Damping material filled foam metal embedded periodic cavity type underwater sound absorption structure

A damping material and periodic technology, applied in the direction of sound-producing equipment, instruments, etc., to achieve the effect of improving low-frequency sound absorption performance, excellent mechanical properties, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

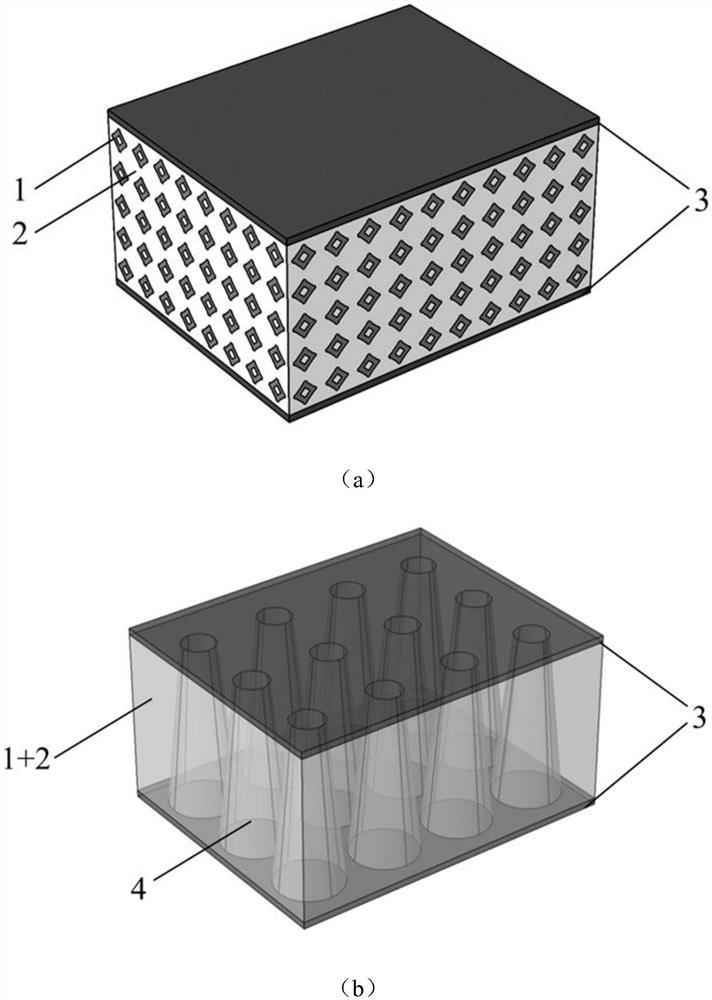

Method used

Image

Examples

Embodiment

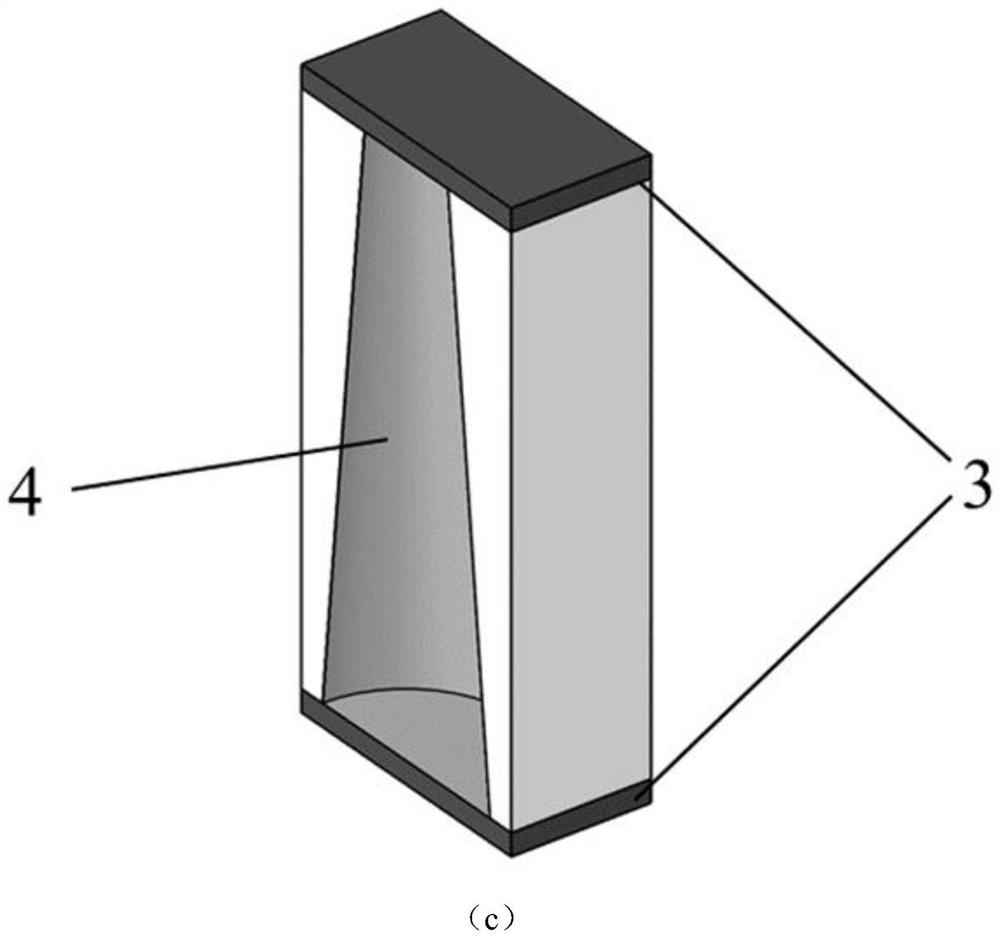

[0044] Examples of materials:

[0045] Metal aluminum: characterized by a density of 2700kg / m 3 , Young's modulus 70GPa, Poisson's ratio 0.33.

[0046] Soft damping material: characterized by a density of 980kg / m 3 , Young's modulus 6MPa, Poisson's ratio 0.497, loss factor 0.5.

[0047] Hard damping material: characterized by a density of 1100kg / m 3 , Young's modulus 30MPa, Poisson's ratio 0.493, loss factor 0.3.

[0048] Water: characterized by a density of 1000kg / m 3 , the speed of sound is 1500m / s.

[0049] The structure size of embodiment:

[0050] The simulation calculation uses the tetrahedron model of open-cell aluminum foam, the cell side length is 8mm, the diameter of the aluminum foam skeleton is 2mm, the porosity is 70.1%, and the thickness of the aluminum foam is 50mm; the covering layer of hard damping material is the same up and down, and the thickness is 2mm ;Cavity 4 see figure 1 (c), the diameter of the upper surface is 10mm, the diameter of the lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com