Environment-friendly recycled concrete

A recycled concrete and environmentally friendly technology, applied in the field of concrete, can solve the problems of shortage of natural sand and gravel resources, pollution of waste concrete, etc., and achieve the effect of simple processing technology, delaying consolidation time, and maintaining slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes specific embodiments of the present invention, as well as comparative examples and detection results; in order to show the technical solutions and beneficial effects of the present invention in detail.

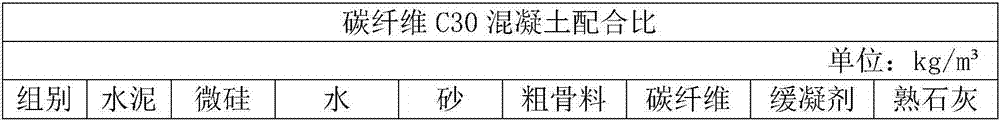

[0022] In the embodiment, the cement adopts 325 conventional cement, the sand adopts natural fine sand, and the recycled coarse aggregate made by crushing waste concrete has a particle size of 20-40 mm, a carbon fiber grade of T700, a length of 10-20 mm, and a retarder grade of ZLC-A1.

[0023] The pretreatment of the carbon fiber is to weigh 1.6% of the total weight of the carbon fiber and dissolve the silane coupling agent in an appropriate amount of water; soak the carbon fiber in an aqueous solution and then take it out to dry; or spray the aqueous solution evenly on the surface of the carbon fiber and then dry it.

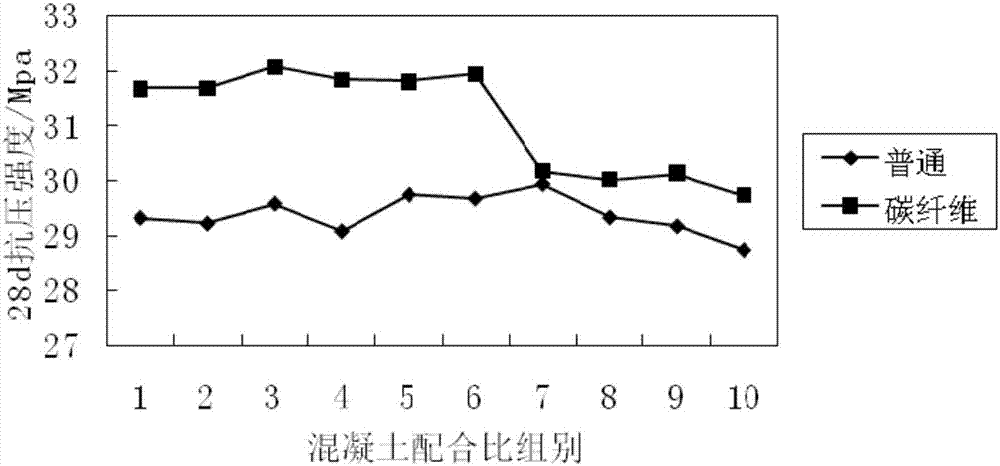

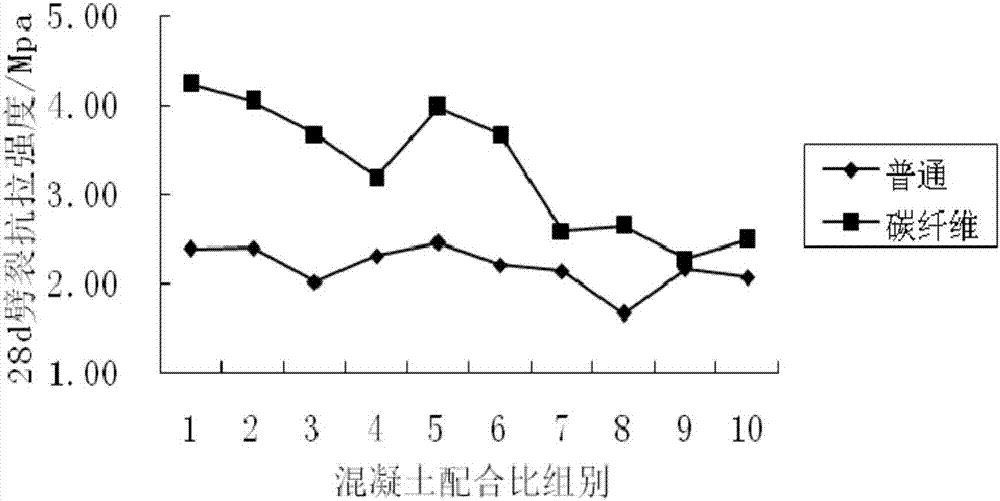

[0024] Then, according to the C30 ratio, 10 sets of concrete samples were prepared by adding micro-silica powder, carbon fiber, retarde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com