Low-sound-velocity metamaterial layer and medium-low-frequency efficient sound-absorbing metamaterial composite structure made of same

A composite structure and metamaterial technology, which is applied in the field of metamaterial composite structures with high-efficiency sound absorption at medium and low frequencies, can solve problems such as engineering application constraints and large overall thickness of the structure, and achieve improved low-frequency sound absorption coefficient, small overall thickness, and improved mid-range Effect of Low Frequency Sound Absorption Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

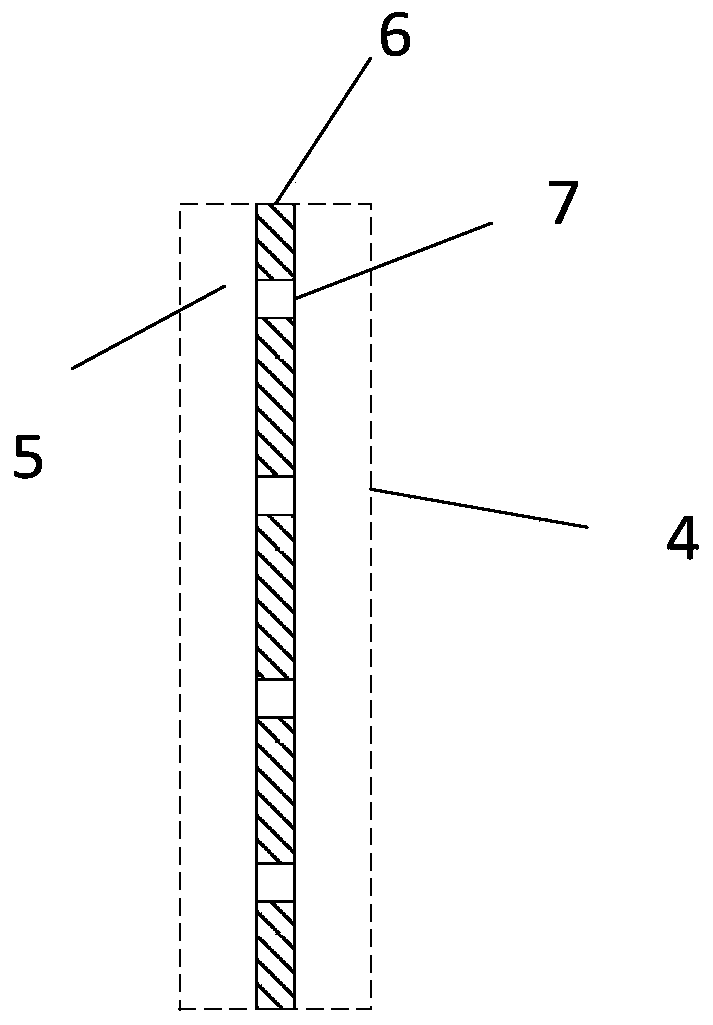

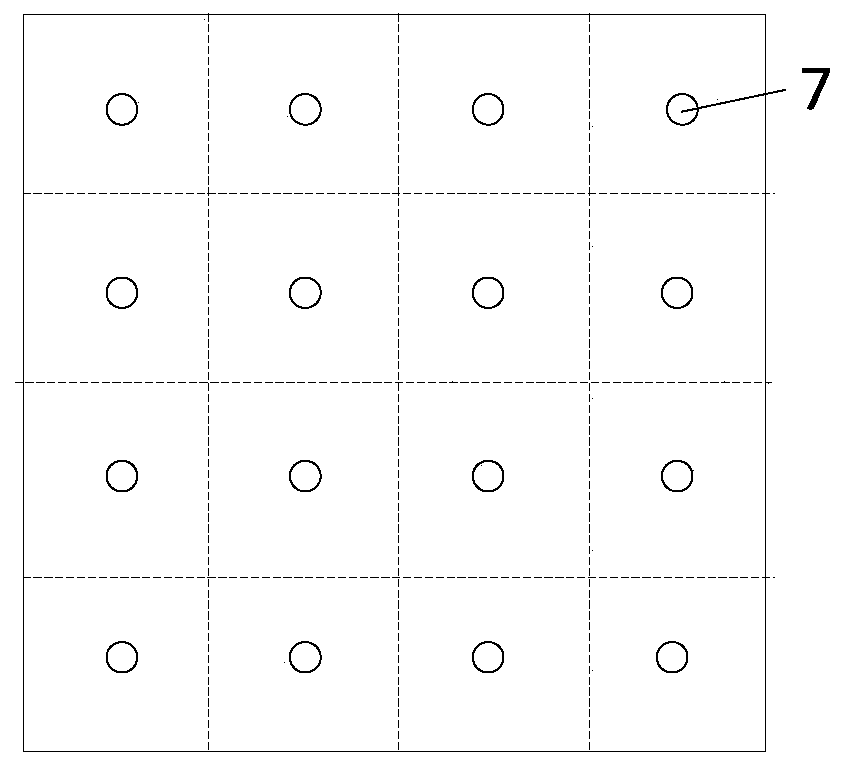

[0055] A sheet of metamaterial having a thickness of 20 mm comprising a perforated sheet of 1 mm thickness disposed in the middle thereof, the perforated sheet being made of a hard resin. The distance between adjacent perforations on the perforated sheet is 20 mm, the perforation radius is 1 mm, and the maximum effective control frequency is 1150 Hz. Substituting the combination of the above formulas, the normal sound velocity of the metamaterial sheet in the range of 20-1150Hz is 78-89m / s, of which the normal sound velocity at 200Hz is 88.8m / s, and the normal sound velocity at 500Hz is 87.4m / s, the normal sound velocity at 1000Hz is 81.2m / s.

Embodiment 2

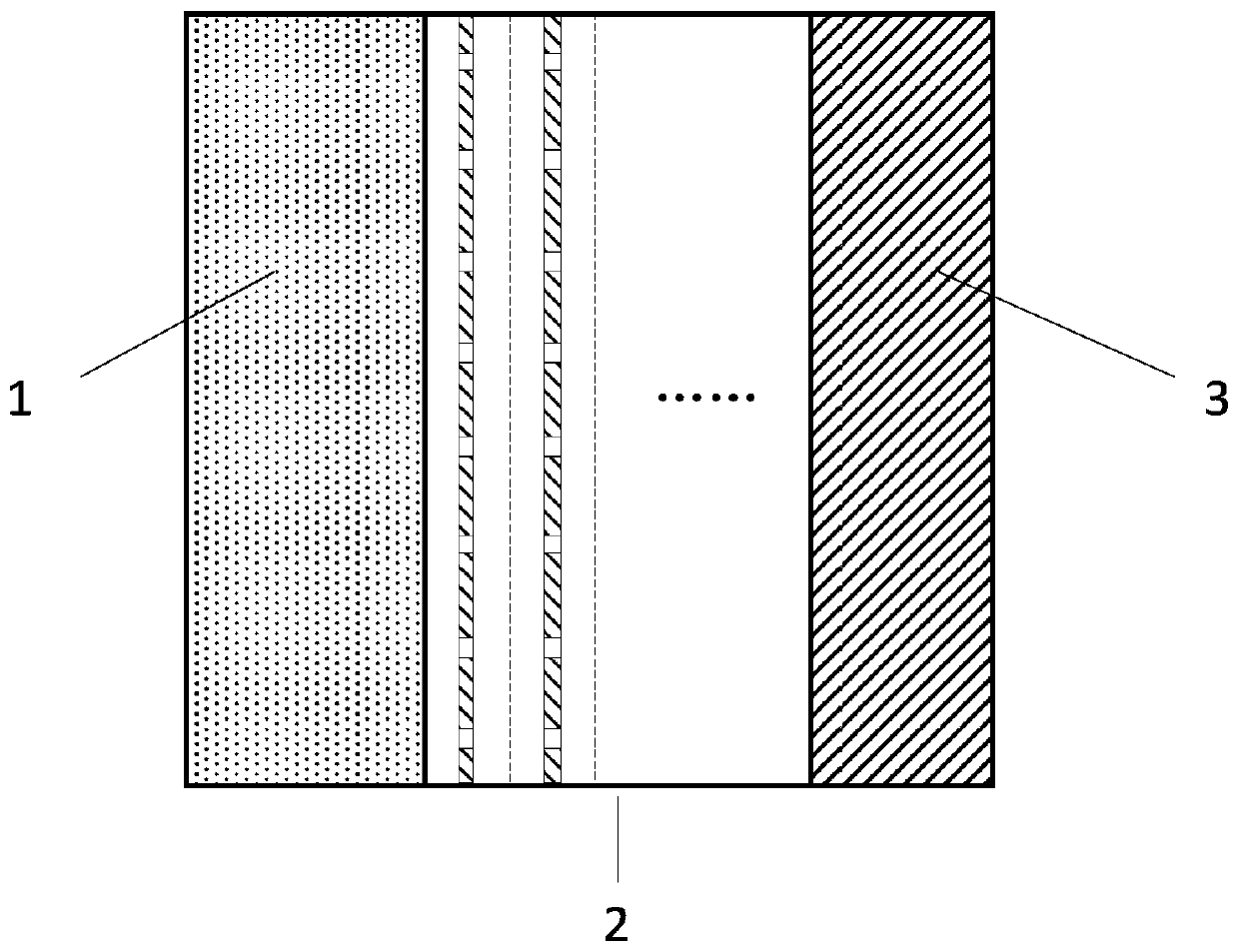

[0057] A metamaterial composite structure with high-efficiency sound absorption at medium and low frequencies, the porous sound-absorbing material layer has a flow resistance of 20000Pa·s / m 2 It is made of some kind of polyurethane sound-absorbing material with a thickness of 20mm; the low sound velocity metamaterial layer is composed of a layer of metamaterial sheet; the thickness of the metamaterial sheet is 20mm, including a perforated sheet with a thickness of 1mm, and the perforated sheet is made of hard Made of resin, the perforation spacing is 20mm, and the perforation radius is 1mm; the hard reflective material is a flat concrete wall.

[0058] Figure 4 It is the effect sound absorption curve of the second embodiment. It can be known by calculation that within the range of 100-2000 Hz, the normal sound velocity of the metamaterial sheet is 60-89 m / s. Figure 4 It shows that when there is an air cavity between the porous sound-absorbing material and the hard reflecti...

Embodiment 3

[0060] A metamaterial composite structure with high-efficiency sound absorption at medium and low frequencies. The porous sound-absorbing material layer is composed of a certain flow resistance rate of 40000Pa·s / m 2 It is made of porous sound-absorbing material with a thickness of 10mm. There is a 100mm air cavity between the porous sound-absorbing material layer and the hard reflective material. The peak value of sound absorption is around 800Hz. Under the premise of reducing the amount of acoustic materials, the peak of sound absorption is moved to 400Hz. After design, the original plan is replaced by a metamaterial composite structure with high-efficiency sound absorption at low and medium frequencies. The low-sonic metamaterial layer is composed of 5 layers of metamaterial sheets. The thickness of the metamaterial sheet is 20mm, and the perforated sheet of the metamaterial sheet is made of aluminum alloy. The thickness of the perforated sheet is 1 mm, the perforation radiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com