A Continuous Gradient Opening Double Porosity Sound Absorbing Device and Its Application

A sound-absorbing device, double-hole technology, applied to sound-generating devices, instruments, floors, etc., to achieve excellent sound-absorbing performance, good broadband sound-absorbing performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

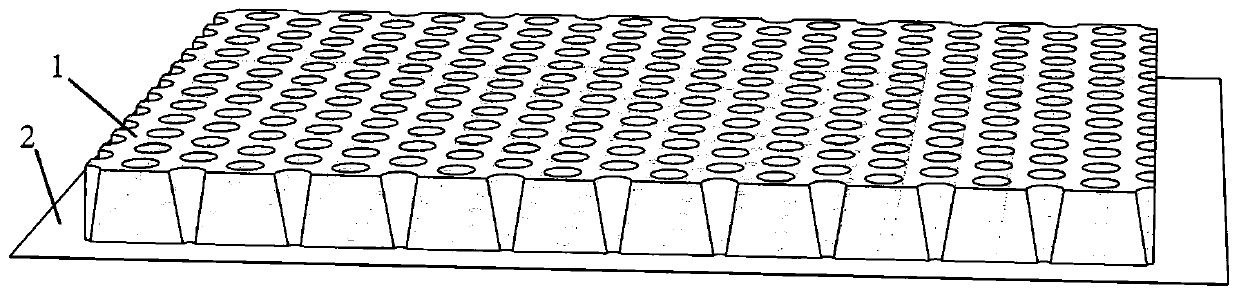

[0049] See figure 1 with figure 2 In a perforated porous material plate 1 with a total height of 60mm, truncated cone holes are periodically opened, the porosity of the base porous material is 90%, and the flow resistance rate is 47700N·s / m 2 , The characteristic length of viscous is 24μm, the characteristic length of thermal is 200μm, and the degree of tortuosity is 1.29; the apertures at both ends of the frustum hole are 30mm and 6mm, respectively. Volume) is 17.58%; the side of the small end face of the frustum hole of the perforated porous material plate 1 is placed on the rigid backing to simulate the design of the sound-absorbing material close to the indoor wall, the wall of the transportation tool and the inside of the machine The situation on the wall.

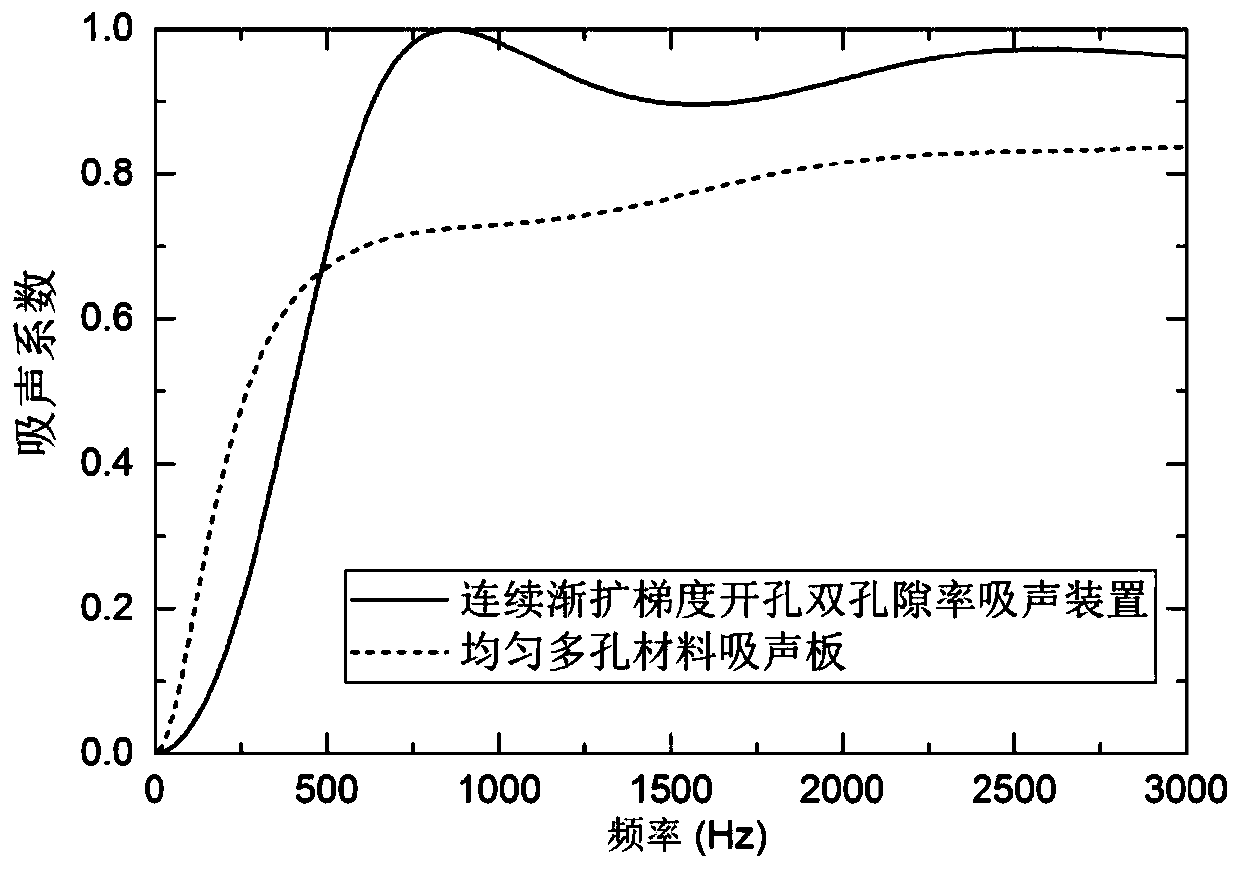

[0050] See figure 2 Compared with the same base material and the same thickness of uniform porous material plate without openings, the structure of the present invention can appear the sound absorption peak earlier at 8...

Embodiment 2

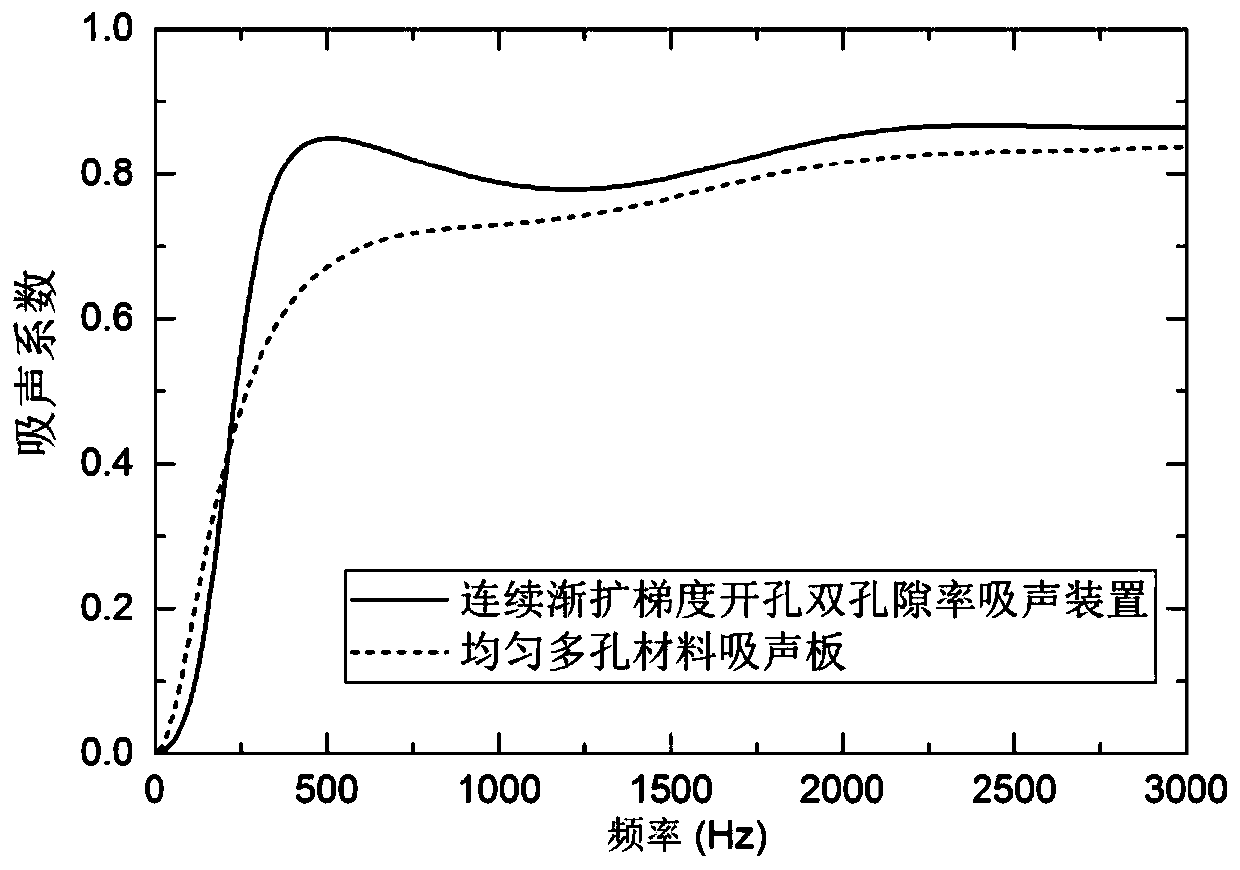

[0052] Set the aperture of the frustum hole in implementation 1 to 6mm and 3mm. At this time, the opening rate of the sound-absorbing plate is 4%, and the base porous material parameters and other structural parameters remain unchanged. The side of the small end of the frustum hole is placed on the rigid backing to simulate the situation where the designed sound-absorbing material is tightly attached to the indoor wall, the wall of the transportation tool and the inner wall of the machine. For the sound absorption coefficient of Example 2 of the present invention, see image 3 Compared with a uniform porous material plate with the same base material and the same thickness without openings, this embodiment can appear the sound absorption peak earlier at 510Hz, the peak sound absorption coefficient is 0.85, and it can be realized in the range above 220Hz Improved sound absorption.

Embodiment 3

[0054] Set the aperture of the frustum hole in implementation 1 to 23mm and 4mm. At this time, the opening rate of the sound-absorbing panel is 40%, and the base porous material parameters and other structural parameters remain unchanged. Similarly, the perforated porous material plate 1 The side of the small end of the frustum hole is placed on the rigid backing to simulate the situation where the designed sound-absorbing material is tightly attached to the indoor wall, the wall of the transportation tool and the inner wall of the machine. For the sound absorption coefficient of Example 3 of the present invention, see Figure 4 Compared with a uniform porous material plate with the same base material and the same thickness without openings, this embodiment has an earlier sound absorption peak at 1490 Hz, and the peak sound absorption coefficient is close to 1, and it is achieved in the range above 880 Hz. Enhance sound absorption.

[0055] Through Examples 1 to 3, it can be seen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com