Guiding and guarding clamping device and rolling machine

A technology of clamping device and guide, which is applied in the field of steel rolling machinery, can solve the problems that the guide device cannot be prevented from falling out, cannot be flexibly adjusted, and has poor load capacity, and achieves the effects of convenient maintenance and replacement, large load capacity, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The above-mentioned technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are only part of the embodiments of the present invention, rather than all the embodiments.

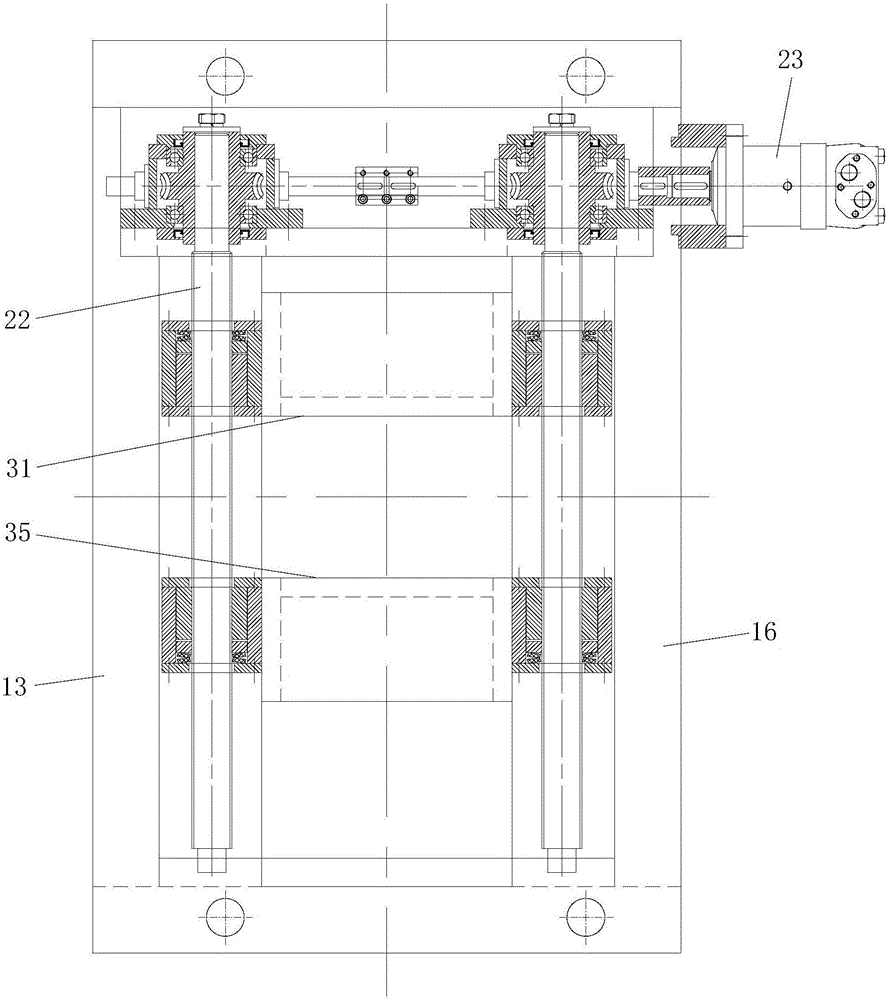

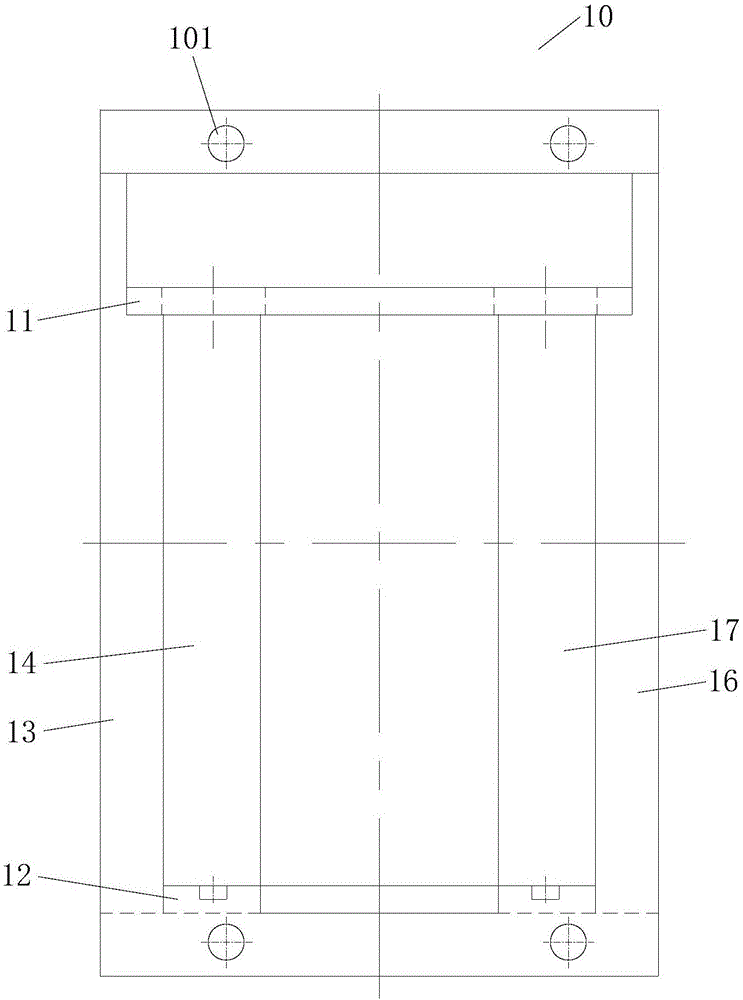

[0066] See figure 1 As shown, the present invention provides a guide and guard clamping device, which includes a frame 10, an adjustment mechanism and a guide and guard mechanism.

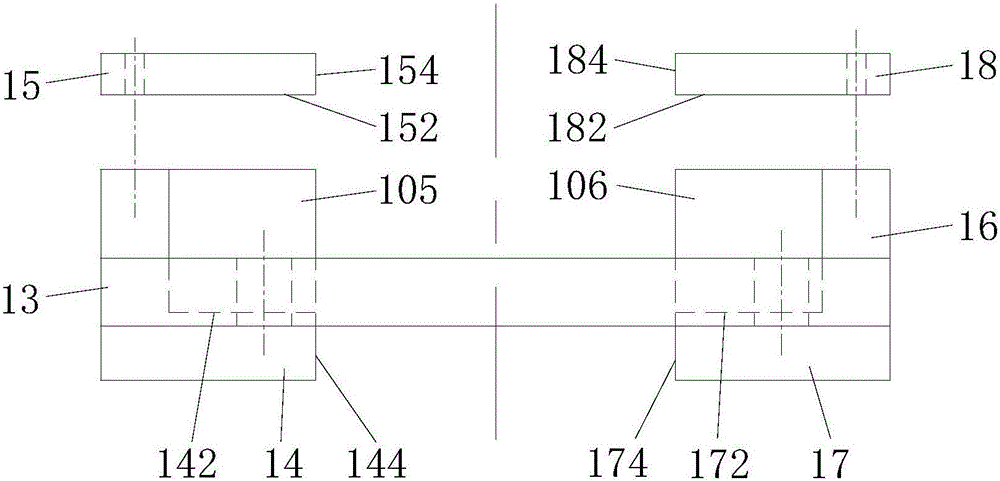

[0067] Please combine figure 2 , image 3 with Figure 4 As shown, the frame 10 includes an upper beam 11 and a lower beam 12 arranged oppositely, a first side wall 13 and a second side wall 16 arranged oppositely, a first front pressure plate 14 and a first rear pressure plate 15 arranged oppositely, and The second front pressure plate 17 and the second rear pressure plate 18. The first front pressure plate 14 and the first rear pressure plate 15 are both vertically connected to the first side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com