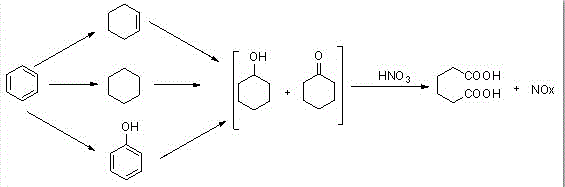

Process for preparing adipic acid through cleaning catalytic oxidation of cyclohexanone, catalyst, and catalyst preparation method

A technology of cyclohexanone and adipic acid, which is applied in the oxidative preparation of carboxylic acid, chemical instruments and methods, catalysts for physical/chemical processes, etc. Effect of specific surface area and overall catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

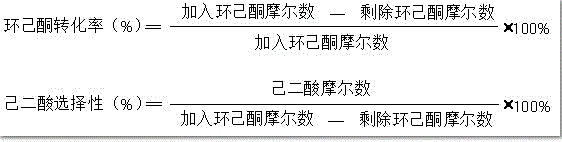

[0018] Example 1: At a temperature of 90° C. and a pressure of 0.6 MPa, air is used as an oxidant, 400 g of cyclohexanone and 1.0 g of catalyst M1-TS are put into a reactor for reaction. The result of reacting for 9 hours was as follows: the conversion rate of cyclohexanone was 31.6%, and the selectivity of adipic acid was 88.3%.

Embodiment 2

[0019] Example 2: At a temperature of 90° C. and a pressure of 0.6 MPa, air is used as an oxidant, 400 g of cyclohexanone and 1.0 g of catalyst M2-TS are put into a reactor for reaction. The result of reacting for 9 hours was as follows: the conversion rate of cyclohexanone was 36.0%, and the selectivity of adipic acid was 92.1%.

Embodiment 3

[0020] Example 3: At a temperature of 90° C. and a pressure of 0.6 MPa, air is used as an oxidant, 400 g of cyclohexanone and 1.0 g of catalyst M3-TS are put into a reactor for reaction. The result of reacting for 9 hours was as follows: the conversion rate of cyclohexanone was 66.7%, and the selectivity of adipic acid was 91.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com