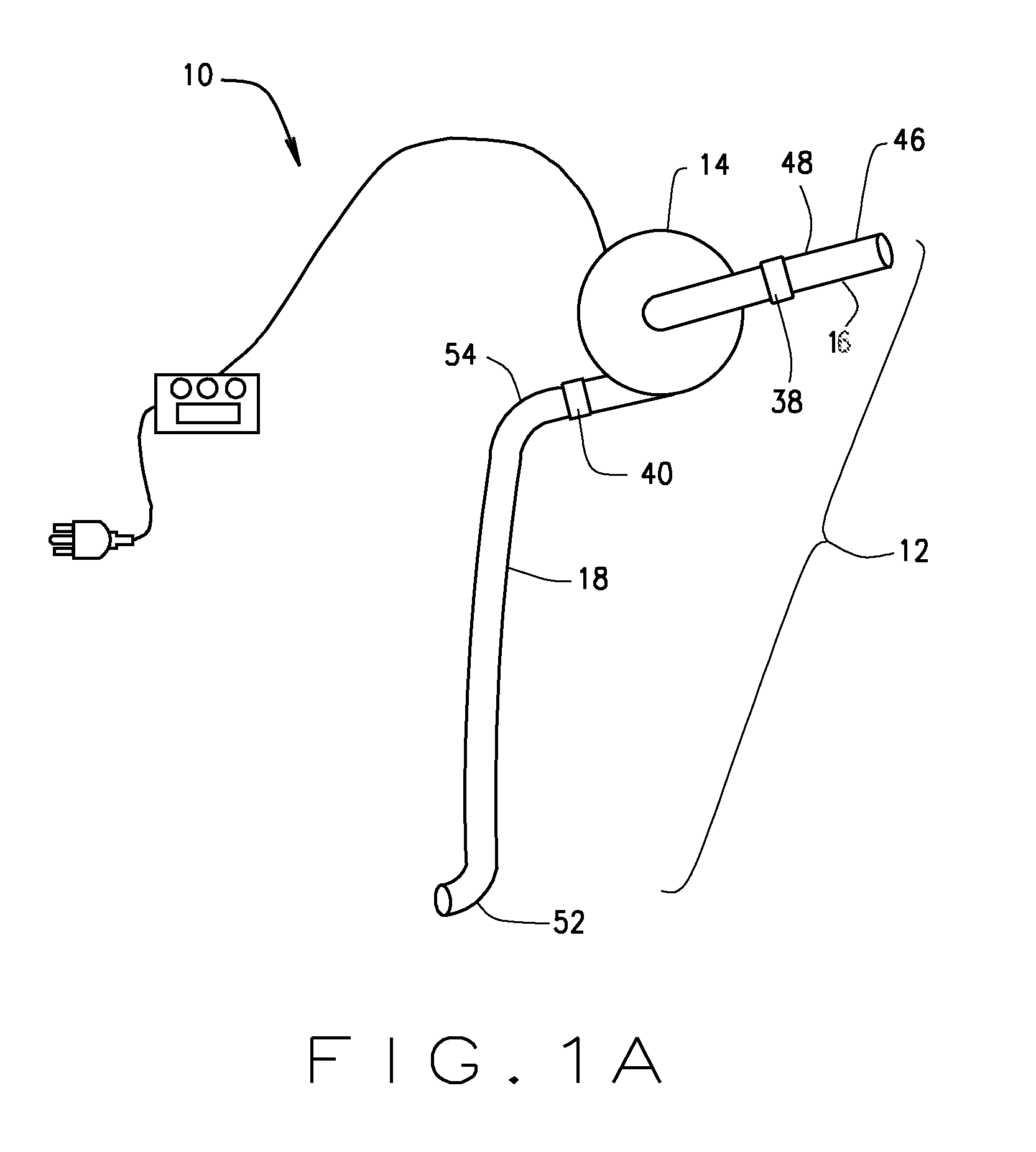

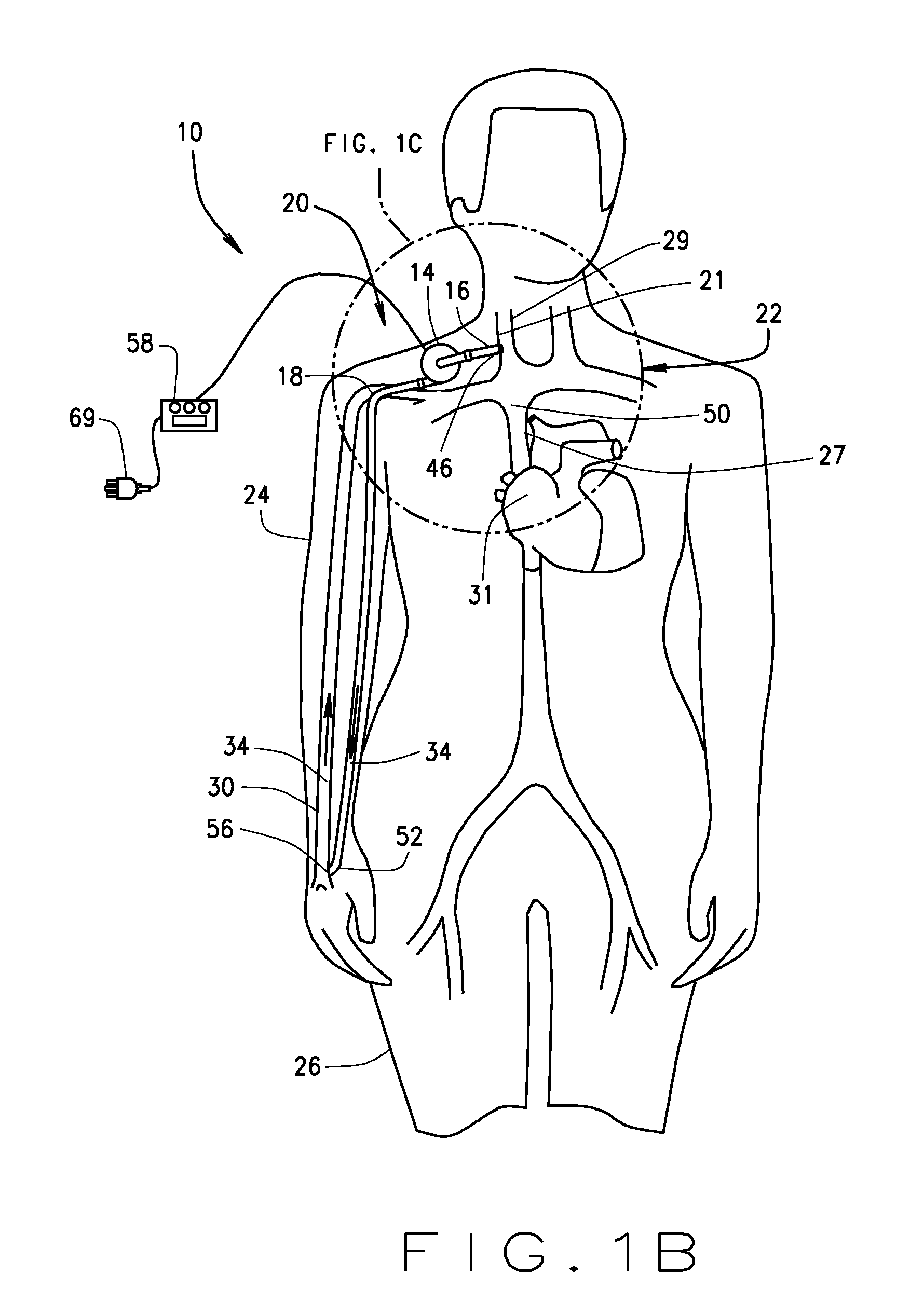

System and method to increase the overall diameter of veins and arteries

ActiveUS9539380B2Increase speedIncrease the diameterOther blood circulation devicesAnaesthesiaWall shearVein

Owner:ARTIO MEDICAL INC

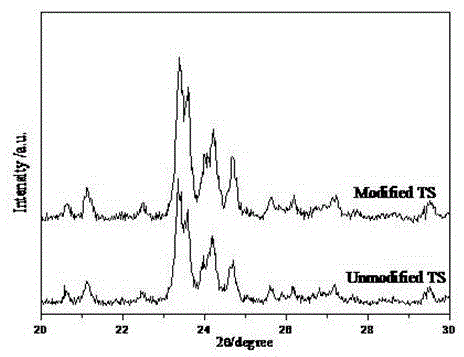

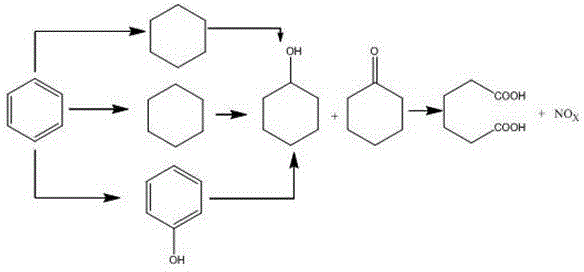

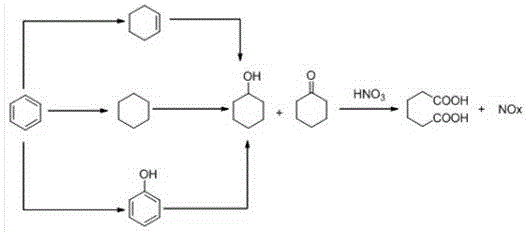

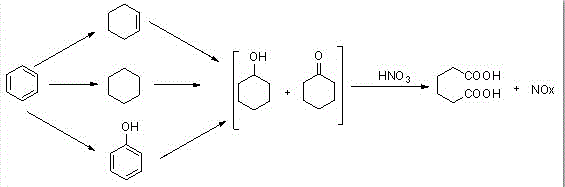

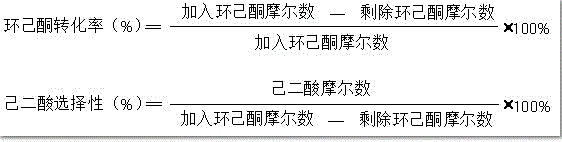

Green process for synthesizing adipic acid from cyclohexanone

InactiveCN105622386ASimple processLow costMolecular sieve catalystsCarboxylic preparation by oxidationCyclohexanoneWater vapor

The invention relates to a green process for synthesizing adipic acid from cyclohexanone, wherein a transition metal modified composite MFI titanium-silicon molecular sieve is adopted as a catalyst and catalyzes molecular oxygen to oxidize cyclohexanone at an operating temperature of 40-180 DEG C under an operating pressure of 0.1-2.0 MPa so as to prepare the adipic acid, wherein a transition metal salt is modified and then is subjected to a high-temperature calcination treatment to form a composite catalyst precursor, and then a water vapor heat treatment is performed to make the transition metal ions be subjected to an ectopic selection treatment process on the catalyst so as to obtain the composite catalyst. According to the present invention, the advantages of high adipic acid selectivity and green process are provided.

Owner:HUNAN NORMAL UNIVERSITY

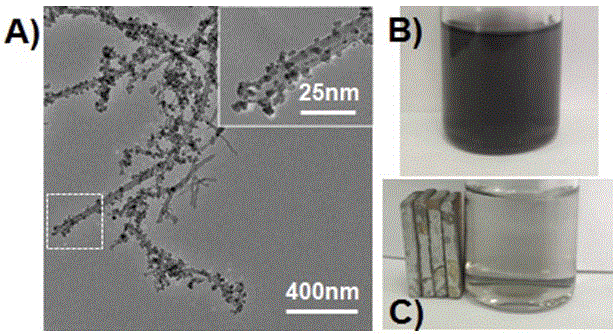

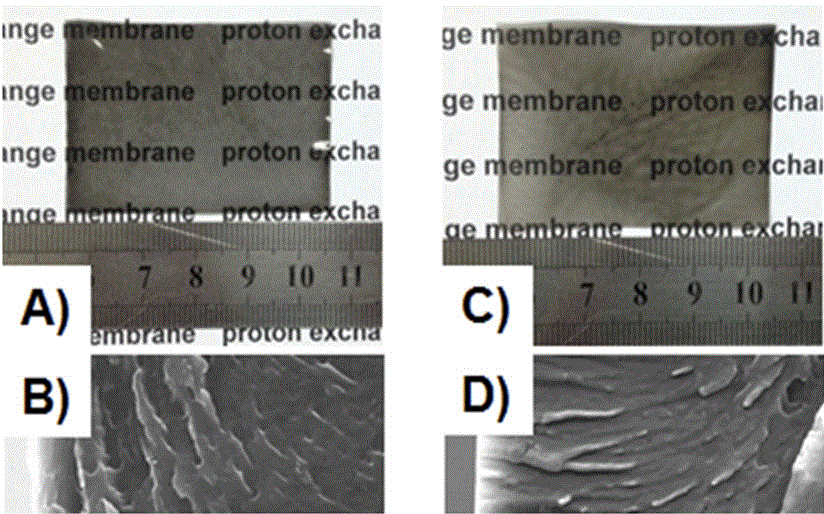

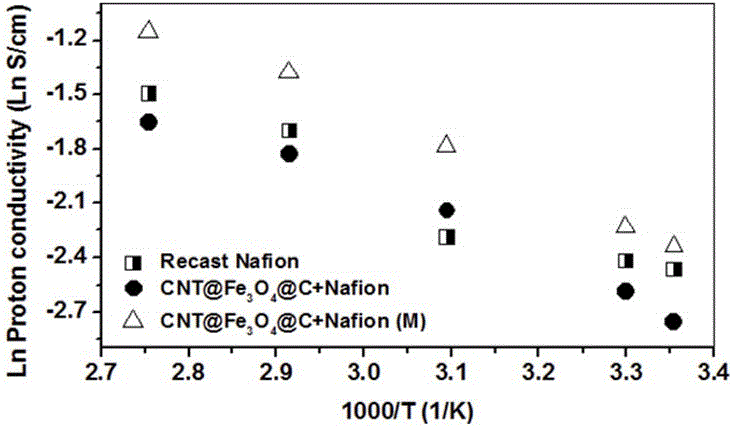

CNT@Fe3O4@C modified polymer hybrid proton exchange membrane and preparation method thereof

ActiveCN106543460AHigh selectivityEasy to operateFinal product manufactureFuel cellsPolymer scienceProton

The invention belongs to the technical field of membranes, and particularly relates to a CNT@Fe3O4@C modified polymer hybrid proton exchange membrane and preparation method thereof. The method comprises the step that one-dimensional (1D) type CNT@Fe3O4@C is uniformly dispersed into a polymer matrix in an oriented mode by means of a magnetic field, and the oriented CNT@Fe3O4@C modified polymer hybrid proton exchange membrane is obtained, wherein the proton conductivity of the proton exchange membrane is obviously improved compared with a pure polymer hybrid proton exchange membrane and is higher than the proton conductivity of a non-oriented CNT@Fe3O4@C modified polymer hybrid proton exchange membrane. Meanwhile, the fuel blocking capacity of the hybrid proton exchange membrane is further improved through orientation arrangement of CNT@Fe3O4@C. Accordingly, the oriented CNT@Fe3O4@C modified polymer hybrid proton exchange membrane has more excellent selectivity. The method is simple in operation process, mild in preparation condition, low in production cost and prone to batched and large-scale production and has a wide application prospect.

Owner:FUDAN UNIV

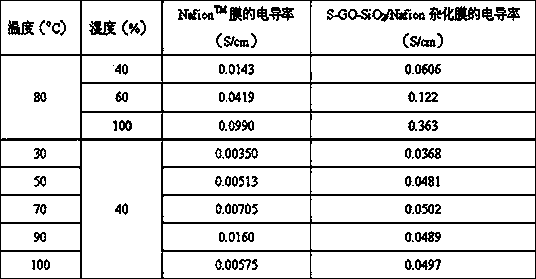

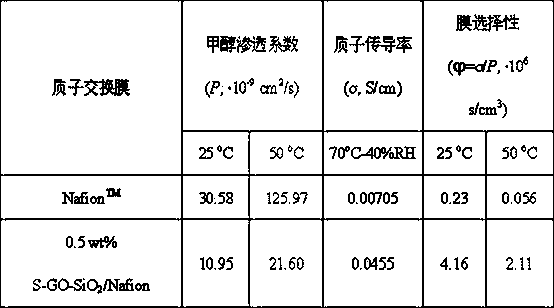

Sulfonated oxidized graphene-silicon dioxide composition/polymer hybridized proton exchange membrane and preparation method thereof

InactiveCN103474681ALow methanol permeabilityGood dispersionFinal product manufactureSolid electrolyte fuel cellsPhysical chemistrySILICONE DIOXIDE

The invention belongs to the technical field of membranes, and specifically relates to a sulfonated oxidized graphene-silicon dioxide composition / polymer hybridized proton exchange membrane and a preparation method thereof. According to the invention, a sulfonated oxidized graphene-silicon dioxide composition is uniformly dispersed in a polymer matrix, and the proton conductivity of the sulfonated oxidized graphene-silicon dioxide composition / polymer hybridized proton exchange membrane prepared by the method is extremely improved compared with a pure polymer proton exchange membrane, and particularly, the proton conductivity is exponentially improved or even improved to an order of magnitudes under a high temperature environment and / or a low humidity environment. Meanwhile, even in the severe condition of high temperature and / or high methanol concentration, the methanol permeability is further greatly reduced, namely, the sulfonated oxidized graphene-silicon dioxide composition / polymer hybridized proton exchange membrane prepared by the method has extremely excellent selectivity. In addition, the method provided by the invention is simple in operational process, mild in preparation condition, lower in production cost and easy for massive and scaled production, and has a good industrial production basis and a wide application prospect.

Owner:FUDAN UNIV

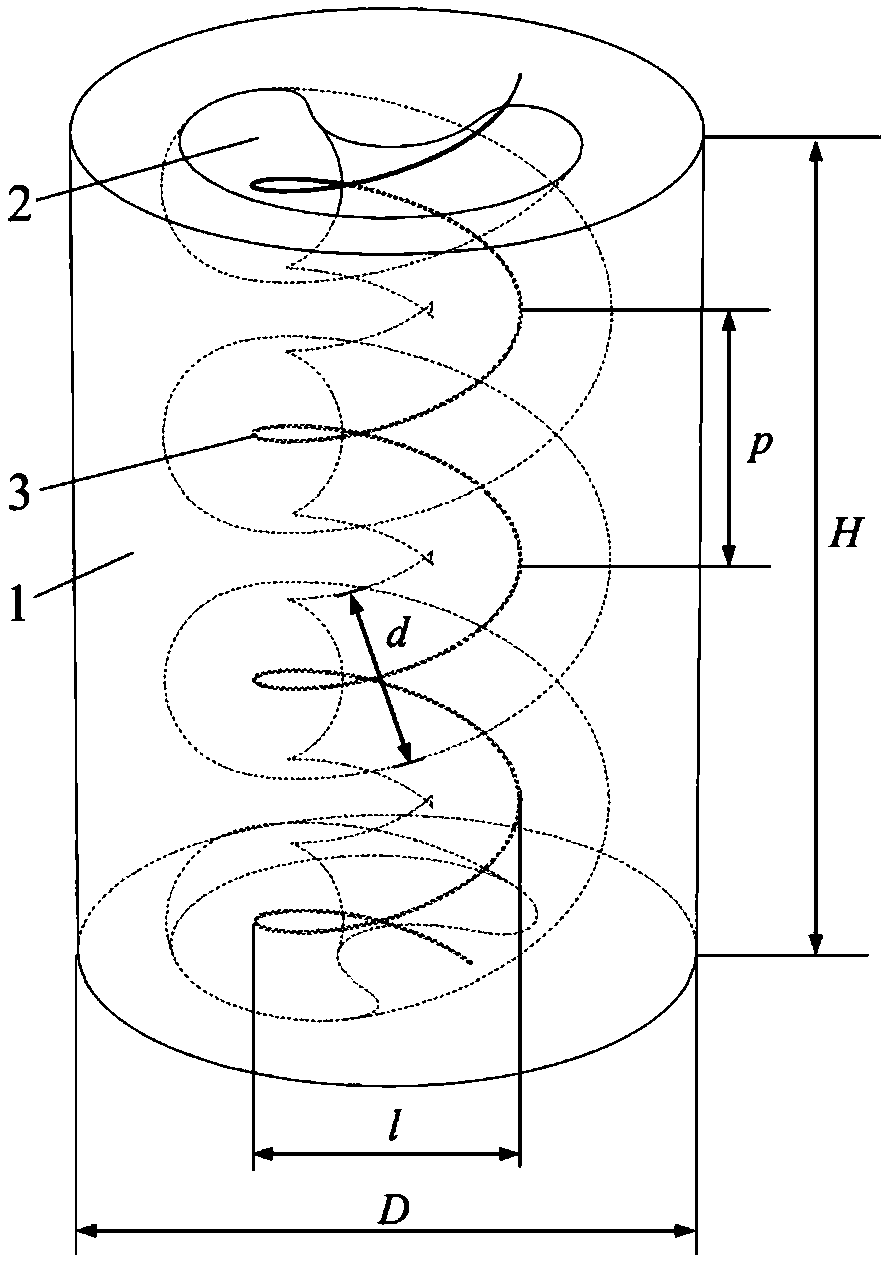

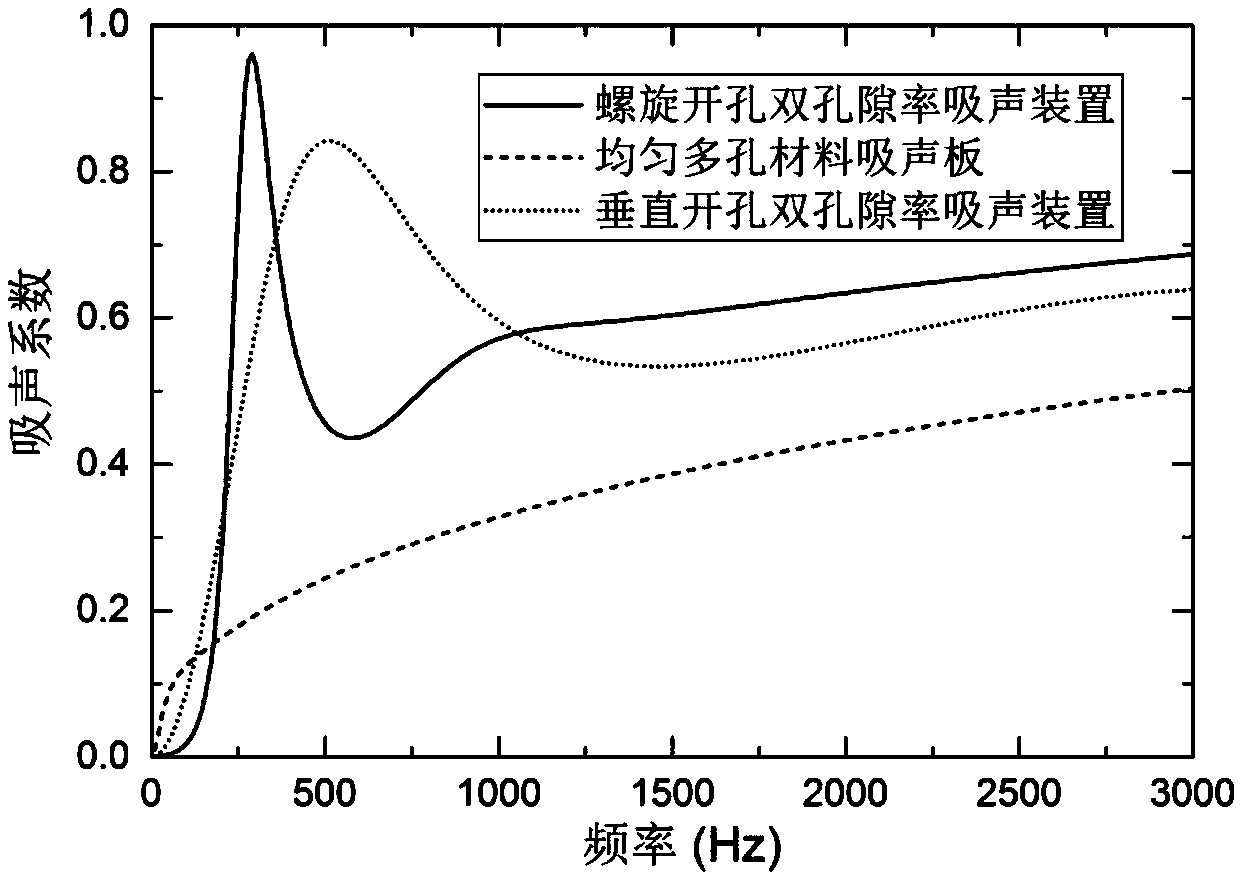

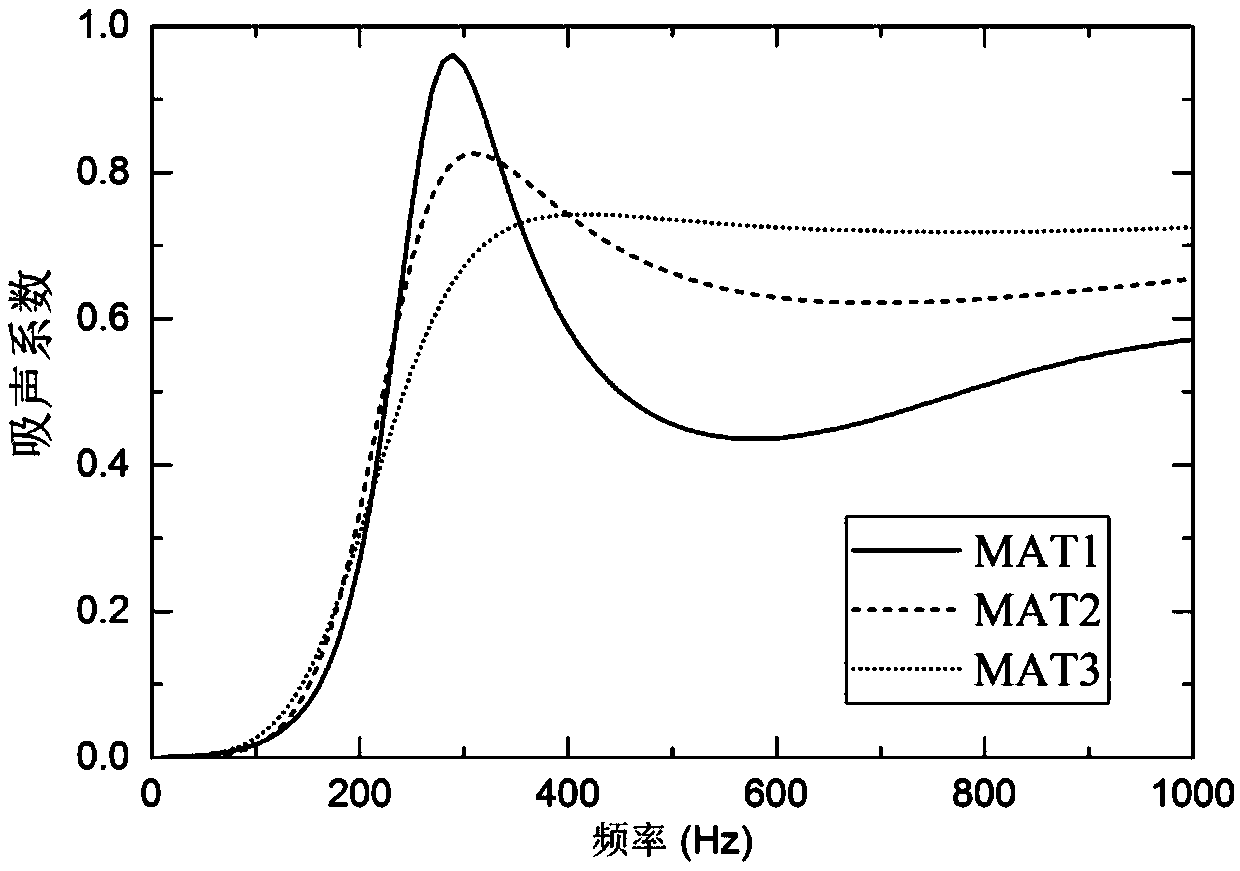

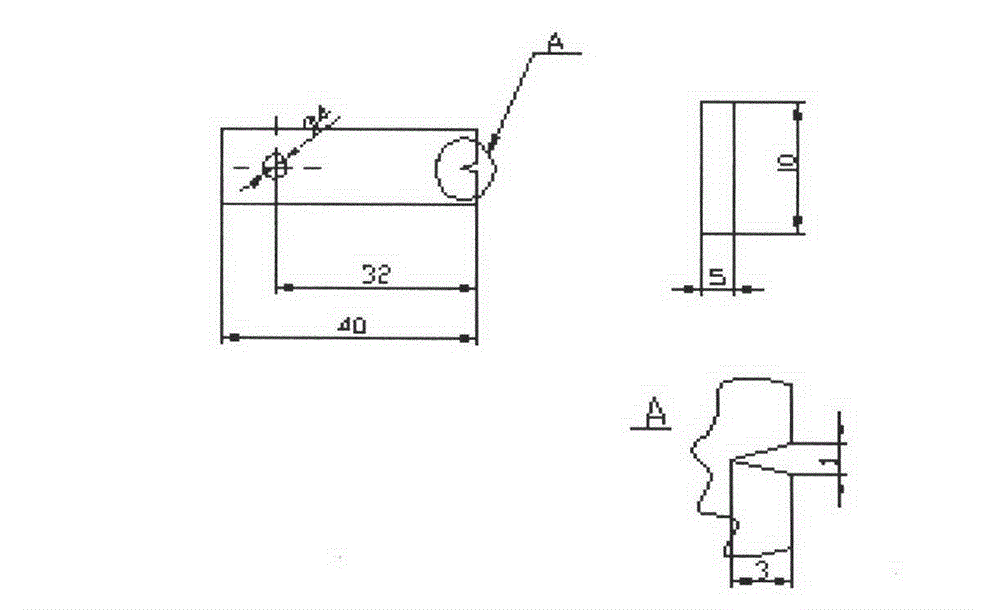

Spiral hole dual-porosity sound absorbing device and application thereof

PendingCN109686354AImprove low-frequency sound absorption performanceExcellent low frequency sound absorption performanceSound producing devicesPorositySound energy

The invention discloses a spiral hole dual-porosity sound absorbing device and application thereof. The device is realized by forming a spiral hole in a substrate of a porous material, and the sinuosity of wound waves entering the porous material is greatly improved by a spiral channel. The sound waves first enter the spiral hole at a low frequency band and then enter micro pores of the porous material via the spiral hole. By utilizing sound energy dissipation brought by strong coupling of the wound waves between the spiral hole formed in the porous material and the micro pores of the porous material, the low-frequency sound absorption property of the sound absorbing material in the invention is enhanced. Moreover, by combining the consistently good high-frequency sound absorption propertyof the porous material, the spiral hole dual-porosity sound absorbing device disclosed by the invention can reach a sound absorption peak value at an ultralow frequency under the condition that the thickness is small, and also has a certain medium-high frequency sound absorbing ability. The device disclosed by the invention is simple in structure and practical and has excellent and wide application prospects.

Owner:XI AN JIAOTONG UNIV

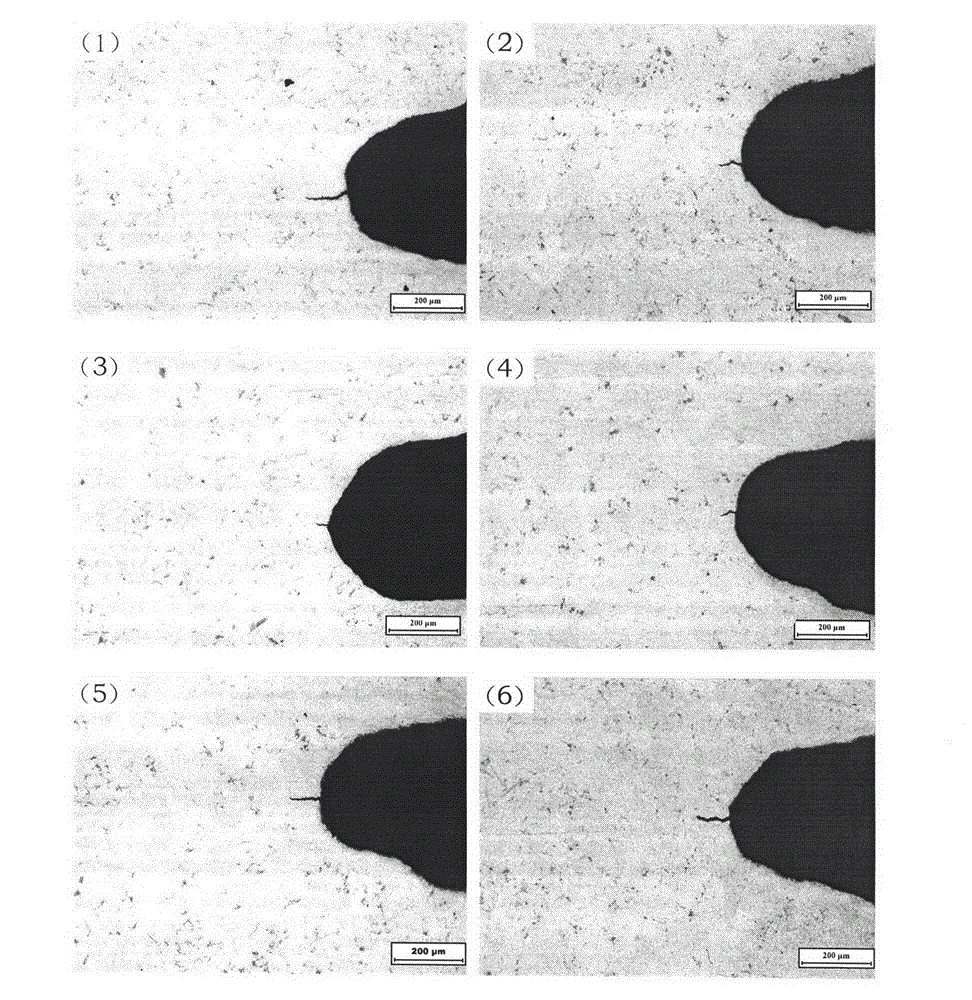

Multi-component zinc-aluminium alloy capable of enhancing thermal fatigue property

ActiveCN102719705AImprove plasticityImprove thermal fatigue resistanceThermal fatigueMedium frequency

A multi-component zinc-aluminium alloy capable of enhancing thermal fatigue property belongs to the technical field of zinc-aluminium alloy preparation and is characterized in that No.A00 industrial aluminium ingots, No.0 zinc ingots, electrolytic copper, composite modifier (including 20 to 30 percent of Ni, 15 to 25 percent of Ti, 5 to 15 percent of Mn, 5 to 15 percent of Cr, 5 to 10 percent of Si, 5 to 10 percent of Ce, 5 to 10 percent of La, 1 to 6 percent of Y, 1 to 6 percent of Nb, 1 to 6 percent of V and the balance of aluminium) and pure magnesium are adopted as materials. Calculated according to percentage by weight, 27 to 29 percent of Al, 2 to 2.5 percent of Cu (added in the form of aluminium-copper master alloy containing 50 percent of copper), 0 to 1.2 percent of composite modifier, 0.01 to 0.02 percent of Mg and the balance of Zn are weighed and then smelted in a medium-frequency induction smelting furnace. An ordinary metal mold is adopted to cast round rod-shaped billets, the round bar-shaped billets are machined into test bars which come up to national standard, and thermal fatigue samples are then taken from the billets.

Owner:SHENZHEN MINGLIDA PRECISION MACHINERY

Ditch-type thickener with inclined plate sedimentation promoting structure

The invention discloses a ditch-type thickener with an inclined plate sedimentation promoting structure. The ditch-type thickener comprises a thickening pond, a sedimentation pond and a clean water pond which are sequentially and linearly arranged, wherein the three water ponds are arranged under the ground, and the upper parts of the ponds are provided with top covers; the thickening pond is deeper than other ponds, and a discharging hole is formed in the bottom of the thickening pond; the bottom of the sedimentation pond is provided with a mud removing valve, one end of the mud removing valve is communicated with the front end of the bottom of the sedimentation pond, and the other end of the mud removing valve is communicated with the lower part of the thickening pond and is led to the discharging hole; liquid at the upper part of the tail end of the sedimentation pond is led to a drain hole, and feeding holes are formed in the parts, close to the initial end of the thickening pond, of the top covers; and the sedimentation pond is internally provided with the inclined plate sedimentation promoting structure comprising inclined sedimentation plates which are distributed every other a certain distance along the water flow direction, and the inclined sedimentation plates are arranged in a way that the upper parts of the plates are backwards inclined along the water flow direction. By using the ditch-type thickener, tailings are subjected to concentration treatment, and meanwhile, the extruded clear water is discharged or recycled on site; and the thickener is simple in structure and capable of saving space and achieving the aim of saving electricity and water.

Owner:曾承旺

Full run-down light dispersion composition

InactiveCN1727953AAvoid absorptivityIncrease light sourceNon-linear opticsOptical elementsTitanium dioxidePolymer chemistry

Owner:SHANG KWEI ENTERPRISE

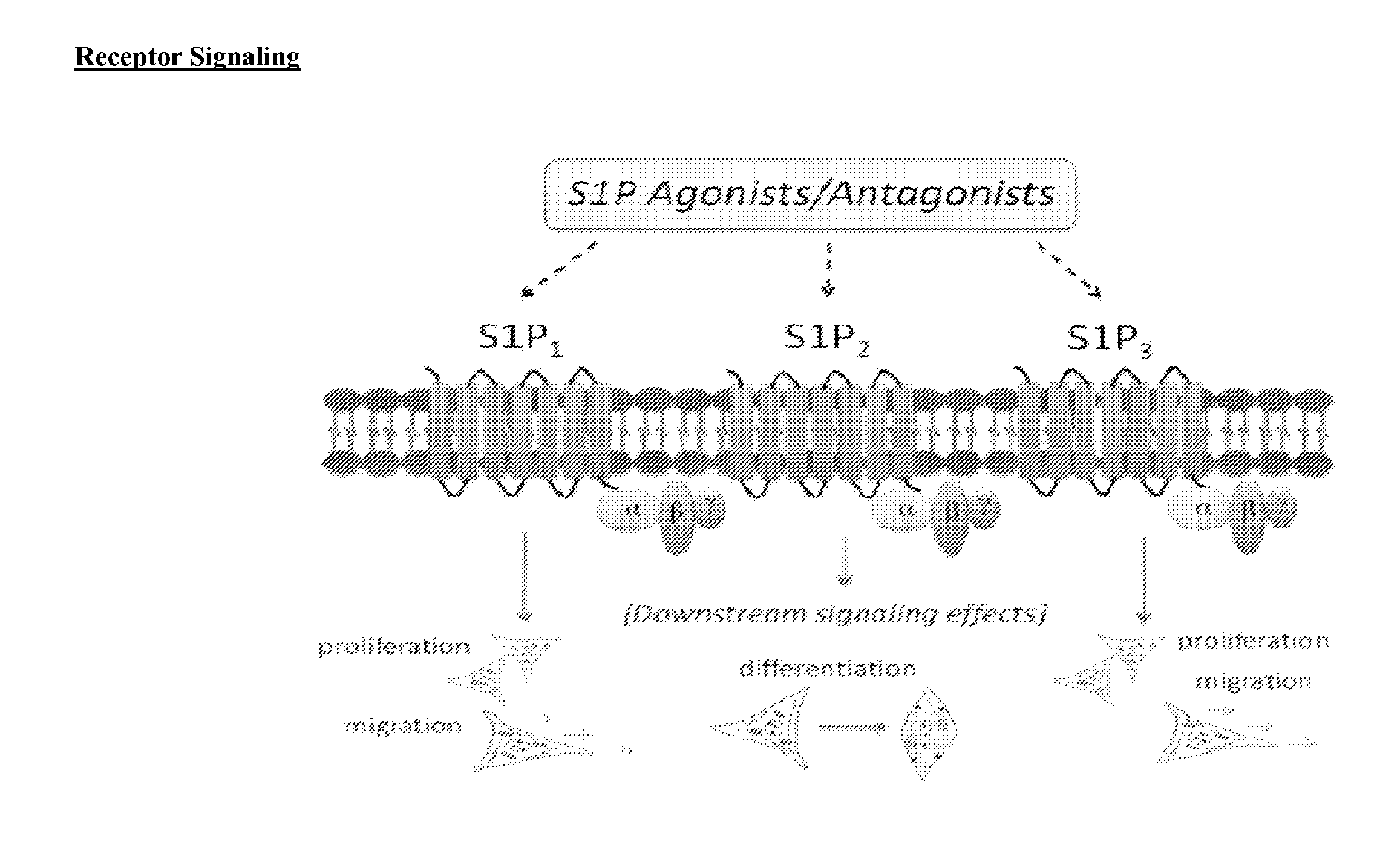

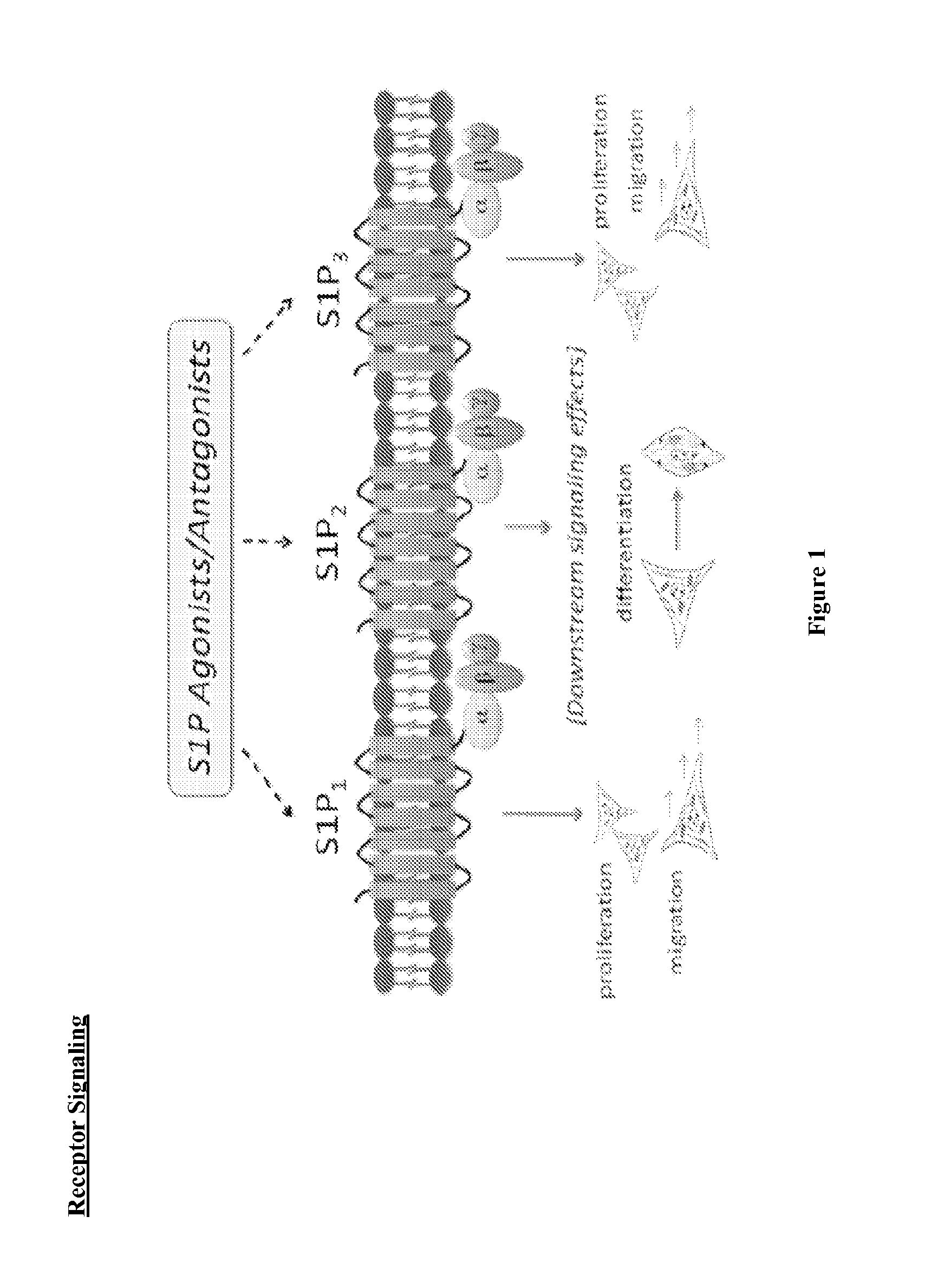

Compositions and methods for tissue engineering and cell based therapies

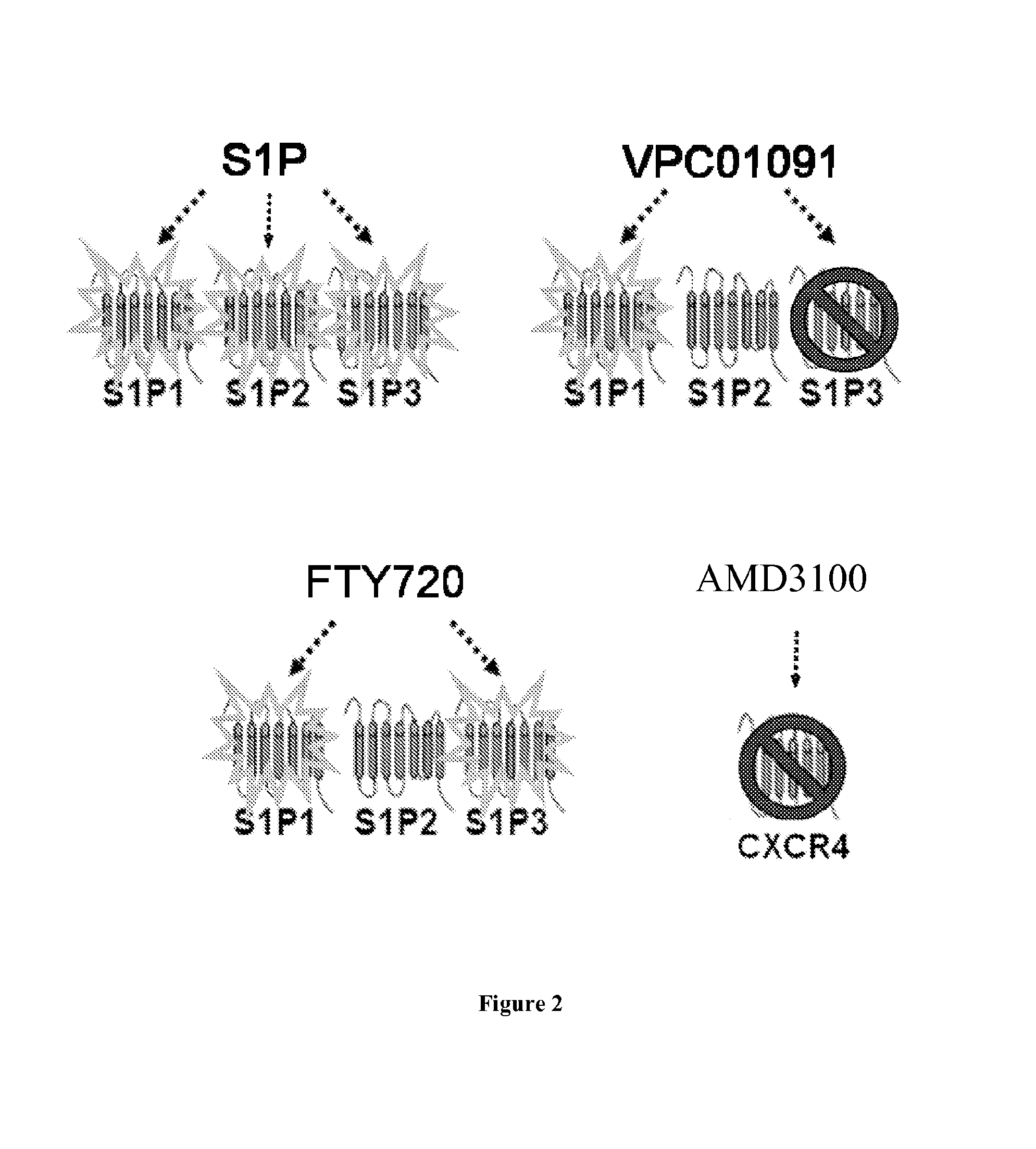

ActiveUS20140094444A1Improves Structural IntegrityRestore normal bone turnoverBiocidePhosphorous compound active ingredientsProgenitorS1P Receptor

The present application discloses strategies to recruit and mobilize stem cells using S1P receptor selective agonists and antagonists as wells as regulators of chemokine receptors. In an in vivo ischemic model, S1P1 / S1P3 activation with FTY720 impeded inflammatory cell infiltration and recruited endothelial progenitor cells (EPCs) with the potential to increase microvascular remodeling. S1P3 expression on marrow-derived cells was essential for this remodeling. Concurrent systemic S1P3 and CXCR4 antagonism mobilized hematopoietic stem cells (HSCs) with the ability to engraft and repopulate blood cells. Pre-treatment of donor HSCs with FTY720 increased homing toward SDF-1 and improved engraftment in marrow. FTY720-coated bone allografts coupled with systemic administration of VPC01091 enhanced bone allograft integration and new bone formation in bone defects. MSCs pre-treated with FTY720 exhibited increased migration toward SDF-1, a CXCR4+ ligand. The results show that S1P is a very powerful role player in pharmacological marrow-derived stem cell mobilization and recruitment.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Process for preparing adipic acid through cleaning catalytic oxidation of cyclohexanone, catalyst, and catalyst preparation method

InactiveCN105622385AHigh activityEvenly dispersedMolecular sieve catalystsCarboxylic preparation by oxidationMolecular sieveCyclohexanone

The invention relates to a process for preparing adipic acid through cleaning catalytic oxidation of cyclohexanone, a catalyst, and a catalyst preparation method, and discloses a transition metal-modified composite MFI titanium silicon molecular sieve and a preparation method thereof, and an adipic acid preparation, wherein a mass ratio of the preferred transition metal salt to the titanium silicon molecular sieve is (0.01-0.2):1. The catalyst preparation process respectively comprises dry ball milling, high temperature calcination, hydrothermal crystallization, and other steps. According to the present invention, the catalyst prepared according to the method is the composite catalyst having the characteristic of high dispersion of the transition metal oxide on the catalyst surface; and the modified composite MFI titanium silicon molecular sieve has high catalytic oxidation activity, and can be recovered and recycled.

Owner:HUNAN NORMAL UNIVERSITY

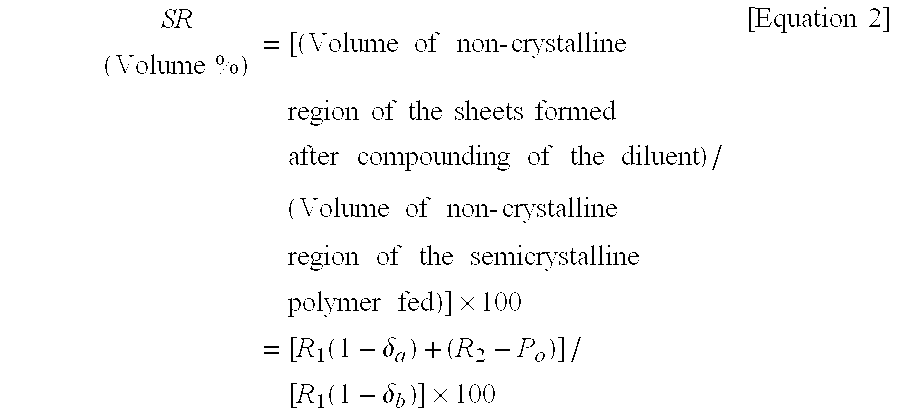

Microporous film of semicrystalline polymers and method for preparing the same

InactiveUS20070138682A1Difficult to obtainIncreased tortuositySemi-permeable membranesMembranesSwelling ratioAverage diameter

Microporous films of the semicrystalline polymer according to the present invention are obtained by stretching semicrystalline polymer sheets extruded through a die with the phase separation between a semicrystalline polymer resin and a diluent, of which sheet is comprised of a crystalline region, a pore region, and a non-crystalline region which is a swollen region swollen by the diluent, and extracting the diluent. The pore region has irregular sizes and shapes, has an average diameter of 0.01 μm to 2 μm, is connected in three dimensions, penetrates the thickness of the sheet, has gas permeability, and has a volume ratio with respect to the volume of the entire composition of 10% to 40%. The swollen non-crystalline region has a swelling ratio of 200% or greater and is a region making micropores of which average diameter is 0.1 μm to 1 μm as the region is split and pores are generated during the process of stretching. Thus manufactured microporous films are characterized by having a gas permeability of 1.3×10−5 Darcy or greater as well as a puncture strength of 0.1 N / μm or greater even without tearing destroying of the pores during stretching.

Owner:SK ENERGY CO LTD (KR)

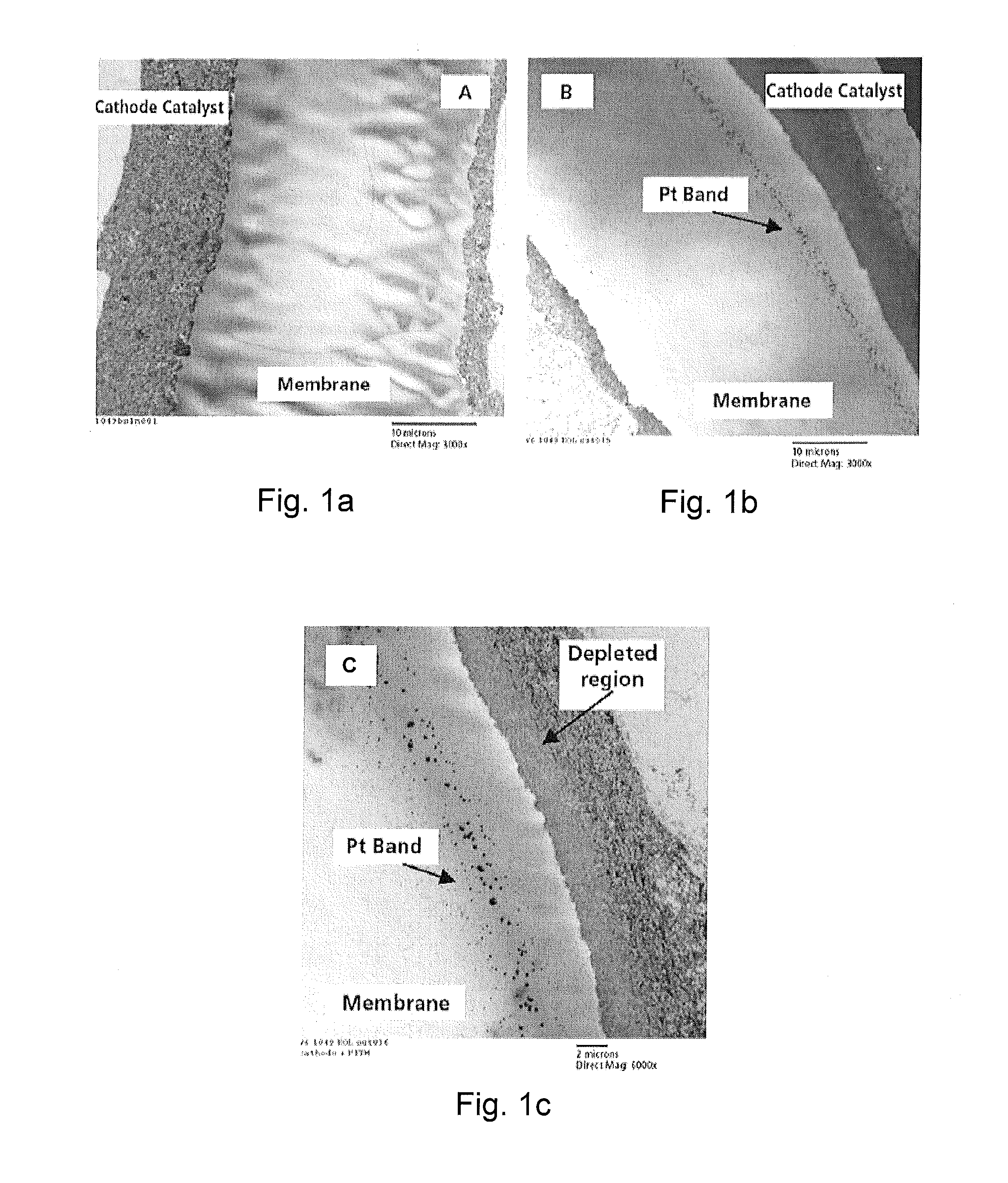

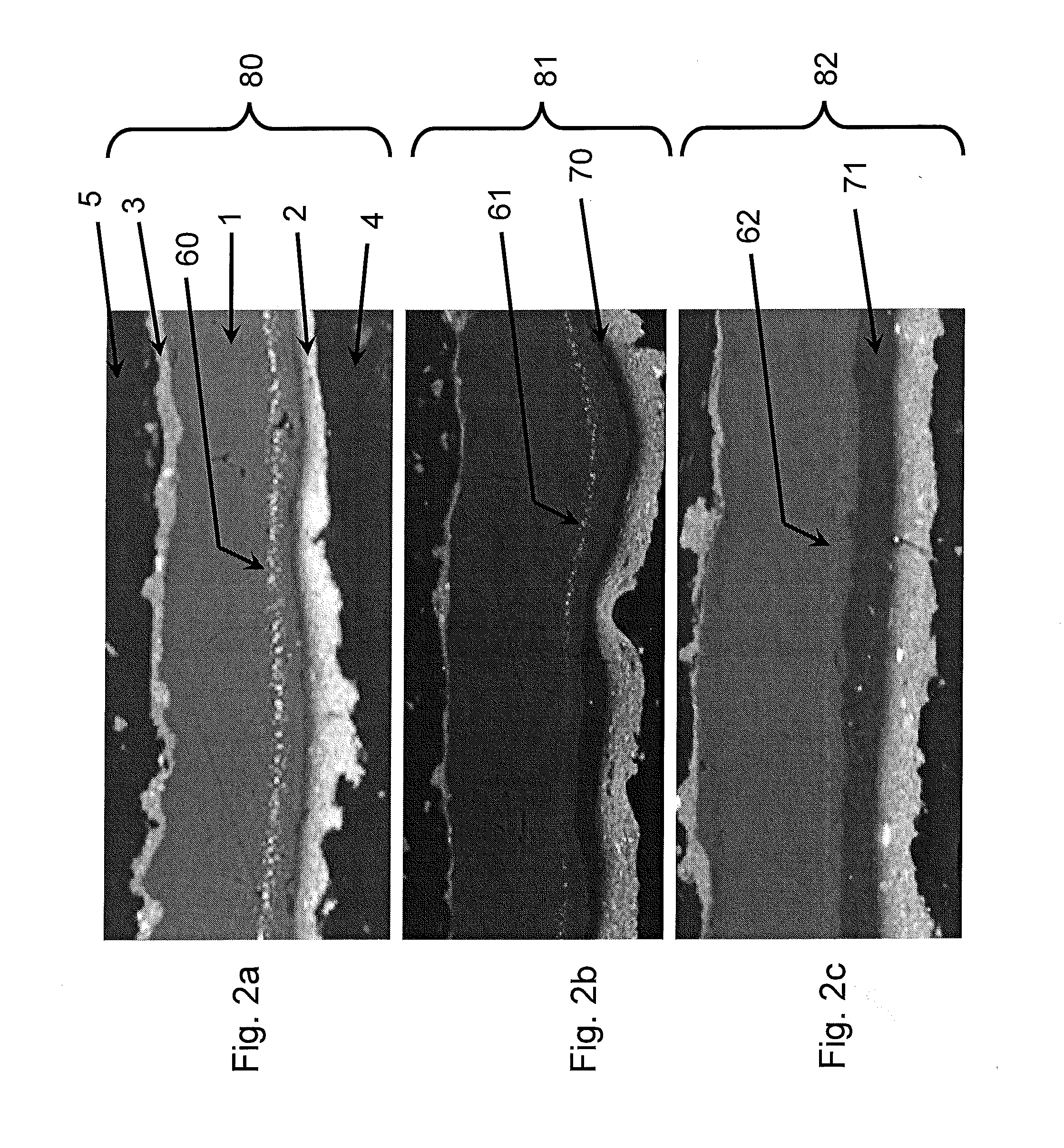

Membrane electrode assembly comprising a catalyst migration barrier layer

ActiveUS20110256466A1Increased durabilityLoss of performanceSolid electrolytesCell electrodesIonomerFuel cells

A membrane electrode assembly for a fuel cell is disclosed, which comprises at least one porous ionomer containing layer disposed at the interface between the cathode electrocatalyst material and the ion exchange membrane of the fuel cell. The porous ionomer containing layer comprises a catalyst migration impeding compound. The membrane electrode assembly exhibits improved stability against Pt dissolution and Pt-band formation within the ion exchange membrane, hence having improved durability and lifetime performance.

Owner:FORD MOTOR CO +1

Nanometer chitosan composite diaphragm of lithium battery and manufacturing method of nanometer chitosan composite diaphragm

InactiveCN104953068ALess investment in equipmentReduce product costCell seperators/membranes/diaphragms/spacersMicrometerPorosity

The invention belongs to the field of manufacturing of lithium batteries, and relates to a nanometer chitosan composite diaphragm of a lithium battery and a manufacturing method of the nanometer chitosan composite diaphragm. An ionic polymer membrane material composed of a (nanometer chitosan sol particles and micrometer chitosan sol particles) network and olefin copolymerized latex / polyethylene oxide is provided. According to the ionic polymer membrane material, the (nanometer chitosan sol particles and micrometer chitosan sol particles) network is adopted as a support body, and the nanometer chitosan composite diaphragm is formed through curtain coating and drying. The diaphragm has excellent three-dimensional network conformation, the porosity is 80% or more, and the thickness of the diaphragm is 5-60 micrometers. The diaphragm has no stress effect or form memory effect, has good chemical stability, form dimensional stability, thermal stability, insulativity and excellent physical mechanical strength (including tension resistance, impact resistance and flexibility in bending and the like), and has good adsorption affinity with an electrolyte. The nanometer chitosan composite diaphragm has positive charge characteristics, and can provide a free channel for positive electric lithium ions.

Owner:SICHUAN XIDANFO LITHIUM BATTERY +1

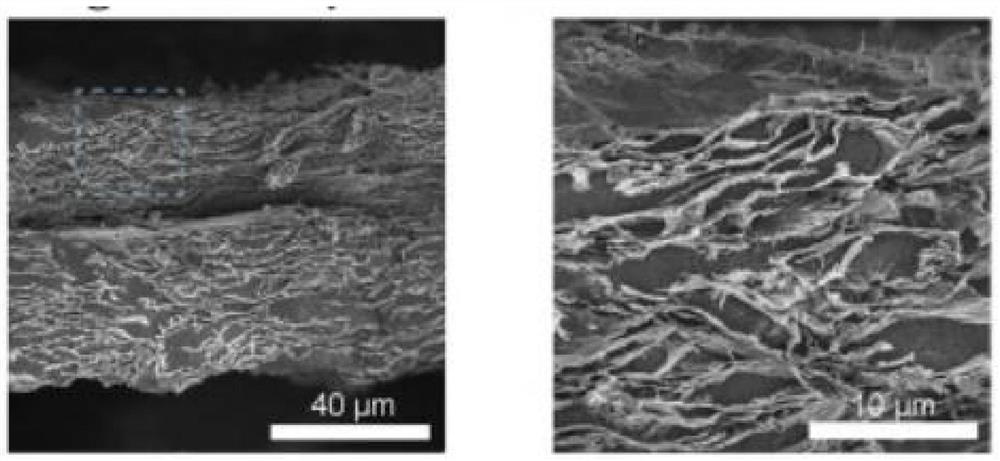

Lithium-sulfur battery, positive electrode and negative electrode materials of lithium-sulfur battery and preparation method thereof

InactiveCN111933948ASolve conductivity problemsImprove conductivityFinal product manufactureNegative electrodesLithium–sulfur batteryElectrical battery

The invention discloses a lithium-sulfur battery, positive electrode and negative electrode materials of the lithium-sulfur battery and a preparation method thereof. The preparation method of the positive electrode and negative electrode materials of the lithium-sulfur battery comprises the following steps: (1) in a nitrogen atmosphere, heating graphene oxide to obtain reduced graphene; and (2) ina nitrogen atmosphere, respectively mixing the reduced graphene obtained in the step (1) with sulfur powder and lithium powder, then respectively carrying out heating reaction in the nitrogen atmosphere, and after the reaction is finished, respectively obtaining the lithium-sulfur battery positive electrode material and the lithium-sulfur battery negative electrode material. The prepared positiveelectrode material and negative electrode material of the lithium-sulfur battery are used for preparing the lithium-sulfur battery, the capacity of the lithium-sulfur battery reaches 400Wh / Kg, and after 160 cycles, the charging efficiency still reaches 98%.

Owner:武汉先见科技有限公司

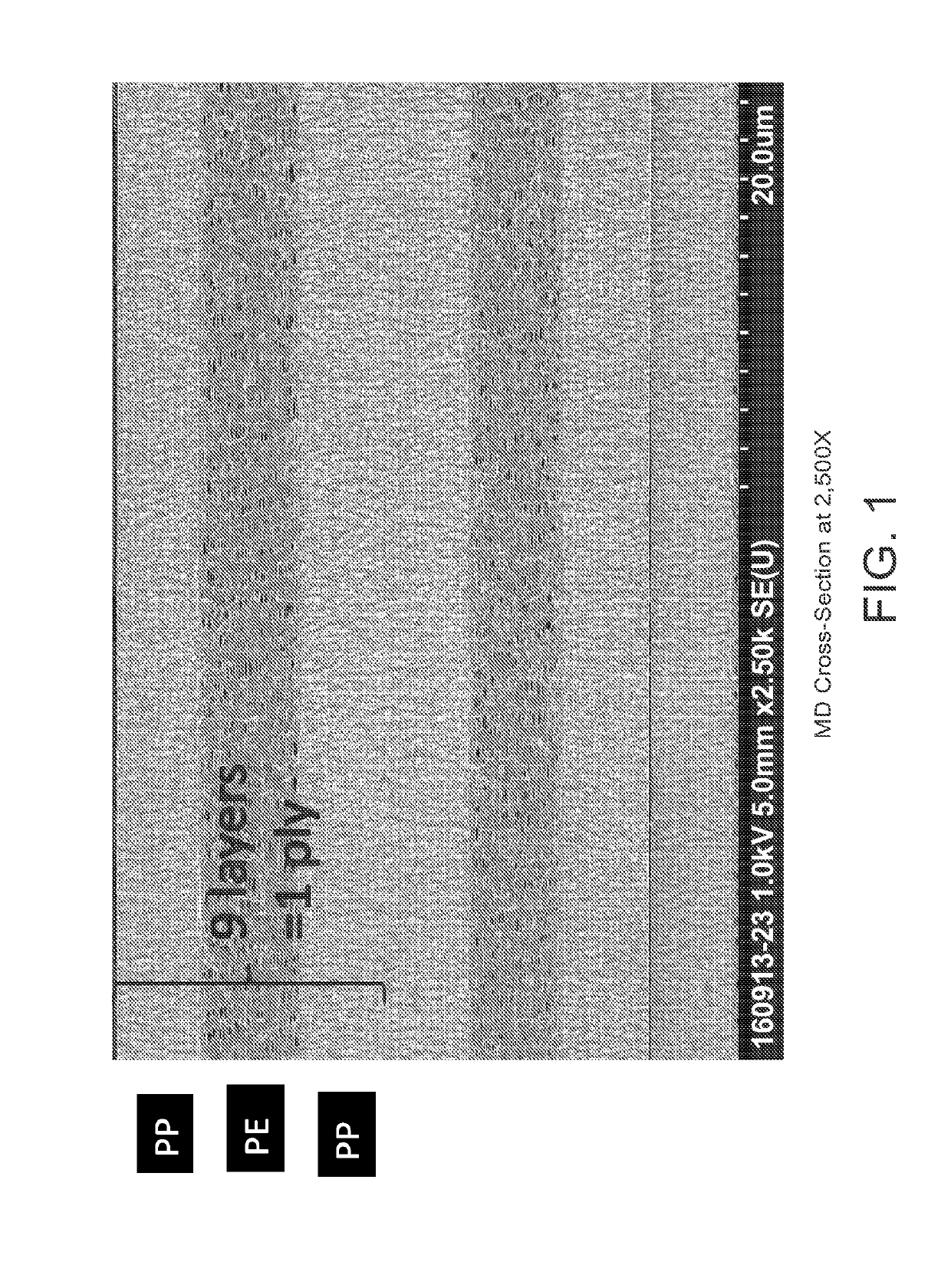

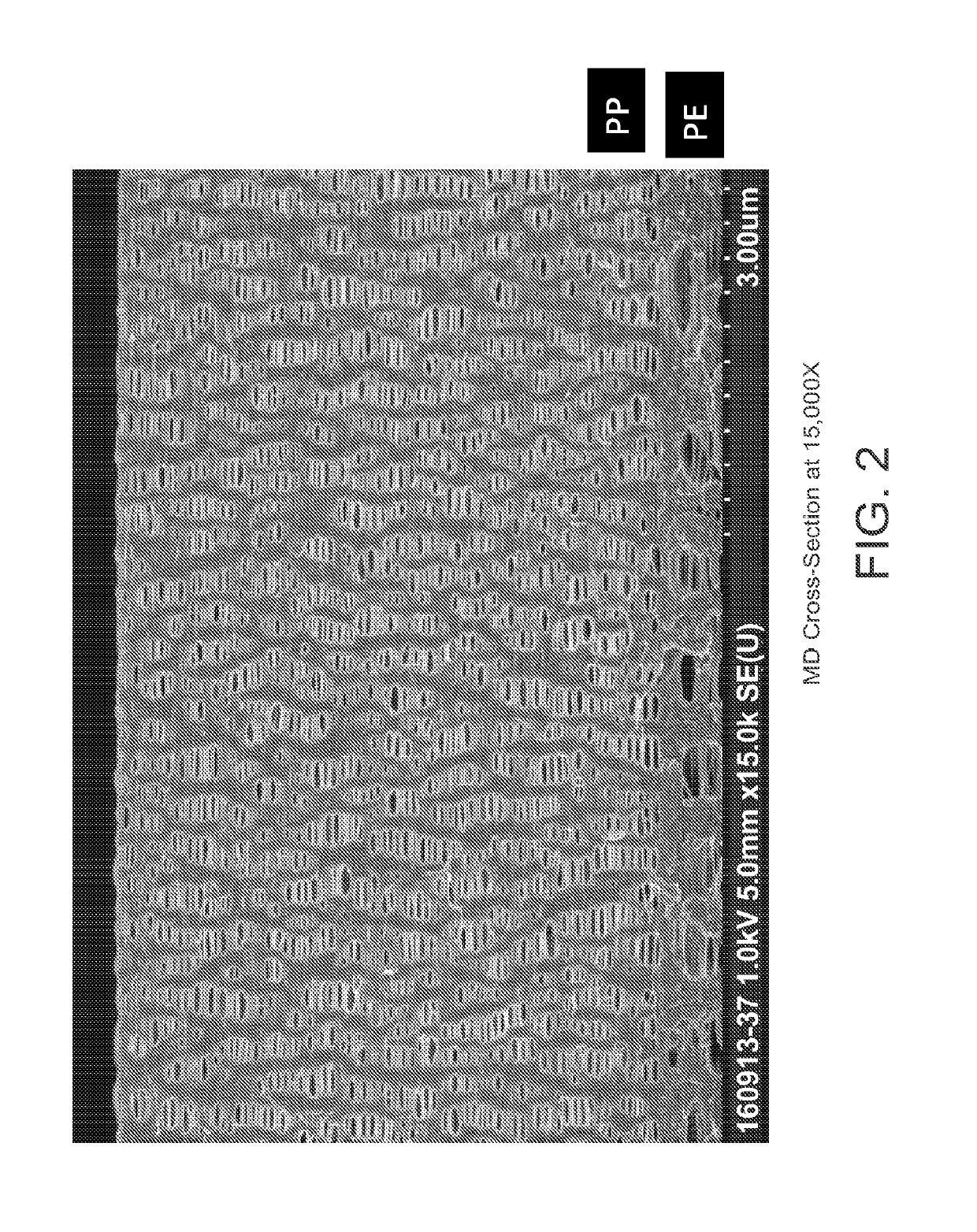

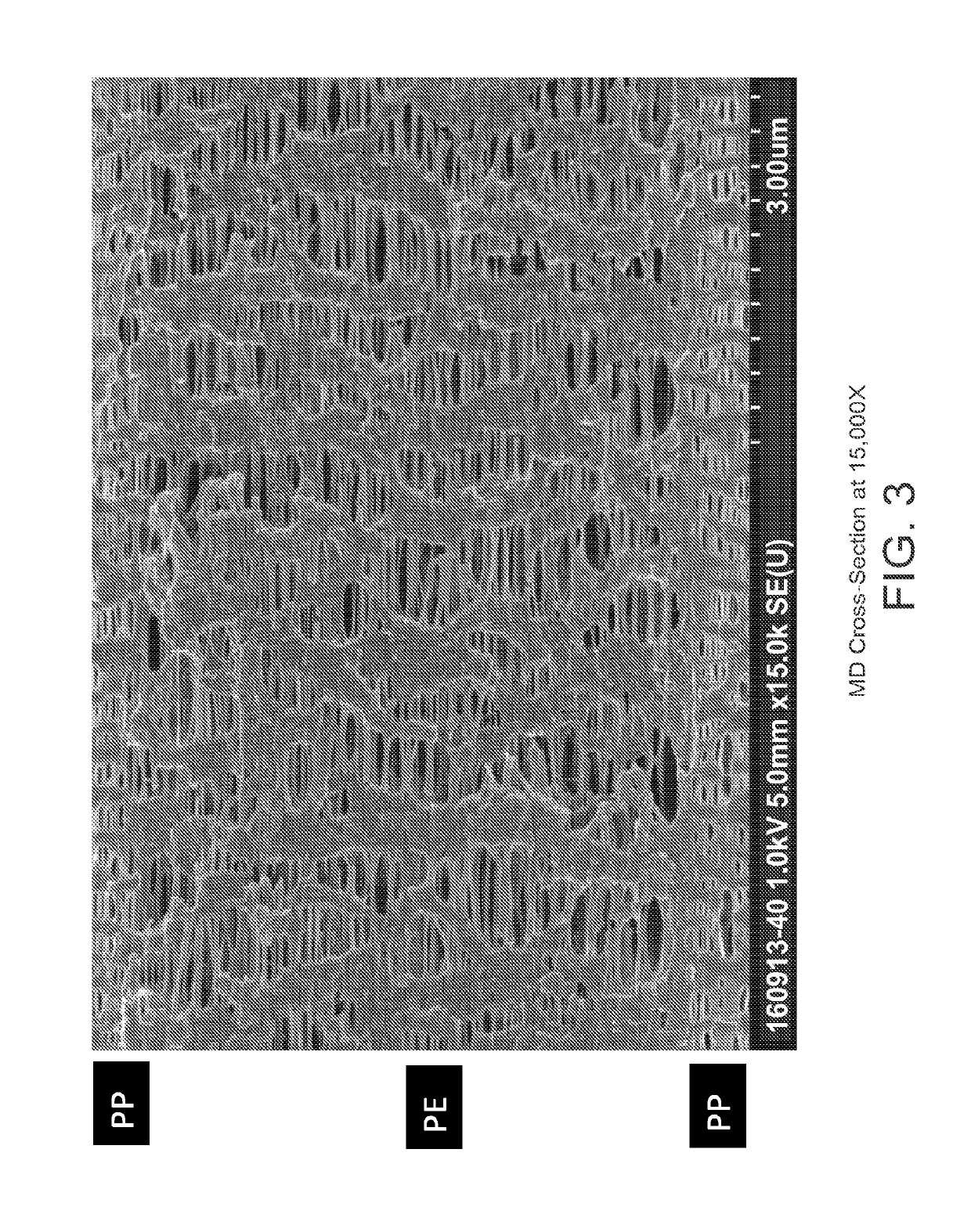

Improved microlayer membranes, mproved battery separators, and related methods

PendingUS20190267599A1Trend downAccelerated shutdownSynthetic resin layered productsLi-accumulatorsDielectricThin membrane

Described herein is a multilayer microporous film or membrane that may exhibit improved properties, including improved dielectric break down and strength, compared to prior monolayer or tri-layer microporous membranes of the same thickness. The preferred multilayer microporous membrane comprises microlayers and one or more lamination barriers. Also disclosed is a battery separator or battery comprising one or more of the multilayer microporous films or membranes. The inventive battery and battery separator is preferably safer and more robust than batteries and battery separators using prior monolayer and tri-layer microporous membranes. Also, described herein is a method for making the multilayer microporous separators, membranes or films described herein.

Owner:CELGARD LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com