Membrane cavity coupling type underwater acoustic board

A coupling-type, sound-absorbing panel technology, which is applied in the direction of sound-generating devices and instruments, can solve the problems of not proposing an underwater low-frequency sub-wavelength sound-absorbing structure, and the effect of lower-frequency sound waves is not good, so as to achieve good broadband sound-absorbing ability and improve Effects of low-frequency sound absorption performance and uniform viscoelastic sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

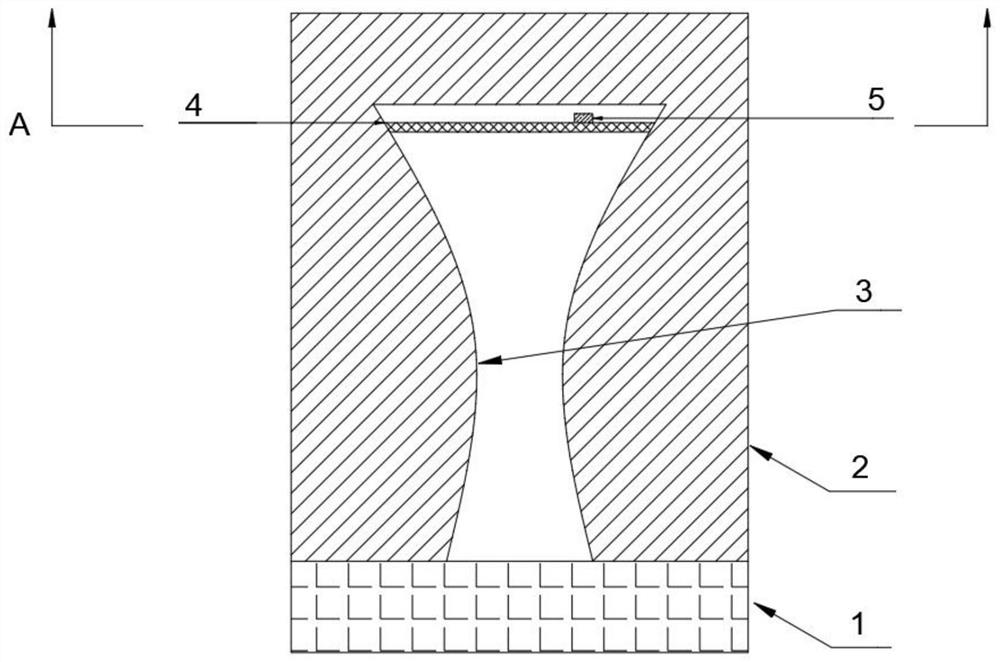

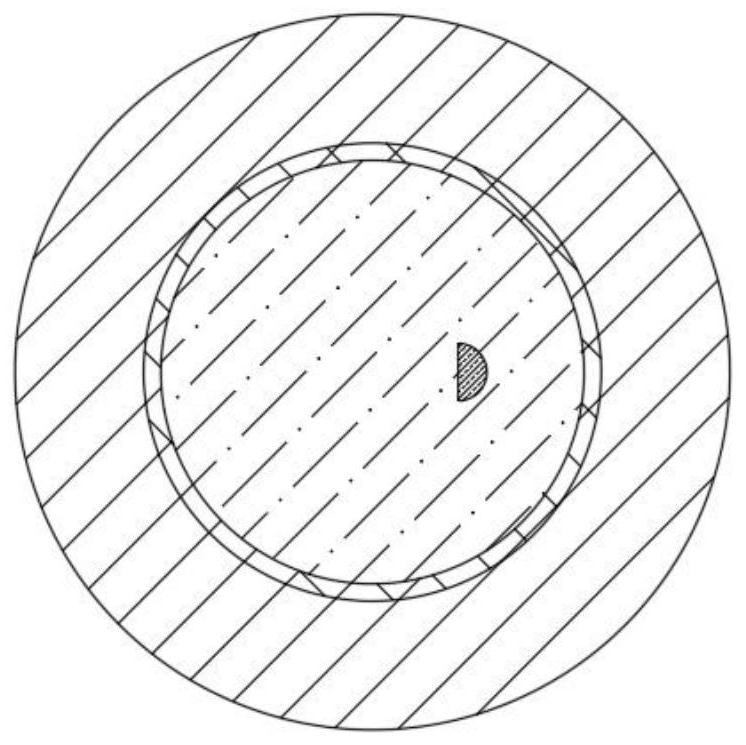

[0027] Combine below Figure 1-3 To illustrate this embodiment, the present invention relates to an underwater low-frequency sound-absorbing structure, specifically a cavity-coupled underwater sound-absorbing panel, including an installation layer 1, a sound-absorbing layer 2, and a structural cavity 3. The sound-absorbing structure In the frequency range of 3000Hz, the average sound absorption coefficient can be more than 0.7.

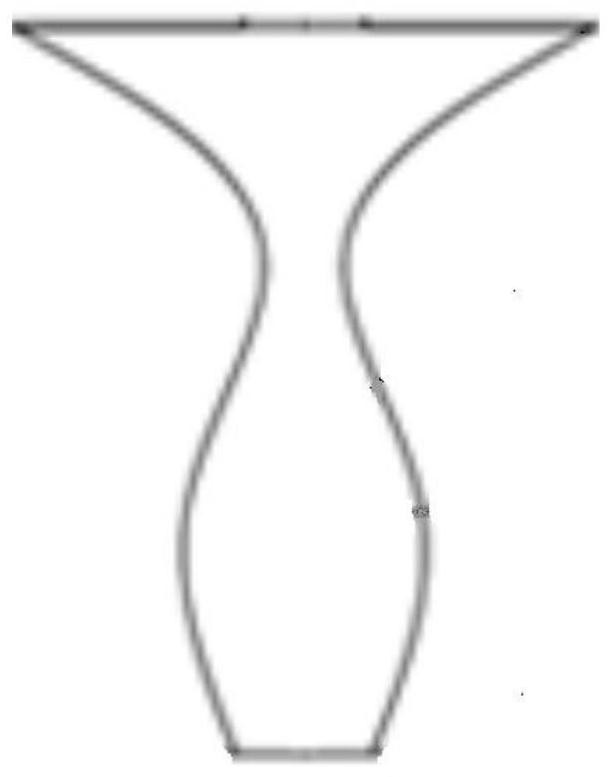

[0028] The sound-absorbing layer 2 and the installation layer 1 are press-fitted and bonded, and the interior of the sound-absorbing layer 2 is provided with a plurality of structural cavities 3, and the structural cavities 3 are double trumpet-shaped or vase-shaped with gradually changing apertures. One or a combination of both, the lower surface of the structural cavity 3 is flush with the bottom surface of the sound-absorbing layer 2 , a thin film structure 4 is arranged in the structural cavity 3 , and an asymmetric mass block 5 is arranged on the...

specific Embodiment approach 2

[0030] Combine below Figure 1-3 This embodiment will be described. This embodiment will further describe the first embodiment. The sound-absorbing layer 2 is made of a viscoelastic damping material.

specific Embodiment approach 3

[0032] Combine below Figure 1-3 This embodiment will be described, and this embodiment will further describe the second embodiment, the elastic damping material is polyurea. A new generation of materials is selected as the base material to match the acoustic impedance of water, which ensures the impedance matching of the cavity structure and the water contact side, while taking into account the uniform viscoelastic sound absorption performance, water resistance and corrosion resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com