Cohesive soil large-scale triaxial sample consolidating apparatus and consolidating method thereof

A technology for triaxial samples and cohesive soils, which is used in measurement devices, preparation of test samples, strength characteristics, etc., can solve the problems of accelerating the consolidation and drainage of triaxial samples, difficult to ensure electrical conductivity stability, and inconvenient operation. , to shorten the consolidation time, avoid leakage and short-circuit accidents, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited by the specific embodiments, but by the claims.

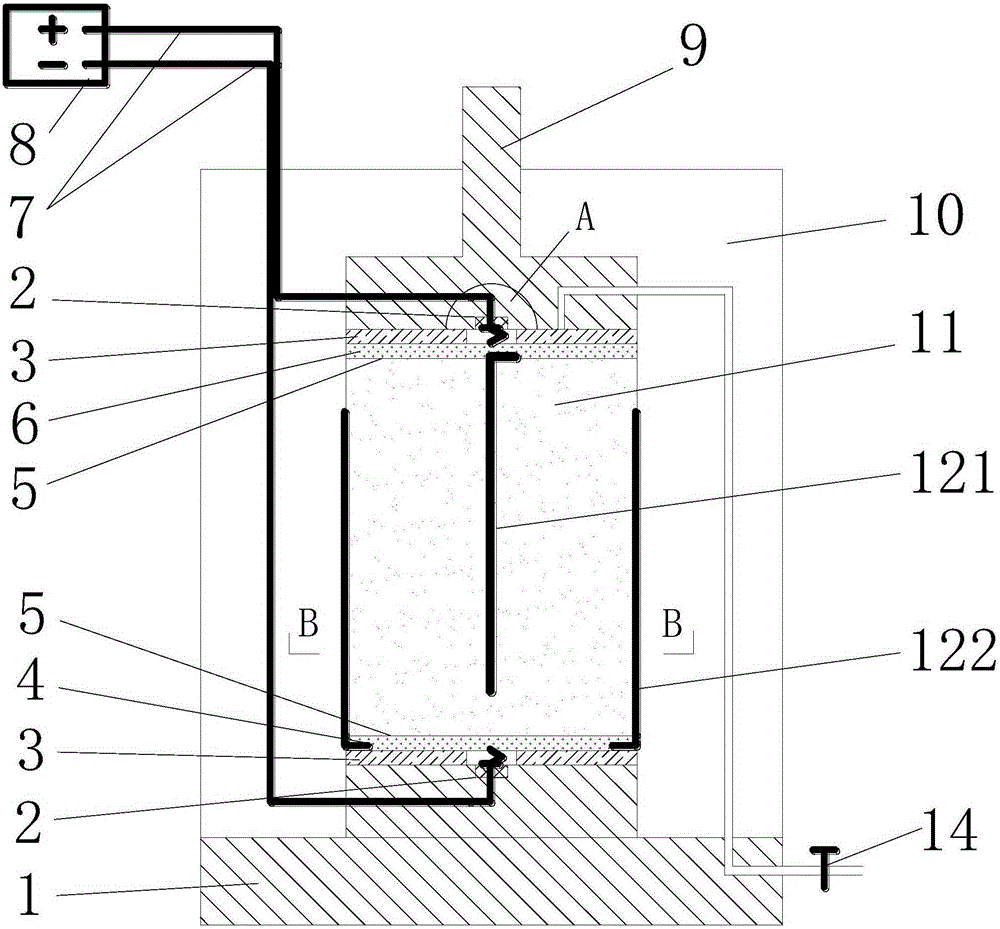

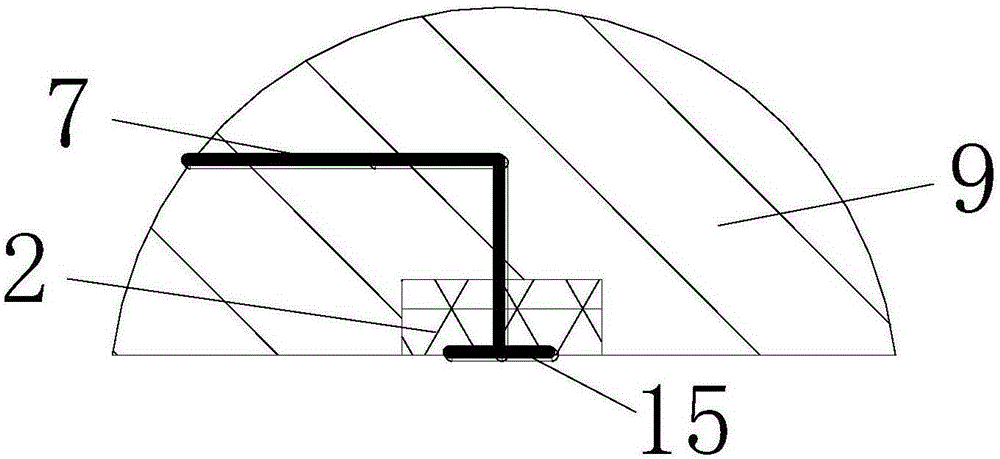

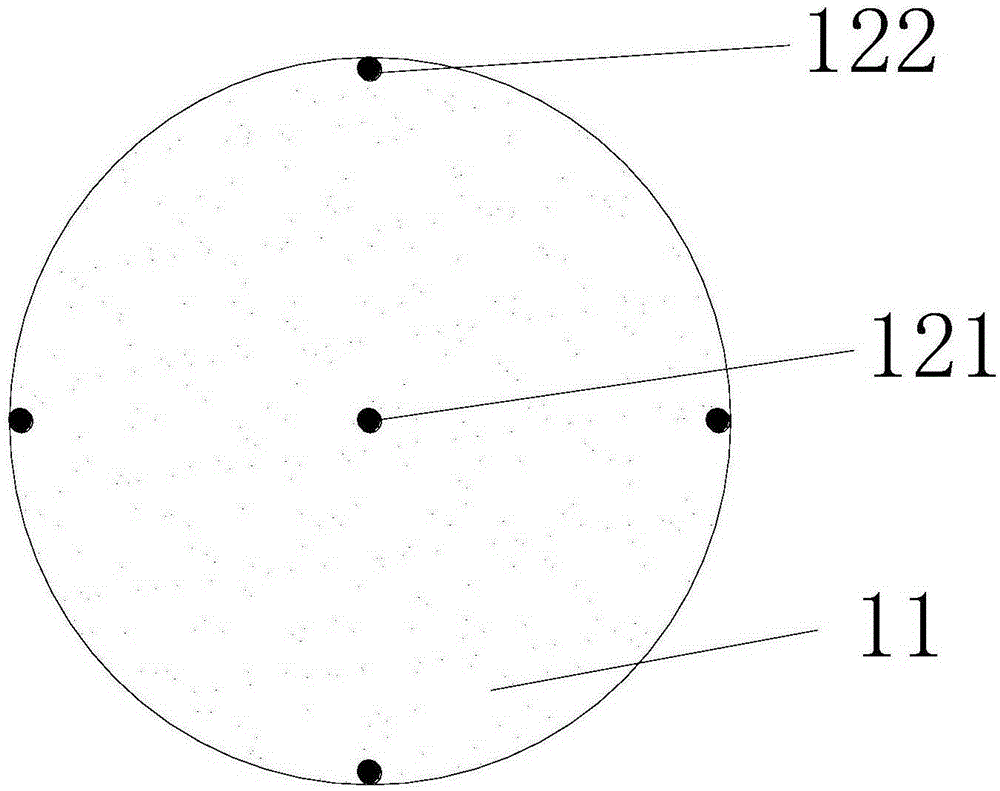

[0037] The cohesive soil large-scale triaxial sample consolidation device of the present invention comprises a triaxial sample 11, a base 1, a top cover 9, an electrode 12, a DC power supply 8, a bottom permeable plate 4, a top permeable plate 6 and an insulating composite plate 3. The top cover 9, the top permeable plate 6, the triaxial sample 11, the bottom permeable plate 4, and the base 1 are arranged sequentially from top to bottom, and between the top permeable plate 6 and the top cover 9, the bottom permeable plate 4 and the base 1 Insulation composite plates 3 are arranged between them; it is characterized in that: Negative electrodes 122 are arranged at equal intervals around the cohesive soil triaxial sample 11, positive elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com