Sludge curing device and method combining vacuum grouting and resistance heating

A resistance heating and curing device technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of long consolidation time, failure to achieve reinforcement effect, low consolidation degree, etc., and reduce secondary piling processing probability, shorten the consolidation time of silt soil, and improve the strength and integrity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

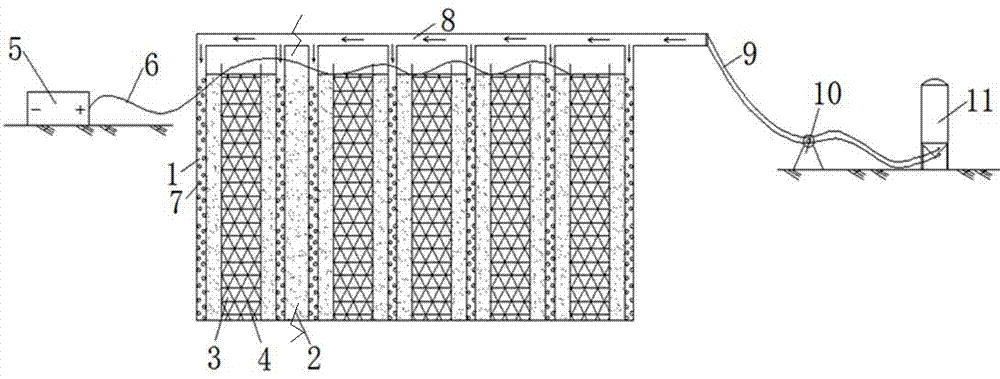

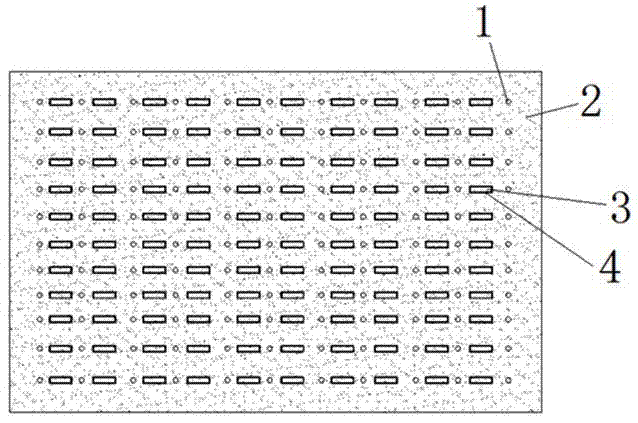

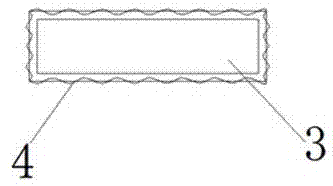

[0034] like Figure 1-4 Shown: This embodiment is a sludge solidification device combined with vacuum grouting combined with resistance heating, including a grouting pipe 1, a drain plate 3, a horizontal drain pipe, a resistance wire 4, a horizontal grouting conduit 8, a grouting hose 9, Grouting pump 10 and curing agent slurry storage tank 11; wherein, grouting pipe 1 is provided with a plurality of, and each grouting pipe 1 is formed with several grouting holes 7, and multiple grouting pipes 1 are connected with horizontal grouting respectively. The conduit 8 is connected, and the drainage board 3 is set between two adjacent grouting pipes 1. The plurality of drainage boards 3 are respectively connected to the horizontal drainage pipes, and the horizontal drainage pipes are connected to the external drainage pipes. The resistance wire 4 is wound on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com