Patents

Literature

36results about How to "Improve low-frequency sound absorption performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-frequency sound absorption needling non-woven composite materials and preparation method thereof and application thereof

InactiveCN103106898AImproved sound absorptionImprove sound absorptionSound proofingSound producing devicesKapok fiberEconomic benefits

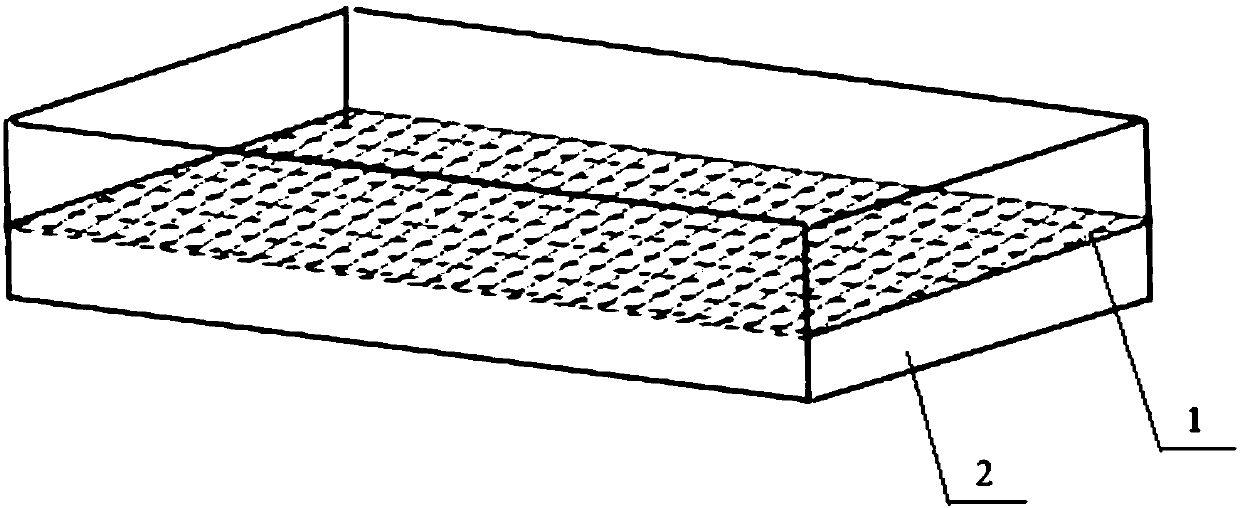

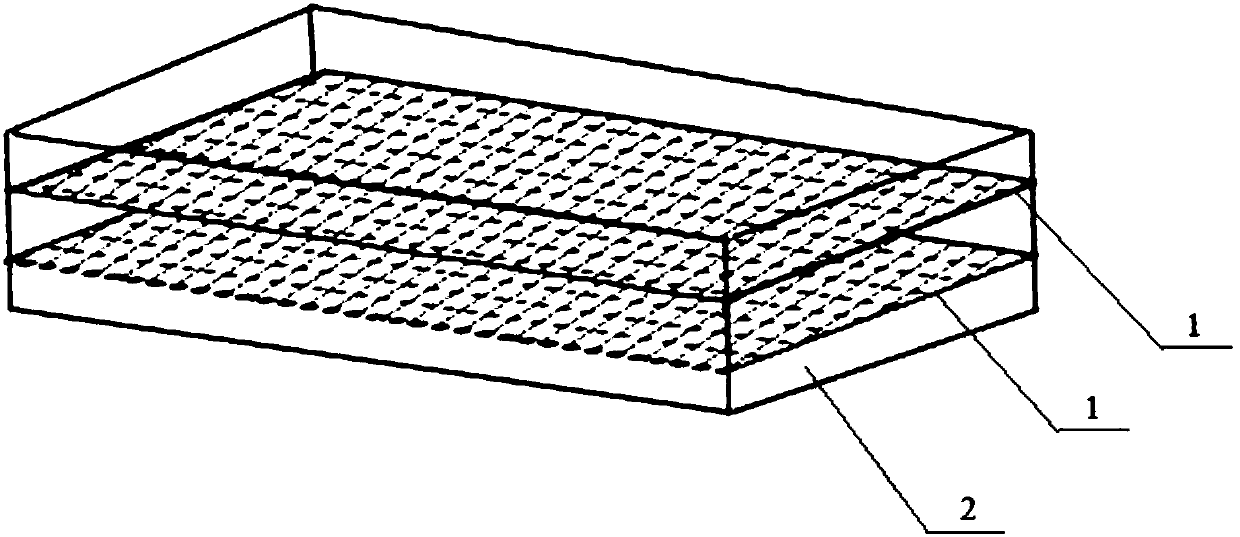

The invention relates to low-frequency sound absorption needling non-woven composite materials and a preparation method of the low-frequency sound absorption needling non-woven composite materials and application of the low-frequency sound absorption needling non-woven composite materials. The composite materials comprise kapok fibers or hollow Dacron non-woven fabric and polyethylene films. The preparation method comprises: mixing, opening, carding and meshing are conducted to 60%-90% kapok fibers and 40%-10% hollow Dacron non-woven fabric according to mass percent; a fiber mesh is inputted in a needling machine so as to conduct needling reinforcement, the fiber mesh is reeled and cut off so as to obtain kapok or hollow Dacron needle non-woven fabric; the polyethylene films in 0.06mm-0.10mm are smoothly placed on one side of the needle non-woven fiber mesh, and are composited, taken out and cooled, and then the low-frequency sound absorption needling non-woven composite materials are obtained. The composite materials can be applied to the field of automotive trim, construction, high-speed rail and the like. The sound absorption materials have the advantages of being light in weight, simple in operation of the preparation method, good in economic benefit and suitable for industrial production.

Owner:DONGHUA UNIV

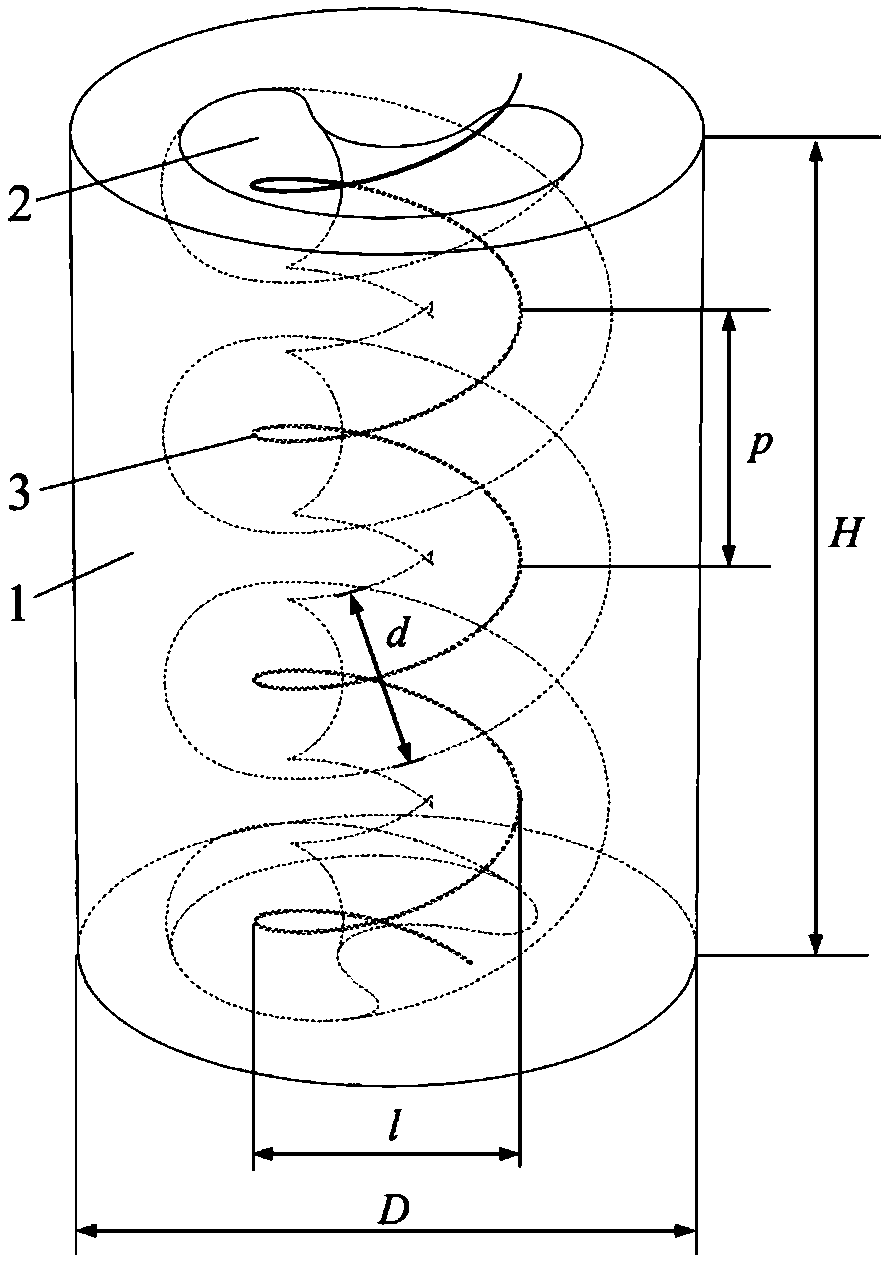

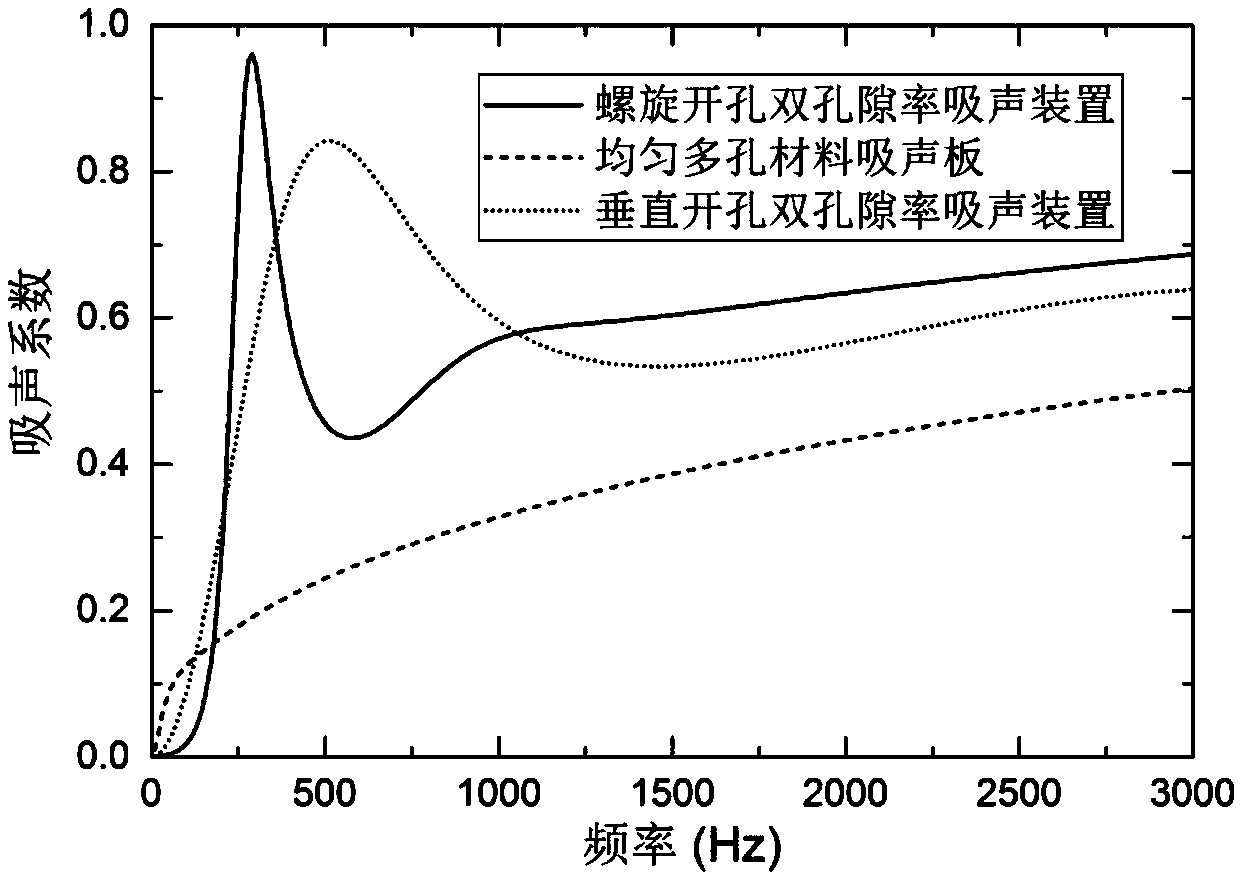

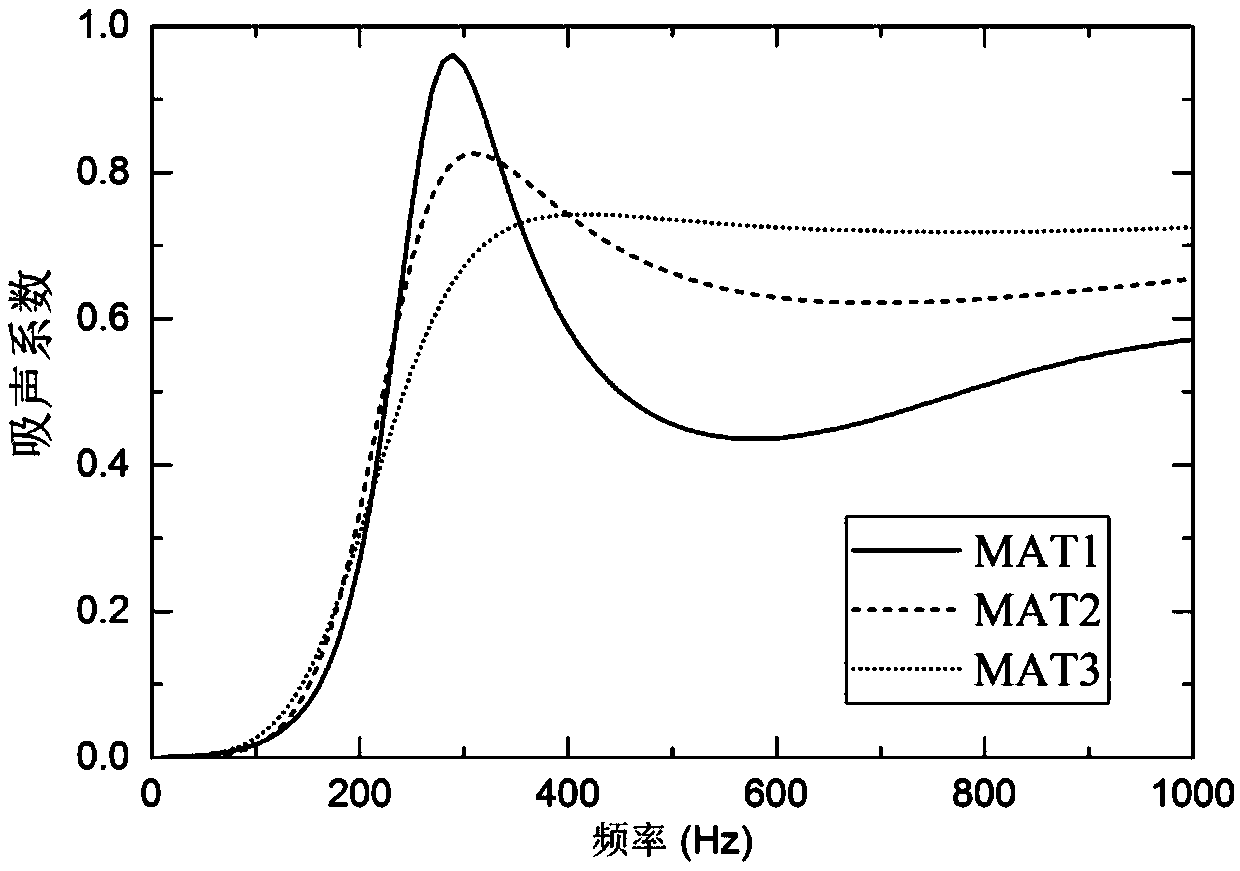

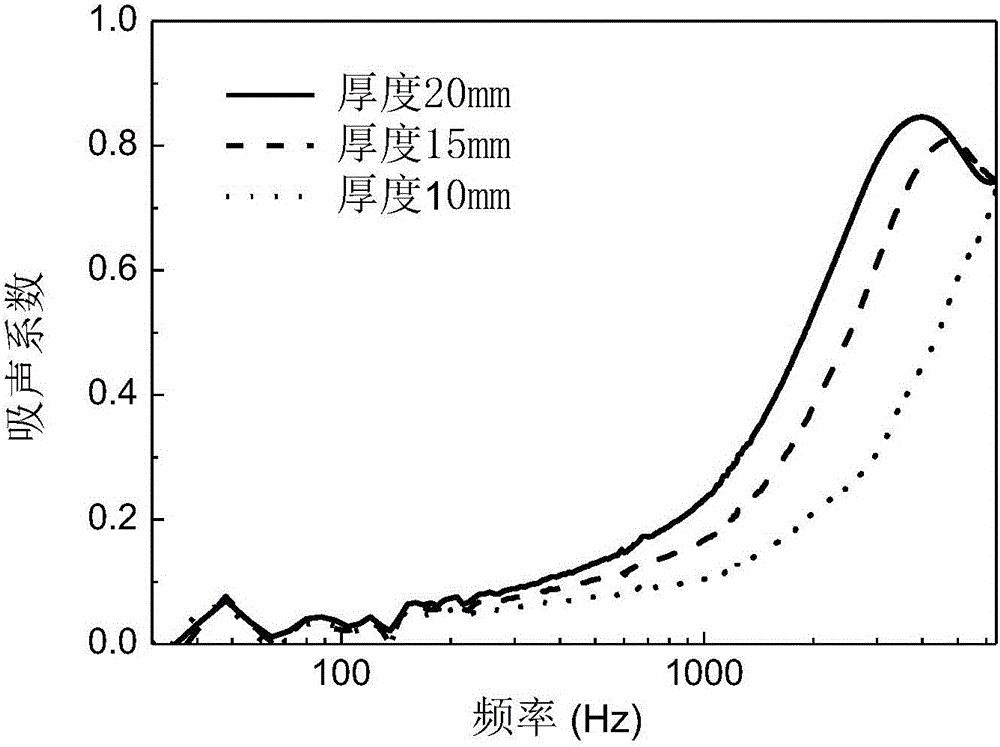

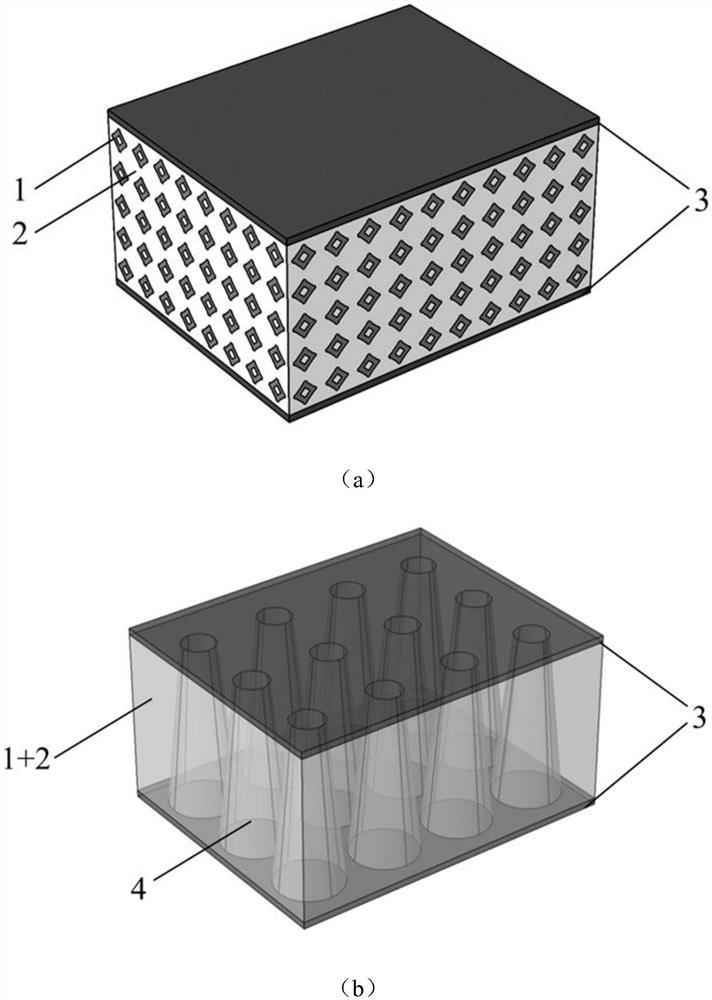

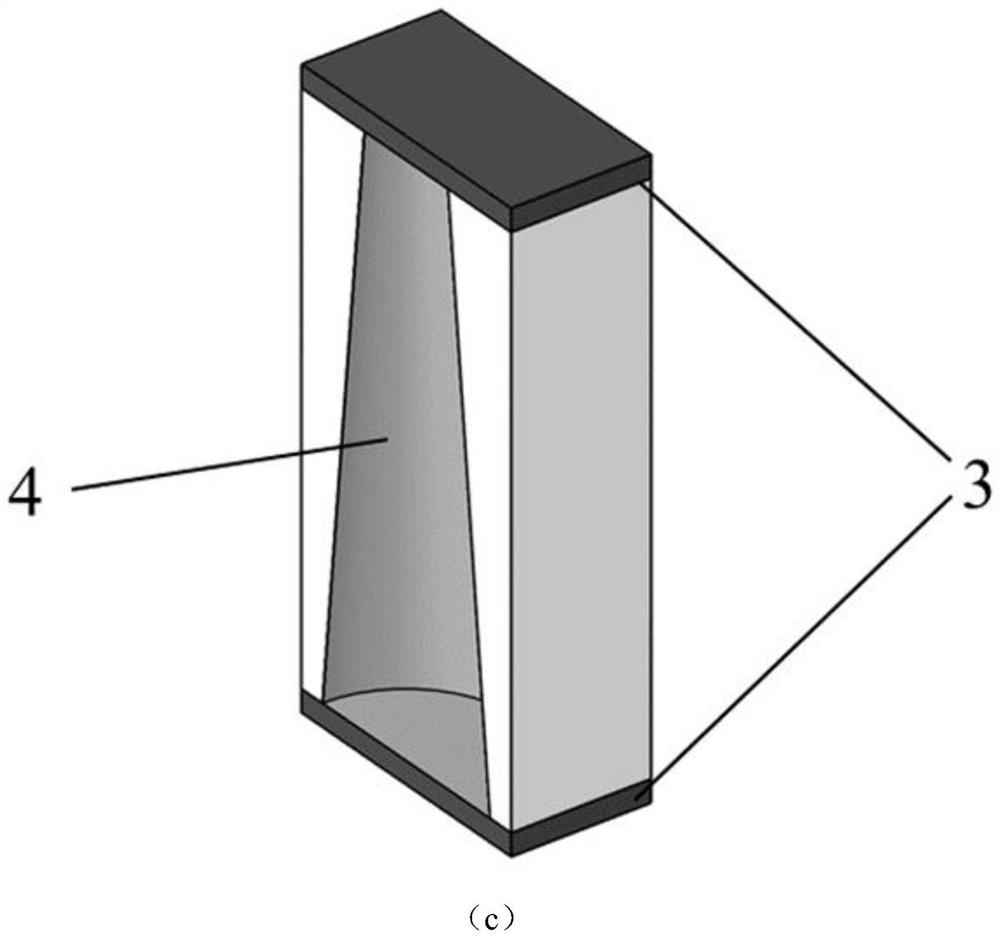

Spiral hole dual-porosity sound absorbing device and application thereof

PendingCN109686354AImprove low-frequency sound absorption performanceExcellent low frequency sound absorption performanceSound producing devicesPorositySound energy

The invention discloses a spiral hole dual-porosity sound absorbing device and application thereof. The device is realized by forming a spiral hole in a substrate of a porous material, and the sinuosity of wound waves entering the porous material is greatly improved by a spiral channel. The sound waves first enter the spiral hole at a low frequency band and then enter micro pores of the porous material via the spiral hole. By utilizing sound energy dissipation brought by strong coupling of the wound waves between the spiral hole formed in the porous material and the micro pores of the porous material, the low-frequency sound absorption property of the sound absorbing material in the invention is enhanced. Moreover, by combining the consistently good high-frequency sound absorption propertyof the porous material, the spiral hole dual-porosity sound absorbing device disclosed by the invention can reach a sound absorption peak value at an ultralow frequency under the condition that the thickness is small, and also has a certain medium-high frequency sound absorbing ability. The device disclosed by the invention is simple in structure and practical and has excellent and wide application prospects.

Owner:XI AN JIAOTONG UNIV

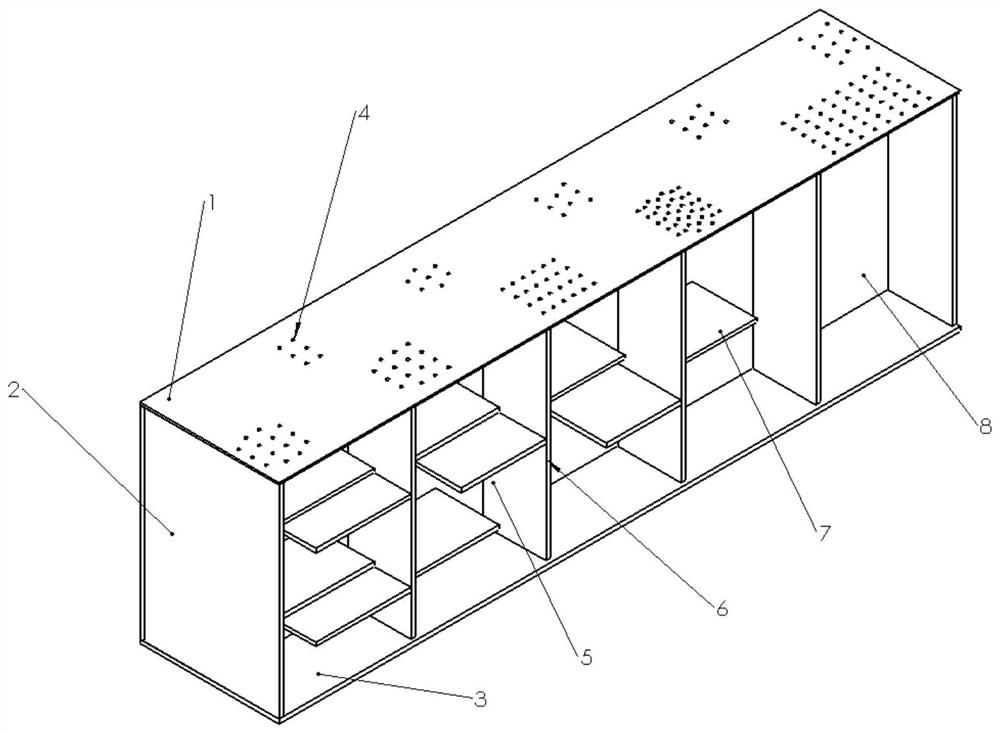

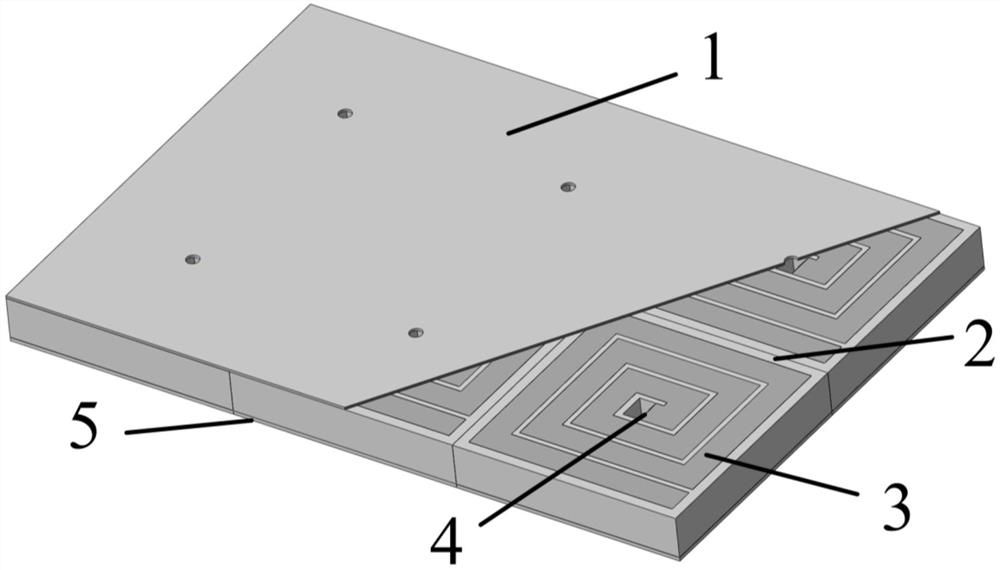

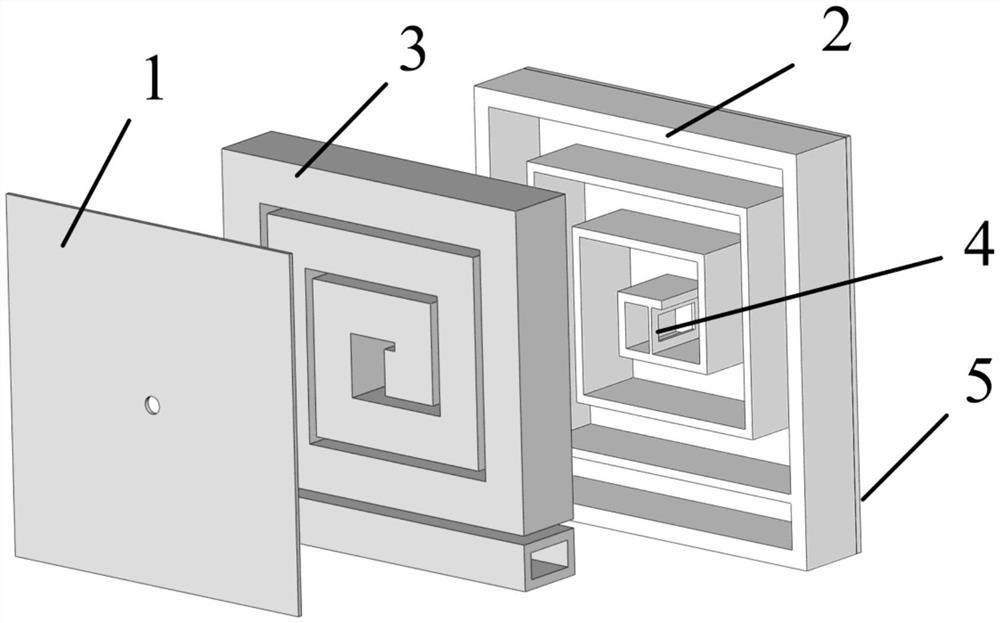

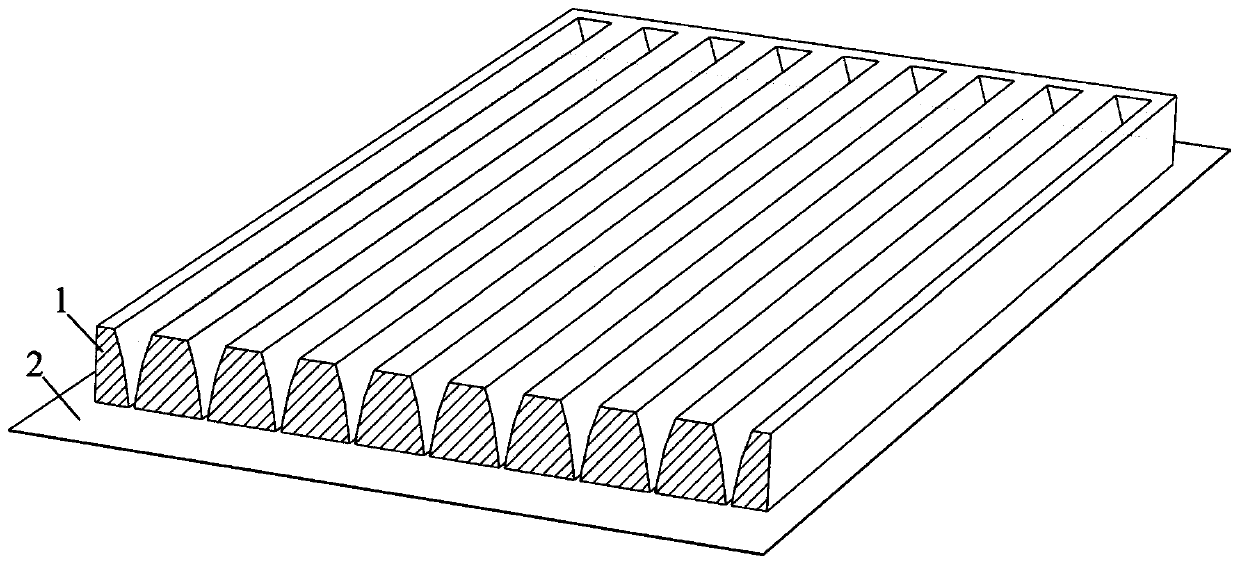

Broadband folding back cavity micro-perforated sound absorption structure

PendingCN113488013AReduce thicknessImprove sound absorption performanceSound producing devicesBroadbandWide band

The invention discloses a broadband folding back cavity micro-perforated sound absorption structure which solves the problems that an existing sound absorption structure is complex in structure, limited in overall sound absorption frequency band and the like, and adopts the technical scheme that the broadband folding back cavity micro-perforated sound absorption structure comprises a sound absorption back cavity defined by a bottom plate, a cover plate with micro-perforated holes and side plates. The sound absorption back cavity is divided into a plurality of sound absorption units which are not communicated with one another by a plurality of longitudinal main partition plates; and each sound absorption unit is divided into continuous zigzag cavities folded left and right by multiple layers of transverse sub-partition plates which are arranged in an up-down staggered mode, and the micro-perforated holes in the cover plate are located at the inlet ends of the zigzag cavities. The structure is simple, the size is smaller and thinner, the depth of each zigzag cavity can be conveniently controlled, and the ultra-broadband sound absorption effect is achieved.

Owner:NAVAL UNIV OF ENG PLA

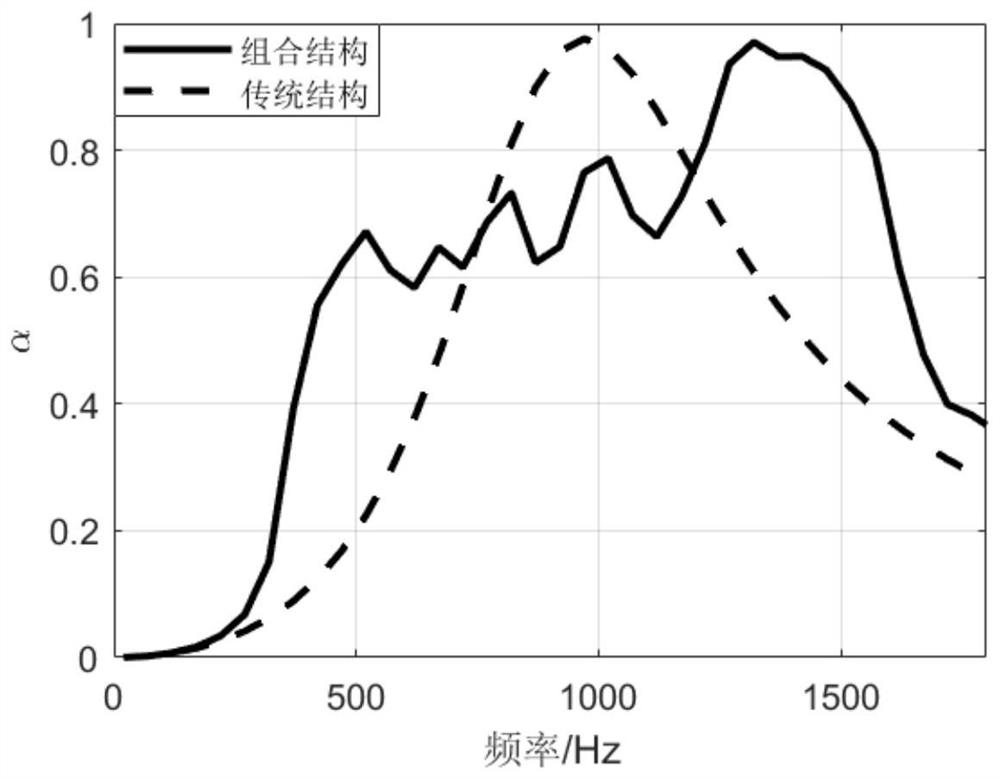

Range hood with shock absorption and noise reduction structure

InactiveCN111396956AImprove sound absorption performanceImprove broadband sound absorption effectDomestic stoves or rangesPump componentsNoiseEngineering

The invention provides a range hood with a shock absorption and noise reduction structure. The range hood includes a smoke collecting cover, a fan shell arranged on the smoke collecting cover and a fan installed in the fan shell. The fan shell is internally provided with a noise reduction device. The noise reduction device includes a shock absorbing seat and a plurality of sound absorption plates.The shock absorbing seat includes a shock absorbing cover plate and a shock absorbing base. The fan is installed on the shock absorbing cover plate, the shock absorbing base is fixedly connected withthe two sides of the fan shell, and a gap for air passing is reserved between the shock absorbing base and the fan shell. A first magnetic sheet is embedded at the bottom of the shock absorbing base,a second magnetic sheet is arranged on the shock absorbing base, and the first magnetic sheet and the second magnetic sheet have the same polarity. The multiple sound absorption plates are arranged in the circumferential direction on the inner wall of the fan shell located below the fan, and a plurality of sound absorption protrusions are arranged on the sides, facing the middle of the fan shell,of the sound absorption plates. According to the range hood, the noise of the range hood is greatly reduced by the cooperation of the shock absorbing base and the sound absorption plates.

Owner:合肥柏隆科技发展有限公司

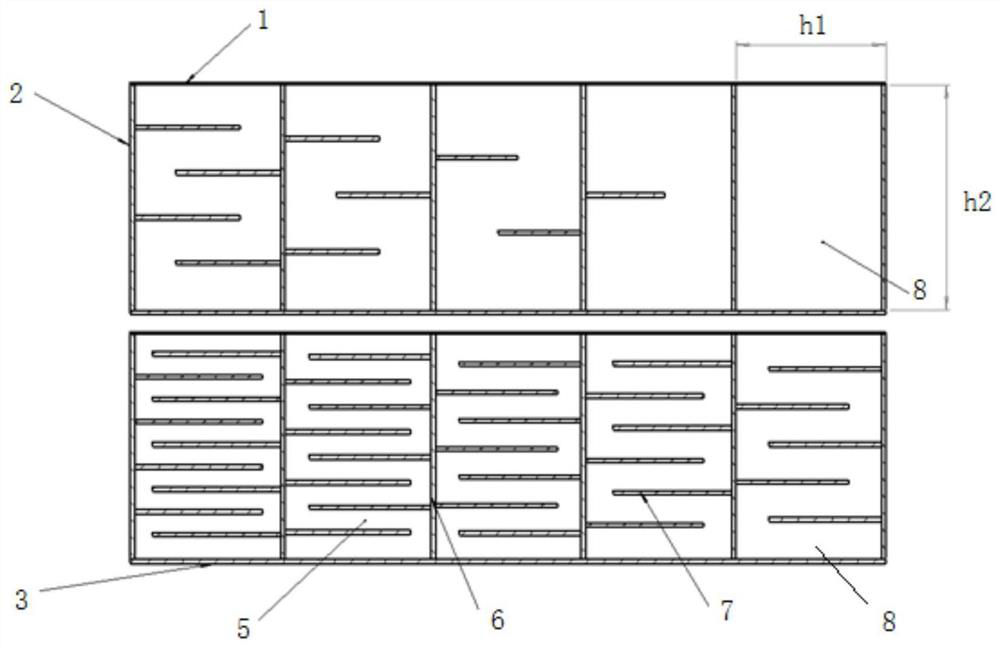

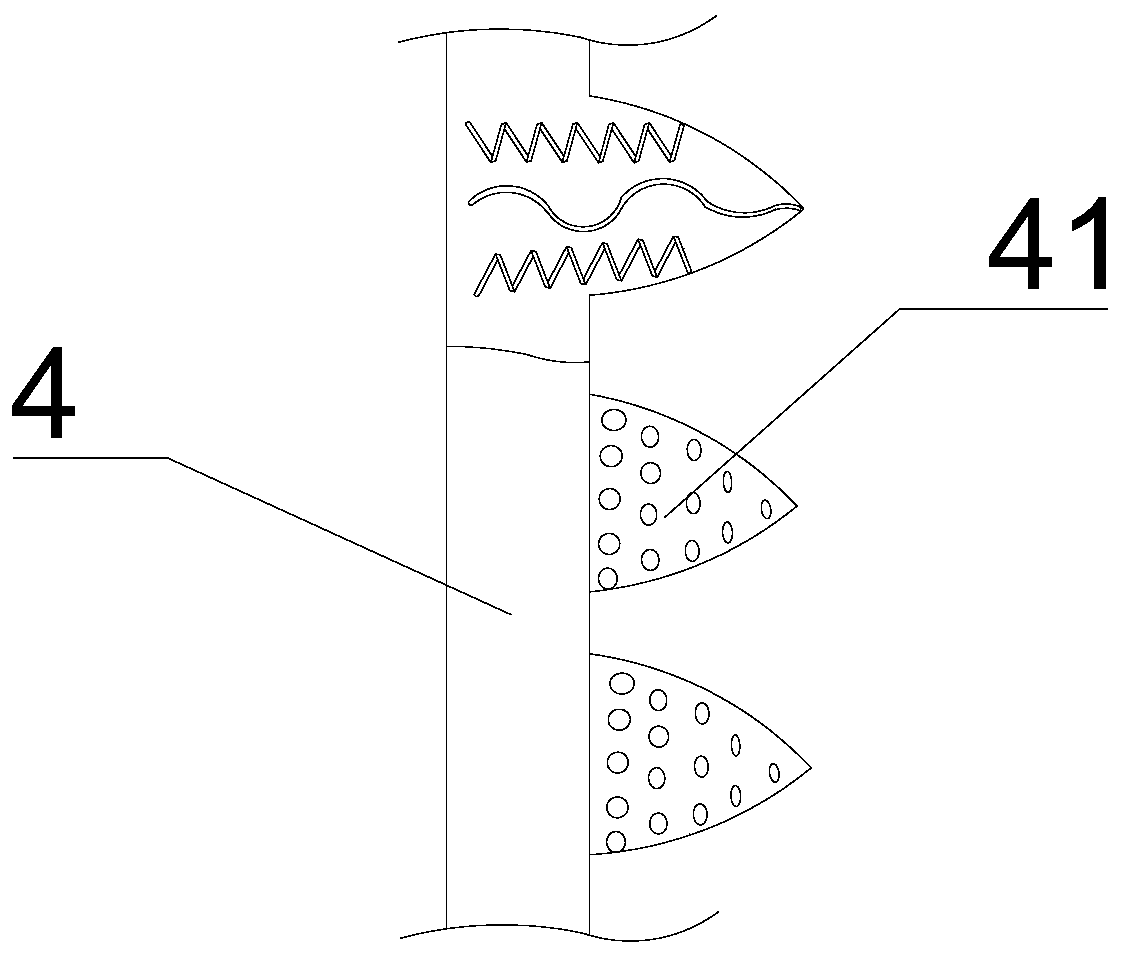

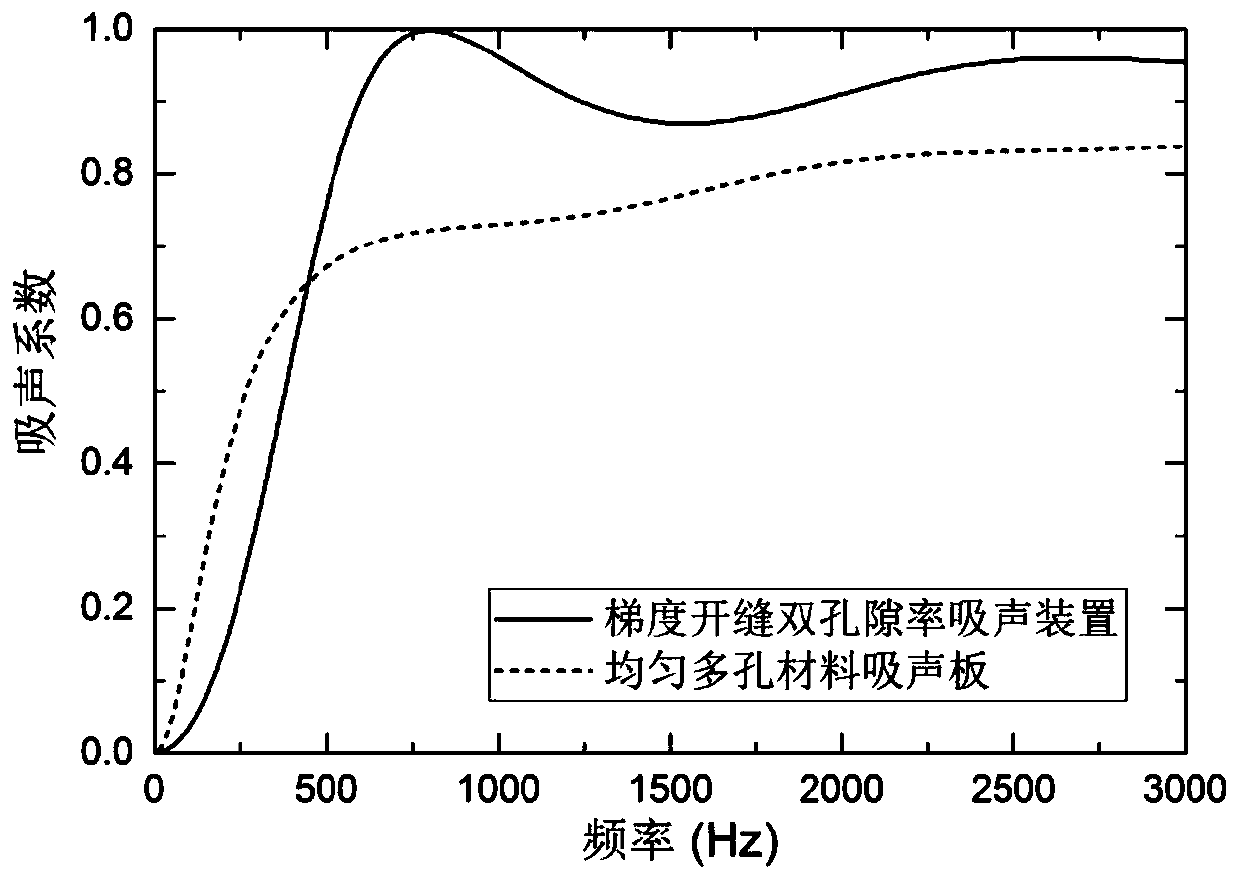

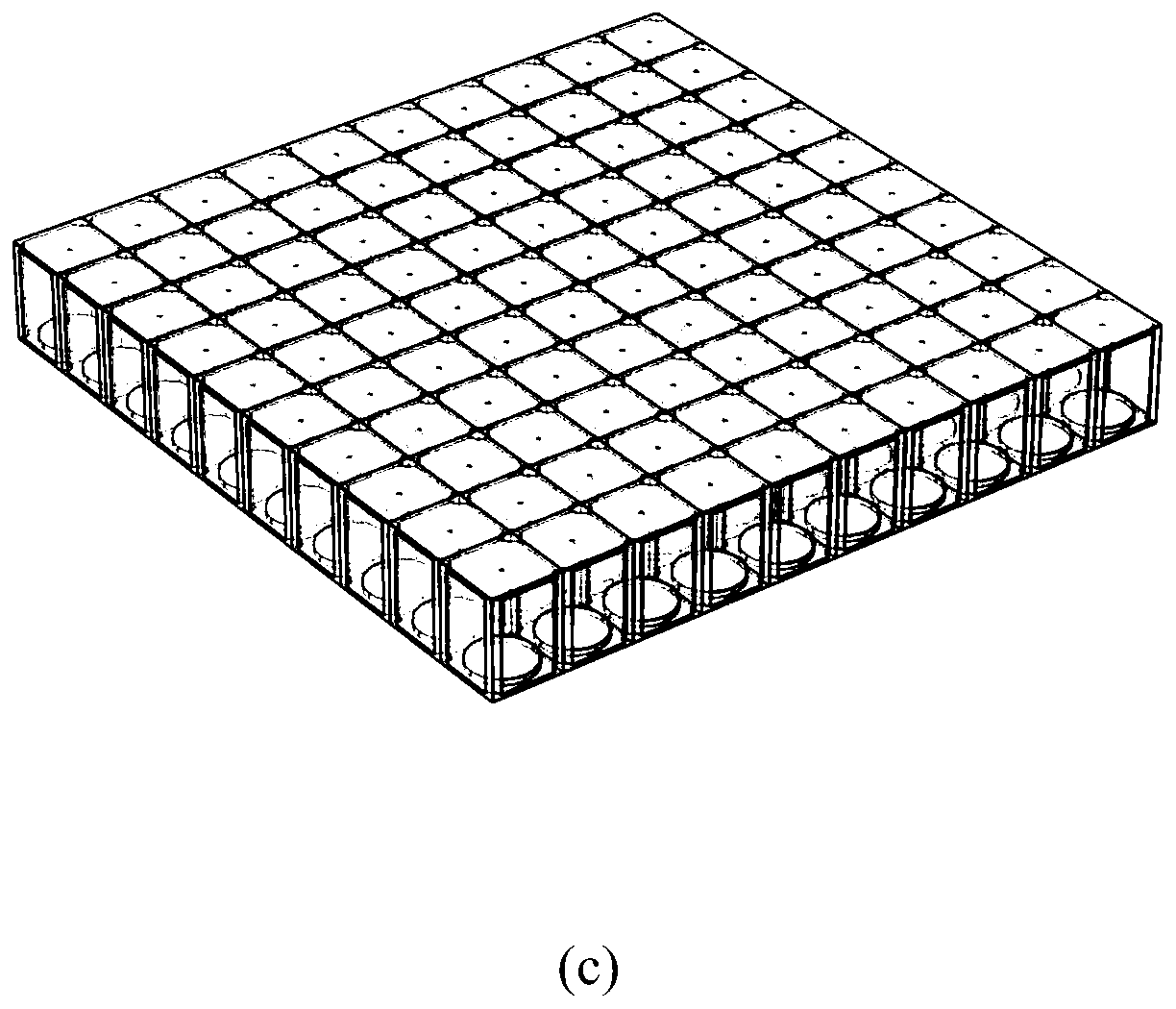

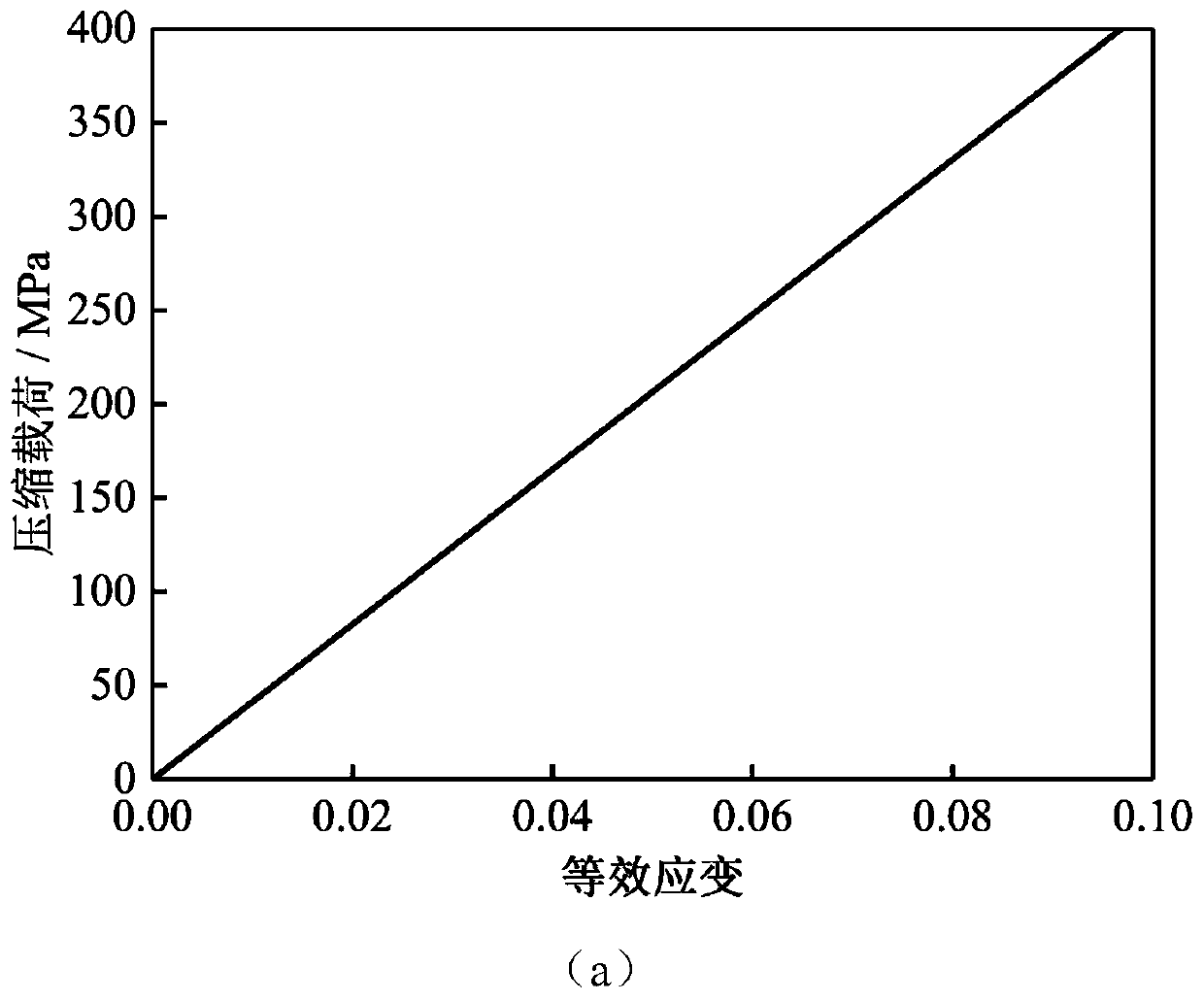

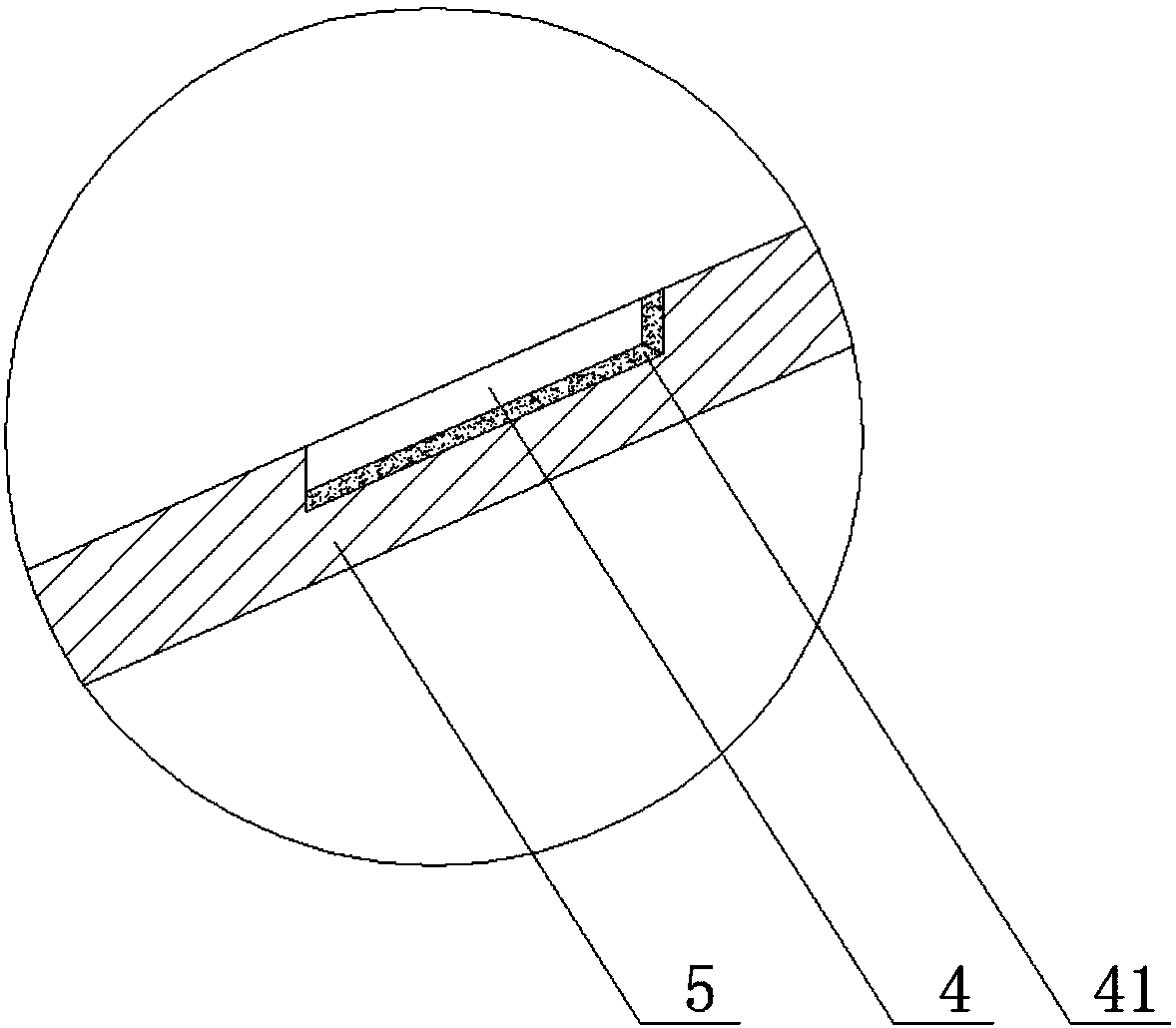

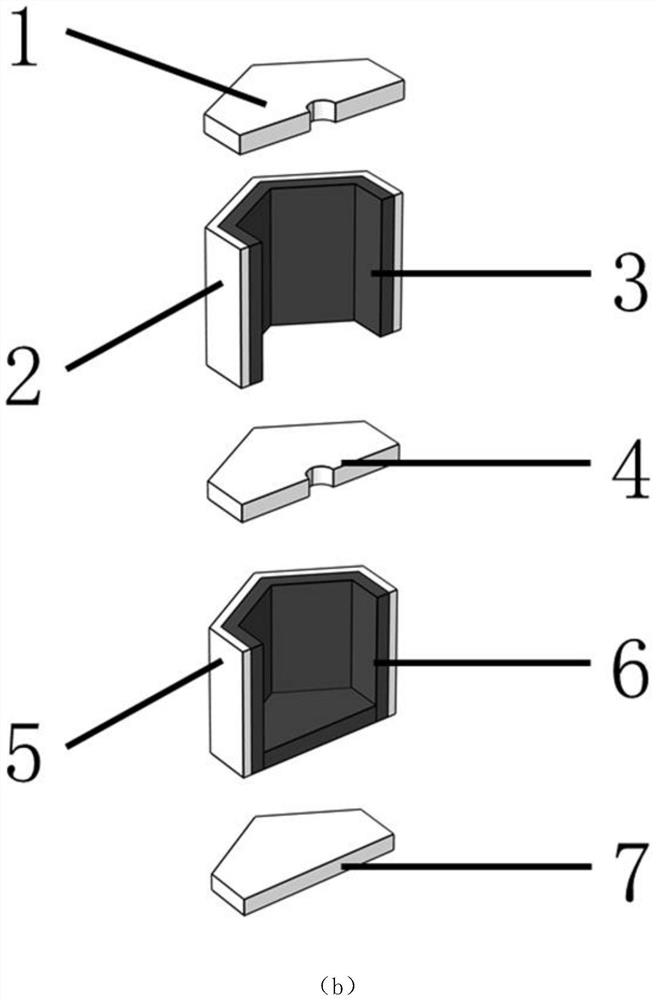

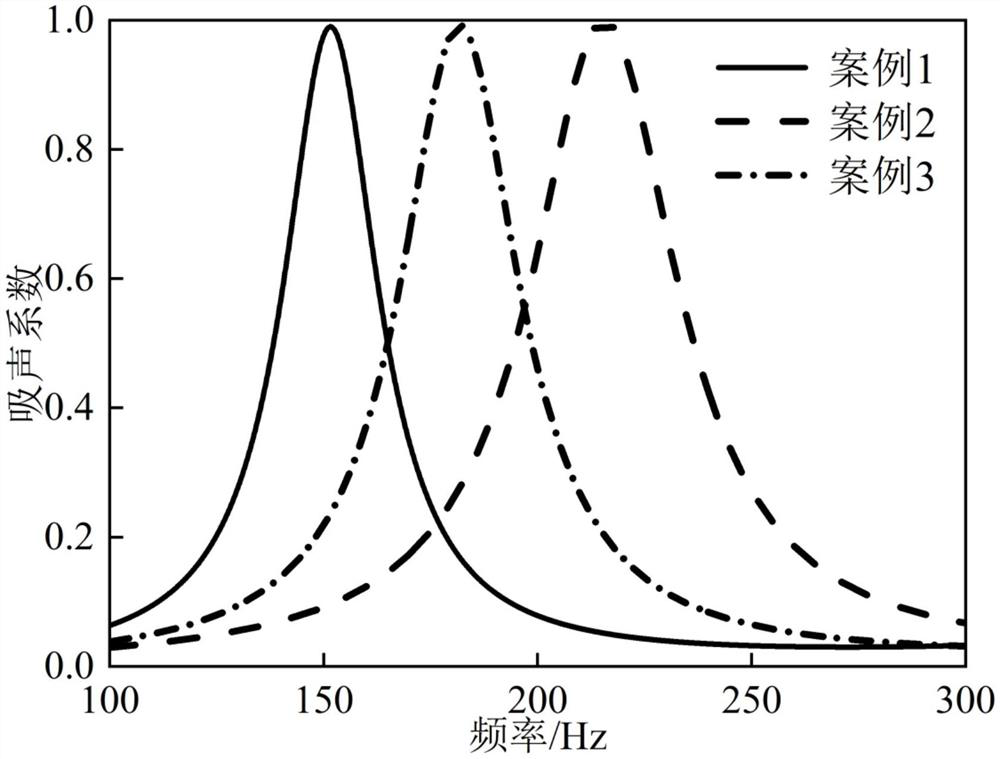

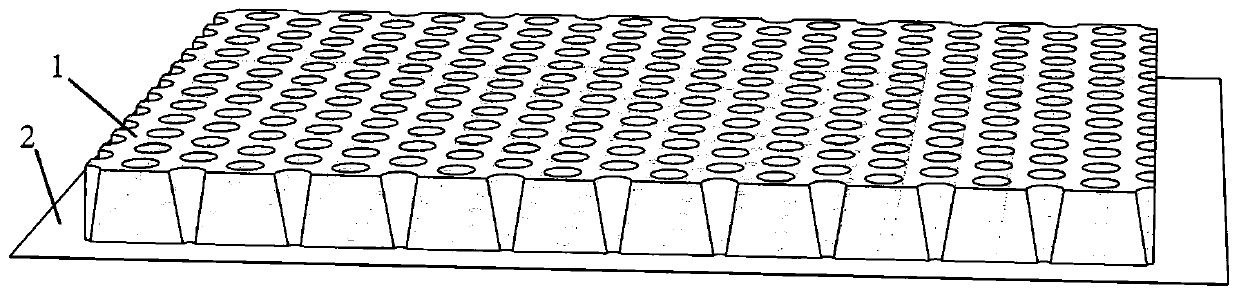

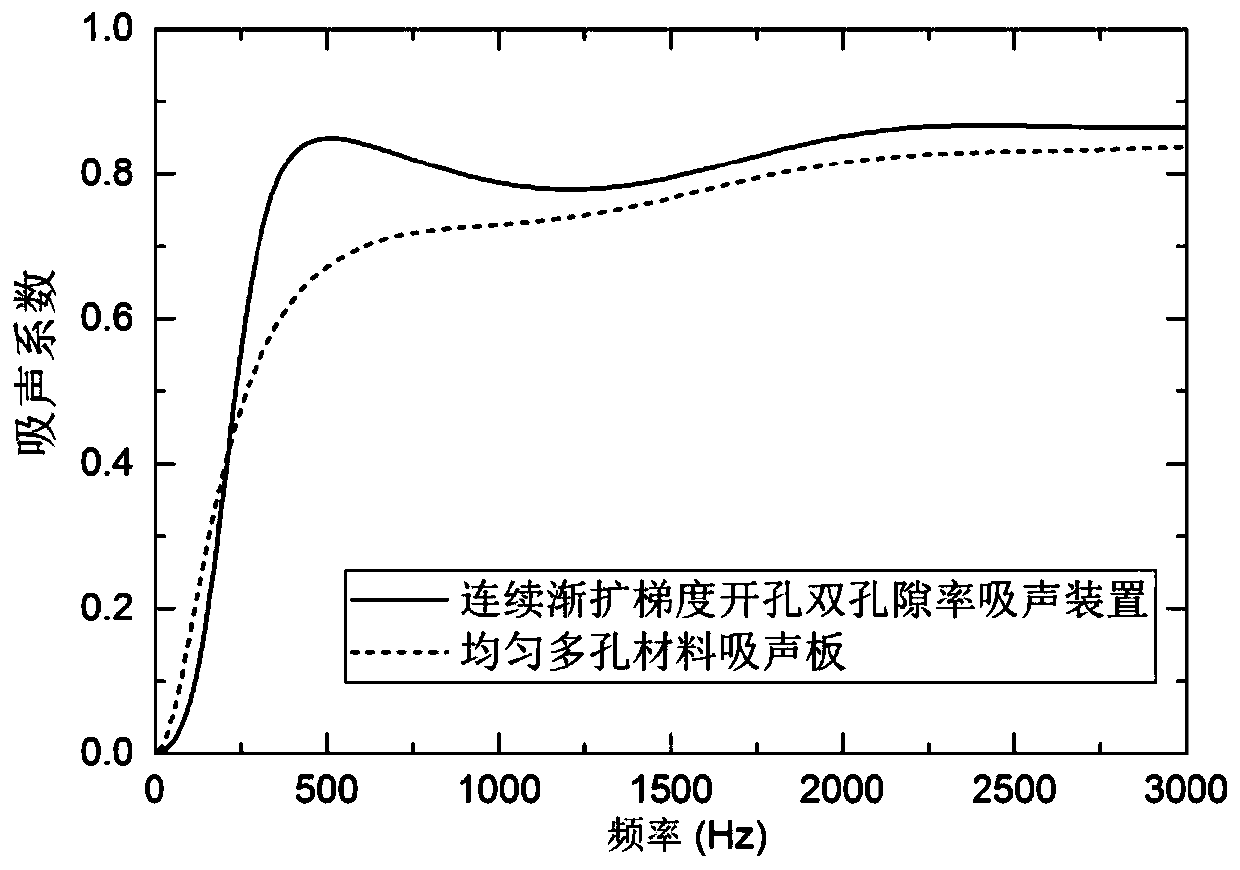

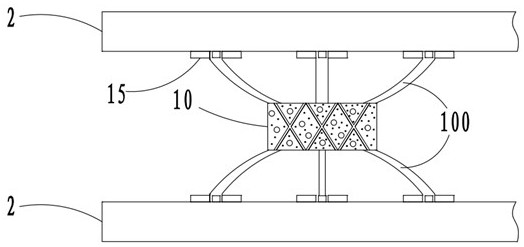

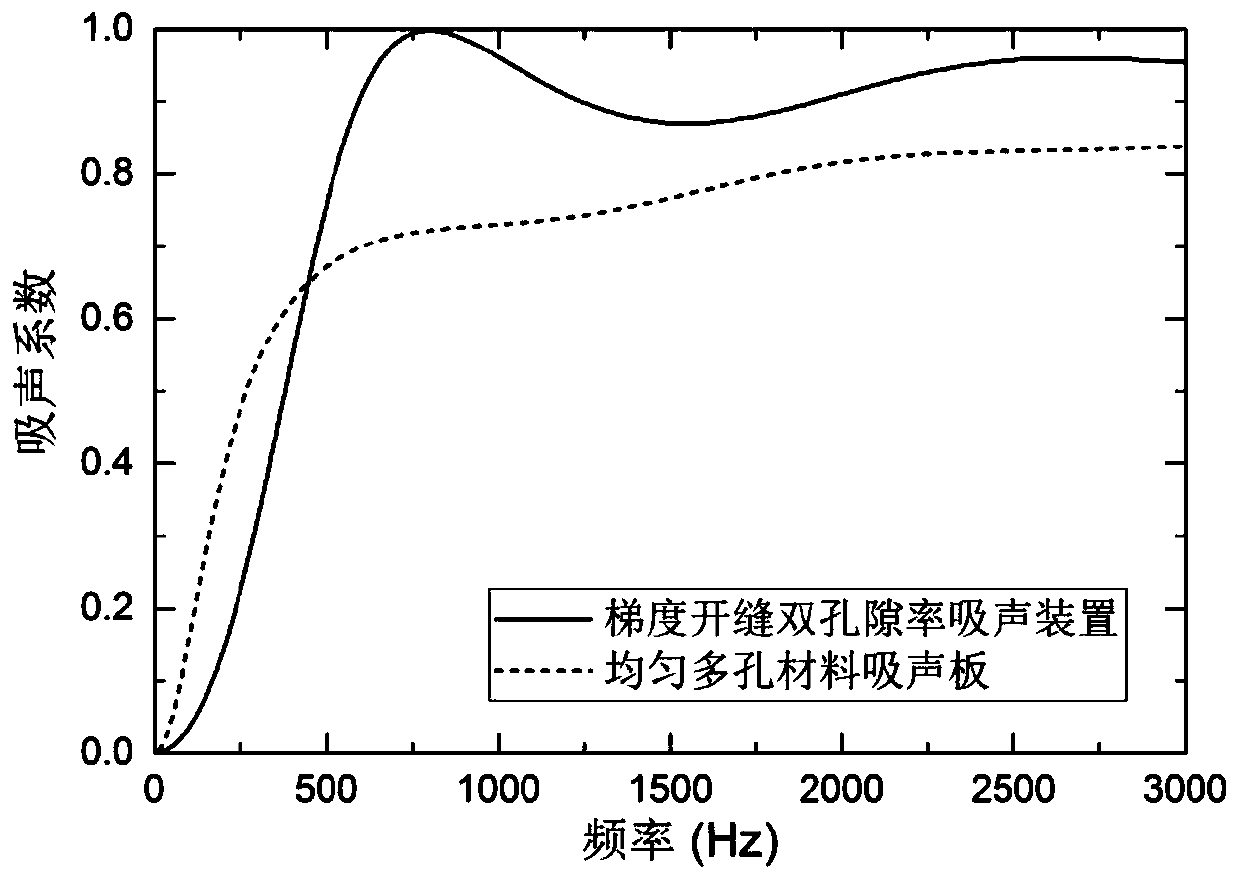

Gradient slitting double-porosity sound absorbing device and application thereof

ActiveCN109707059AImprove low-frequency sound absorption performanceSimple structureSound proofingSound producing devicesPorosityMedium frequency

The invention discloses a gradient slitting double-porosity sound absorbing device and application thereof. The gradient slitting double-porosity sound absorbing device comprises a seamed porous material plate and rigid backing; the seamed porous material plate is arranged on the rigid backing, a plurality of gradient slits are formed in the seamed porous material plate periodically at intervals,and the slitting direction of the gradient slits is perpendicular to the seamed porous material plate. The gradient slitting double-porosity sound absorbing device is simple and practical in structure, has a superior sound absorbing property and a flexible sound absorbing adjusting function in a low frequency band, a medium frequency band and a high frequency band, and has good and wide application prospects.

Owner:XI AN JIAOTONG UNIV

Straight-column type lattice-enhanced mixed underwater sound absorption structure

InactiveCN110310617AAchieve lightweight designImprove sound absorption performanceSound producing devicesResonanceAcoustics

The invention discloses a straight-column type lattice-enhanced mixed underwater sound absorption structure. The straight-column type lattice-enhanced mixed underwater sound absorption structure comprises cubic cells; a cavity and a local resonance body are arranged in each cubic cell; the cavity and the local resonance body are located in the center of each cubic cell in the horizontal direction;the local resonance body is close to the top of each cubic cell; the cavity is located at the bottom of each cubic cell of a damping layer in the vertical direction; and the cubic cells are arrayed to form the straight-column type lattice-enhanced mixed underwater sound absorption structure. The underwater sound absorption structure disclosed by the invention has excellent sound absorption performance and good water pressure resistance, and meanwhile, the lightweight design of the underwater sound absorption structure is realized; and the underwater sound absorption structure is a multifunctional integrated structure with the functions of bearing, sound absorption, sound insulation and light weight.

Owner:XI AN JIAOTONG UNIV +1

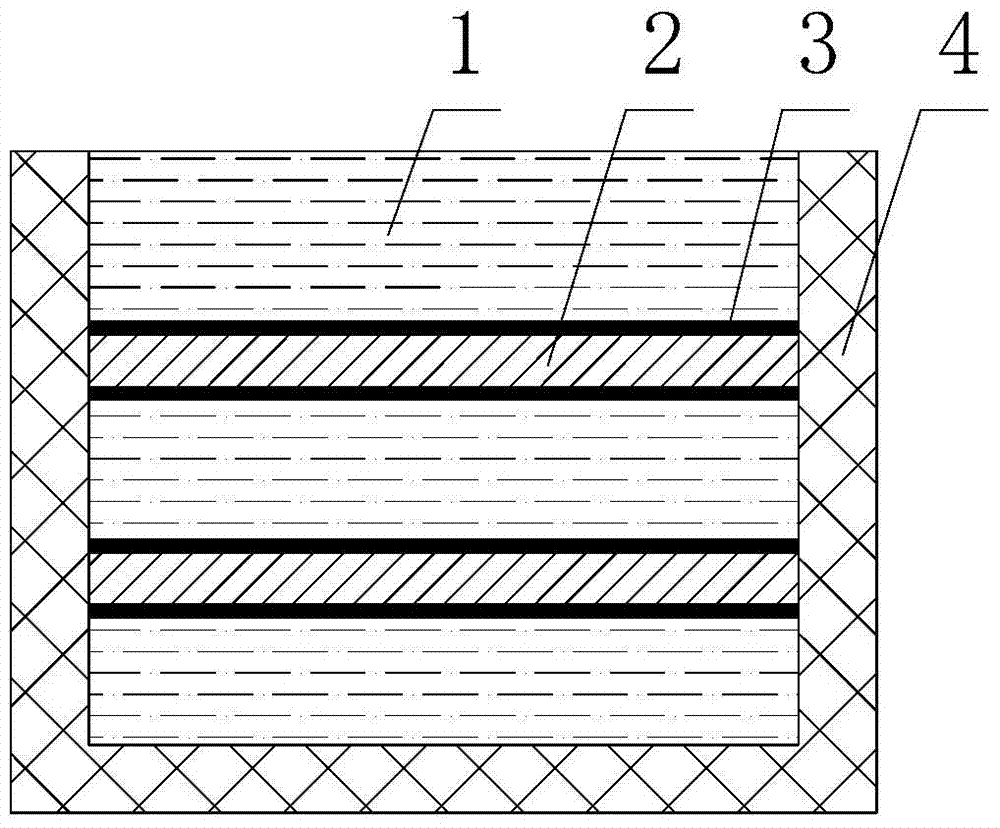

Composite sound absorption structure for improving set low frequency sound absorption performance

InactiveCN105931629AImprove low-frequency sound absorption performanceImprove sound absorptionSound producing devicesAcoustic metamaterialsAcoustics

The invention discloses a composite sound absorption structure for improving set low frequency sound absorption performance, and belongs to the technical field of acoustics, the structure is formed by an upper felt layer, a middle felt layer and a lower felt layer which are fixedly connected in sequence; the upper felt layer, the middle felt layer and the lower felt layer are metal fiber felts; wherein the upper felt layer and the lower felt layer has the same thickness which is 1.5mm-5mm; the thickness of the middle felt layer is equal to or lower than the same of the upper felt layer and the lower felt layer; more than one through holes are uniformly arranged on the surface of the middle felt layer, the axis direction of the through holes is the same with the height direction of the middle felt layer; thin films are fixed to the internal through holes; the shape of each thin film is the same with the radial section shape of each through hole, and the thin films in all through holes are in the same plane; a mass block is fixed to each thin film; the structure is used for improving the sound absorption performance of the metal fiber felt in 0-1500Hz low frequency range, an acoustic metamaterial interlayer and the mass block are introduced to improve the material set low frequency sound absorption performance, and the structure has characteristics of adjustable frequency and good sound absorption performance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

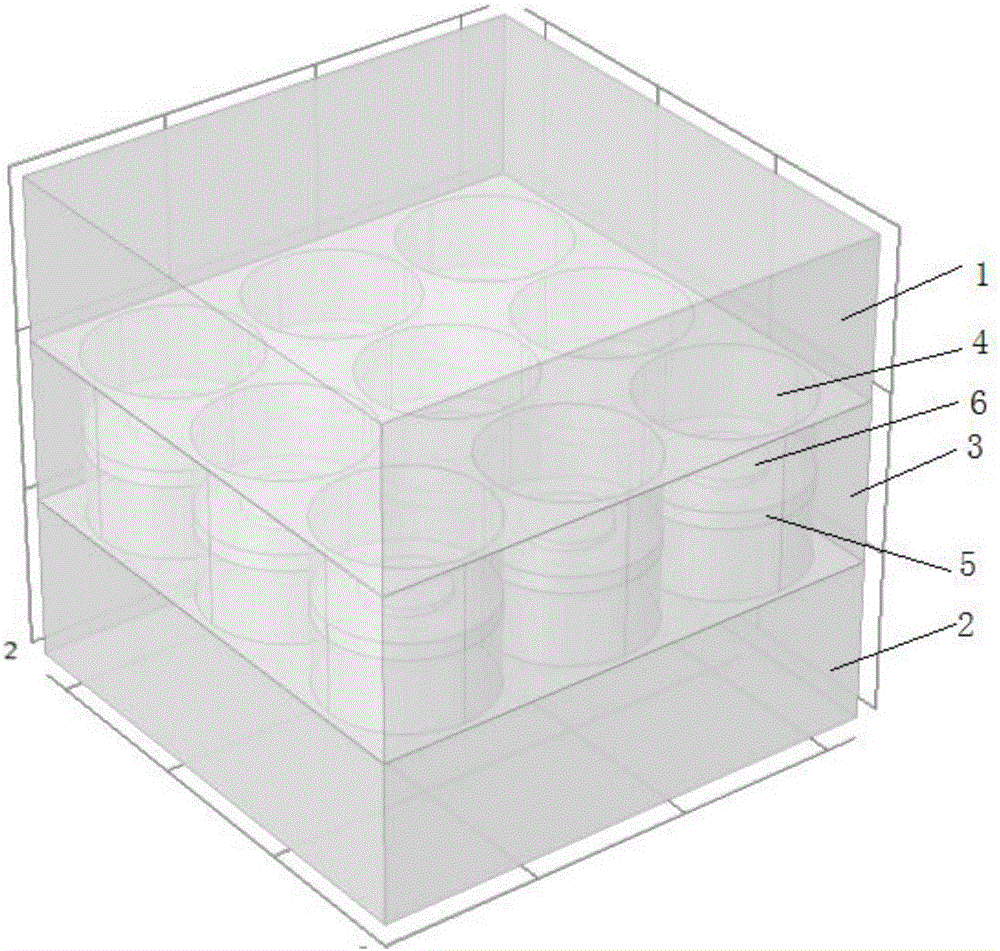

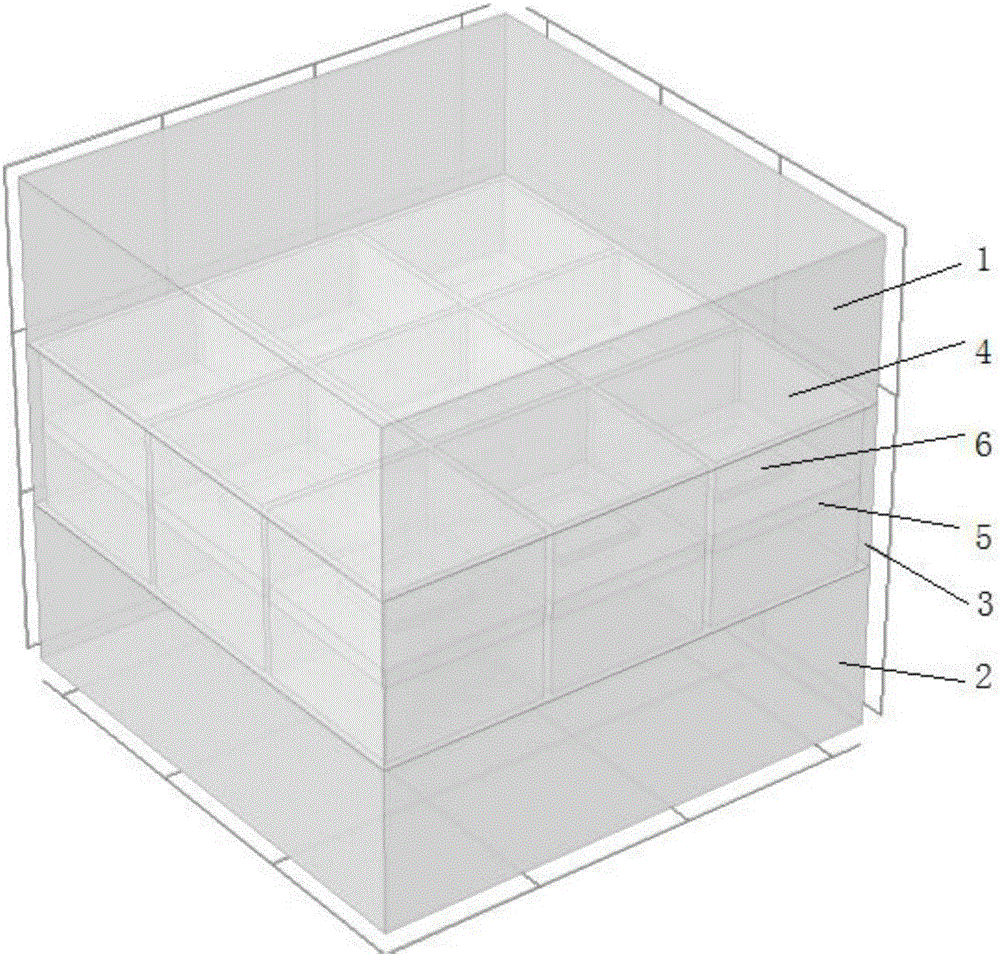

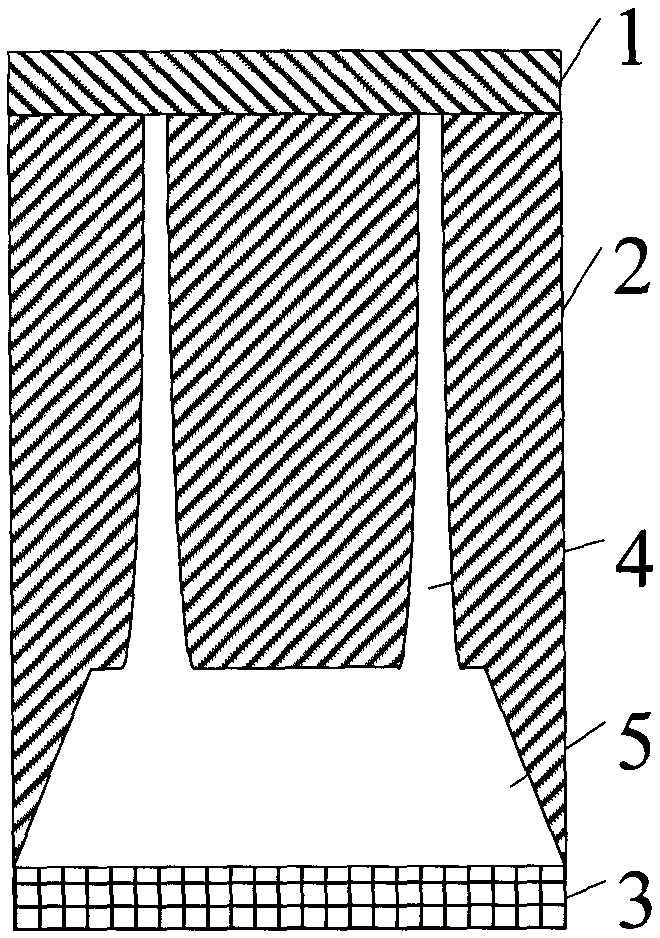

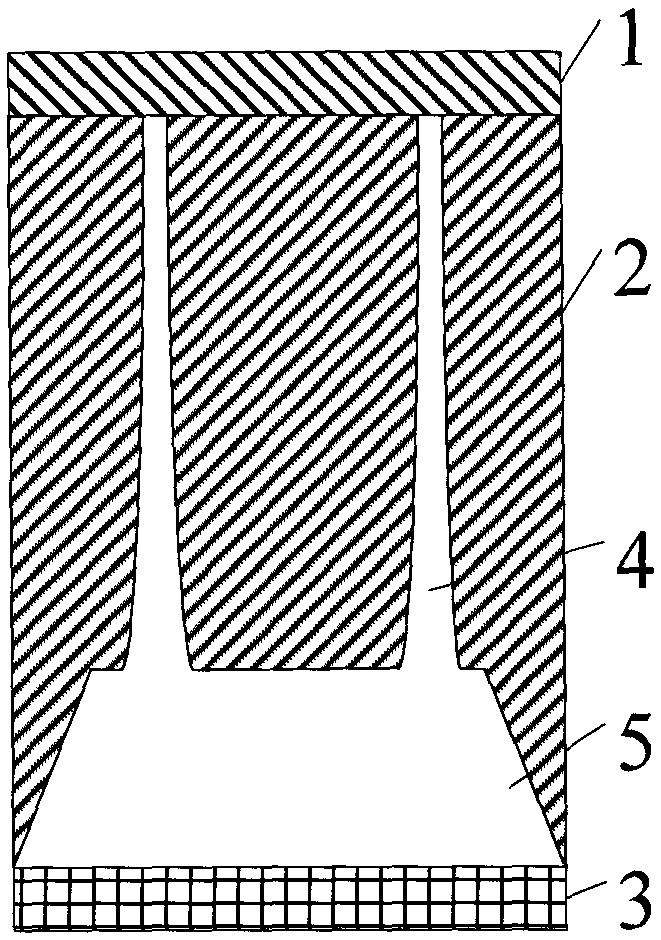

Multilayer material combined cavity anechoic tile

InactiveCN105620697AImprove low-frequency sound absorption performanceMature materials and workmanshipSound producing devicesUnderwater vesselsPhysicsAdhesive

The invention relates to a multilayer material combined cavity anechoic tile which consists of a surface layer, a punching layer and a base layer, wherein mixed type cavity structures consisting of circular-table-shaped cavities and horn-shaped cavities are arranged in the punching layer in an arrayed manner; a punching rate of the circular-table-shaped cavities is 10-20%; a punching rate of the horn-shaped cavities is 1-2%; each mixed type cavity structure consists of one circular-table-shaped cavities and two to six horn-shaped cavities; the surface layer is made of sound transmission polyurethane elastomer; the punching layer is made of polyurethane double-layer compound foam sound absorption material; the base layer is made of butyl rubber matched with the impedance of a housing of an underwater navigation vehicle; and the surface layer, the punching layer and the base layer are glued through an adhesive sequentially, and are subjected to integrated cold-press moulding.

Owner:NAVAL UNIV OF ENG PLA

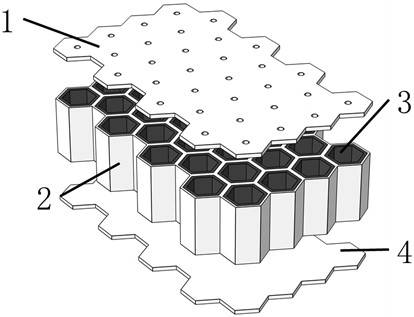

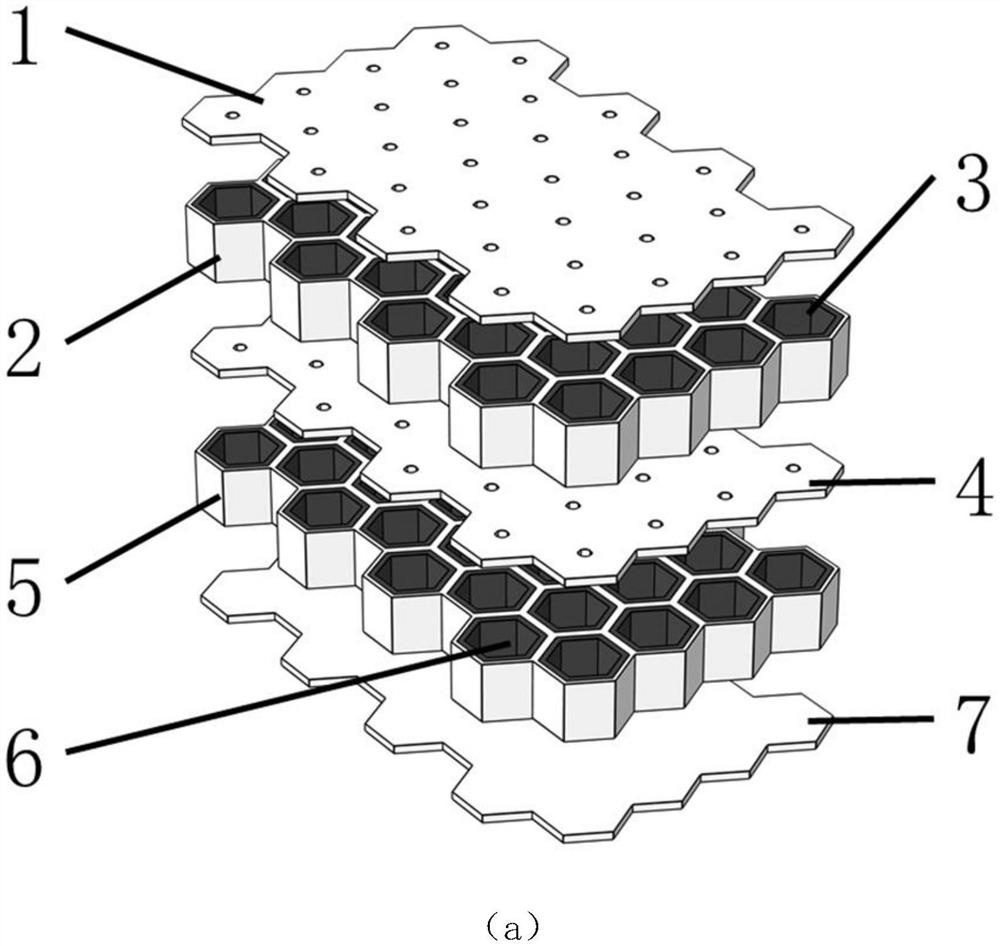

Damping lining hexagonal honeycomb perforated plate underwater sound absorption metamaterial

PendingCN111739502AImprove acoustic impedance characteristicsImprove low-frequency sound absorption performanceSynthetic resin layered productsSound producing devicesResonant cavityUnderwater

The invention provides a damping lining hexagonal honeycomb perforated plate underwater sound absorption metamaterial. A plurality of honeycomb resonant cavity units are formed by welding or gluing aperforated upper panel, a honeycomb layer core and a lower panel, and damping lining layers are adhered to the side walls and the bottom surfaces of honeycomb resonant cavity units, so that the acoustic impedance characteristic of the structure is improved, and the low-frequency sound absorption performance of the structure is improved. According to the light honeycomb sandwich plate structure, onthe premise that good low-frequency underwater sound absorption performance is achieved, the weight of the structure is reduced, the bearing performance of the structure is guaranteed, and the problems that a traditional underwater sound absorption structure is generally poor in low-frequency sound absorption performance, heavy in weight and poor in bearing performance are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

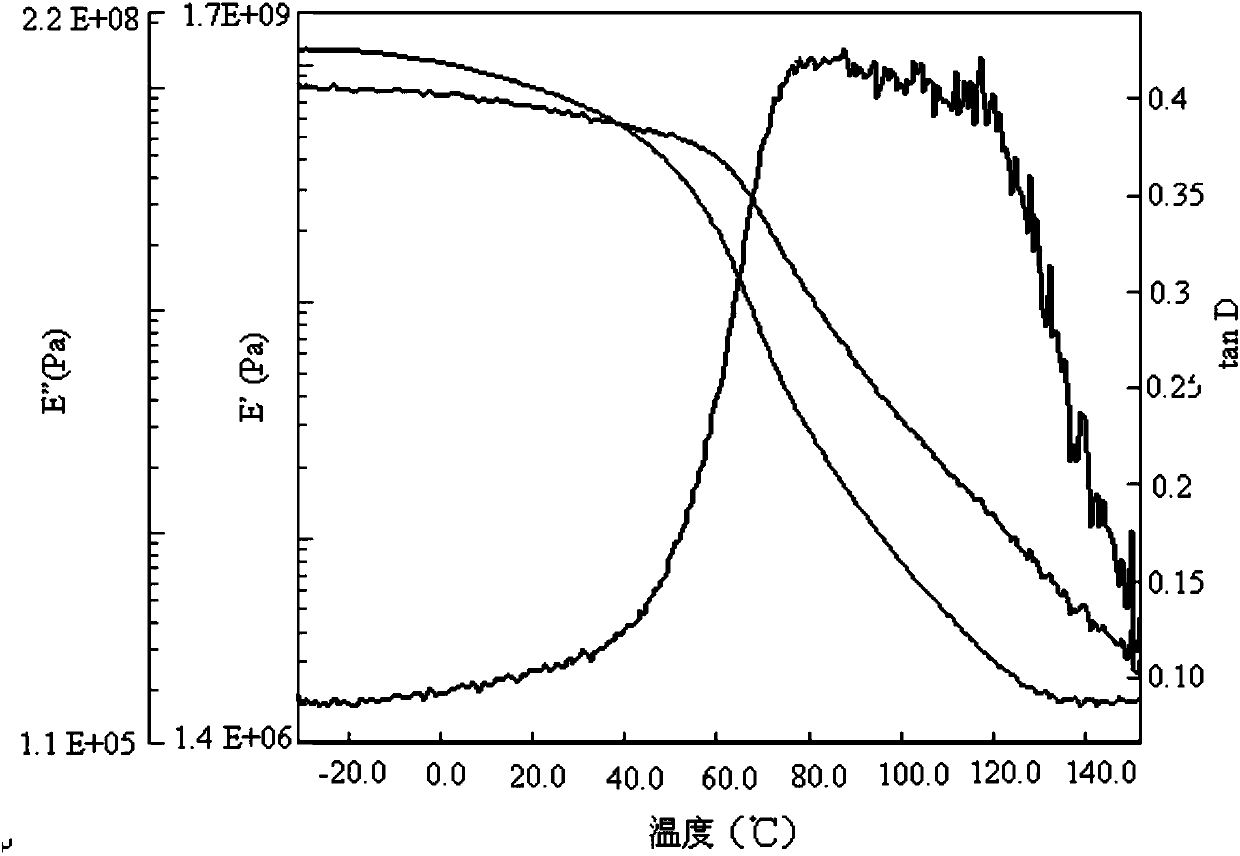

Metal net sandwiched structure composite damping material and preparation method thereof

InactiveCN107813559AImprove low-frequency sound absorption performanceImprove damping performanceLamination ancillary operationsLaminationEpoxyElastomer

The invention discloses a metal net sandwiched structure composite damping material and a preparation method thereof, relates to a composite damping material and a preparation method thereof and aimsto solve the technical problem that a conventional damping sound-insulating material is narrow in damping temperature domain. The metal net sandwiched structure composite damping material is preparedfrom an epoxy resin grafting modified polyurethane macromolecule elastomer and a metal gauze through compounding. The preparation method comprises the following steps: I, pretreating a metal net; II,preparing an epoxy resin grafting modified polyurethane prepolymer; III, uniformly stirring the prepolymer with a diamine chain extender so as to obtain a casting liquid; and IV, putting the metal netinto a mold, further casting the casting liquid into a mold cavity, and curing, thereby obtaining the metal net sandwiched structure composite damping material. The damping temperature domain of thematerial is 60-130 DEG C, and the material can be applied to fields such as protection, modern automobiles, ships and aerospace fields.

Owner:HEILONGJIANG HEIKE TECH CO LTD

Novel sound absorbing composite board used for transformer station

The invention discloses a novel sound absorbing composite board used for a transformer station. The composite board comprises a composite board body, an aluminum fiber sound absorbing board, a fillingmaterial, a backboard, and side boards. The composite board body is formed by the aluminum fiber sound absorbing board, the filling material, and the backboard from outside to inside. Two sides of the composite board body are provided with the side boards. One end of the composite board body is provided with a limiting boss, and the other end of the composite board body is provided with a limiting groove matched with the limiting boss. The aluminum fiber sound absorbing board and a micropunch plate are used as basic materials of the novel sound absorbing composite board used for a transformerstation. The aluminum fiber board and the micropunch plate form a first layer resonating cavity. Themicropunch plate and a wall form a second layer resonating cavity. The first layer resonating cavity is filled with polyester fibers. The impedance double-resonance sound absorbing system can reinforce low frequency sound absorption performance, and can also expand high-efficiency sound absorptionfrequency bands, and is convenient to install.

Owner:DEQING JINGYING INFORMATION TECH CO LTD

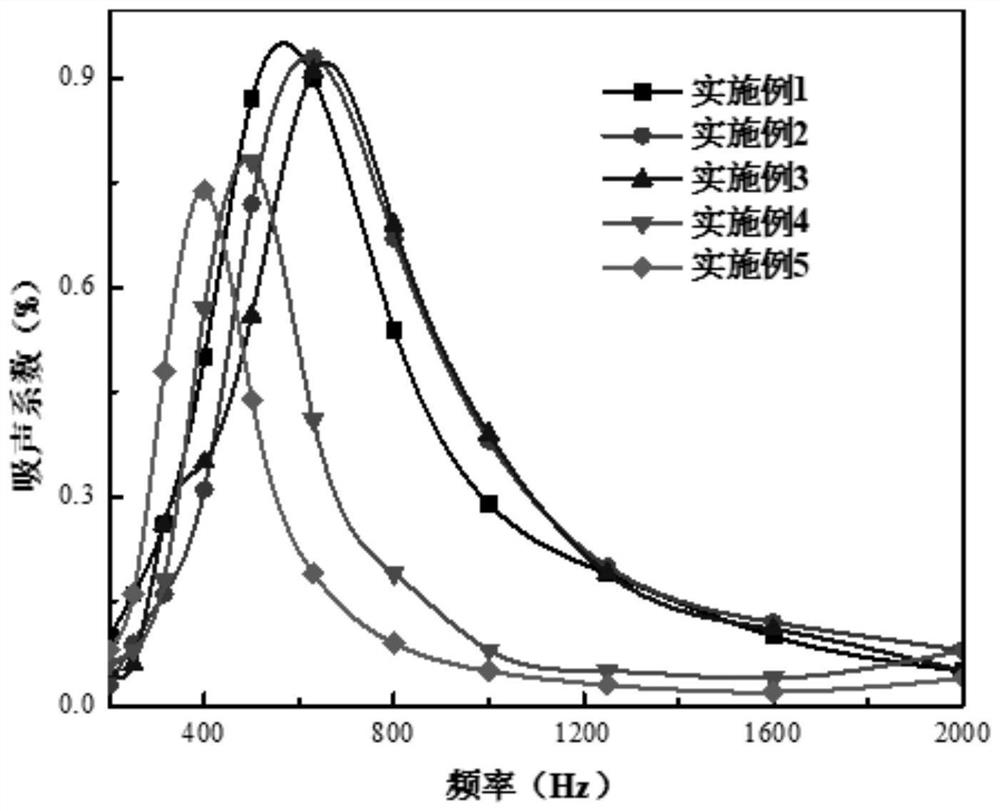

Rare earth oxide/butyronitrile rubber-polyurethane foam double layered composite material for low frequency sound absorption and preparation method thereof

ActiveCN108641140AExcellent mid-low frequency sound absorption effectReduce thicknessSynthetic resin layered productsLaminationVulcanizationRare earth

The invention belongs to the technical field of material processing, and particularly relates to a rare earth rubber-polyurethane foam composite layered material used for low frequency sound absorption and a preparation method thereof. The method comprises the following steps: pretreating rare earth oxide powder; sequentially adding nitrile rubber, zinc oxide, stearic acid, zinc stearate, an anti-aging agent, an accelerator, carbon black, rare earth oxide powder, sulfur and a softener into an internal mixer or an open mill for mixing and vulcanization treatment to obtain a rare earth oxide-nitrile rubber composite material for low frequency sound absorption; using a binder to compound the rare earth oxide-nitrile rubber composite material and polyurethane foam according to the structure with the rare earth oxide-nitrile rubber composite material on one side facing the sound wave and the polyurethane foam on the other side to obtain the rare earth oxide / butyronitrile rubber-polyurethanefoam double layered composite material. The rare earth oxide / butyronitrile rubber-polyurethane foam double layered composite material has a plurality of energy dissipation mechanisms such as magneticacoustic conversion, damping dissipation and interface resonance, has an excellent mid-low frequency sound absorption effect, is light in quality and small in thickness, and has broad application prospects in the field of sound absorption.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

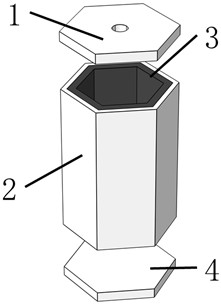

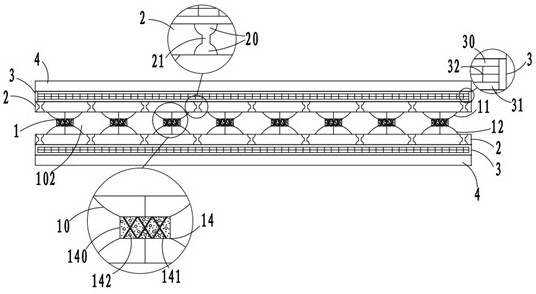

Underwater sound absorption metamaterial structure of damping lining double-layer honeycomb perforated plate

ActiveCN111696502AImprove acoustic impedance characteristicsImprove low-frequency sound absorption performanceWatercraft hull designSynthetic resin layered productsResonant cavityHoneycomb

The invention discloses an underwater sound absorption metamaterial structure of a damping lining double-layer honeycomb perforated plate. The underwater sound absorption metamaterial structure comprises a perforated upper panel, a first-layer honeycomb layer core, a sandwich perforated panel, a second-layer honeycomb layer core and a lower panel which are connected in sequence from top to bottom;a plurality of honeycomb resonant cavity units are arranged in each of the first-layer honeycomb layer core and the second-layer honeycomb layer core; the perforated upper panel is periodically provided with first holes corresponding to each honeycomb resonant cavity unit of the first-layer honeycomb layer core structure, and the interlayer perforated panel is periodically provided with second holes corresponding to each honeycomb resonant cavity unit of the second-layer honeycomb layer core structure; a first damping lining layer is arranged in each honeycomb resonant cavity unit of the first-layer honeycomb layer core, and a second damping lining layer is arranged in each honeycomb resonant cavity unit of the second-layer honeycomb layer core. The underwater sound absorption metamaterial structure has excellent low-frequency sound-absorbing performance, good bearing performance and light weight performance, can be correspondingly adjusted according to actual working condition requirements, and is simple in structure and easy to manufacture.

Owner:XI AN JIAOTONG UNIV +1

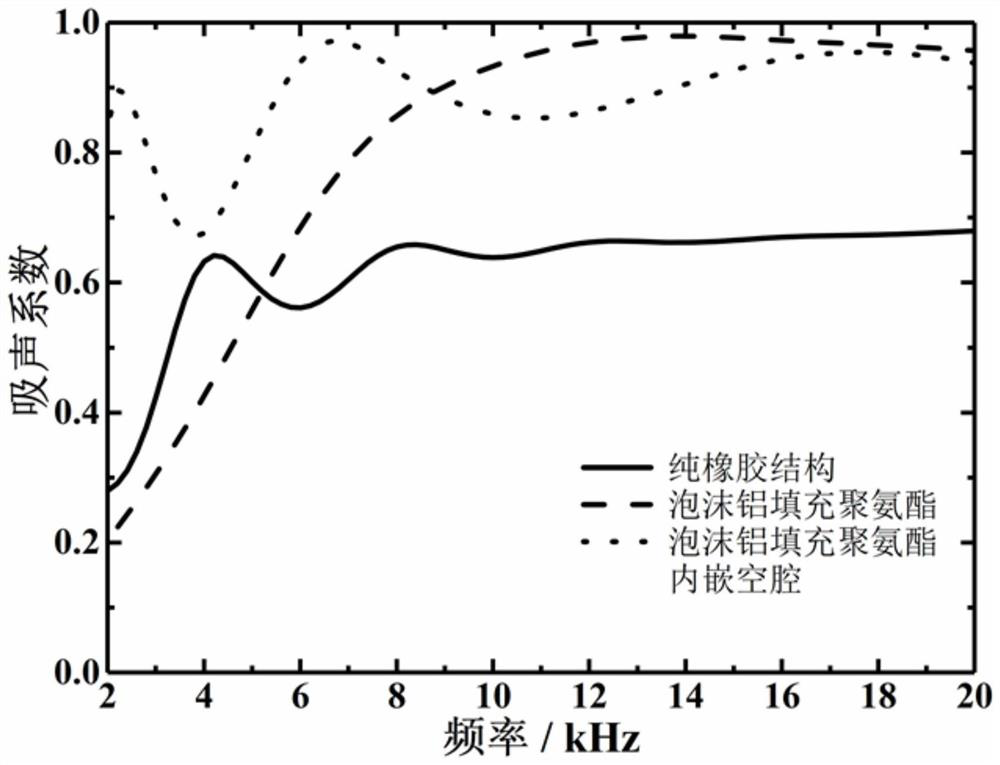

Damping material filled foam metal embedded periodic cavity type underwater sound absorption structure

ActiveCN111696510AWith carrying capacityImprove sound absorption performanceSound producing devicesMetal frameworkAcoustics

The invention discloses a damping material filled foam metal embedded periodic cavity type underwater sound absorption structure comprising an open-cell foam metal framework, the open-cell foam metalframework is filled with a soft damping material, the upper surface and the lower surface of the open-cell foam metal framework are each provided with a hard damping material covering layer, the harddamping material covering layers and the open-cell foam metal framework form a sealing structure, and a plurality of holes are periodically formed in the sealing structure to form a cavity. The damping material filled foam metal embedded periodic cavity type underwater sound absorption structure has excellent mechanical properties and good underwater sound-absorbing performance, has more adjustable parameters including structural parameters and material parameters in the design aspect, can be correspondingly adjusted according to actual working condition requirements, and is simple in structure and easy to manufacture.

Owner:XI AN JIAOTONG UNIV +1

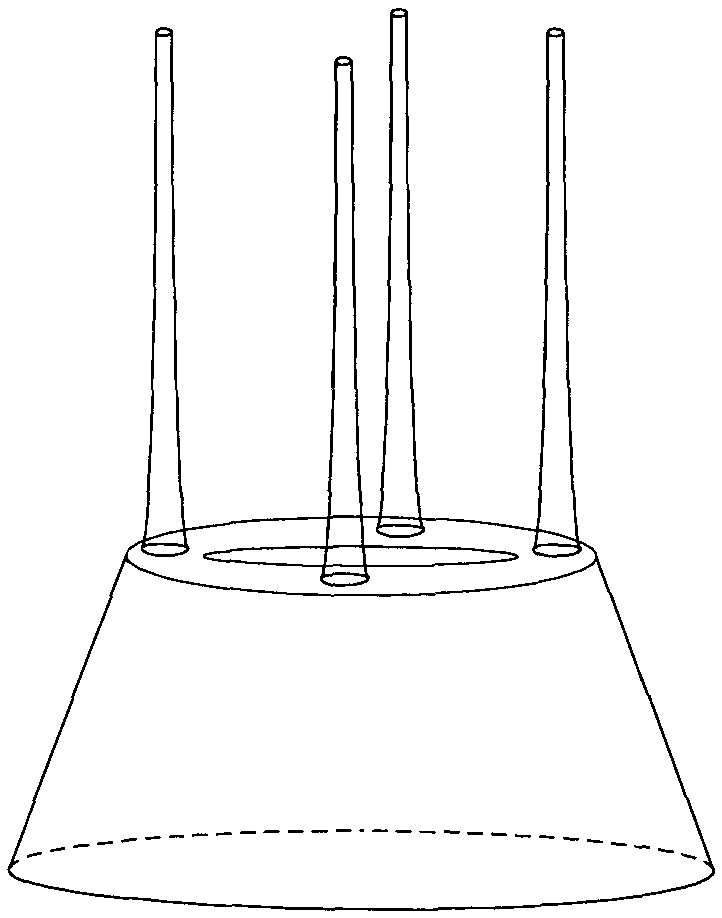

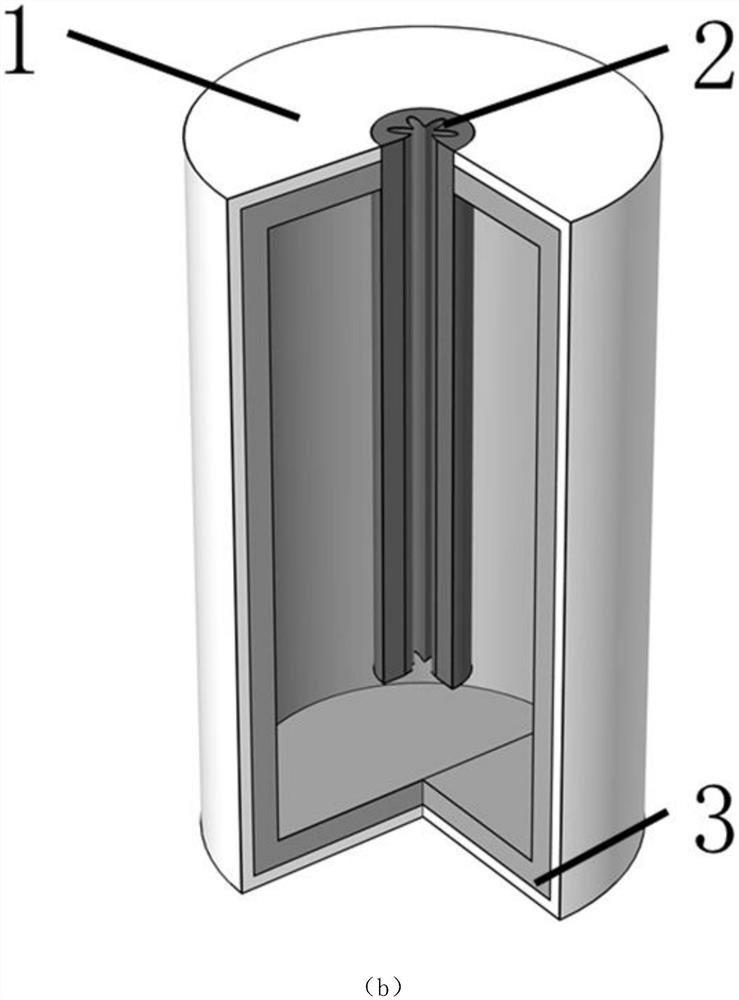

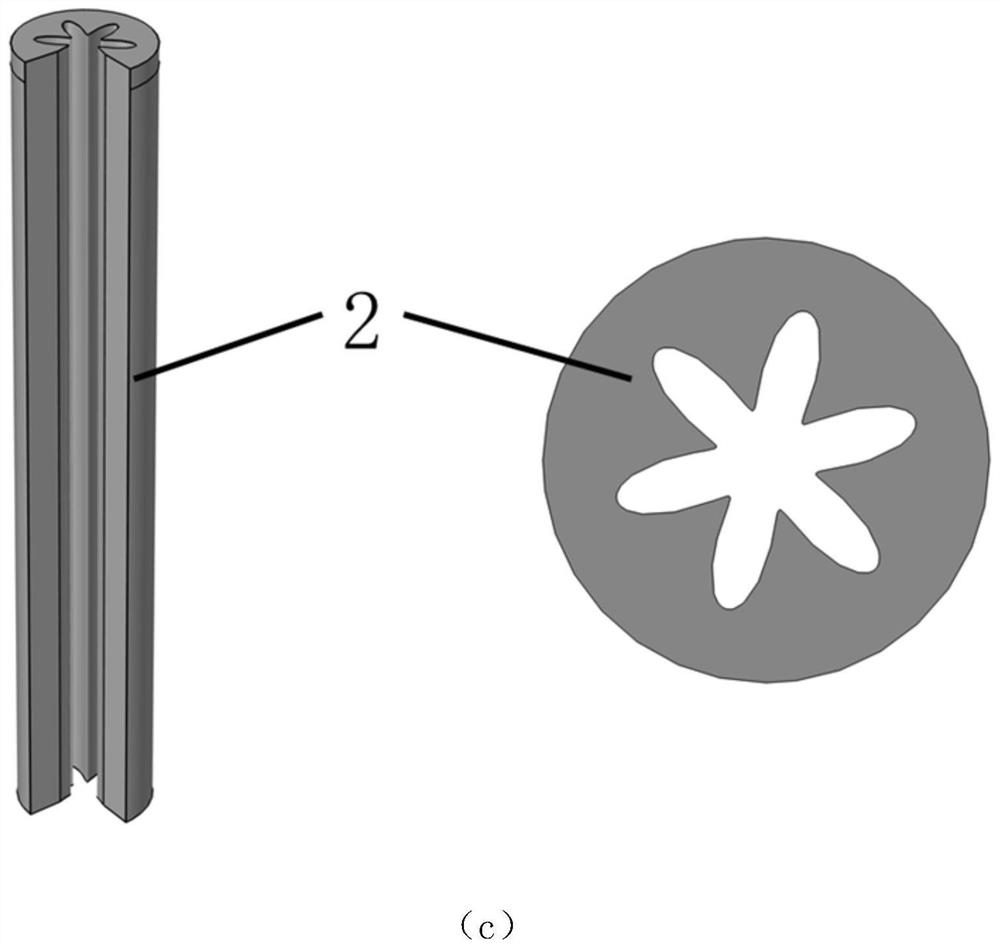

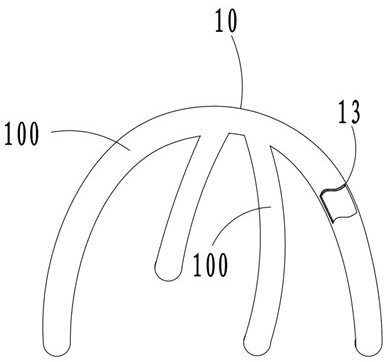

Petal-shaped inner insertion pipe type underwater Helmholtz resonance cavity structure

ActiveCN111696504AImprove acoustic impedance characteristicsImprove low-frequency sound absorption performanceSound producing devicesHelmholtz resonatorEngineering

The invention discloses a petal-shaped inner insertion pipe type underwater Helmholtz resonance cavity structure; a damping lining layer is arranged on the inner wall of a cavity body, a hole is formed in the center of one end of the cavity body, a petal-shaped inner insertion pipe is arranged in the hole, and the petal-shaped inner insertion pipe and the cavity body are connected in a welded or glued mode to form the petal-shaped inner insertion pipe type underwater Helmholtz resonance cavity structure. The petal-shaped inner insertion pipe type underwater Helmholtz resonance cavity structurehas excellent low-frequency sound-absorbing performance and good bearing performance and light weight performance. And more adjustable structural parameters are provided in the design aspect, corresponding adjustment can be conducted according to actual working condition requirements, the structure is simple, and manufacturing is easy.

Owner:XI AN JIAOTONG UNIV +1

Sound absorption and noise reduction material

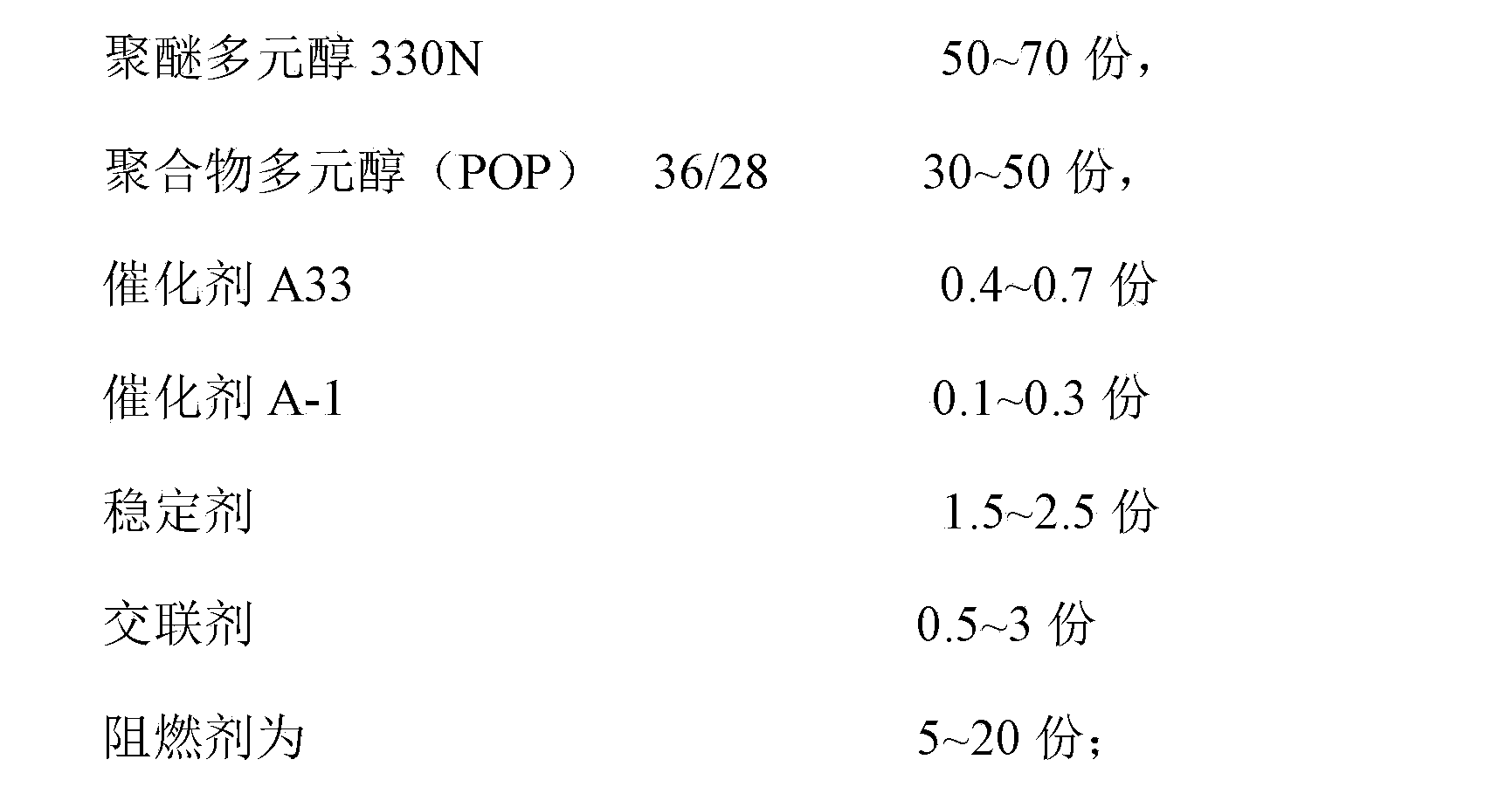

InactiveCN103087506BImprove low-frequency sound absorption performanceFlame retardantPolyolMelamine phosphate

The invention discloses a sound absorption and noise reduction material. The material is a polyurethane composite material prepared by taking polyurethane as a base material and an agricultural byproduct as filler. The sound absorption and noise reduction material disclosed by the invention comprises the following components in parts by weight: 5-40 parts of filler, 30-70 parts of modified diphenylmethane diisocyanate, 50-70 parts of polyether polyol 330N, 30-50 parts of polymer polylol 36 / 28, 0.4-0.7 part of catalyst A33, 0.1-0.3 part of catalyst A-1, 1.5-2.5 parts of stabilizer, namely silicon oil, 0.5-3 parts of cross-linking agent, namely diethanolameine and 5-20 parts of flame retardant, namely ammonium polyphosphate and melamine phosphate. The greatest difference between the material disclosed by the invention and a pure polyurethane foam material is as follows: the material has better sound absorption performance at medium and low frequencies and simultaneously has flame resistance, no toxicity and other performances of other general polyurethane materials. The filler used by the material disclosed by the invention is low in cost and easy to obtain, and the preparation process of the material is simple. The material disclosed by the invention is suitable for occasions and environments with strict requirements for acoustics; and by taking the material prepared by taking rice husk as the filler for example, the sound absorption coefficient of the thickness of 40mm can achieve 0.996 (50Hz-1600Hz).

Owner:JILIN UNIV

Double-helix coupling underwater sound absorption metasurface structure

PendingCN112185326AImprove acoustic impedance characteristicsImprove low-frequency sound absorption performanceSound producing devicesEngineeringFrequency sound

The invention discloses a double-helix coupling underwater sound absorption metasurface structure which comprises a layer core, a plurality of double-helix coupling units are arranged in the layer core at intervals, a cavity is formed in the spiral center of each double-helix coupling unit, an annular partition plate is arranged between each cavity and a spiral channel, and a spiral damping lininglayer is arranged on the side wall of each spiral channel. A perforated upper panel is arranged at the top of the layer core, small holes are periodically formed in the perforated upper panel corresponding to cavities of the double-helix coupling units, a lower panel is arranged at the bottom of the layer core, and the perforated upper panel, the layer core and the lower panel are connected to form a double-helix coupling underwater sound absorption metasurface structure. The double-helix coupling underwater sound absorption metasurface structure has excellent low-frequency sound-absorbing performance and ultra-thin sub-wavelength structure size. And more adjustable structural parameters are provided in the design aspect, corresponding adjustment can be conducted according to actual working condition requirements, the structure is simple, and manufacturing is easy.

Owner:XI AN JIAOTONG UNIV

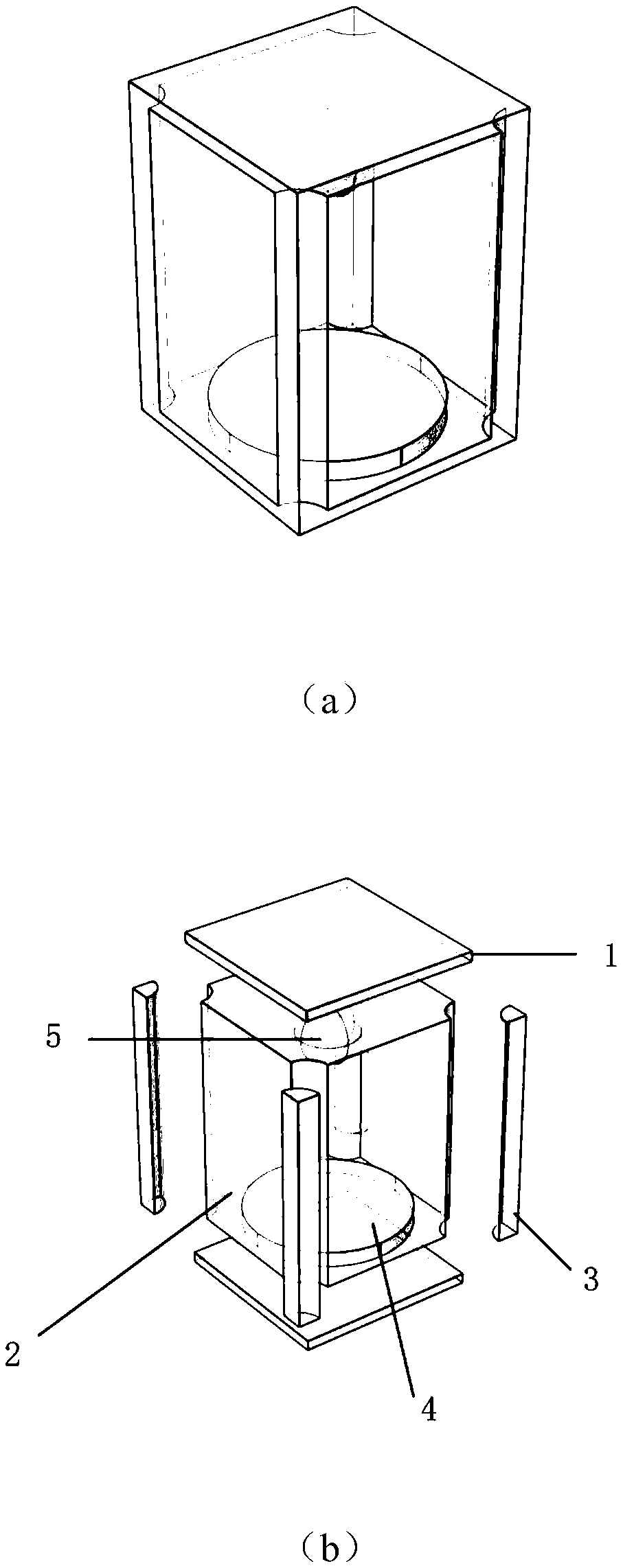

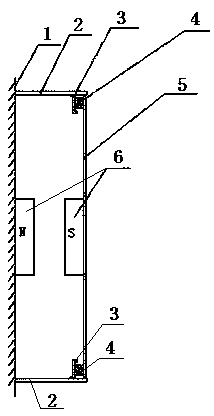

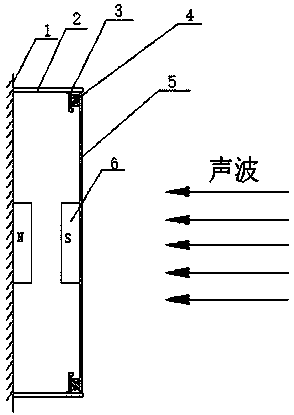

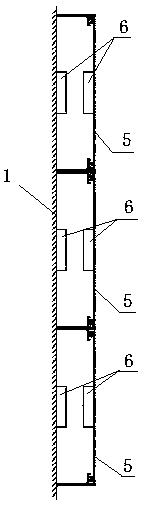

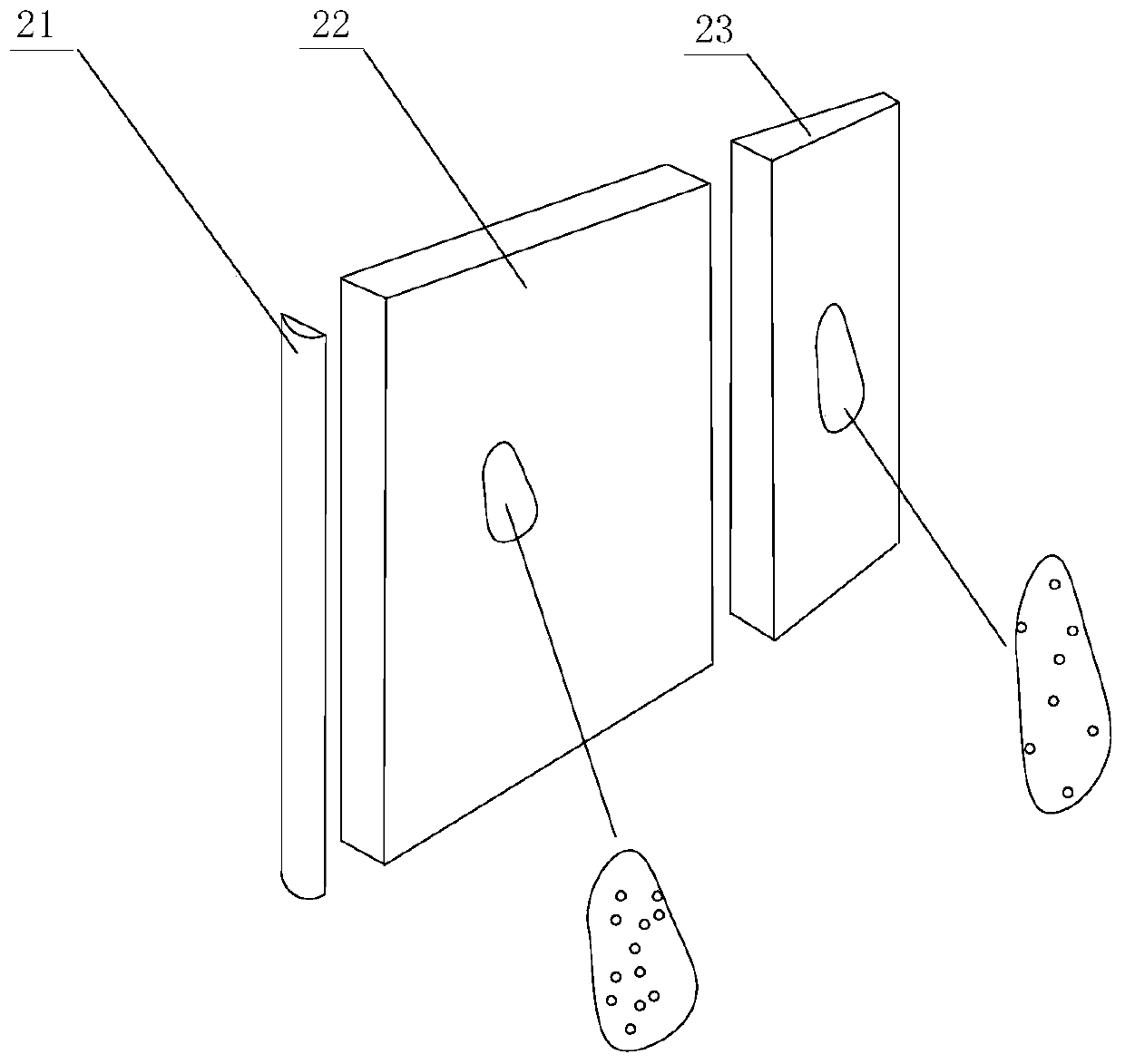

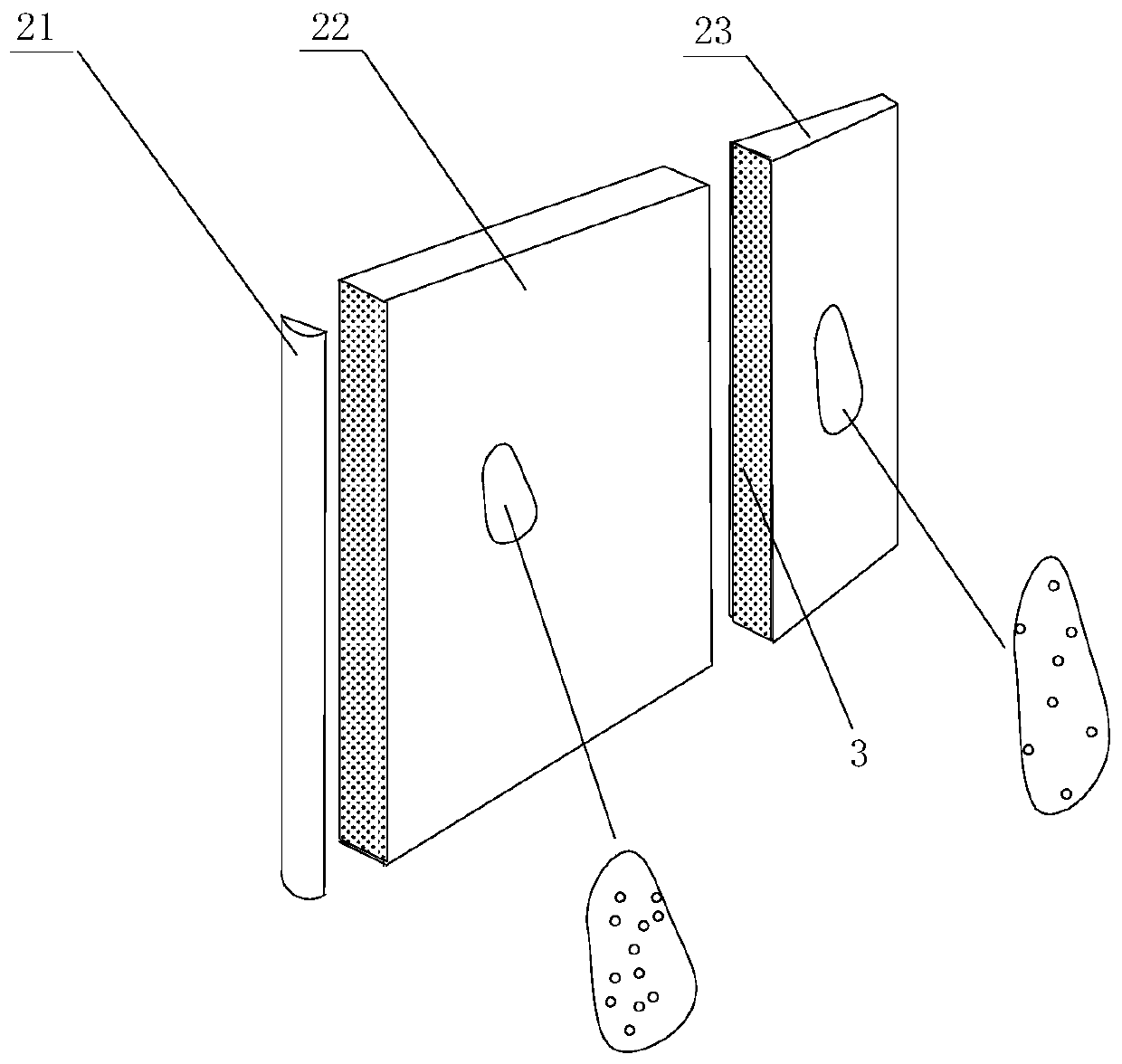

Structure improving low frequency sound absorption performance through magnetism

ActiveCN108447465AReduce mechanical resistance elastic coefficientLower damping factorSound producing devicesResonant cavityNoise control

The invention discloses a structure improving low frequency sound absorption performance through magnetism. The structure comprises two identical lateral supports perpendicular to the wall surface anda mechanical impedance plate parallel with the wall surface, wherein the wall surface, the mechanical impedance plate and the two lateral supports form a square resonant cavity, the resonant cavity is internally provided with a pair of magnetic material blocks, one magnetic material block is fixedly connected with the wall surface, the other magnetic material block is fixedly connected with the mechanical impedance plate, the two magnetic material blocks are arranged face to face, the sizes of the magnetic material blocks are identical, polarities of the magnetic material blocks are opposite,and a viscoelastic material ring is adhered between the two lateral supports and the mechanical impedance plate. The attraction force of the magnetic material blocks is the same as the sound pressurein the direction and is opposite to the elastic force of the viscoelastic material ring, the magnetic force generated by the magnetic material blocks counteracts a part of the elastic force of the viscoelastic material ring, the elastic force of the elastic material ring is reduced, and the low frequency sound absorption performance is improved.

Owner:JIANGSU UNIV

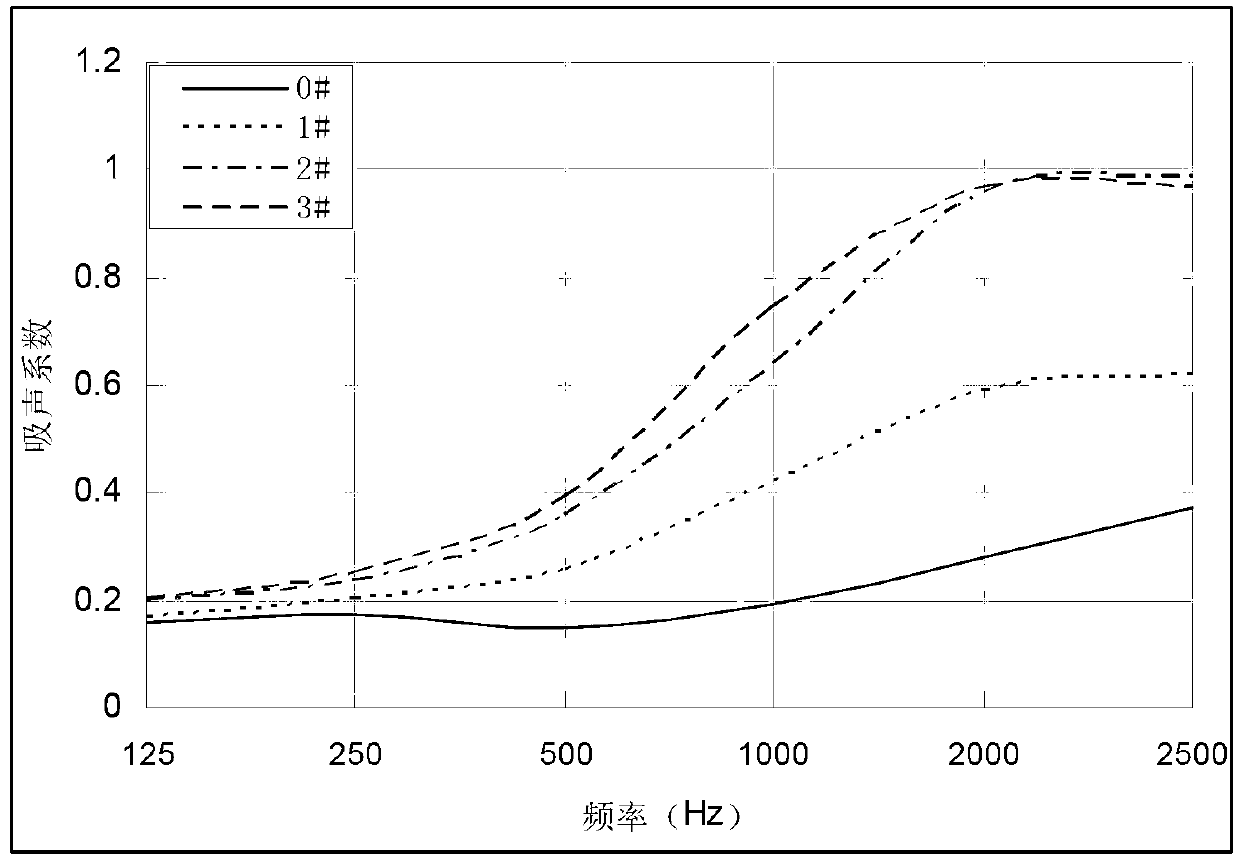

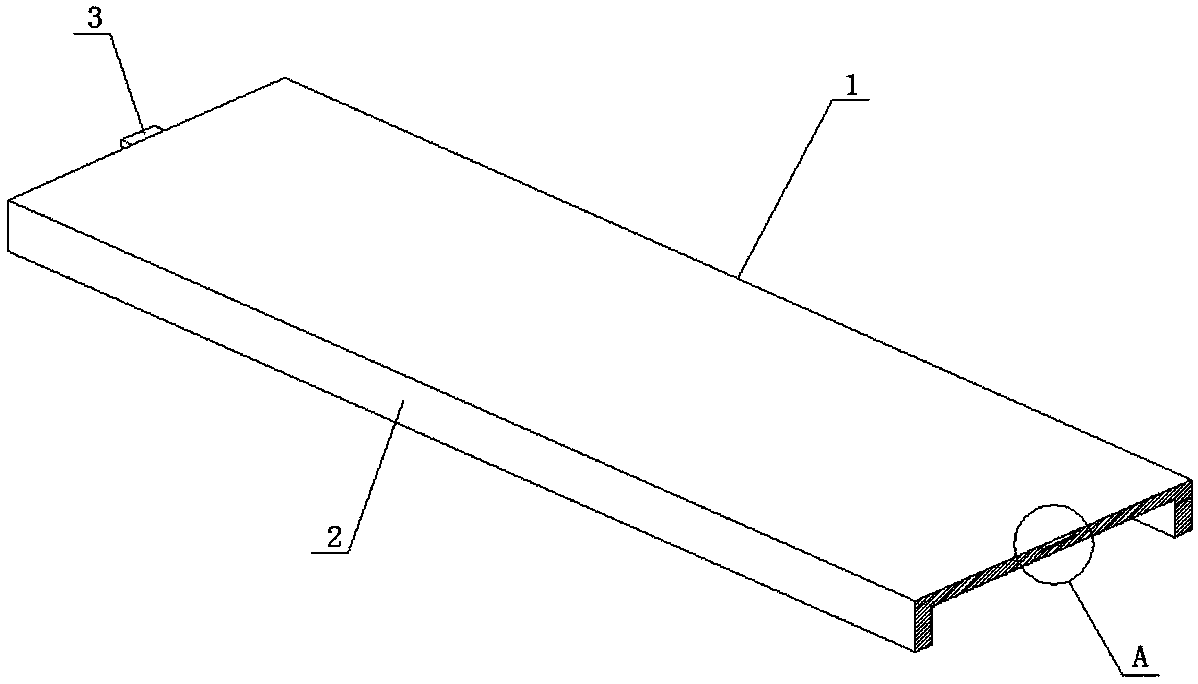

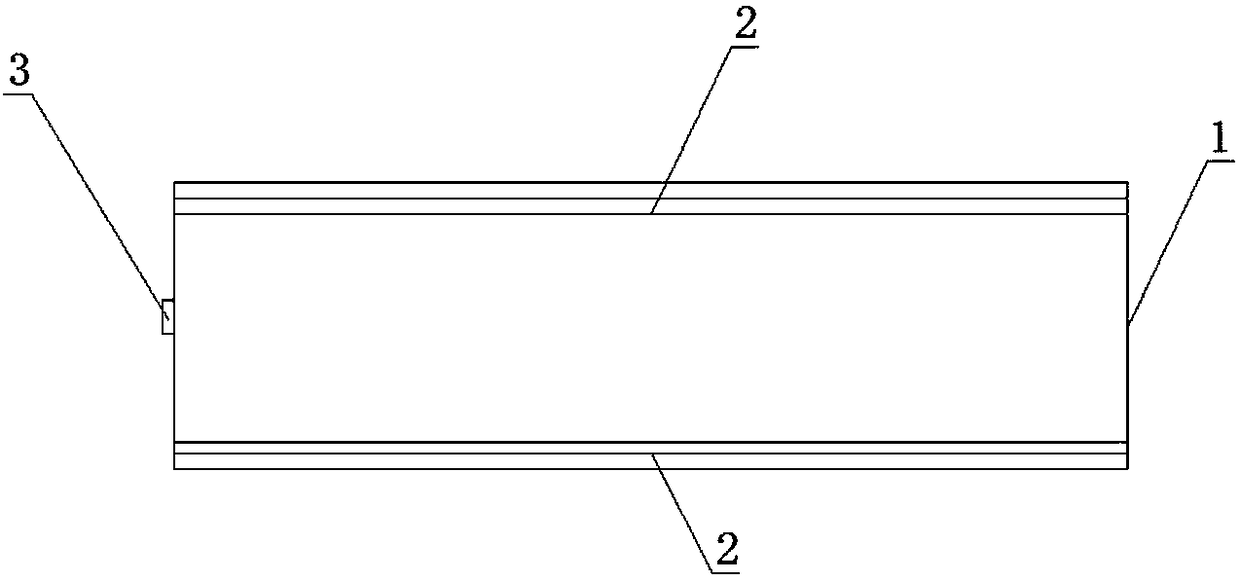

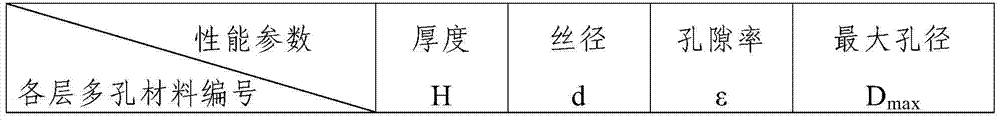

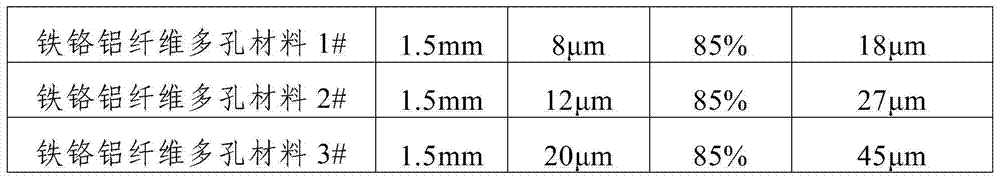

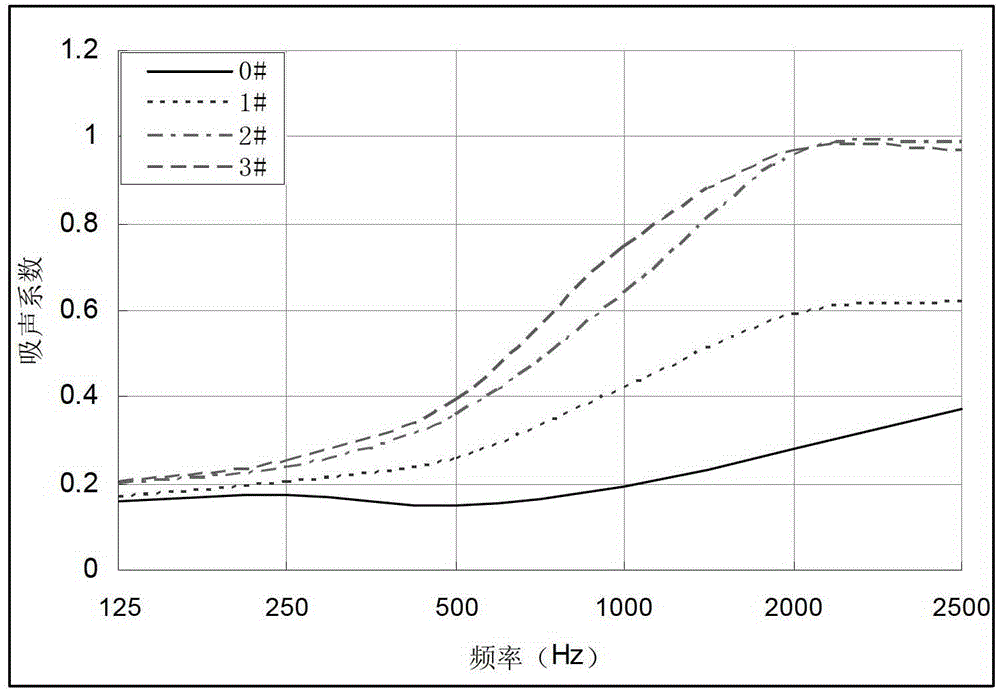

A kind of preparation method of low-frequency sound-absorbing material

ActiveCN105127431BSolve the shortcomings of poor low-frequency sound absorption performanceImprove low-frequency sound absorption performanceSound producing devicesFiberPolyvinyl alcohol

The invention provides a method for preparing a low-frequency sound-absorbing material, which includes the following steps: 1. Mix aluminum powder and polyvinyl alcohol aqueous solution uniformly to obtain slurry, and then apply the slurry evenly on the surface of aluminum foil; 2. Select multiple Layer iron-chromium-aluminum fiber porous material; 3. Stack the selected iron-chromium-aluminum fiber porous material in order, and insert aluminum foil coated with slurry between every two adjacent layers of iron-chromium-aluminum fiber porous material, Obtain the billet to be sintered; 4. Put the billet to be sintered into a sintering mold, put it into a vacuum sintering furnace for sintering, and obtain a low-frequency sound-absorbing material. The sound-absorbing material prepared by the invention has an average sound-absorption coefficient of 0.25-0.35 at a frequency of 50 Hz-500 Hz, has excellent sound-absorbing performance, and can be widely used in the field of precision electronic components with low-frequency sound-absorbing requirements or other sound-absorbing materials place.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A low-frequency sound-absorbing needle-punched nonwoven composite material and its preparation method and application

InactiveCN103106898BImprove low-frequency sound absorption performanceExcellent low frequency sound absorption performanceSound proofingSound producing devicesKapok fiberEconomic benefits

The invention relates to low-frequency sound absorption needling non-woven composite materials and a preparation method of the low-frequency sound absorption needling non-woven composite materials and application of the low-frequency sound absorption needling non-woven composite materials. The composite materials comprise kapok fibers or hollow Dacron non-woven fabric and polyethylene films. The preparation method comprises: mixing, opening, carding and meshing are conducted to 60%-90% kapok fibers and 40%-10% hollow Dacron non-woven fabric according to mass percent; a fiber mesh is inputted in a needling machine so as to conduct needling reinforcement, the fiber mesh is reeled and cut off so as to obtain kapok or hollow Dacron needle non-woven fabric; the polyethylene films in 0.06mm-0.10mm are smoothly placed on one side of the needle non-woven fiber mesh, and are composited, taken out and cooled, and then the low-frequency sound absorption needling non-woven composite materials are obtained. The composite materials can be applied to the field of automotive trim, construction, high-speed rail and the like. The sound absorption materials have the advantages of being light in weight, simple in operation of the preparation method, good in economic benefit and suitable for industrial production.

Owner:DONGHUA UNIV

Light and thin low-frequency sound absorption material and preparation method and application thereof

ActiveCN112659689AImprove low-frequency sound absorption performanceExcellent low frequency sound absorption performanceSynthetic resin layered productsLaminationPolypropylenePolyester

The invention relates to a light and thin low-frequency sound absorption material and a preparation method and application thereof, the sound absorption material comprises four layers, the upper layer is bark crepe woven fabric, the middle layer is two layers of honeycomb woven fabric, and the lower layer is polyester warp knitted fabric / polyurethane foam / polypropylene non-woven fabric flame fusion laminated composite material. The preparation method comprises the following steps: warping, drawing-in and weaving hollow polyester yarns to respectively obtain a bark crepe woven fabric and a honeycomb woven fabric; laminating the polyester warp-knitted fabric, polyurethane foam and polypropylene non-woven fabric by adopting a flame fusion laminating method to obtain a polyester warp-knitted fabric / polyurethane foam / polypropylene non-woven fabric flame fusion laminated composite material; and laminating the four layers of materials by adopting a yarn sewing method to obtain the light and thin low-frequency sound absorption material. The sound absorption material can be applied to the fields of automotive trim, buildings, high-speed rails and the like; and the sound absorption material is light and thin, the thickness is 6.45 mm, the preparation method is simple, the economic benefit is good, and the sound absorption material is suitable for industrial production.

Owner:WUHAN TEXTILE UNIV

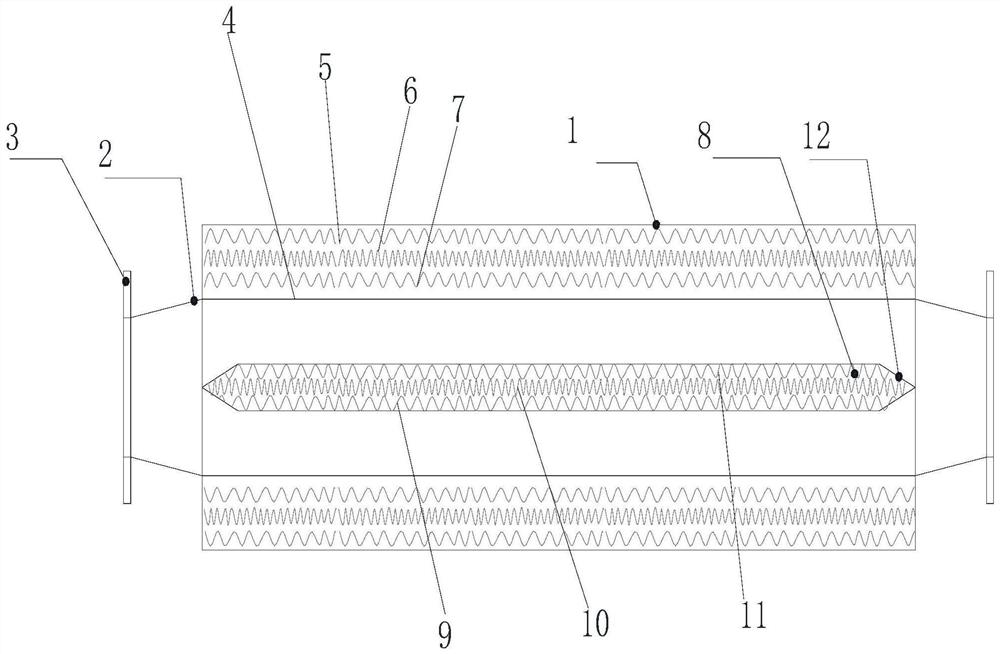

Medium and low frequency silencer for Roots fan

InactiveCN111927781ASimple structureImprove the noise reduction effectRotary piston pumpsRotary piston liquid enginesNoiseEngineering

The invention provides a medium and low frequency silencer for a Roots fan, and belongs to the technical field of silencers. The medium and low frequency silencer is a silencer used for handling medium and low frequency noise and solving the problems that produced silencers existing on the market are small in size, short in effective noise elimination section, small in noise elimination amount andpoor in medium and low frequency noise elimination effect. The medium and low frequency silencer for the Roots fan comprises a silencer shell, and further comprises a perforated steel plate and a sound absorbing sheet. The gap between the perforated steel plate and the silencer shell is sequentially filled with low-unit-weight centrifugal glass wool, medium-unit-weight centrifugal glass wool andhigh-unit-weight centrifugal glass wool from outside to inside. The sound absorbing sheet is inserted into a central hole of the perforated steel plate. The sound absorbing sheet comprises low-unit-weight sound absorbing cotton, high-unit-weight sound absorbing cotton and medium-unit-weight sound absorbing cotton, wherein the low-unit-weight sound absorbing cotton, the high-unit-weight sound absorbing cotton and the medium-unit-weight sound absorbing cotton are sequentially arranged. A combined structure is adopted, a sound absorbing cavity is designed behind, and the low frequency sound absorbing effect is improved. Meanwhile, relatively low unit weight glass wool is selected in combination with medium and high frequency noise, so that medium and low frequency noise is effectively reduced.

Owner:NORTH HUAJIN CHEM IND CO LTD

Sound absorber, and preparation method and application thereof

InactiveCN110875030AWide frequency range of sound absorptionImprove sound absorption performanceSound producing devicesPorous substrateSound Absorber

The invention relates to a sound absorber, and a preparation method and an application thereof. The sound absorber comprises a porous substrate, wherein foamed holes are distributed in the porous substrate; the porous substrate is provided with a main surface; and a plurality of openings are distributed in the part or all of the main surface, hole diameters of the openings are 0.5-8mm, depths of the openings are 2-20mm, and spacing between centers of the two adjacent openings is 0.5-10mm. The sound absorber is provided with the porous substrate that has a certain sound absorption property, andmeanwhile, the openings with specific hole diameters, depths and hole spacing are formed in the main surface of the porous substrate, so that a structural sound absorption layer with a specific shapeis formed; low frequency sound absorption performance can be improved via a resonant sound absorption mechanism; and the structural sound absorption layer effectively enhances sound absorption ability of the porous substrate, significantly improves a sound absorption coefficient of a whole frequency band, and broadens a sound absorption frequency range of the sound absorber, and thus broadband sound absorption is achieved.

Owner:BYD CO LTD

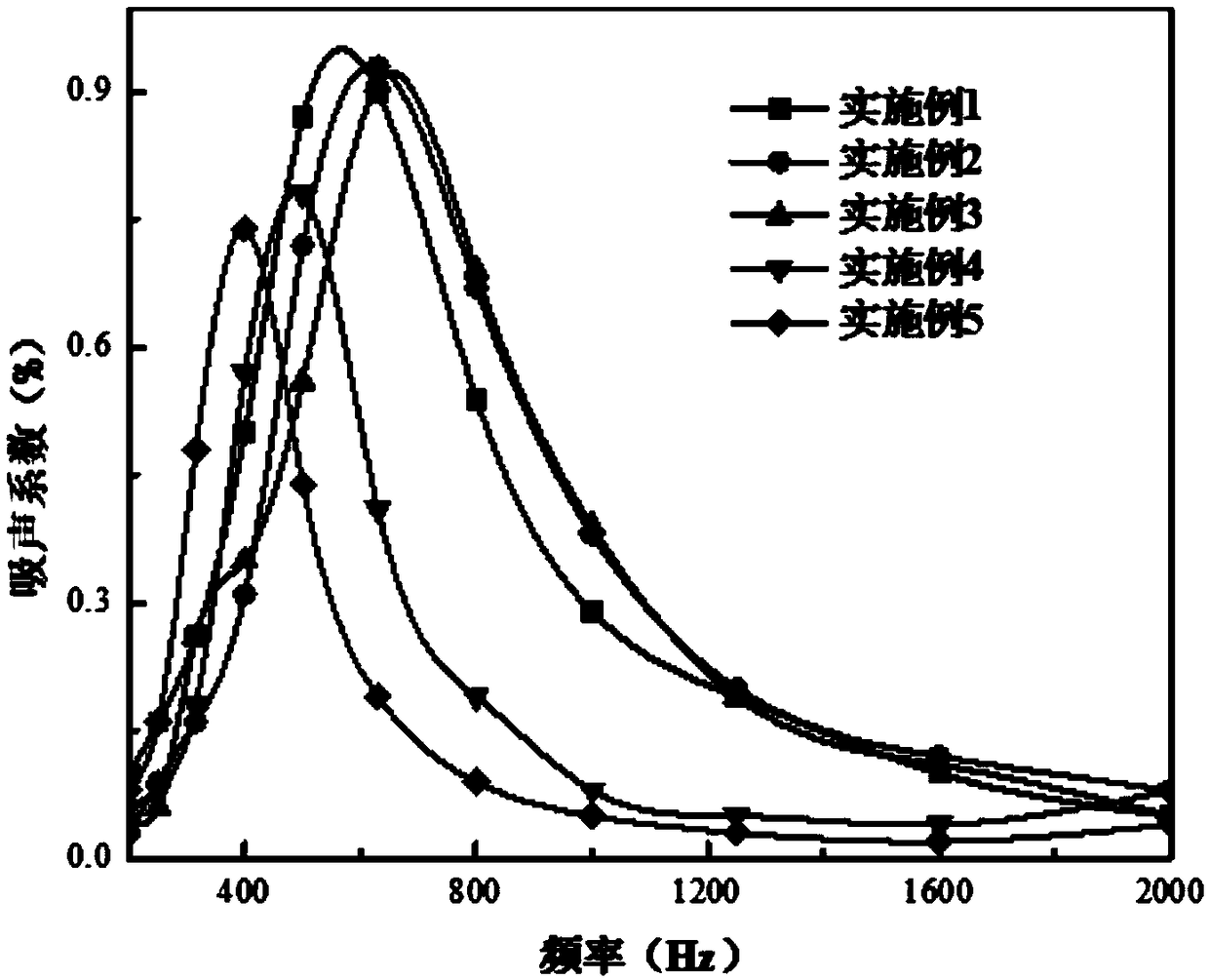

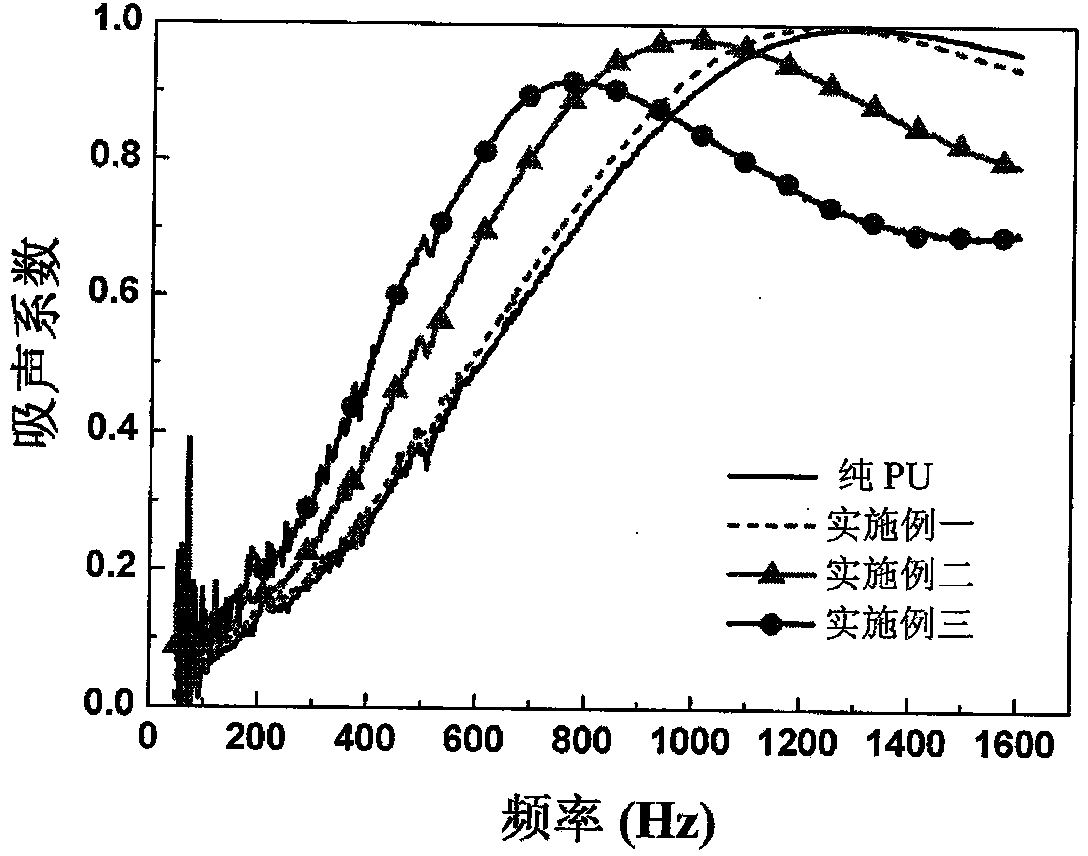

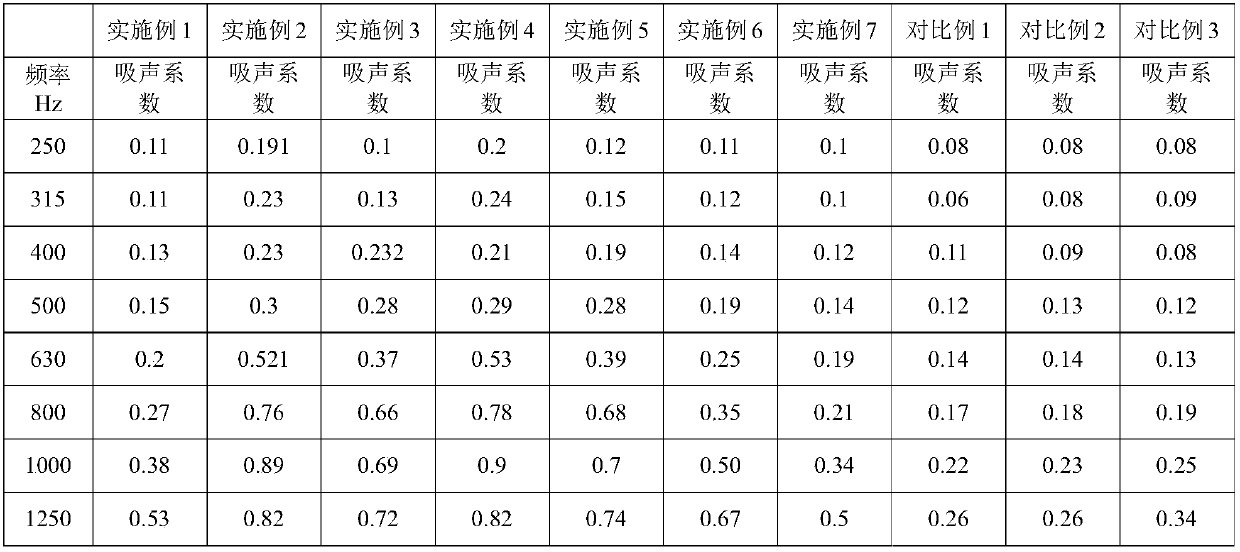

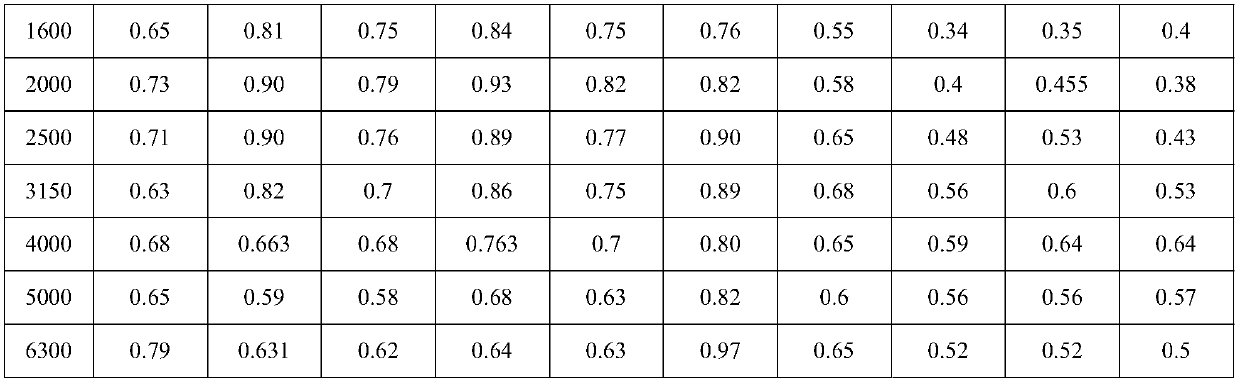

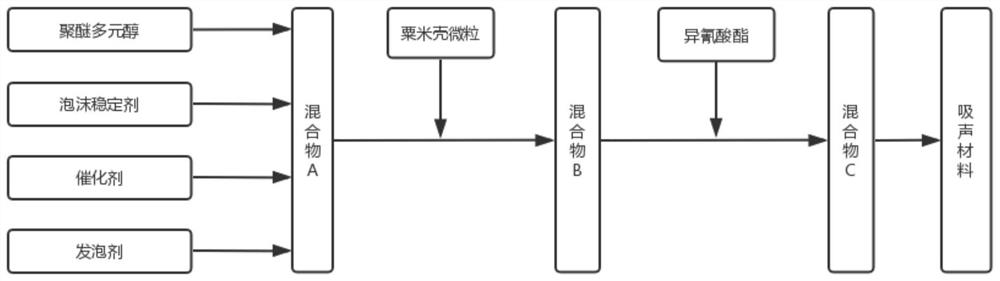

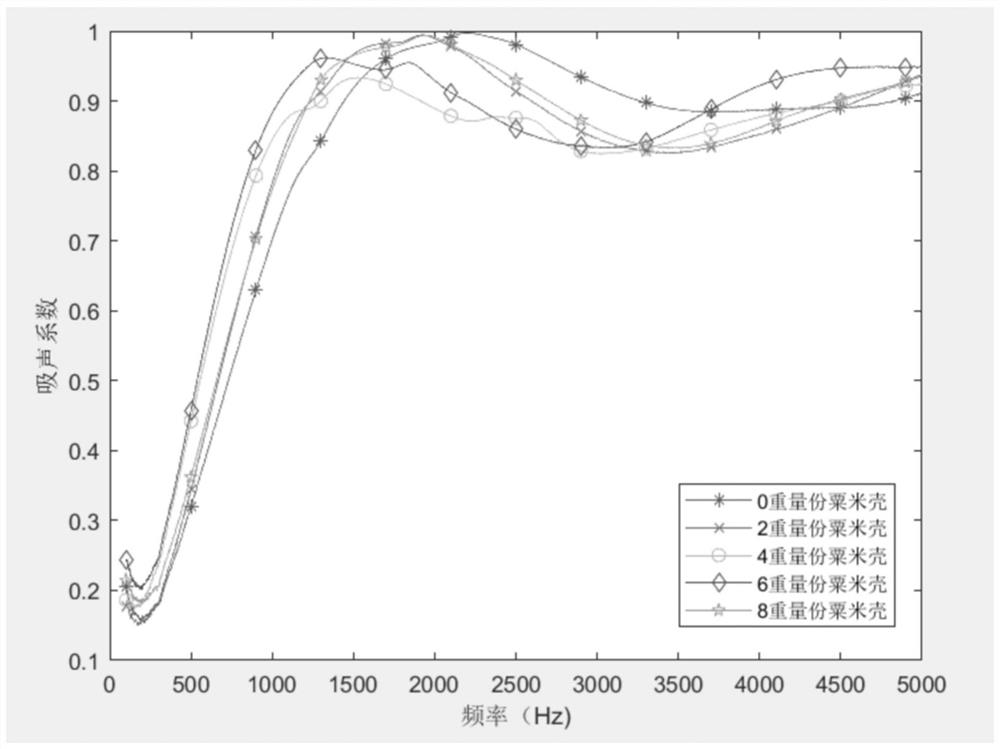

Polyurethane composite sound absorption material containing natural plant components and preparation method thereof

PendingCN113150237AImprove low-frequency sound absorption performanceImprove acoustic performancePolymer sciencePtru catalyst

The invention provides a polyurethane composite sound absorption material containing natural plant components. The polyurethane composite sound absorption material comprises the following components: polyether polyol, a foam stabilizer, a catalyst, a foaming agent, diphenylmethane diisocyanate and corn shells. The invention further provides a preparation method of the polyurethane composite sound absorption material containing the natural plant components. The corn husks are added to improve the low-frequency sound absorption performance of polyurethane, the sound absorption coefficient of the polyurethane composite sound absorption material containing the natural plant components at the low frequency reaches 0.968, the average sound absorption coefficient reaches 0.608, the sound absorption peak frequency is 1338.11 Hz, the acoustic performance is superior to that of traditional polyurethane foam, and the polyurethane composite sound absorption material belongs to an efficient sound absorption material. The preparation method of the polyurethane composite sound absorption material is simple and wide in application range.

Owner:WUHAN UNIV OF SCI & TECH

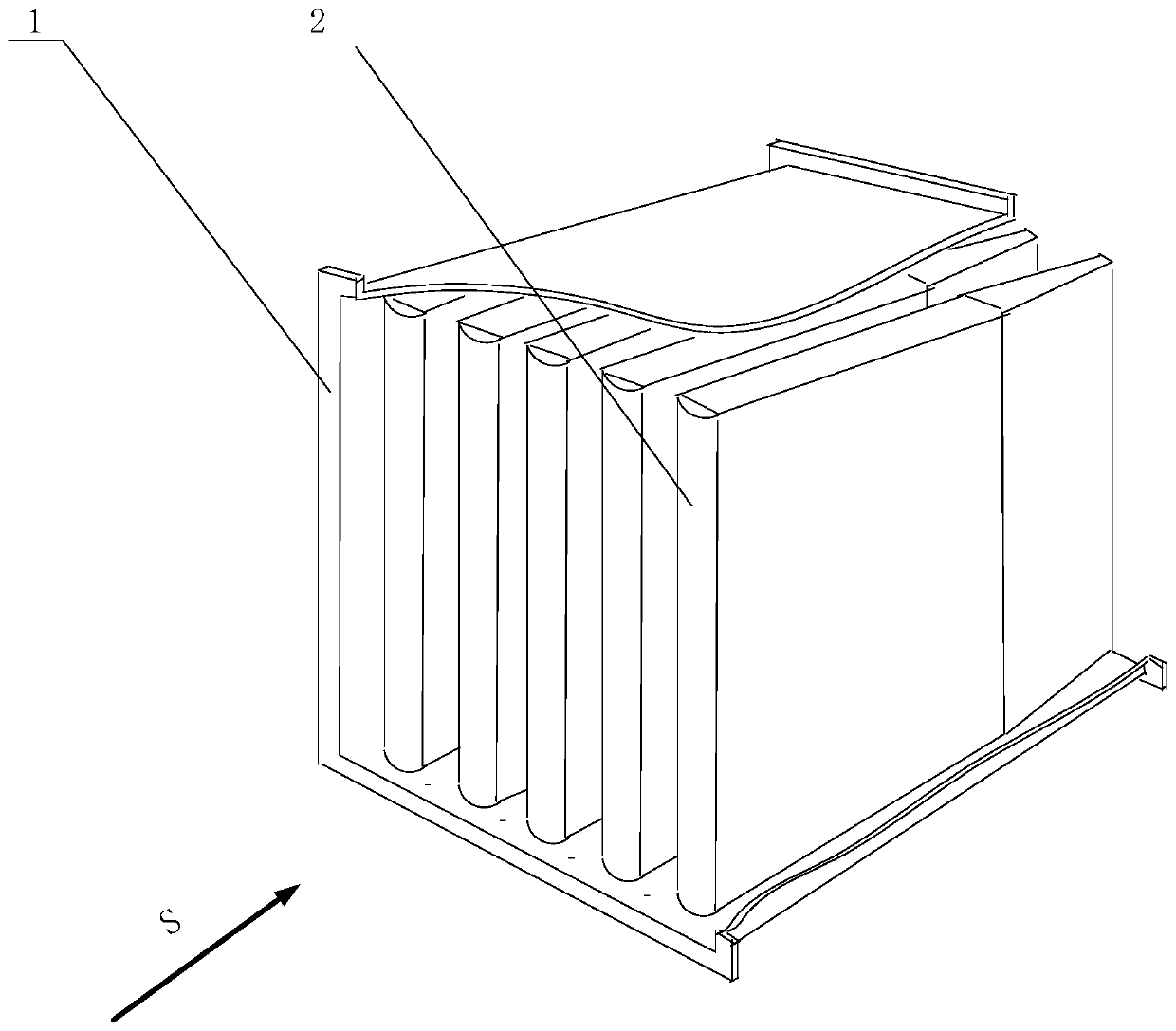

Silencing sheet

PendingCN111489727AGood overall sound attenuationEasy accessSound producing devicesFrequency spectrumNoise

The invention relates to the technical field of silencing sheets, in particular to a silencing sheet which comprises a noise elimination sheet shell which is at least partially composed of a perforated plate; and a sound absorption material which is uniformly filled in the silencing sheet shell; a front edge plate, a middle face plate and a gradually-shrinking face plate are sequentially arrangedon the silencing piece shell in the airflow direction S. The middle face plate and the gradually-shrinking face plate are each composed of two kinds of perforated plates with different perforation rates. According to the silencing sheet provided by the invention, different perforation rates are adopted for the middle panel part and the tapered panel part, so that silencing can be carried out on different frequency spectrum parts of a noise source, and the optimal overall silencing amount under the same pressure loss condition is achieved.

Owner:HUADIAN HEAVY IND CO LTD

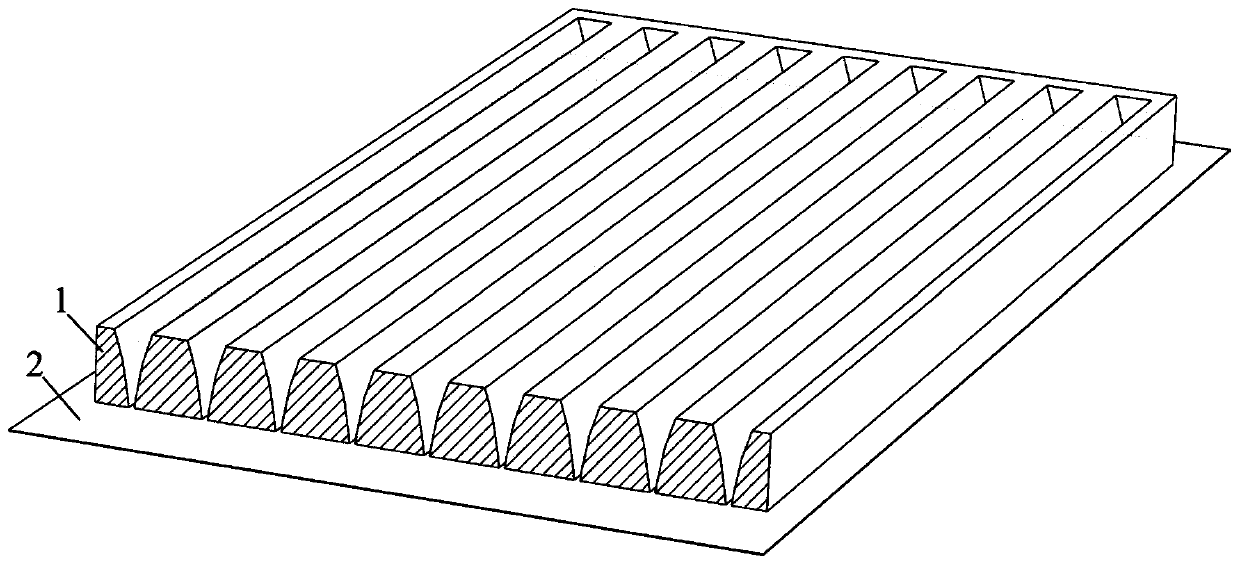

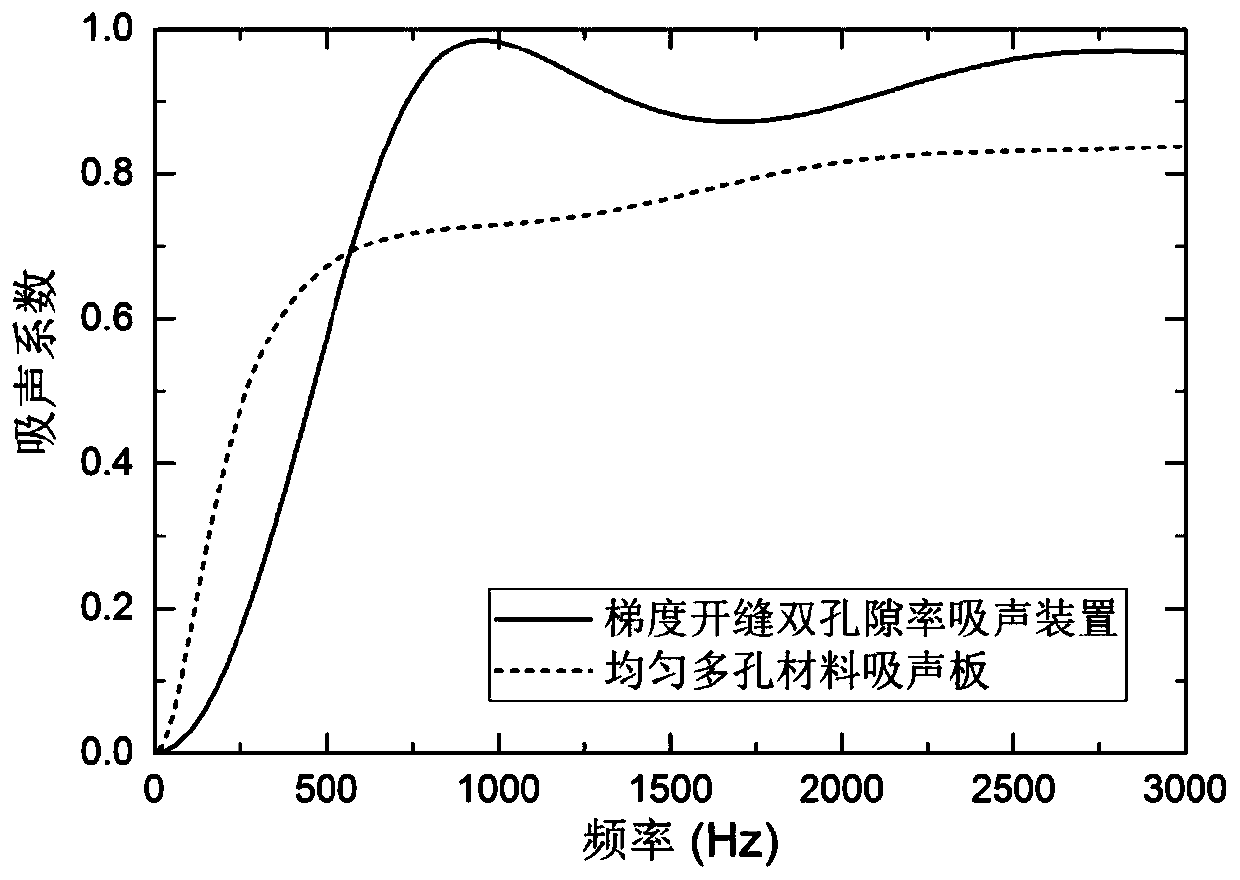

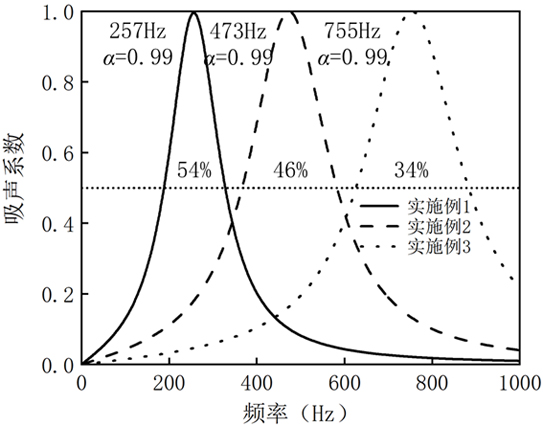

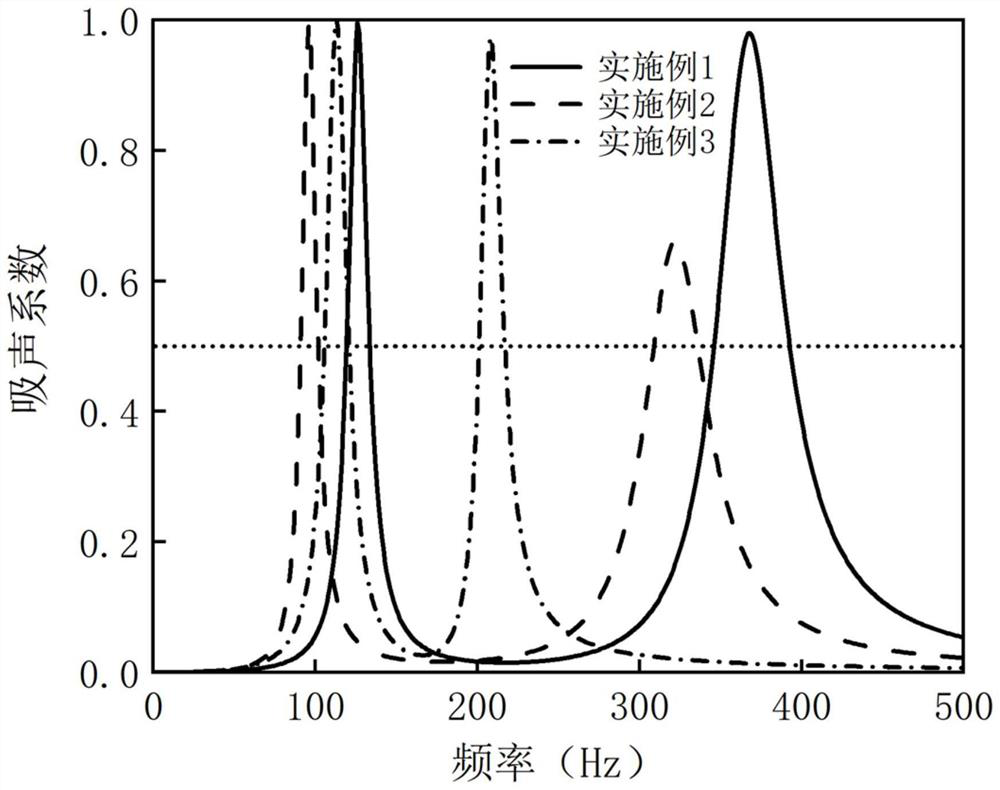

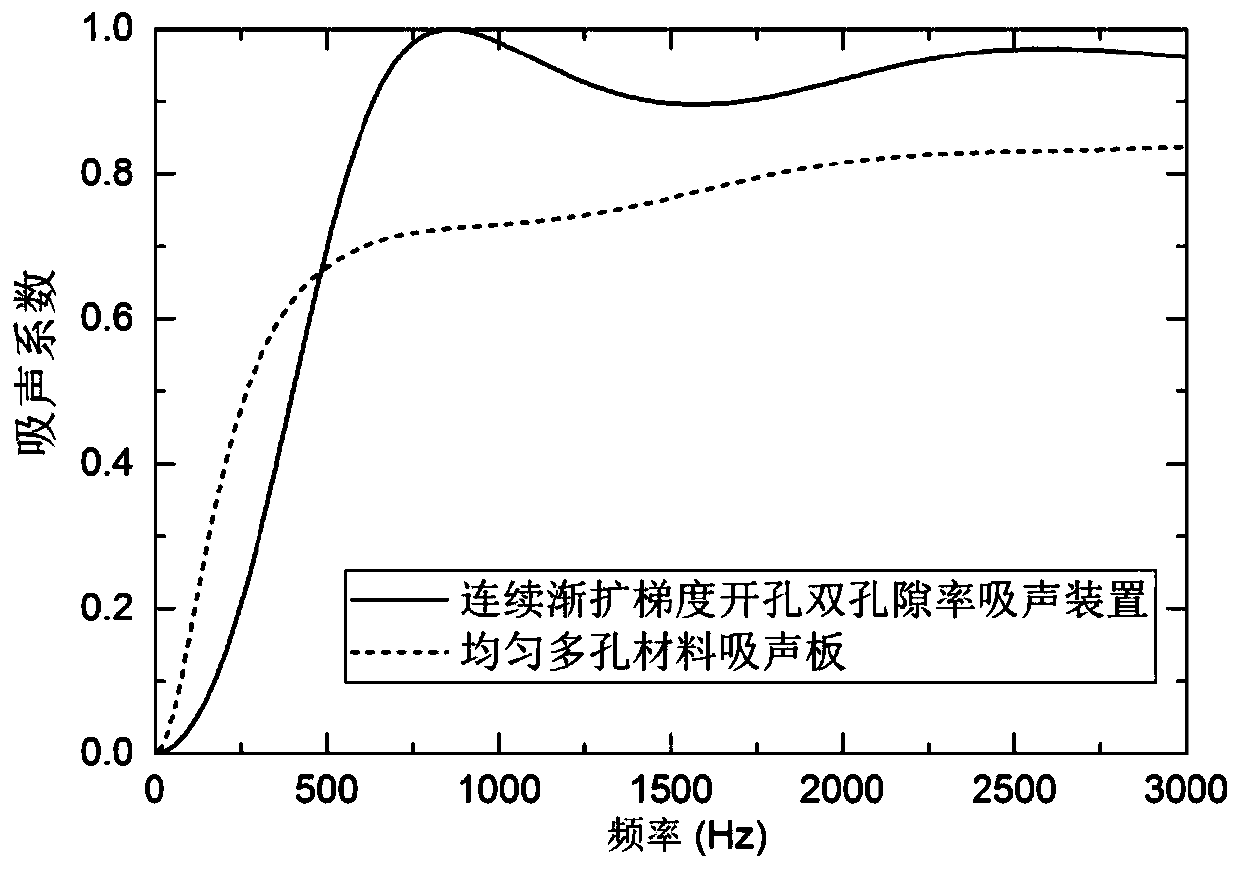

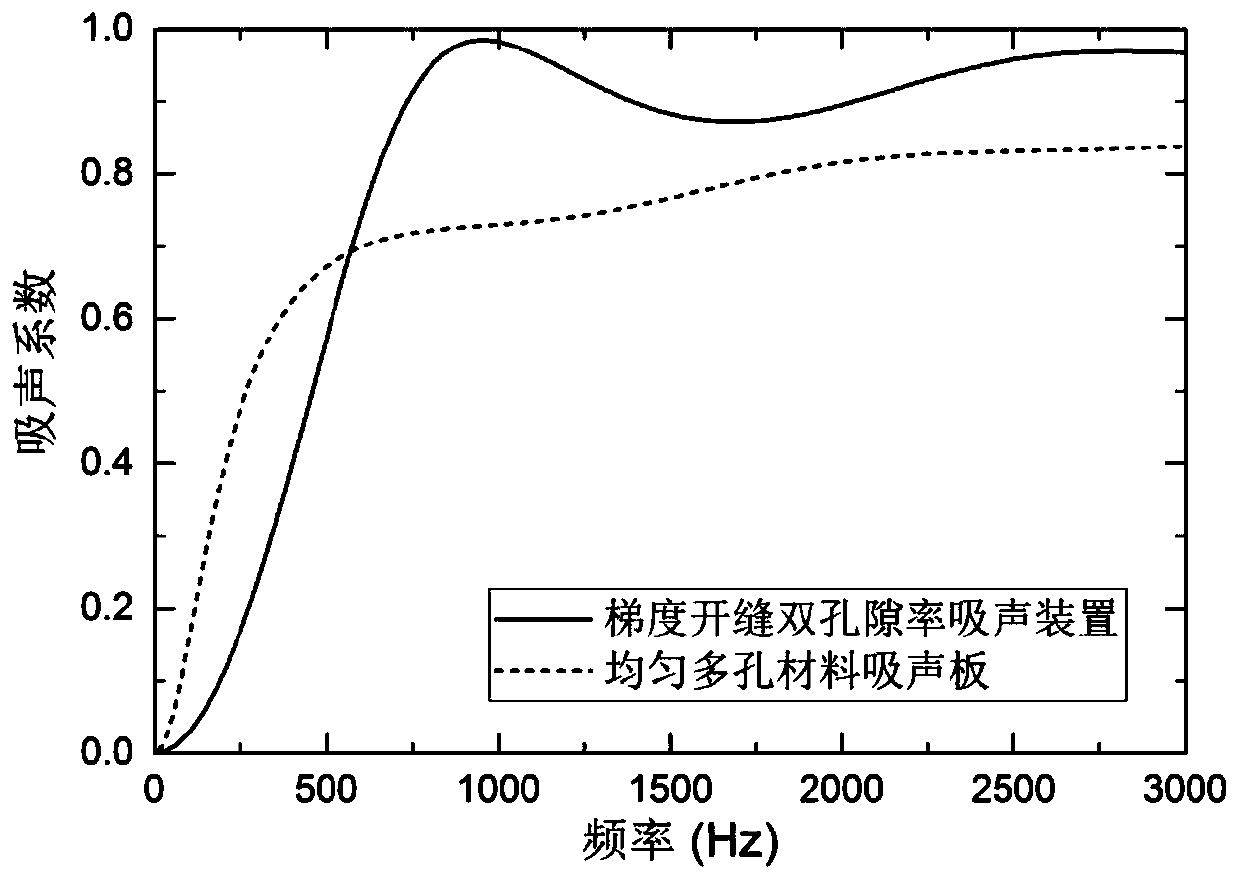

A Continuous Gradient Opening Double Porosity Sound Absorbing Device and Its Application

ActiveCN109707060BImprove low-frequency sound absorption performanceSimple structureSound proofingSound producing devicesLow frequency bandPore diameter

The invention discloses a continuously and gradually enlarging gradient punching double-porosity sound absorbing device and application thereof. A porous material is adopted as a substrate of a perforated porous material plate, gradient holes are periodically formed in the perforated porous material plate, the punching direction is perpendicular to the perforated porous material plate, the punching pore diameter continuously become larger or smaller in the thickness direction, and according to actual requirements, the gradient double-porosity sound absorbing plate can be directly placed on rigid backing, or a hollow cavity is reserved between the sound absorbing plate and the rigid backing to further improve the sound absorbing property. The continuously and gradually enlarging gradient punching double-porosity sound absorbing device is simple and practical in structure, has a superior sound absorbing property and a flexible sound absorbing adjusting function in a low frequency band, amedium frequency band and a high frequency band, and has good and wide application prospects.

Owner:XI AN JIAOTONG UNIV

Composite wallboard structure of impact-resistant foam metal composite material for aircraft manufacturing

ActiveCN114771803AImprove sound insulationImprove impact resistanceFuselage bulkheadsWeight reductionFrequency soundProtection layer

The invention provides a composite wallboard structure of an anti-impact foam metal composite material for aircraft manufacturing, and belongs to the technical field of aircraft manufacturing. Comprising a sound absorption core material, transition connection layers arranged at the upper end and the lower end of the sound absorption core material, two glass fiber protection layers connected with the sides, away from the sound absorption core material, of the transition connection layers, and outer skin connected with the sides, away from the transition connection layers, of the glass fiber protection layers. Components among the sound absorption core material, the transition connection layer, the glass fiber protection layer and the outer skin are connected compactly, the overall mechanical strength of the composite wall plate structure is high, the impact resistance characteristic is good, meanwhile, the open-cell foamed aluminum with the high porosity is adopted, the low-frequency sound absorption effect of the composite wall plate structure can be improved, and meanwhile the composite wall plate structure can be used for sound absorption. And the weight of the composite wall plate structure can be reduced, and the comfort in a cabin of an airplane is improved.

Owner:CHINA AIRPLANT STRENGTH RES INST

Rare earth oxide/nitrile rubber-polyurethane foam double-layer composite material for low-frequency sound absorption and its preparation method

ActiveCN108641140BExcellent mid-low frequency sound absorption effectReduce thicknessSynthetic resin layered productsLaminationPolymer scienceVulcanization

The invention belongs to the technical field of material processing, and particularly relates to a rare earth rubber-polyurethane foam composite layered material used for low frequency sound absorption and a preparation method thereof. The method comprises the following steps: pretreating rare earth oxide powder; sequentially adding nitrile rubber, zinc oxide, stearic acid, zinc stearate, an anti-aging agent, an accelerator, carbon black, rare earth oxide powder, sulfur and a softener into an internal mixer or an open mill for mixing and vulcanization treatment to obtain a rare earth oxide-nitrile rubber composite material for low frequency sound absorption; using a binder to compound the rare earth oxide-nitrile rubber composite material and polyurethane foam according to the structure with the rare earth oxide-nitrile rubber composite material on one side facing the sound wave and the polyurethane foam on the other side to obtain the rare earth oxide / butyronitrile rubber-polyurethanefoam double layered composite material. The rare earth oxide / butyronitrile rubber-polyurethane foam double layered composite material has a plurality of energy dissipation mechanisms such as magneticacoustic conversion, damping dissipation and interface resonance, has an excellent mid-low frequency sound absorption effect, is light in quality and small in thickness, and has broad application prospects in the field of sound absorption.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A Gradient Slit Double Porosity Sound Absorbing Device and Its Application

ActiveCN109707059BImprove low-frequency sound absorption performanceSimple structureSound proofingSound producing devicesLow frequency bandMedium frequency

The invention discloses a gradient slitting double-porosity sound absorbing device and application thereof. The gradient slitting double-porosity sound absorbing device comprises a seamed porous material plate and rigid backing; the seamed porous material plate is arranged on the rigid backing, a plurality of gradient slits are formed in the seamed porous material plate periodically at intervals,and the slitting direction of the gradient slits is perpendicular to the seamed porous material plate. The gradient slitting double-porosity sound absorbing device is simple and practical in structure, has a superior sound absorbing property and a flexible sound absorbing adjusting function in a low frequency band, a medium frequency band and a high frequency band, and has good and wide application prospects.

Owner:XI AN JIAOTONG UNIV

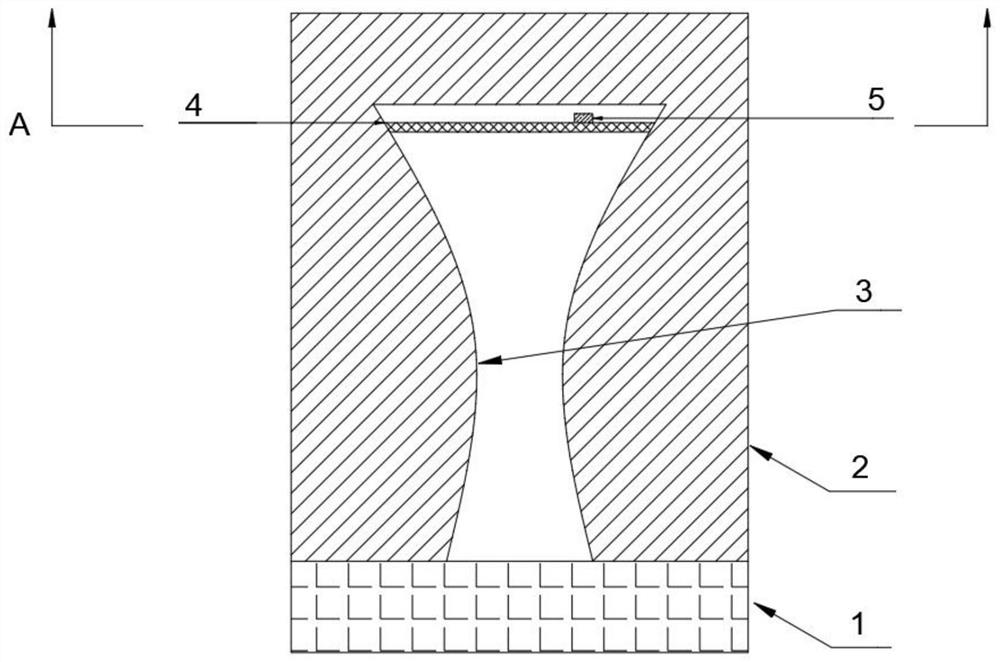

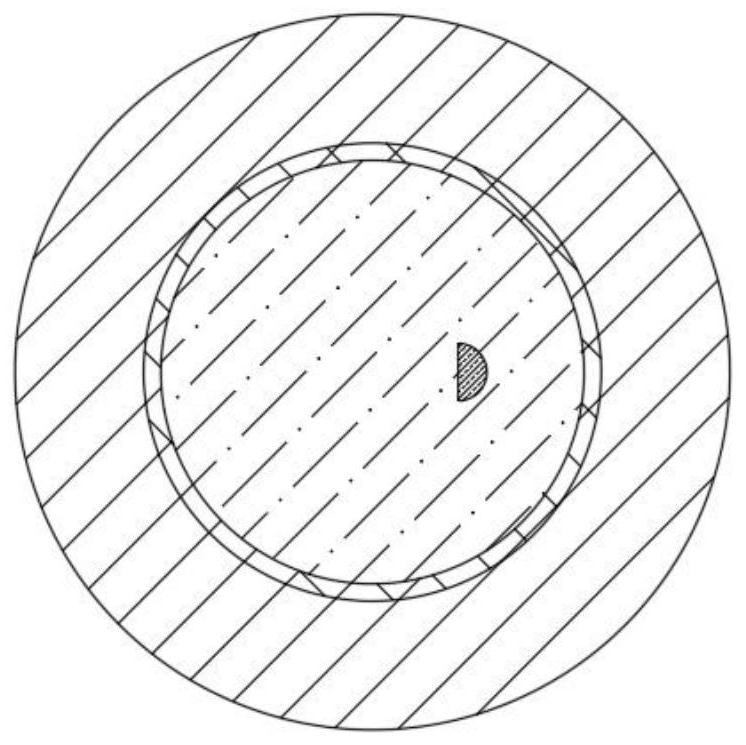

Membrane cavity coupling type underwater acoustic board

PendingCN112017625AGood underwater broadband sound absorption abilityImpedance matchingSound producing devicesThin membraneEngineering

The invention aims to provide an underwater sound absorption structure with a good low-frequency sound absorption effect. The average sound absorption coefficient of the sound absorption structure canreach 0.7 or above within the frequency range of 3000Hz. The invention relates to an underwater low-frequency sound absorption structure, in particular to a membrane cavity coupling type underwater acoustic board, which comprises an installation layer, a sound absorption layer and a structure cavity. The average sound absorption coefficient of the sound absorption structure can be 0.7 or above within the frequency range of 3000Hz. The sound absorption layer and the installation layer are laminated and bonded, wherein a plurality of structural cavities are formed in the sound absorption layer,each structural cavity is one or a combination of two of a double-horn shape or a vase shape with the gradually-changed hole diameter, the lower surface of each structural cavity is flush with the bottom surface of the sound absorption layer, a film structure is arranged in each structural cavity, and an asymmetric mass block is arranged on the film structure.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com