Ceramic-based composite material strength prediction method considering bearing of broken fibers

A technology for composite materials and strength prediction, applied in computer materials science, special data processing applications, instruments, etc., can solve the problems of fiber loss of load capacity, reduction of fiber volume fraction, failure to consider the load capacity of broken fibers, etc., to achieve the goal of improving accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

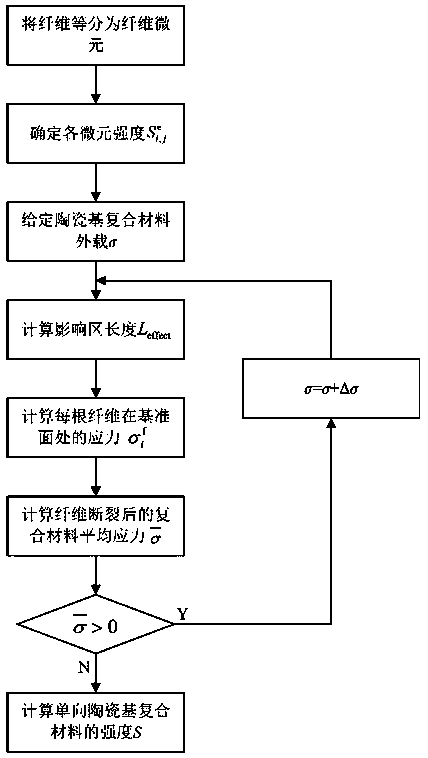

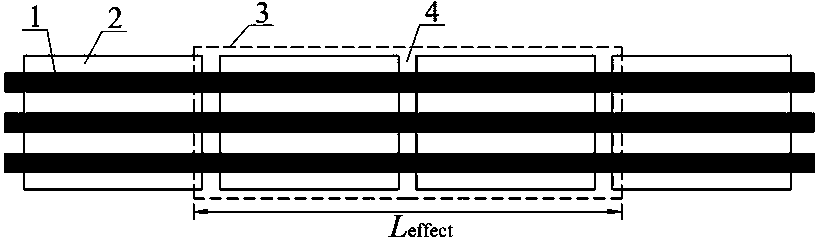

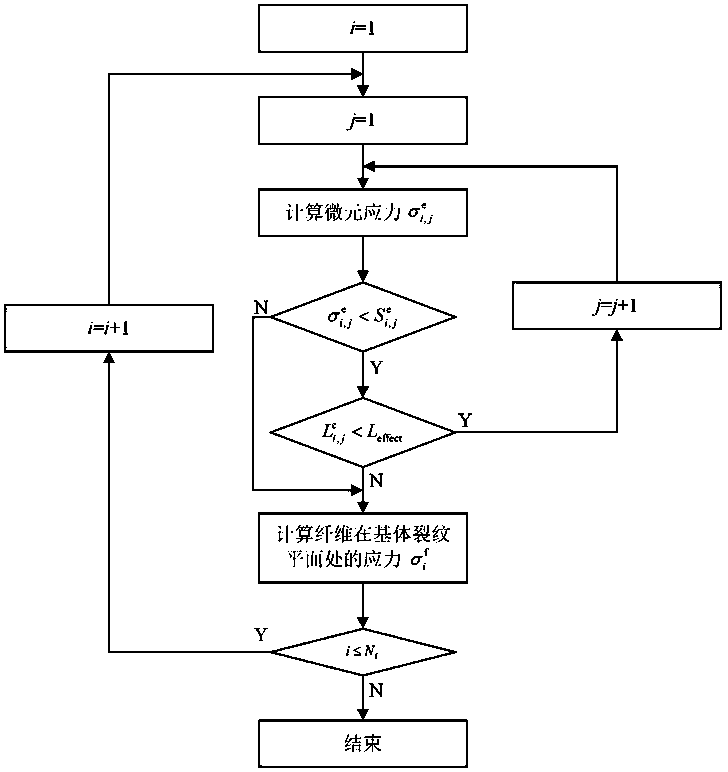

Method used

Image

Examples

Embodiment

[0040] In order to enable those skilled in the art to better understand the technical solutions and beneficial effects of the present application, the present application conducts strength prediction for SiC / SiC ceramic matrix composites in the examples. Each fiber in the SiC / SiC ceramic matrix composite material is equally divided into many fiber micro-units, and the length of each micro-unit is Δl=0.02mm. In this embodiment, the SiC fiber strength distribution is as follows:

[0041] Table 1 Defect parameters of SiC fibers at different levels

[0042]

[0043] S in the table j Indicates the strength of the jth level defect, P(A j ) means the length is L f = The probability of the jth level defect appearing on the fiber of 25mm. From P(A in Table 1 j ) to calculate the probability of defects at all levels appearing on fiber microelements Use a computer to generate a random number ξ (0j , then it is considered that there is the jth type of defect on the micro-element...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com