Metal net sandwiched structure composite damping material and preparation method thereof

A composite damping material and sandwich structure technology, applied in metal layer products, chemical instruments and methods, lamination, etc. Elasticity and strength, the effect of improving low-frequency sound absorption and damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

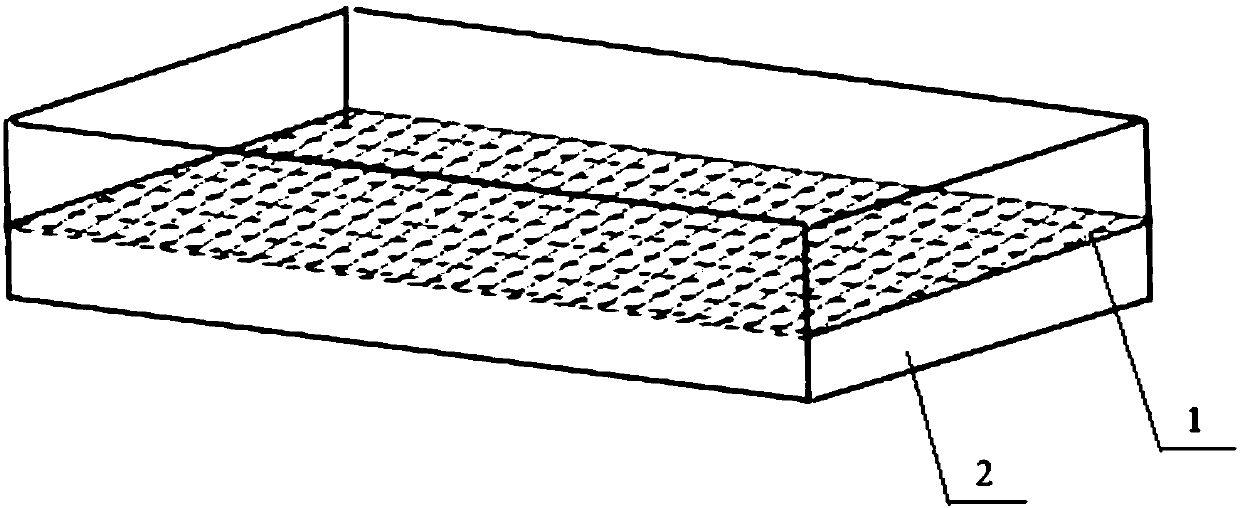

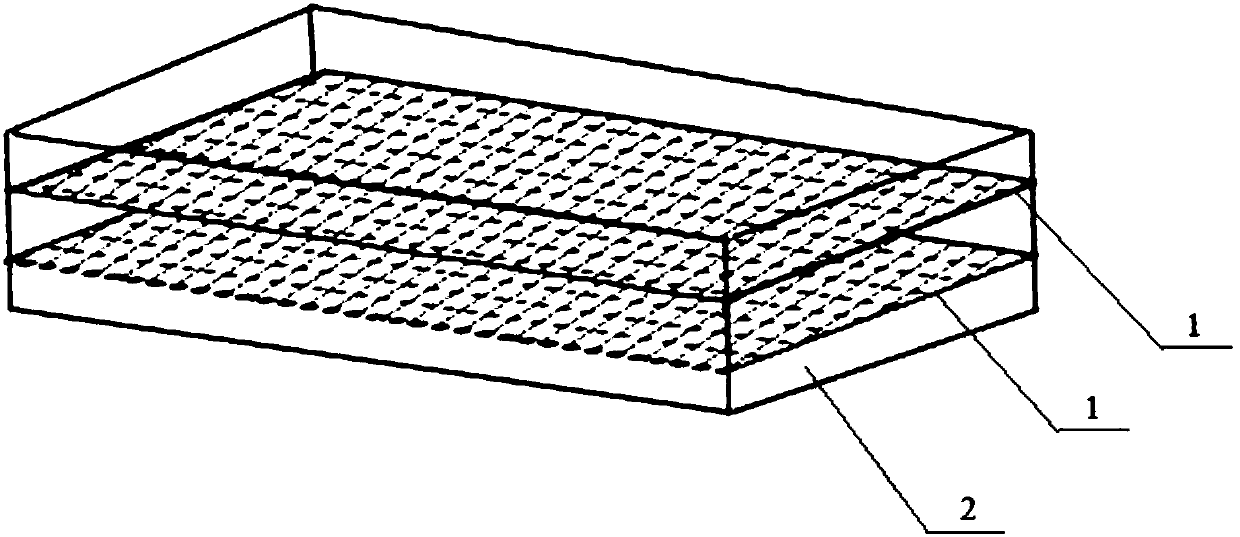

[0017] Embodiment 1: The metal mesh sandwich structure composite damping material in this embodiment is composed of epoxy resin graft modified polyurethane polymer elastomer and wire mesh, wherein the wire mesh is single-layer or multi-layer;

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the wire mesh is brass mesh, red copper mesh or steel mesh; others are the same as Embodiment 1.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the metal wires of the wire mesh are weaved in plain weave or twill weave; others are the same as Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com