Dish washer

A technology for dishwashers and dish racks, which is applied to the washing machine/washing machine for tableware, parts of the washing machine/rinsing washing machine for tableware, cleaning equipment, etc. Small and other problems, to achieve the effect of strong water flow, less water, and large water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

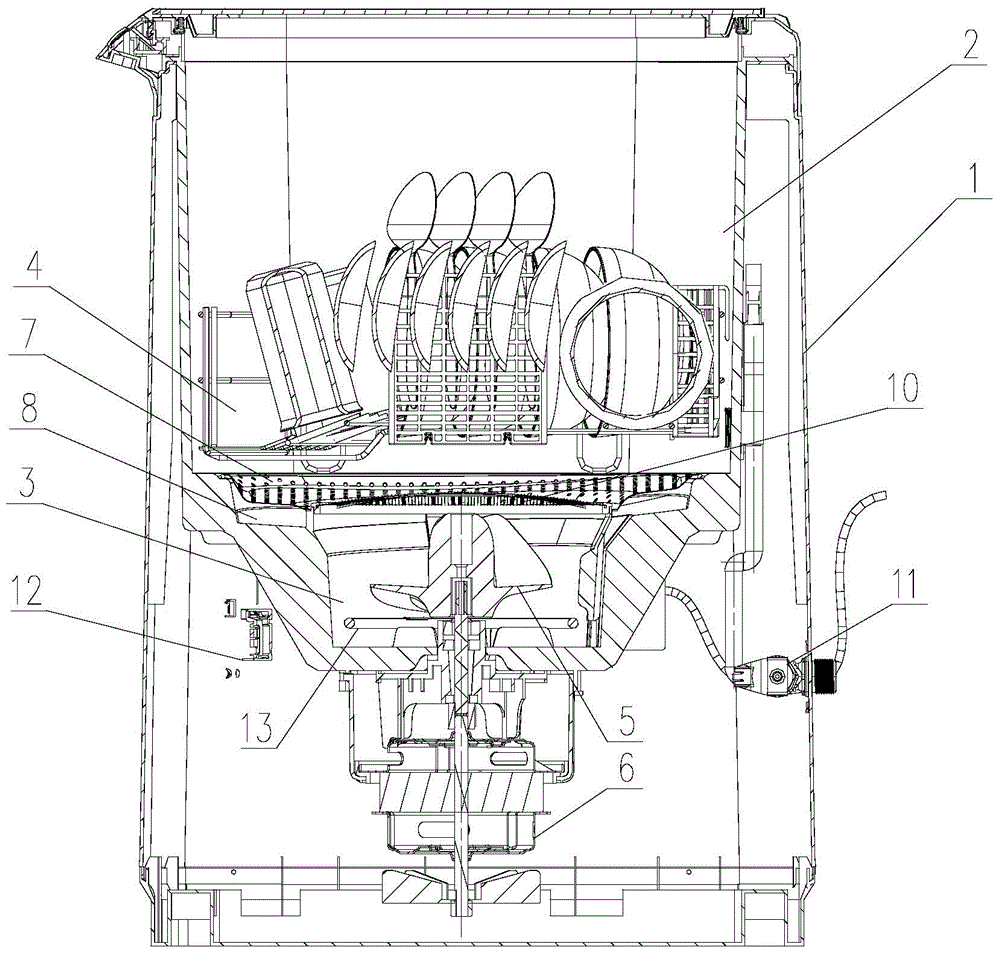

[0031] Such as figure 1 , figure 2 As shown, a dishwasher provided in this embodiment includes a box body 1 and an inner container 2. The box body 1 plays a supporting role for structures such as the inner container 2 arranged inside it. The bottom of the box body 1 is set There is a base, and the upper part is provided with a loam cake.

[0032] The washing of the tableware is all completed in the inner container 2, the bottom of the inner container 2 is provided with a sump 3, and the inner container 2 is provided with a bowl rack 4 for placing the tableware to be cleaned, and the bowl rack 4 is located at the bottom of the sump 3. upper part. A screw propeller 5 is installed in the sump 3 , and the screw propeller 5 rotates under the drive of the driving motor 6 . Specifically, the above-mentioned screw propeller 5 is a pumping paddle, and the pumping paddle includes a rotating shaft and several helical blades arranged on the outer circumference of the rotating shaft. ...

Embodiment approach 2

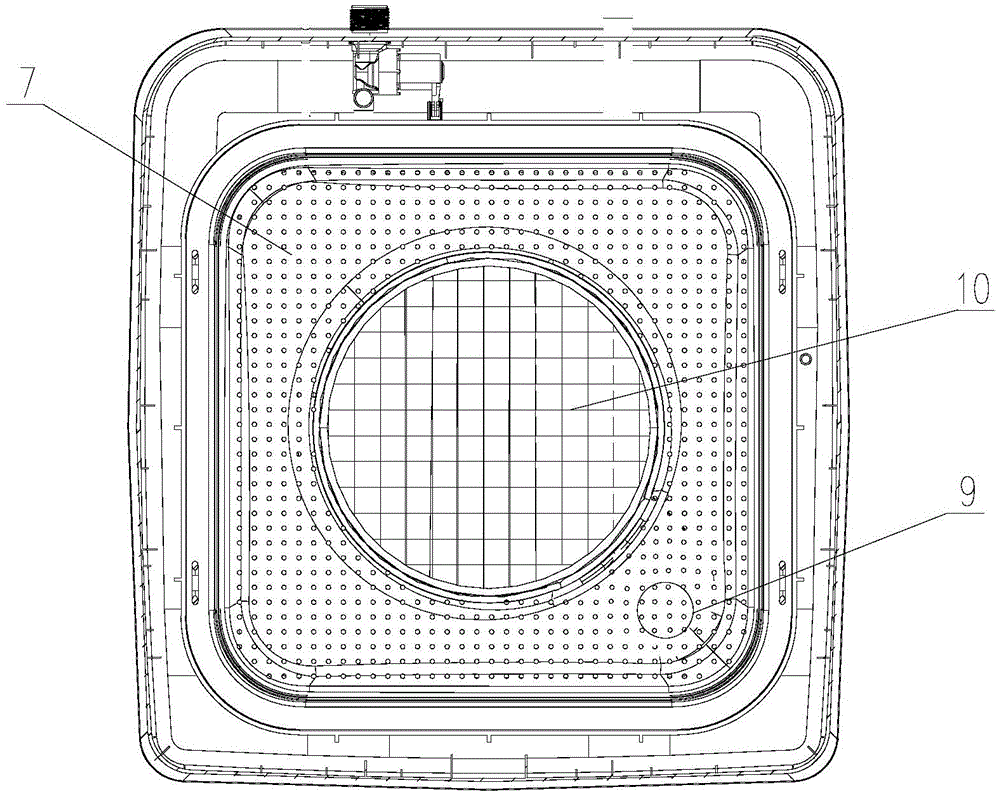

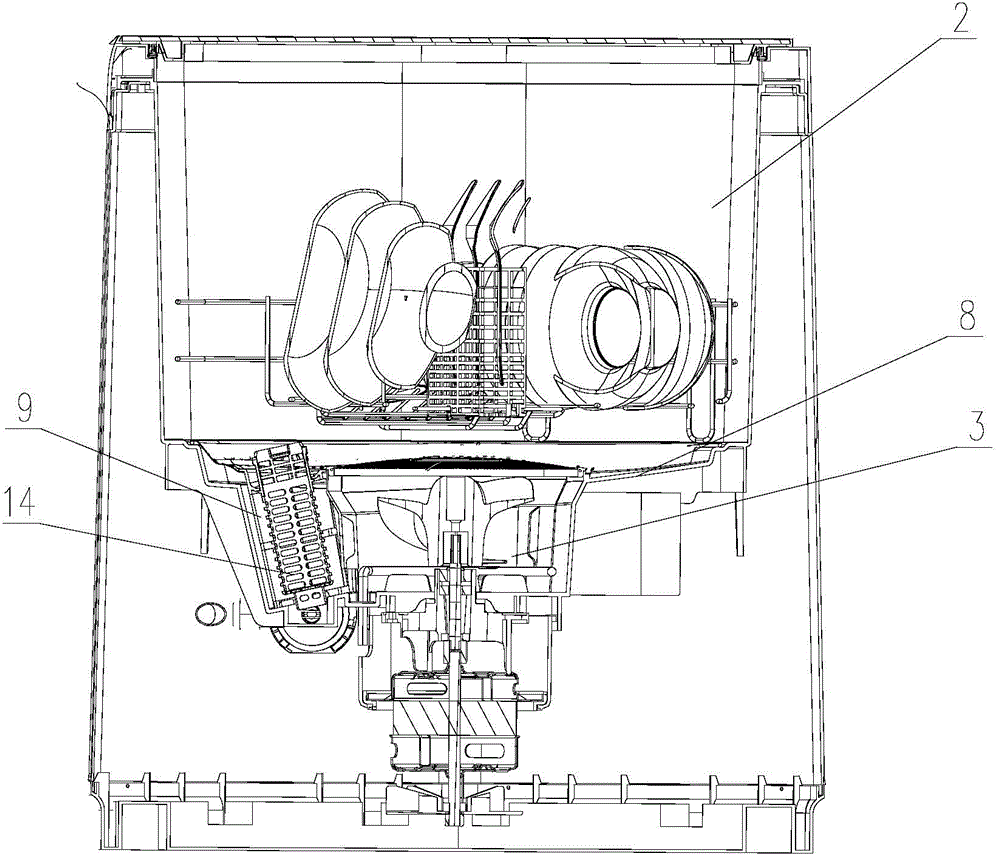

[0041] In this manner, the difference between this embodiment and Embodiment 1 is that the two filter the residue differently. Specifically, such as image 3 , Figure 4 As shown, at least one return channel 9 connecting the sump 3 and the bottom of the liner 2 is provided on the side wall of the sump 3 , and a filter element 14 is disposed in the return channel 9 . More specifically, a circumferential groove 8 is provided at the bottom of the inner tank 2 , and the circumferential groove 8 is arranged along the outer circumference of the sump 3 and communicates with the sump 3 through the return channel 9 with the filter element 14 . Circumferential groove 8 can play the effect of diversion to the cleaning liquid that returns to sump 3, in order to further improve the diversion effect of circumferential groove 8, the bottom of circumferential groove 8 has certain slope, facilitates cleaning liquid to flow into backwater channel 9.

[0042] The specific filtering method for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com