Sound absorption and noise reduction material

A noise reduction and sound absorption technology, applied in the field of sound absorption and noise reduction materials, can solve problems such as sound absorption performance needs to be improved, and achieve the effects of improving the working and living environment, improving low-frequency sound absorption performance, and good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

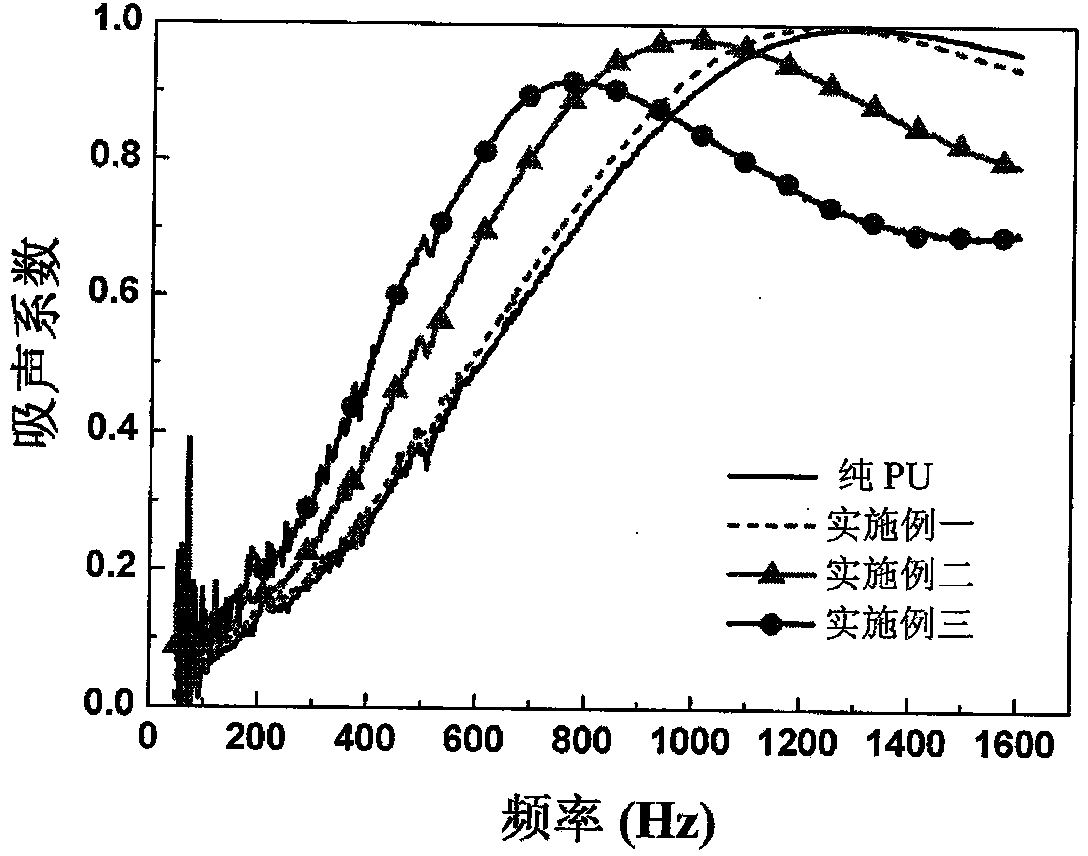

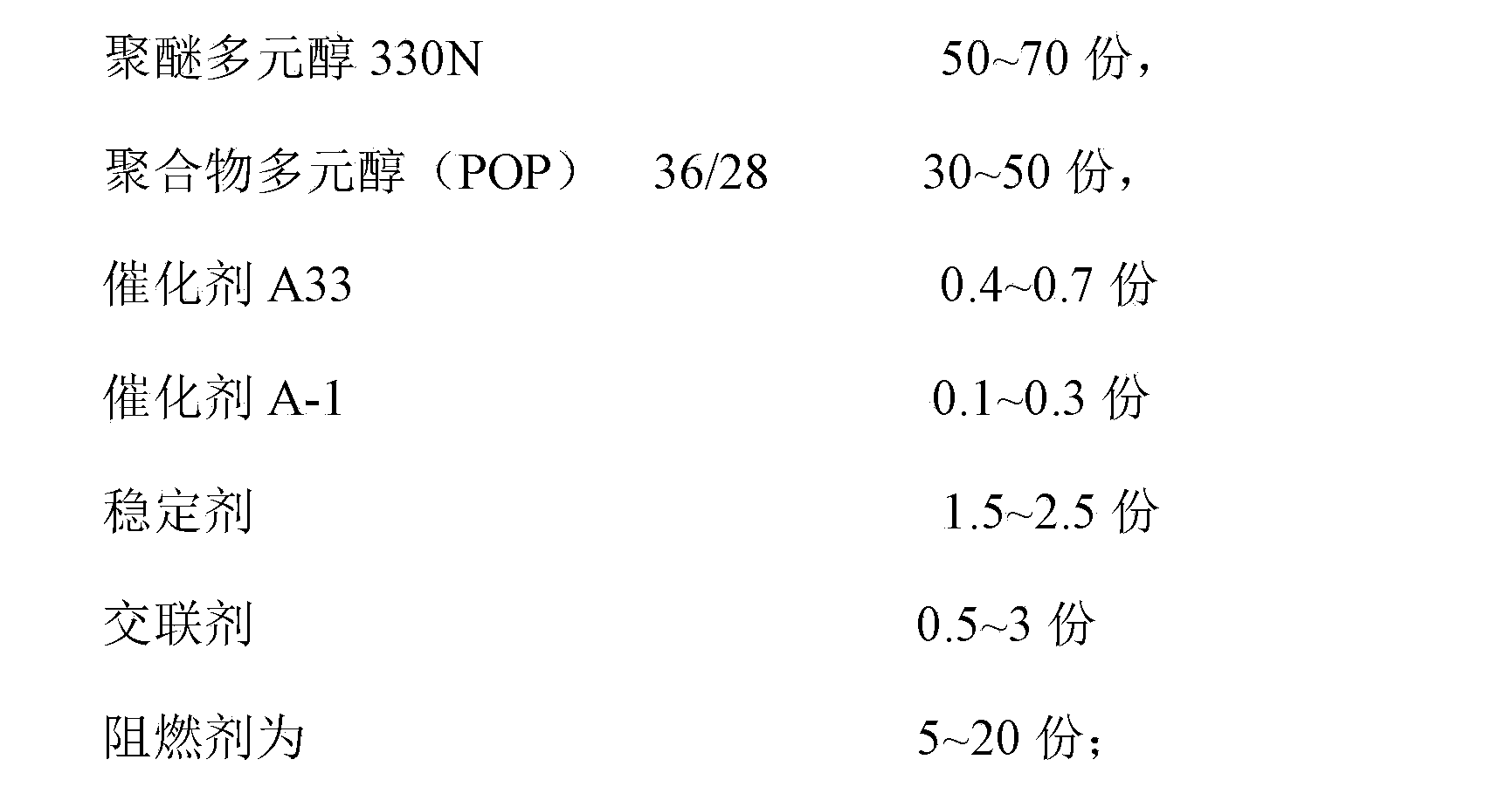

[0021] The filler chooses crushed rice husk with a particle size of 2mm, mixes the components uniformly in the following proportions, and foams them in a constant temperature mold to prepare a foam with a thickness of 40mm. The average sound absorption coefficient in the low frequency range can reach 0.45, The highest sound absorption coefficient is 0.996.

[0022] Rice husk: 5 parts; Modified diphenylmethane diisocyanate: 45 parts; Polyether polyol 330N: 60 parts; Polymer polyol 36 / 28: 40 parts; Catalyst A33: 0.6 parts; Catalyst A-1: 0.1 parts parts; silicone oil: 1.8 parts; diethanolamine: 2 parts; melamine phosphate: 10 parts; deionized water: 2 parts.

Embodiment 2

[0024] Complete rice husk is selected as filler, and the following ingredients are uniformly mixed, and foamed and molded in a constant temperature mold to prepare a foam with a thickness of 40mm. The average sound absorption coefficient in the low frequency range can reach 0.59, and the highest sound absorption coefficient is 0.97. .

[0025] Rice husk: 10 parts; Modified diphenylmethane diisocyanate: 40 parts; Polyether polyol 330N: 50 parts; Polymer polyol 36 / 28: 50 parts; Catalyst A33: 0.6 parts; Catalyst A-1: 0.1 parts parts; silicone oil: 1.5 parts; diethanolamine: 2 parts; melamine phosphate: 15 parts; deionized water: 2 parts.

Embodiment 3

[0027] Wheat straw with a length of 5 mm is selected as the filler, and the following ingredients are uniformly mixed in the following proportions, and foamed and molded in a constant temperature mold to prepare a foam with a thickness of 40 mm. The average sound absorption coefficient in the low frequency range can reach 0.52, and the highest absorption The sound coefficient is 0.93.

[0028] Wheat straw: 15 parts; Modified diphenylmethane diisocyanate: 45 parts; Polyether polyol 330N: 60 parts; Polymer polyol 36 / 28: 40 parts; Catalyst A33: 0.6 parts; Catalyst A-1: 0.2 parts parts; silicone oil: 1.5 parts; diethanolamine: 2 parts; melamine phosphate: 20 parts; deionized water: 2 parts.

[0029] The properties of the material are as follows:

[0030]

[0031] The comparison of the sound absorption coefficient curves of the three embodiments of the present invention figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com