Thrust bearing applying interface sliding technology

A thrust bearing and sliding technology, applied in the field of thrust bearings, can solve the problems of complex structure and size, and achieve the effect of low manufacturing cost, small size, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

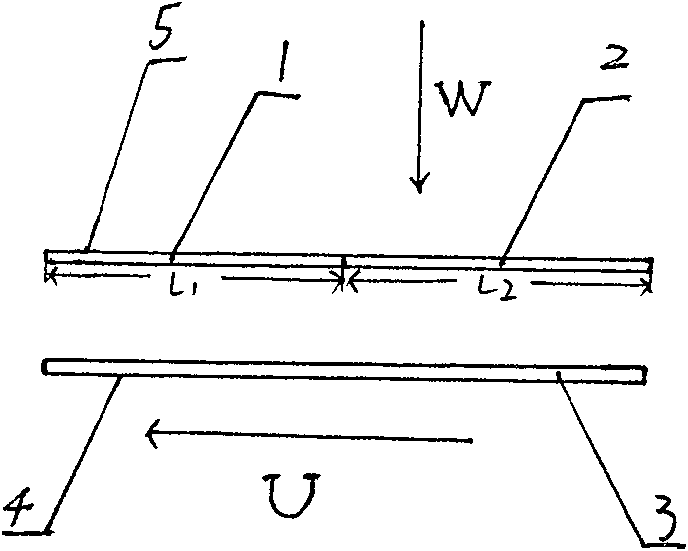

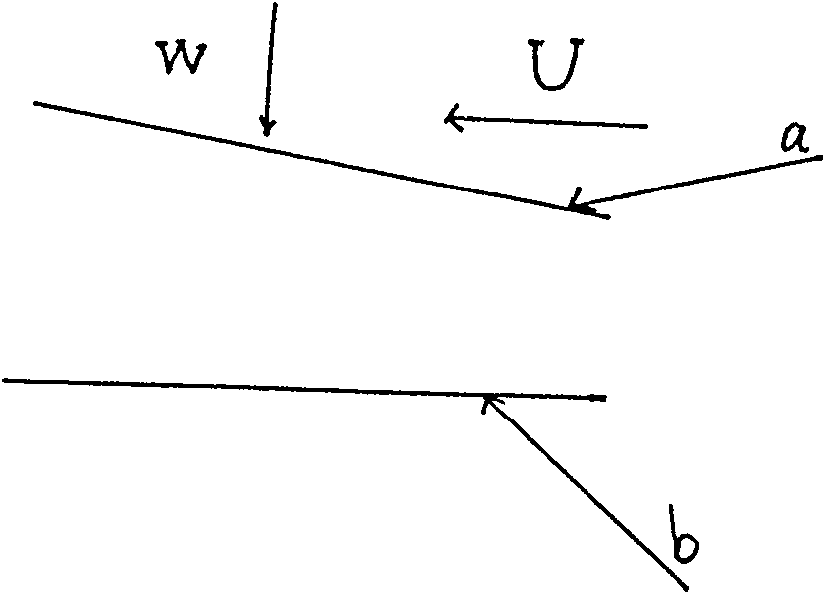

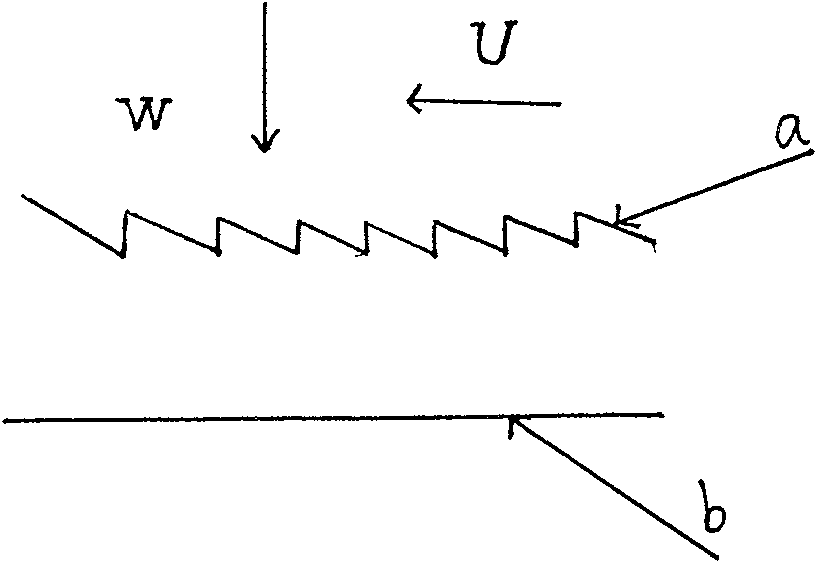

[0036] Example 1. refer to figure 1 . A thrust bearing using interface sliding technology, which includes a stationary plate 5 and a moving plate 4 parallel to each other, the gap between the stationary plate 5 and the moving plate 4 is filled with fluid lubricating oil, and the part of the stationary plate 5 The lower surface is provided with II coating 2, the remaining lower surface is provided with I coating 1, and the upper surface of the moving flat plate 4 is provided with III coating 3, so that a certain relative movement between the stationary flat plate 5 and the moving flat plate 4 Just make these two flat plates form a thrust bearing; the I coating 1 is a fluorocarbon coating; the II coating 2 and III coating 3 are mica powder coatings modified by a silane coupling agent.

Embodiment 2

[0037] Example 2. In the thrust bearing described in Example 1, the II coating 2 or III coating 3 is prepared by the following method: adding a silane coupling agent into an organic solvent to form a solution with a concentration of 0.1%, and using the silane coupling agent Add the mica powder into the solution at a ratio of 1:100 by weight of the coupling agent to the mica powder, mix evenly, apply the mixture on the surface of the static plate 5 or the moving plate 4, and form a coating after air-drying.

Embodiment 3

[0038] Example 3. In the thrust bearing described in Example 1, the II coating 2 or III coating 3 is prepared by the following method: adding a silane coupling agent into an organic solvent to form a solution with a concentration of 0.3%, and using the silane coupling agent Add the mica powder into the solution at a ratio of 2:100 by weight of the joint agent and the mica powder, mix evenly, apply the mixture on the surface of the static plate 5 or the moving plate 4, and form a coating after air-drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com