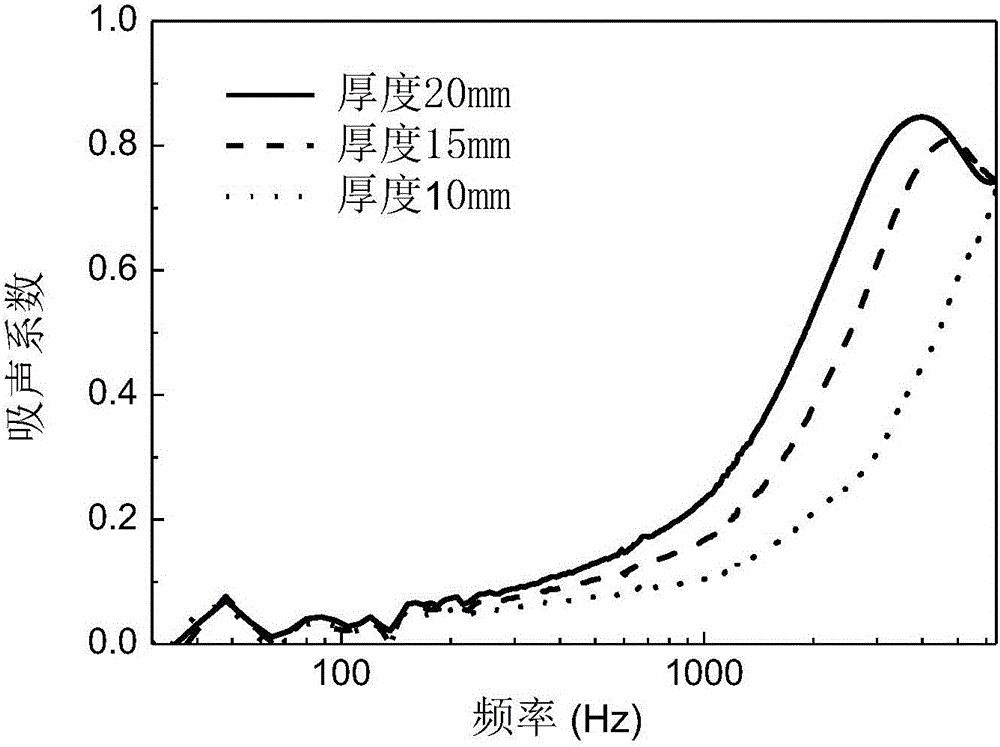

Composite sound absorption structure for improving set low frequency sound absorption performance

A sound absorption and performance technology, applied in the field of acoustics, can solve the problems of distortion or damage of sensitive components, poor low frequency sound absorption, etc., to achieve the effect of enhancing sound absorption capacity, improving sound absorption performance, and improving low frequency sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

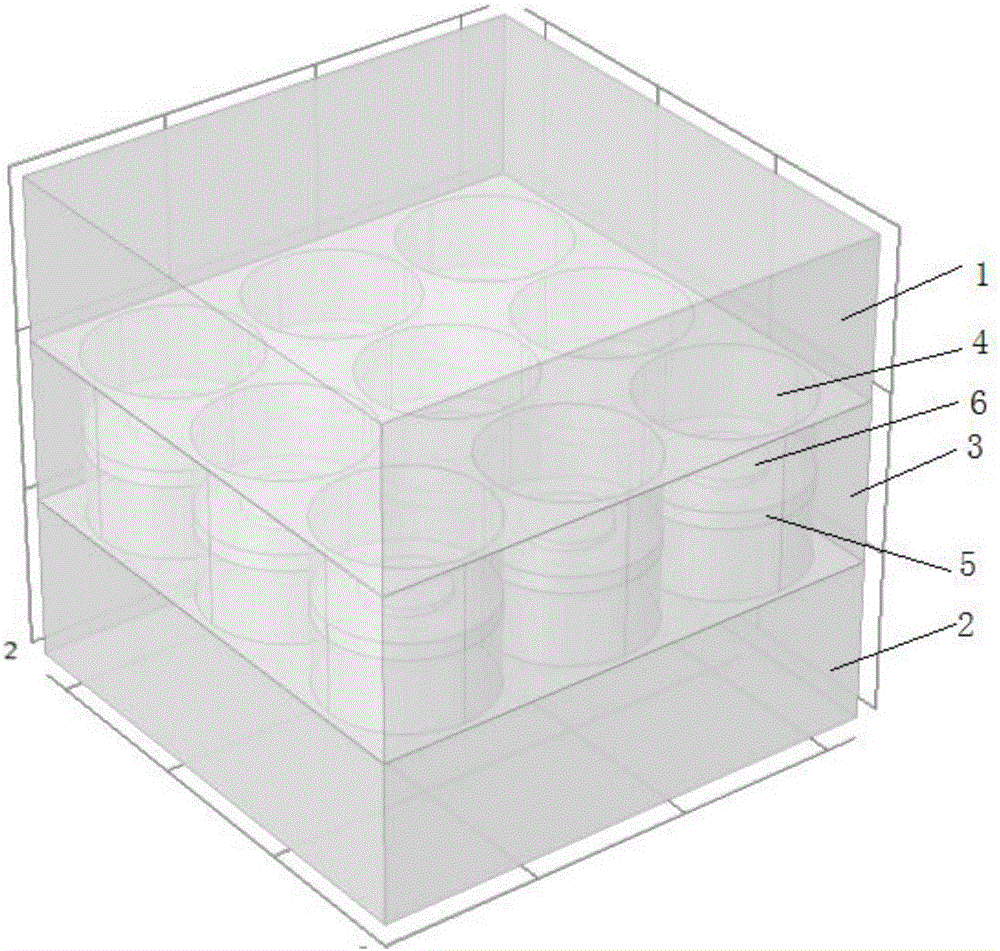

[0050] In order to strengthen the sound absorption coefficient at a specific frequency of 960 Hz, the upper felt layer 1, the lower felt layer 2 and the middle felt layer 3 are all made of stainless steel metal fiber felt with a porosity of 90%, and the diameter of the felt wire is 50 μm; the film 5 is selected The modulus is 50Mp and the density is 1097kg / m 3 , the rubber material with Poisson's ratio of 0.33, the mass block 6 is selected with a modulus of 200GP and a density of 7870kg / m 3 1. An aluminum block with a Poisson's ratio of 0.3;

[0051] See attached Figure 4 , the composite sound-absorbing structure is evenly divided into a unit cell configuration, the unit cell configuration includes a through hole 4 and a film 5, when the through hole 4 is square or circular, the side length of the through hole 4 or The inner diameter is a, the thickness of the upper felt layer 1 is b1, the thickness of the lower felt layer 2 is b3, the thickness of the middle felt layer 3 i...

example 2

[0055] In order to strengthen the sound absorption coefficient at a specific frequency of 960 Hz, the upper felt layer 1, the lower felt layer 2 and the middle felt layer 3 are all made of stainless steel metal fiber felt with a porosity of 90%, and the diameter of the felt wire is 50 μm; the film 5 is selected The modulus is 50Mp and the density is 1097kg / m 3 , the rubber material with Poisson's ratio of 0.33, the mass block 6 is selected with a modulus of 200GP and a density of 7870kg / m 3 1. An aluminum block with a Poisson's ratio of 0.3;

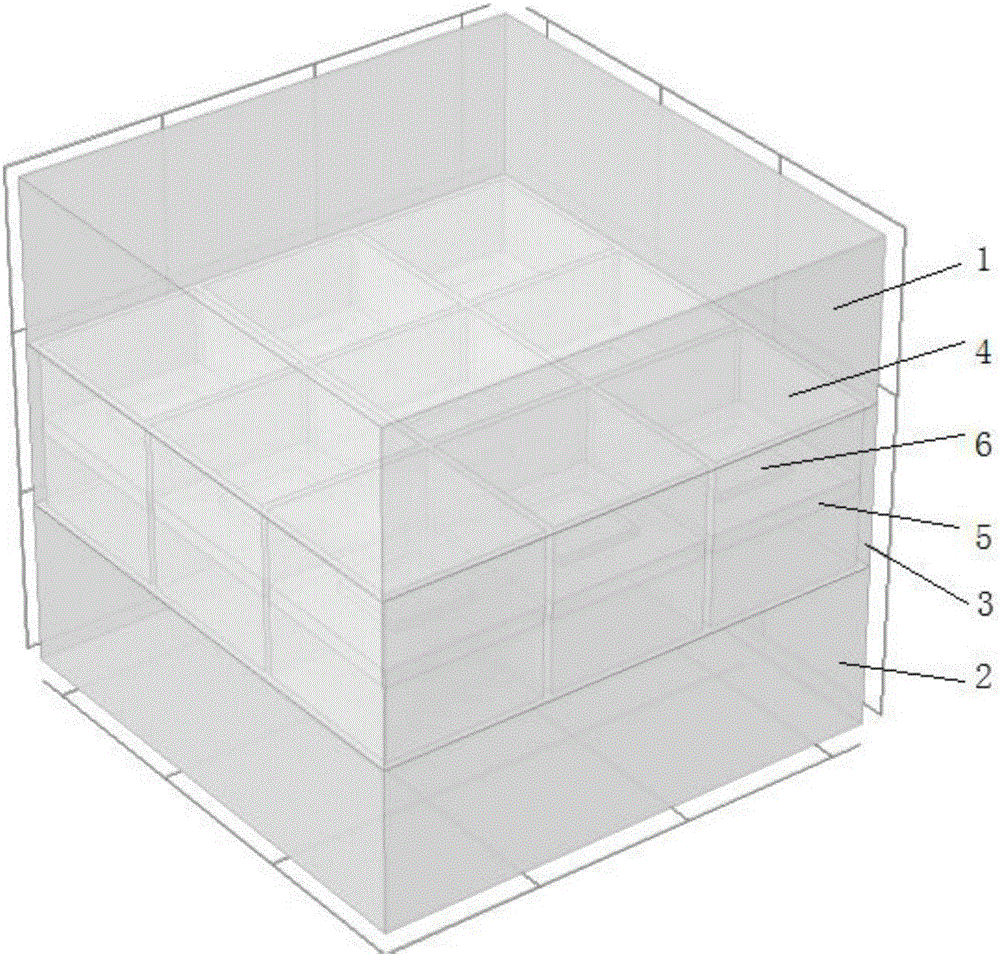

[0056] See attached Figure 5 , the composite sound-absorbing structure is evenly divided into a unit cell configuration, the unit cell configuration includes a through hole 4 and a film 5, when the through hole 4 is formed by butting the large ends of two frustum-shaped cavities , the maximum inner diameter of the through hole 4 is a, the smallest inner diameter of the through hole 4 is c, and c is arrive Between; the overall thic...

example 3

[0060] In order to strengthen the sound absorption coefficient at a specific frequency of 200 Hz, the upper felt layer 1, the lower felt layer 2 and the middle felt layer 3 are all made of stainless steel metal fiber felt with a porosity of 90%, and the diameter of the felt wire is 50 μm; the film 5 is selected The modulus is 50Mp and the density is 1097kg / m 3 , the rubber material with Poisson's ratio of 0.33, the mass block 6 is selected with a modulus of 200GP and a density of 7870kg / m 3 1. An aluminum block with a Poisson's ratio of 0.3;

[0061] See attached Figure 4 , the composite sound-absorbing structure is evenly divided into a unit cell configuration, the unit cell configuration includes a through hole 4 and a film 5, when the through hole 4 is square or circular, the side length of the through hole 4 or The inner diameter is a, the thickness of the upper felt layer 1 is b1, the thickness of the lower felt layer 2 is b3, the thickness of the middle felt layer 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com