Spiral hole dual-porosity sound absorbing device and application thereof

A sound-absorbing device and dual-porosity technology, which is applied to sound-producing instruments, instruments, etc., can solve the problems that the effective sound-absorbing frequency bandwidth is not as good as that of porous materials, the thickness of the back cavity is increased, and the low-frequency sound-absorbing effect is poor, so as to achieve a good application prospect. , the effect of promoting diffusion and increasing tortuosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

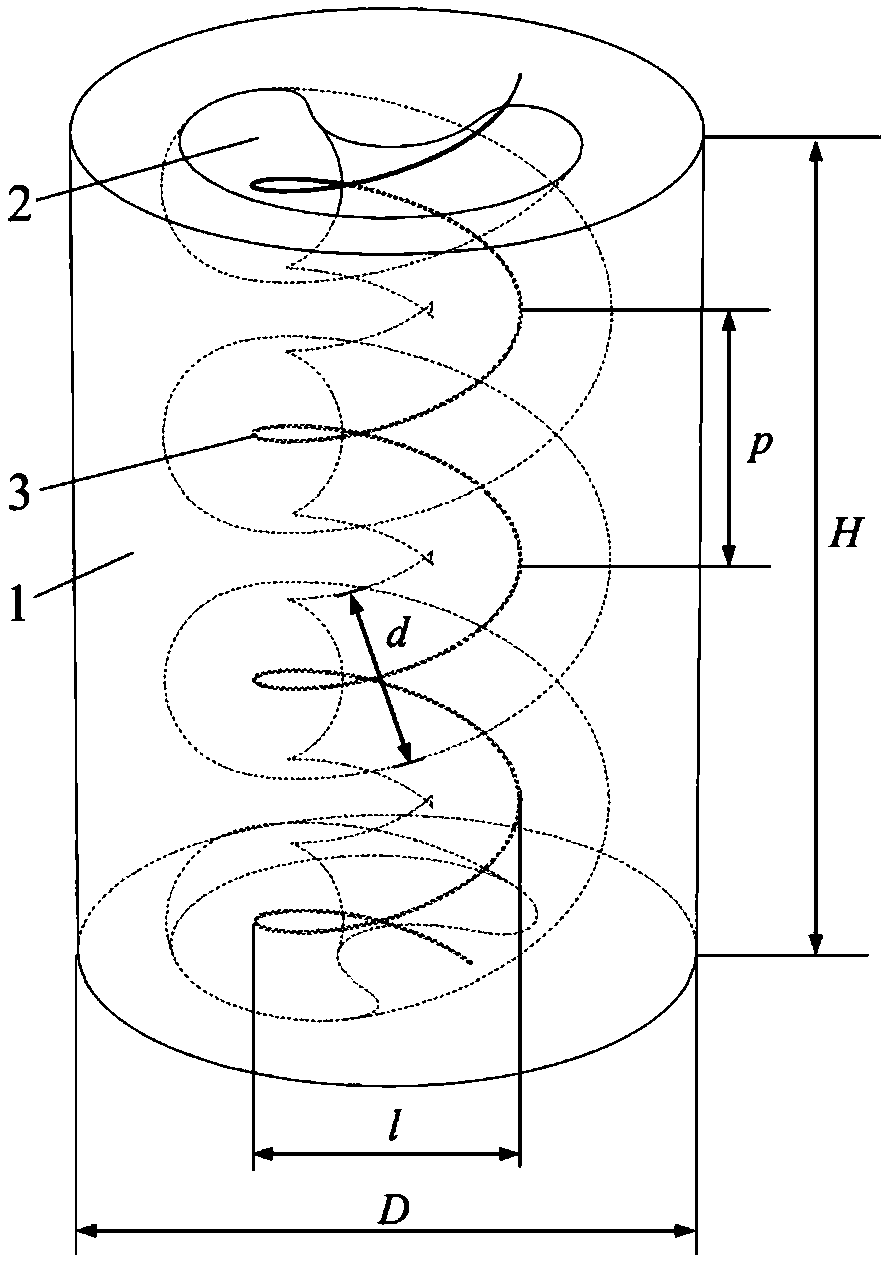

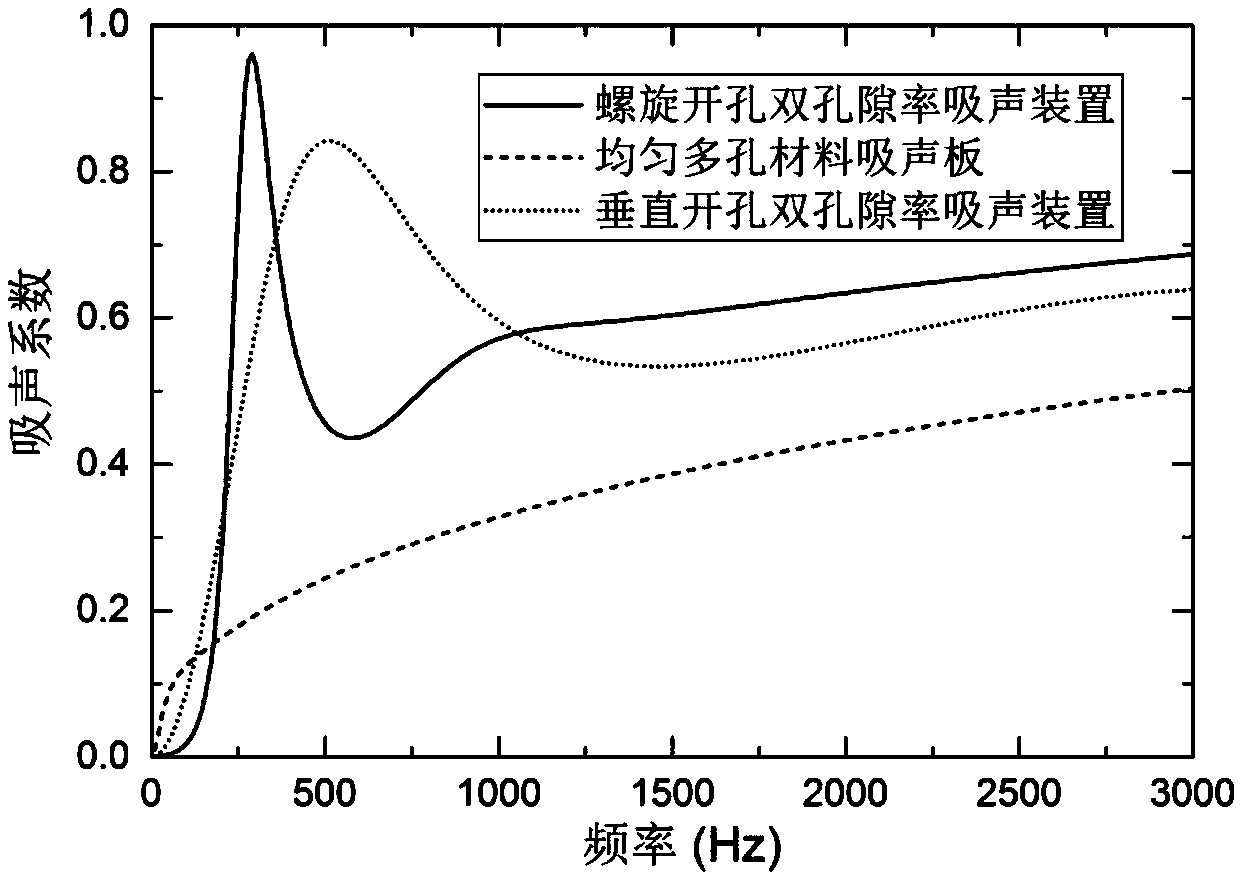

[0053] see figure 1 Cells in and figure 2 In the sound absorption curve of the unit cell, a spiral hole 2 is set in a porous material substrate 1 with a total height H of 50mm and a diameter D of 35mm. The porosity of the substrate porous material is 90%, and the flow resistance rate is 489336N·s / m 2 , the viscous characteristic length is 19.7 μm, the thermal characteristic length is 36 μm, and the tortuosity is 1.05; the helical hole 2 is opened with the helix 3 as the guide, and the helical hole 2 is circular in the direction perpendicular to the helix 3, and the diameter of the circle is The aperture d of the spiral hole is 10mm, the spiral radius l of the spiral 3 is 15mm for this spiral diameter, the pitch p of the spiral 3 is 15mm, and the opening ratio of the spiral hole 2 (the total volume of the opening accounts for the base The total volume) is 26.5%; the lower end of the sound-absorbing device is placed on a rigid backing to simulate the situation where the desi...

Embodiment 2

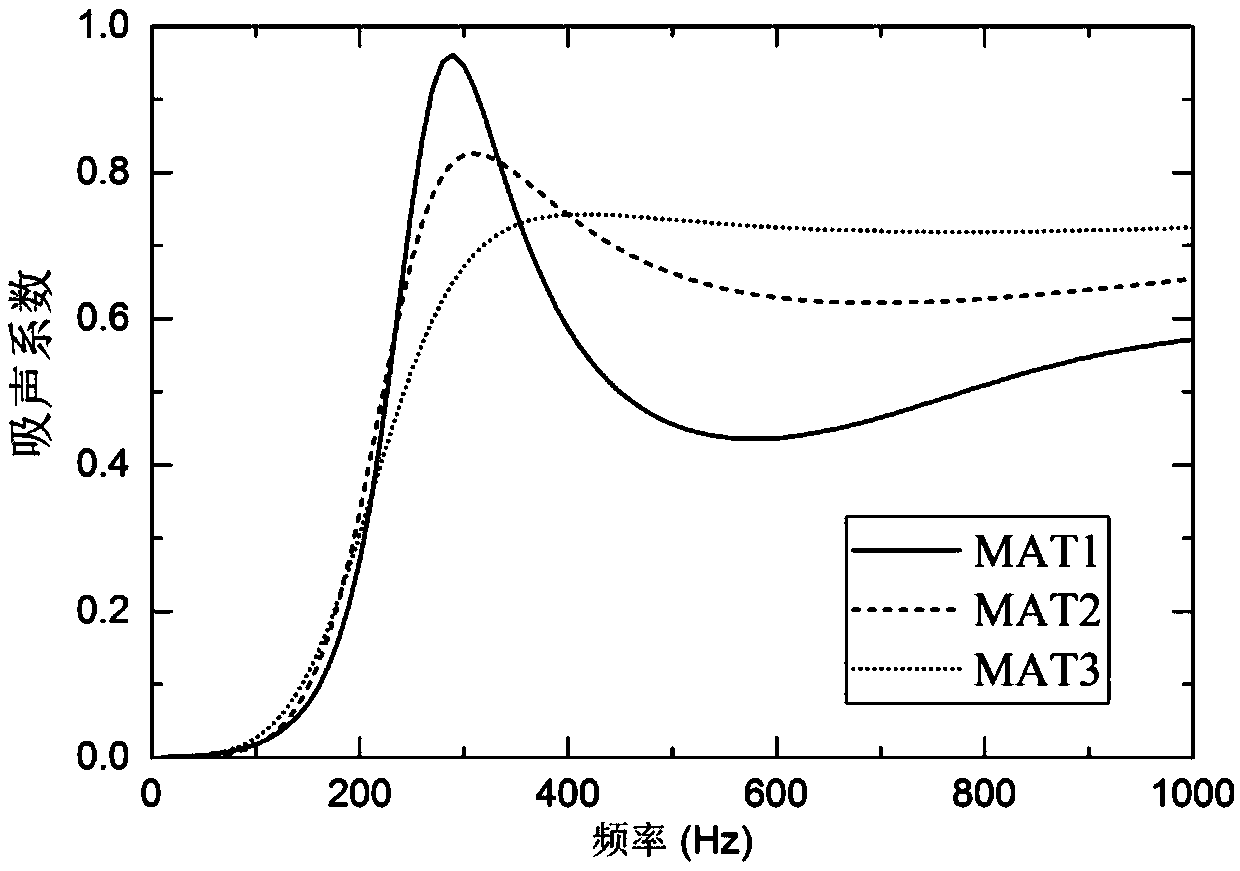

[0056] see Figure 3 to Figure 7 , with the material parameters and structural parameters in Example 1 as default values, using the single variable method, the influence of different substrate porous materials and structural dimensions on the sound absorption coefficient of the invented spiral opening double-porosity sound-absorbing device is given; image 3 The parameters of the three porous materials are: porous material MAT1, the porosity is 90%, and the flow resistance is 489336N·s / m 2 , the viscous characteristic length is 19.7μm, the thermal characteristic length is 36μm, and the tortuosity is 1.05; the porous material MAT2 has a porosity of 99% and a flow resistance of 200000N·s / m 2 , the viscous characteristic length is 17.48μm, the thermal characteristic length is 34.96μm, and the tortuosity is 1; the porous material MAT3 has a porosity of 94% and a flow resistance of 135000N·s / m 2 , the viscous characteristic length is 49 μm, the thermal characteristic length is 166...

Embodiment 3

[0063] see Figure 8 The schematic diagram of the cells in , in the porous material substrate 1, there are intertwined and connected double helical holes, the height of the substrate material is 50mm, and the diameter is 50mm; the porosity of the porous material of the substrate is 90%, and the flow resistance rate is 489336N·s / m 2 , the viscous characteristic length is 19.7 μm, the thermal characteristic length is 36 μm, and the tortuosity is 1.05. The two helical holes 2 provided are the same, the apertures are 10mm, the helical diameter of the corresponding helix is 30mm, and the pitch is 30mm, and the two helical holes are connected to each other by three connected straight holes 4 with a diameter of 8mm. Connected to further increase the contact area between the opened holes and the porous material, at this time the porosity is 30%. The sound absorption coefficient of embodiment 2 of the present invention sees Figure 9 . Compared with porous material boards with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com