Switched reluctance motor variable-angle PI control method, controller and speed adjusting system

A switched reluctance motor and controller technology, which is applied in control systems, AC motor control, electronic commutation motor control, etc., can solve the problems of poor resistance of switched reluctance motors, slow system dynamic response, and high actual average speed. To achieve the effect of simple and reliable control method, strong versatility, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

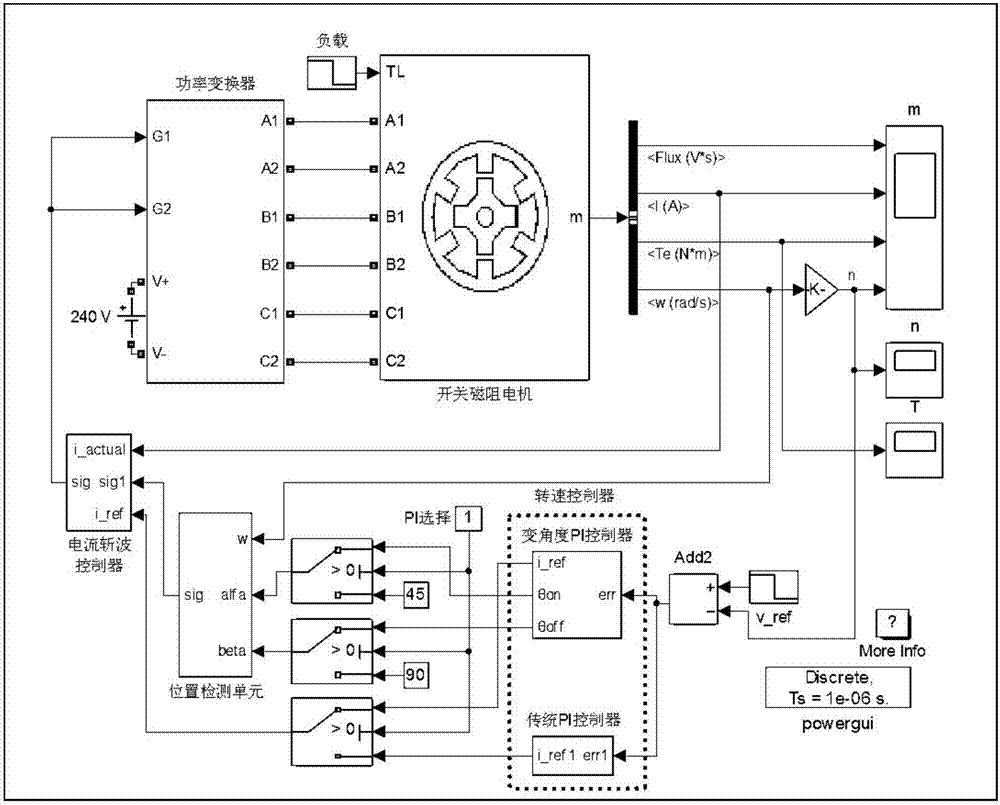

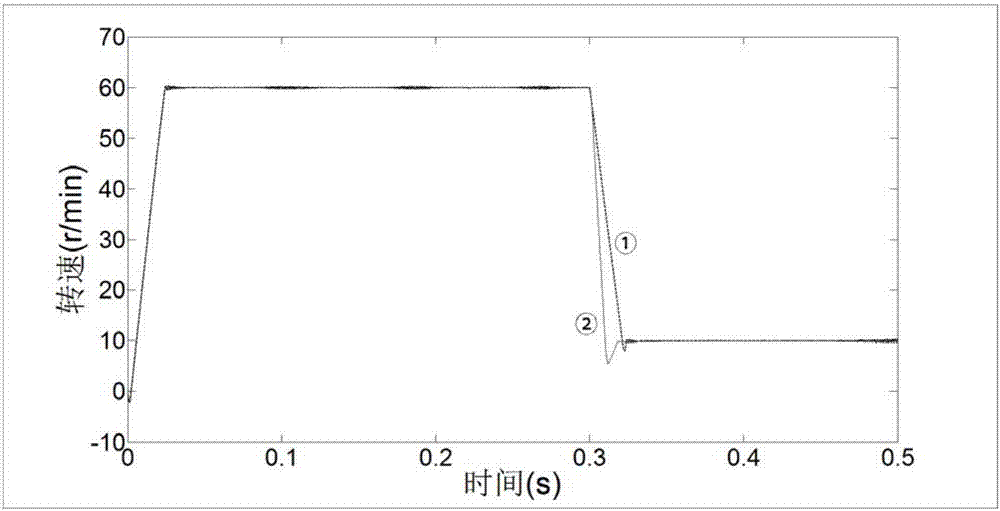

[0026] based on figure 1The simulink simulation model shown is used to test the control effect under the traditional PI control and the control of the present invention and collect data to fit the curve. The speed curves of the traditional PI control and the control of the present invention when the given speed changes stepwise from 60rpm to 10rpm are as follows image 3 As shown, the corresponding torque curve is shown as Figure 4 As shown, ① in the figure is the traditional PI control; ② is the control of the present invention. image 3 In the above, before the given speed step changes, the two methods achieve almost the same control effect, but after the given speed is stepped down, under the traditional PI control, it takes 31ms to reach the new steady state, while in this Under the inventive PI control, the new steady state was reached after only 18 ms.

[0027] The speed curves of the traditional PI control method and this method when the steady-state load at 60rpm c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com