Hot-melting bonding guide pipe type plastic drainage plate

A plastic drainage board, hot-melt bonding technology, applied in infrastructure engineering, soil protection, construction, etc., to achieve the effect of improving the overall strength, good toughness, and increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

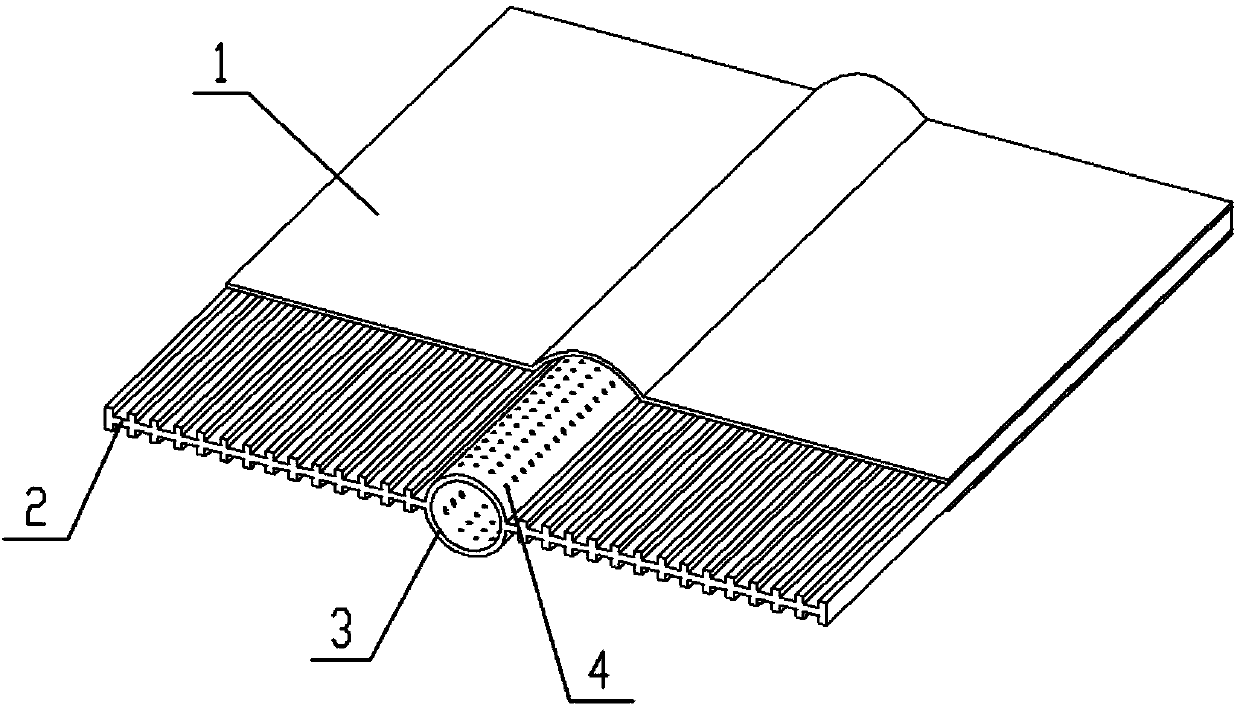

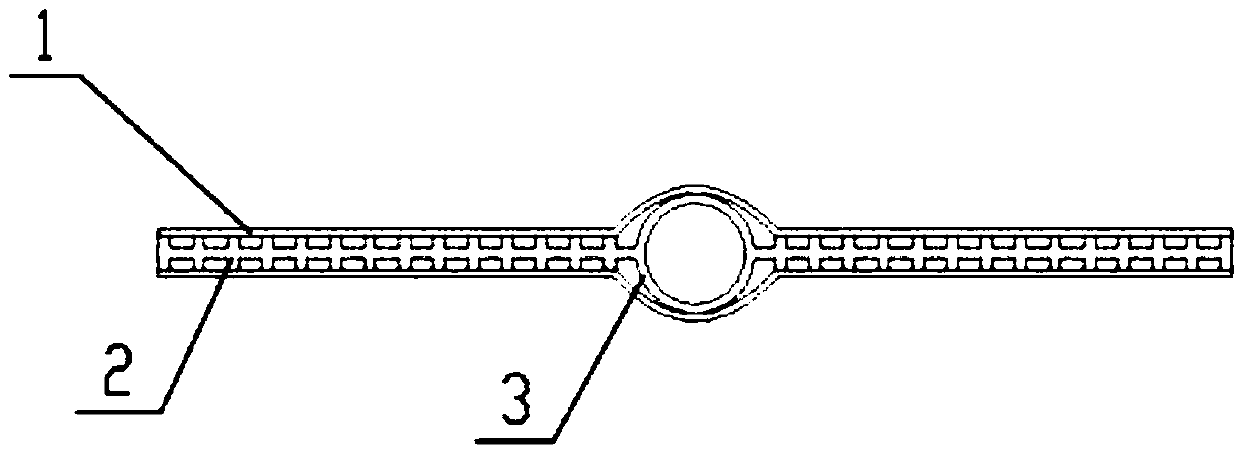

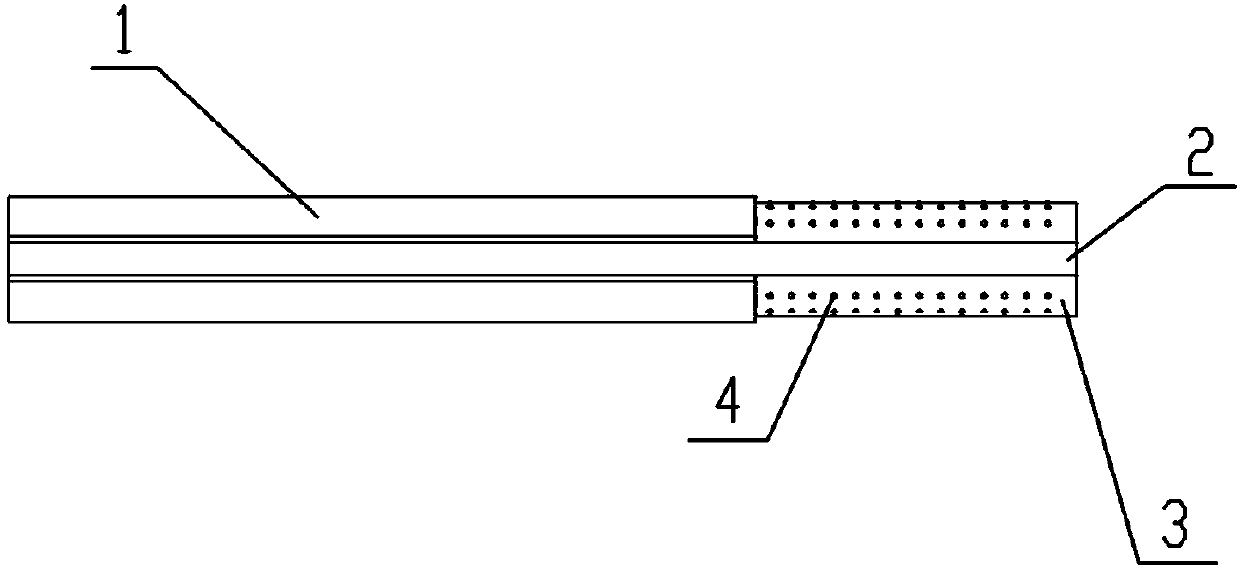

[0022] as attached Figure 1 to Figure 4 As shown, a hot-melt bonding duct-type plastic drainage board includes a plastic core plate 2 and a water-permeable filter membrane 1 wrapped outside the plastic core plate 2, and the water-permeable filter membrane 1 is bonded to the water through a hot-melt bonding process. The plastic core board 2 is bonded together, which completely solves the defect that the core board of the sewn and bonded drainage board and the permeable filter membrane 1 are not tightly wrapped, which may easily cause the blockage of the drainage groove during use, and greatly improves the structural stability. reliability.

[0023] The plastic core board 2 is provided with drainage grooves. The middle part of the plastic core board 2 is provided with a central conduit 3, and the pipe wall of the central conduit 3 is provided with evenly distributed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com