Sound absorption and noise reduction material for clothes and preparation method of sound absorption and noise reduction material

A noise reduction and sound absorption technology, applied in the direction of sound-producing equipment, textiles and papermaking, instruments, etc., can solve the problems of little research on the sound-absorbing and noise-reducing function of maternity clothing, great harm to babies, and limited effect, etc. Low-frequency sound absorption performance, good economic and social value, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1): Prepare polyvinyl alcohol spinning solution, add polyvinyl alcohol into distilled water, wherein the concentration of polyvinyl alcohol is 10wt.% (if polyvinyl alcohol is 1g, then add 9g of distilled water), 90 ℃ constant temperature magnetic stirring 20 to 24 hours to obtain a uniform solution;

[0027] Step 2): Electrospinning is carried out on the basis of melt-blown nonwoven fabric: the applied voltage is 18kV, the spinning speed is 1mL / h, and the spinning distance is 13cm;

[0028] Step 3): drying at room temperature;

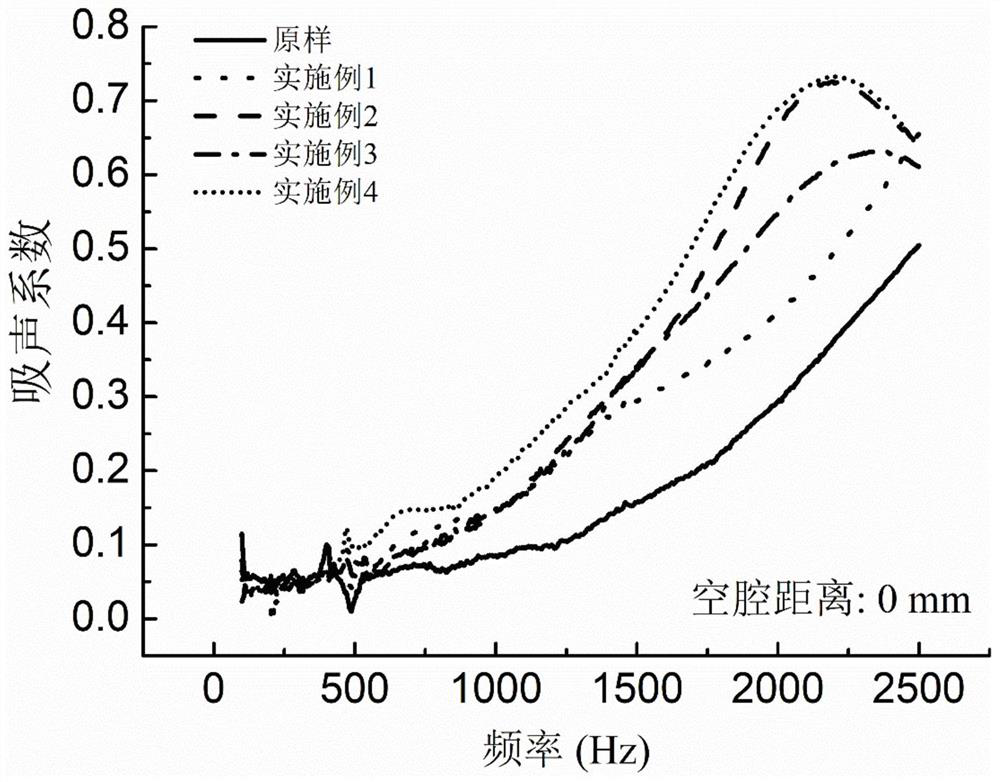

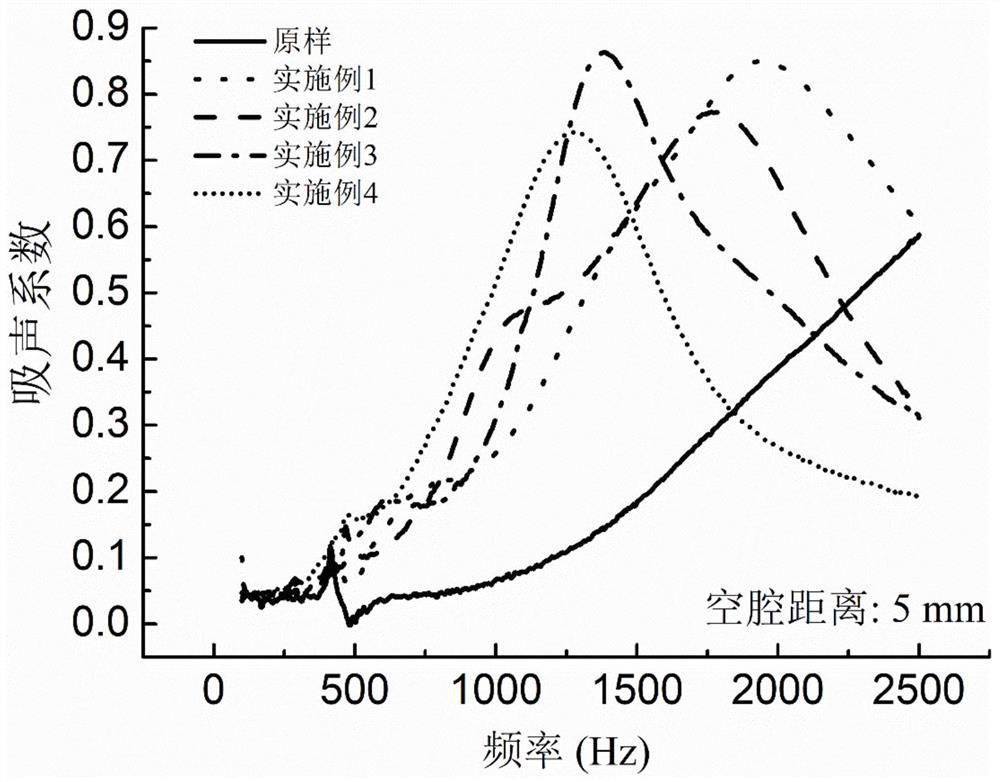

[0029] Step 4): Cover the nanofiber membrane with another layer of melt-blown nonwoven fabric, and combine the nanofiber membrane with the two layers of melt-blown nonwoven fabric by hot pressing to obtain a sound-absorbing and noise-reducing material. Coefficients such as figure 1 (cavity depth 0mm), figure 2 (cavity depth 5mm) shown.

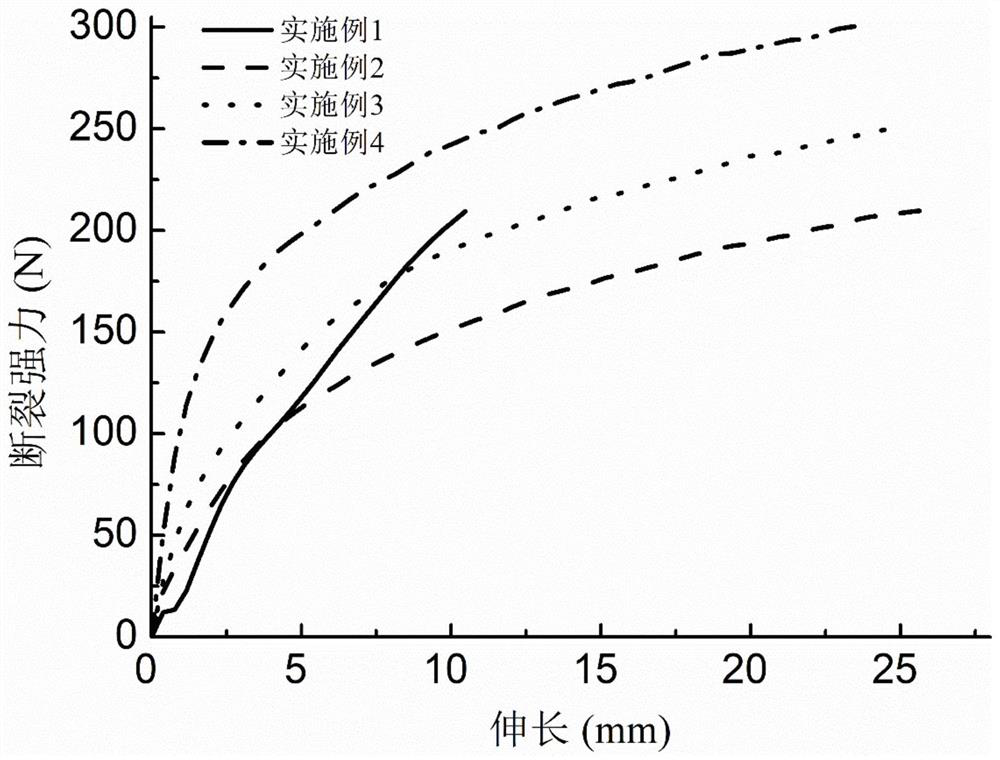

[0030] The mechanical properties of nanofibrous membranes are image 3 As shown, the average sound...

Embodiment 2

[0032] Step 1): Prepare polyvinyl alcohol spinning solution, add polyvinyl alcohol into distilled water, and stir magnetically at a constant temperature of 90°C to obtain a uniform polyvinyl alcohol solution, then add polyethylene oxide, wherein the concentration of polyvinyl alcohol is 10wt.%, The concentration of polyethylene oxide is 0.5wt.% (if the distilled water is 8.95g, add 1g of polyvinyl alcohol and 0.05g of polyethylene oxide), stir magnetically for 20-24h to obtain a uniform solution;

[0033] Step 2): Electrospinning is carried out on the basis of melt-blown nonwoven fabric: the applied voltage is 18kV, the spinning speed is 1mL / h, and the spinning distance is 13cm;

[0034] Step 3): drying at room temperature;

[0035] Step 4): Cover the nanofiber membrane with another layer of melt-blown nonwoven fabric, and combine the nanofiber membrane with the two layers of melt-blown nonwoven fabric by hot pressing to obtain a sound-absorbing and noise-reducing material. C...

Embodiment 3

[0038] Step 1): Prepare polyvinyl alcohol spinning solution, add polyvinyl alcohol into distilled water, add TiO2, and stir at a constant temperature of 90°C to obtain a uniform polyvinyl alcohol solution, then add polyethylene oxide, wherein the concentration of polyvinyl alcohol is 10wt %, the concentration of polyethylene oxide is 1wt.% (such as distilled water is 8.9g, then add polyvinyl alcohol 1g, polyethylene oxide 0.1g), magnetic stirring for 20 ~ 24h, to obtain a uniform solution;

[0039] Step 2): Electrospinning is carried out on the basis of melt-blown nonwoven fabric: the applied voltage is 18kV, the spinning speed is 1mL / h, and the spinning distance is 13cm;

[0040] Step 3): drying at room temperature;

[0041] Step 4): Cover the nanofiber membrane with another layer of melt-blown nonwoven fabric, and combine the nanofiber membrane with the two layers of melt-blown nonwoven fabric by hot pressing to obtain a sound-absorbing and noise-reducing material. Coeffici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com