Broadband folding back cavity micro-perforated sound absorption structure

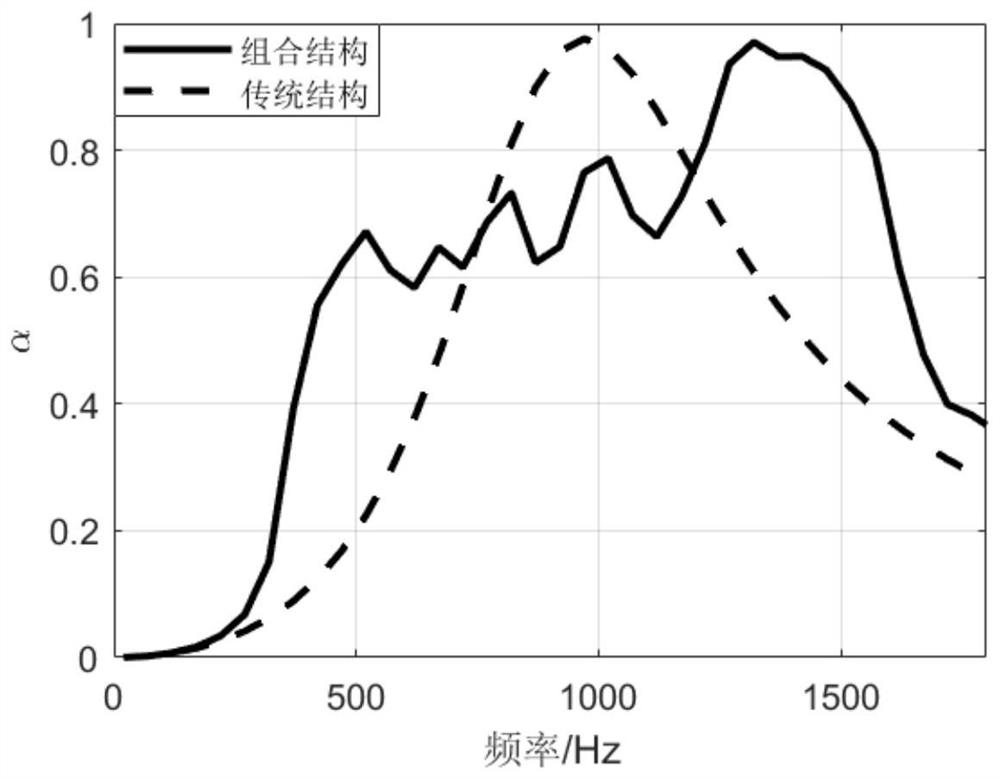

A micro-perforation, wide-band technology, applied in the direction of sound-producing instruments, instruments, etc., can solve the problems of affecting the sound absorption effect, high manufacturing cost, complex structure, etc., achieving good adaptability, avoiding interference problems, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

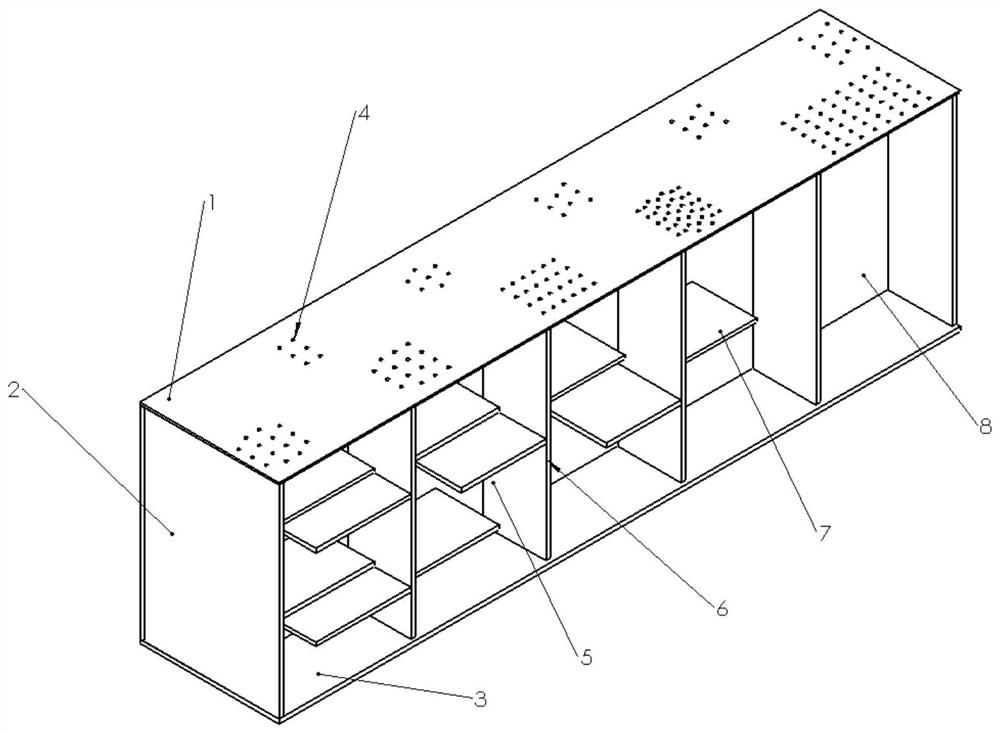

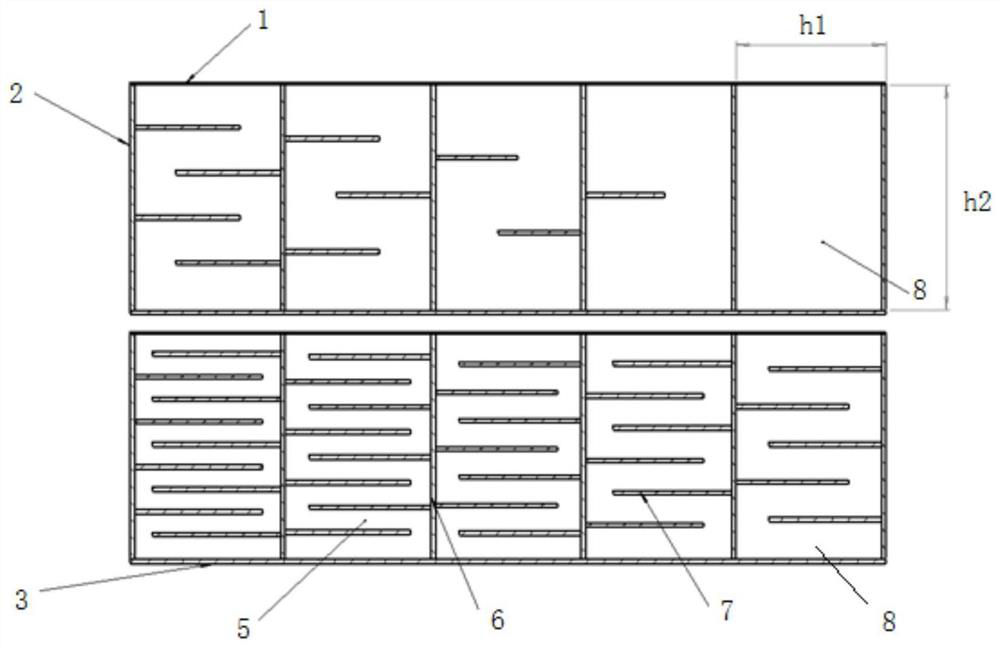

[0027] see figure 2 , the side wall 2, the bottom plate 3, the longitudinal main partition 6 and the transverse sub-partition 7 are all directly printed with the overall back cavity by 3D printing. The thickness of side wall 2, bottom plate 3, longitudinal main partition 6 and transverse sub-partition 7 is 0.6mm, and the length and width of the bottom plate are 100mm*20mm, which are divided into 10 independent small units, and the first row is from left to right 1st floor, 2nd floor, 3rd floor, 4th floor, 5th floor, the second row from left to right is 6th floor, 7th floor, 8th floor, 9th floor, 10th floor, the length and width of the front and rear side panels are 100mm* 30mm, the length and width of the left and right side panels are 20mm*30mm. The thickness dimension of the sound-absorbing back cavity in the direction perpendicular to the bottom plate 3 is the same as that of the side wall in the direction perpendicular to the bottom plate 3, and its value is 30mm. The pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com