Fast tensioning anchor cable structure and construction method thereof

A construction method and anchor cable technology, which is applied in the direction of earthwork drilling, bolt installation, mining equipment, etc., can solve the problem of lengthening the length of the grouting body in the anchorage section, the prestress cannot meet the design requirements, and the anti-rust oil is difficult to clean, etc. problem, to achieve the effect of increasing the holding force and anchoring force, and reducing the time for the grouting body to consolidate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

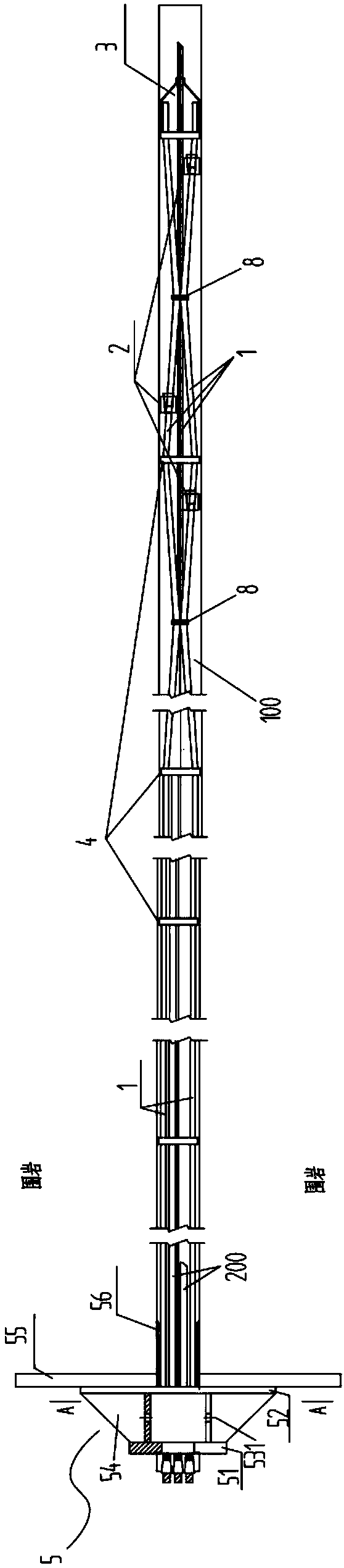

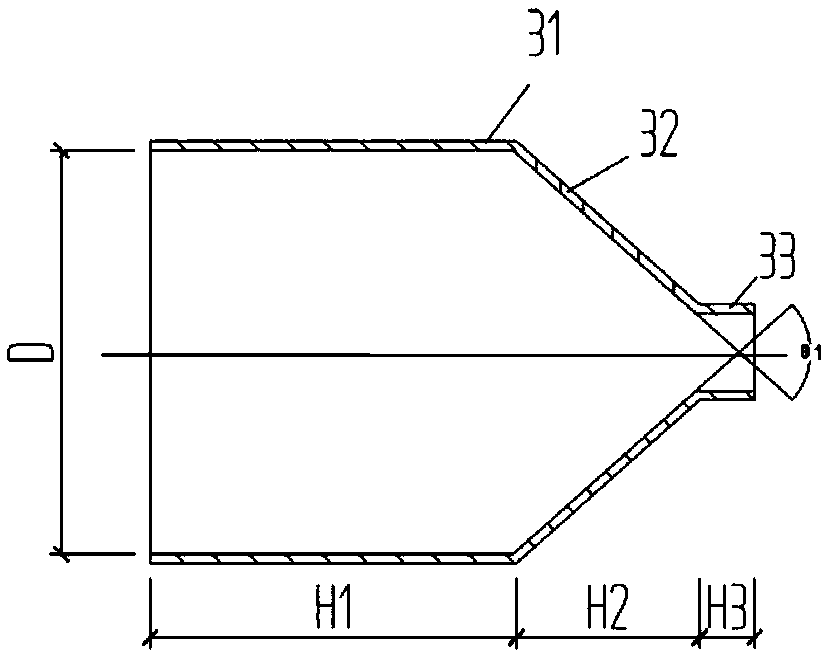

[0035] figure 1 The anchor cable structure of the present invention is shown, which includes: at least one anchor cable steel strand 1 arranged in the borehole 100; anchor cable barb 2, which is sleeved on at least one anchor cable steel strand 1, used to enhance the gripping force between the anchor cable steel strand 1 and the grouting body when grouting into the borehole 100 to form the grouting body, preferably, in this embodiment , each of the anchor cable steel strands 1 is evenly spaced with a number of anchor cable barbs 2; The wire 1 passes through, so as to guide the anchor cable steel strand 1 into the borehole 100 .

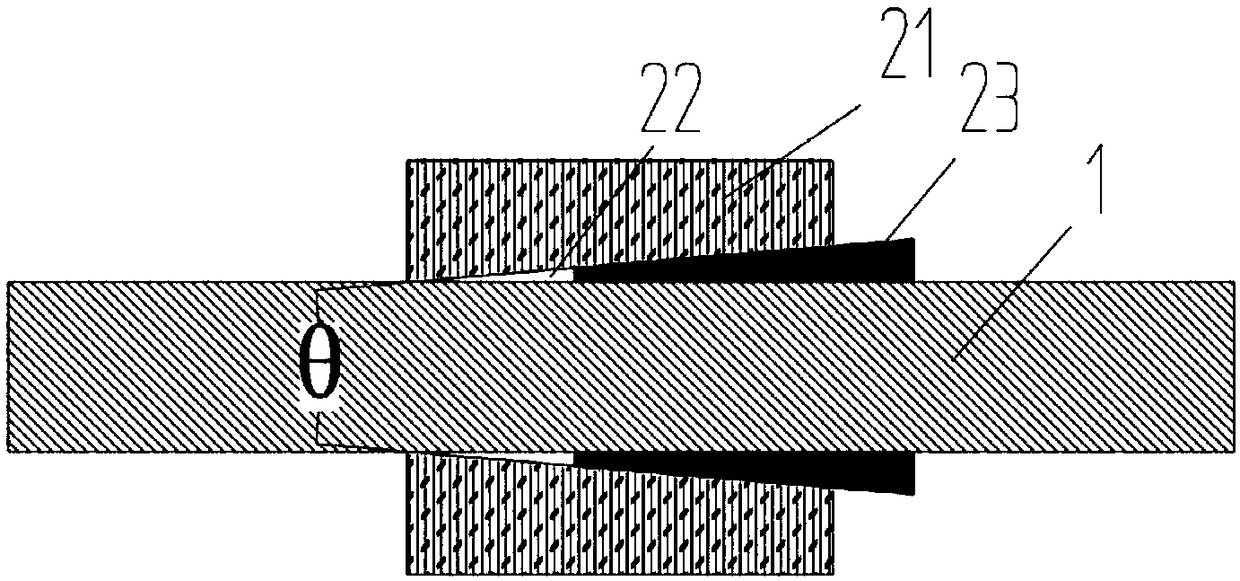

[0036] like figure 2 As shown, the anchor cable barb 2 includes: an outer anchor ring 21, and a perforation 22 with a trapezoidal longitudinal section through which the anchor cable steel strand 1 can pass is opened inside. Preferably, the perforation 22 The longitudinal section is an isosceles trapezoid, and its cone angle θ is 8-12° (preferably ...

Embodiment 2

[0048] This embodiment also provides a construction method for the tunnel surrounding rock anchorage structure as described in Embodiment 2, which includes the following steps:

[0049] S1. Use the HT150 mine down-the-hole drilling rig to open at least one hole in the surrounding rock of the tunnel; the dedicated HT150 mine down-the-hole drilling rig can realize rapid drilling, and the drilling construction can be completed within 1 hour;

[0050] S2. Fixing the steel pier on the inner wall of the tunnel, and setting spacers and guides in the borehole;

[0051] S3. One end of the steel strand of the anchor cable passes through the guide and the spacer and then extends into the borehole, and the grouting pipe passes through the grouting pipe inlet and outlet holes, the third through hole and the grouting hole of the spacer and then extends into the borehole;

[0052] And S4. Grouting the inside of the borehole through the grouting pipe, and the grouting slurry includes sulfoal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com