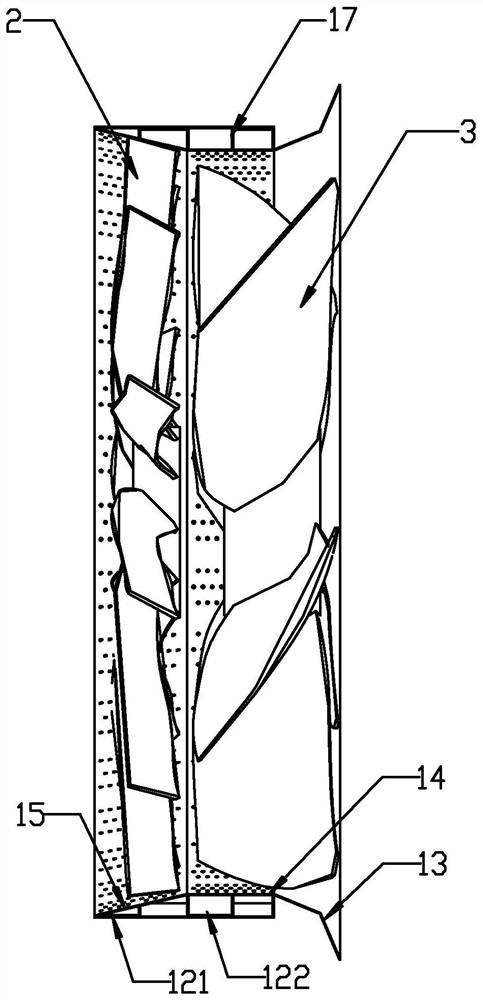

A noise-reducing fan wind guide ring and a fan including the wind guide ring

An air guide ring and noise-reducing technology, which is applied in the field of noise-reducing fan air guide rings and fans including the air guide ring, can solve problems such as inability to achieve a good noise reduction effect, and achieve the goal of reducing middle and low frequency noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

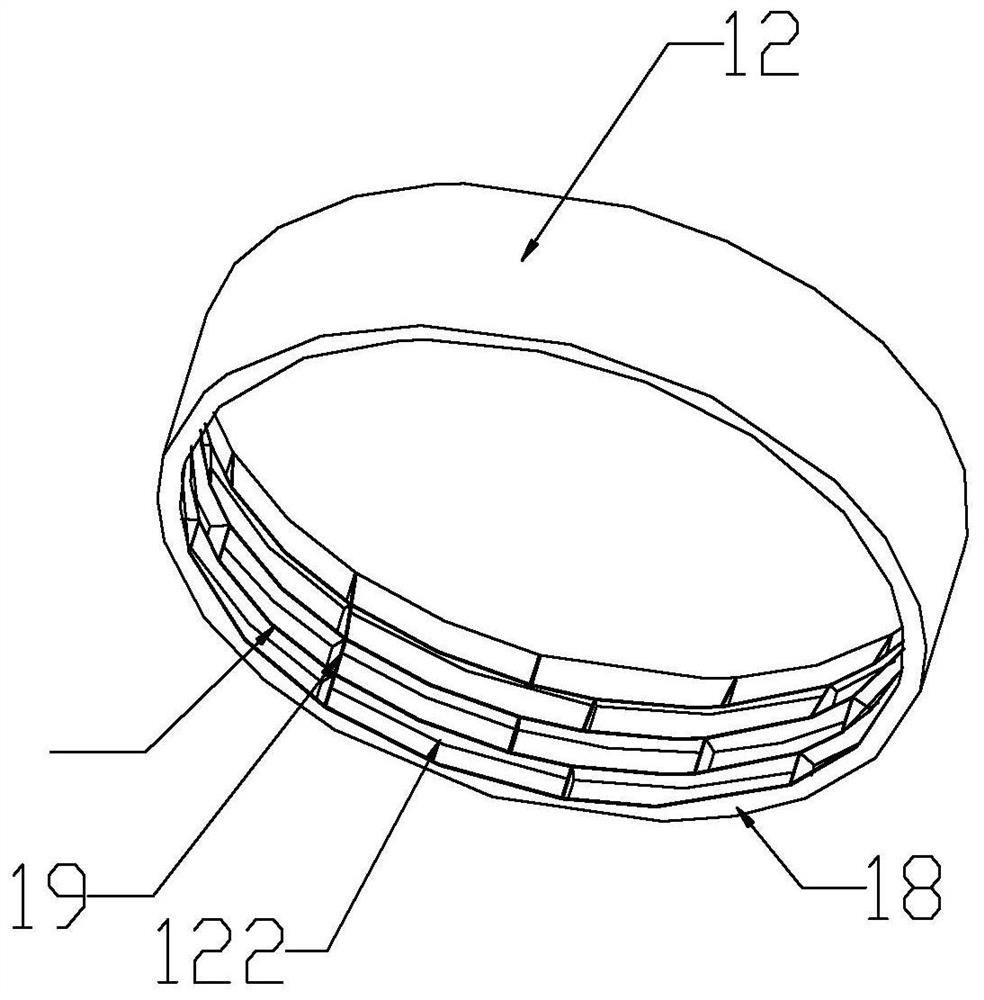

Embodiment 2

[0059] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. In this embodiment, the distance between two adjacent risers 19 in each layer of the resonant cavity is arranged in a sequentially increasing or decreasing manner.

Embodiment 3

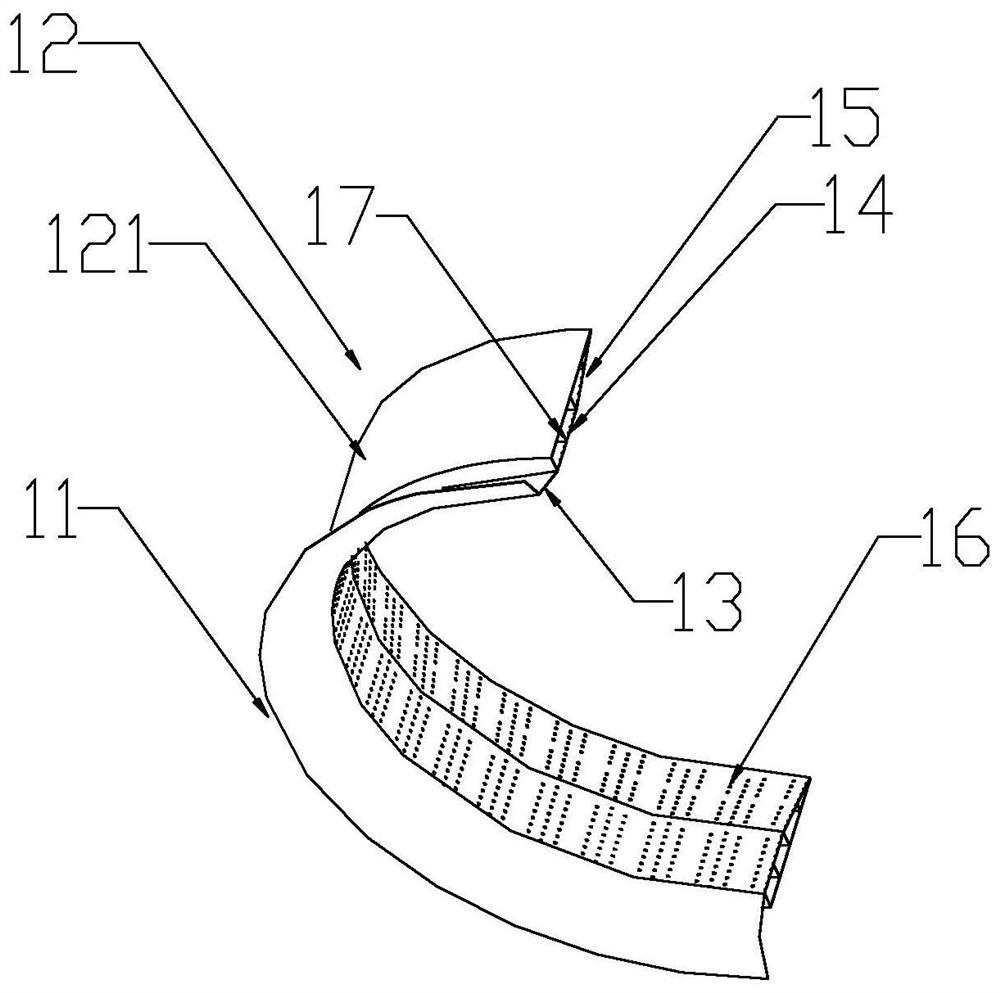

[0061] Such as figure 2As shown, this embodiment only describes the difference from the above embodiment, and the rest of the technical features are the same as the above embodiment. In this embodiment, the unit resonant cavity 122 is filled with sound-absorbing materials. The sound-absorbing material filled in the unit resonant cavity 122 can reduce the high-frequency noise in the fan 3. Since the wavelength of the high-frequency noise is relatively short, it cannot form reflection in the unit resonant cavity 122. Therefore, the unit resonant cavity 122 cannot prevent high-frequency noise. Noise reduction, but filling the unit resonant cavity 122 with sound-absorbing materials can effectively reduce high-frequency noise. The sound-absorbing material is one or more of inorganic fiber sound-absorbing materials, inorganic foam sound-absorbing materials, and foam plastic sound-absorbing materials. Preferably in this embodiment, the sound-absorbing material is one or more of me...

Embodiment 4

[0063] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. In this embodiment, part of the unit resonant cavity 122 is filled with sound-absorbing material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com