Polyurethane composite sound absorption material containing natural plant components and preparation method thereof

A technology of sound-absorbing materials and natural plants, applied in the field of material science, can solve problems such as poor low-frequency sound-absorbing performance, and achieve the effects of wide application range, improved low-frequency sound-absorbing performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

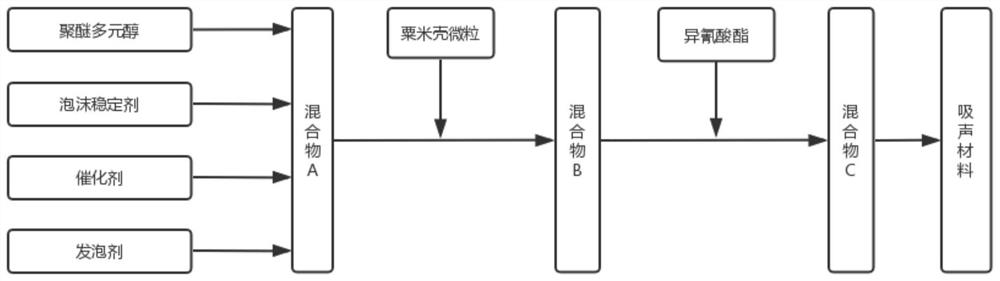

[0025] The invention provides a polyurethane composite sound-absorbing material containing natural plant components and a preparation method of the polyurethane composite sound-absorbing material.

[0026] Polyurethane composite sound-absorbing material

[0027] The polyurethane composite sound-absorbing material includes the following components: polyether polyol, foam stabilizer, catalyst, foaming agent diphenylmethane diisocyanate and corn hulls.

[0028] In one or more embodiments of the present invention, the polyurethane composite sound-absorbing material includes the following components by weight: 100 parts by weight of polyether polyol, 1.5 parts by weight of foam stabilizer, 1.2 parts by weight of catalyst, 4.0 parts by weight of foaming agent, 69 parts by weight of diphenylmethane diisocyanate and 2-8 parts by weight of corn hulls.

[0029] In one or more embodiments of the present invention, the polyether polyol is selected from one or both of polyether polyol 330...

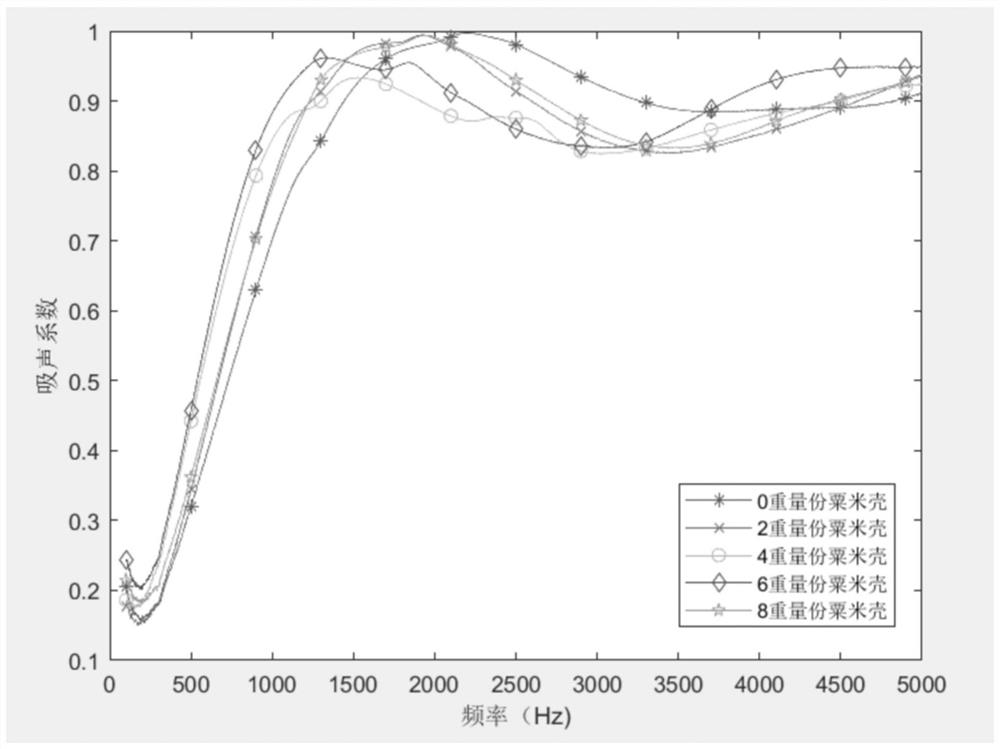

Embodiment 1

[0042]Polyurethane composite sound-absorbing material containing natural plant components: including the following components: 100 parts by weight of polyether polyol (60 parts by weight of polyether polyol 330N, 40 parts by weight of polyether polyol 3630), 1.5 parts by weight of Foam stabilizer (silicone oil), 1.2 parts by weight of catalyst (0.2 parts by weight of bis(dimethylaminoethyl) ether mass fraction is 70% dipropylene glycol solution and 1 weight part of triethylenediamine mass fraction is 33% dipropylene glycol solution), 4.0 parts by weight of blowing agent (deionized water), 69 parts by weight of diphenylmethane diisocyanate and 2 parts by weight of corn hulls. The grain size of the corn husk is less than 1mm.

[0043] The steps of a method for preparing a polyurethane composite sound-absorbing material containing natural plant components are as follows:

[0044] Step 1): According to the components and parts by weight in the above formula, 60 parts by weight of...

Embodiment 2

[0050] Polyurethane composite sound-absorbing material containing natural plant components: including the following components: 100 parts by weight of polyether polyol (60 parts by weight of polyether polyol 330N, 40 parts by weight of polyether polyol 3630), 1.5 parts by weight of Foam stabilizer (silicone oil), 1.2 parts by weight of catalyst (0.2 parts by weight of bis(dimethylaminoethyl) ether mass fraction is 70% dipropylene glycol solution and 1 weight part of triethylenediamine mass fraction is 33% dipropylene glycol solution), 4.0 parts by weight of blowing agent (deionized water), 69 parts by weight of diphenylmethane diisocyanate and 4 parts by weight of corn hulls. The grain size of the corn husk is less than 1mm.

[0051] The steps of the preparation method of the polyurethane composite sound-absorbing material containing natural plant components are as follows:

[0052] Step 1): According to the components and parts by weight in the above formula, 60 parts by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com