Patents

Literature

49results about How to "Excellent low frequency sound absorption performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

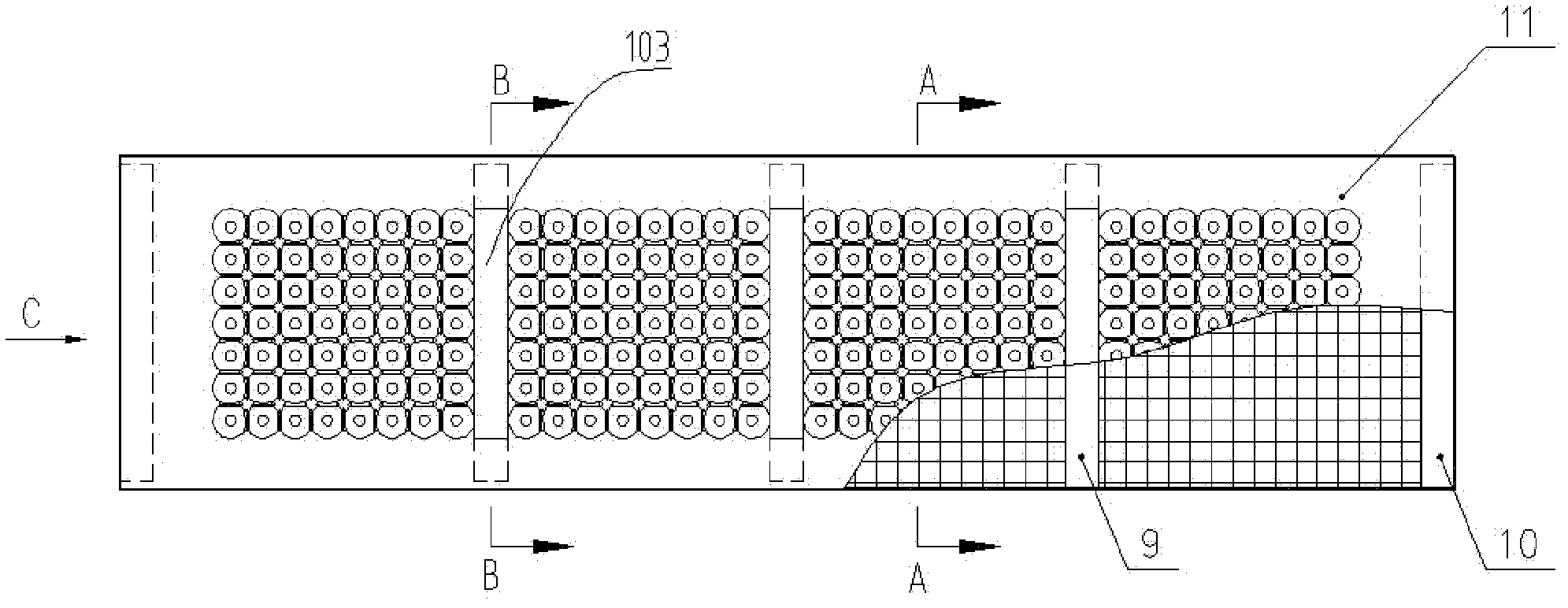

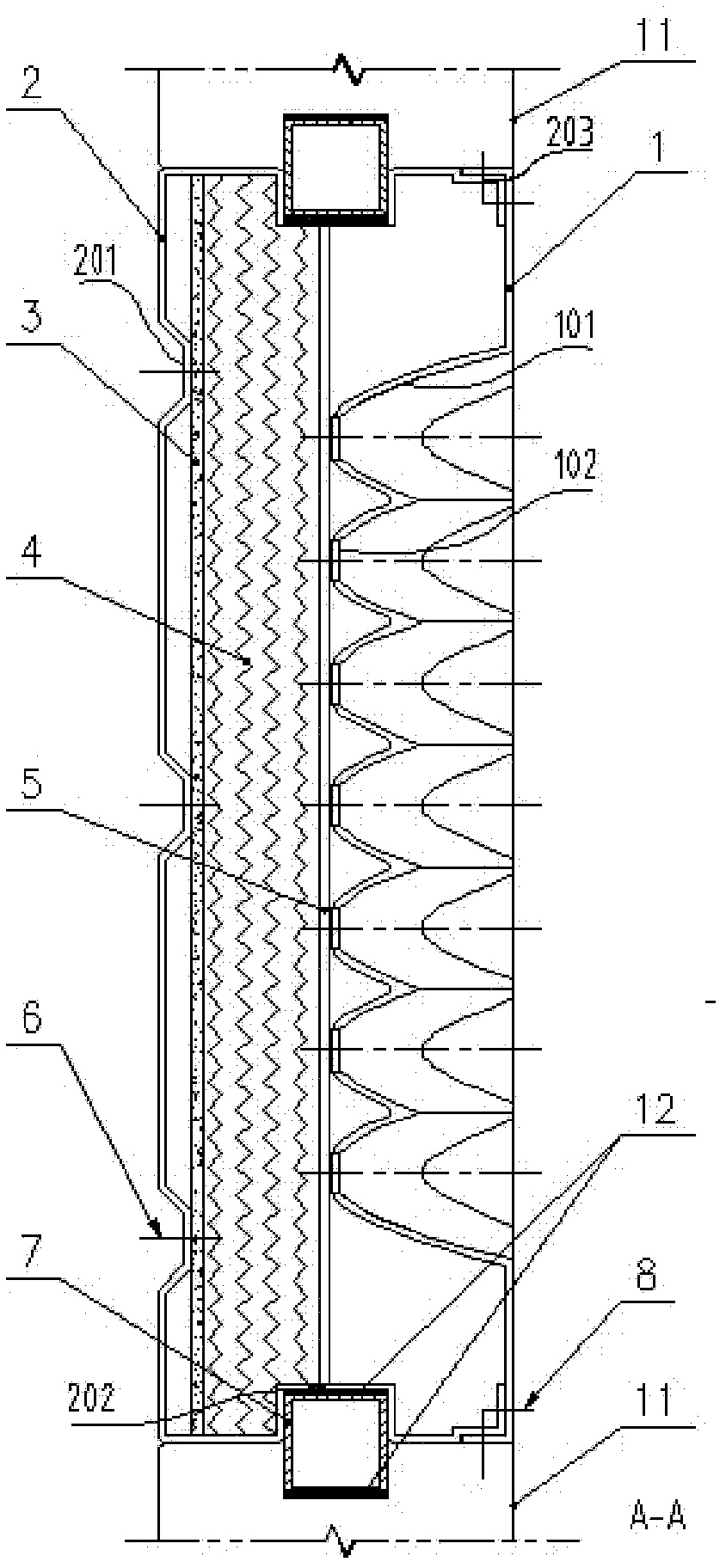

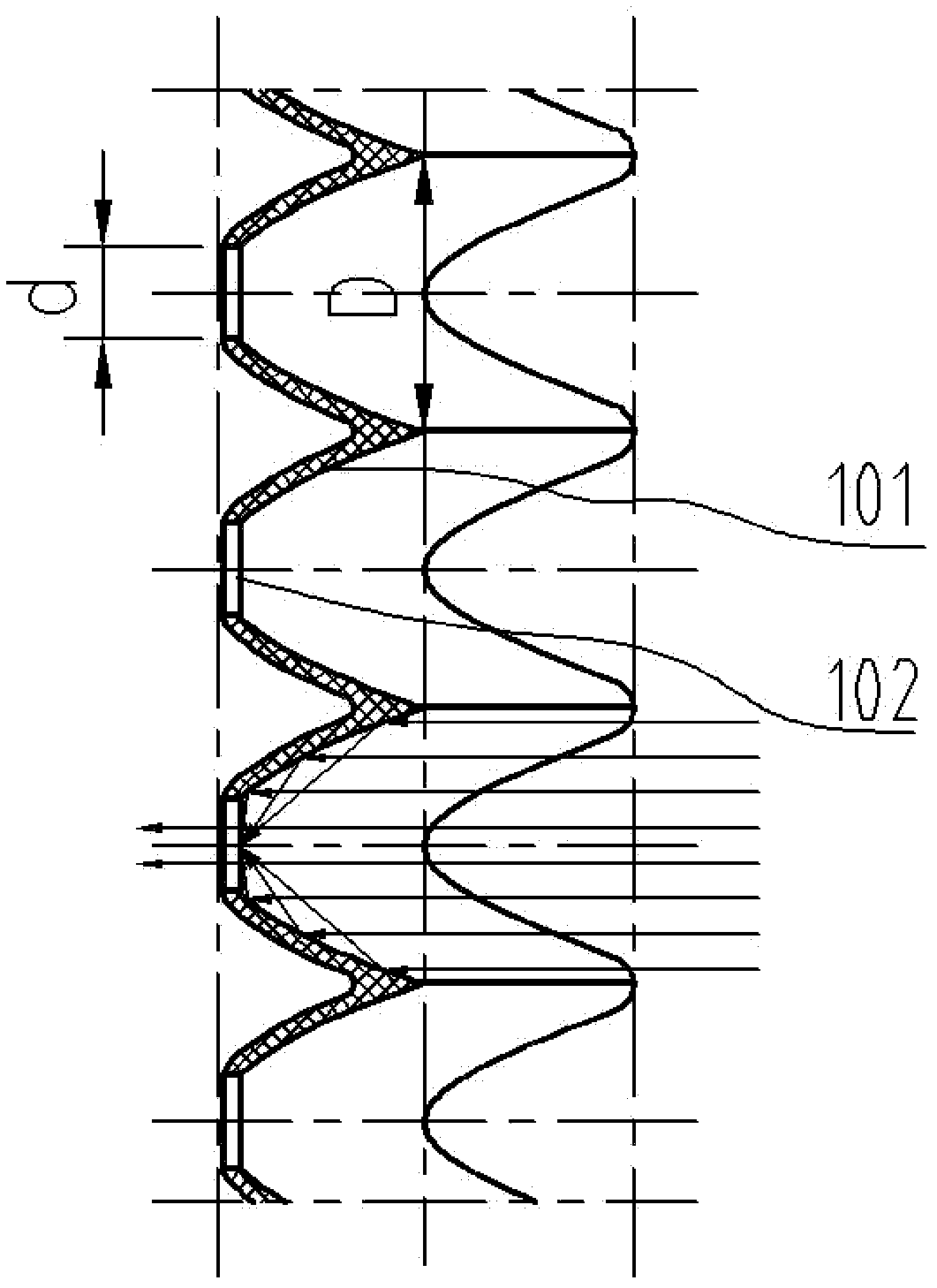

Cup-shaped noise reduction and sound absorption member

ActiveCN102926334AImprove sound absorptionAchieve Impedance MatchingNoise reduction constructionWoolEngineering

The invention belongs to the technical field of a sound barrier acoustic member, and specifically relates to a cup-shaped noise reduction and sound absorption member of a sound barrier. The cup-shaped noise reduction and sound absorption member is composed of a plurality of cup-shaped noise reduction and sound absorption member units, wherein a panel of each unit is composed of a plurality of rectangular arrays and trapezoidal transverse bars; each rectangular array is composed of a plurality of uniformly distributed reflector cups with a paraboloid-shaped acoustic construction; diffraction holes are formed in the bottom of each reflector cup; a rectangular connecting groove is respectively arranged in the longitudinal center on the upper surface and the lower surface of a back plate of each unit; the connecting groove and the rectangular connecting grooves of other sound absorption member units in the same position form a square cavity during installation, wherein a square steel pipe is embedded in the cavity as a connecting piece for clamping two adjacent cup-shaped noise reduction and sound absorption member units; a sound insulation plate is mounted in a tubular cavity which is formed by connecting the panel and the back plate; support frames are arranged on the transverse bars inside the cavity; and spaces divided by the support frame are filled with sound absorption wools and gauzes. The cup-shaped noise reduction and sound absorption member has stronger sound absorption ability, and the low-frequency sound absorption ability is improved.

Owner:秦皇岛耀华装备集团股份有限公司

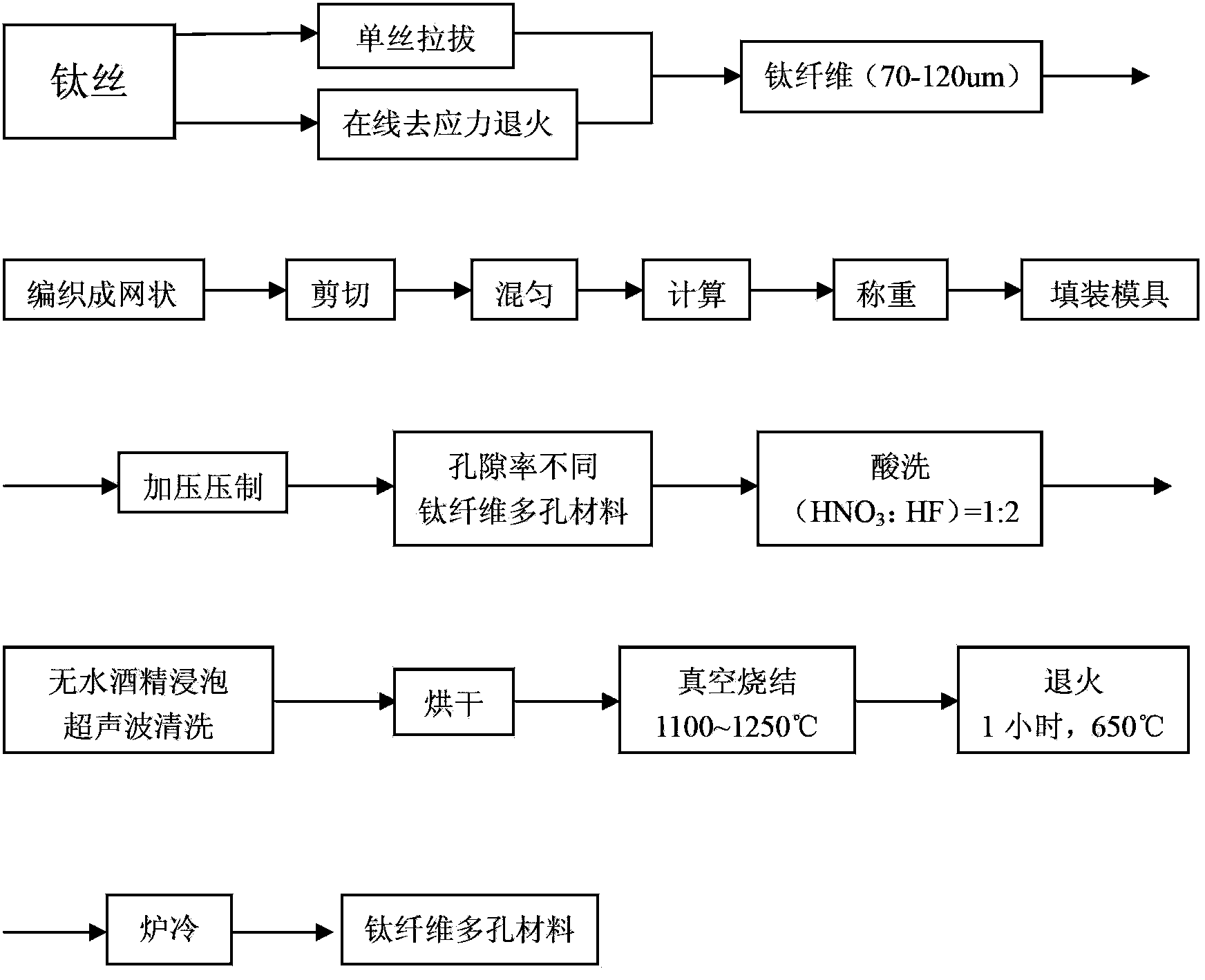

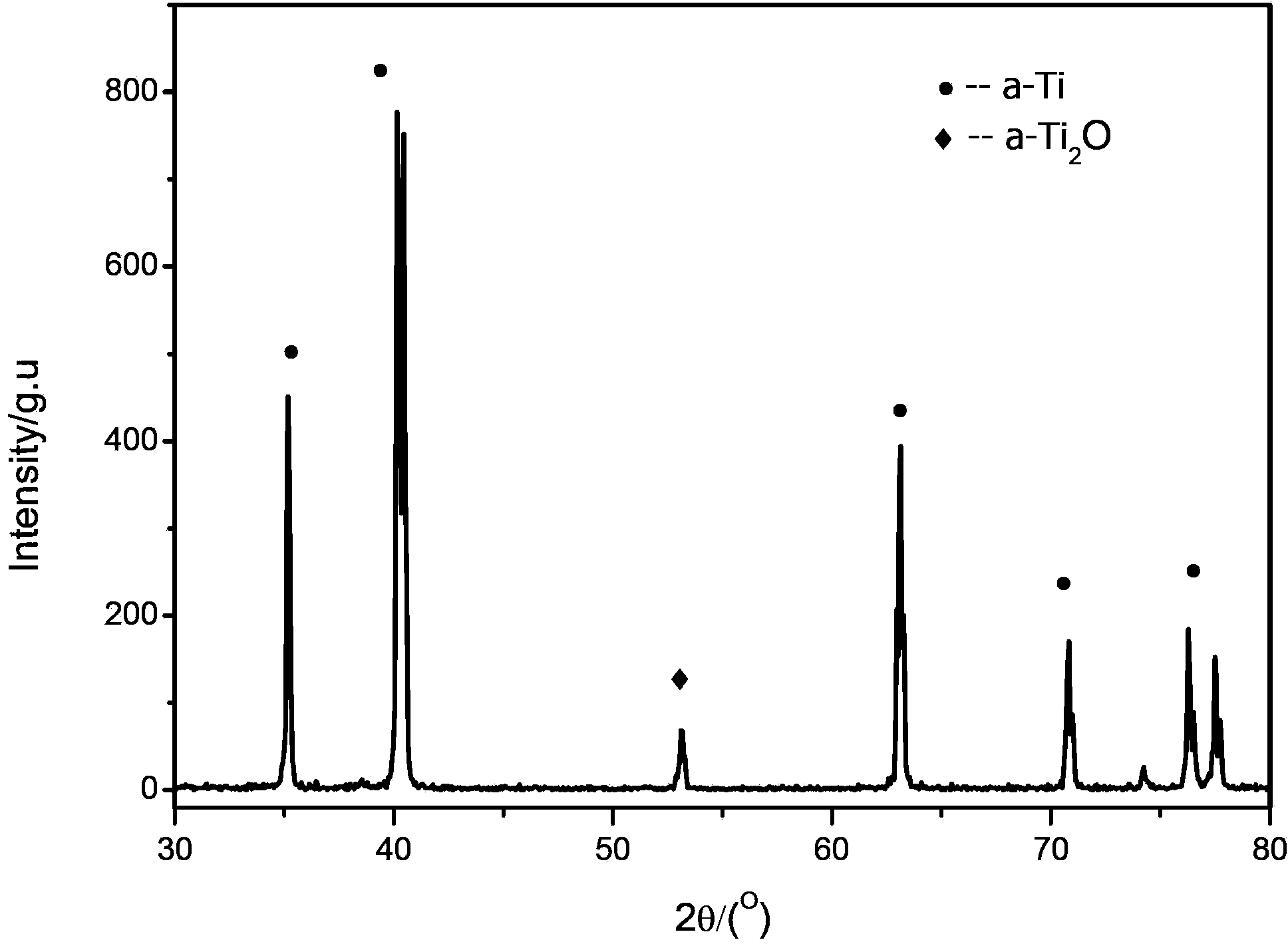

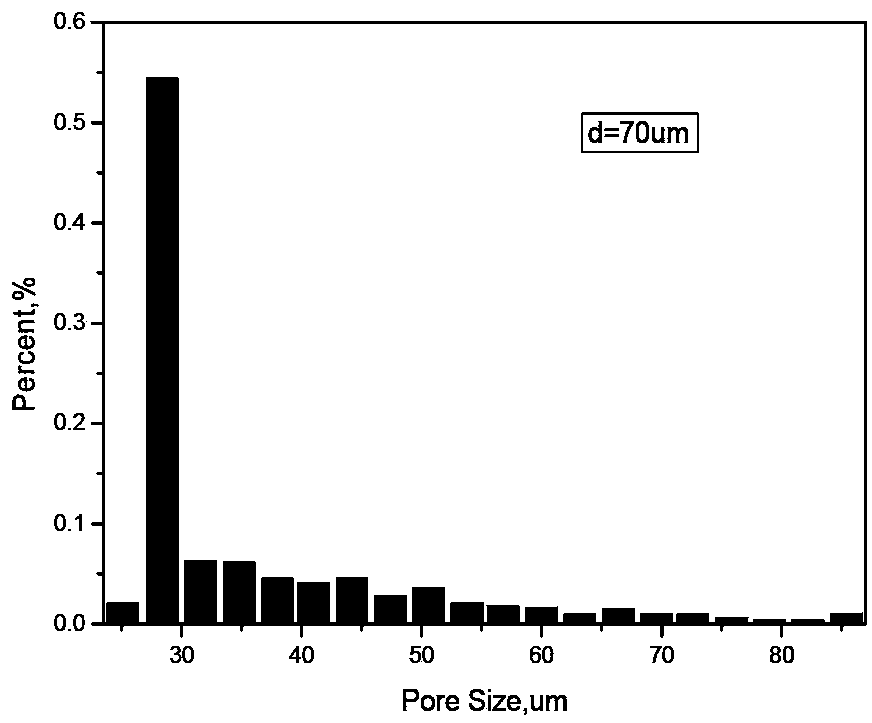

Preparation method of titanium fiber porous material

The invention provides a preparation method of a titanium fiber porous material, which has controllable fiber diameter and porosity. The material is prepared by: drawing a titanium wire into a fibrous state, and then carrying out weaving and compression molding. After the material is prepared, pickling is conducted to remove of the oxide on the surface of the titanium fiber porous material, and then the material is subjected to high temperature sintering by a vacuum sintering furnace. By means of the method provided in the invention, a sintered titanium fiber porous material can be obtained, and all properties of the titanium fiber porous material are greatly improved. Thus, the method provides an important basis for realization of product industrialization.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

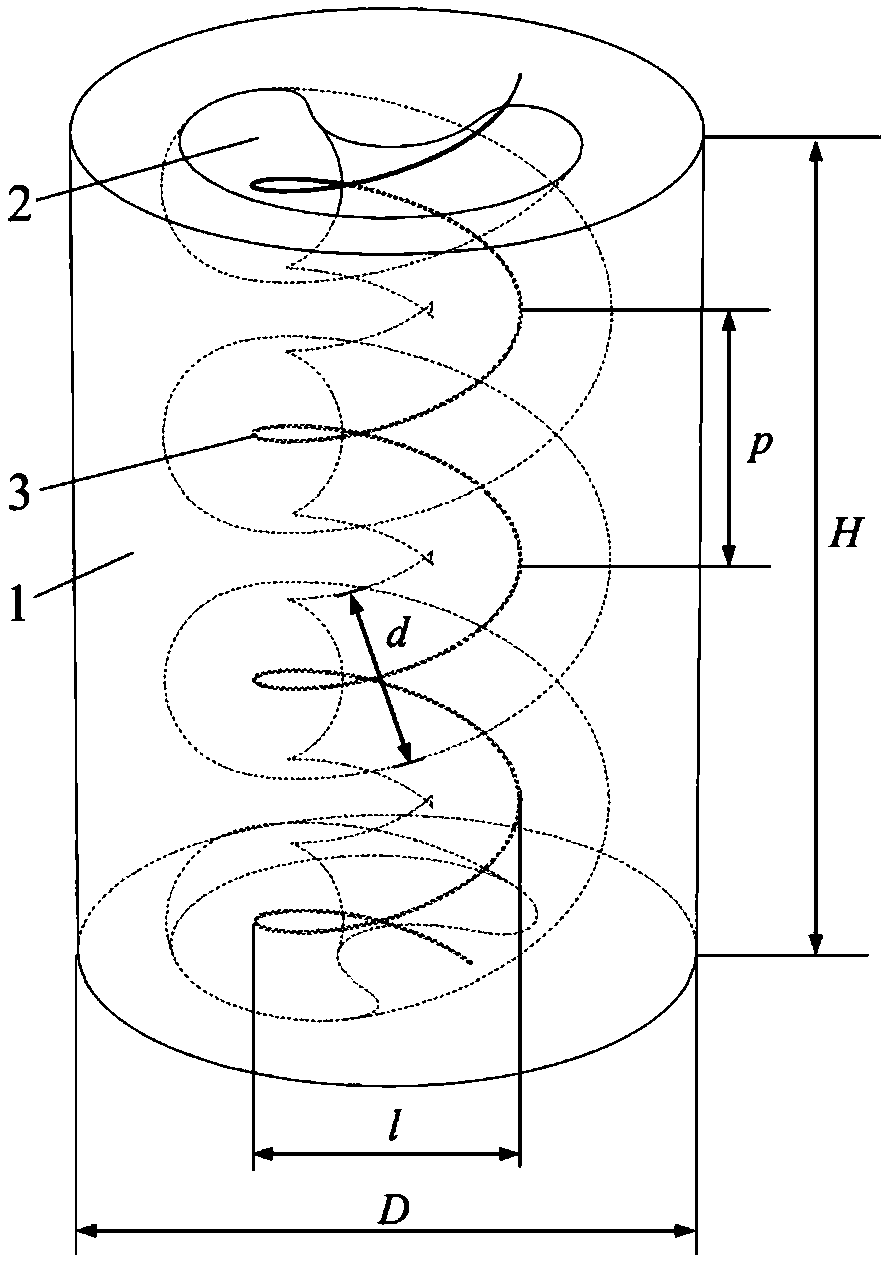

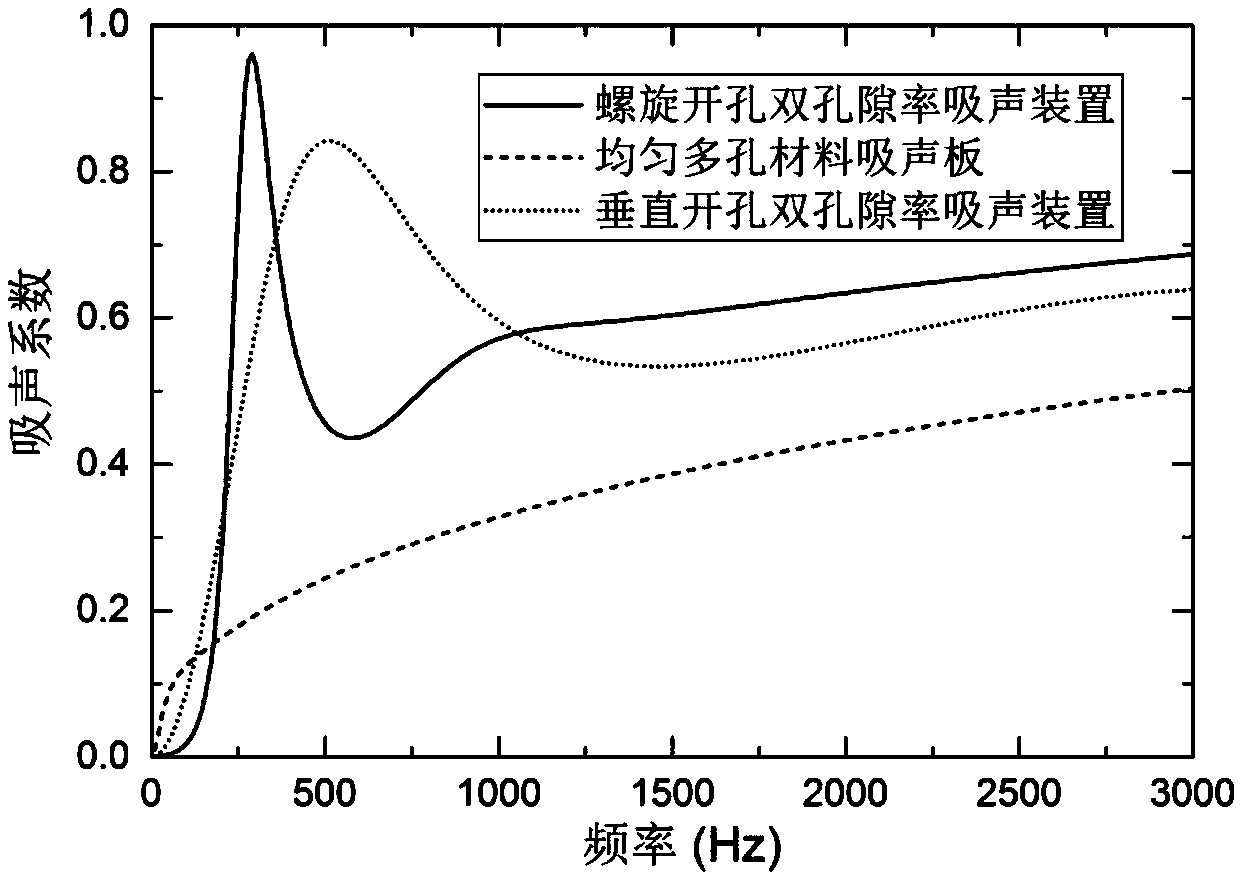

Spiral hole dual-porosity sound absorbing device and application thereof

PendingCN109686354AImprove low-frequency sound absorption performanceExcellent low frequency sound absorption performanceSound producing devicesPorositySound energy

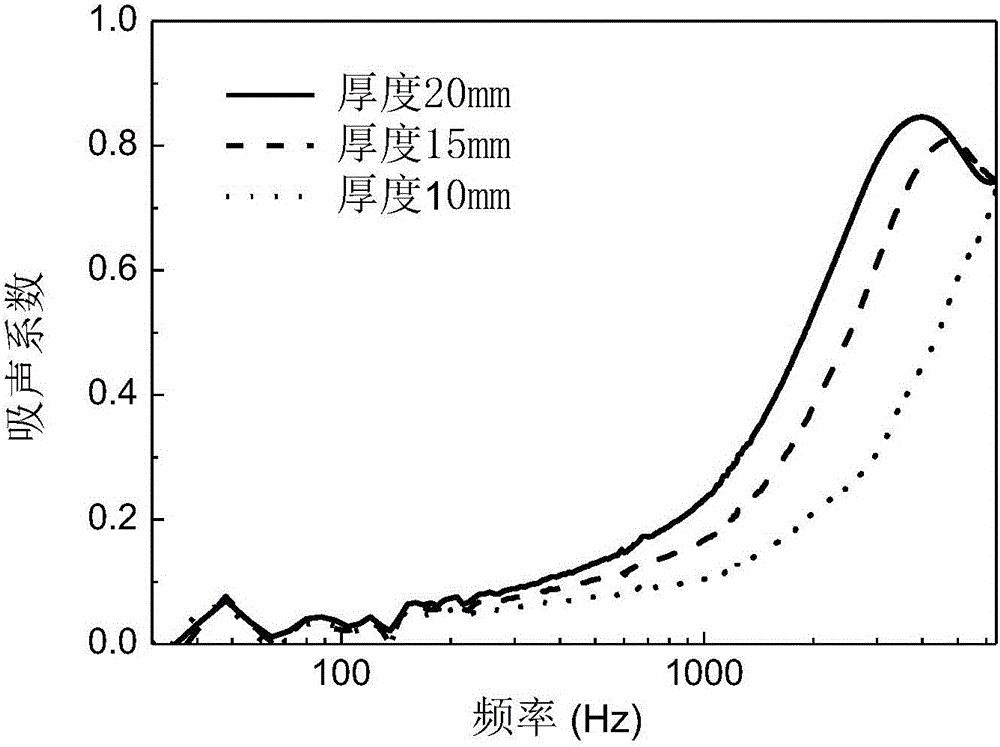

The invention discloses a spiral hole dual-porosity sound absorbing device and application thereof. The device is realized by forming a spiral hole in a substrate of a porous material, and the sinuosity of wound waves entering the porous material is greatly improved by a spiral channel. The sound waves first enter the spiral hole at a low frequency band and then enter micro pores of the porous material via the spiral hole. By utilizing sound energy dissipation brought by strong coupling of the wound waves between the spiral hole formed in the porous material and the micro pores of the porous material, the low-frequency sound absorption property of the sound absorbing material in the invention is enhanced. Moreover, by combining the consistently good high-frequency sound absorption propertyof the porous material, the spiral hole dual-porosity sound absorbing device disclosed by the invention can reach a sound absorption peak value at an ultralow frequency under the condition that the thickness is small, and also has a certain medium-high frequency sound absorbing ability. The device disclosed by the invention is simple in structure and practical and has excellent and wide application prospects.

Owner:XI AN JIAOTONG UNIV

Polygon structure composite acoustic board based on negative mass

InactiveCN105109147AHigh specific strengthHigh specific stiffnessSynthetic resin layered productsMetal layered productsEpoxyNegative mass

The invention discloses a polygon structure composite acoustic board based on the negative mass. The board comprises polygon structure layers which have the negative mass effect in the Z direction, the polygon structure layers are bonded to the two sides of an intermediate layer through bonding layers, so that an integral whole is formed, the intermediate layer is made of ethylene-vinyl acetate copolymer, silicone rubber or latex, the bonding layers are made of two-component epoxy resin adhesive, and the polygon structure layers are made of aluminum alloy or other light-weight alloy materials and metal materials. By means of the polygon structure layers of the negative mass effect, the integral structure is high in specific strength, specific rigidity and shear modulus, impact-resistant and heat-insulative, the good low-frequency sound absorption performance is achieved, what is more important, the surface density of the integral structure is low, the structure is simple, the board has the advantages of being easy to process and manufacture and convenient to achieve, the whole performance of equipment is not affected, and meanwhile requirements of vibration damping and noise reduction can be met.

Owner:XI AN JIAOTONG UNIV

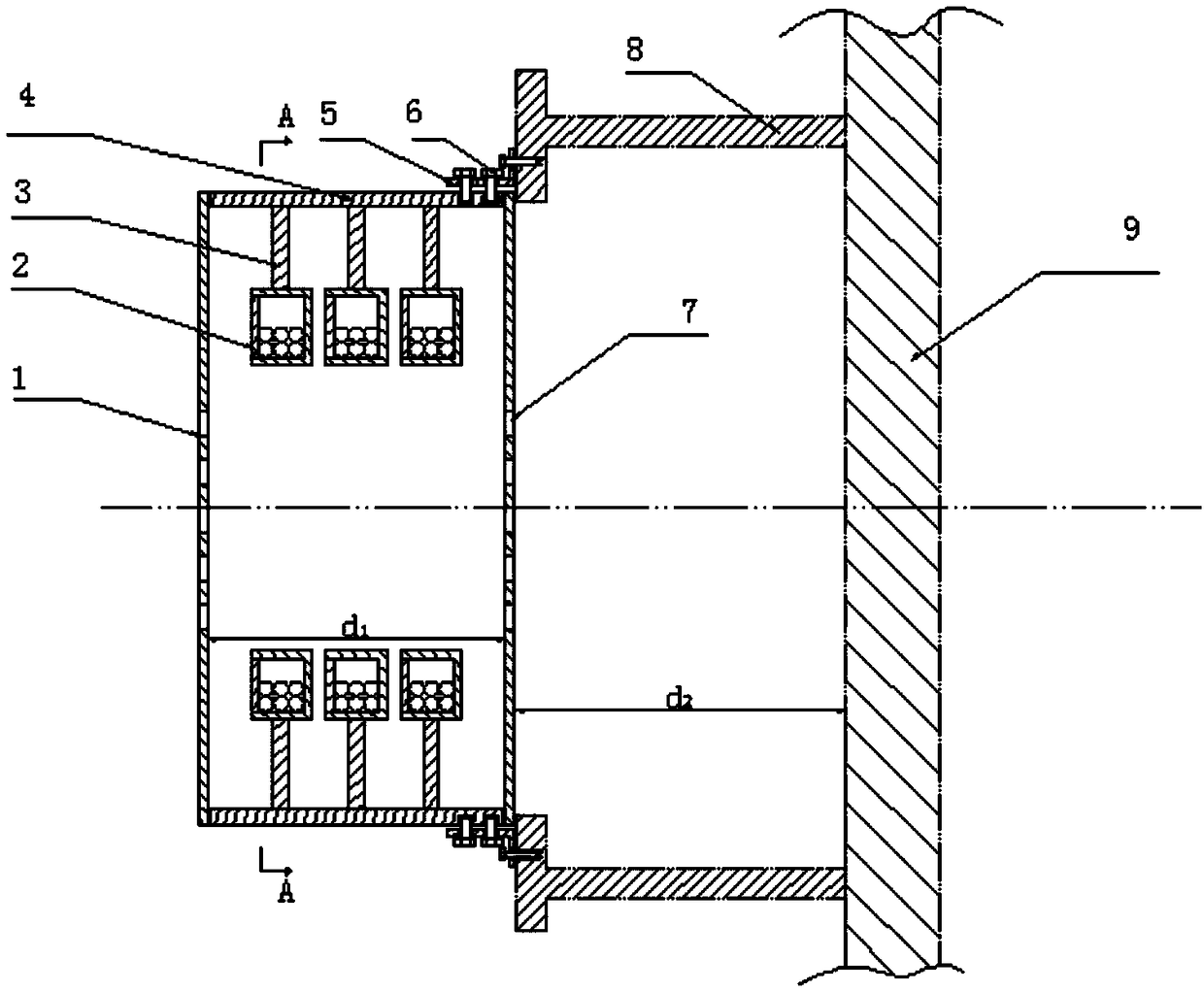

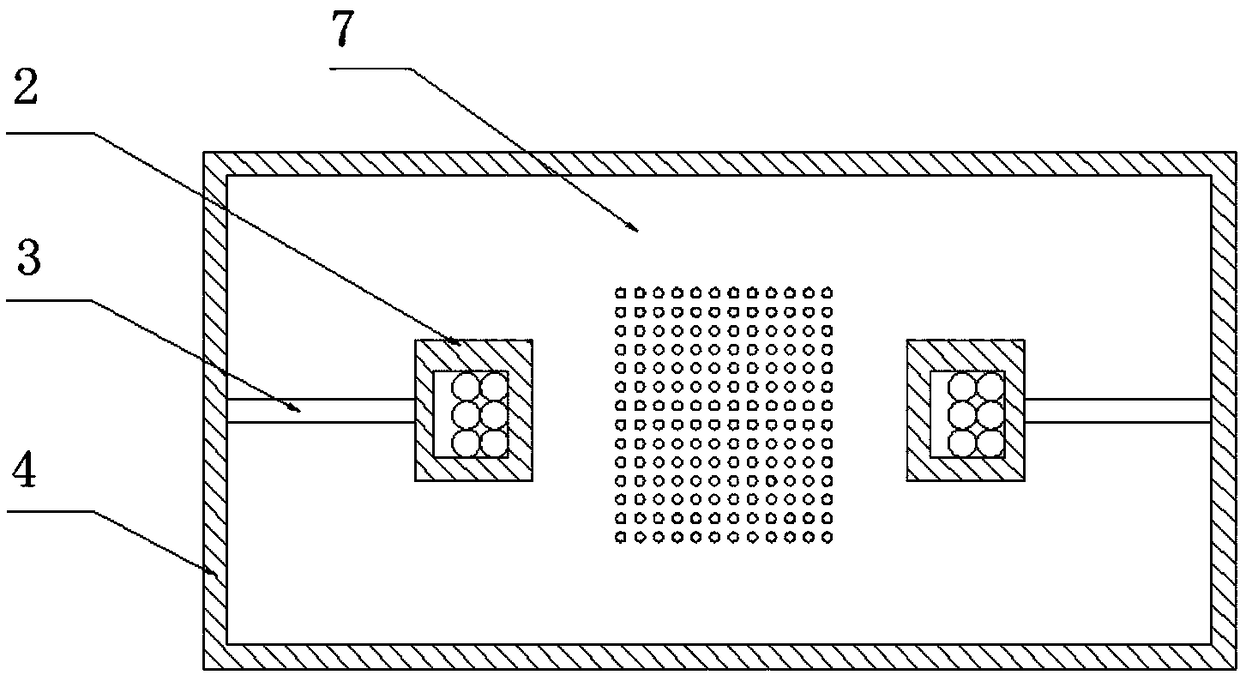

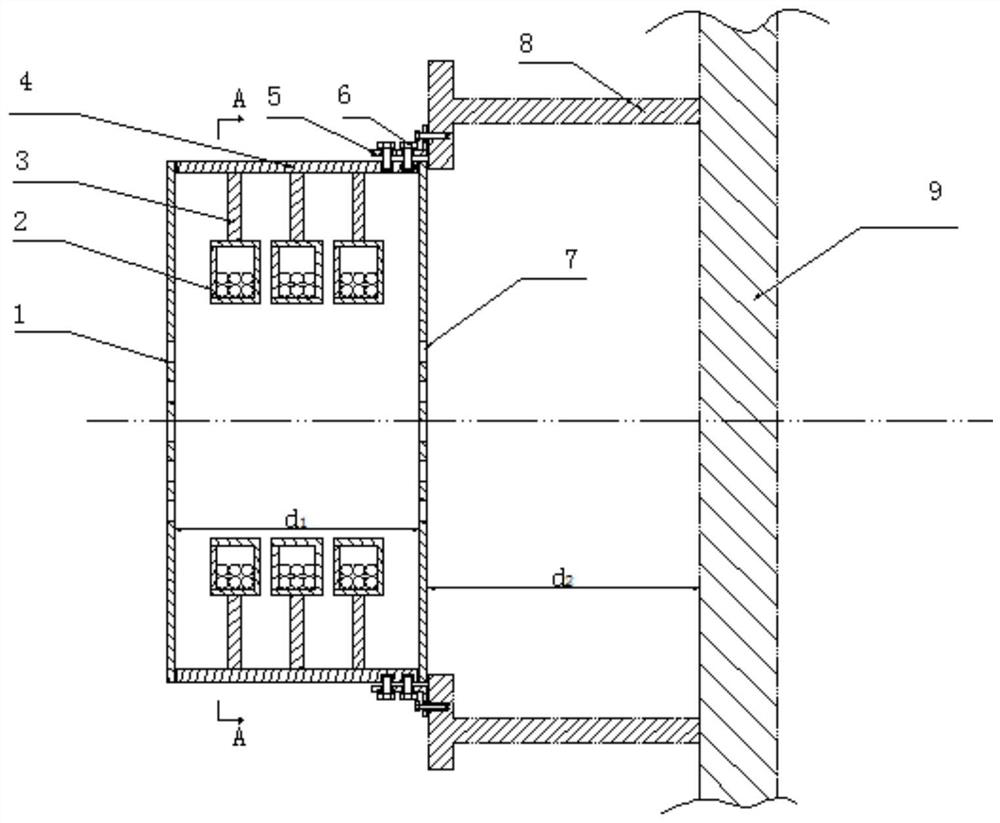

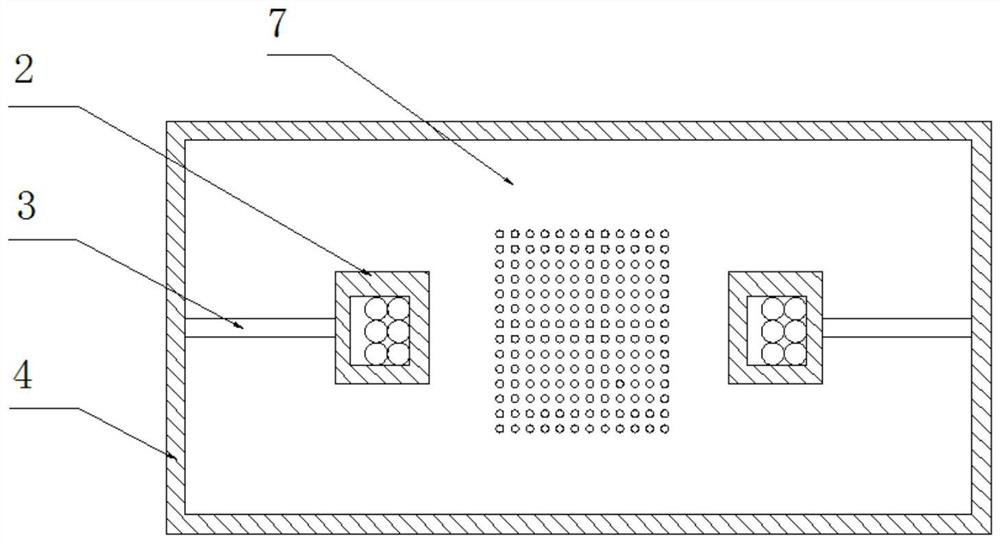

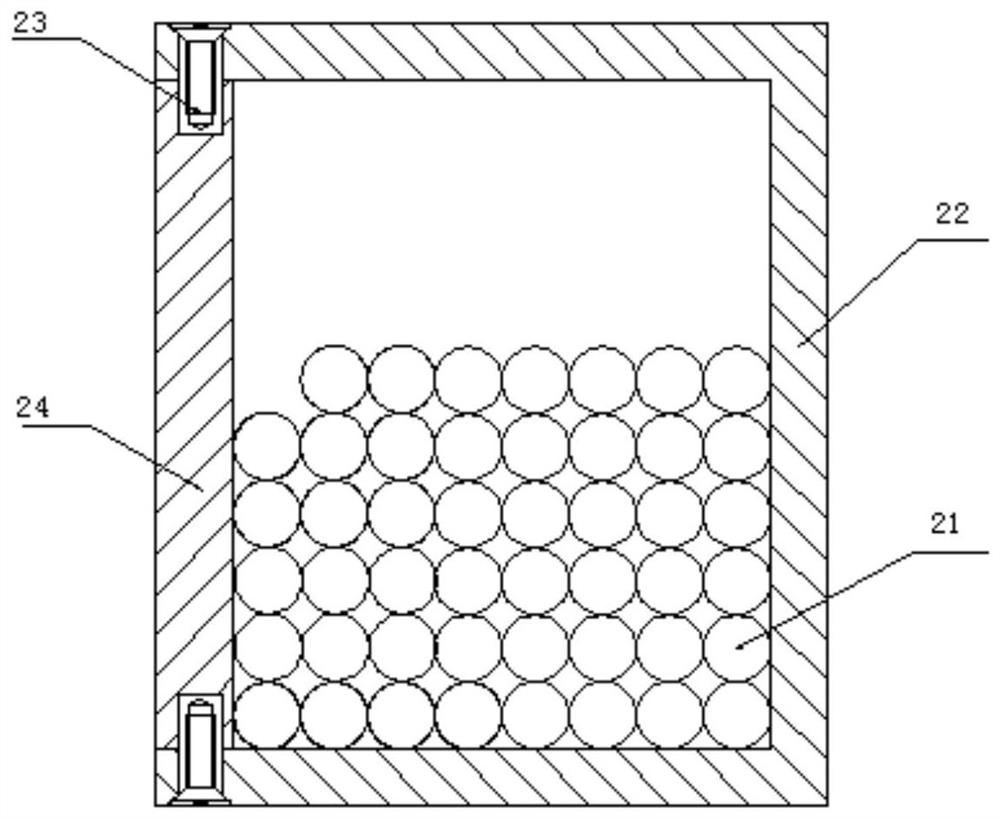

A composite structural member for reducing noise and vibration in a ship cabin

ActiveCN109018193AReduce vibrationEnhanced Damping ControlHull panellingsMicro perforated plateWorking environment

The invention discloses a composite structural member for reducing noise and vibration in a ship cabin., The member comprises a outer layer micro-perforated plate, a framework and an inner layer micro-perforated plate, all of which are connected through connecting parts and enclosing walls for a chamber. The outer layer micro-perforated plate and the inner layer micro-perforated plate are fixedlyconnected and combined into a double-layer micro-perforated cavity through a frame, and a plurality of rows of multi-layer particle dampers are fixedly connected on two side walls corresponding to the frame in the cavity through elastic connecting rods. The outer layer micro-perforated plate and the inner layer micro-perforated plate are fixedly connected to each other through a frame. The invention can optimize the sound absorption coefficient of the micro-perforated plate without changing the cabin structure, broaden the sound absorption frequency band, improve the sound absorption effect,reduce the vibration of the cabin structure, and create a good cabin working environment. Moreover, the invention has the advantages of compact structure and convenient installation. It has a good prospect of engineering application.

Owner:JIANGSU UNIV OF SCI & TECH

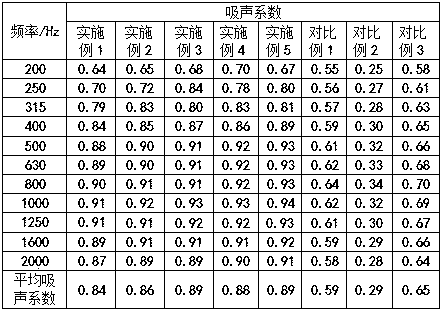

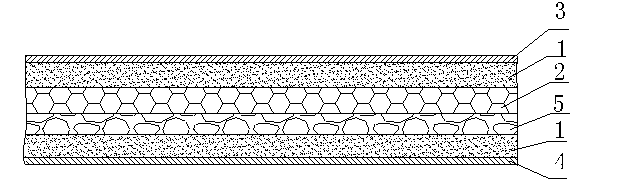

Layered structural composite material for low-frequency sound absorption and preparation method of layered structural composite material

InactiveCN107283950AExcellent low frequency sound absorption performanceSynthetic resin layered productsBarium titanateMaterials processing

The invention belongs to the field of material processing, and particularly relates to a layered structural composite material for low-frequency sound absorption and a preparation method of the layered structural composite material. The method comprises the following steps: mixing and ball milling barium titanate powder and a titanate coupling agent to obtain modified barium titanate powder; mixing and vulcanizing ZnO, stearic acid, zinc stearate, magnesium oxide, anti-aging agent, accelerant TMTD, accelerant CZ, conducting carbon black, modified barium titanate powder and sulfur, and obtaining a piezoelectric composite material; and compounding the piezoelectric composite material and polyurethane foam by utilizing a binder to obtain the layered structural composite material according to a structure that an intermediate layer is formed by polyurethane foam, and two sides are formed by the piezoelectric composite material. The piezoelectric composite material and the polyurethane foam are used as a sound absorption material structure, so that by utilizing a synergistic effect of a piezoelectric effect and porous foam, the layered structural composite material obtains an excellent low-frequency sound absorption effect in the case of smaller material thickness.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Lightweight noise reduction composite foam material and method for preparing same

The invention discloses a lightweight noise reduction composite foam material and a method for preparing the same. The lightweight noise reduction composite foam material comprises, by weight, 42-62 parts of polyvinyl chloride, 14-23 parts of rock wool, 7-15 parts of styrene butadiene rubber, 10-20 parts of glass micro-spheres, 2-8 parts of glass fibers, 0.5-1.5 parts of foaming agents, 0.3-0.8 part of lubricants, 0.2-0.6 part of antioxidants and 0.5-0.9 part of coupling agents. The lightweight noise reduction composite foam material and the method have the advantages that the lightweight noise reduction composite foam material which is a foamable polyvinyl chloride and inorganic matter mixed sound absorption material prepared by the aid of the method is lightweight and is high in strength, and good sound absorption effects can be realized by the lightweight noise reduction composite foam material; low-frequency sound absorption of foamable polymers can be improved by the aid of the excellent low-frequency sound absorption performance of inorganic materials, and the low and medium-frequency sound absorption performance of the lightweight noise reduction composite foam material canbe greatly improved by the added rock wool; the polyvinyl chloride can be reinforced by the glass fibers and is filled with the glass micro-spheres, and effects of integrally reducing the density of polyvinyl chloride composite materials can be realized by hollow structures of the glass micro-spheres.

Owner:合肥卓创新材料有限公司

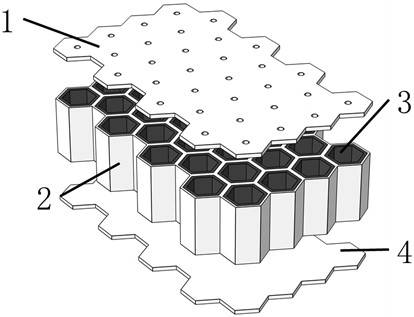

Underwater sound absorption structure of damping lining hierarchical honeycomb perforated plate

ActiveCN111739501AExcellent low frequency sound absorption performanceBroaden the sound absorption bandwidthSynthetic resin layered productsSound producing devicesUnderwaterHoneycomb

The invention provides an underwater sound absorption structure of a damping lining hierarchical honeycomb perforated plate. A perforated upper panel, a hierarchical honeycomb layer core and a lower panel are welded or glued to form a plurality of honeycomb resonant cavity units, and damping lining layers are adhered to the side walls and the bottom surfaces of a central honeycomb resonant cavityunit and node honeycomb resonant cavity units, so that the acoustic impedance characteristic of the structure is improved, and the low-frequency sound absorption performance of the structure is improved. On the premise that good low-frequency underwater sound absorption performance is achieved, the structural weight is reduced, and the structural bearing performance is guaranteed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Preparation of sisal fiber porous material capable of improving high, medium and low frequency sound absorption performance

InactiveCN106351075AIncrease surface areaExcellent low frequency sound absorption performancePulp properties modificationAcoustic absorptionPolyurethane adhesive

The invention relates to a preparation method of a sisal fiber porous material for improving the sound absorption performance of medium and low frequency. Hundreds of micron-sized sub-fibers are bonded with polyurethane adhesive to obtain a fiber composite sound-absorbing material. The sound-absorbing material has the advantages of simple preparation method, environmental protection, low cost, wide sources, and excellent sound absorption performance of medium and low frequency.

Owner:UNIV OF JINAN

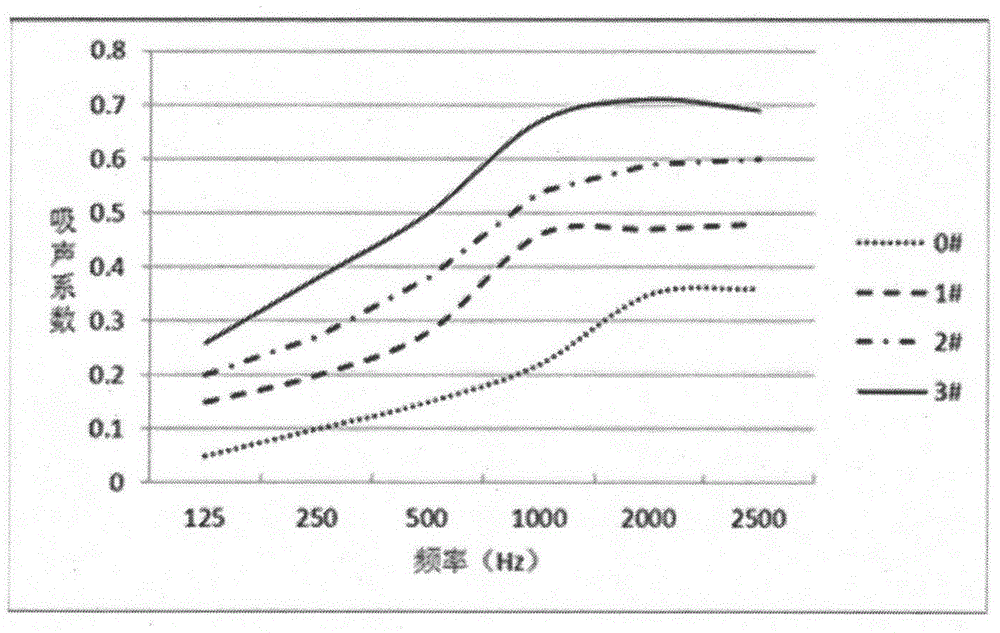

Composite sound absorption structure for improving set low frequency sound absorption performance

InactiveCN105931629AImprove low-frequency sound absorption performanceImprove sound absorptionSound producing devicesAcoustic metamaterialsAcoustics

The invention discloses a composite sound absorption structure for improving set low frequency sound absorption performance, and belongs to the technical field of acoustics, the structure is formed by an upper felt layer, a middle felt layer and a lower felt layer which are fixedly connected in sequence; the upper felt layer, the middle felt layer and the lower felt layer are metal fiber felts; wherein the upper felt layer and the lower felt layer has the same thickness which is 1.5mm-5mm; the thickness of the middle felt layer is equal to or lower than the same of the upper felt layer and the lower felt layer; more than one through holes are uniformly arranged on the surface of the middle felt layer, the axis direction of the through holes is the same with the height direction of the middle felt layer; thin films are fixed to the internal through holes; the shape of each thin film is the same with the radial section shape of each through hole, and the thin films in all through holes are in the same plane; a mass block is fixed to each thin film; the structure is used for improving the sound absorption performance of the metal fiber felt in 0-1500Hz low frequency range, an acoustic metamaterial interlayer and the mass block are introduced to improve the material set low frequency sound absorption performance, and the structure has characteristics of adjustable frequency and good sound absorption performance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

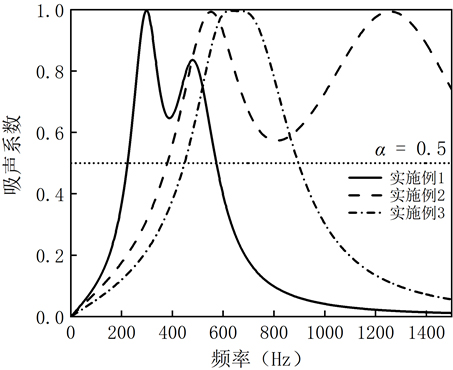

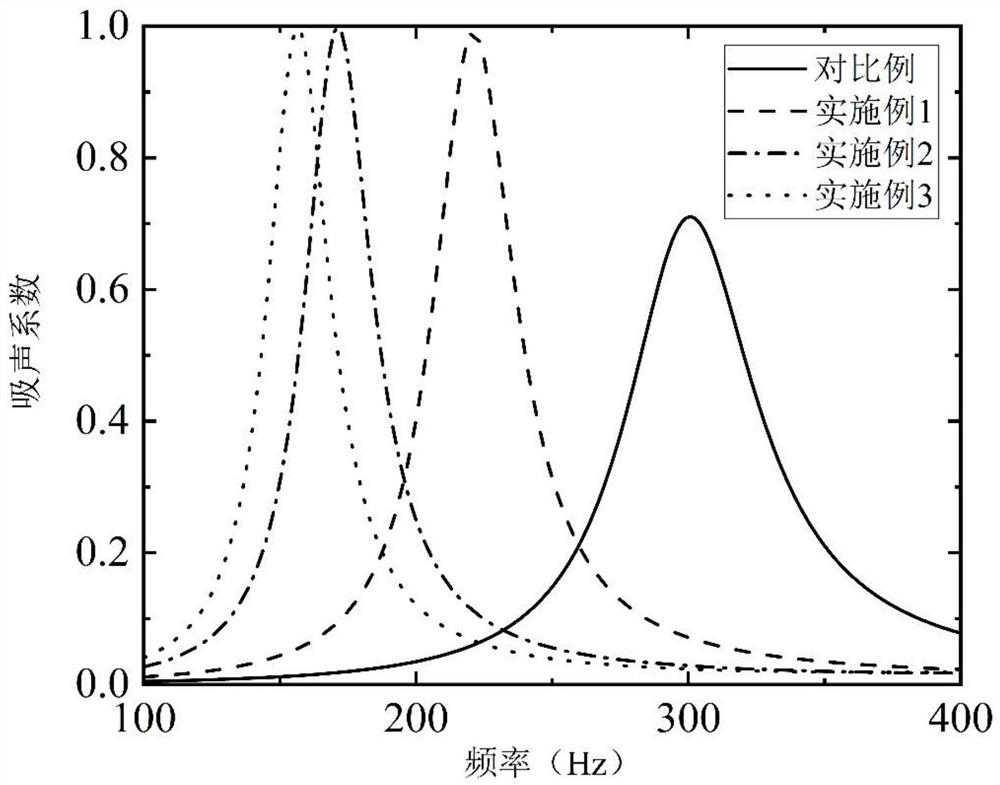

Low-frequency sound-absorbing rubber-based composite material and preparing method thereof

The invention provides a low-frequency sound-absorbing rubber-based composite material and a preparing method thereof. The low-frequency sound-absorbing rubber-based composite material is characterized by being prepared from ethylene propylene diene monomer rubber and kawo kawo fibers, wherein the mass ratio of the ethylene propylene diene monomer rubber to the kawo kawo fibers is (80-100):(5-15). The prepared low-frequency sound-absorbing composite material is excellent in low-frequency sound-absorbing performance, the average sound absorption coefficient at 125-1000 Hz is larger than 0.34, and the maximum sound absorption coefficient reaches 0.71; the prepared sound-absorbing composite material is light and thin (1-3 mm), and the preparing method is easy to operate, good in economic benefit and suitable for industrial production. The composite material can be used in automotive interiors, buildings, high-speed rails and other places with big noise, the preparing method is easy and convenient to operate, and the composite material is good in low-frequency sound-absorbing effect, wide in sound-absorbing frequency band, moderate in price and suitable for industrial production.

Owner:DONGHUA UNIV

Sound-absorbing structure of photosensitive resin material

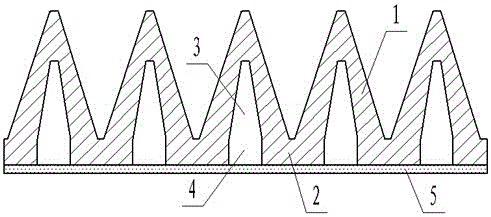

PendingCN106205587AGuaranteed normal transmissionImprove sound absorption performanceSound producing devicesSound energyResonance

The invention discloses a sound-absorbing structure of a photosensitive resin material. The structure comprises wedges and a bottom plate. The wedges are distributed on one surface of the bottom plate in an array. The bottom plate and the wedges are integrated formed by means of photosensitive resin through 3D printing. Through holes are formed in the bottom plate, wedge cavities are formed in the wedges, the wedge cavities correspond to the through holes, and the other surface of the bottom plate is provided with a micro-perforated panel. The compound sound-absorbing structure composed of the bottom plate and the wedges is adopted, the whole structure uses the impedance matching principle, the wedges are used for achieving effective transmission of low-frequency sound waves, and a base is used for effectively consuming the sound waves transmitting into the base. Besides, the micro-perforated panel on the bottom plate, the through holes in the bottom plate and the wedge cavities form a pipe cavity coupled resonance structure, the sound absorbing characteristic of pipe cavity coupled resonance is well used for consuming sound energy, and the sound absorbing effect is further improved.

Owner:GUIZHOU UNIV

Annular slotted low-frequency underwater sound absorption deep sub-wavelength superstructure

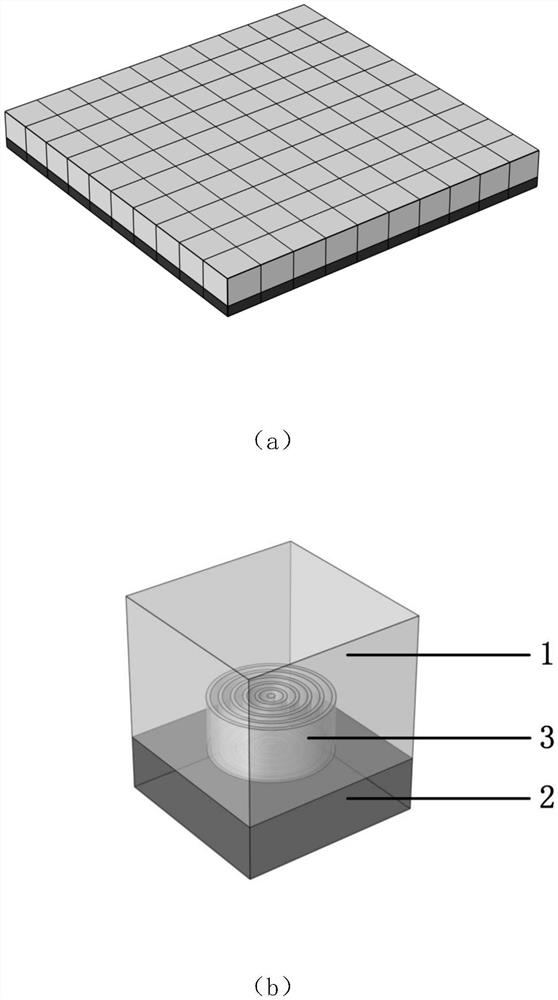

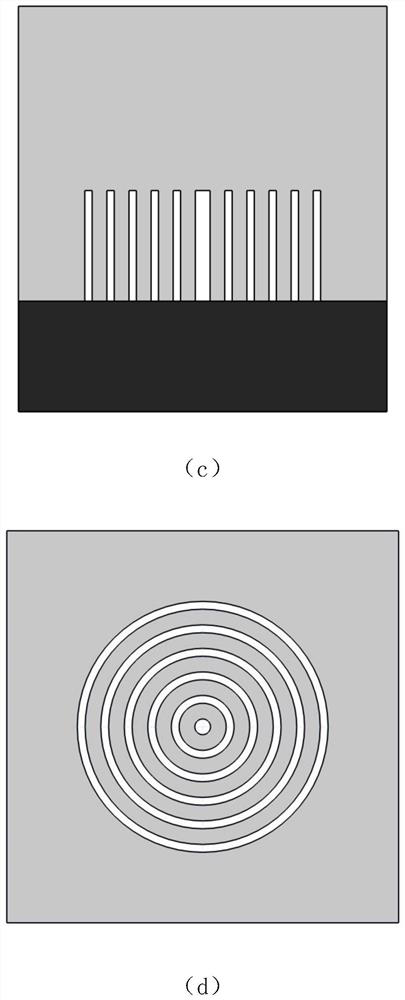

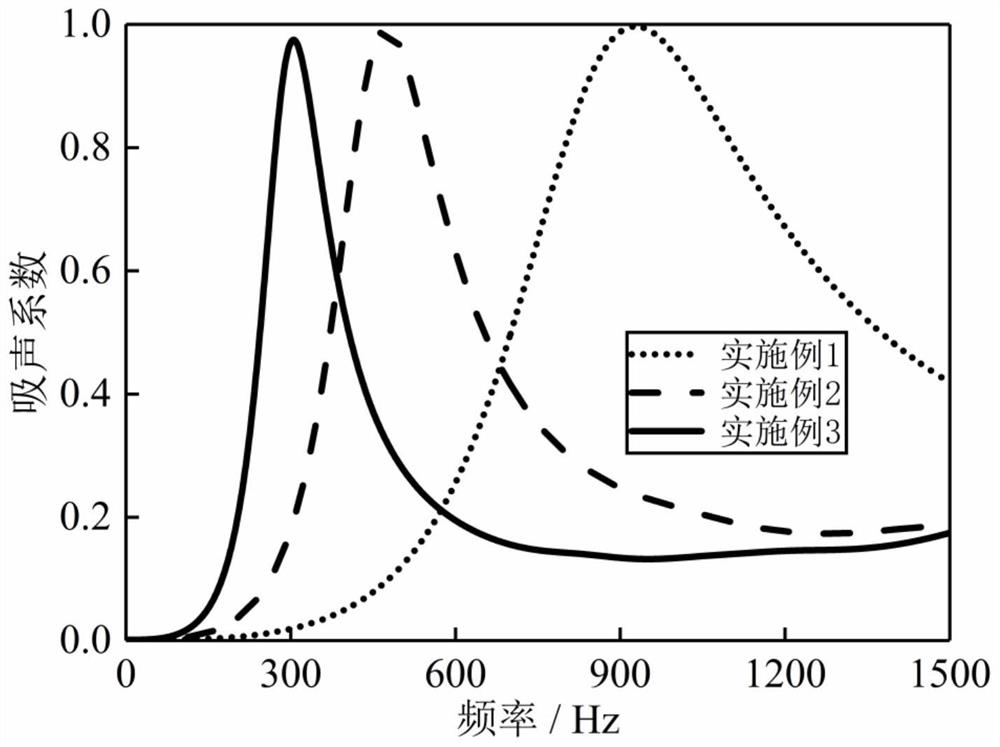

ActiveCN111696505ASimple structureThe structure has excellent low frequency sound absorption performanceSound producing devicesUnderwaterEngineering

The invention discloses an annular slotted low-frequency underwater sound absorption deep sub-wavelength superstructure. Each cell is of a cube structure, a plurality of annular grooves in each cell are distributed in a concentric circle mode, the annular grooves are located in the center of rubber in the horizontal direction, the annular grooves are located in the lower side of the rubber in thevertical direction, and the plurality of cells are arranged in an array mode to form the annular slotted low-frequency underwater sound absorption deep sub-wavelength superstructure. By means of the structure, low-frequency perfect sound absorption of a deep sub-wavelength size structure is achieved, the structure can be laid on the surface of underwater equipment, the requirement for underwater low-frequency vibration and noise reduction is met, the structure has wide engineering application prospects, and a brand-new solution is provided for the low-frequency vibration and noise reduction problem of the underwater equipment.

Owner:XI AN JIAOTONG UNIV +1

Acoustic stealth covering layer and application thereof

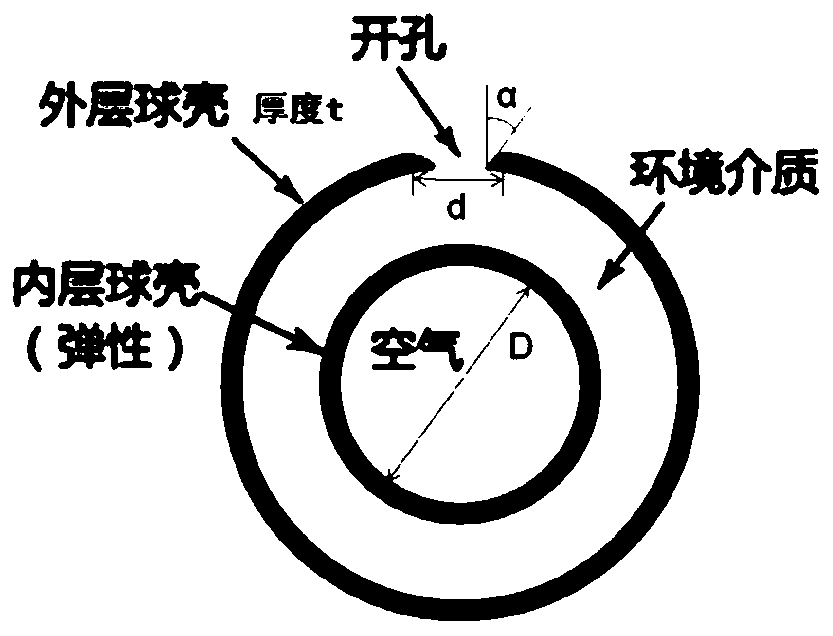

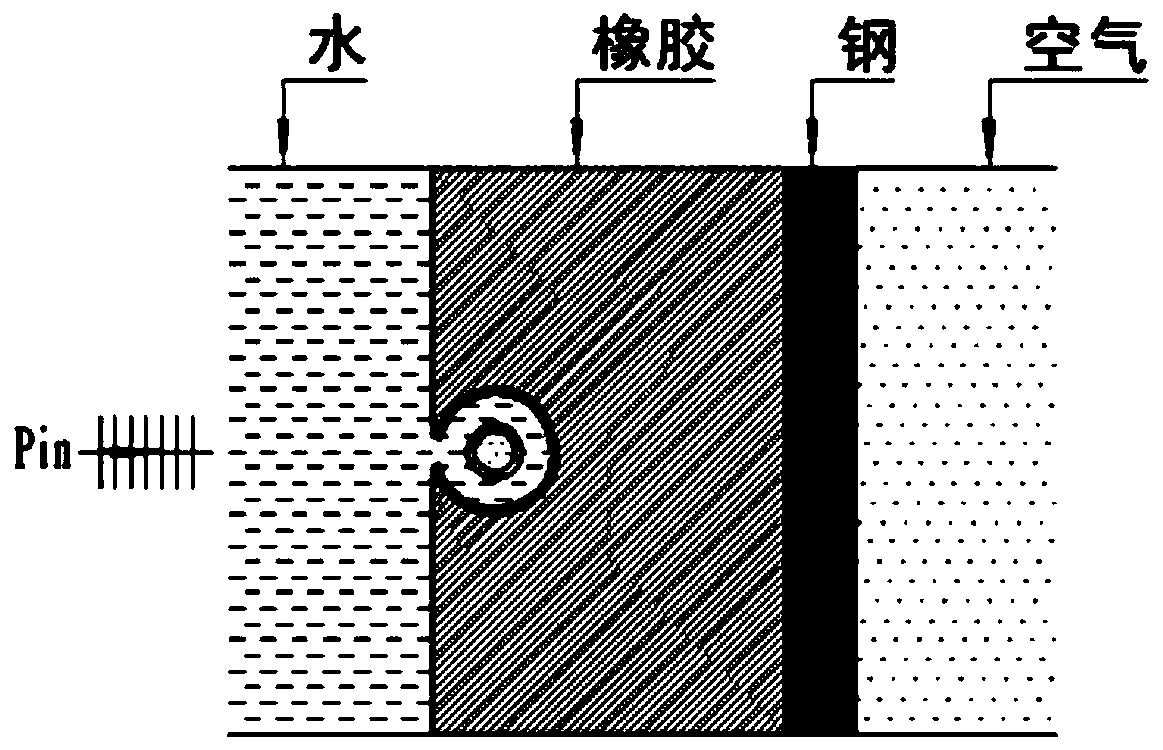

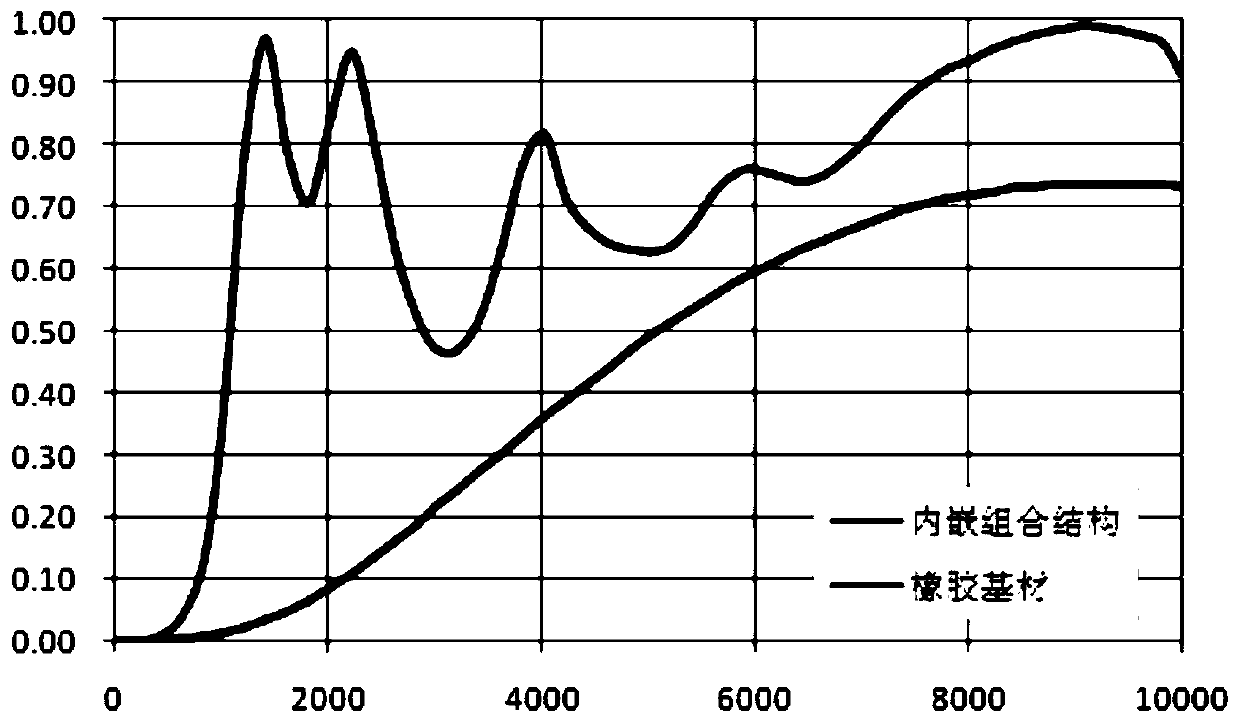

PendingCN111009232ASimple structureSmall sizeSound producing devicesRubber layered productsEngineeringFrequency sound

The invention relates to an acoustic stealth covering layer and application thereof, the acoustic stealth covering layer covers the surface of an acoustic protection body, and the acoustic stealth covering layer is composed of a sound absorption covering layer and one or more combined sound absorption structures embedded in the sound absorption covering layer; each combined sound absorption structure is composed of a double-layer spherical shell, a round hole is formed in the surface of the outer-layer spherical shell, the hole right faces the outer surface of the sound absorption covering layer and is communicated with media outside the sound absorption covering layer, the inner-layer spherical shell is placed in the outer-layer spherical shell, and the inner-layer spherical shell is filled with air. The acoustic stealth covering layer provided by the invention is simple in structure, the size of the combined sound absorption structures in the acoustic stealth covering layer is small,the whole acoustic stealth covering layer is easy to realize, the acoustic stealth covering layer has good broadband sound absorption performance, particularly good low-frequency sound absorption performance, and the sound absorption frequency band of the acoustic stealth covering layer can be designed by changing the size parameters of the inner spherical shell and the outer spherical shell of the combined sound absorption structures.

Owner:CHINA SHIP DEV & DESIGN CENT

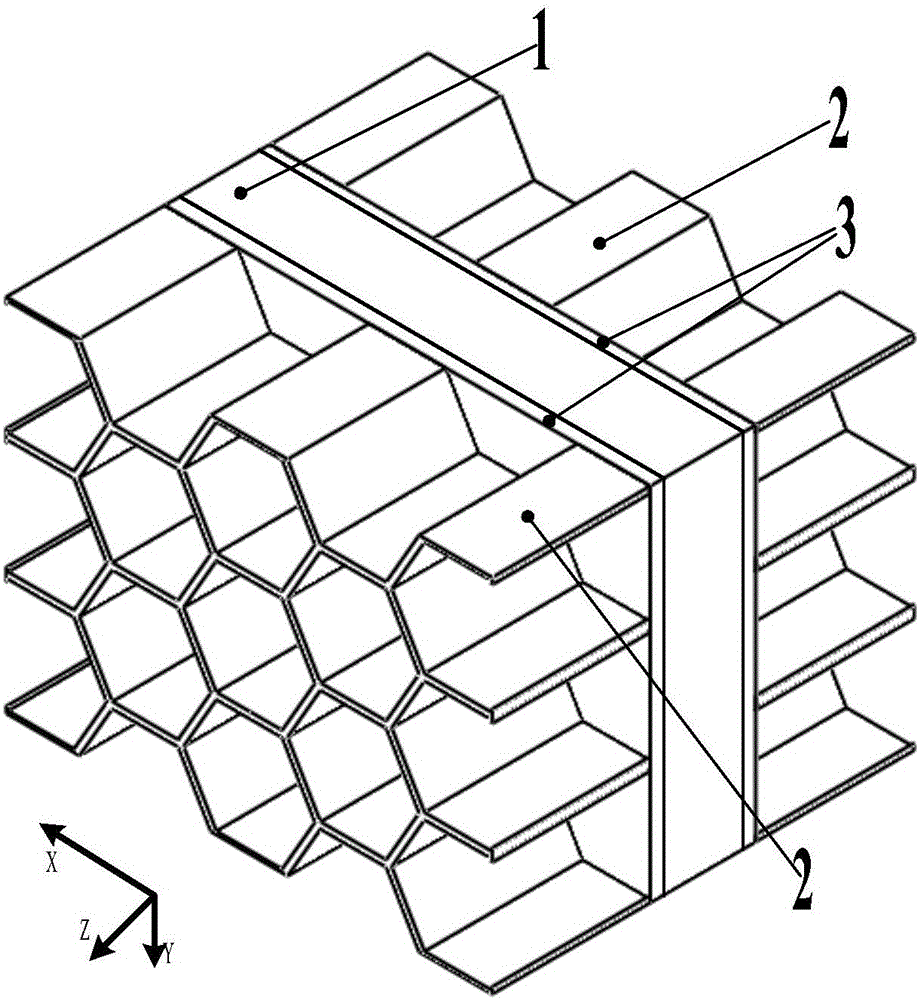

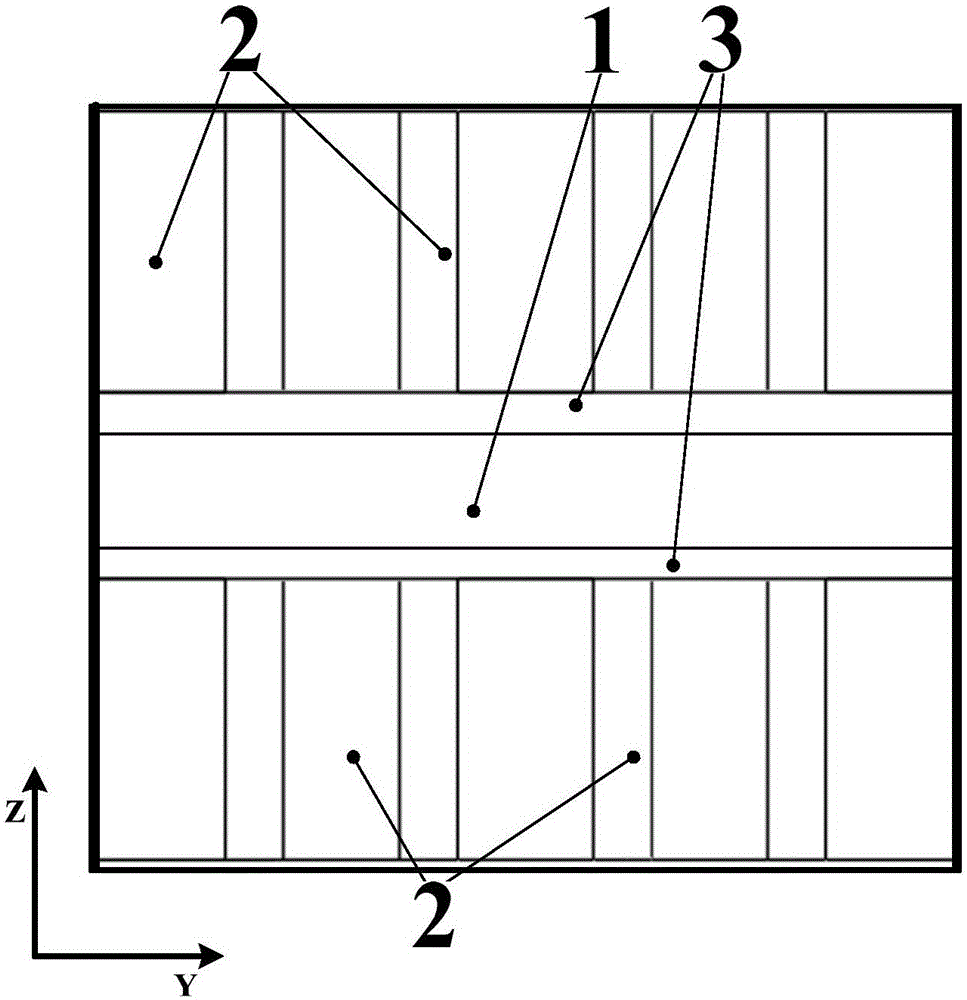

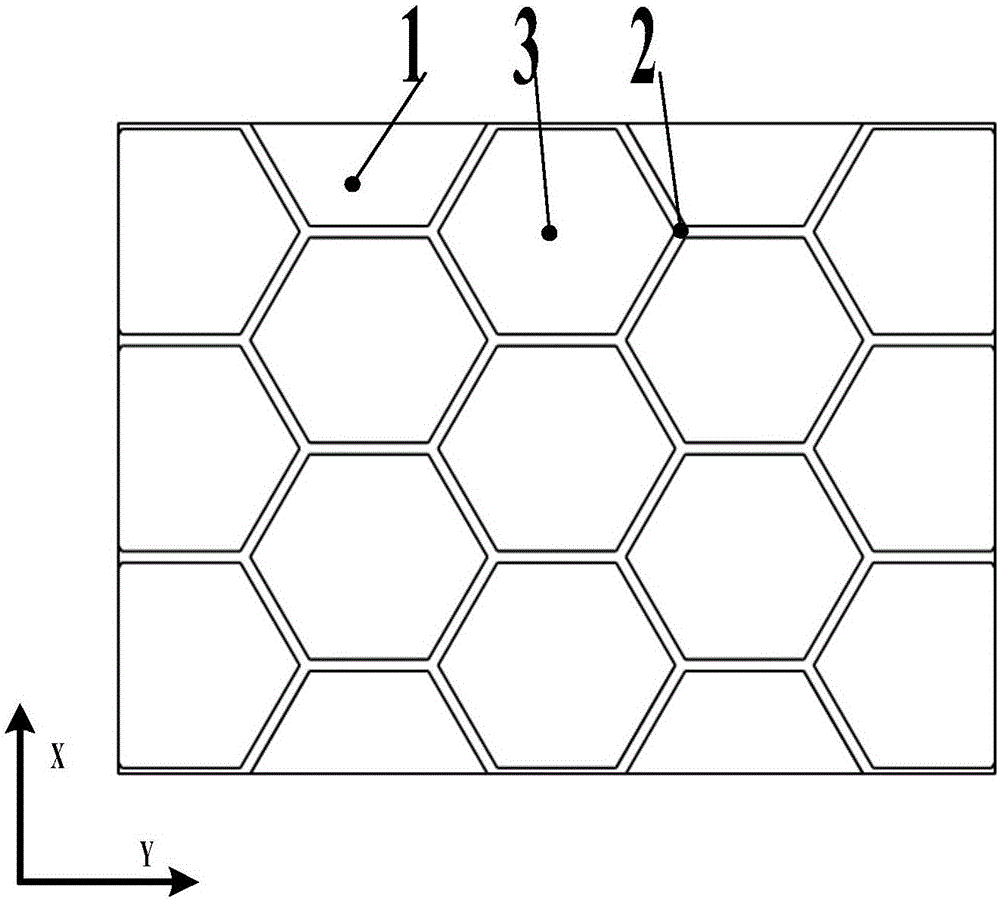

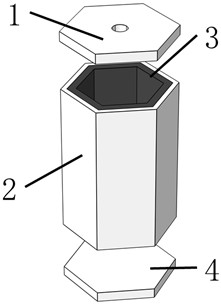

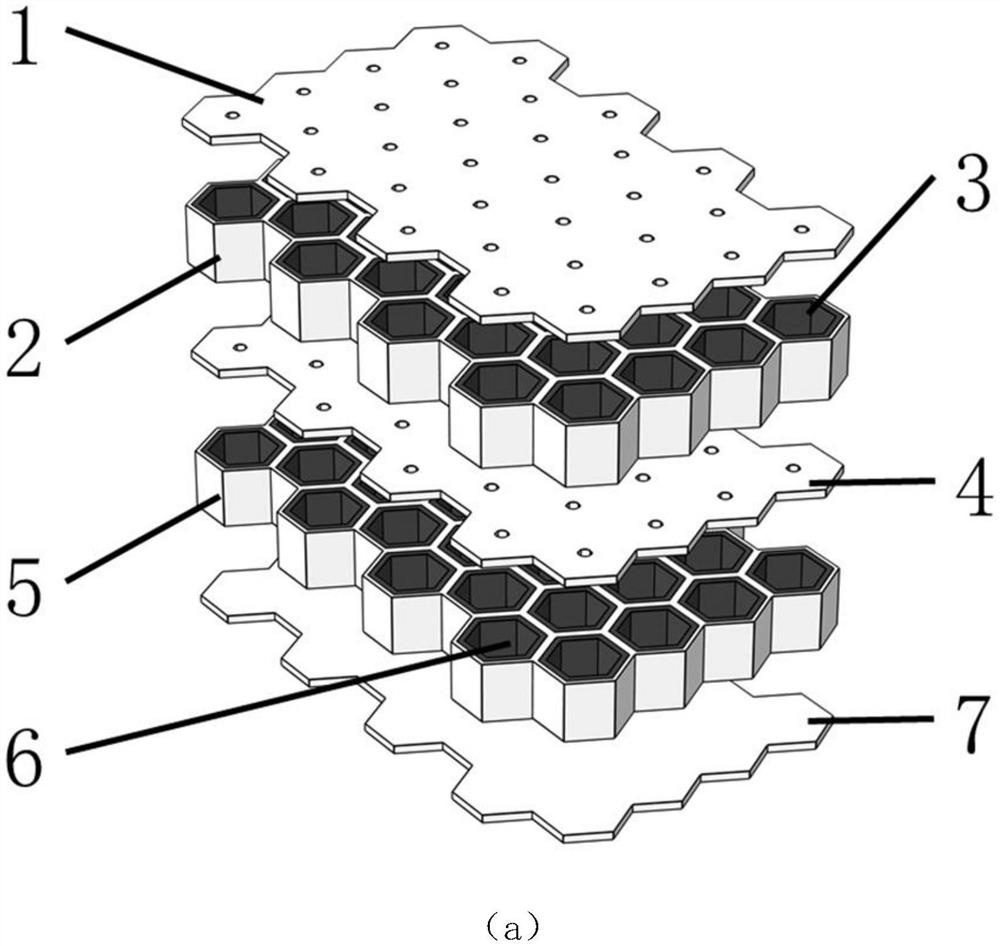

Damping lining hexagonal honeycomb perforated plate underwater sound absorption metamaterial

PendingCN111739502AImprove acoustic impedance characteristicsImprove low-frequency sound absorption performanceSynthetic resin layered productsSound producing devicesResonant cavityUnderwater

The invention provides a damping lining hexagonal honeycomb perforated plate underwater sound absorption metamaterial. A plurality of honeycomb resonant cavity units are formed by welding or gluing aperforated upper panel, a honeycomb layer core and a lower panel, and damping lining layers are adhered to the side walls and the bottom surfaces of honeycomb resonant cavity units, so that the acoustic impedance characteristic of the structure is improved, and the low-frequency sound absorption performance of the structure is improved. According to the light honeycomb sandwich plate structure, onthe premise that good low-frequency underwater sound absorption performance is achieved, the weight of the structure is reduced, the bearing performance of the structure is guaranteed, and the problems that a traditional underwater sound absorption structure is generally poor in low-frequency sound absorption performance, heavy in weight and poor in bearing performance are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

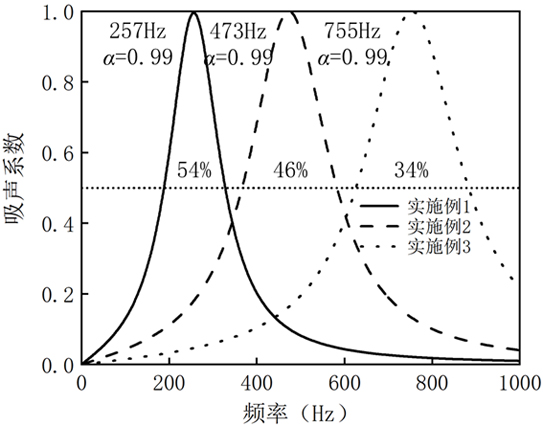

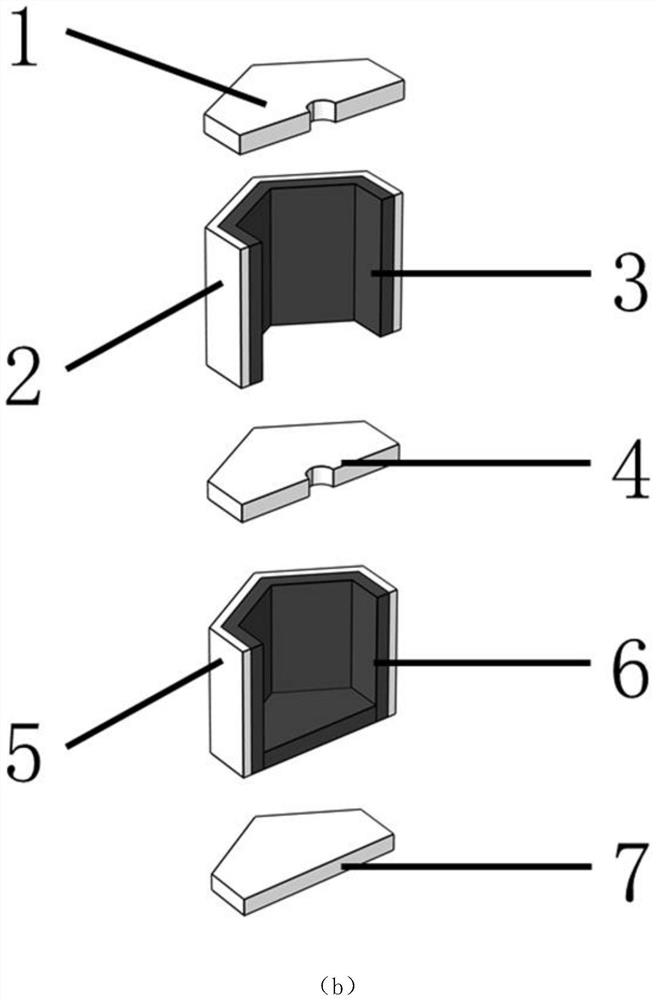

Rough folding type sub-wavelength low-frequency sound absorption structure

PendingCN113362797AImprove acoustic impedance characteristicsExcellent low frequency sound absorption performanceSound producing devicesResonant cavityHelmholtz resonator

The invention discloses a rough folding type sub-wavelength low-frequency sound absorption structure, which is characterized in that a plurality of rough corrugated partition plates are arranged in a cavity to form a Helmholtz resonant cavity, and form an S-shaped neck micro-channel in the Helmholtz resonant cavity. The rough folding type sub-wavelength low-frequency sound absorption structure is excellent in low-frequency sound absorption performance, good in sound absorption performance adjustability and bearing performance, simple in structure, and convenient for large-scale machining and manufacturing.

Owner:XI AN JIAOTONG UNIV

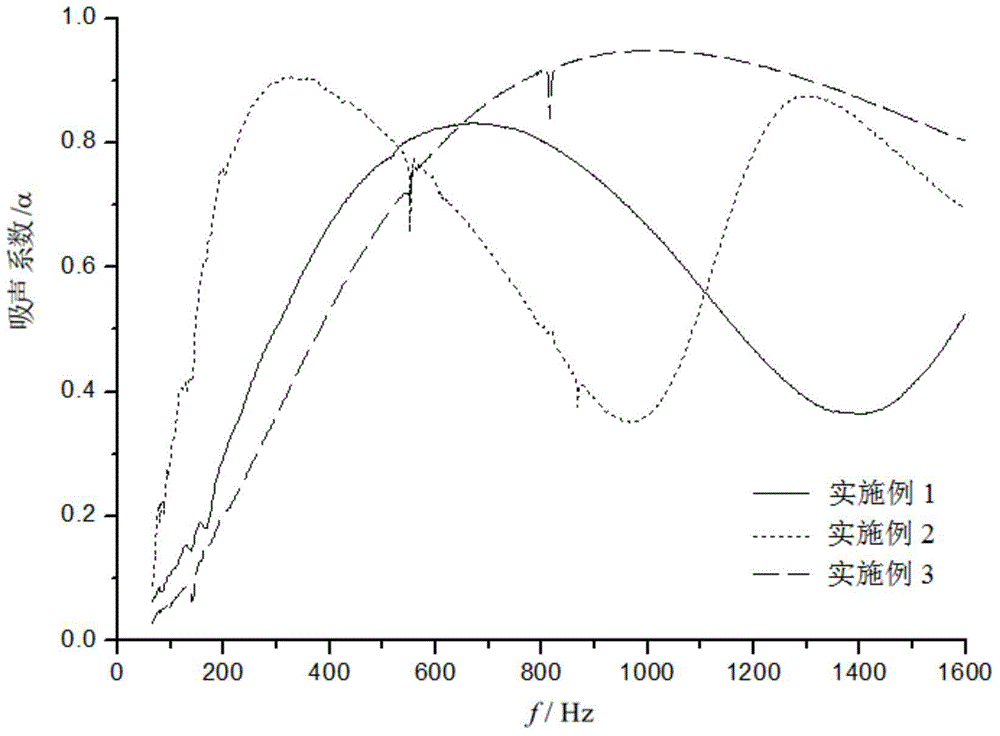

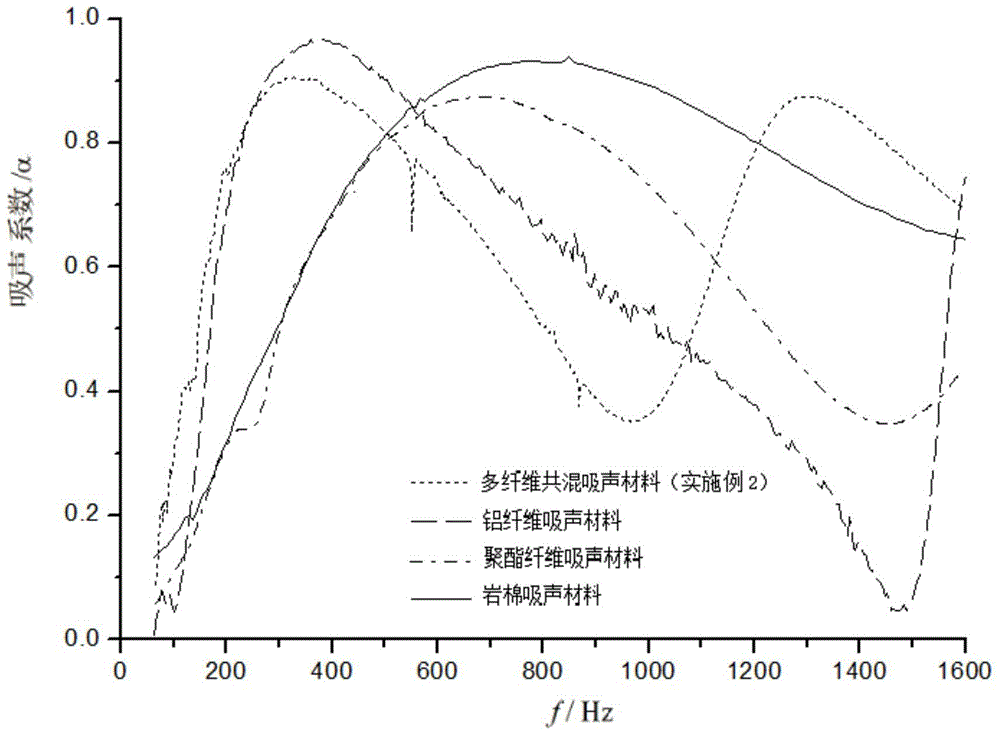

Multi-fiber blended sound-absorbing material

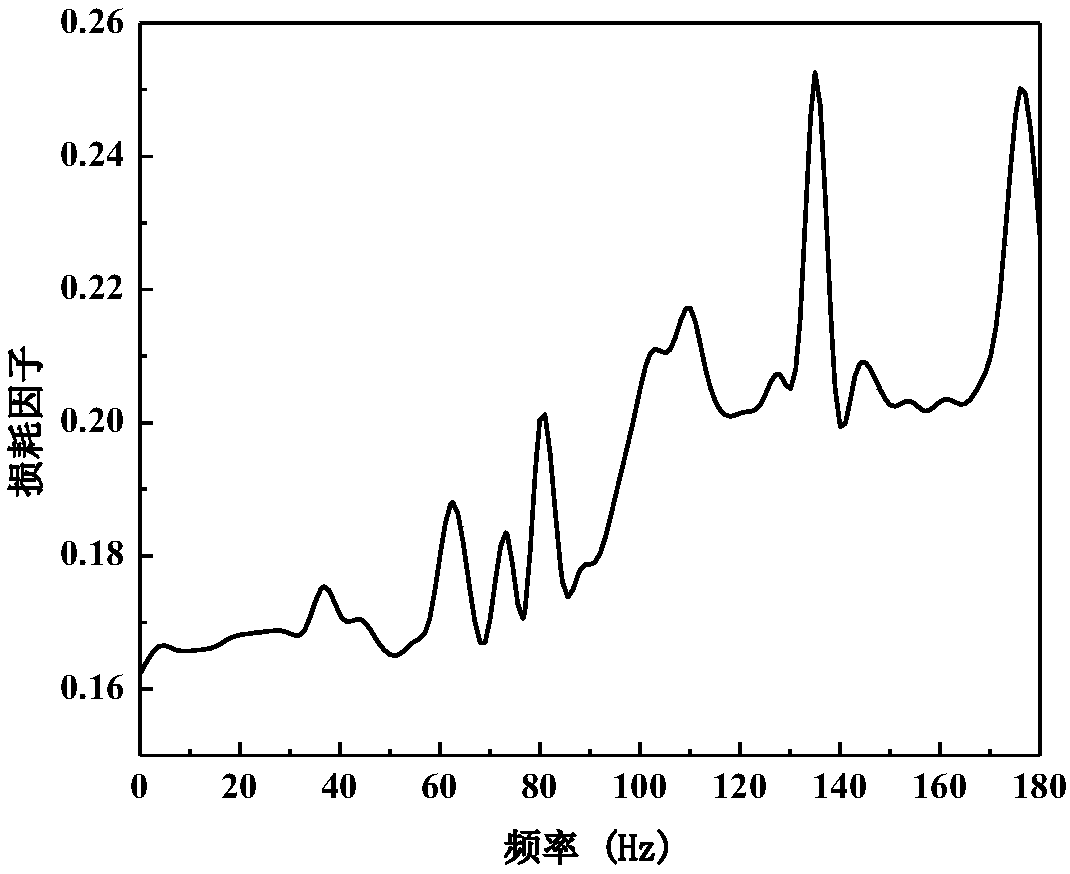

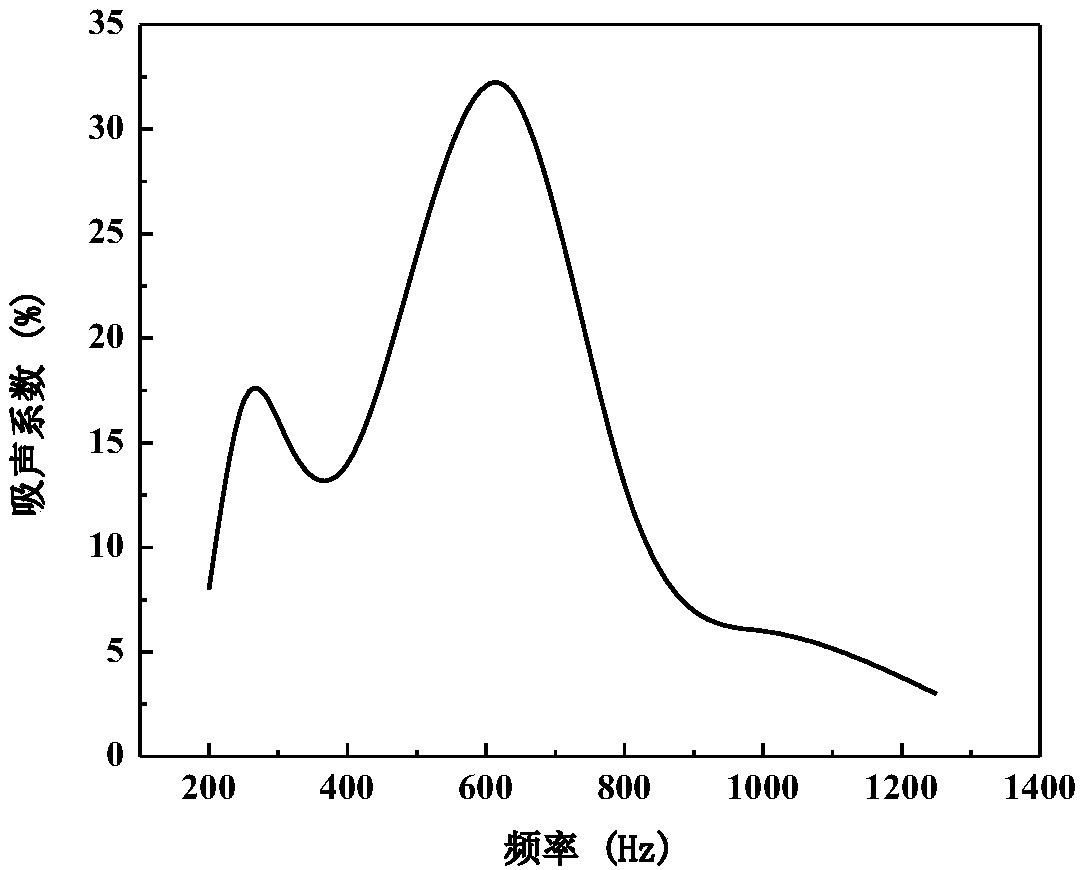

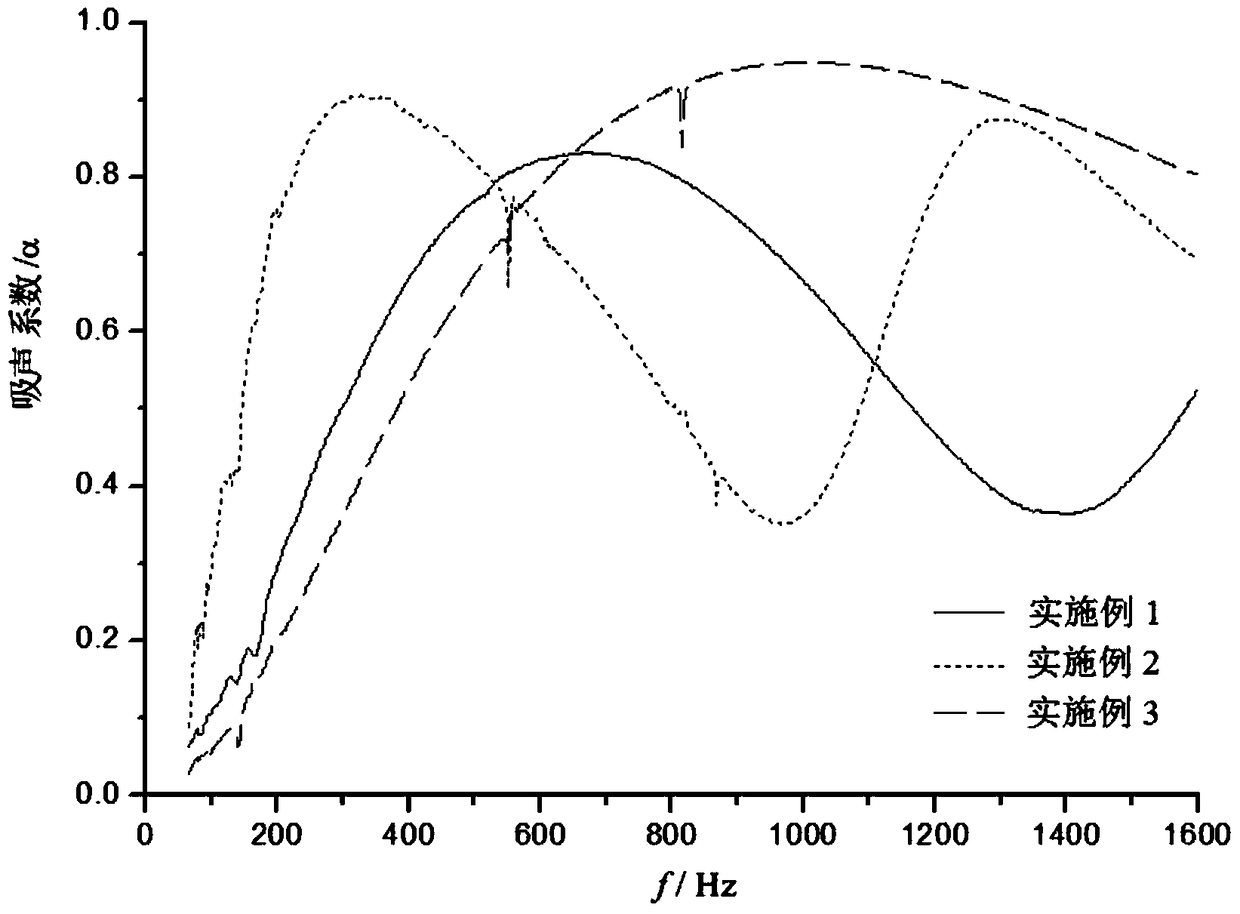

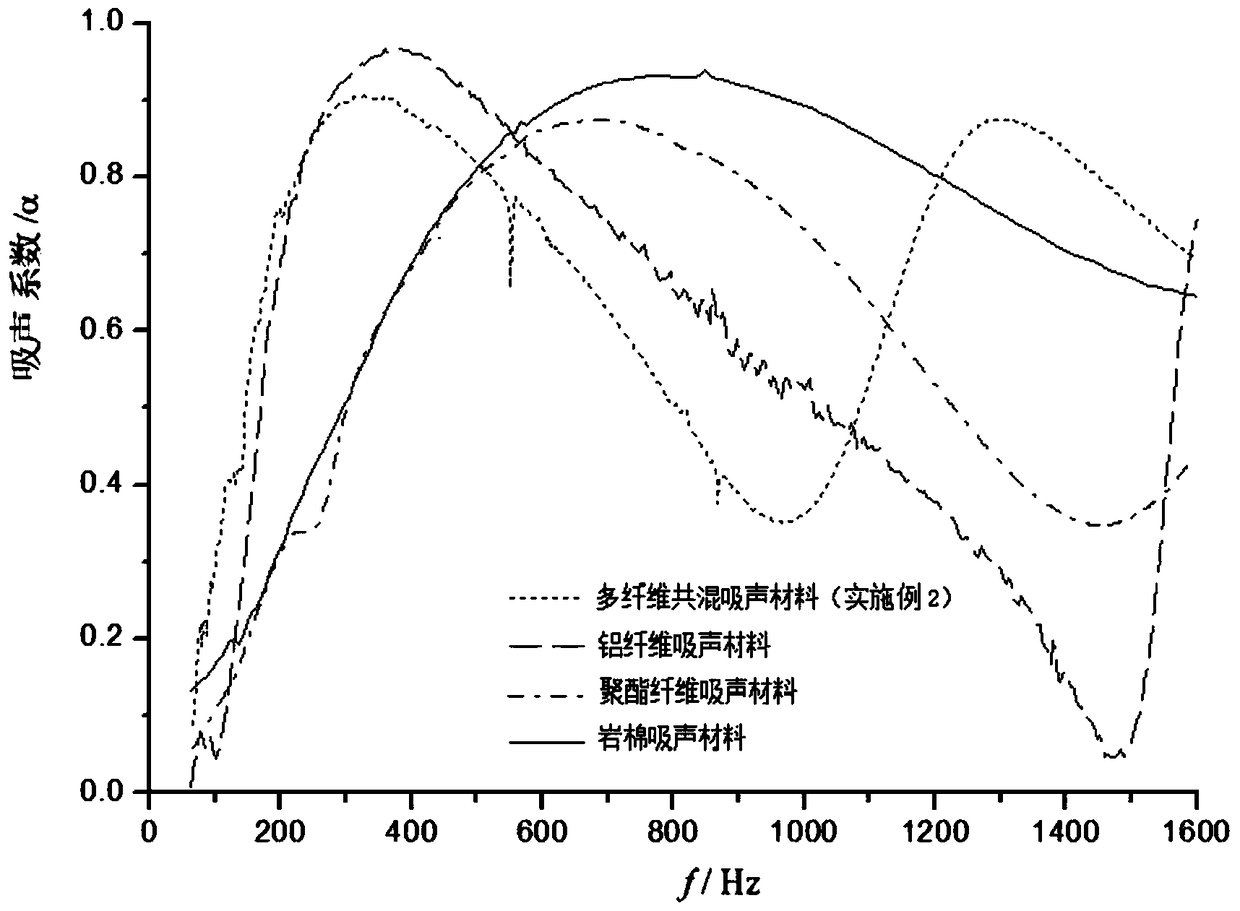

ActiveCN104695134ASimple preparation processNo pollutionNon-woven fabricsSound producing devicesPolyesterPolymer science

The invention relates to a multi-fiber blended sound-absorbing material comprising aluminum fibers and organic composite polymer fibers. The multi-fiber blended sound-absorbing material is characterized in that the aluminum fibers 50-100 micrometers in diameter are made of pure aluminum; the organic composite polymer fibers 20-50 micrometers in diameter include polyester fibers (on the inner layer) and polypropylene fibers (on the outer layer). A blend fiber design thought is adopted, the aluminum fibers and the organic composite polymer fibers are blended, the polypropylene fibers melt during bake forming according to a low melting point, the aluminum fibers are adhered to the polyester fibers, and the multi-fiber blended sound-absorbing material with damping energy dissipation property is produced.

Owner:STATE GRID CORP OF CHINA +3

Underwater sound absorption metamaterial structure of damping lining double-layer honeycomb perforated plate

ActiveCN111696502AImprove acoustic impedance characteristicsImprove low-frequency sound absorption performanceWatercraft hull designSynthetic resin layered productsResonant cavityHoneycomb

The invention discloses an underwater sound absorption metamaterial structure of a damping lining double-layer honeycomb perforated plate. The underwater sound absorption metamaterial structure comprises a perforated upper panel, a first-layer honeycomb layer core, a sandwich perforated panel, a second-layer honeycomb layer core and a lower panel which are connected in sequence from top to bottom;a plurality of honeycomb resonant cavity units are arranged in each of the first-layer honeycomb layer core and the second-layer honeycomb layer core; the perforated upper panel is periodically provided with first holes corresponding to each honeycomb resonant cavity unit of the first-layer honeycomb layer core structure, and the interlayer perforated panel is periodically provided with second holes corresponding to each honeycomb resonant cavity unit of the second-layer honeycomb layer core structure; a first damping lining layer is arranged in each honeycomb resonant cavity unit of the first-layer honeycomb layer core, and a second damping lining layer is arranged in each honeycomb resonant cavity unit of the second-layer honeycomb layer core. The underwater sound absorption metamaterial structure has excellent low-frequency sound-absorbing performance, good bearing performance and light weight performance, can be correspondingly adjusted according to actual working condition requirements, and is simple in structure and easy to manufacture.

Owner:XI AN JIAOTONG UNIV +1

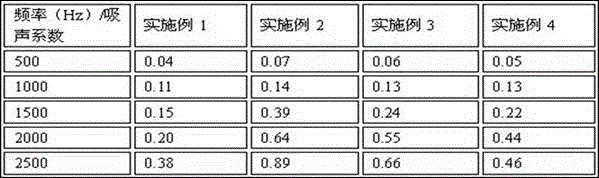

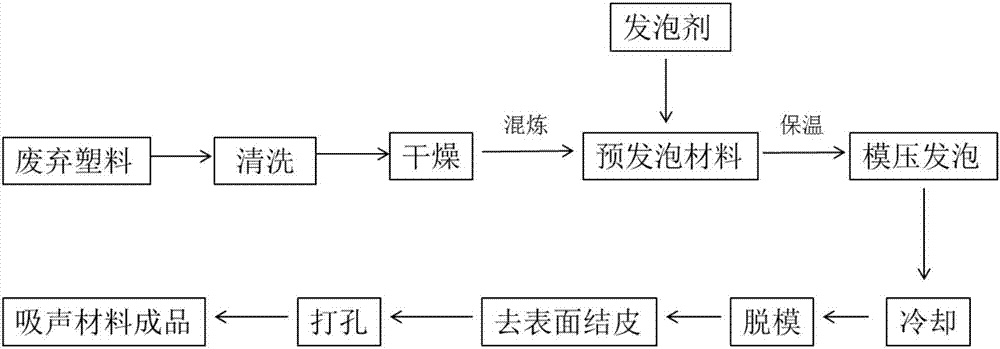

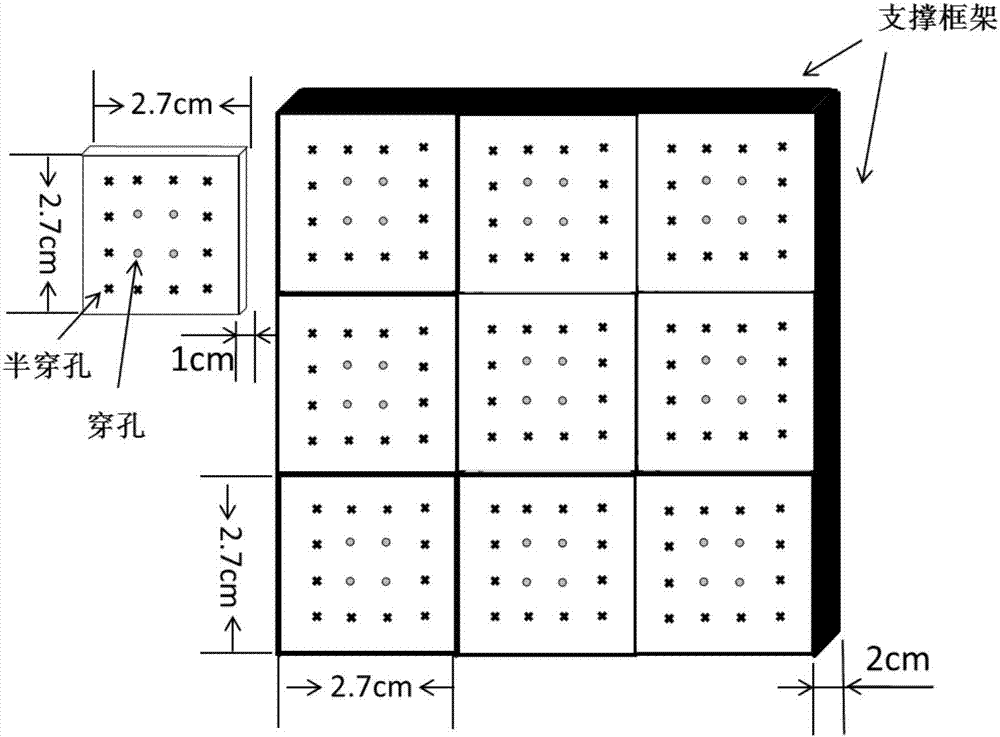

Technology for preparing composite hole structure broadband sound absorption material through waste plastic

InactiveCN106881876AWide frequency range of sound absorptionExcellent low frequency sound absorption performanceManufacturing technologyEngineering

The invention provides a technology for preparing a sound absorption material which is of a composite hole structure and is broad in sound absorption frequency through waste plastic. The technology specifically includes the processes of mixing, foaming, perforating, back cavity creating and the like. The technology is characterized in that after foaming, perforating, semi-perforating and back cavity treatment are conducted, sound absorption material hole channels are arranged in a criss-cross manner, the product is endowed with good low-frequency, medium-frequency and high-frequency broadband sound absorption effects, and the sound absorption frequency range of the material is greatly enlarged; the machining process is simple and easy to conduct, three waste is not generated, and the finished product can be recovered, re-machined and recycled after being abandoned; and the manufacturing technology is low in construction cost, the engineering installation is simple, the overall engineering thickness is generally 1 cm to 3 cm, the relative density is about 0.50 ton / m<3>, and the technology is suitable for establishing and use of sound absorption facilities of high-speed rails, city elevated roads, bridges, highway tunnels, building ceilings and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

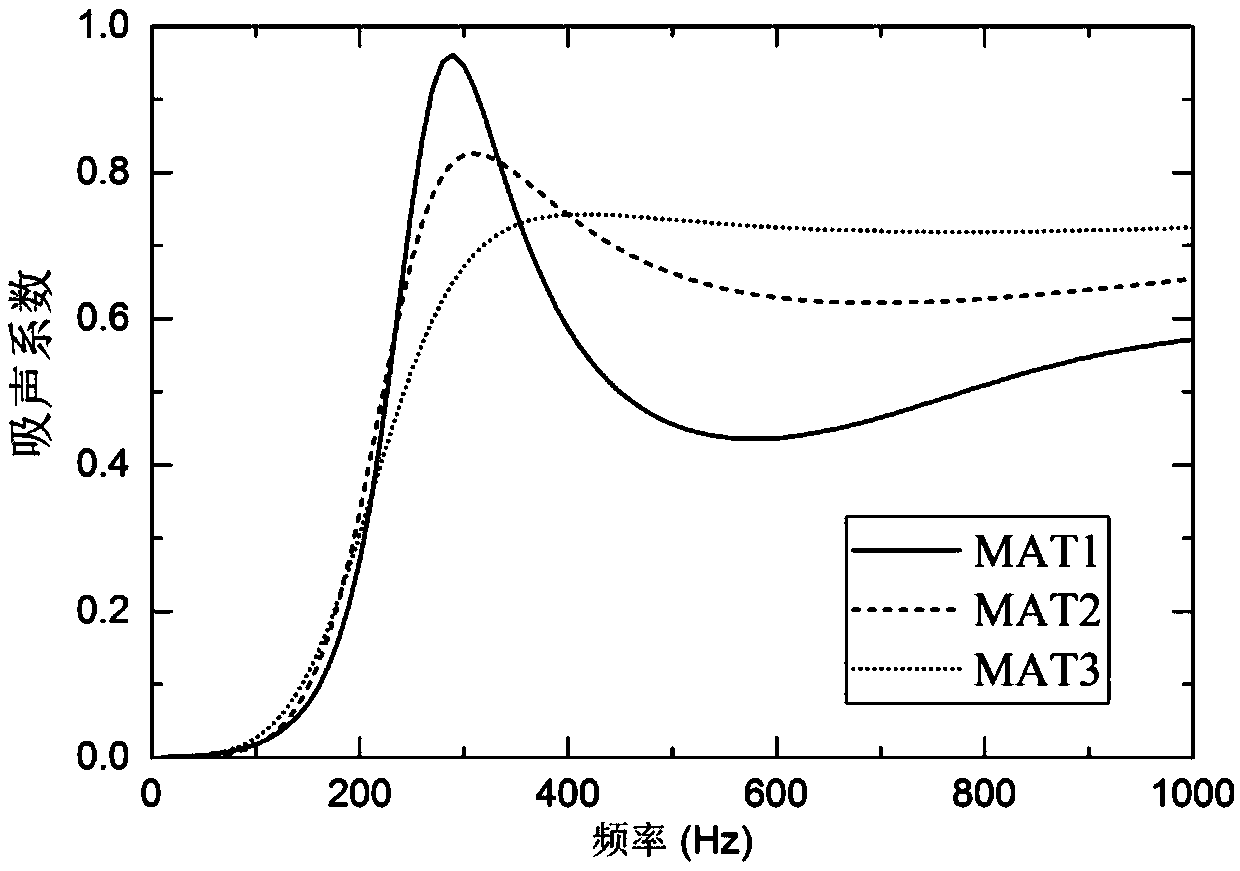

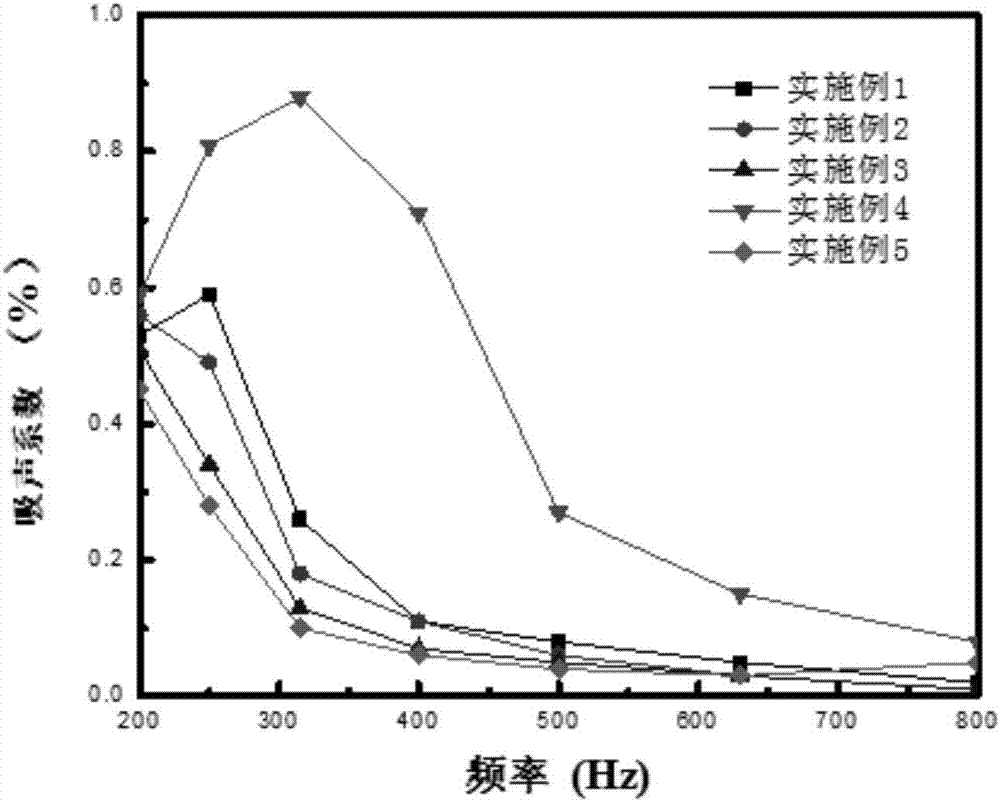

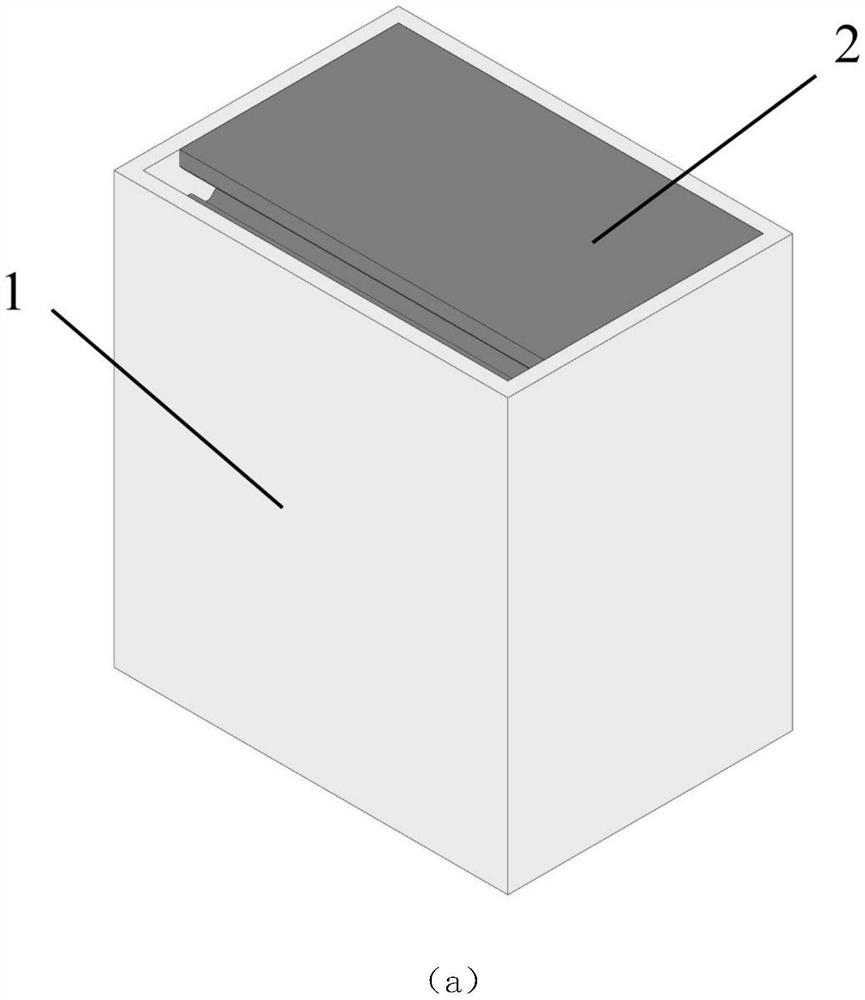

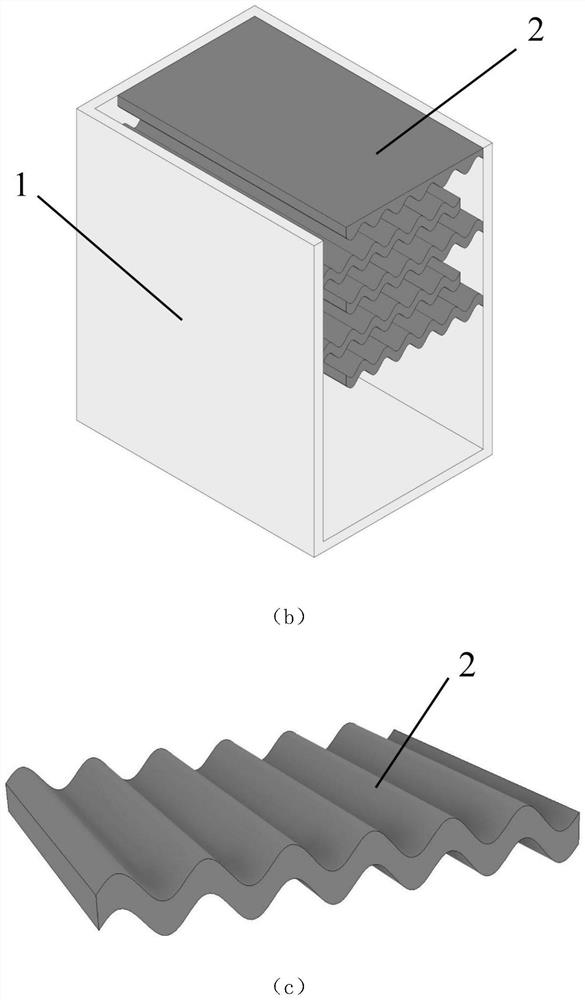

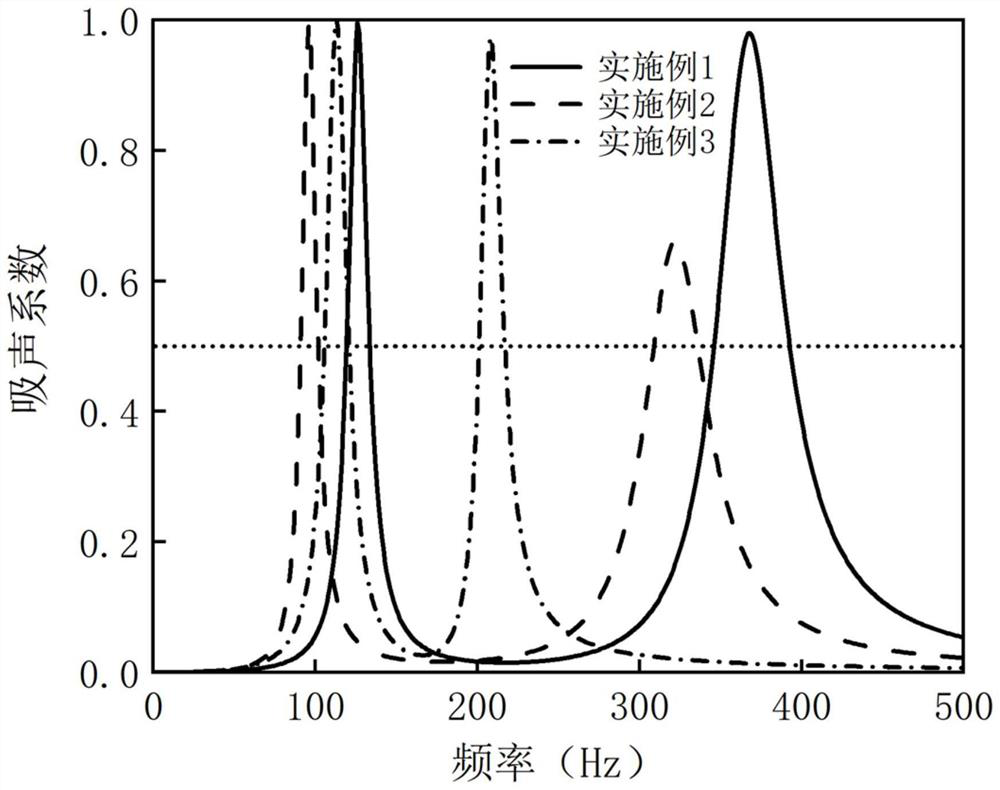

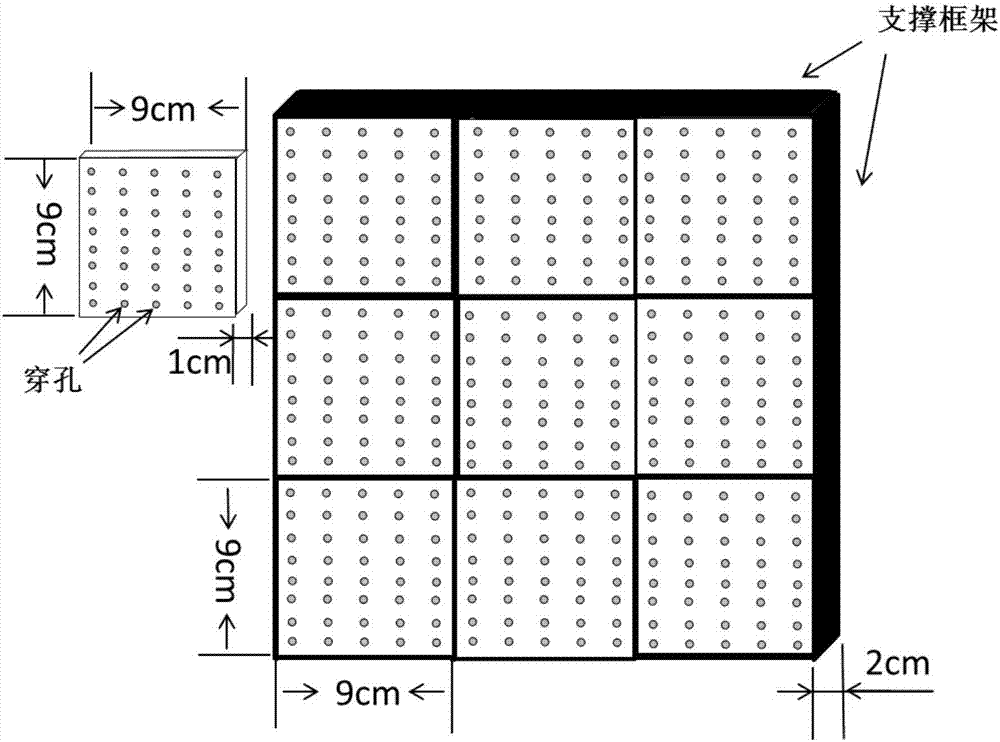

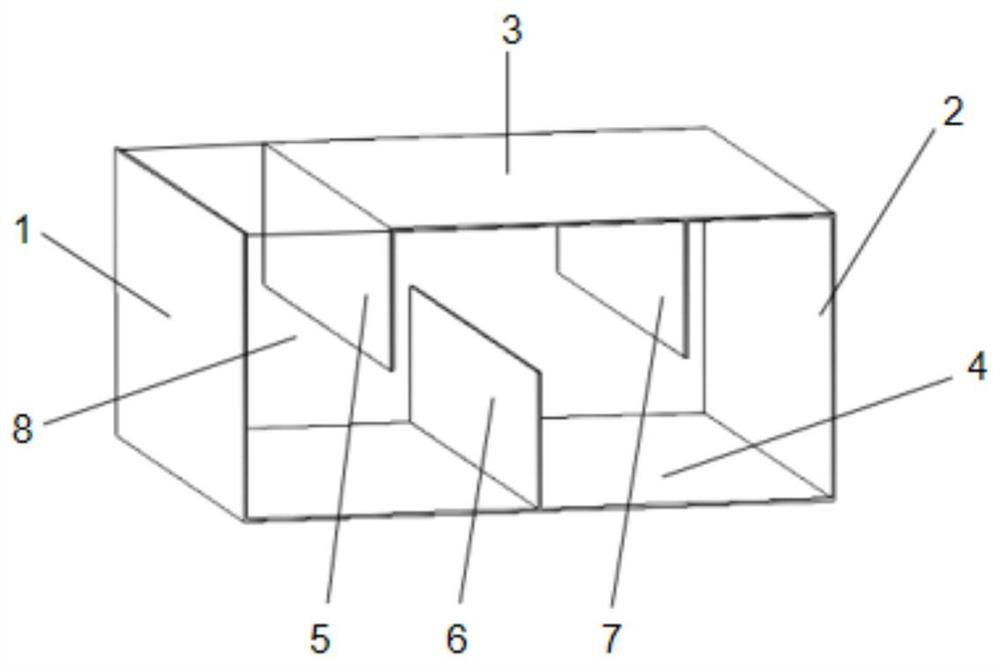

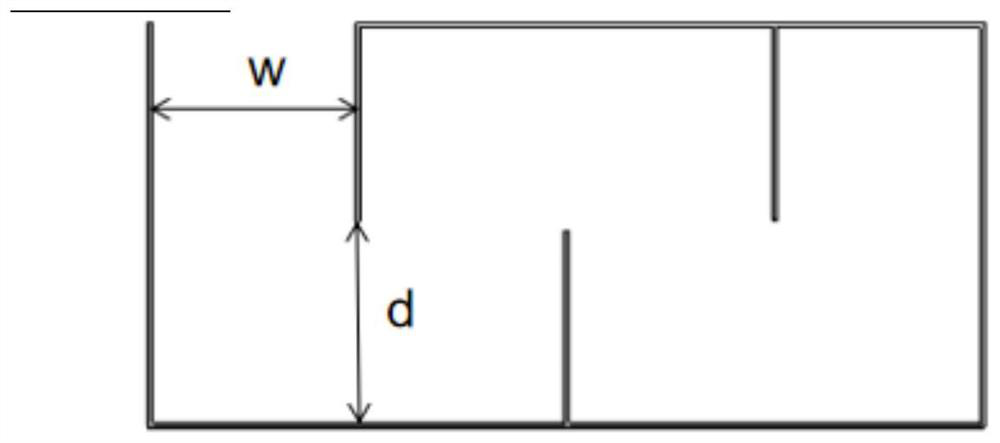

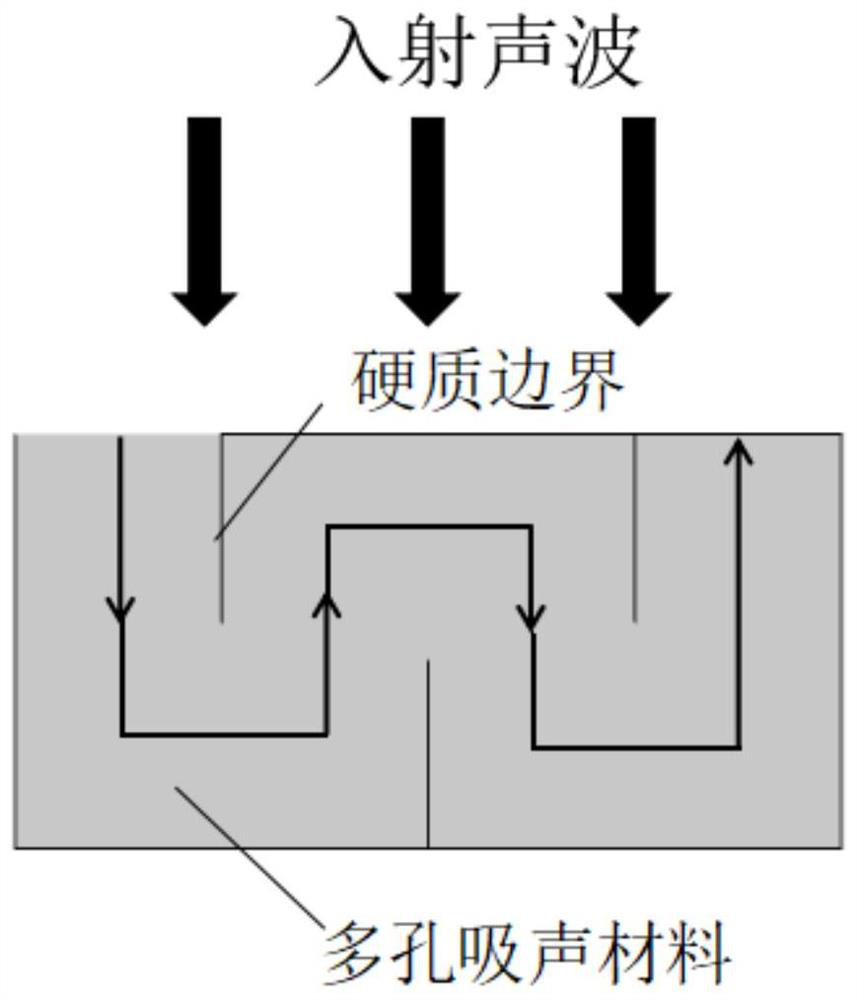

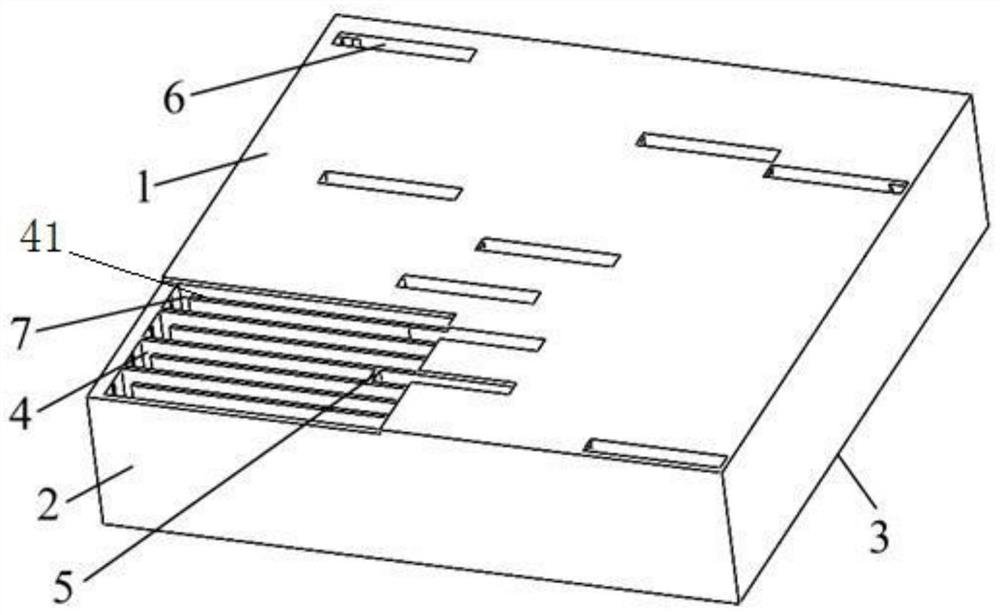

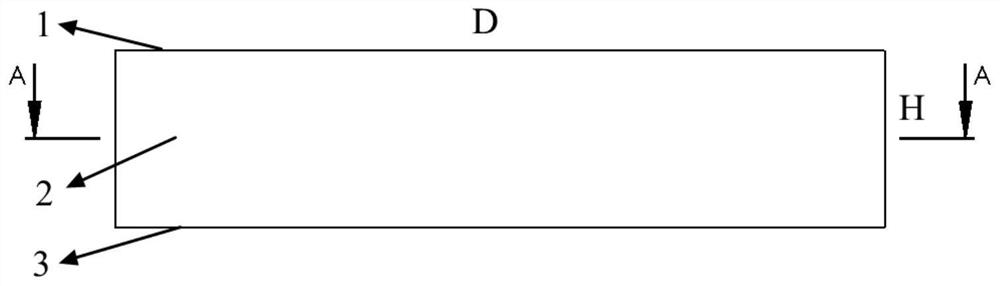

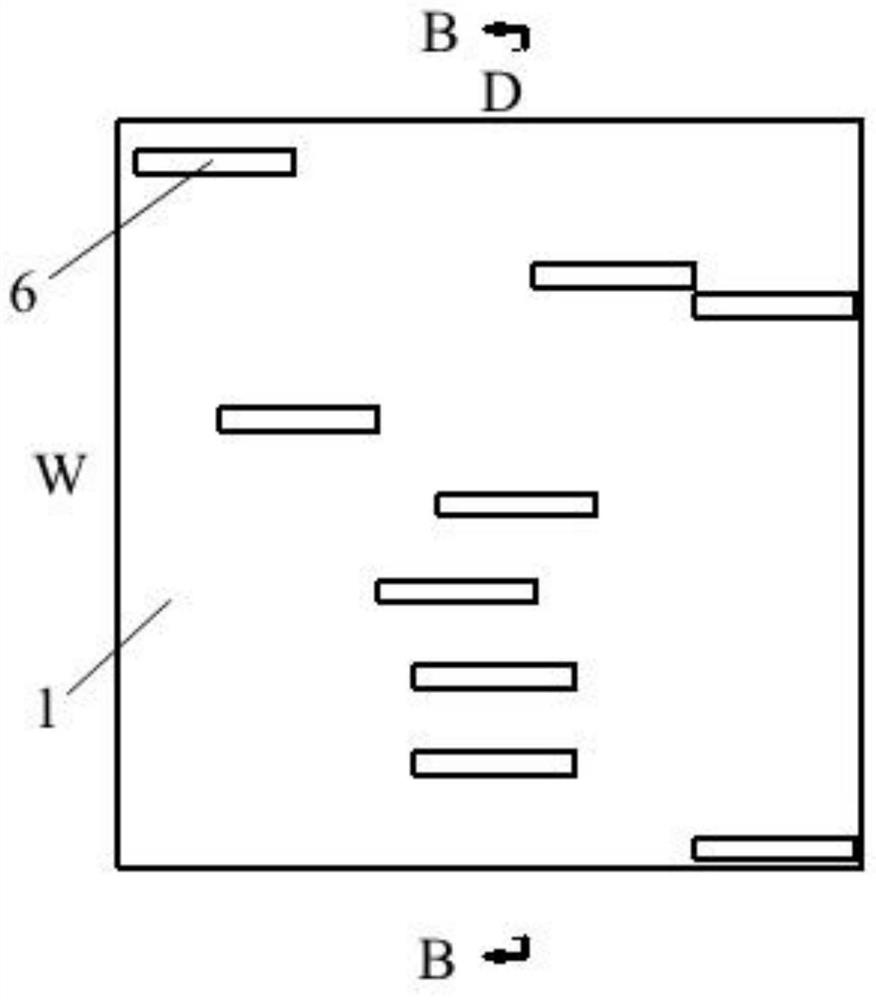

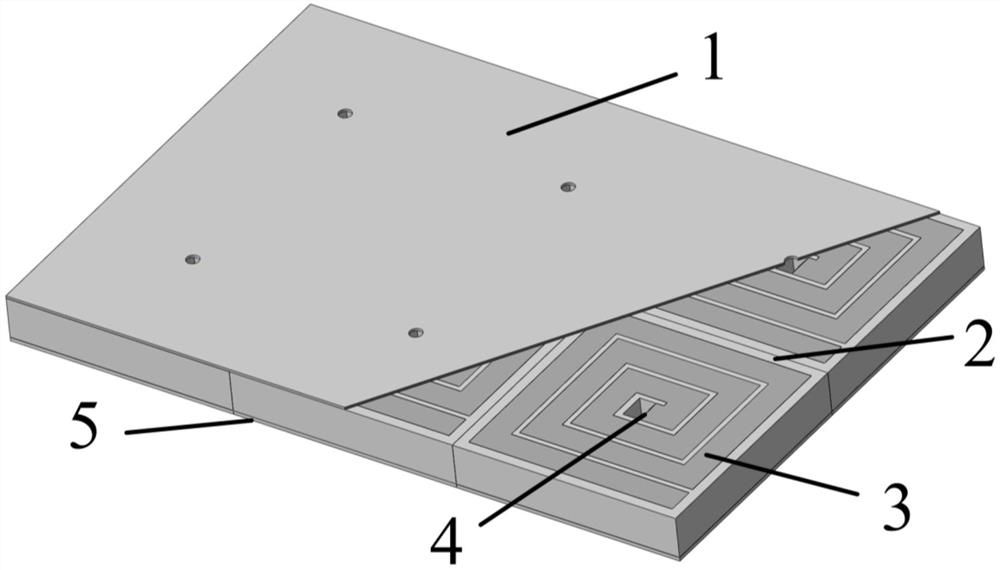

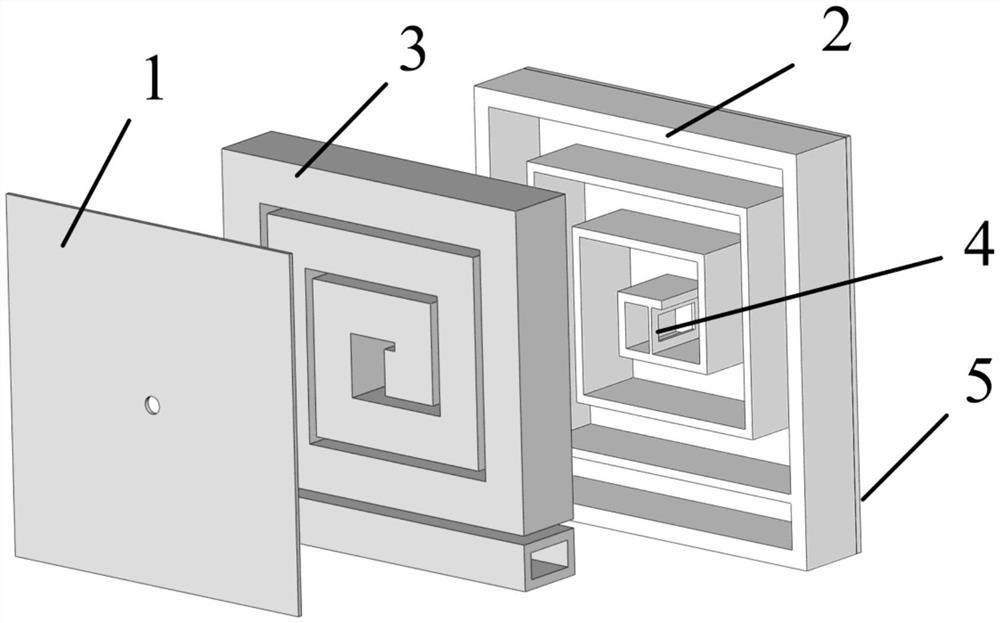

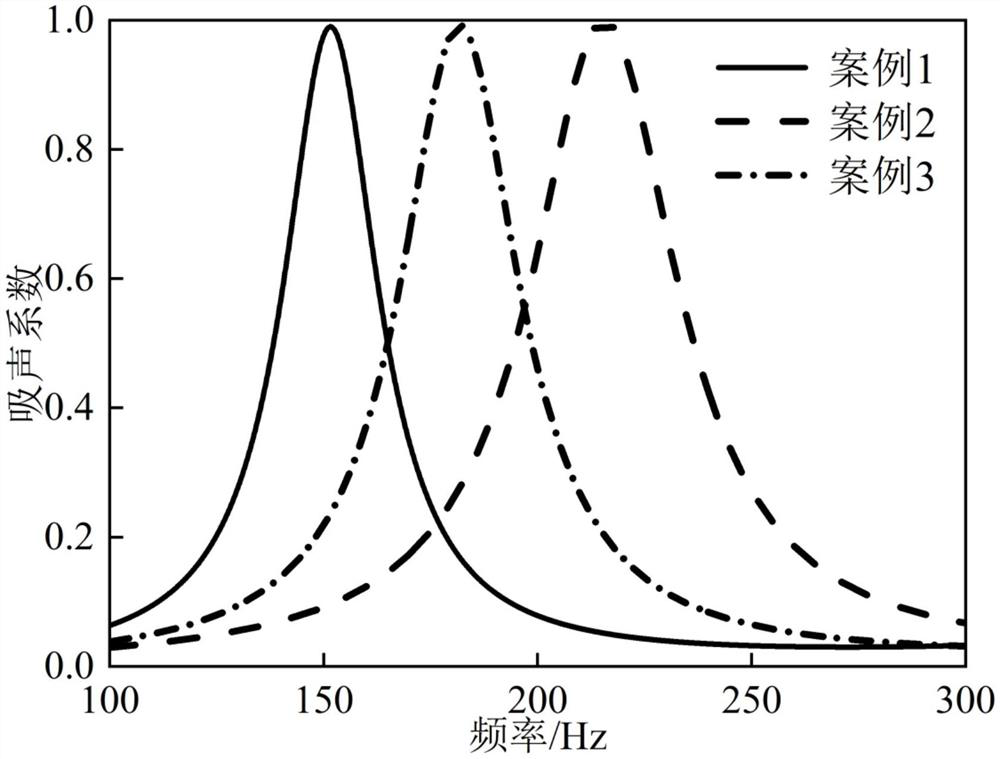

Space bending porous superstructure with adjustable sound absorption frequency band and low-frequency broadband sound absorption performance

PendingCN113628604AExcellent low frequency sound absorption performanceExtended propagation pathSound producing devicesSound energyNoise

The invention relates to a space bending porous superstructure with an adjustable sound absorption frequency band and low-frequency broadband sound absorption performance. The space bending porous superstructure comprises a left side plate, a right side plate, an upper panel, a bottom lining plate, a partition plate and a porous sound absorption material, wherein the left side plate, the right side plate, the upper panel, the bottom lining plate and the partition plate form a space bending channel, and the porous sound absorption material is embedded in the space bending channel. Under the condition that material thickness is not increased, the propagation path of sound waves is greatly increased, and sound energy loss is increased, so the superstructure has excellent low-frequency sound absorption performance; the superstructure has the advantage of large absorption bandwidth, and when the wave crest frequencies are similar, the superstructure has a sound absorption coefficient of 0.8 or above and has bandwidth of 220 Hz; a sound absorption frequency band can be adjusted by adjusting the channel number or channel layout of a space bending structure, and low-frequency broadband sound absorption can be achieved by arranging units of different sound absorption frequency bands in parallel; and the superstructure is simple in structure, easy to produce and low in cost, and has wide engineering application prospects in a low-frequency noise field.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low-frequency broadband flat plate sound absorption structure

PendingCN112712784ACompact structureLight in massSound proofingSound producing devicesSound sourcesNoise

The invention discloses a low-frequency broadband flat plate sound absorption structure, which comprises a frame, a front panel and a rear back plate which are fixedly arranged on the upper side and the lower side of the frame, and a sound absorber which is defined by the frame, the front panel and the rear back plate and used for absorbing low-frequency noise; a plurality of sound absorption holes are formed in the front panel, one sides of the sound absorption holes face the sound source, and the other side is connected with the sound absorber. The sound absorber consists of a plurality of clapboards arranged in the frame in parallel, one ends of the clapboards are fixed with the inner wall of one side of the frame, and the other ends are in clearance fit with the inner wall of the other side of the frame; the partition plates divide the space in the frame into serpentine channels, frame inner walls used for separation are arranged on the channels, and the channels between the adjacent frame inner walls form MIE type resonant cavities. The low-frequency broadband flat plate sound absorption structure is compact in structure, light in weight, small in surface density, wide in low-frequency sound absorption frequency band and good in low-frequency sound absorption performance.

Owner:NANJING UNIV

Multifunctional glass wool

InactiveCN103132607AReasonable structureThermal insulationHeat proofingSound proofingThermal insulationGlass wool

The invention discloses multifunctional glass wool. The multifunctional glass wool comprises two layers of glass wool boards, and is characterized in that glass wool felts are arranged between the two layers of glass wool boards, aluminum foil paper is pasted on the outer surface of the upper layer glass wool board, and heat-collecting paper is pasted on the outer surface of the lower layer glass wool board. The multifunctional glass wool has the advantages of being reasonable in structure, capable of having functions of thermal insulation and noise elimination, and strong in practicability.

Owner:NANTONG DINGLI ENERGY SAVING MATERIALS

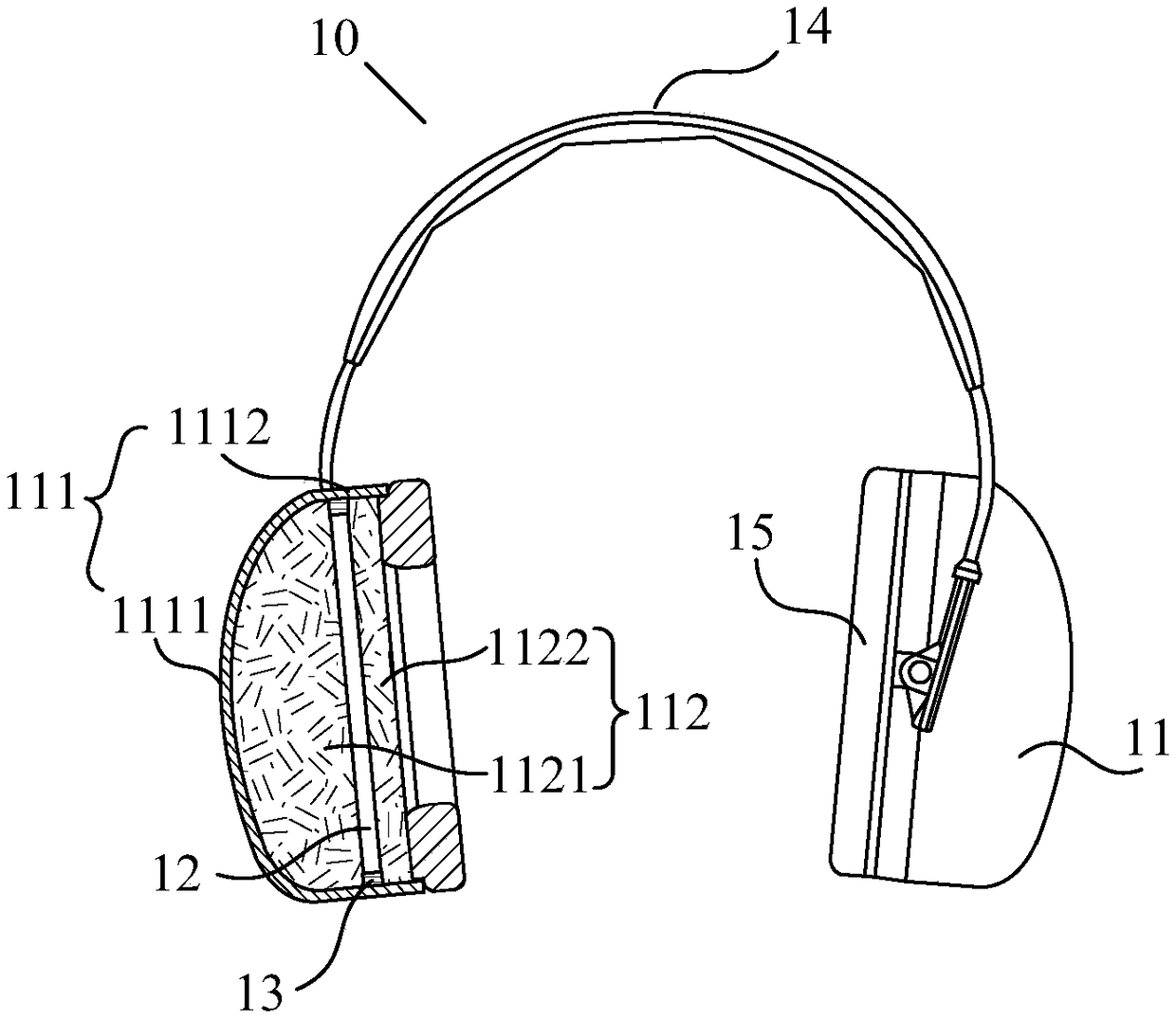

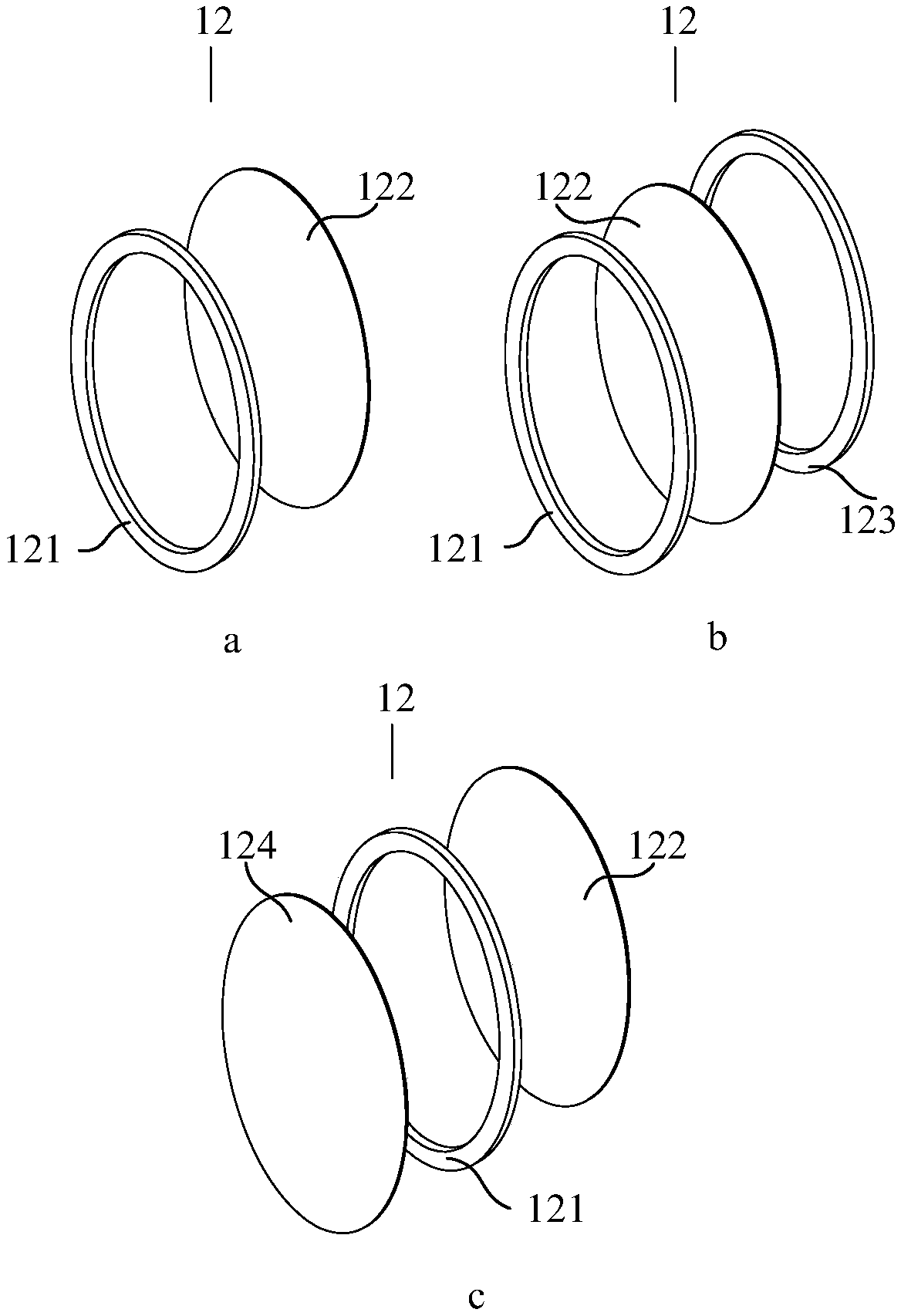

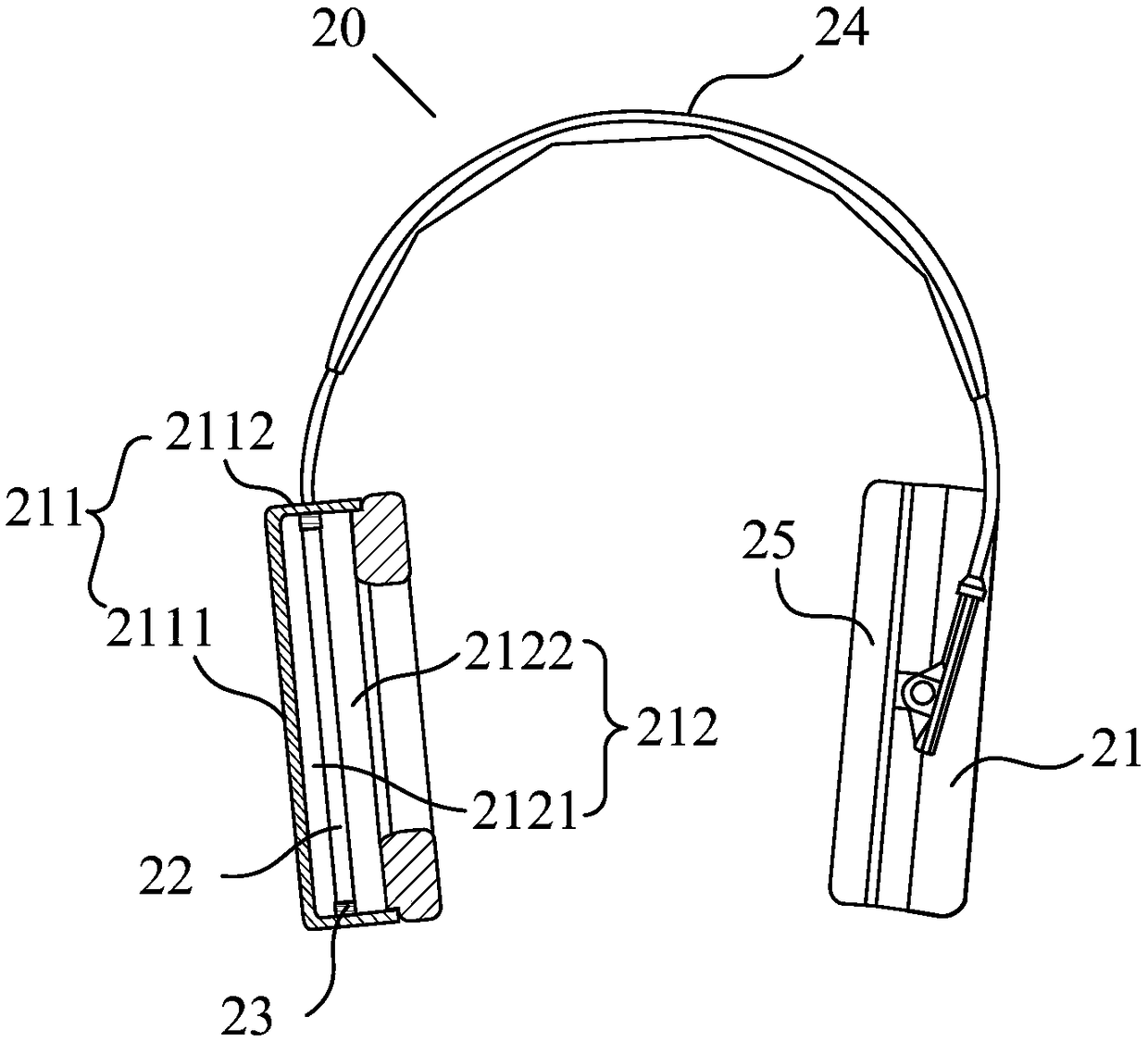

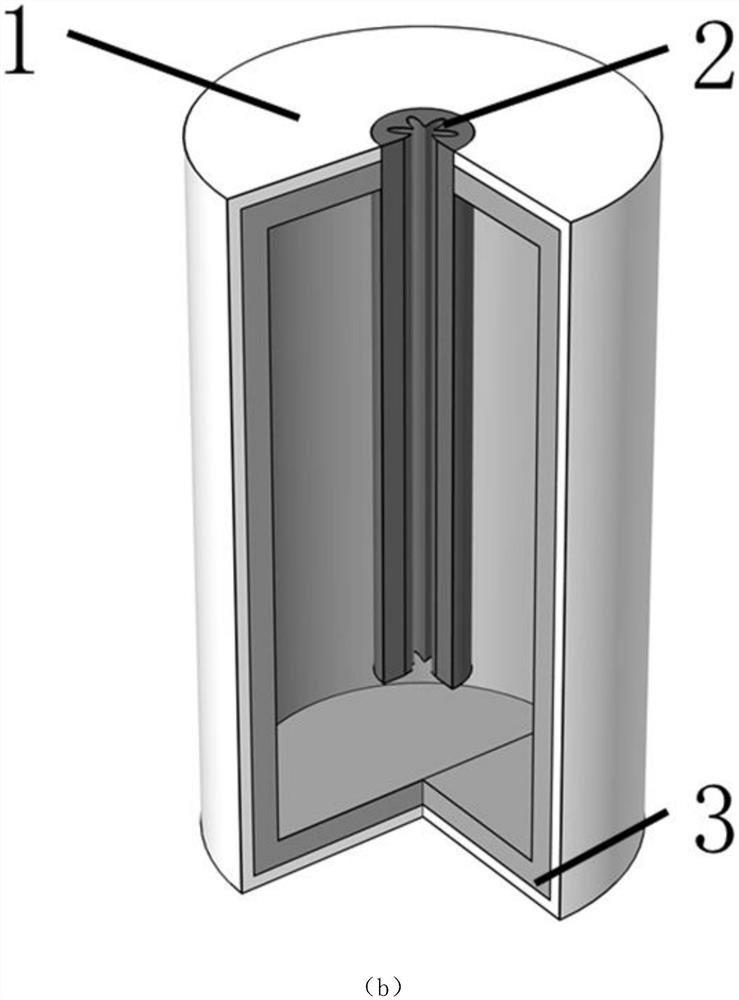

Earmuff

The invention relates to an earmuff. The earmuff comprises at least one ear cup. The ear cup further comprises a shell. The shell comprises a quasi vertical end which is far away from the ear side andparallel to the ear approximately, and a quasi horizontal end which is perpendicular to the ear approximately. The shell is provided with an accommodating cavity; an ultra-material spacer is arrangedin the accommodating cavity, and the ultra-material spacer comprises a side frame and a thin sheet arranged in the side frame; at least one ultra-material spacer is arranged. The earmuff is concise and light and thin in structure and comfortable to wear, can isolate and absorb low frequency noise transmitted to ears effectively, and does not affect voice communication at relatively high frequency.

Owner:上海超颖声学科技有限公司

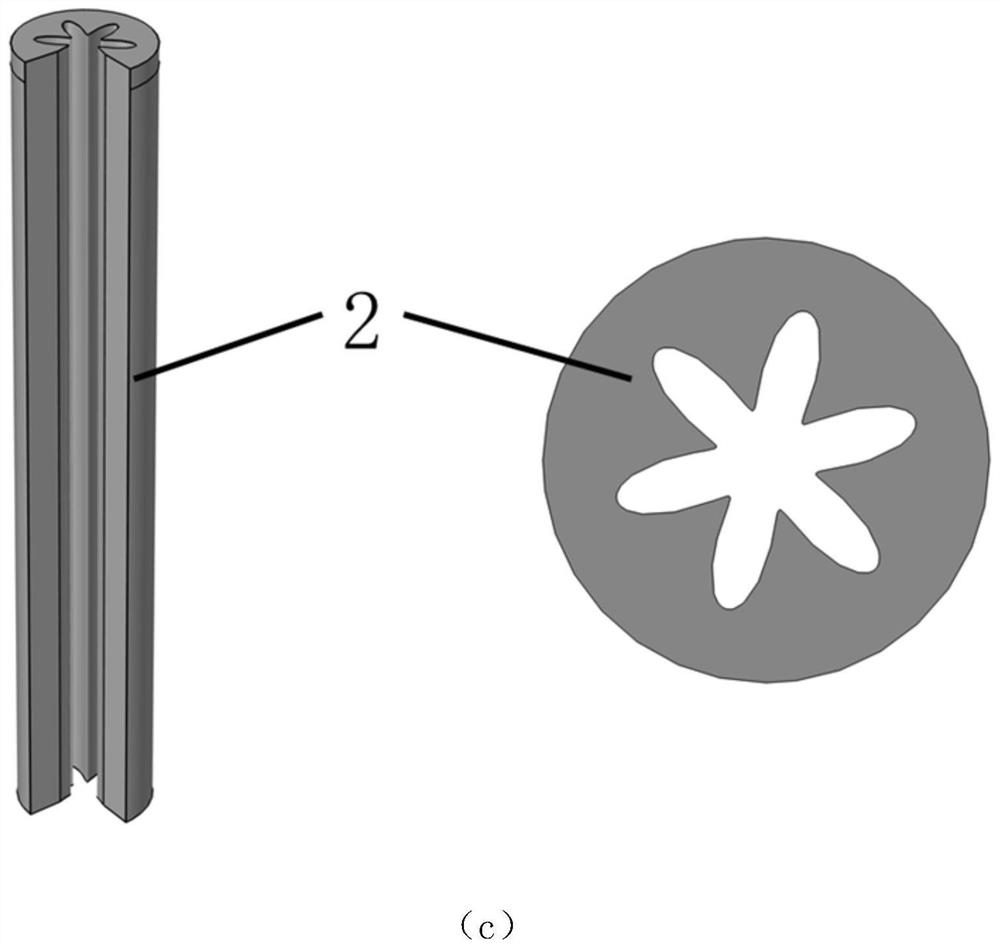

Petal-shaped inner insertion pipe type underwater Helmholtz resonance cavity structure

ActiveCN111696504AImprove acoustic impedance characteristicsImprove low-frequency sound absorption performanceSound producing devicesHelmholtz resonatorEngineering

The invention discloses a petal-shaped inner insertion pipe type underwater Helmholtz resonance cavity structure; a damping lining layer is arranged on the inner wall of a cavity body, a hole is formed in the center of one end of the cavity body, a petal-shaped inner insertion pipe is arranged in the hole, and the petal-shaped inner insertion pipe and the cavity body are connected in a welded or glued mode to form the petal-shaped inner insertion pipe type underwater Helmholtz resonance cavity structure. The petal-shaped inner insertion pipe type underwater Helmholtz resonance cavity structurehas excellent low-frequency sound-absorbing performance and good bearing performance and light weight performance. And more adjustable structural parameters are provided in the design aspect, corresponding adjustment can be conducted according to actual working condition requirements, the structure is simple, and manufacturing is easy.

Owner:XI AN JIAOTONG UNIV +1

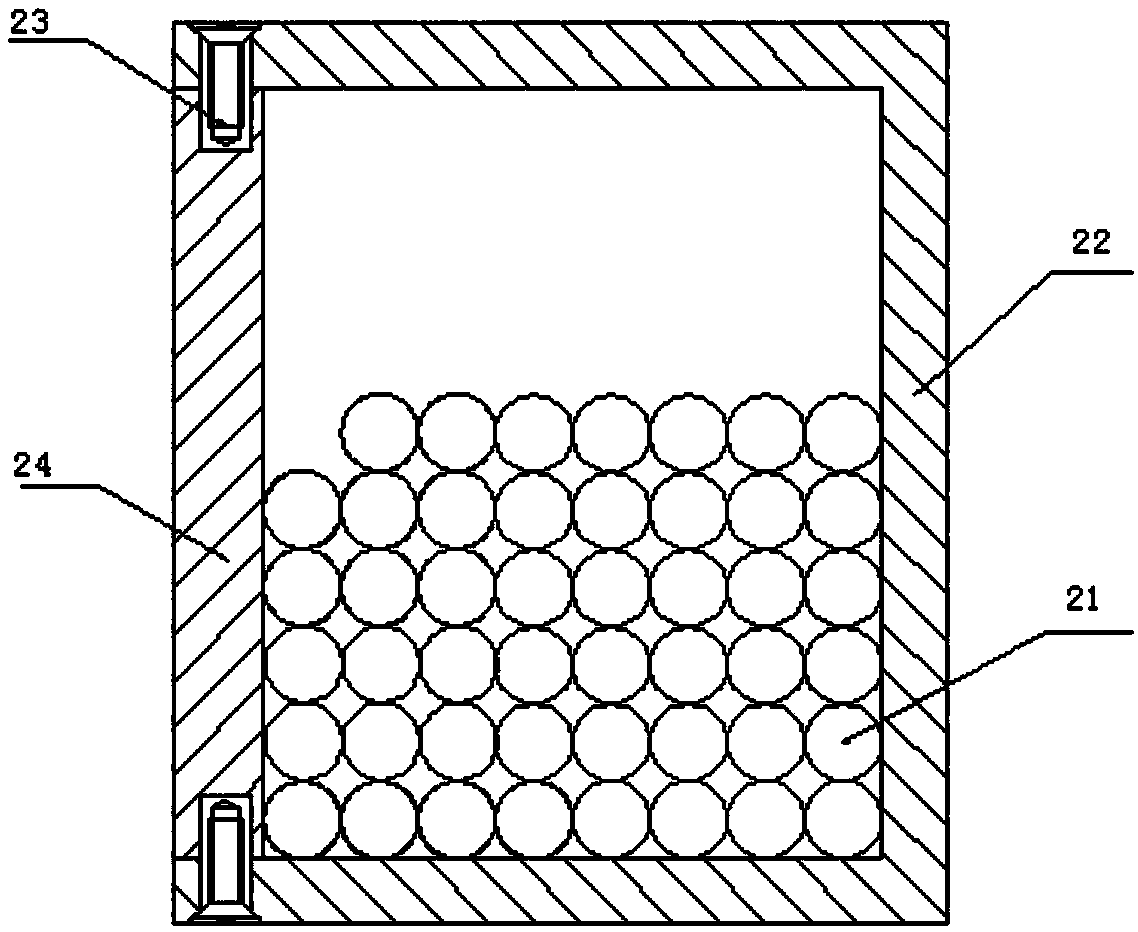

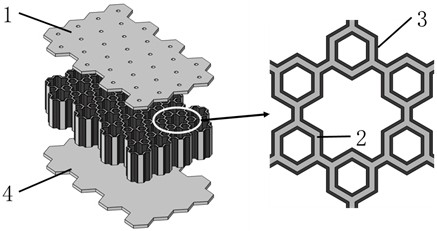

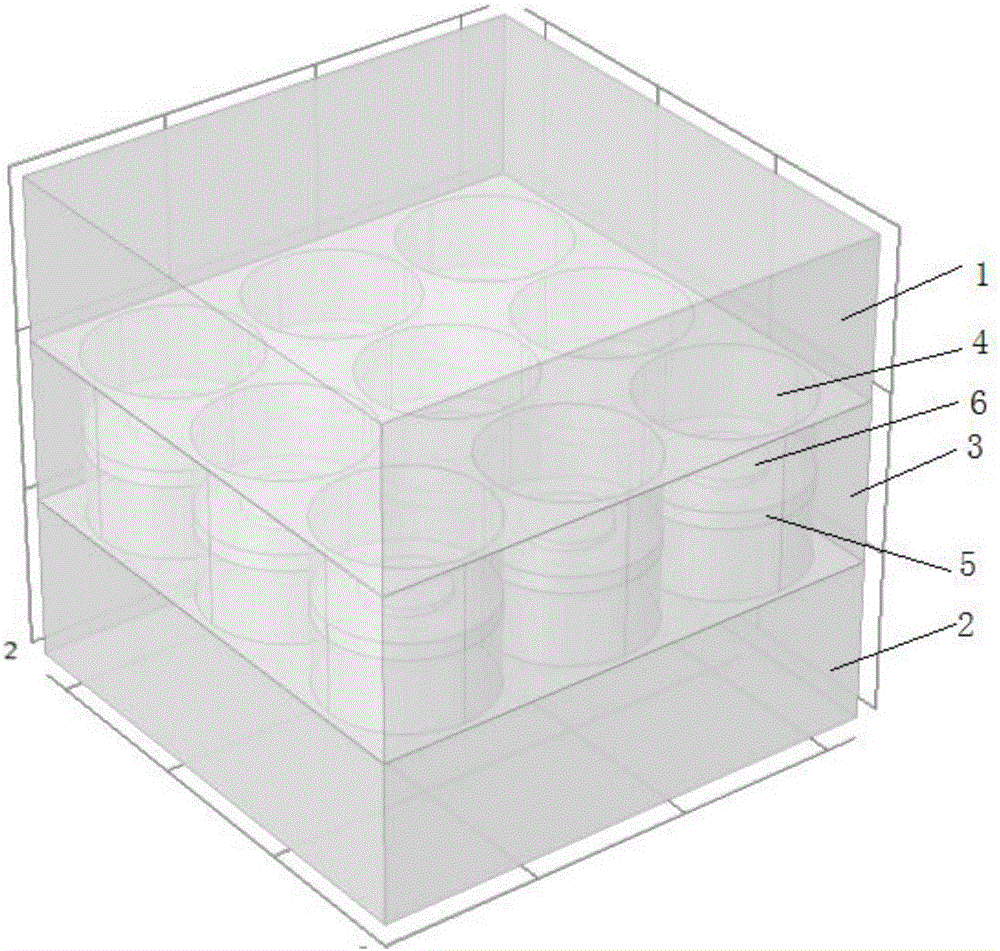

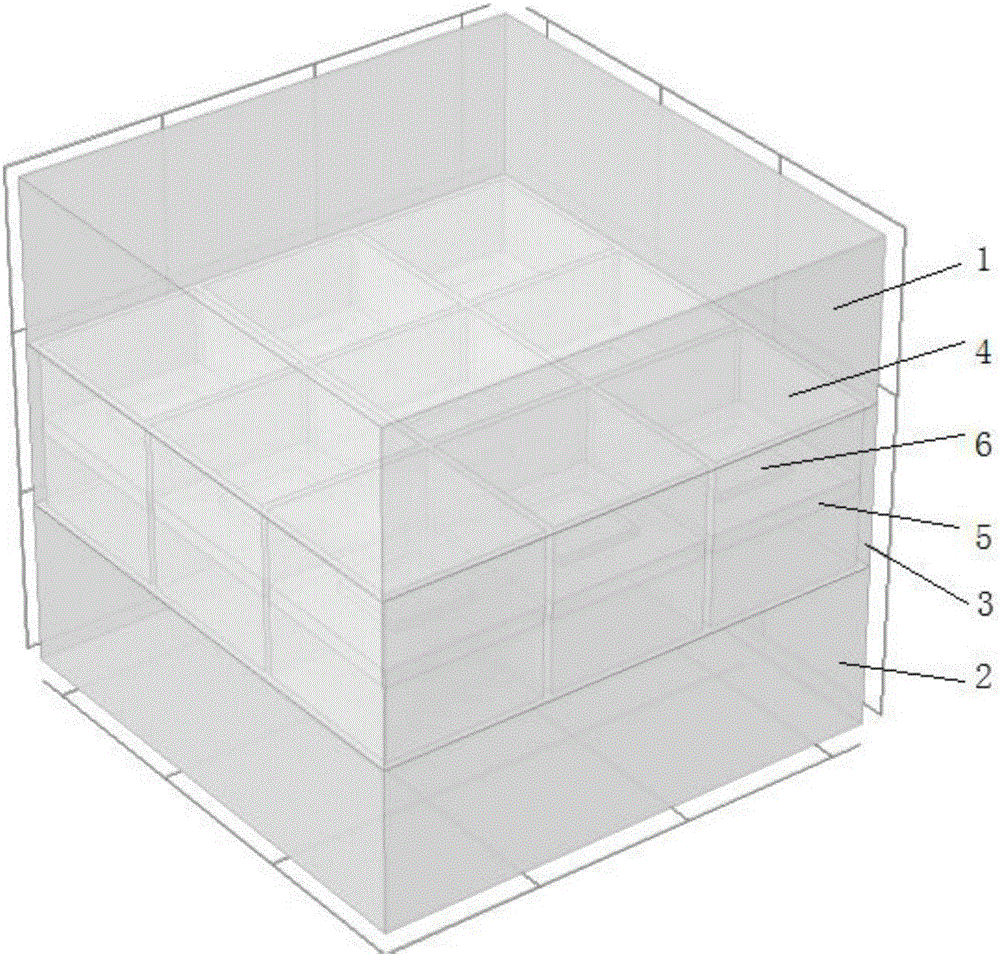

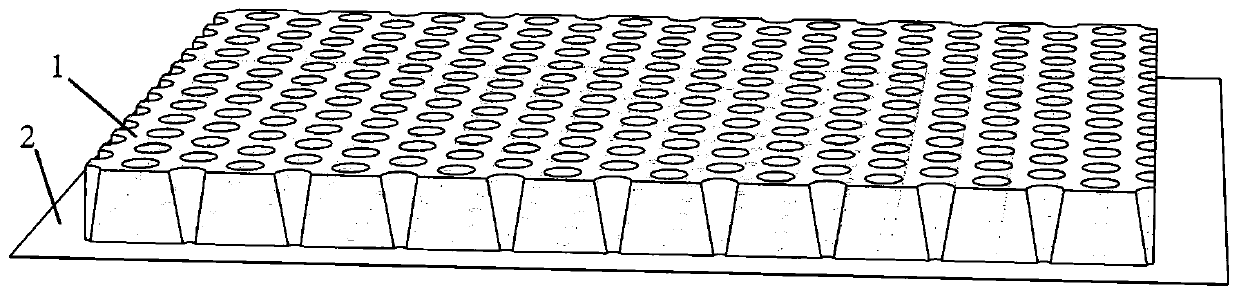

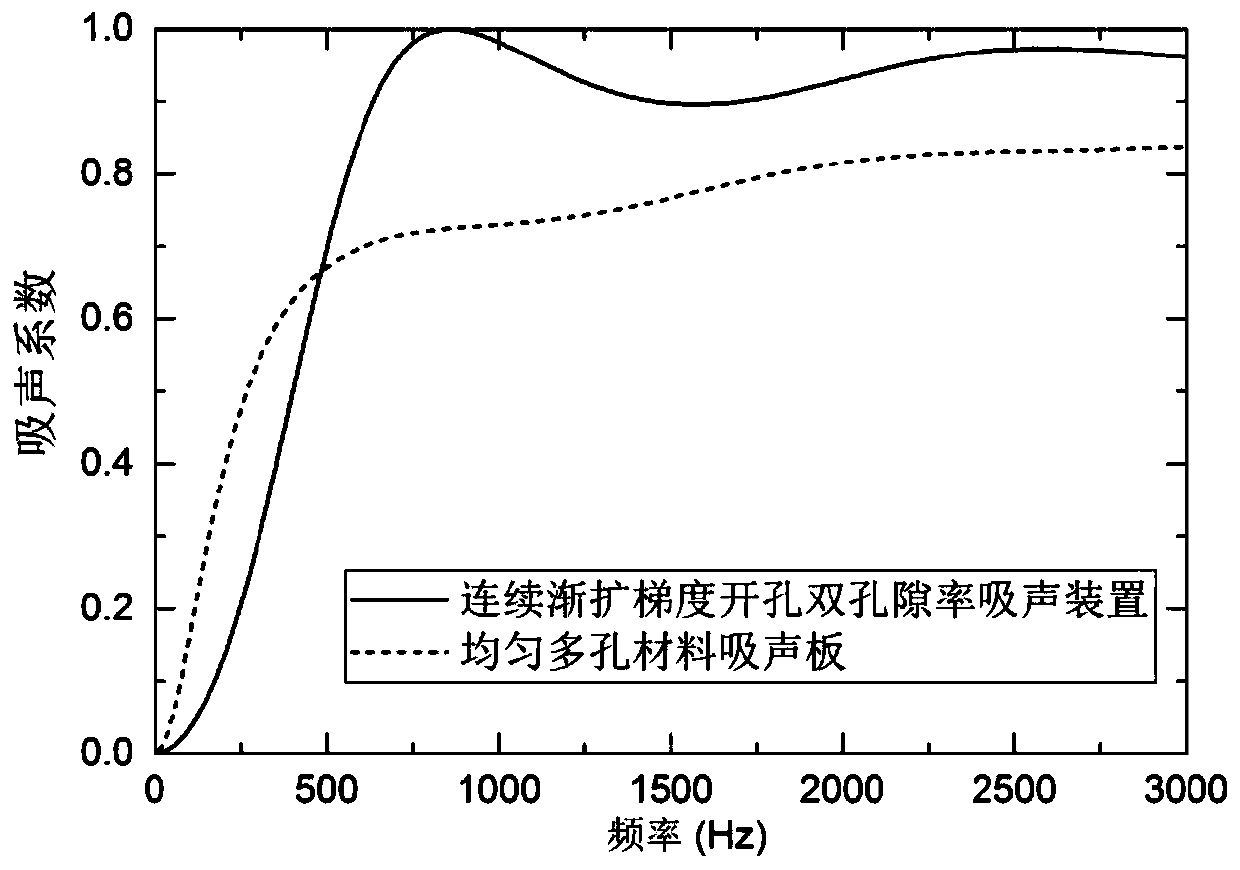

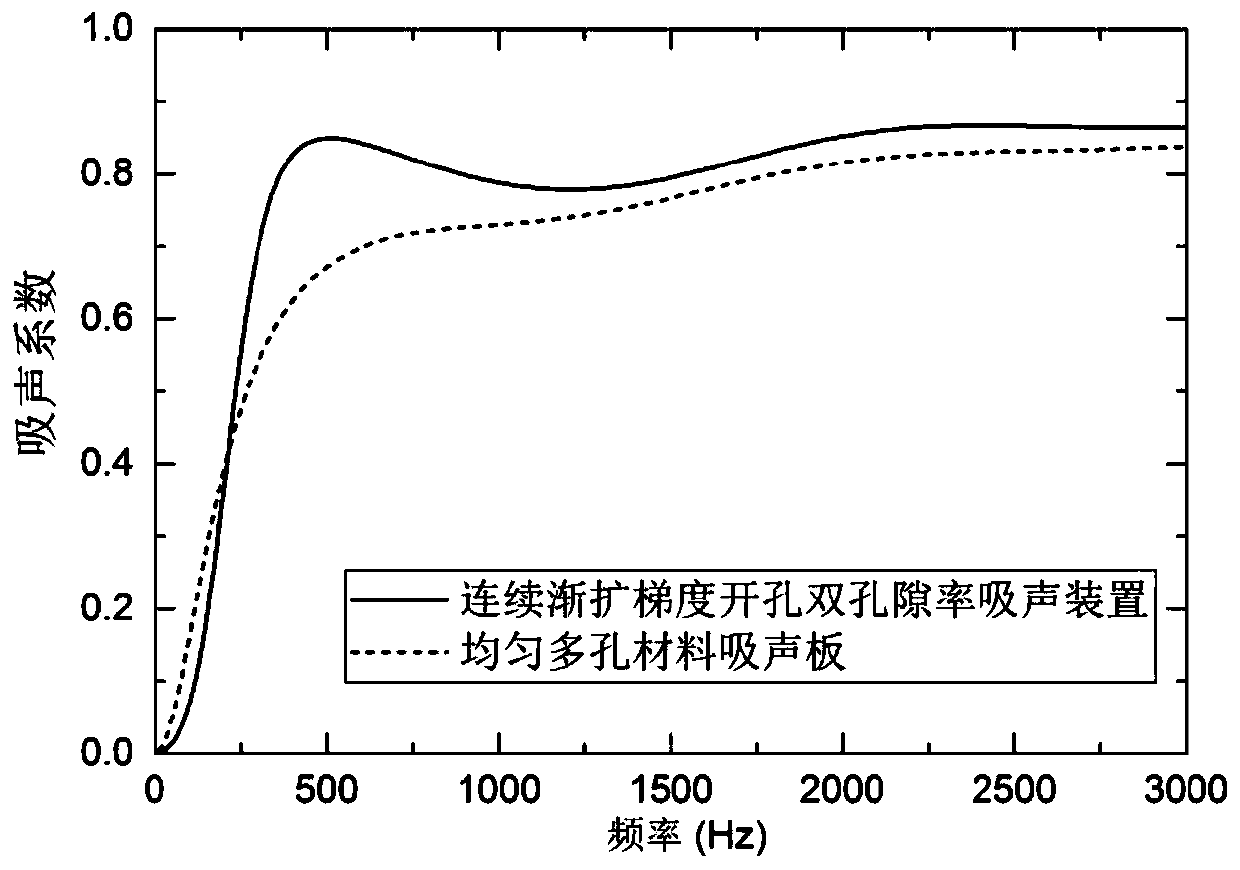

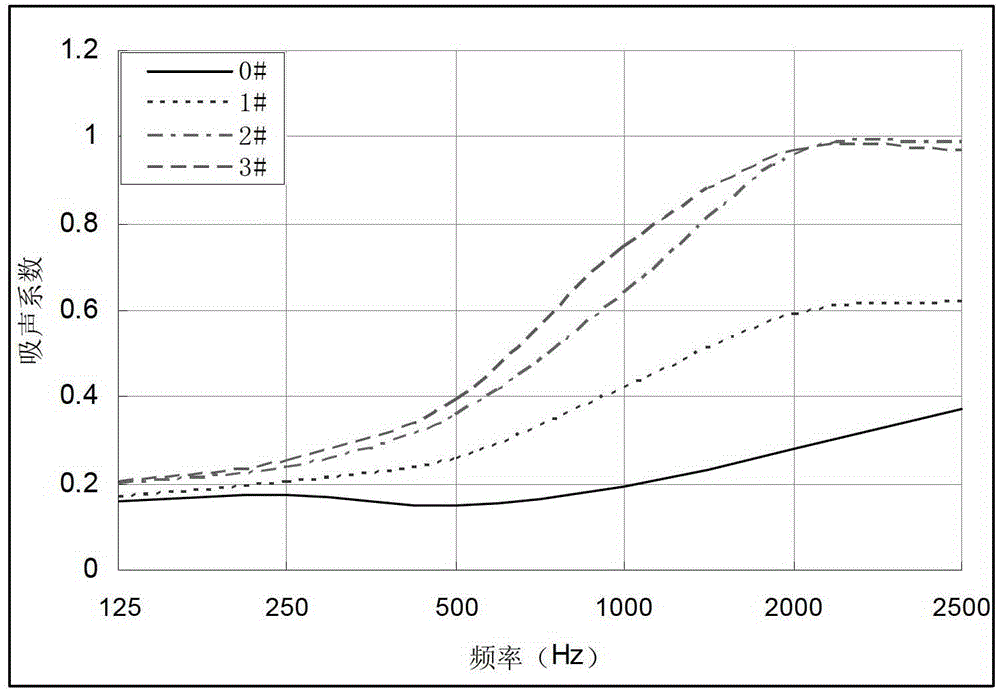

Continuously and gradually enlarging gradient punching double-porosity sound absorbing device and application thereof

ActiveCN109707060AImprove low-frequency sound absorption performanceSimple structureSound proofingSound producing devicesPunchingIntermediate frequency

The invention discloses a continuously and gradually enlarging gradient punching double-porosity sound absorbing device and application thereof. A porous material is adopted as a substrate of a perforated porous material plate, gradient holes are periodically formed in the perforated porous material plate, the punching direction is perpendicular to the perforated porous material plate, the punching pore diameter continuously become larger or smaller in the thickness direction, and according to actual requirements, the gradient double-porosity sound absorbing plate can be directly placed on rigid backing, or a hollow cavity is reserved between the sound absorbing plate and the rigid backing to further improve the sound absorbing property. The continuously and gradually enlarging gradient punching double-porosity sound absorbing device is simple and practical in structure, has a superior sound absorbing property and a flexible sound absorbing adjusting function in a low frequency band, amedium frequency band and a high frequency band, and has good and wide application prospects.

Owner:XI AN JIAOTONG UNIV

Double-helix coupling underwater sound absorption metasurface structure

PendingCN112185326AImprove acoustic impedance characteristicsImprove low-frequency sound absorption performanceSound producing devicesEngineeringFrequency sound

The invention discloses a double-helix coupling underwater sound absorption metasurface structure which comprises a layer core, a plurality of double-helix coupling units are arranged in the layer core at intervals, a cavity is formed in the spiral center of each double-helix coupling unit, an annular partition plate is arranged between each cavity and a spiral channel, and a spiral damping lininglayer is arranged on the side wall of each spiral channel. A perforated upper panel is arranged at the top of the layer core, small holes are periodically formed in the perforated upper panel corresponding to cavities of the double-helix coupling units, a lower panel is arranged at the bottom of the layer core, and the perforated upper panel, the layer core and the lower panel are connected to form a double-helix coupling underwater sound absorption metasurface structure. The double-helix coupling underwater sound absorption metasurface structure has excellent low-frequency sound-absorbing performance and ultra-thin sub-wavelength structure size. And more adjustable structural parameters are provided in the design aspect, corresponding adjustment can be conducted according to actual working condition requirements, the structure is simple, and manufacturing is easy.

Owner:XI AN JIAOTONG UNIV

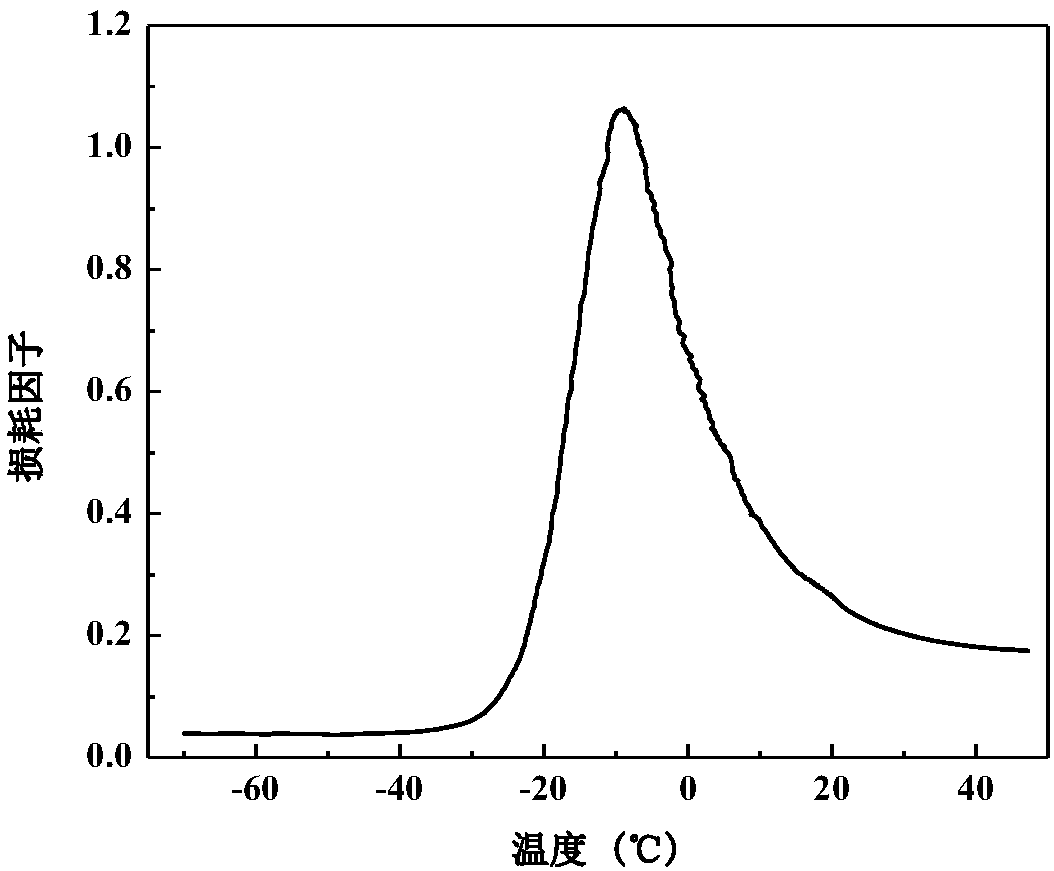

A barium titanate/rubber piezoelectric composite material for low-frequency sound absorption and its preparation method

InactiveCN106750656BWide damping temperature rangeHigh storage modulusPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionNitrile rubberBarium titanate

The invention belongs to the field of low-frequency sound-absorbing materials, and in particular relates to a barium titanate / rubber piezoelectric composite material for low-frequency sound absorption and a preparation method thereof. In the present invention, the barium titanate ceramic powder is first pretreated, and then the piezoelectric ceramic is used as the functional phase, the conductive carbon black is used as the conductive phase, and the nitrile rubber is used as the matrix, and the principle of combining the piezoelectric effect and the volume effect is used to prepare the Barium titanate / rubber piezoelectric composite material for low-frequency sound absorption, the damping temperature range of the barium titanate / rubber piezoelectric composite material is wider, and the storage modulus is higher; based on the principle of piezoelectric effect and volume effect, the The above-mentioned barium titanate / rubber piezoelectric composite material can obtain better low-frequency sound absorption effect under the condition of smaller thickness.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A multi-fiber blended sound-absorbing material

ActiveCN104695134BExcellent low frequency sound absorption performanceSimple preparation processSound producing devicesNon-woven fabricsPolyesterPolymer science

The invention relates to a multi-fiber blended sound-absorbing material comprising aluminum fibers and organic composite polymer fibers. The multi-fiber blended sound-absorbing material is characterized in that the aluminum fibers 50-100 micrometers in diameter are made of pure aluminum; the organic composite polymer fibers 20-50 micrometers in diameter include polyester fibers (on the inner layer) and polypropylene fibers (on the outer layer). A blend fiber design thought is adopted, the aluminum fibers and the organic composite polymer fibers are blended, the polypropylene fibers melt during bake forming according to a low melting point, the aluminum fibers are adhered to the polyester fibers, and the multi-fiber blended sound-absorbing material with damping energy dissipation property is produced.

Owner:STATE GRID CORP OF CHINA +3

A low-frequency sound-absorbing needle-punched nonwoven composite material and its preparation method and application

InactiveCN103106898BImprove low-frequency sound absorption performanceExcellent low frequency sound absorption performanceSound proofingSound producing devicesKapok fiberEconomic benefits

The invention relates to low-frequency sound absorption needling non-woven composite materials and a preparation method of the low-frequency sound absorption needling non-woven composite materials and application of the low-frequency sound absorption needling non-woven composite materials. The composite materials comprise kapok fibers or hollow Dacron non-woven fabric and polyethylene films. The preparation method comprises: mixing, opening, carding and meshing are conducted to 60%-90% kapok fibers and 40%-10% hollow Dacron non-woven fabric according to mass percent; a fiber mesh is inputted in a needling machine so as to conduct needling reinforcement, the fiber mesh is reeled and cut off so as to obtain kapok or hollow Dacron needle non-woven fabric; the polyethylene films in 0.06mm-0.10mm are smoothly placed on one side of the needle non-woven fiber mesh, and are composited, taken out and cooled, and then the low-frequency sound absorption needling non-woven composite materials are obtained. The composite materials can be applied to the field of automotive trim, construction, high-speed rail and the like. The sound absorption materials have the advantages of being light in weight, simple in operation of the preparation method, good in economic benefit and suitable for industrial production.

Owner:DONGHUA UNIV

A composite structural part for noise reduction and vibration reduction in ship cabins

ActiveCN109018193BIncreased sound absorption frequency bandImprove the sound absorption coefficientHull panellingsMicro perforated plateWorking environment

The invention discloses a composite structural member for noise reduction and vibration reduction in a ship cabin, which comprises an outer micro-perforated plate, a frame and an inner micro-perforated plate connected to the cabin surrounding wall through a connecting piece, the outer micro-perforated plate The plate and the inner micro-perforated plate are fixedly connected by the frame to form a double-layer micro-perforated cavity body, and the two side walls corresponding to the frame in the cavity body are fixedly connected with multiple rows of multi-layer particle dampers through elastic connecting rods . The invention can optimize the sound absorption coefficient of the micro-perforated plate without changing the structure of the cabin, widen its sound absorption frequency band, improve the sound absorption effect, reduce the vibration of the cabin structure, and create a good working environment for the cabin; and the invention has a compact structure , Easy to install. It has good engineering application prospect.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com