Rare earth oxide/butyronitrile rubber-polyurethane foam double layered composite material for low frequency sound absorption and preparation method thereof

A technology of rare earth oxide and polyurethane foam, which is applied in the field of material processing, can solve problems such as poor sound absorption performance, and achieve the effects of improving low-frequency sound absorption performance, light weight, and improving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

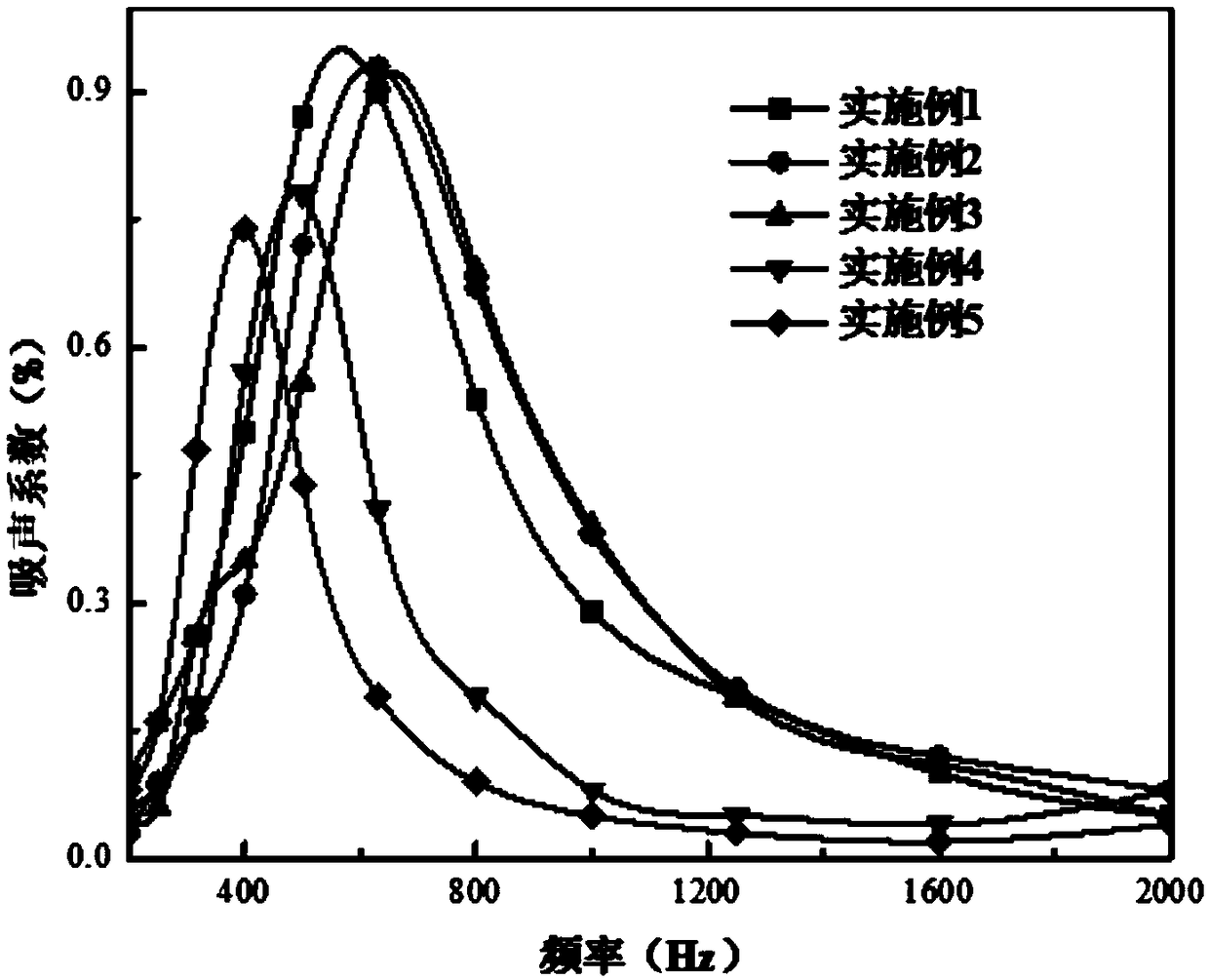

Examples

Embodiment 1

[0022] A Gd for low frequency sound absorption 2 o 3 The preparation method of / acrylonitrile-butadiene rubber composite material-polyurethane foam double-layer composite material, its preparation steps are as follows:

[0023] (1) Pretreatment of rare earth oxide powder: according to the parts by weight of each raw material: 100 parts of rare earth oxide, 1 to 5 parts of coupling agent, select rare earth oxide and titanate coupling agent; The raw materials were put into a ball mill and ball milled at a high speed of 1500r / min for 30min to obtain the modified rare earth oxide for later use;

[0024] (2) Rubber mixing formula: 100 parts of nitrile rubber; 5 parts of zinc oxide; 0.75 parts of zinc stearate; 0.75 parts of stearic acid; 2 parts of antioxidant RD; 1.5 parts of sulfur; 2 parts of accelerator TMTD; accelerator CZ 1 part; 20 parts of carbon black; modified Gd 2 o 3 25 parts of powder; add nitrile rubber, zinc oxide, stearic acid, zinc stearate, antioxidant RD, acce...

Embodiment 2

[0028] A La for low frequency sound absorption 2 o 3 The preparation method of / acrylonitrile-butadiene rubber composite material-polyurethane foam double-layer composite material, its preparation steps are as follows:

[0029] (1) Pretreatment of rare earth oxide powder: according to the parts by weight of each raw material: 100 parts of rare earth oxide, 1 to 5 parts of coupling agent, select rare earth oxide and titanate coupling agent; The raw materials were put into a ball mill and ball milled at a high speed of 1500r / min for 30min to obtain the modified rare earth oxide for later use;

[0030] (2) Rubber mixing formula: 100 parts of nitrile rubber; 5 parts of zinc oxide; 0.75 parts of zinc stearate; 0.75 parts of stearic acid; 2 parts of antioxidant RD; 1.5 parts of sulfur; 2 parts of accelerator TMTD; accelerator CZ 1 part; 20 parts of carbon black; modified La 2 o 3 25 parts of powder; add nitrile rubber, zinc oxide, stearic acid, zinc stearate, antioxidant RD, acce...

Embodiment 3

[0034] A Y for low frequency sound absorption 2 o 3 The preparation method of / acrylonitrile-butadiene rubber composite material-polyurethane foam double-layer composite material, its preparation steps are as follows:

[0035] (1) Pretreatment of rare earth oxide powder: according to the parts by weight of each raw material: 100 parts of rare earth oxide, 1 to 5 parts of coupling agent, select rare earth oxide and titanate coupling agent; The raw materials were put into a ball mill and ball milled at a high speed of 1500r / min for 30min to obtain the modified rare earth oxide for later use;

[0036] (2) Rubber mixing formula: 100 parts of nitrile rubber; 5 parts of zinc oxide; 0.75 parts of zinc stearate; 0.75 parts of stearic acid; 2 parts of antioxidant RD; 1.5 parts of sulfur; 2 parts of accelerator TMTD; accelerator CZ 1 part; carbon black 20 parts; modified Y 2 o 3 25 parts of powder; add nitrile rubber, zinc oxide, stearic acid, zinc stearate, antioxidant RD, accelerat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com