Sound absorber, and preparation method and application thereof

A technology of sound absorbing body and porous matrix, which is applied in the direction of sound-producing equipment, instruments, etc., can solve the problem of limited improvement of sound absorbing performance, and achieve the effect of broadening the frequency range of sound absorbing, enhancing sound absorbing ability and improving sound absorbing coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

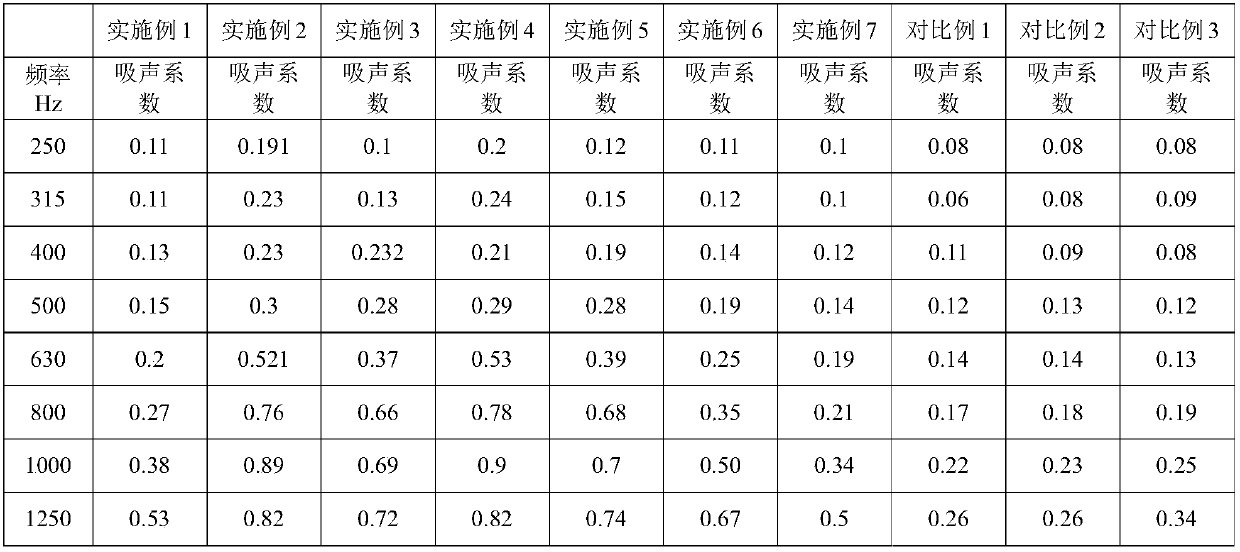

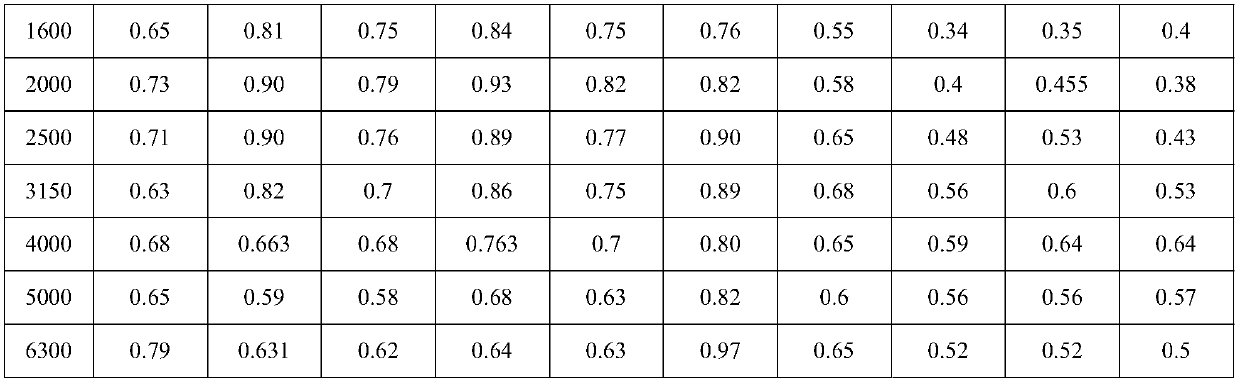

Examples

Embodiment 1

[0041] In this embodiment, the foaming material includes component A: 100 parts by weight of polyether polyol (1027 commercially purchased from Zhejiang Yongjie Automotive Electronics Co., Ltd., with a number average molecular weight of 5000 g / mol, a functionality of 3, and a hydroxyl value of 26-30, viscosity is 900-1100mPa s), crosslinking catalyst A33 (purchased from Huntsman Company) 0.5 parts by weight, foaming catalyst A1 (purchased from Huntsman Company) 0.2 parts by weight, silicone oil 9800, 0.8 parts by weight 3 parts by weight of water; Component B: 40 parts by weight of modified MDI isocyanate (Wanhua Chemical, trade number 8053).

[0042] The preparation method of the sound absorbing body is as follows:

[0043] Mix the above components A and B evenly and pour them into the mold for foaming. The temperature of the mold is 50°C. After demoulding, a porous matrix in the shape of a cylinder is obtained. The rate is 90%, the density is 90kg / m 3 , the axial thickness...

Embodiment 2

[0045] The materials and preparation method of Example 1 are used, except that, for the openings formed by laser drilling, the distance between the centers of two adjacent openings is 5 mm.

Embodiment 3

[0047] The materials and preparation method of Example 1 were used, except that the diameter of the holes formed by laser drilling was 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com