Patents

Literature

243results about How to "Adjust depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for constructing spinel structure on surface layer of lithium-rich manganese-based positive electrode material

ActiveCN107215900AImprove structural stabilityReduce interfacial tensionSecondary cellsPositive electrodesControl mannerIon exchange

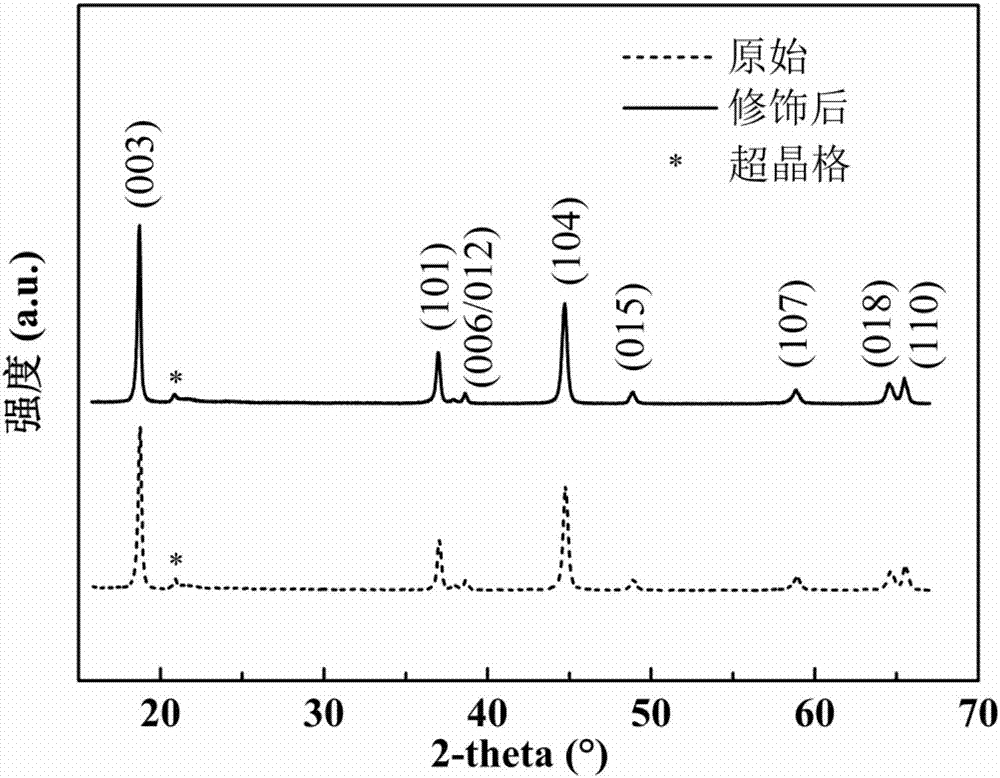

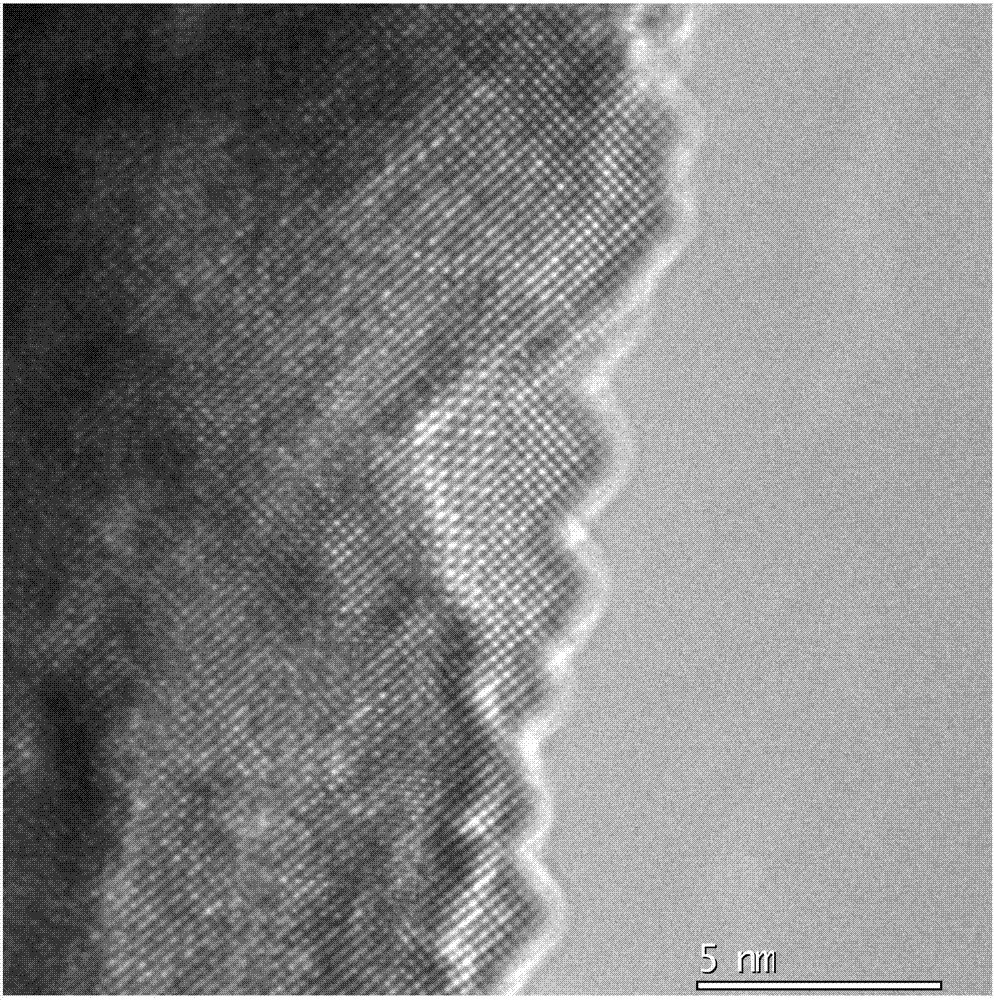

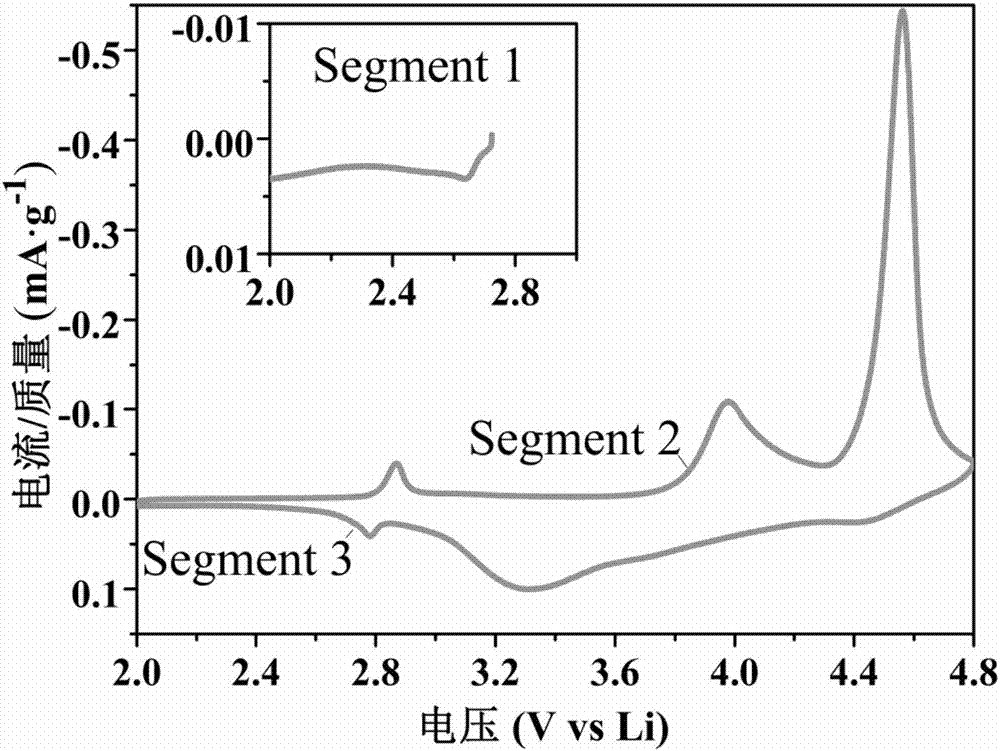

The invention relates to a method for constructing a spinel structure on a surface layer of a lithium-rich manganese-based positive electrode material and belongs to the field of chemical energy storage batteries. The method comprises the following steps: adding the lithium-rich manganese-based positive electrode material into a weakly acidic aqueous solution, and performing Li+ and H+ ion exchange; and performing heat treatment on the positive electrode material subjected to the ion exchange to enable the surface lithium-poor structure to be changed into the spinel structure, thereby obtaining the lithium-rich manganese-based positive electrode material with the spinel structure on the surface layer. According to the method disclosed by the invention, the surface structure of the body material is changed into the spinel structure, so that a lithium-ion transport channel is kept smooth, the rate capability of the lithium-rich manganese-based positive electrode material is improved, and the first-cycle coulombic efficiency is improved. In addition, according to the method disclosed by the invention, the depth of the constructed spinel layer can be effectively regulated by regulating the concentration and treatment time of weak acid, so that the electrochemical performance of the electrode material is adjusted. The control manner is simple and feasible, the reaction time does not need to be strictly controlled, and the reproducibility and reliability are high.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

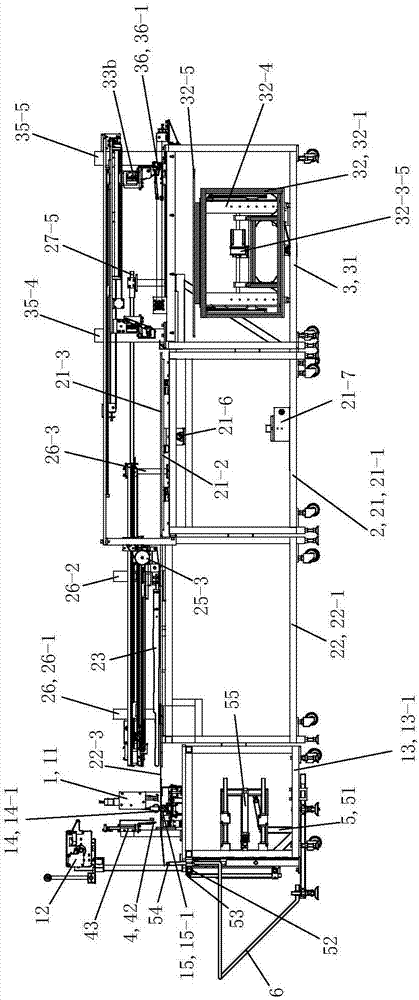

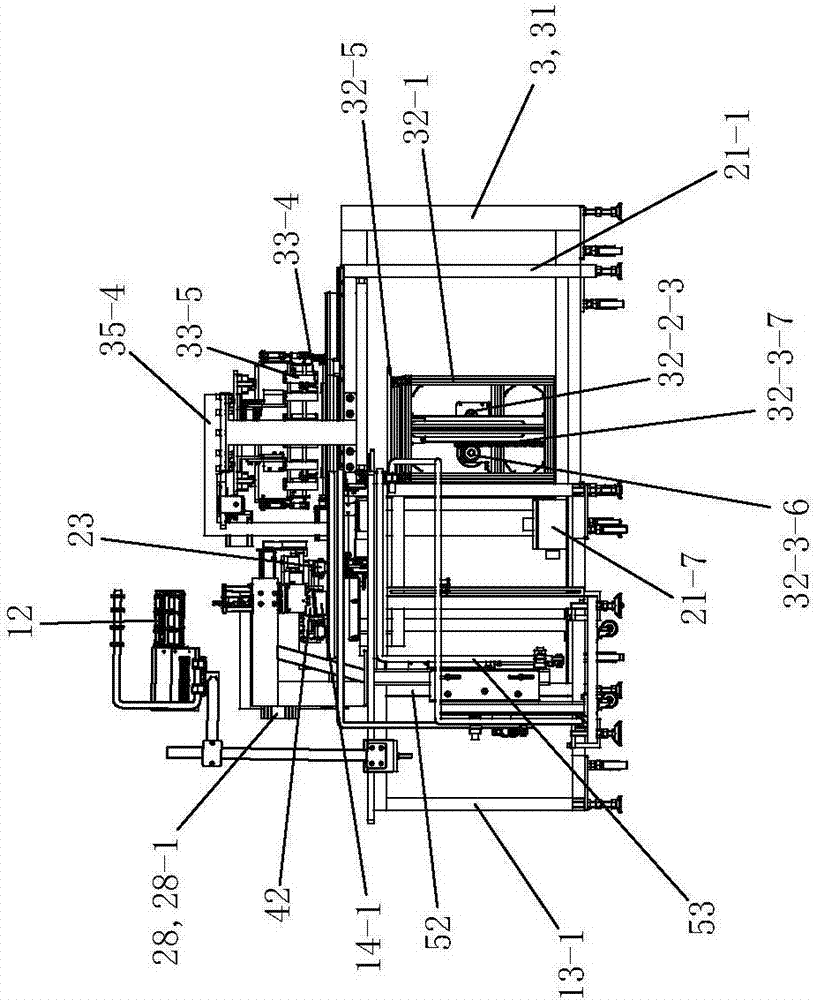

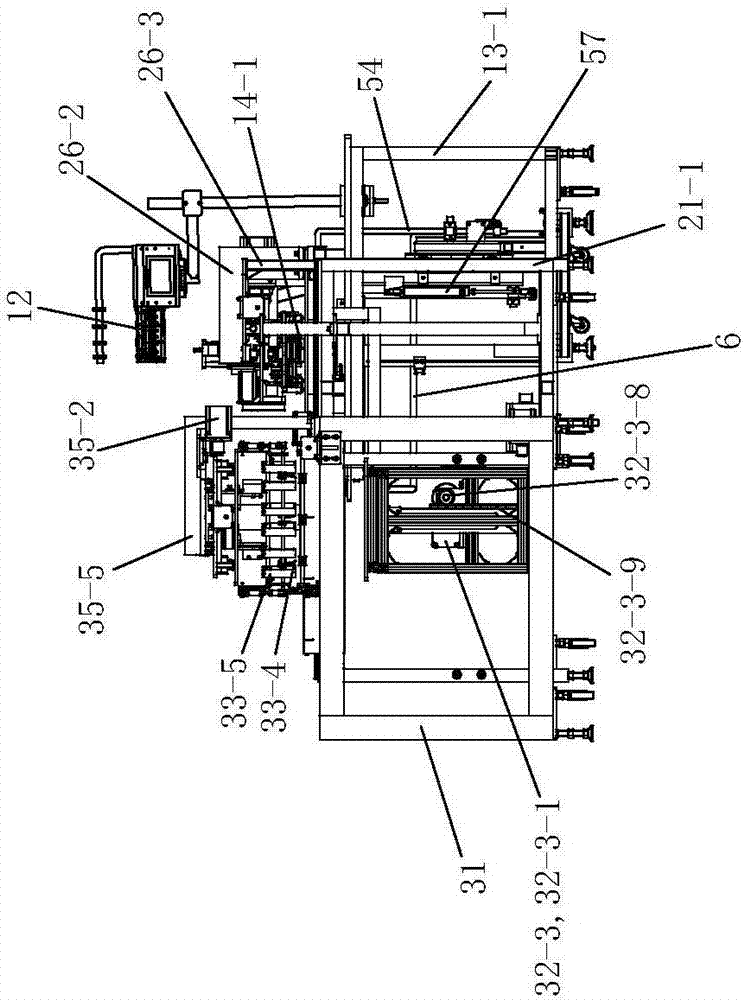

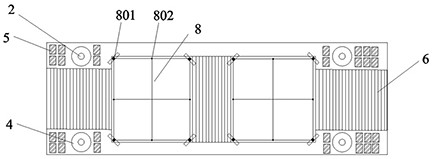

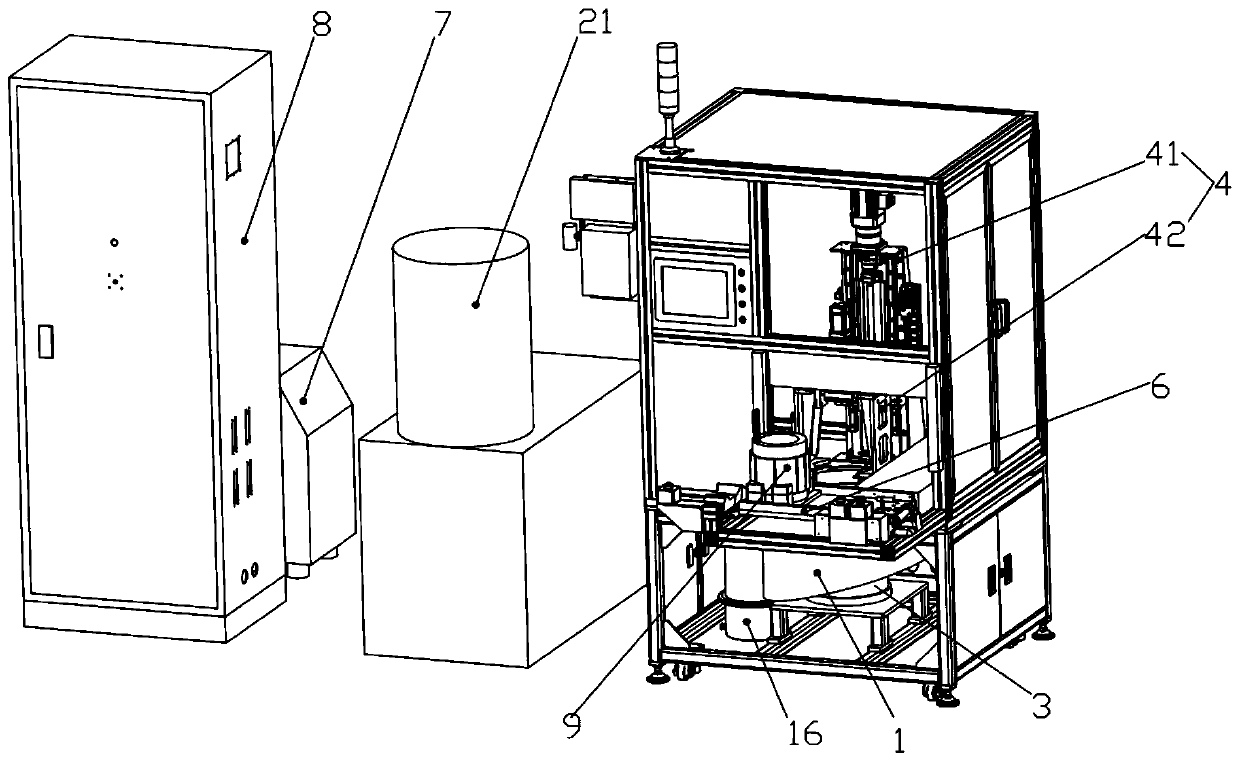

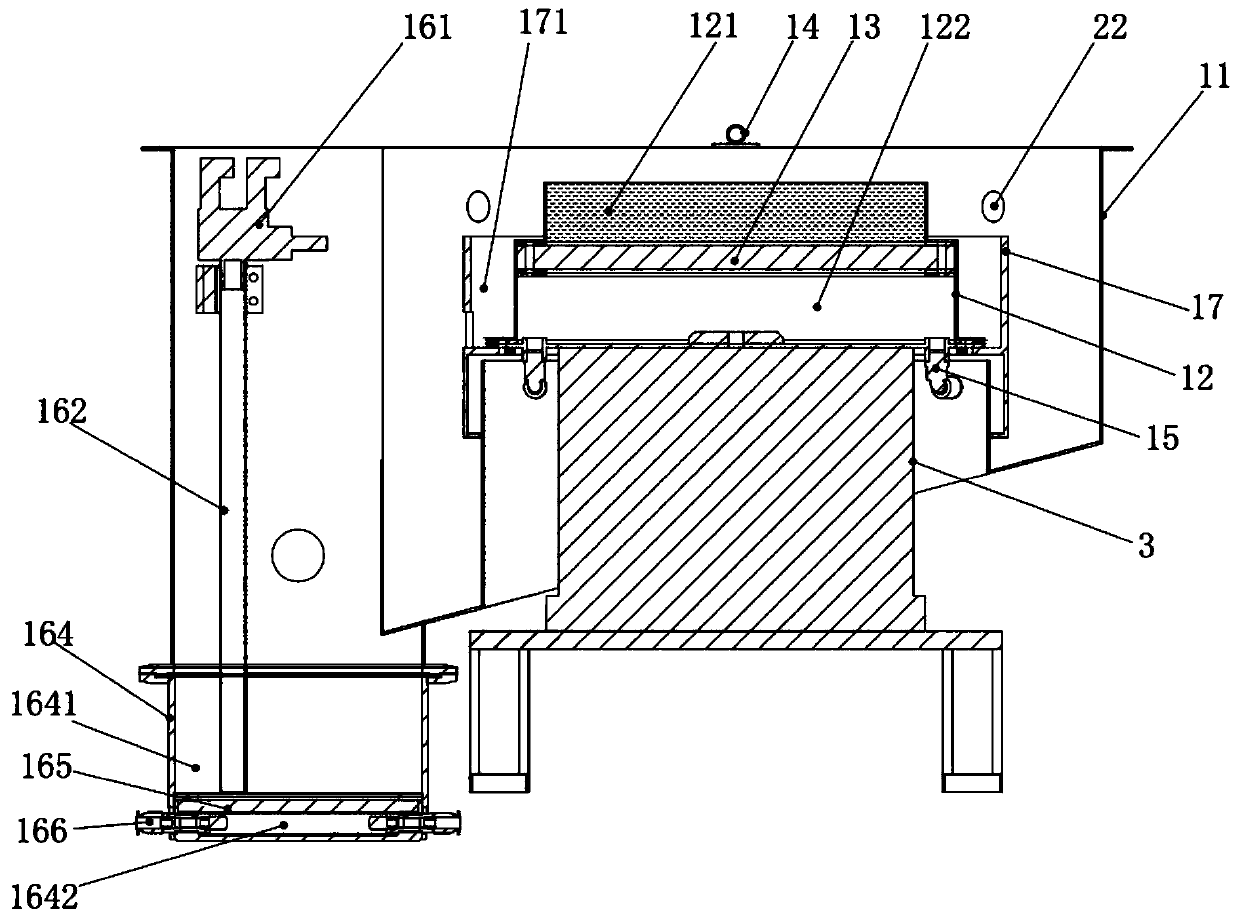

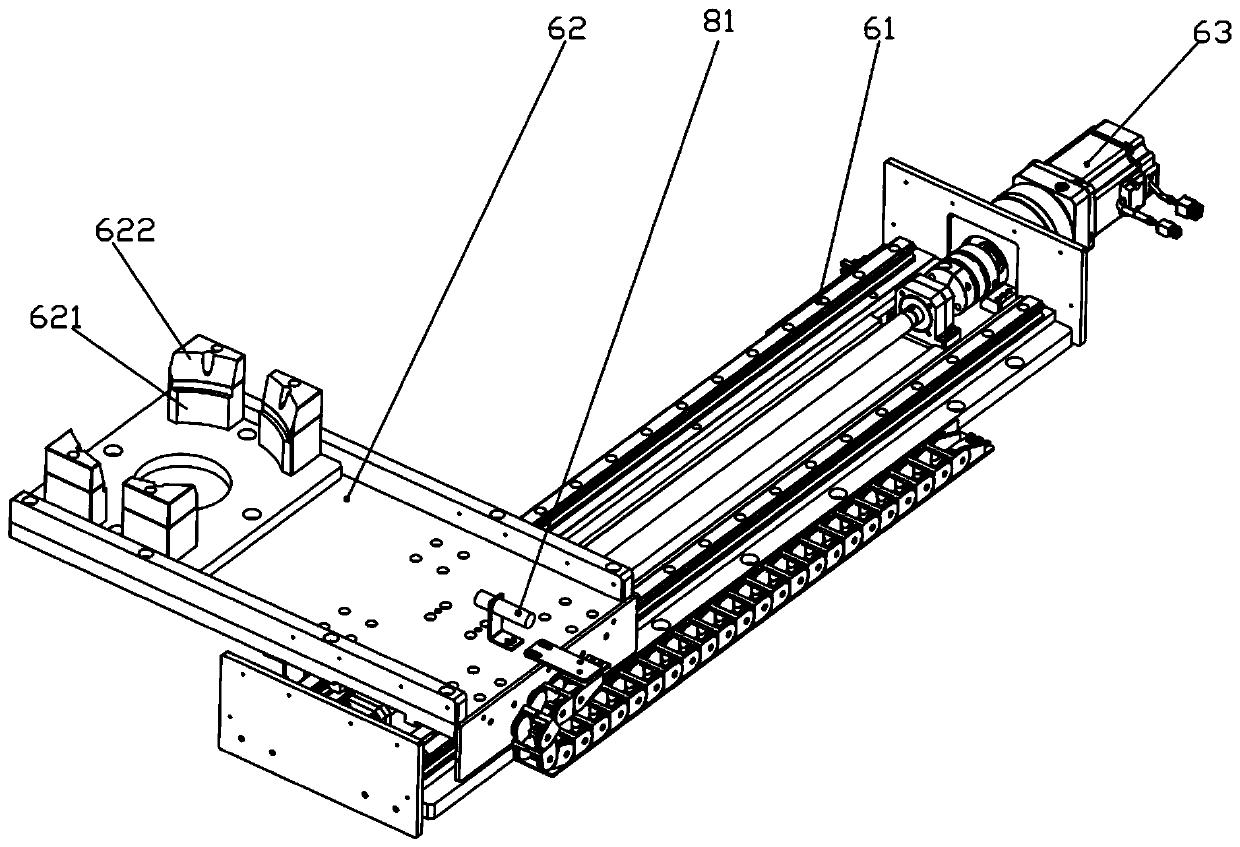

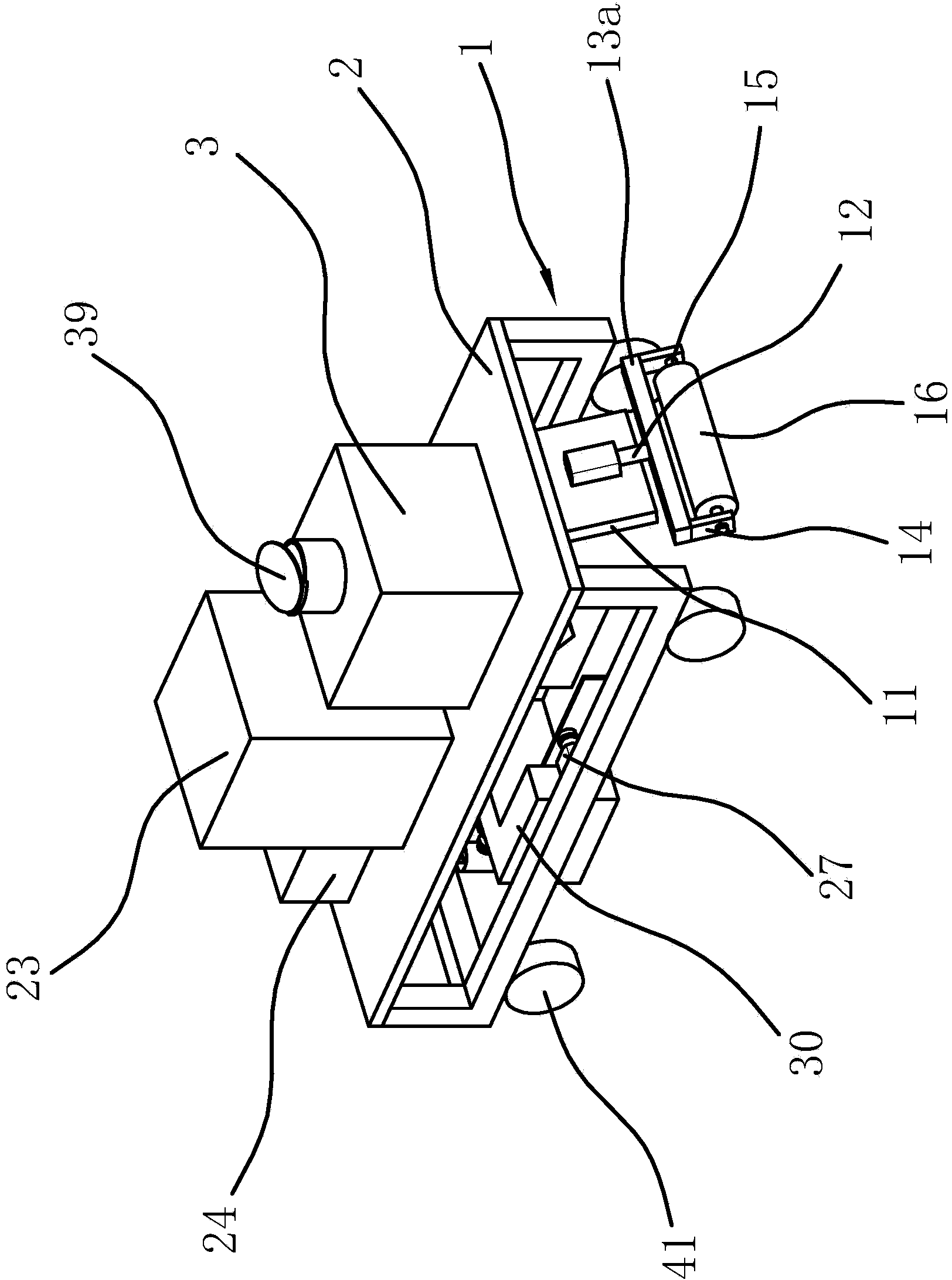

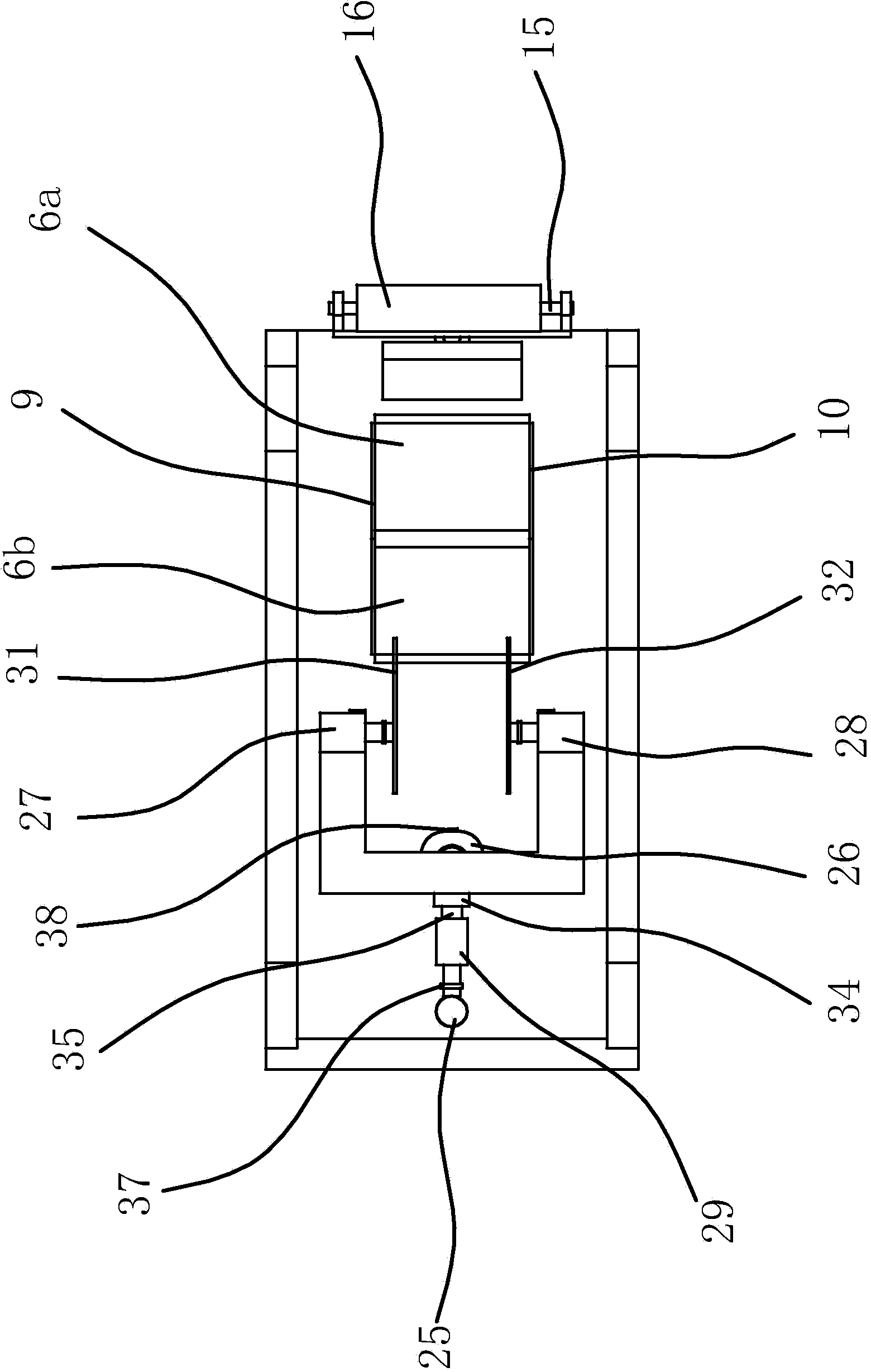

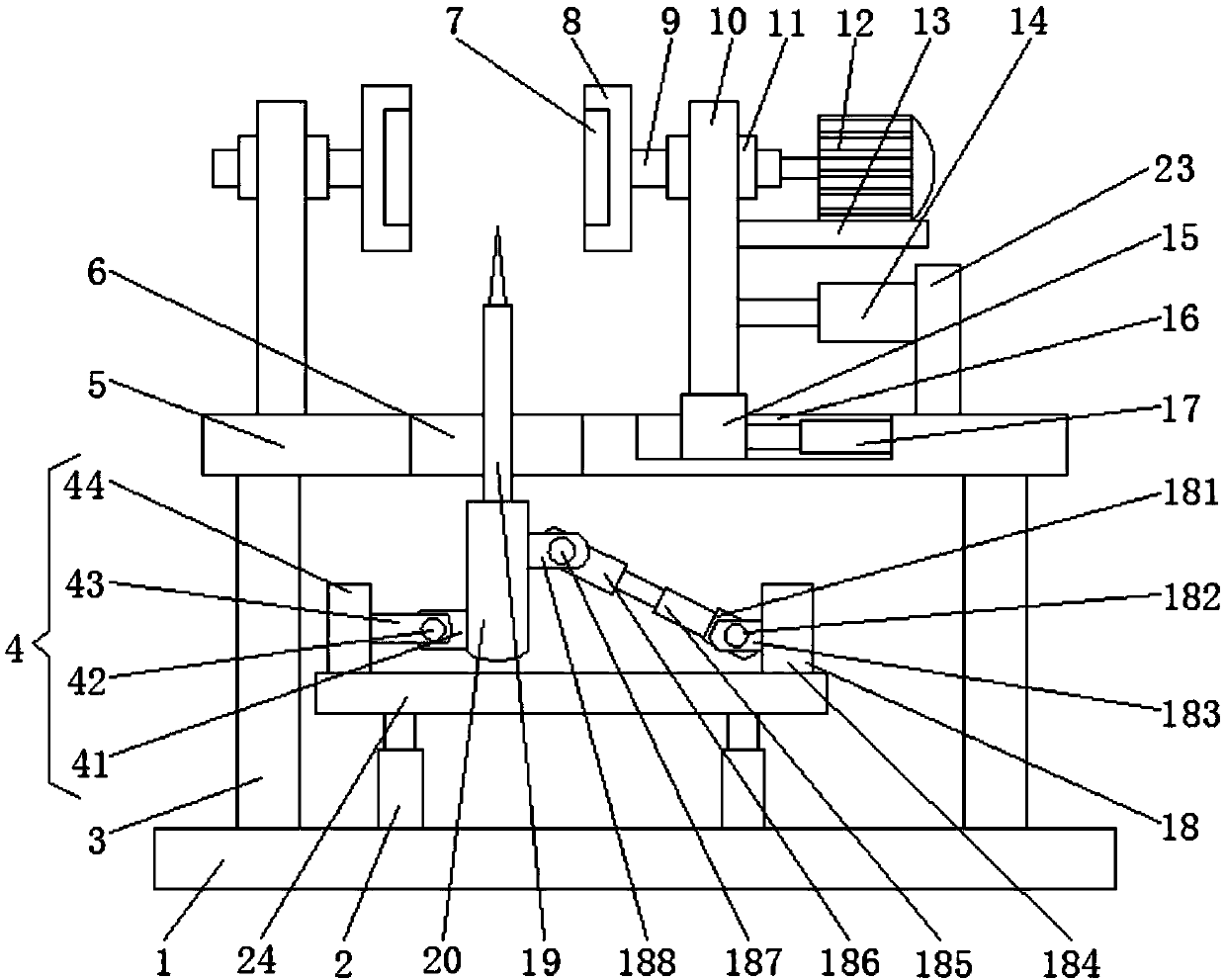

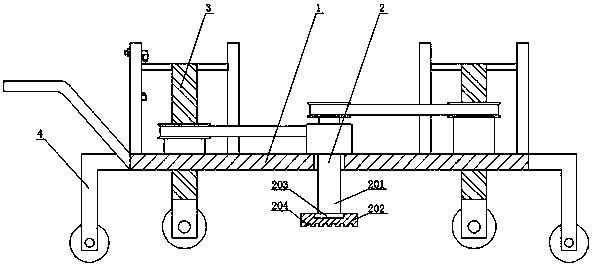

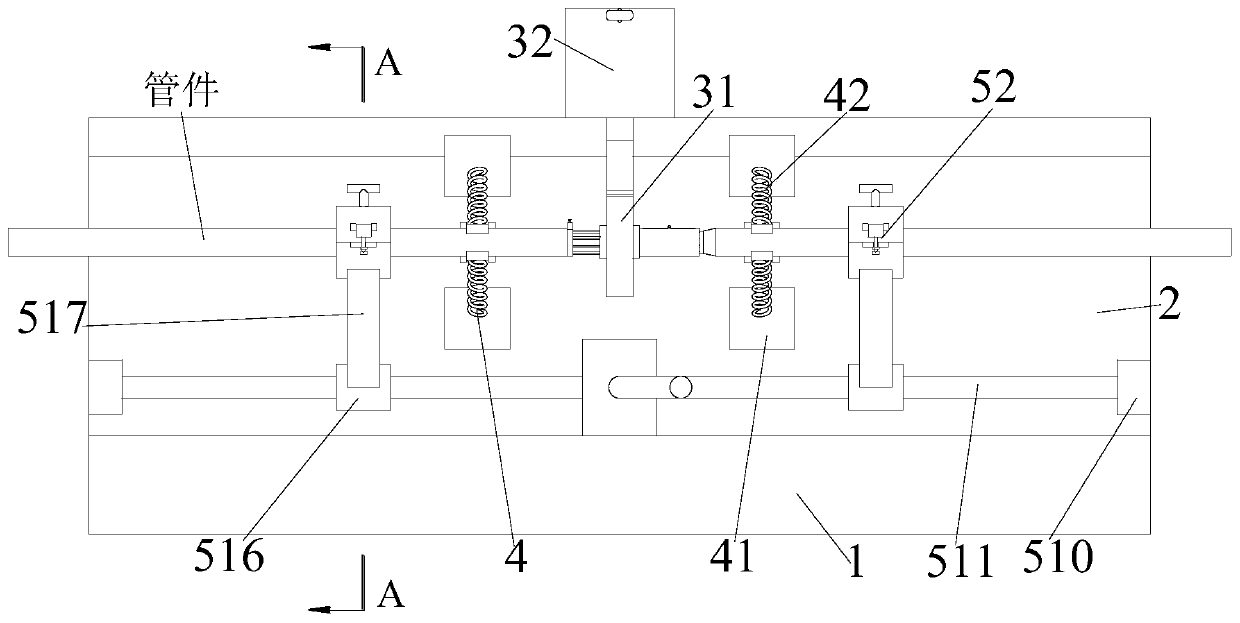

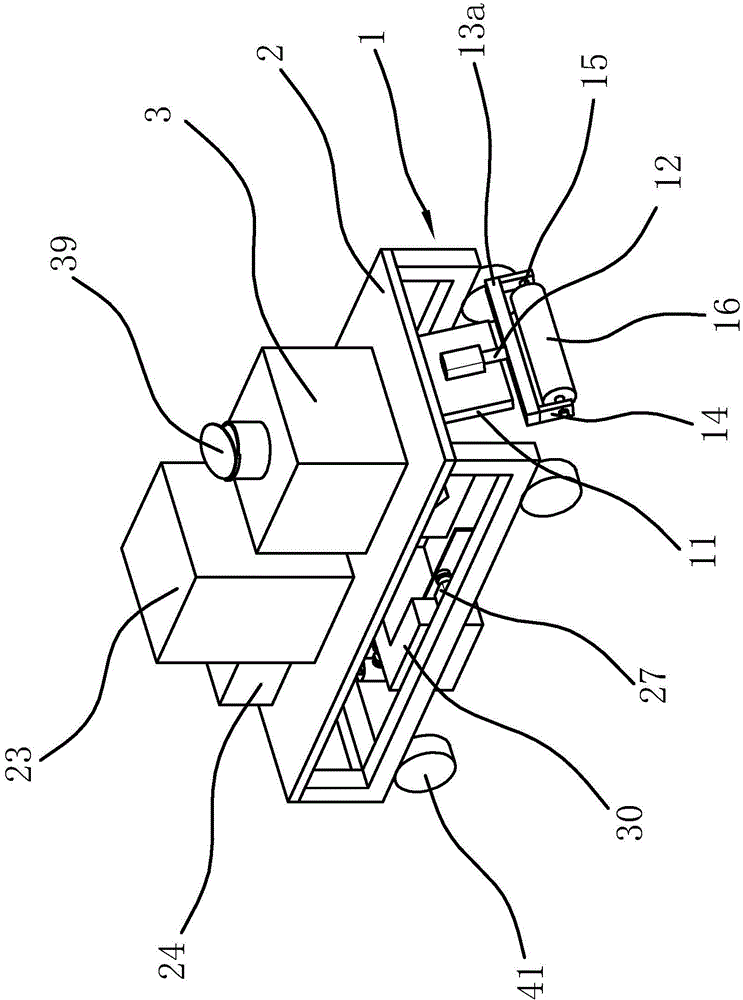

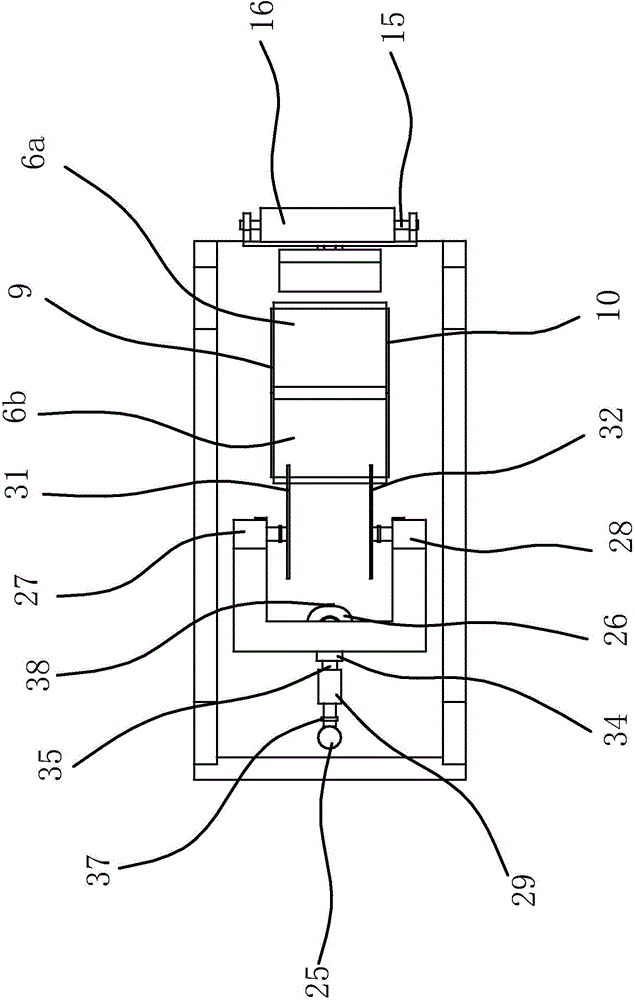

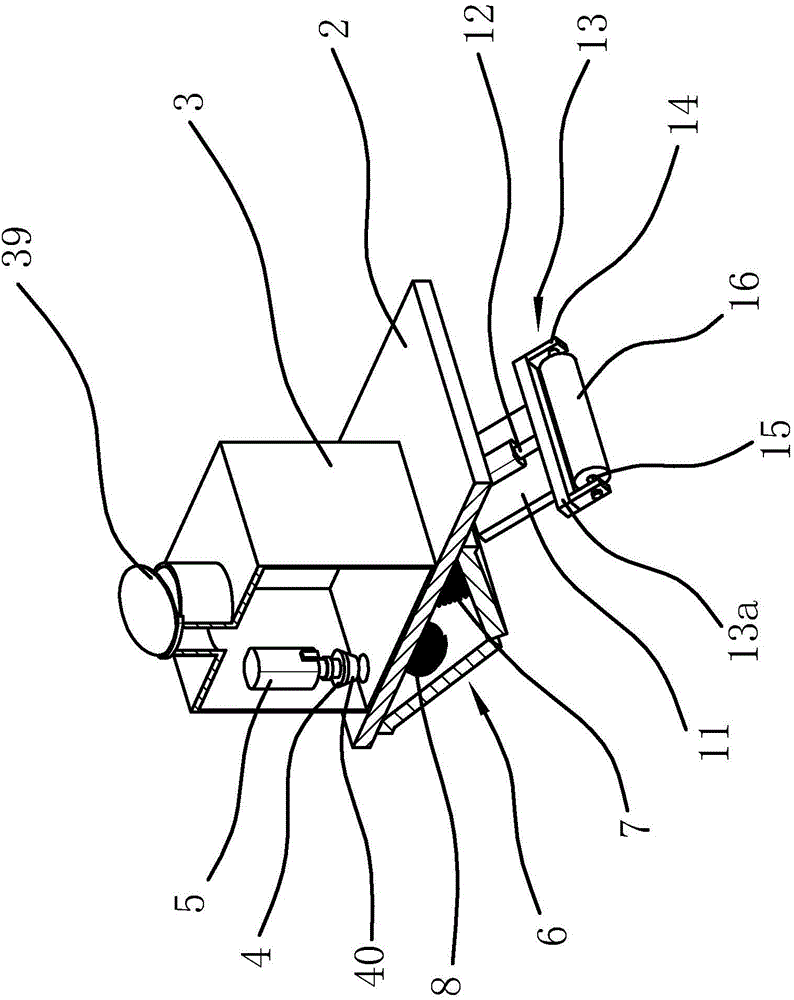

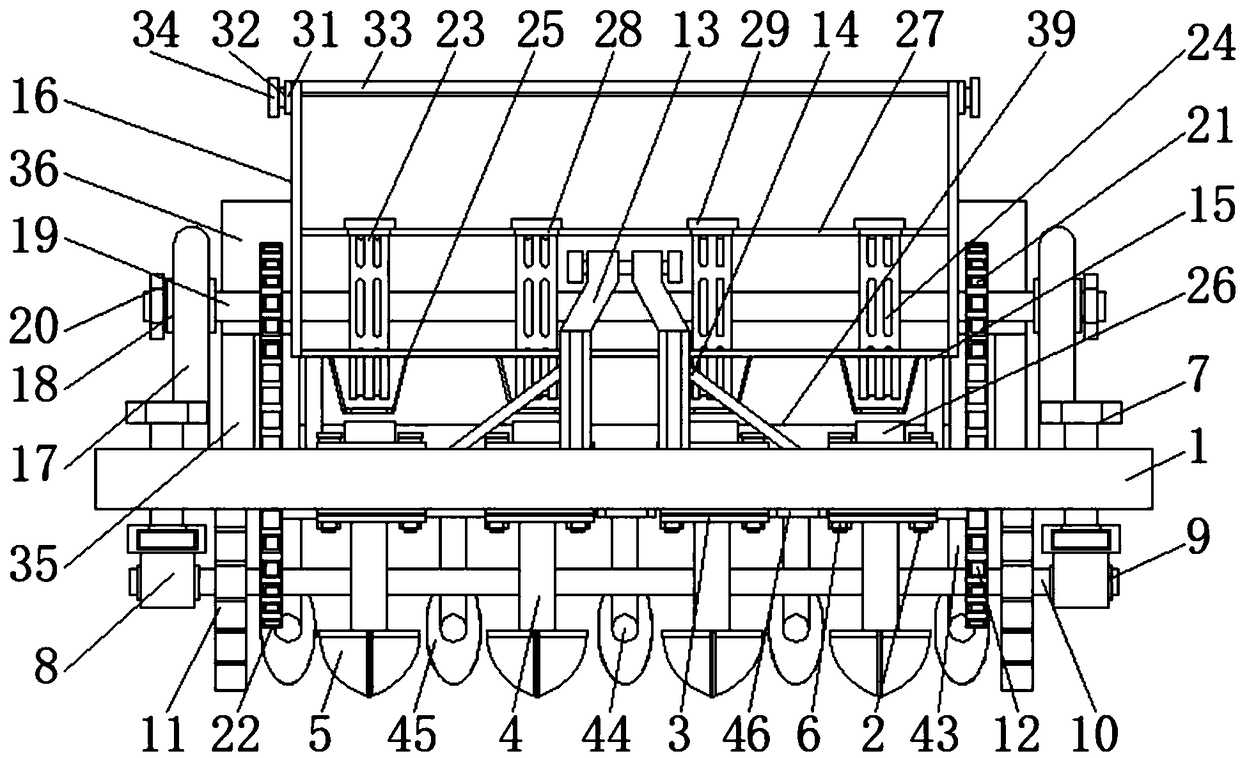

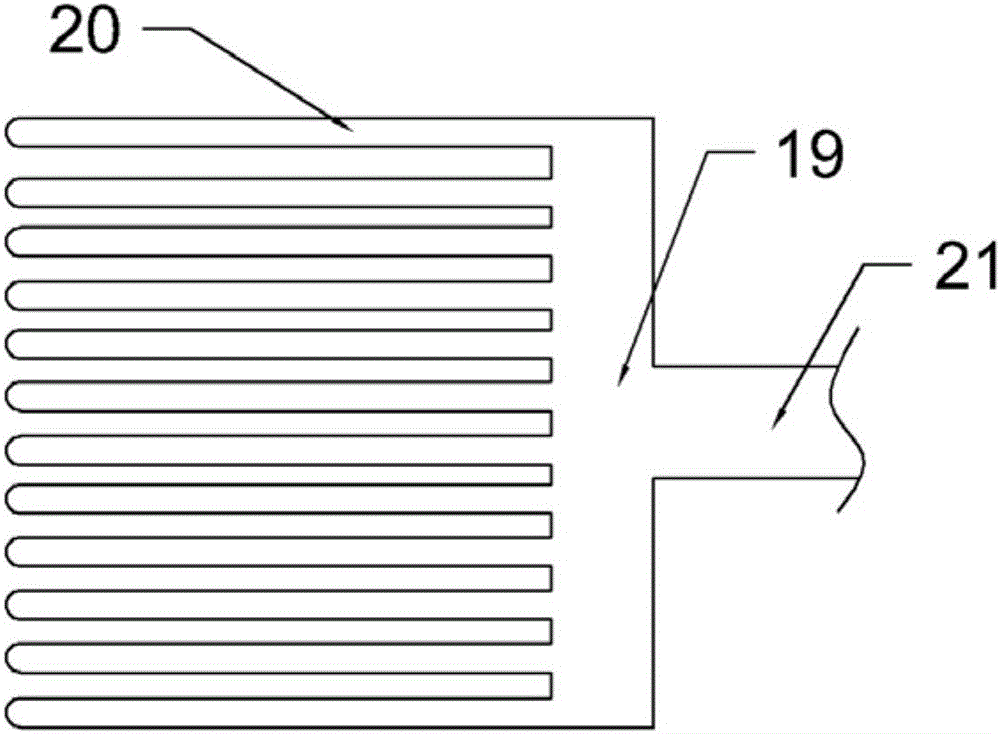

Full-automatic multi-trim-strip sewing equipment

ActiveCN107190425ASimple structureSewn flatWorkpiece carriersWork-feeding meansEngineeringSewing machine

The invention discloses full-automatic multi-trim-strip sewing equipment. The full-automatic multi-trim-strip sewing equipment comprises a sewing device, wherein the sewing device comprises a multi-needle sewing machine, a trim-strip feeding device, a first work platform, an upper tug assembly and a lower tug assembly. The full-automatic multi-trim-strip sewing equipment is characterized by further comprising a feeding device, and lower tugs of the lower tug assembly are driving wheels. The feeding device comprises a discharging table assembly, a feeding table assembly, pressing foot assemblies, and a pressing foot two-stage driving assembly. A discharging panel of the discharging table assembly is arranged on a discharging shelf in a way of moving front and back, and a feeding table panel of the feeding table assembly is fixedly arranged on a feeding table mounting shelf. The feeding table surface is communicated with a first panel and a discharging panel of the first work platform. The pressing foot assemblies comprise pressure feet. The pressure feet are arranged above the discharging panels, a feeding table panel, and the first panel in a way of moving left and right through the pressing foot two-stage driving assembly, and are used for delivering fabric of to-be-sewed trim-strips located on the discharging panel to the first panel through the feeding table panel after pressing the fabric.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

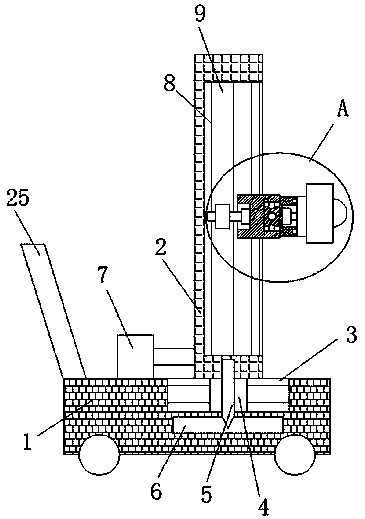

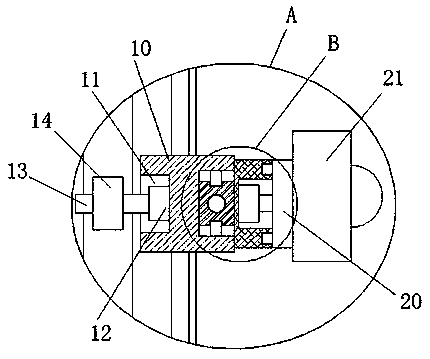

Wall grooving machine for water and electricity equipment installation

InactiveCN109203251ASmooth rotationDepth is easy to controlWorking accessoriesStone-like material working toolsElectricityElectric machine

The invention discloses a wall grooving machine for water and electricity equipment installation. The wall grooving machine comprises a base, the top of the base is provided with a sliding slot, a sliding block is slidingly installed in the sliding slot, and a vertical plate is fixedly installed on the top of the sliding block. The bottom of the vertical plate is in contact with the top of the base, one side of the vertical plate is provided with a moving groove, the top inner wall and the bottom inner wall of the moving groove are fixedly equipped with the same rack, and a horizontal plate isslidingly installed in the moving groove. One side of the horizontal plate is provided with a first mounting slot, and the inner wall of one side of the first mounting slot is fixedly equipped with afirst rotating motor whose output shaft is fixedly equipped with a rotating rod. According to the wall grooving machine, the adjustment of the position of a grooving machine body is facilitated, at the same time, the rotation of the grooving machine body is facilitated, the lateral and longitudinal grooving at different positions of the wall is facilitated, at the same time, the movement distanceof the vertical plate can be accurately adjusted, so the depth of grooving of a grooving wheel is controllable, the structure is simple, and the wall grooving machine is convenient to use.

Owner:邵帅

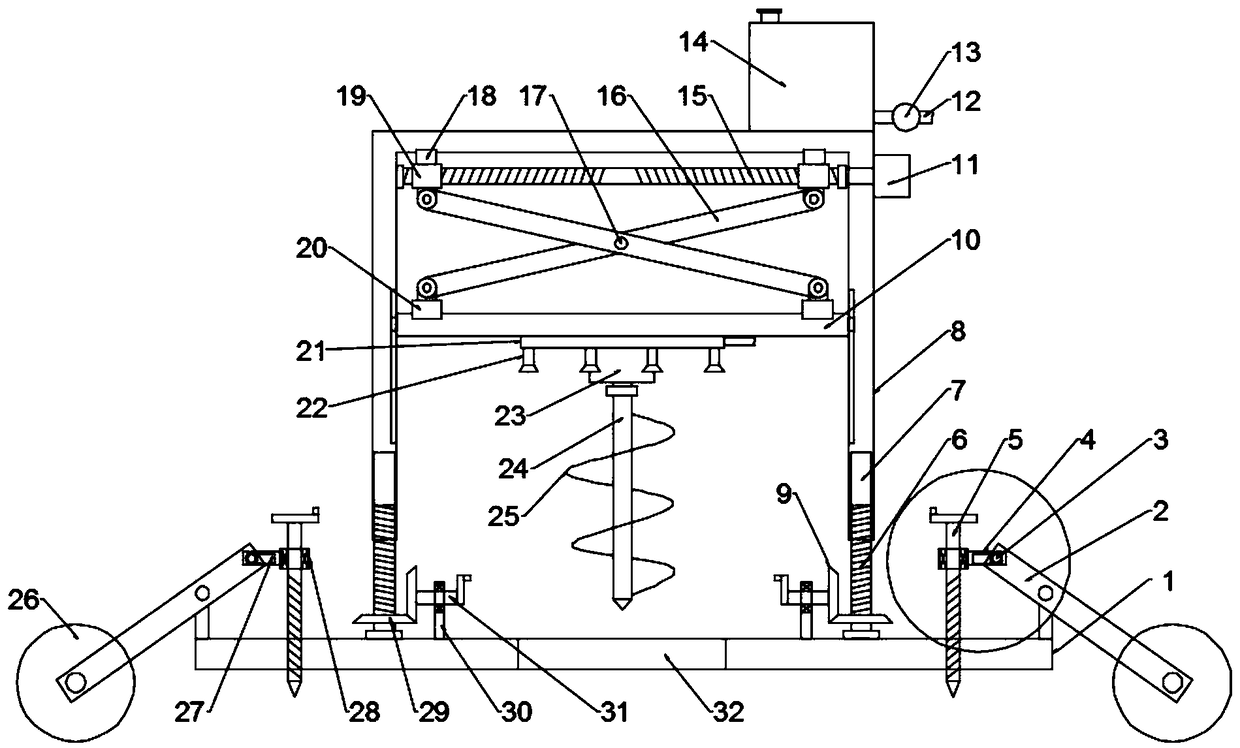

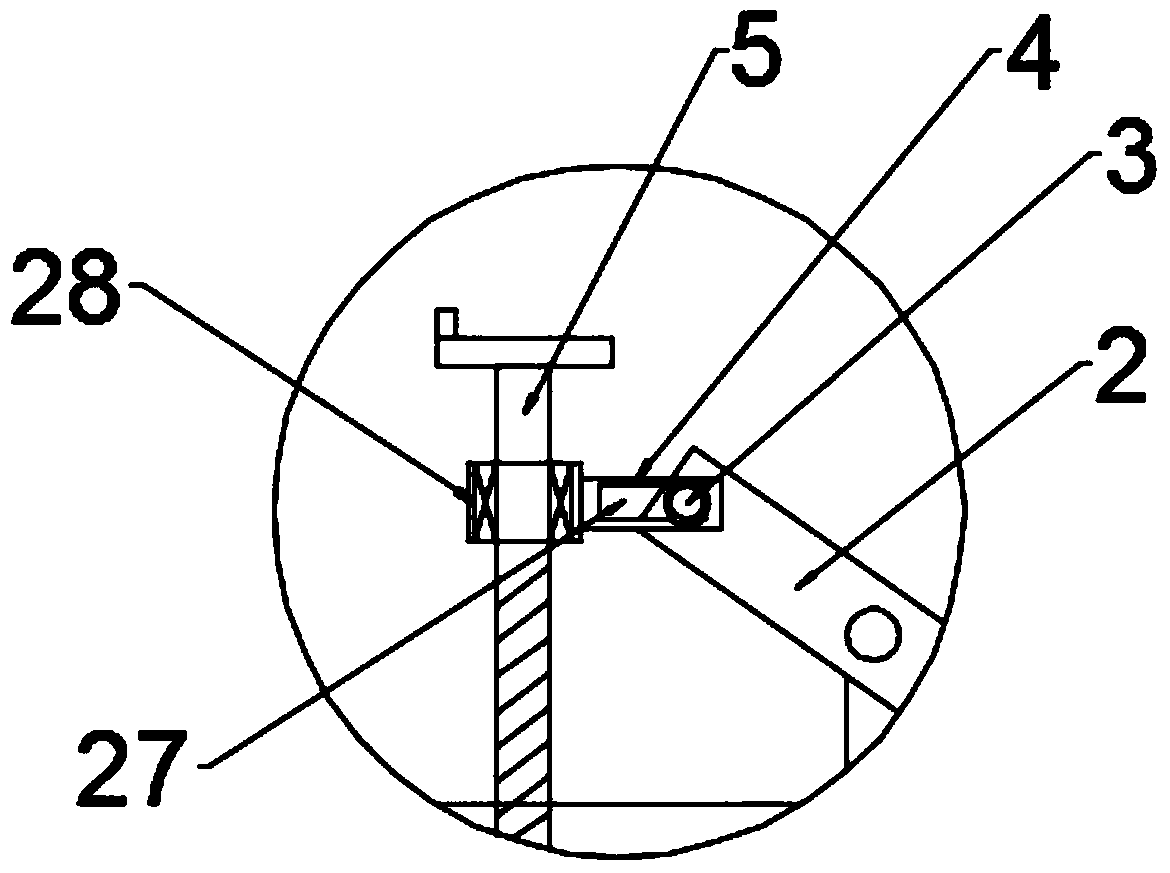

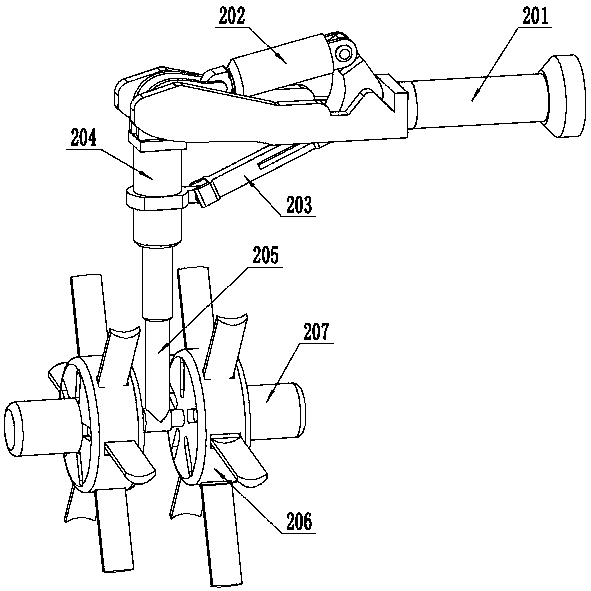

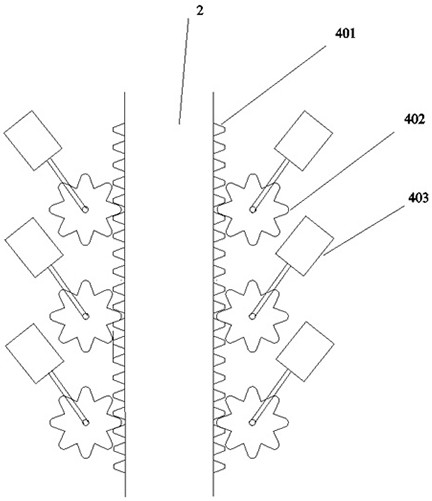

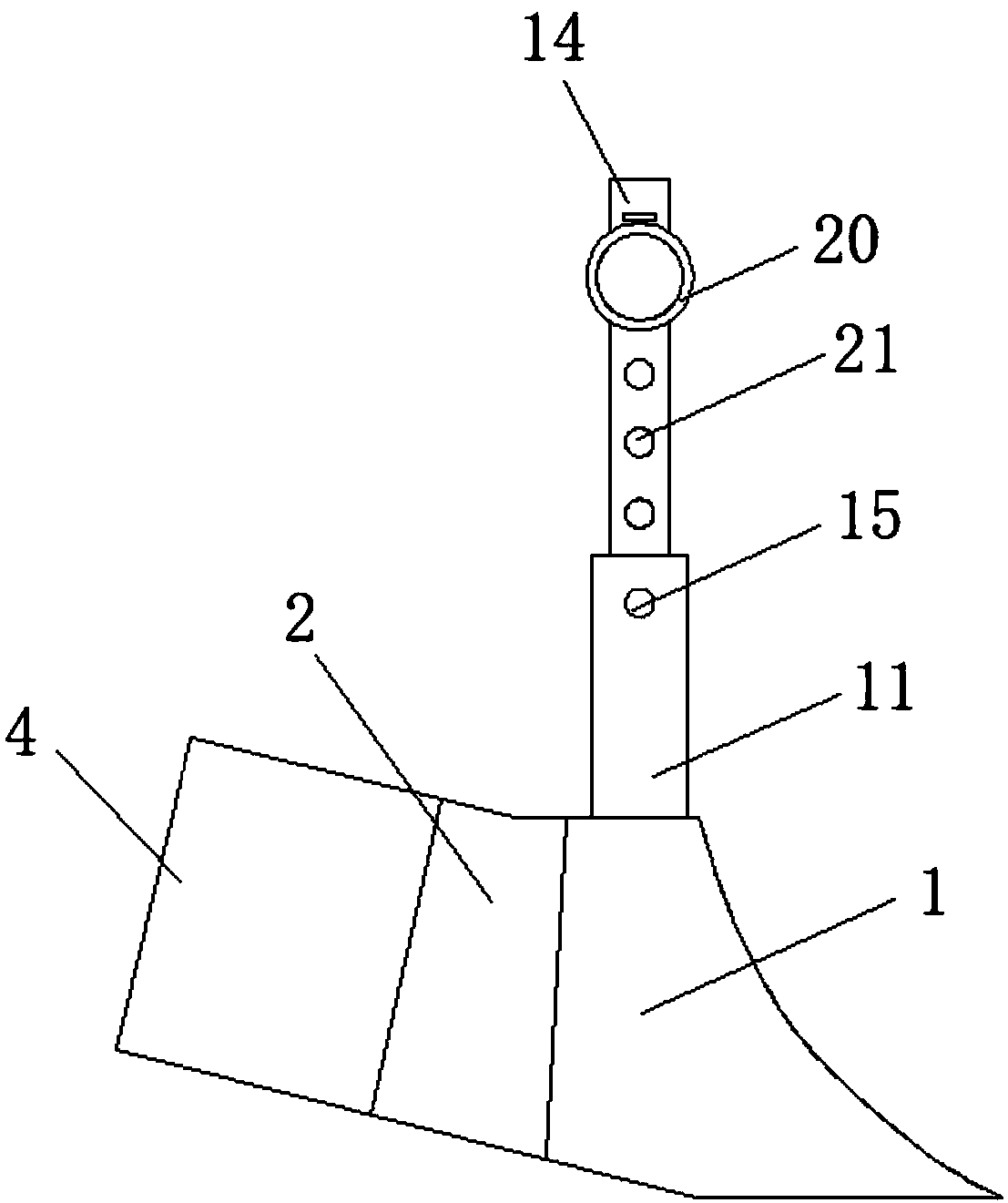

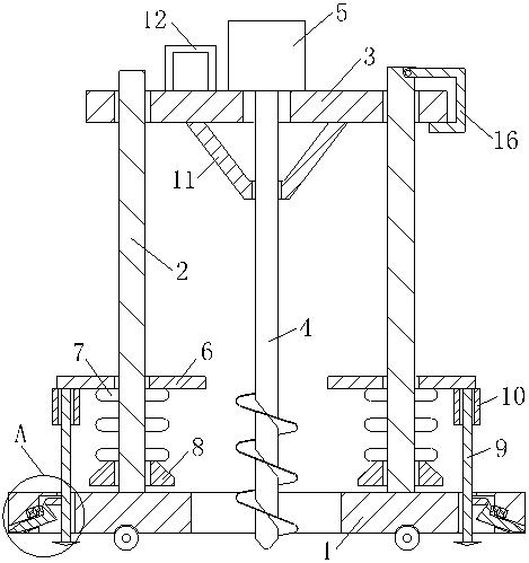

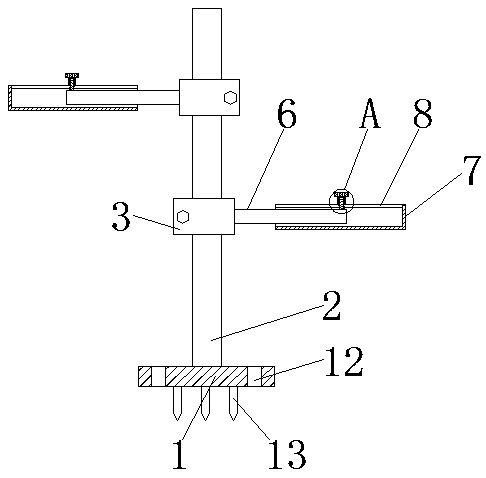

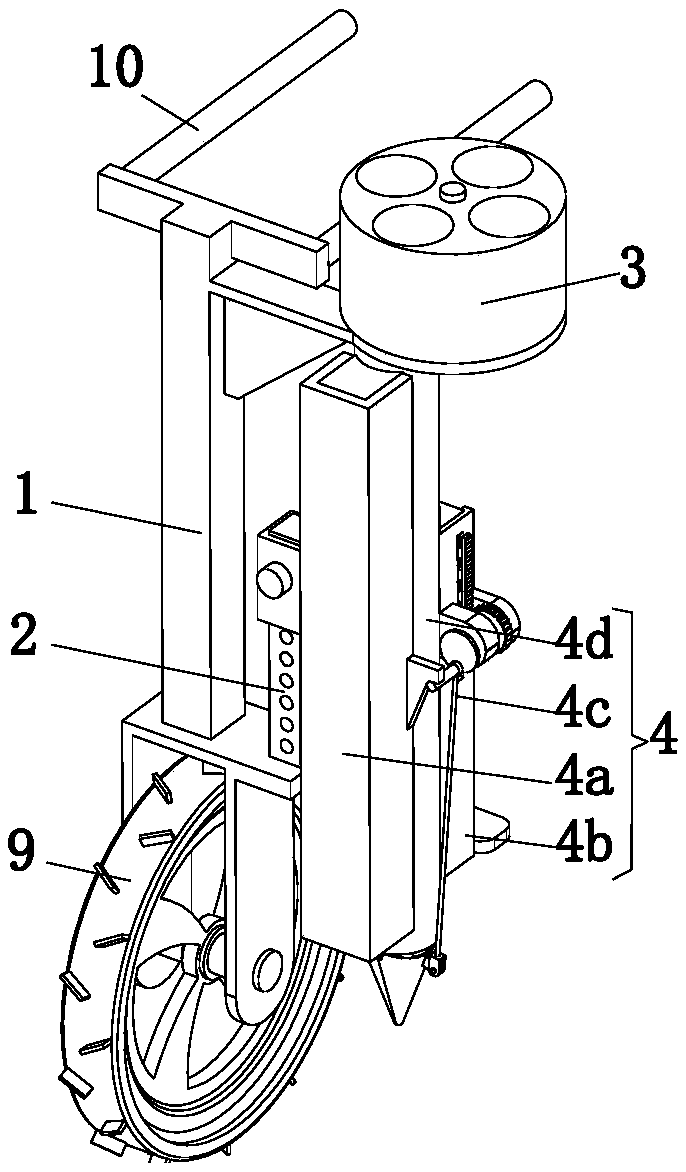

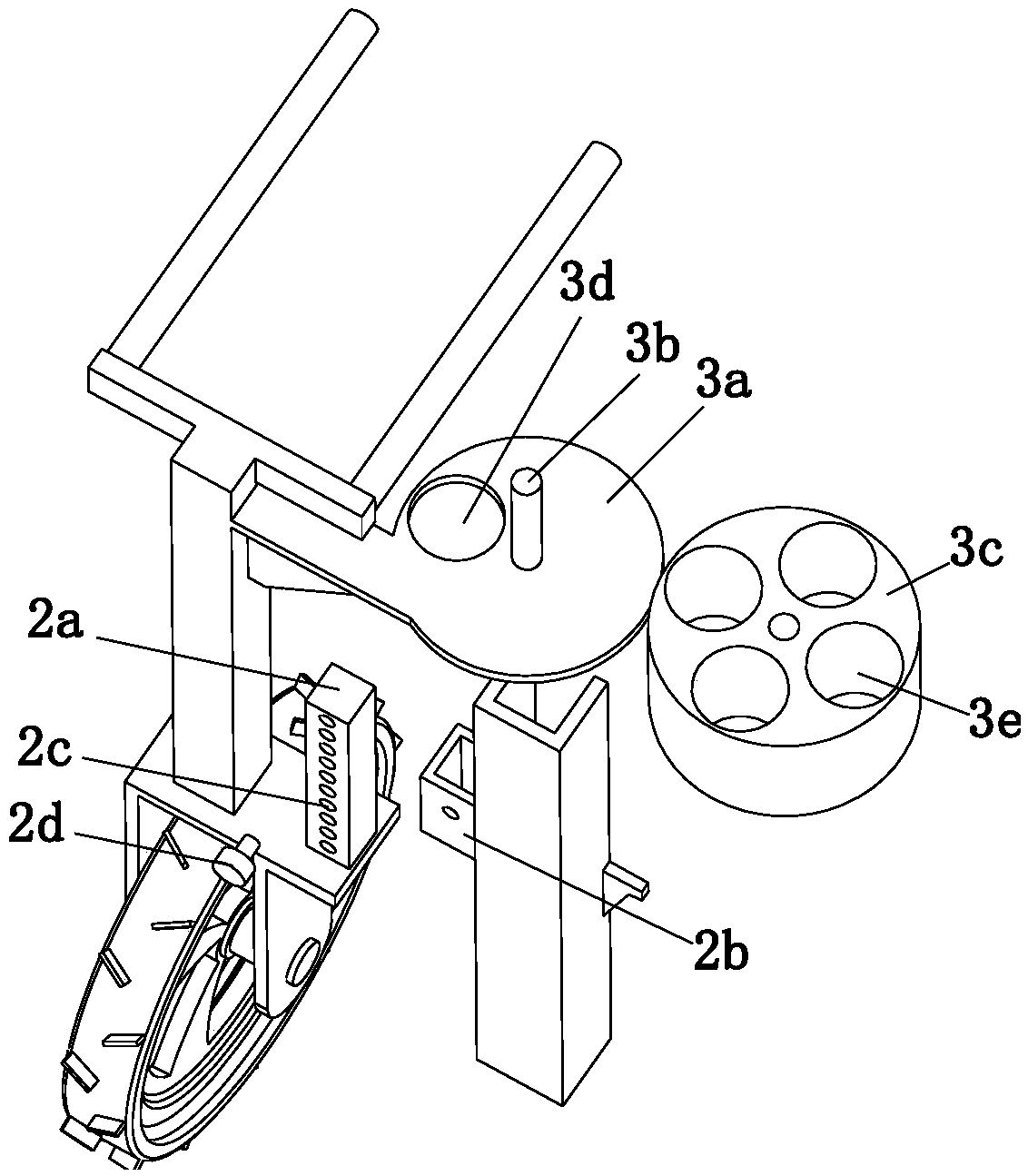

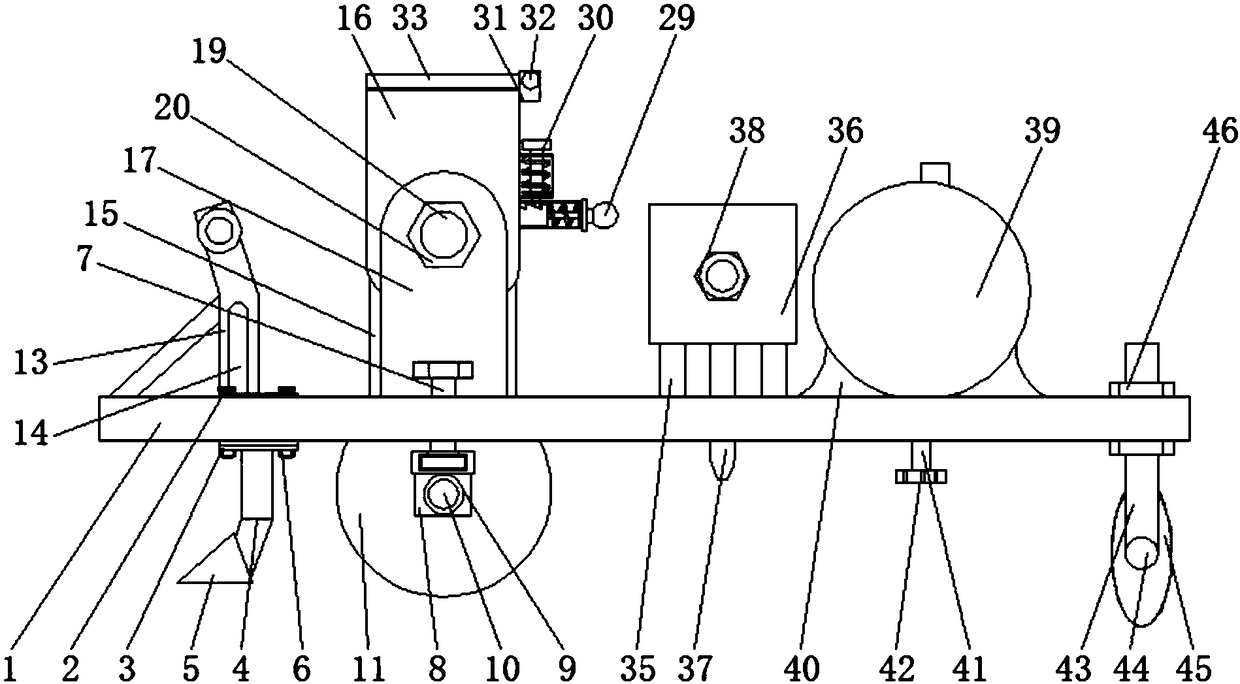

Digging and fertilizing device for forestry planting

InactiveCN108633389AEasy to moveAdjust depthPlantingPressurised distribution of liquid fertiliserSpiral bladeEngineering

The invention discloses a digging and fertilizing device for forestry planting, and the digging and fertilizing device for forestry planting comprises a bottom plate, a drill rod, a spiral blade, a first threaded rod, a first sleeve, a connecting rod, a mounting rod, a roller, a door type frame, a mounting plate, a first motor, an annular water pipe, a spray head, a fertilizer water tank, a two-way screw rod, a second motor, a second sleeve, a connecting rod and an adjusting device, wherein the adjusting device comprises a second threaded rod, a first helical gear and a second helical gear. The digging and fertilizing device is provided with the first threaded rod, the connecting rod, the mounting rod and the roller, the whole device is stably supported and fixed, the movement of the device is facilitated, the digging and fertilizing device is provided with the second motor, the two-way screw rod, the connecting rod, the mounting plate and the adjusting device for adjusting the distance between the drill rod and the ground, so that the drilling depth can be adjusted, the fertilizer water tank, the annular pipe and the spray head are arranged for spraying water and fertilizers to dug pits, and the work efficiency is improved.

Owner:魏焰

Agricultural soil preparing device

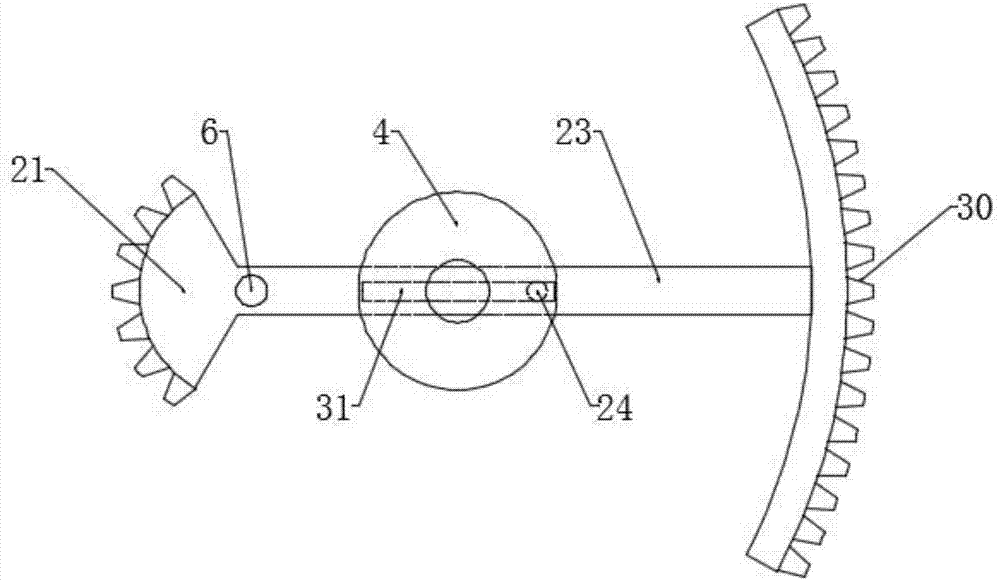

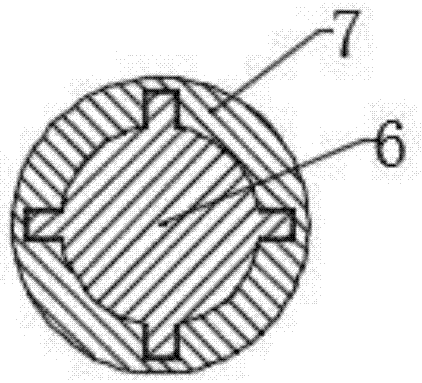

InactiveCN107980257AImprove spraying efficiencyIncrease profitSpadesPloughsAgricultural engineeringBevel gear

The invention discloses an agricultural soil preparing device which comprises a bottom plate, an installation plate, an electric push rod, a furrow plow, an L-shaped pipe, a motor, a round plate, a swing rod, a smashing rake, a sector gear, a first rotating shaft, a sleeve, a first bevel gear, a second bevel gear, a stirring shaft and a first gear. By arranging the motor, the round plate, the swing rod, the sector gear, the first gear, the first rotating shaft, the sleeve, a water tank and a water pump, water and fertilizer are directly sprayed after soil preparing, the spraying range is large, work efficiency is improved, water and fertilizer spraying efficiency is improved, the growth of crops is facilitated, a stirring rod is driven by the stirring shaft to rotate forward and backward,liquid fertilizer is better dissolved in water, and the fertilizer utilization rate is increased; by arranging the smashing rake, an arc-shaped rack, a second gear, a spring and a flat floor, the smashing rake is driven by the swing rod to continuously swing, smashing is sufficient, the range is large, and the work efficiency is improved; by arranging the electric push rod and the installation plate, the soil preparing depth adjusting effect is achieved, and different agricultural planting requirements are met.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

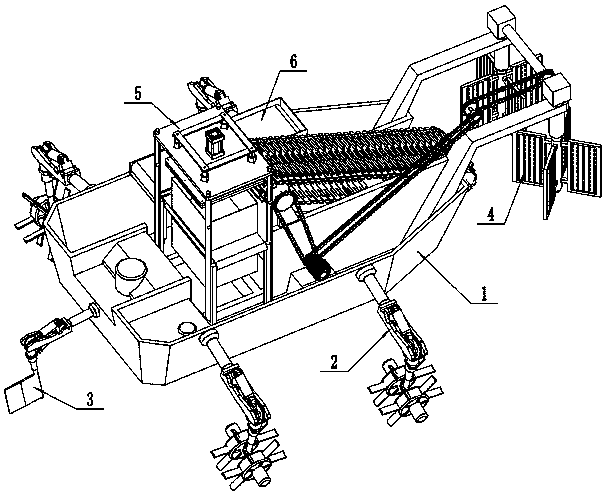

Surface refuse cleaning ship

ActiveCN109159861AAdjustable angleAdjust depthWater cleaningWaterborne vesselsMarine engineeringCompression device

A surface refuse cleaning ship including the hull, travelling device, steering gear, the cleaning unit is fixed above the hull, the compression device is fixed on the hull and arranged behind the cleaning unit, and the box-changing cache unit is fixed on the hull and arranged below the compression device; The present invention causes the hull to travel by means of a traveling device, the steeringdevice controls the direction of the ship 's hull, The garbage is collected into a garbage bin by a cleaning unit, the garbage in the garbage bin is compacted by a compressing device, the filled garbage bin is cached by a cache unit for changing the bin, and the garbage is further collected by the next empty garbage bin, thereby increasing the amount of garbage collected in a single job and improving the work efficiency.

Owner:华琳琳

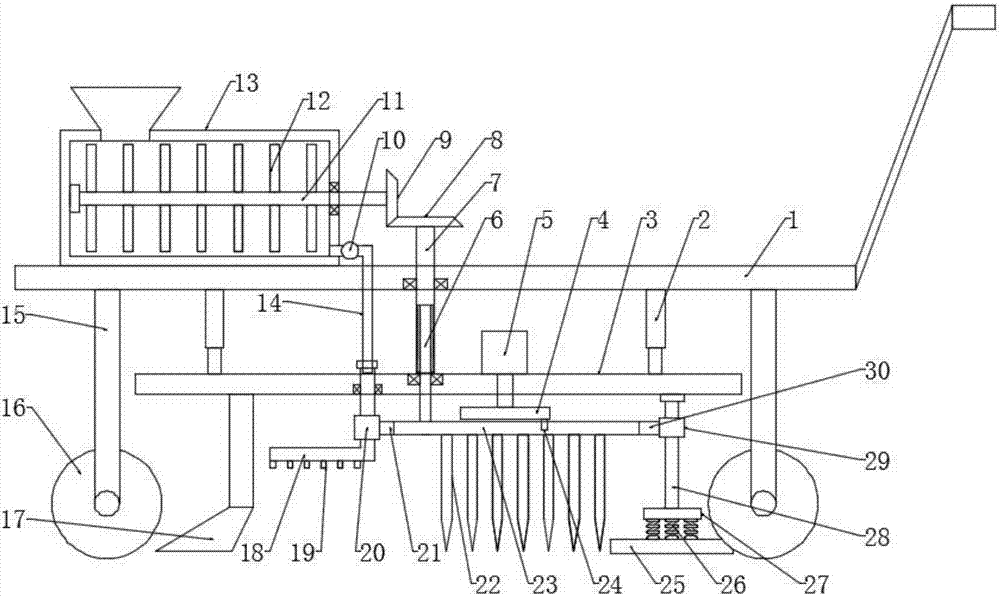

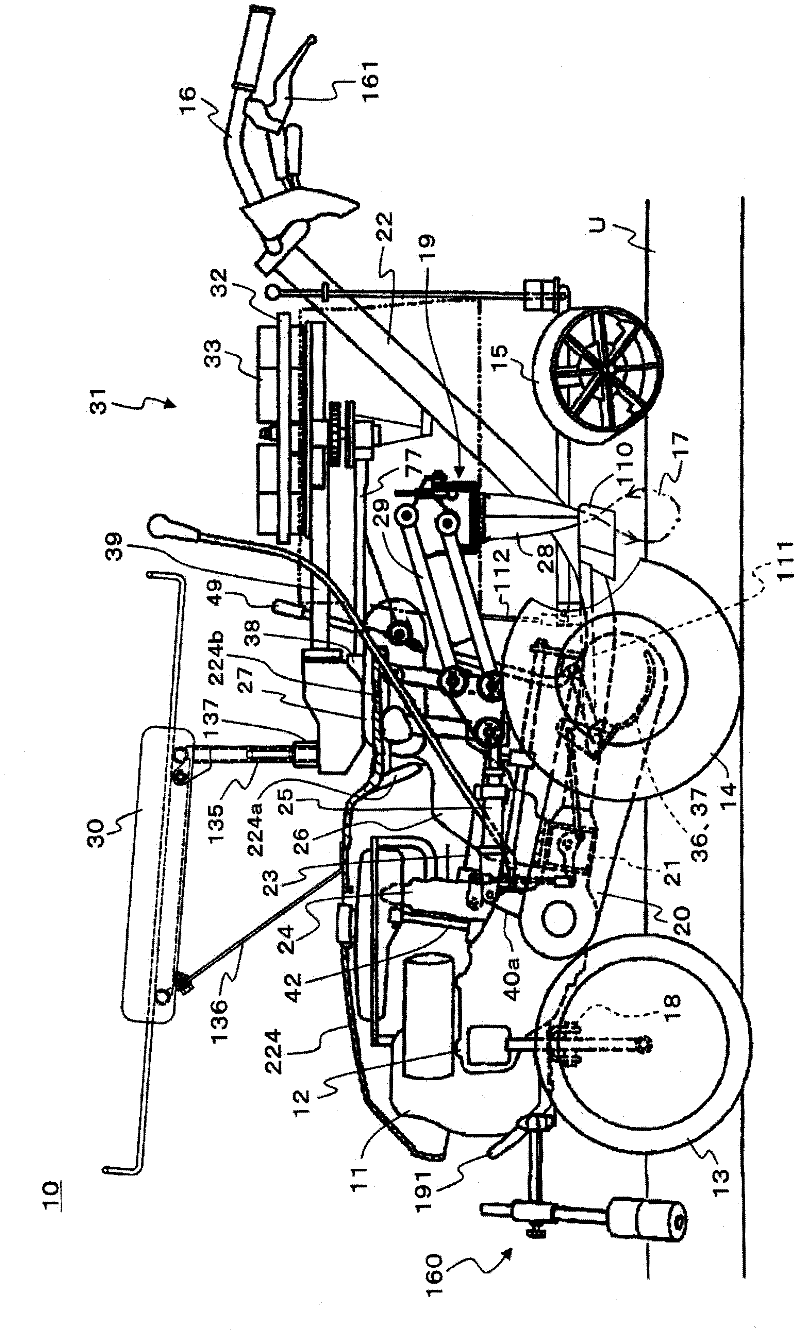

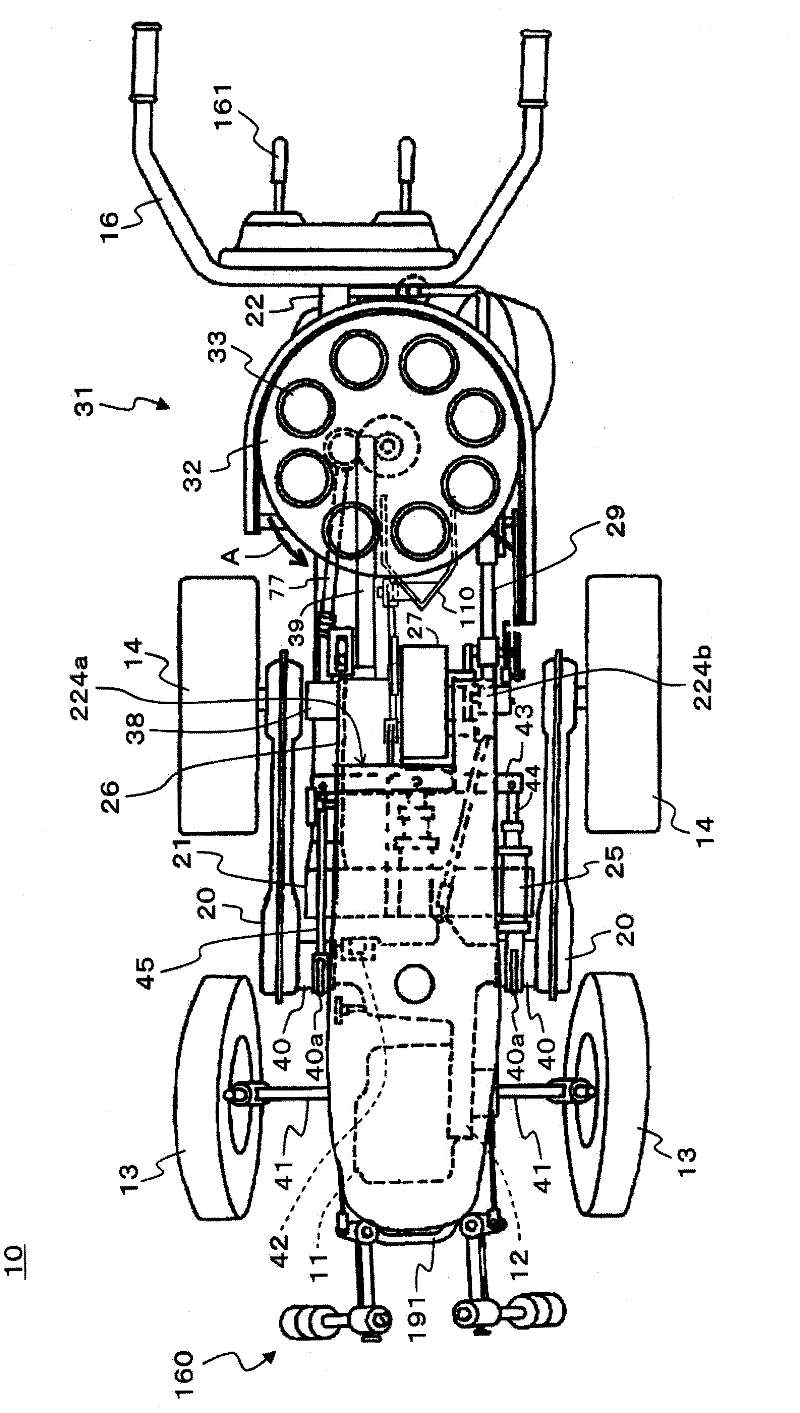

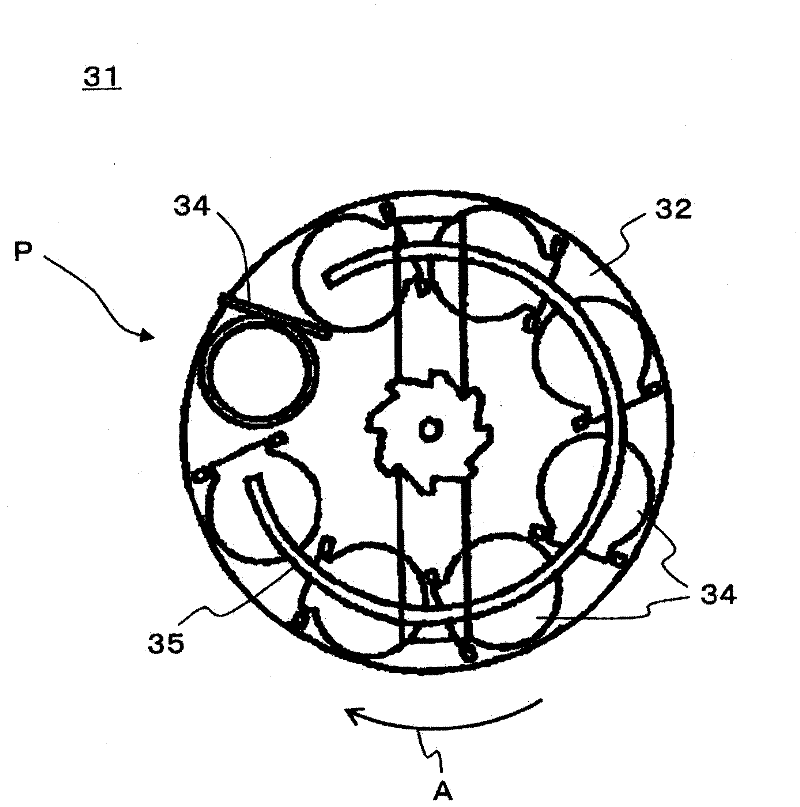

Transplanter

The present invention provides a transplanter which is provided with a planting tool (28) that receives transplanting object from a feeding part that is supported on a driving body and moves to a lower farmland surface for planting. The transplanter is provided with the following components: a pit digging member (110) which forms pits at the periphery of the planting according to driving of the body, and an interlocking lifting mechanism which causes the pit digging member (110) to be interlocked with the planting tool (28) and lifts. The transplanter of the invention is provided with a simple-structure planting part which can form a pit for storing water at the periphery of each planting object which is planted by the planting device.

Owner:ISEKI & CO LTD

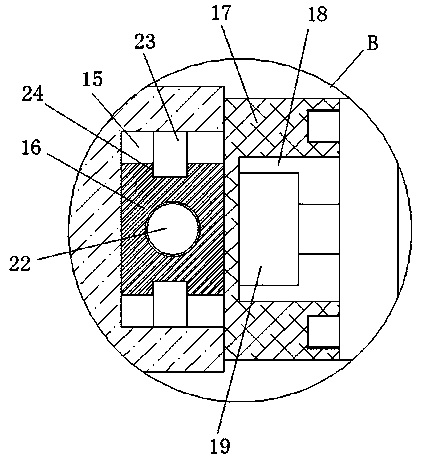

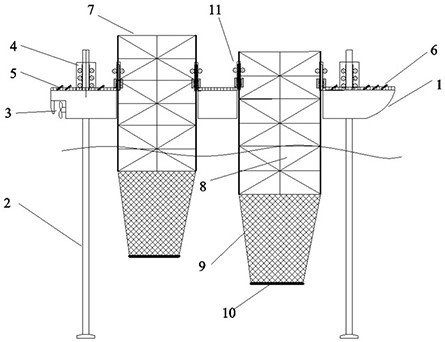

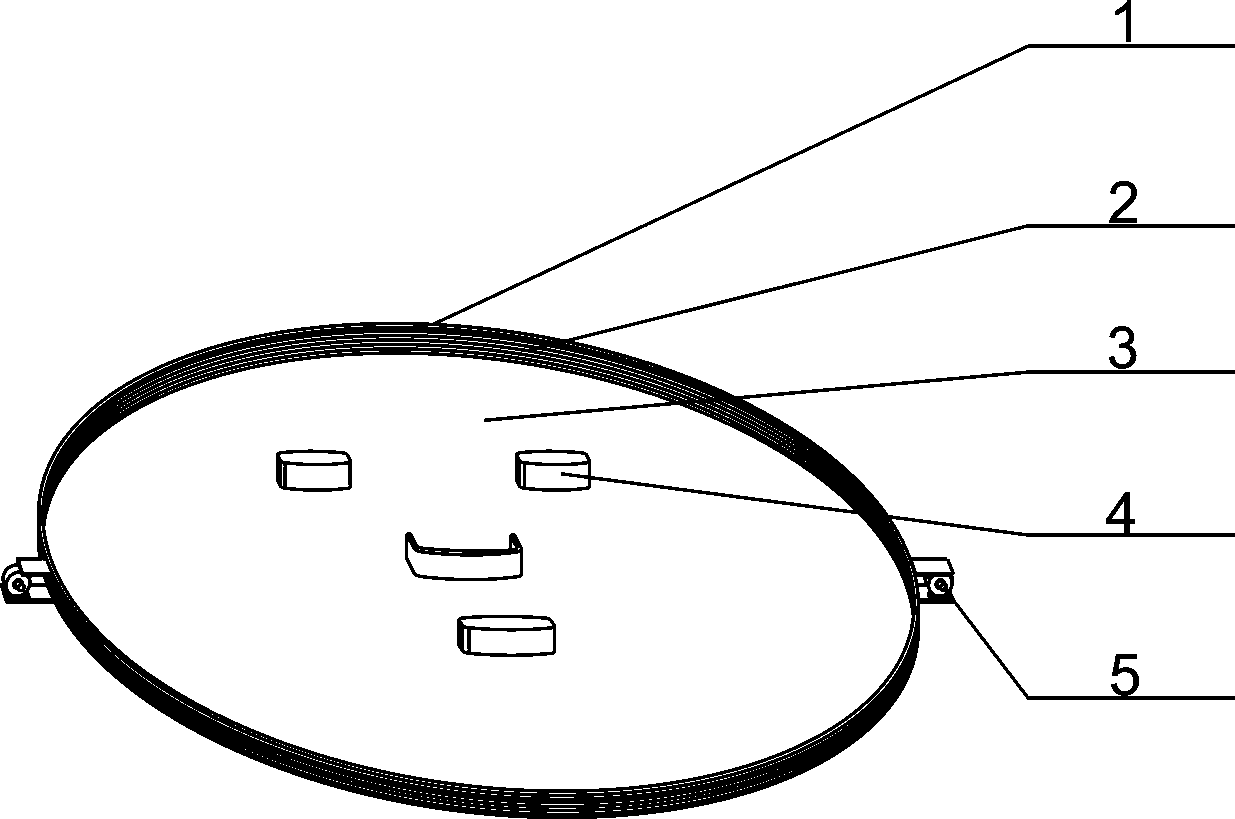

Self-propelled self-elevating mariculture ship and operation method thereof

PendingCN112167135AReduce corrosionReduce shakingClimate change adaptationPisciculture and aquariaHull structureMariculture

The invention discloses a self-propelled self-elevating mariculture ship and an operation method thereof, and relates to the field of ocean engineering equipment design. The self-propelled self-elevating mariculture ship is characterized in that net cages are connected with a hull through net racks, and lifting and fixing of the net cages are achieved by using a net cage lifting and locking system. In the culture state, the culture ship hull is supported at a certain height above the water surface through multiple pile legs, the hull is prevented from being directly acted by wave current loads, and shaking of the hull is reduced; after culture is finished or when typhoon needs to be avoided, the hull is lowered to a floating state through a lifting system, the pile legs are folded, and moving navigation is achieved through a propelling and steering system; compared with a floating type culture ship, corrosion caused by the fact that the hull floats in seawater can be relieved, fatiguedamage of the hull structure under the long-term action of wave flow is avoided, and hull shaking is small; the self-propelled self-elevating mariculture ship has the self-propelled characteristic, and the maneuverability of net cage culture is greatly improved; and the net cages can be prevented from bearing huge wave force on the water surface, shaking of net cage systems is reduced, and the structural safety of the net cage systems is improved.

Owner:JIANGSU UNIV OF SCI & TECH

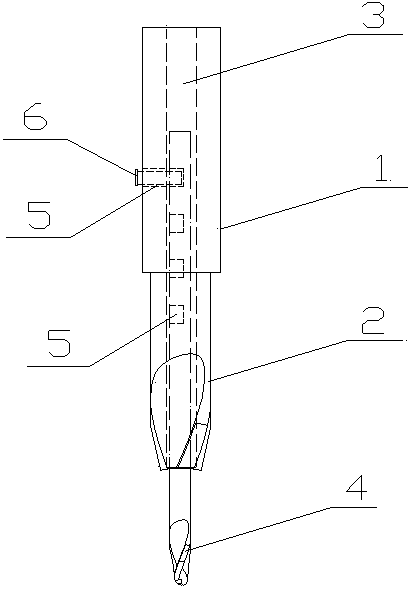

Stepped drill capable of adjusting depth of stepped hole

InactiveCN104107936AAdjustable lengthAdjust depthTransportation and packagingStepped drillsPetroleum engineeringDrill hole

The invention aims to provide a stepped drill capable of adjusting depth of a stepped hole. The stepped drill comprises a drill handle and a first drill blade mounted at the end of the drill handle. The stepped drill is characterized in that the stepped drill is provided with an accommodation hole extending from the head end of the first drill blade into the drill handle or the tail end of the drill handle, a second drill blade is mounted in the accommodation hole and exposed outside the accommodation hole, and the diameter of the second drill blade is small than that of the first drill blade. The stepped drill is provided with a fixing structure used for fixing the first drill blade and the second drill blade relatively. The stepped drill is capable of adjusting the exposure length of the second drill hole blade since the first drill blade is of hollow structure, thus, depth of the stepped hole drilled is adjustable, and the stepped drill is more convenient to use and highly practical.

Owner:SUZHOU WENDING MOLD

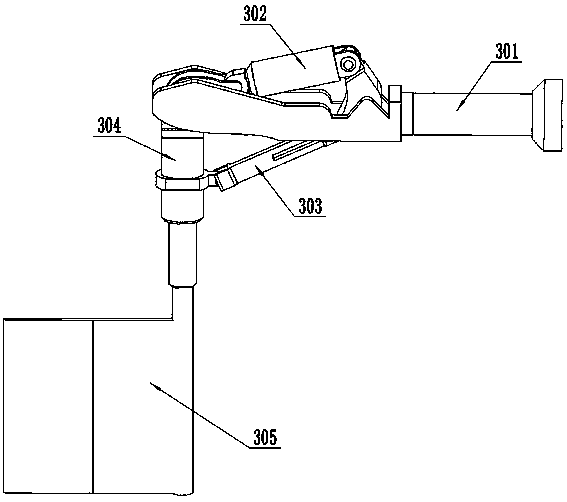

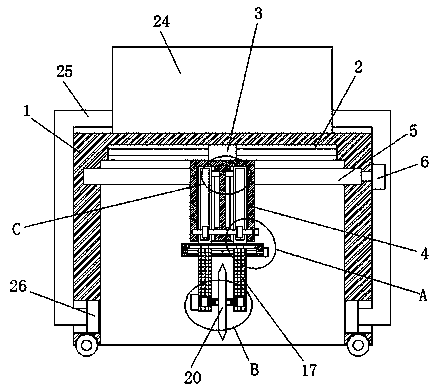

Heat coating device and heat coating process method

ActiveCN110721877AImprove fluidizationEasy to recycleLiquid surface applicatorsCoatingsMechanical engineeringPhysics

The invention relates to the technical field of heat coating, in particular to a heat coating device and a heat coating process method. The heat coating device comprises a workpiece grabbing mechanism, a rotating mechanism and a fluidized bed. The fluidized bed comprises a dust collection hood, a fluidized bin arranged in the dust collection hood and a first fluidized plate arranged in the fluidized bin. The fluidized bin is divided by the first fluidized plate into a fluidized pool and a first air inflation cavity up and down. The first inflation cavity communicates with the fluidized pool through micropores in the first fluidized plate. Feeding openings are formed above the fluidized pool. The first air inflation cavity is provided with a first air inlet. The workpiece grabbing mechanismcan grab to-be-coated heated workpieces, and the to-be-coated portions of the workpieces are stretched in or moved out of the fluidized pool. The rotating mechanism can enable the workpieces and thefluidized pool to rotate oppositely. The heat coating device has the advantages that the fluidization effect of heat coating powder is good, the workpiece immersion procedure in the heat coating process is quite reasonable, the workpieces can be in sufficient contact with the heat coating powder in a fluidized state, and stability of heat coating quality can be improved.

Owner:广东省机械研究所有限公司

A road pavement sewing machine

The invention discloses a road pavement sewing machine, including a mounting box, wherein the bottom of the mounting box is an opening, and the top inner wall of the mounting box is provided with a moving groove. A moving block is slidably installed in that moving groove, and a fixing plate is fixedly installed at the bottom of the moving block. A screw rod is rotatably mounted on the inner wallsof both sides of the mounting box, and the screw rod is threadably connected with the fixing plate; a first rotating electric machine is fixedly mounted on one side of the mounting box; an output shaft of the first rotating electric machine is welded with one end of the screw rod. Two sliding slots are arranged at the bottom of the fixing plate, and sliding plates are slidably mounted in the two sliding slots. The machine is convenient to adjust the height and the position of the saw blade, to cut at different positions, to adjust the cutting depth, to prevent the dust from being larger when the saw blade is cut by spraying water through the nozzle, and to replace the saw blade when the saw blade is seriously worn.

Owner:熊振

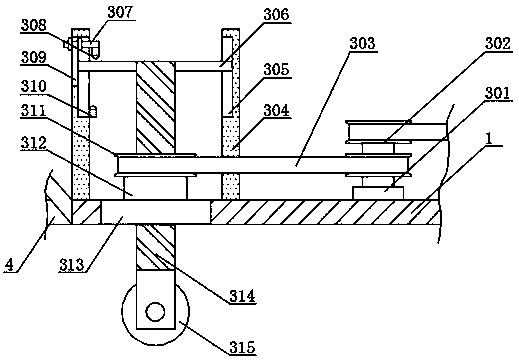

Garden fertilization device

InactiveCN104380894AGuaranteed depthGuaranteed to be consistentPlantingWatering devicesLand levelingFertilizer

The invention provides a garden fertilization device and belongs to the technical field of machinery. The problem in the prior art that garden vegetation can not be fertilized at high efficiency and high utilization rate is solved. The garden fertilization device comprises a rack and a bottom plate, wherein a fertilization mechanism is fixed on the bottom plate and comprises a chemical fertilizer box; the lower end of the bottom plate is hinged to a sealed door; a ditching structure is further fixed on the bottom plate; a land leveling and irrigation mechanism is fixed on the bottom plate and comprises a water tank, a water pump and a nozzle; the land leveling and irrigation mechanism further comprises a vertical air cylinder, a longitudinal air cylinder I, a longitudinal air cylinder II, a transverse air cylinder and a mounting plate; a pushing plate I is fixed at the end part of a piston rod of the longitudinal air cylinder I; a pushing plate II is fixed at the end part of a piston rod of the longitudinal air cylinder II; and the transverse air cylinder is arranged at the other side of the mounting plate in a sliding manner. The garden fertilization device has the advantages that ditching and fertilization can be carried out automatically and fertilized ditches are filled up and irrigated so that the working efficiency and the utilization rate of chemical fertilizers are improved.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

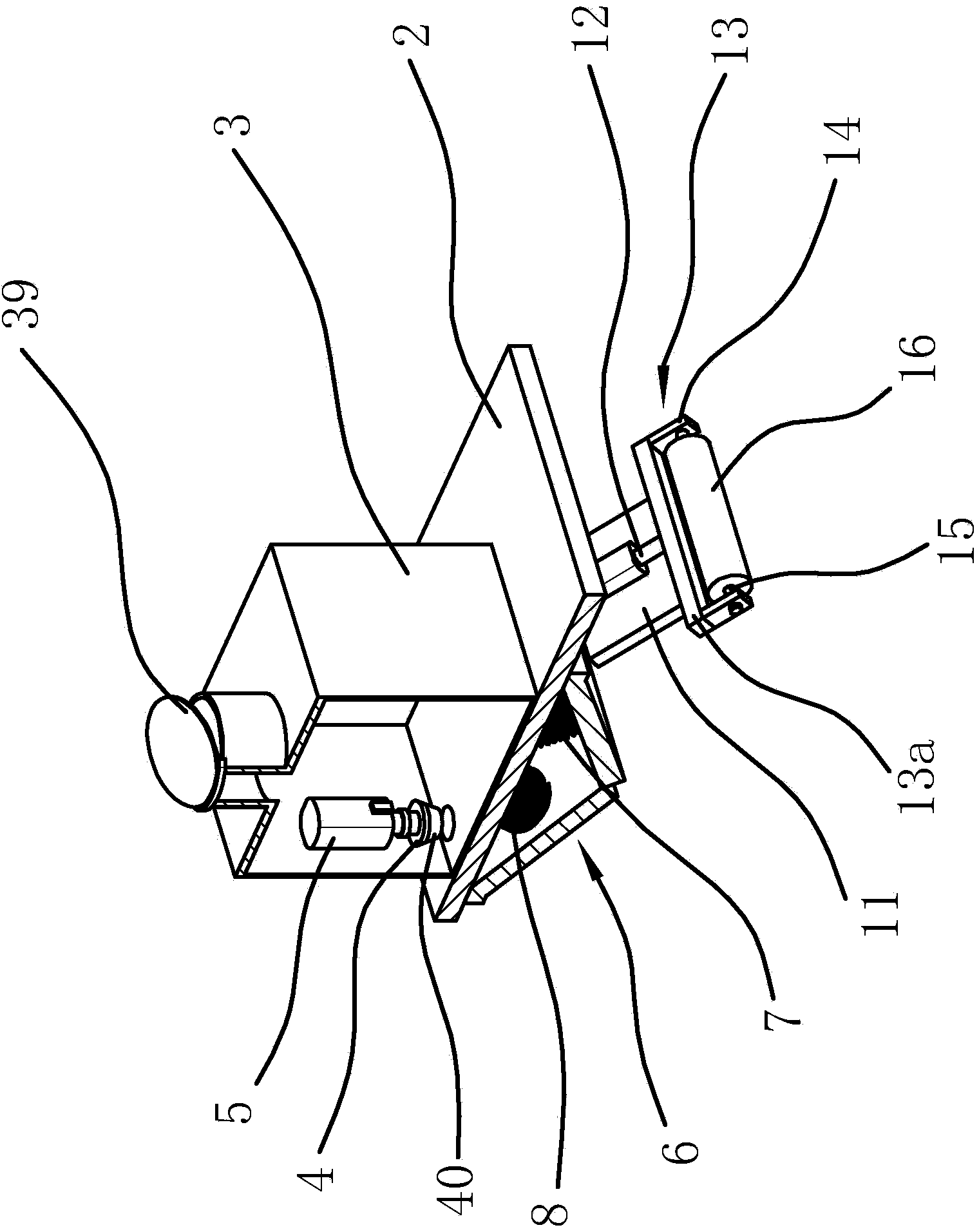

Wood surface grooving machine convenient to adjust cutting angle

InactiveCN107856142AEasy to set upAdjust the tilt angleWood mortising machinesWood slotting machinesEngineeringAngle of inclination

The invention discloses a wood surface grooving machine convenient to adjust a cutting angle. The wood surface grooving machine convenient to adjust the cutting angle comprises a bottom plate, whereinan upper surface of the bottom plate is fixedly connected with an upper surface of a first support plate through two first electric push rods; and the upper surface of the first support plate is fixedly connected with two side faces of a connecting plate through a first movable device. According to the wood surface grooving machine convenient to adjust the cutting angle, through arranging the first electric push rods, people can conveniently adjust a grooving depth of a circular wood surface; and through arranging a third fixing plate, a first moving plate, a second moving plate, a fourth fixing plate, a third moving plate, a fourth moving plate, a third electric push rod, a first pin shaft, a second pin shaft and a third pin shaft, an inclination angle of a connecting plate can be adjusted through controlling the third electric push rod to extend or shorten, so that an inclination angle of a cutter is conveniently adjusted, and people can conveniently open grooves in different angleson the circular wood.

Owner:盱眙县鹏程铜业有限公司

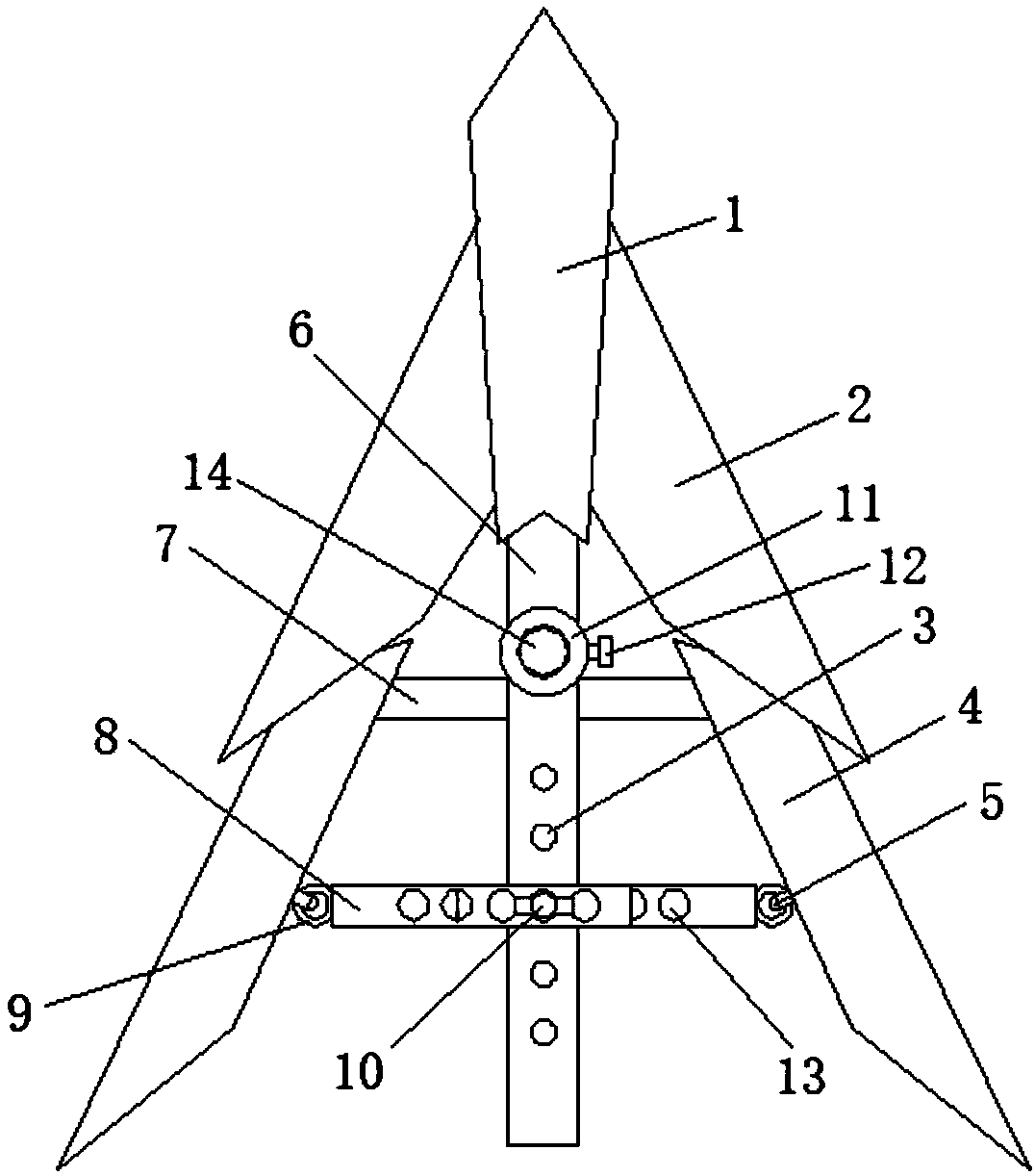

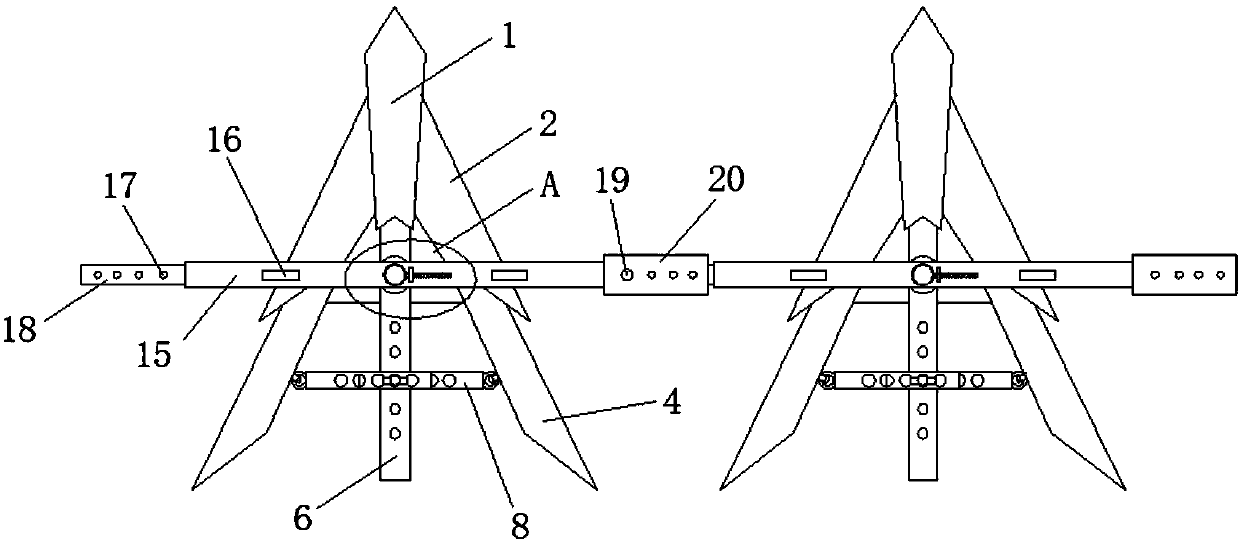

Adjustable furrow opener for crop planting

InactiveCN107683659AAdjustable widthAdjust depthPlantingFurrow making/coveringAgricultural engineeringAgricultural machinery

The invention relates to the technical field of agricultural machinery, in particular to an adjustable ditch opener for planting crops, comprising a body consisting of a shovel head and two fixed soil dividing plates, the two fixed soil dividing plates are respectively It is arranged on both sides of the shovel head, the middle part of the inner side of the shovel head is connected with a horizontally arranged first cross bar, and the bottom surface of the first cross bar is connected with a second cross bar perpendicular to it. The two ends are respectively connected with movable soil dividing plates by hinges, and the middle parts of the inner sides of the two movable soil dividing plates are connected with vertically arranged winding rods through connecting blocks. The movable sleeves on the surrounding rods are provided with connecting rings, The ring is connected with a connecting plate. The invention has the advantages of simple structure, convenient use and easy adjustment, and can separately adjust the width and depth of ditching and the number of one-time ditching, and can meet various use requirements during ditching.

Owner:民勤县金诚农业发展有限公司

Cement concrete pavement grooving device for road engineering

InactiveCN109837829AHeight adjustableEasy steeringRoads maintainenceHydraulic cylinderRoad engineering

The invention discloses a cement concrete pavement grooving device for road engineering and relates to the technical field of road engineering; the cement concrete pavement grooving device comprises abase plate; a steering device is fixedly connected to the middle of the upper surface of the base plate; adjusting devices are fixedly connected to four corners of the base plate, and cutting machines are fixedly connected to the middles of the left side face and the right side face of the base plate. The invention discloses the cement concrete pavement grooving device for road engineering. A hydraulic cylinder is arranged, so the device can rotate around a first bearing; therefore, the device can be conveniently steered; a forward and reverse rotation motor is arranged, so rotation of a threaded ring is realized under the action of a synchronous belt; therefore, a screw rod ascends and descends under a spiral action; by arranging an upper proximity switch, the height of the upper proximity switch can be adjusted up and down under the combined action of a bolt assembly and an adjusting hole; when a sliding rod is close to the upper proximity switch, the forward and reverse rotation motor can stop rotating, therefore the purpose of adjusting the height of the cutting machine is achieved, and the purpose of adjusting the cutting groove depth is achieved.

Owner:李帅

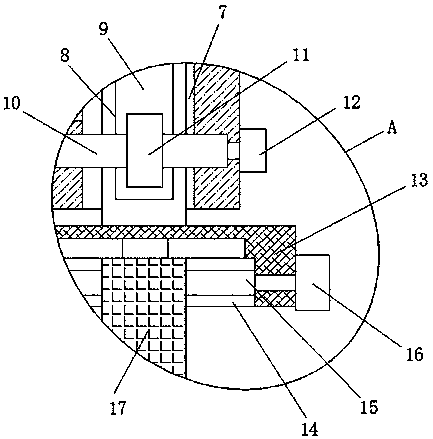

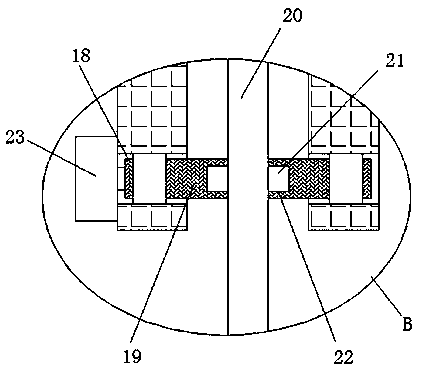

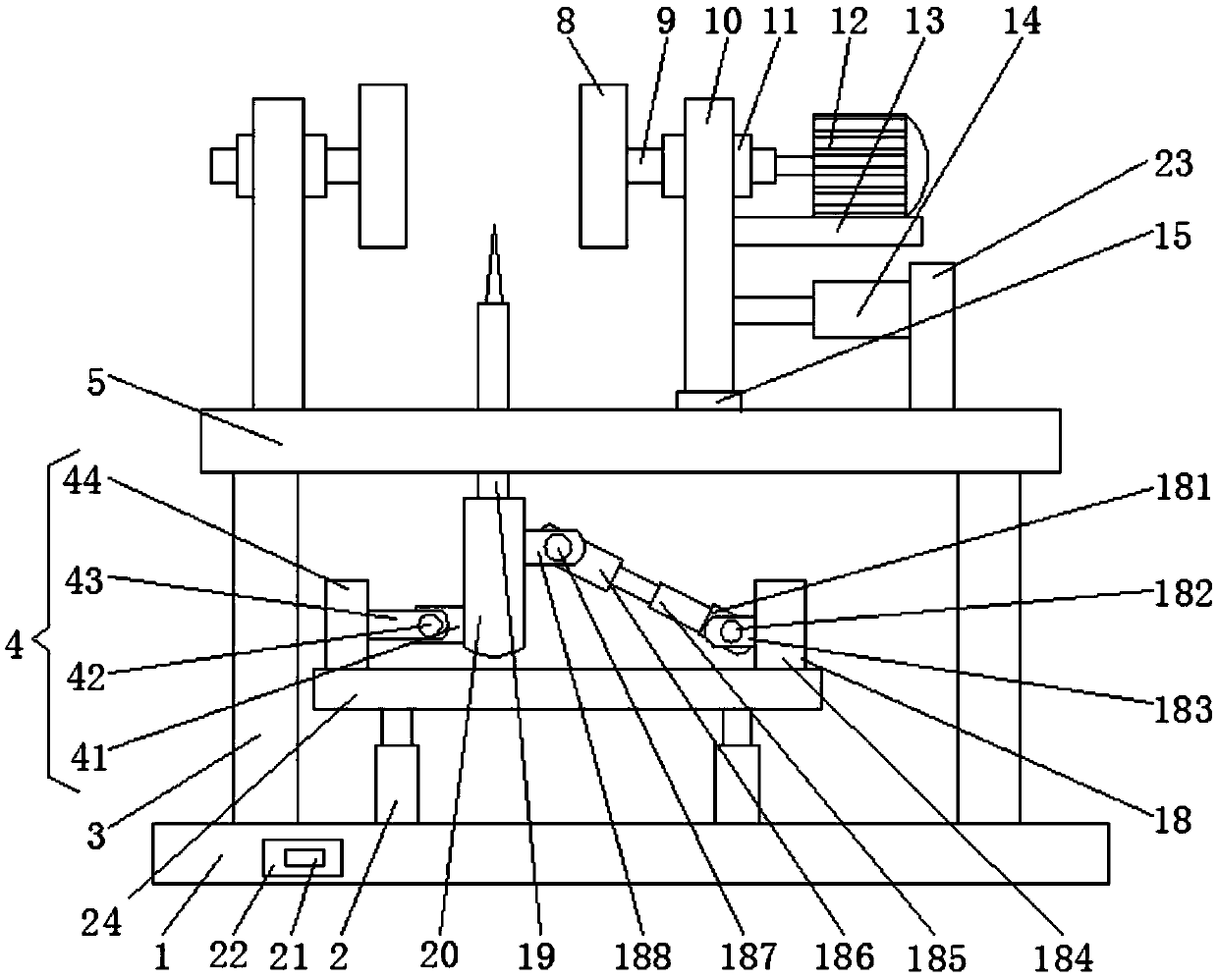

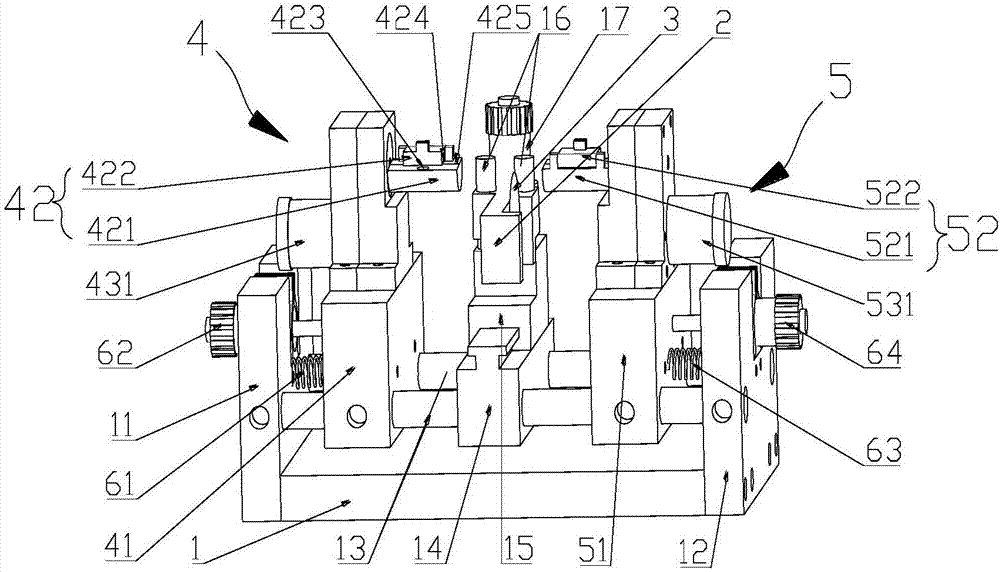

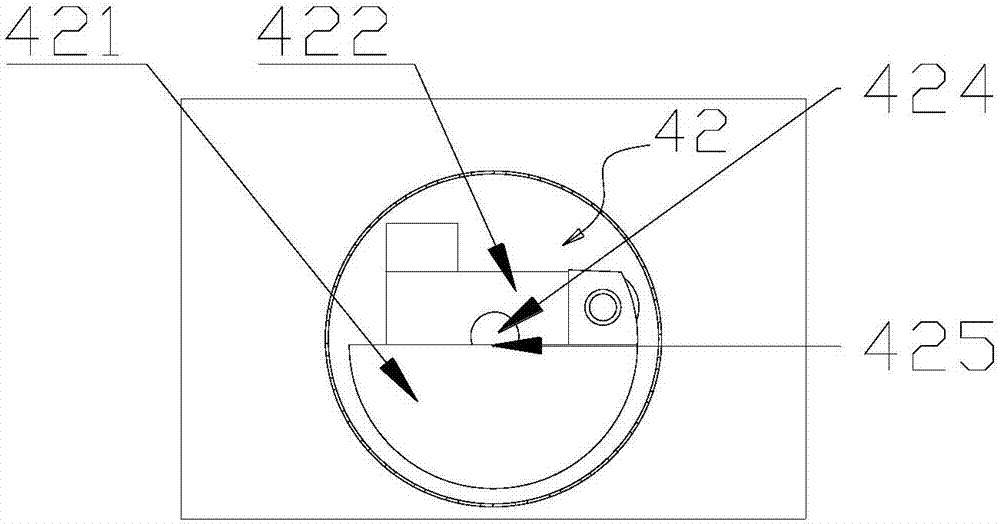

Optical fiber cutting device and cutting method

PendingCN107450128AImprove yieldImprove cutting efficiencyCoupling light guidesEngineeringStructural engineering

The invention discloses an optical fiber cutting device. The device comprises a base; the base is provided with a cutter holder; the cutter holder is provided with a cutter; the base is provided with a left clamping mechanism and a right clamping mechanism which are located at two sides of the cutter holder respectively; the left clamping mechanism comprises a left clamping seat, a left clamping assembly arranged on the left clamping seat and a left driving assembly for driving the left clamping assembly to rotate; and the right clamping mechanism comprises a right clamping seat, a right clamping assembly arranged on the right clamping seat and a right driving assembly for driving the right clamping assembly to rotate. According to the optical fiber cutting device of the invention, the left clamping assembly and the right clamping assembly are adopted to firmly clamp an optical fiber; the optical fiber rotates on the cutter; the cutter is adopted to cut the outer surface of the optical fiber so as to leave scratches on the outer surface of the optical fiber, so that the optical fiber will be fractured at the scratches; the fractured surfaces of the optical fiber are flat; and cutting efficiency is high; and the optical fiber does not move during the cutting process. The invention also discloses an optical fiber cutting method. According to the method, the optical fiber is rotated; the cutter cuts the outer surface of the optical fiber so as to leave scratches on the outer surface of the optical fiber, so that the optical fiber is fractured, and the optical fiber can form a certain cutting surface angle.

Owner:NANJING UNIV OF POSTS & TELECOMM INST AT NANJING CO LTD

Facial mask and preparation method thereof

PendingCN110384648AOvercome inability to prepareMeet repair and maintenanceCosmetic preparationsAntipyreticPreservativeGlycerol

The invention relates to a facial mask, in particular to a facial mask and a preparation method thereof. The facial mask is prepared from the components in parts by weight: 0.8-2 parts of a suaeda salsa extracting solution, 0.5-1 part of a wheat extract, 0.5-1 part of a salix leaf extracting solution, 0.5-1 part of witch hazel powder, 2-3 parts of hydroxypropyl methylcellulose, 0.06-0.08 part of hydrogenated lecithin, 2-3 parts of a vitamin E, 3-5 parts of carbomer, 2-4 parts of glycerol, 0.2-0.26 part of a preservative, and 85-90 parts of water. According to the facial mask, suaeda salsa is finely selected, and the defects that other suaeda salsa cannot be used for preparing facial masks and has very little efficacy are overcome; and by controlling the additive amount of the suaeda salsa,different types of the facial masks placing emphasis on the whitening and freckle removing type, the brightening, smoothening and moisturizing type, the inflammation diminishing and acne removing type, the red blood removing type, the sensitive cell repairing type, the tightening and face-lift type and the like correspondingly are obtained, and various problem skins are repaired and cared.

Owner:碱蓬高新科技(盘锦)有限公司

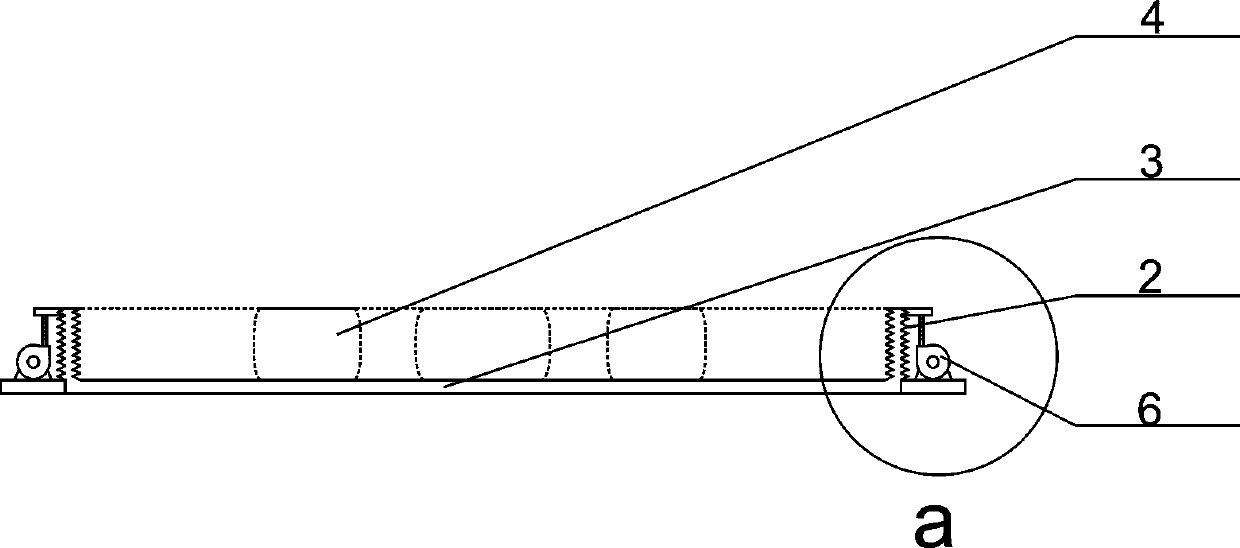

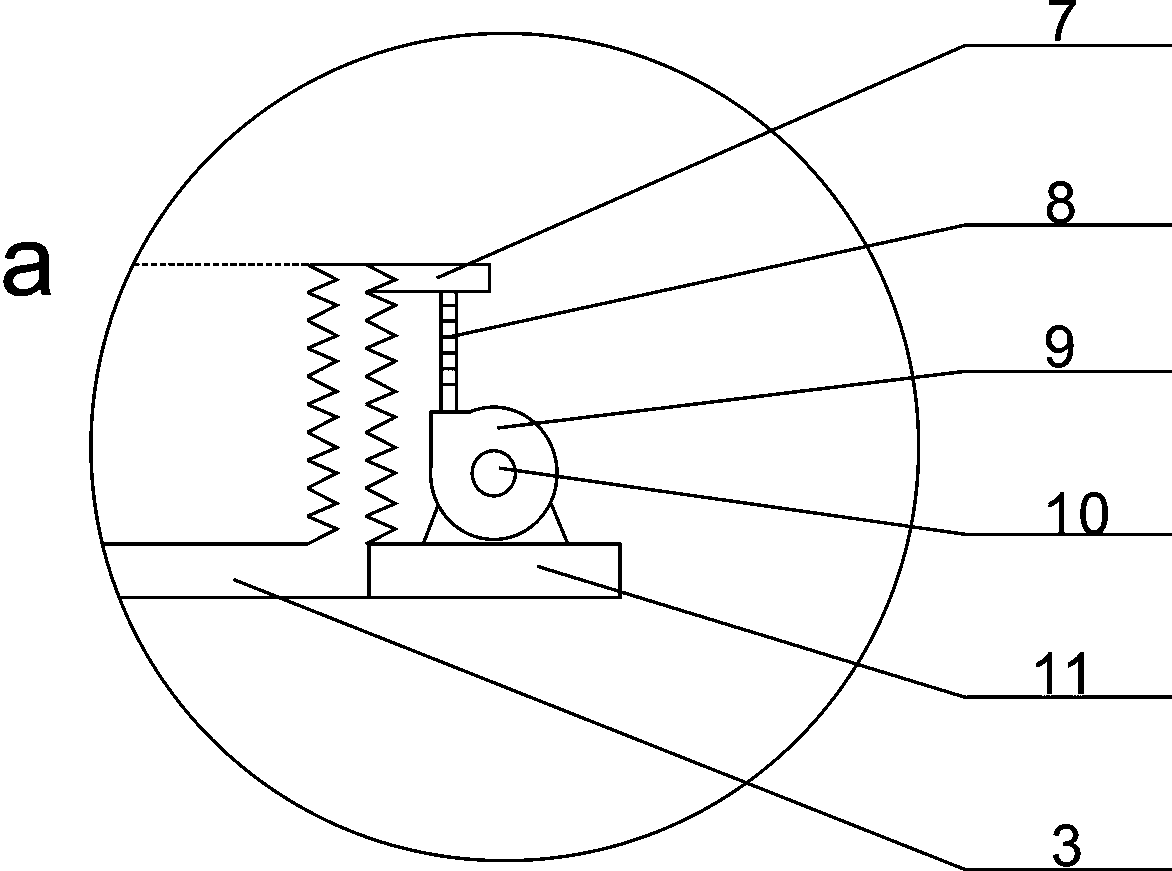

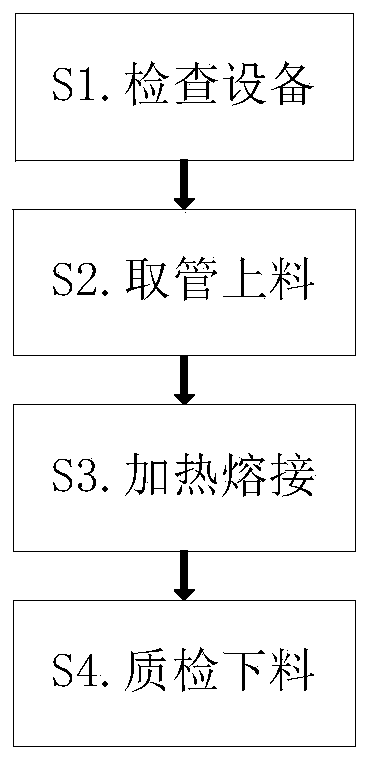

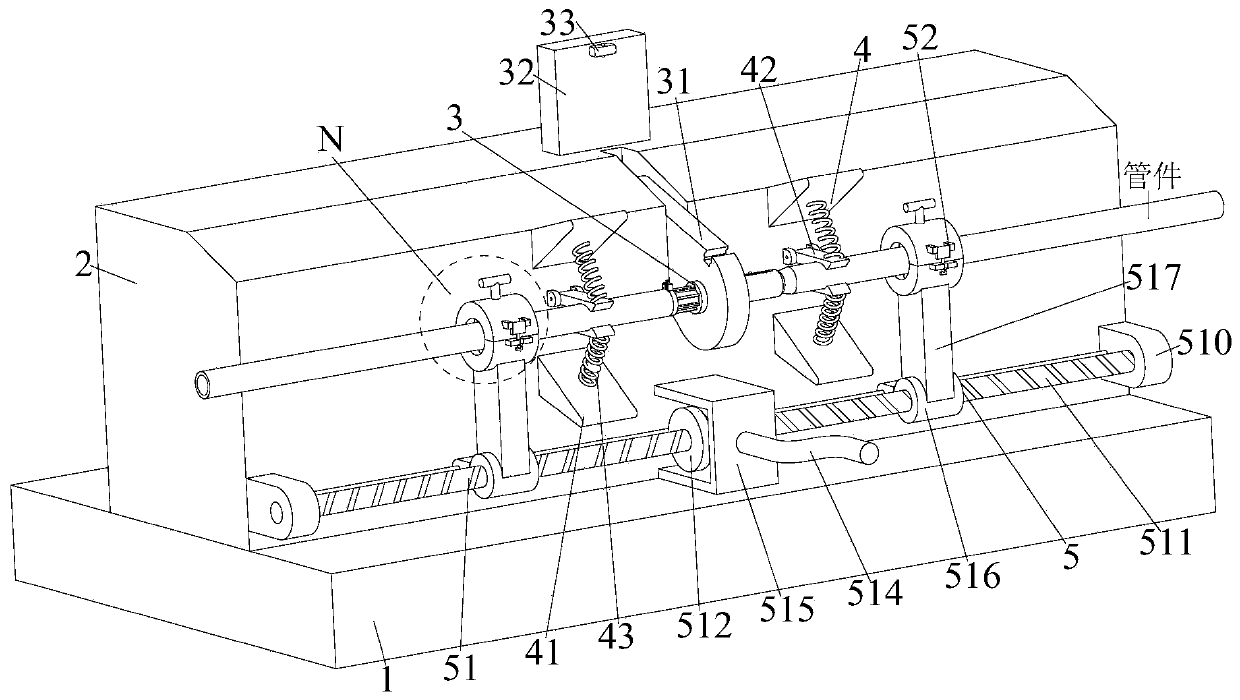

PPR hot water plastic pipe hot melting connection processing method

The invention relates to a PPR hot water plastic pipe hot melting connection processing method. The method involves a workbench, a mounting block, a hot melting device, two limiting devices and a moving device, wherein the upper end of the workbench is provided with the mounting block, the hot melting device is arranged in the middle part of the front end of the mounting block through a hinge, thelimiting devices are symmetrically arranged on the left and right sides of the hot melting device, and the moving device is arranged at the lower side of the front end of the mounting block. The PPRhot water plastic pipe hot melting connection processing method can solve the problems that when a plastic pipe is manually welded, the welding part of the pipe is manually heated and softened firstly, and then manual welding is performed, and thus the welding failure is caused due to the fact that the manual welding time is long, and the welding part is cooled; and when an existing plastic pipe hot melting connection equipment performs welding, the welding part of the pipe is directly heated and softened, after the pipe is softened, the hot melting connection equipment welds the plastic pipestogether directly, and the pipes are prone to slide relatively during welding, and thus the pipe welding failure is caused.

Owner:圣大管业(芜湖)科技有限公司

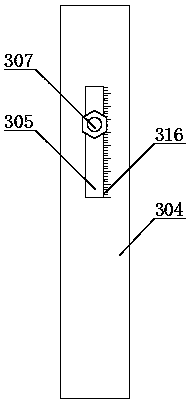

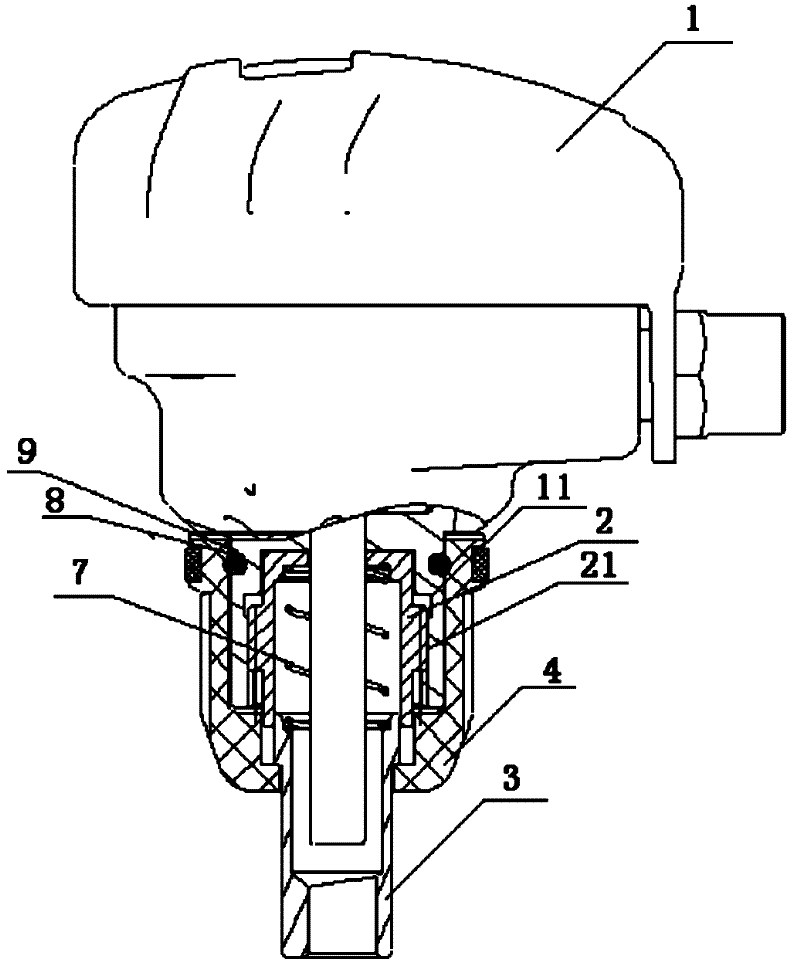

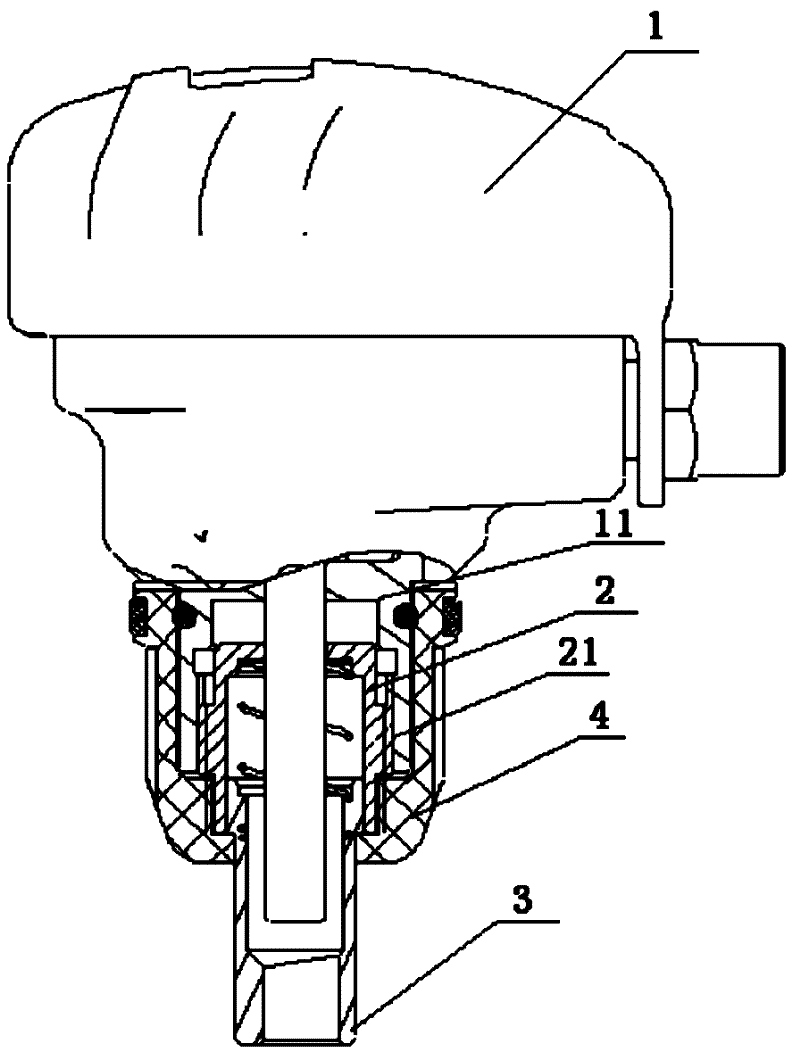

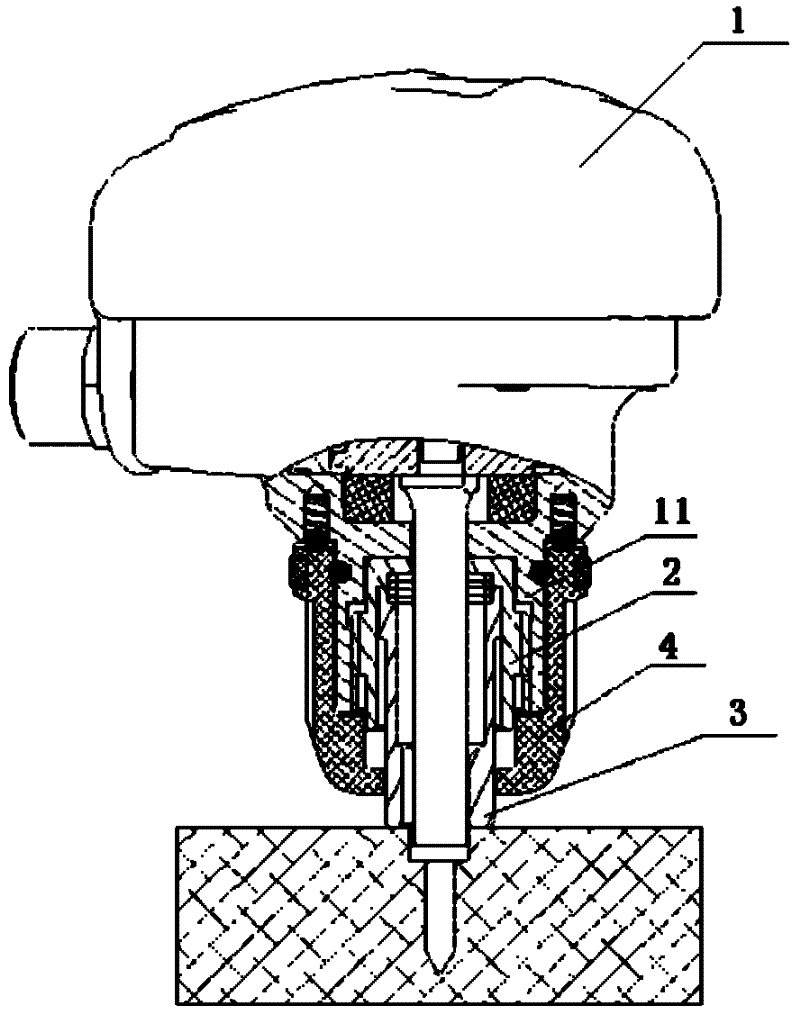

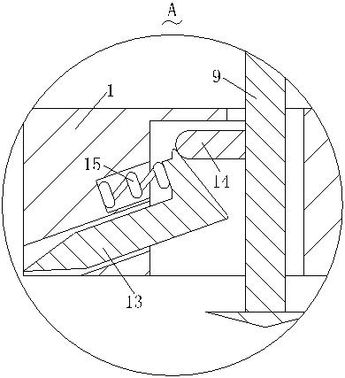

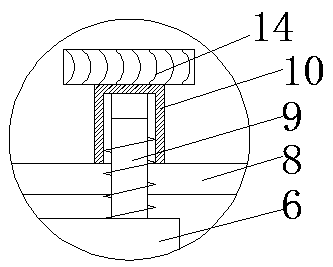

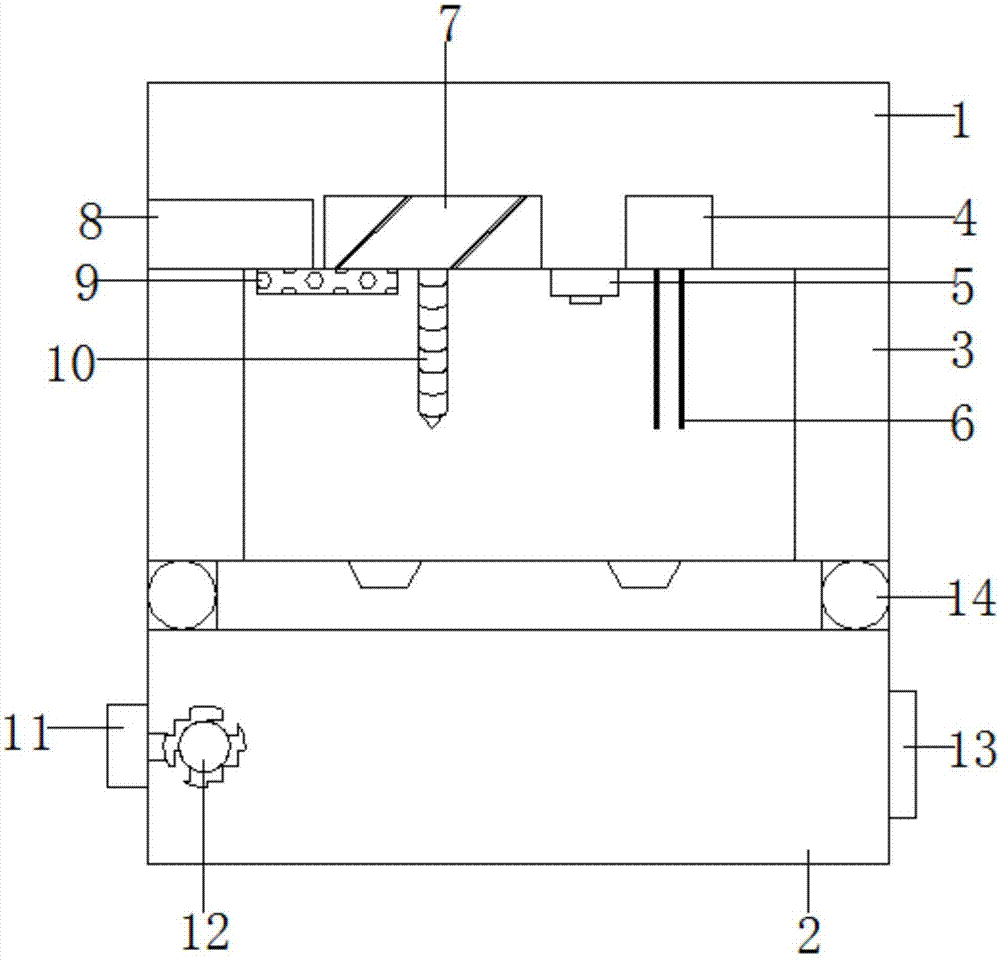

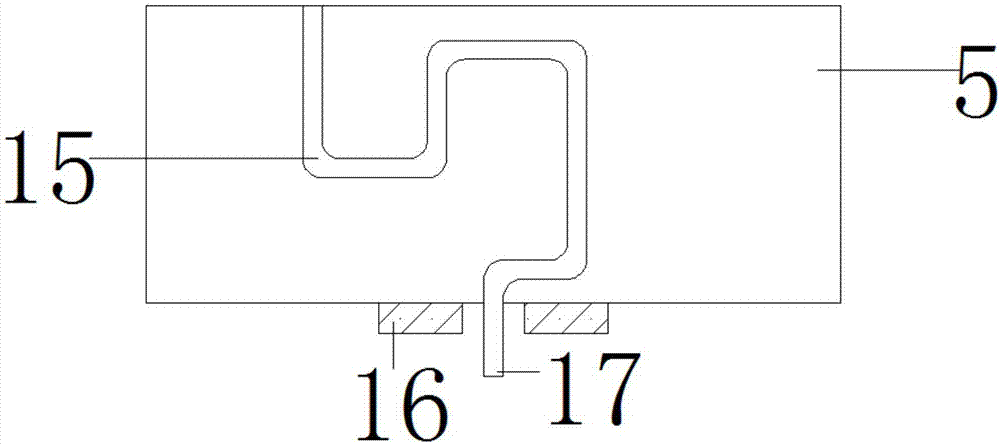

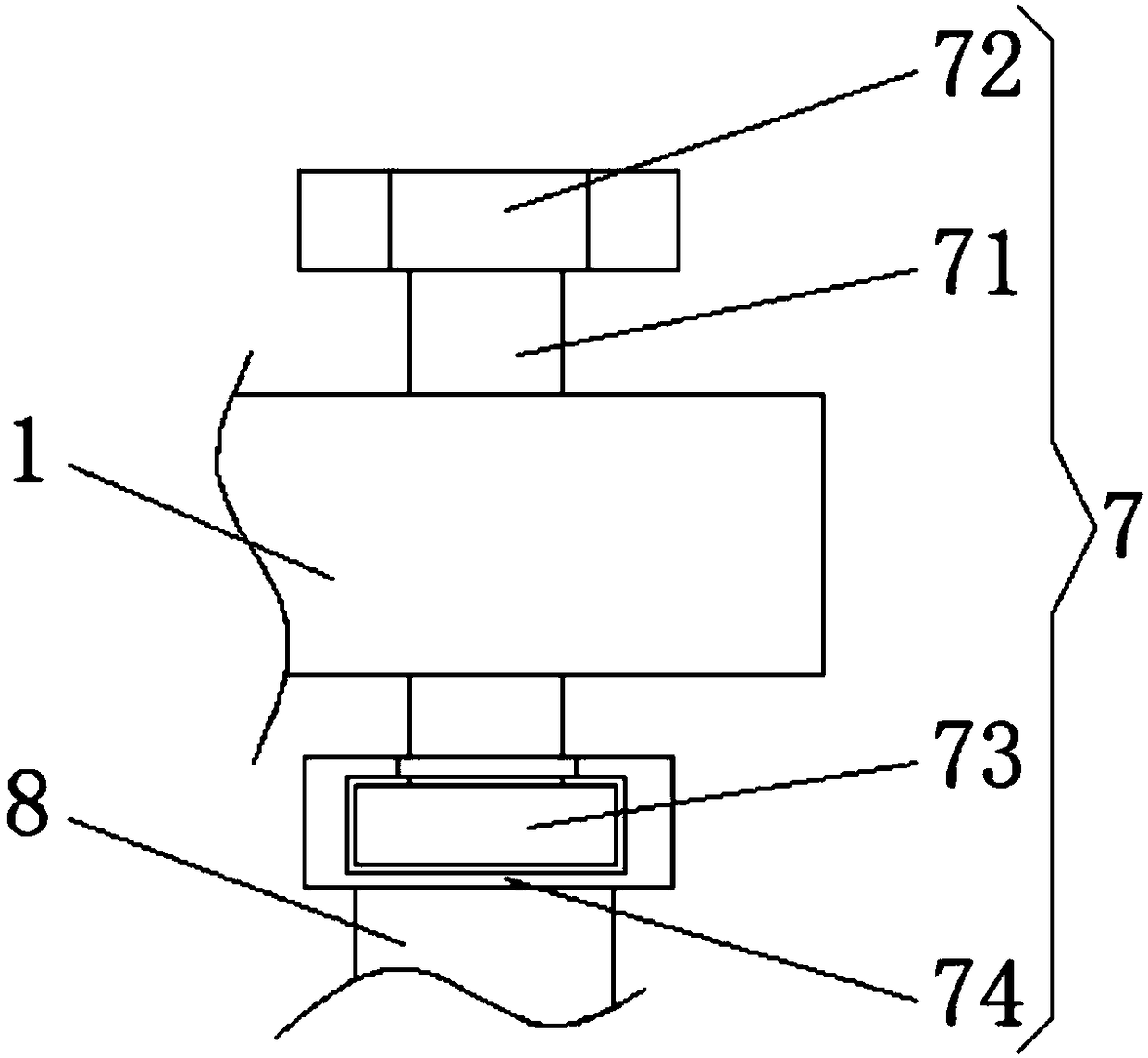

Palm hammer nailing depth adjustment mechanism

ActiveCN102267127AStepless adjustment of nailing depthCompact structureNailing toolsMechanical engineering

Owner:杨明军

Drill hole inside secondary grouting leaking stoppage device

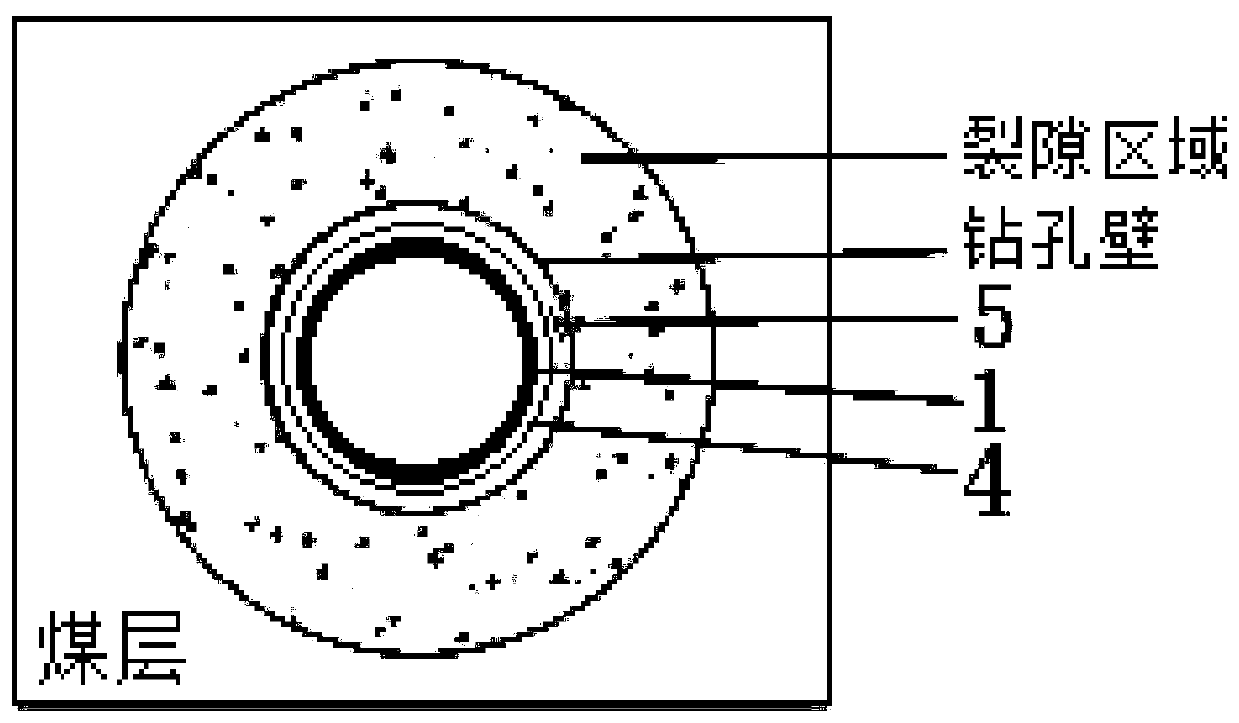

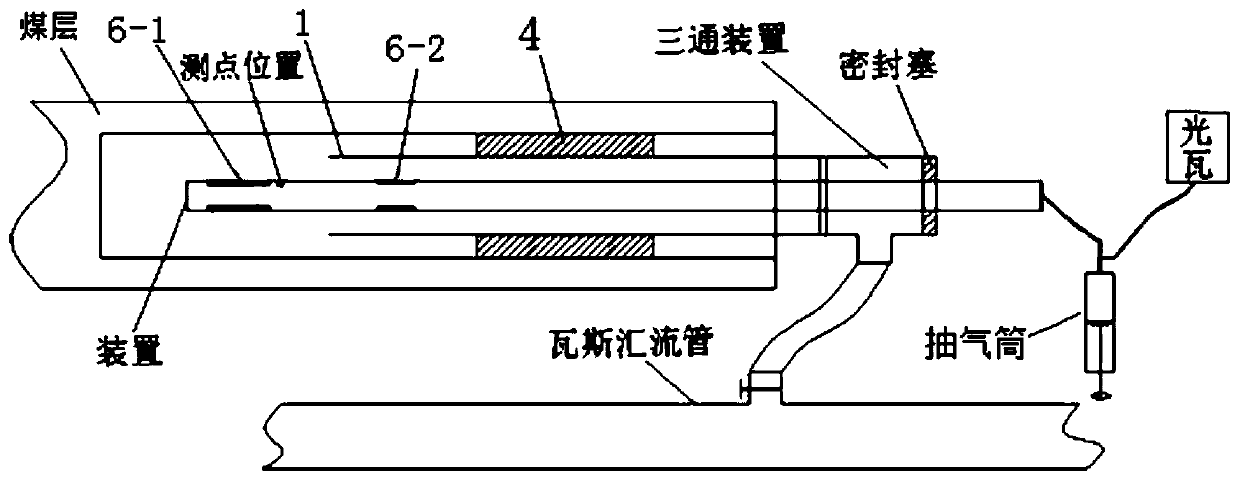

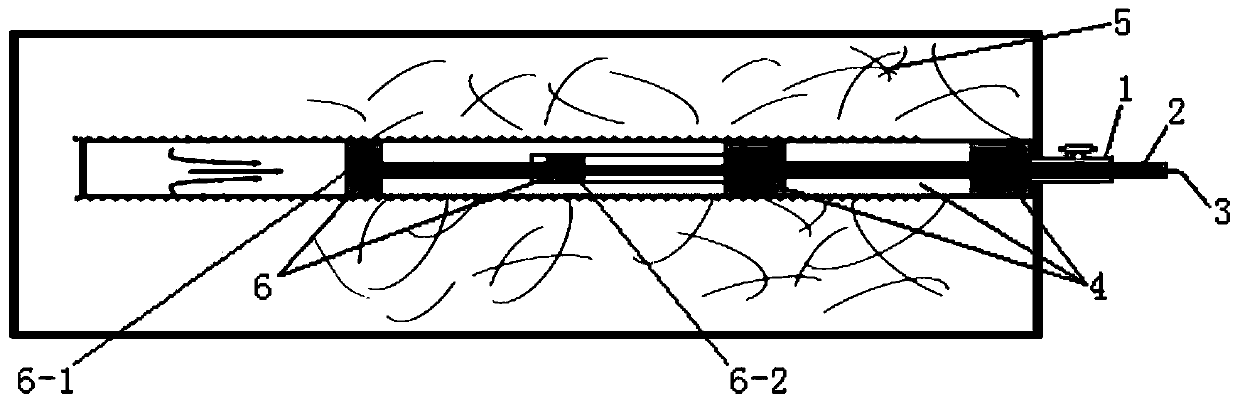

PendingCN111322107AIncrease gas extraction concentration and scalar volumeIncrease gas extraction concentrationGas removalSealing/packingDrill holeGeotechnical engineering

The invention discloses a drill hole inside secondary grouting leaking stoppage device. The drill hole inside secondary grouting leaking stoppage device comprises an injection pipe composed of a plurality of single-section pipes which are connected in sequence, all the single-section pipes comprise gas injection pipes and grouting pipes, the grouting pipes are arranged inside the gas injection pipes in a sleeved manner, wherein the grouting pipes are connected with the grouting pipes, the gas injection pipes are connected with the gas injection pipes, the inner ends of the multiple mutually-connected gas injection pipes stretch out of the inner end of a gas extraction pipe, get over a fracture zone of a drill hole and are connected with and communicate with an inner end gasbag, the parts,located at the inner end of the gas extraction pipe, of the multiple mutually-connected gas injection pipes are connected with and communicate with an outer end gasbag, the gas extraction pipe and oneend of an inlet of the drill hole are further provided with a sealing body, the ends, located at the drill hole inlet, of the multiple gas injection pipes of the injection pipe are connected with gassupply equipment, and the ends, located at the drill hole inlet, of the multiple grouting pipes of the injection pipe are connected with grouting equipment. By means of the drill hole inside secondary grouting leaking stoppage device, precision grouting with pressure can be performed on the failure drill hole fracture development position, so that the gas extraction failure drill hole extractionfunction is activated and restored, and the gas extraction concentration and purity are increased.

Owner:YUWU COAL CO LTD OF SHANXI LUAN GRP +1

Drilling device for engineering investigation

InactiveCN111794678AAvoid damageIncrease the support areaConstructionsDerricks/mastsElectric machinerySupport surface

A drilling device for engineering investigation comprises a base, two supports are fixed to the base, the two supports are in sliding connection with a supporting plate, a motor is started to drive adrill bit to rotate, the supporting plate is pushed downwards to make the drill bit make contact with the ground, the drill bit enters a rock stratum in the rotating process, the rock stratum is drilled, and soil in the rock stratum is brought out; when the drill bit drills downwards and the supporting plate abuts against the baffle, the baffle is pushed to move downwards to squeeze the spring tobuffer the supporting plate, so that the drill bit is buffered and decelerated to drill the rock stratum, and damage caused by the fact that the drill bit descends too fast is prevented; an ejector rod moves downwards to push the two limiting rods to slide out of the base, the compressed spring extends, the two limiting rods are inserted into the ground, the ground gripping capacity of the base isimproved while the supporting area of the base is increased, the base is prevented from moving when the drill drills a rock stratum bottom plate, and damage caused by deviation of the drill is avoided.

Owner:西谛规划设计有限公司

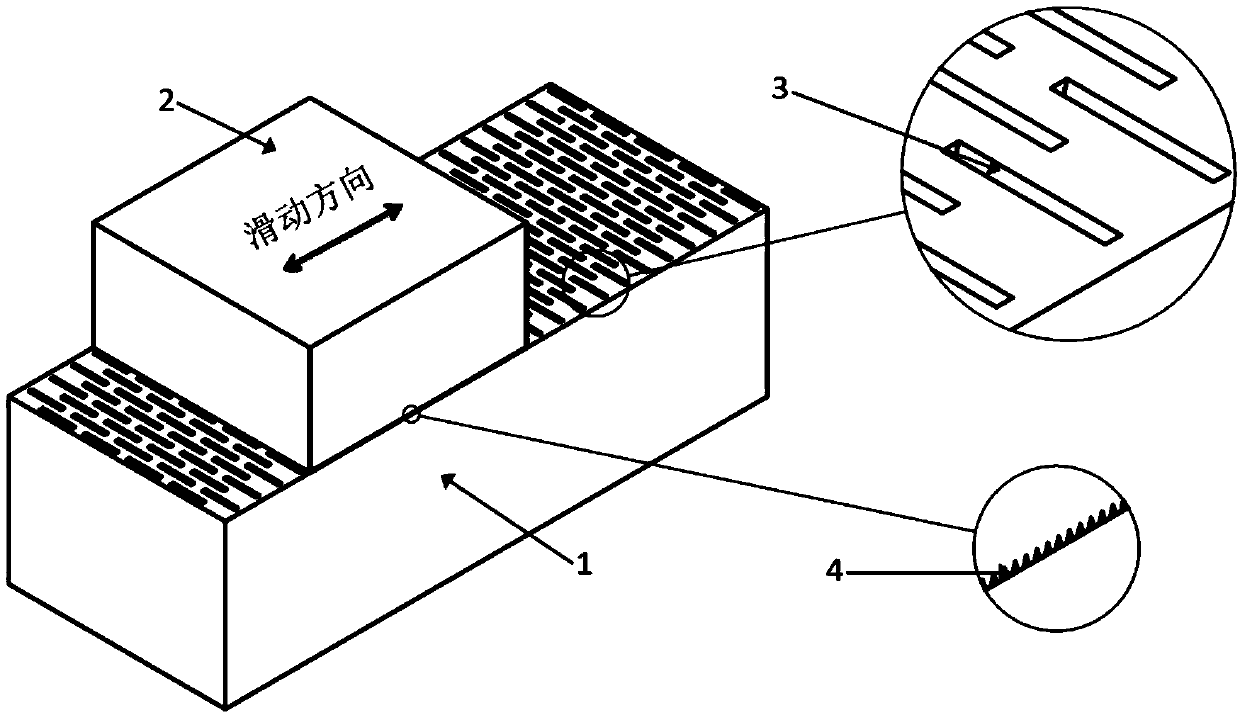

Micro-nano composite texture guide rail and preparation method thereof

ActiveCN109514277AImprove low-speed performancePrevent leakageLarge fixed membersMicro nanoReciprocating motion

The invention belongs to the surface treatment technology for machine tool guide rails, and particularly relates to a micro-nano composite texture guide rail and a preparation method thereof. The micro-nano composite texture guide rail comprises a fixed guide rail and a sliding guide rail, the fixed guide rail is located below the sliding guide rail, and the sliding guide rail can do reciprocatingmotion relative to the fixed guide rail. Multiple micro-texture grooves perpendicular to the sliding direction are formed in the surface, in contact with the sliding guide rail, of the fixed guide rail, and the micro-texture grooves are arranged evenly in a staggered manner. Correspondingly, multiple nano-texture grooves perpendicular to the sliding direction are formed in the surface, in contactwith the fixed guide rail, of the sliding guide rail, and the nano-texture grooves penetrate through the surface of the sliding guide rail. According to the micro-nano composite texture guide rail, the micro-texture grooves perpendicular to the sliding direction are formed in the fixed guide rail of the guide rail, lubricating oil can be stored, and grinding scraps can be collected; and the nano-texture grooves perpendicular to the sliding direction are formed in the sliding guide rail, forming of a lubricating oil film is facilitated, and therefore the functions of enhancing lubricating, reducing friction and improving the performance of the guide rail are achieved.

Owner:SHANDONG UNIV

Tomato planting supporting frame

Owner:吴燕梅

Fertilization mechanism in garden fertilization device

InactiveCN104429256AGuaranteed Ditch DepthGuaranteed to be consistentPlantingWatering devicesFertilizerAgricultural engineering

The invention provides a fertilization mechanism in a garden fertilization device, belonging to the technical field of machinery and aiming at solving the problems that ditches can not be automatically dug in soil, and fertilization can not be carried out in the prior art. According to the fertilization mechanism in the garden fertilization device, the garden fertilization device comprises a rack and a bottom plate; the fertilization mechanism comprises a chemical fertilizer box fixed on the bottom plate; a discharging opening is formed in the bottom of the chemical fertilizer box and a piston plate is arranged in the discharging opening; a telescopic air cylinder I is fixed on the inner wall of the chemical fertilizer box; the end part of a piston rod of the telescopic air cylinder I is fixed on the piston plate; a through hole is formed in the bottom plate and the lower end of the bottom plate is hinged to a closed door; and a ditching structure is further fixed on the bottom plate. The fertilization mechanism in the garden fertilization device has the advantages that the ditches with the consistent depth can be automatically dug and the uniform fertilization is carried out.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Bamboo splint perforating machine capable of recycling waste conveniently

InactiveCN107297791AGuaranteed effectGuaranteed to be smoothStationary drilling machinesRevolution surface grinding machinesEngineeringAir blower

The invention discloses a bamboo strip punching machine for recycling waste materials, which comprises a fixed cavity and a storage cavity. A drill rod is arranged at the bottom of the fixed cavity and is connected with an output shaft of a motor. One side of the drill rod is provided with a There is a distance measurer and the distance measurer is connected to the bottom of the fixed cavity, the other side of the drill rod is provided with a grinding rod and the grinder rod is connected to the output shaft of the grinding motor, a storage box is arranged between the drill rod and the grinder rod and The storage box is connected with the bottom of the fixed chamber, and the inside of the storage chamber is provided with a crushing blade connected with the output shaft of the crushing motor. The invention can ensure the smoothness of the inner wall of the grinding hole through the grinding motor, can clean the sawdust in the bamboo and wood strips through the blower, can clean the sawdust motor of the bamboo and wood strips through the crushing motor, and can clean the wood chips in the bamboo and wood strips through the electric telescopic rod. The punching height and depth can be adjusted, the structure is reliable, safe, environmentally friendly, labor-saving, and suitable for wide promotion and use.

Owner:陈建云

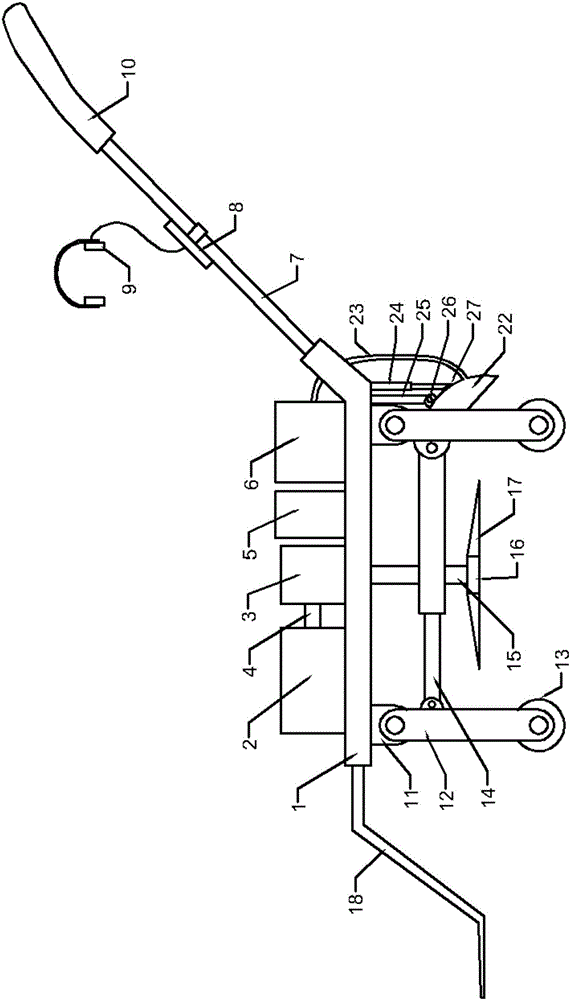

Agricultural transplant device

ActiveCN109220118AReduce laborReduce labor intensityTransplantingAgricultural engineeringAgriculture

The invention relates to the field of agricultural equipment, in particular to an agricultural transplant device. The agricultural transplant device comprises a support frame, an adjustment mechanism,a seedling removing mechanism and a transplanting mechanism; the adjustment mechanism is mounted on one side of the support frame, the transplanting mechanism is fixedly connected with the adjustmentmechanism, the seedling removing mechanism is fixedly connected with the support frame and located above the transplanting mechanism, and the transplanting mechanism comprises a lifting component, adriving component, a transmission component and a transplanting component, the lifting component is fixedly connected with the adjusting mechanism, the transplanting component is fixedly connected with the lifting component, the driving component is mounted on one side of the transplanting component, and the transplanting component and the driving component are in transmission connection through the transmission component. The agricultural transplant device has the advantages that the device does not need to be driven by pedals, and can automatically return to facilitate seedling feeding, so that the labor intensity and the amount of labor of farmers can be further reduced, and the seedling transplanting efficiency can be improved.

Owner:QINGDAO AGRI UNIV

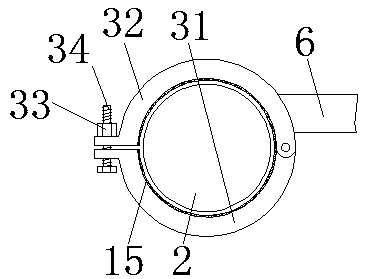

Cutting device for large-diameter plastic blow-down pipes

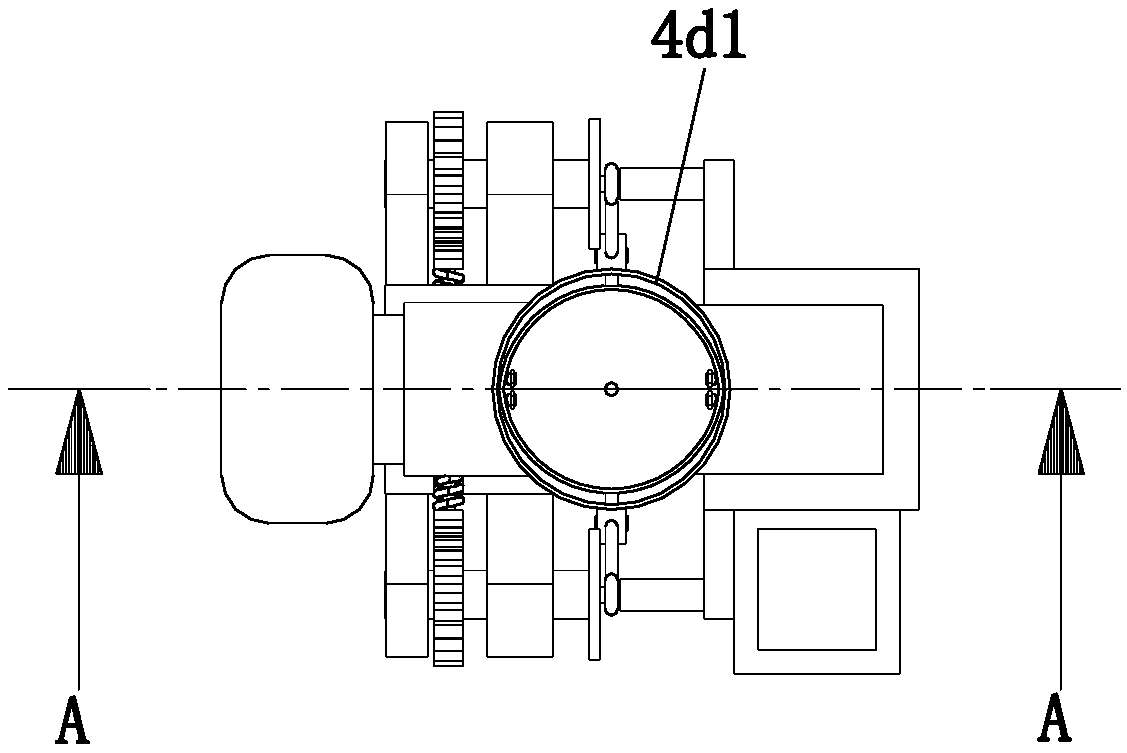

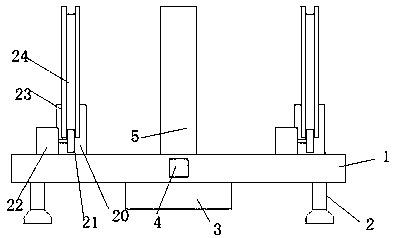

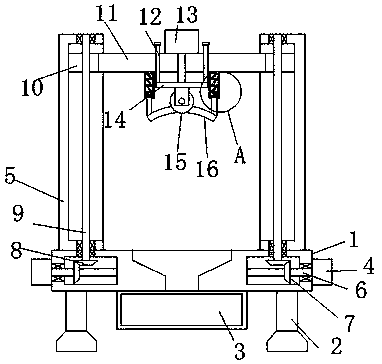

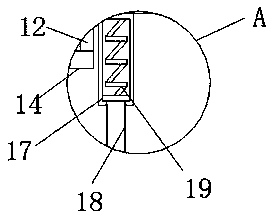

InactiveCN110722615ASmooth rotationImprove rotational stabilityMetal working apparatusElectric machineryStructural engineering

The invention discloses a cutting device for large-diameter plastic blow-down pipes. The cutting device comprises a base. Cavities are formed in the two ends of the side face of the base. A first motor is installed on the side face of the base. An output shaft of the motor is inserted into the cavities and is connected with rotary shafts. The rotary shafts are fixedly sleeved with first bevel gears. Supporting columns are fixed to the two sides of the top of the base. Sliding grooves are formed in the side faces of the supporting columns. Lead screws are rotatably connected into the sliding grooves and penetrate through the supporting columns to be inserted into the cavities. The bottom ends of the lead screws are fixedly sleeved with second bevel gears. According to the cutting device forthe large-diameter plastic blow-down pipes, second motors and racks are arranged so that the blow-down pipes can be evenly rotated during cutting, the rotating stability is high, and the machining safety is improved; and meanwhile, through the arrangement of the first motor, the lead screws and a supporting plate, the cutting depth can be adjusted conveniently, blow-down pipes with different thicknesses can be cut conveniently, using is convenient, and the cutting effect is flexible.

Owner:太仓久庄管业有限公司

Peanut seed sowing machine

InactiveCN108521949APlace evenlyEnsure consistencyPlantingWatering devicesAgricultural engineeringSowing

The invention relates to the technical field of modern agricultural machinery, and discloses a peanut seed sowing machine which comprises a fixing frame. Fastening bolts sleeve the top of the fixing frame in a threaded manner, a fixing plate sleeves the end, which is positioned at the bottom of the fixing frame, of each fastening bolt in a threaded manner, the four fixing plates are equidistantlydistributed at the bottom of the fixing frame, fixing rods are fixedly nested in the middles of the fixing plates, the bottoms of the fixing rods are fixedly connected with the tops of plows, fastening nuts which are positioned below the fixing plates sleeve the fastening bolts in a threaded manner, and limit devices are nested in two sides of the top of the fixing frame in a threaded manner. Thepeanut seed sowing machine has the advantages that seed sowing discs, adjusting devices and fixing devices are used with one another, accordingly, the seed sowing quantities and speeds can be conveniently controlled, seeds can be uniformly sown in soil by the peanut seed sowing machine, the problems of waste of seeds and increase of the seed sowing cost due to the fact that the seed sowing quantities cannot be controlled by devices can be solved, and the seed sowing efficiency can be improved.

Owner:姚朝友

Hay mower easy to adjust

The invention discloses an easy-to-adjust lawn mower, which comprises a car body, the car body is a rectangular flat plate structure, mounting seats are arranged at the bottom of the car body near the four corners, each mounting seat is hinged with support legs, Universal wheels are installed at the bottom of the supporting legs, and the corresponding two supporting legs located on the same side of the car body are connected by height-adjusting telescopic rods; and the support rod, the fork disc is arranged obliquely on the fork rod, the end of the fork rod is fixedly installed at the front end of the car body, and the fork rod is arranged at the front end of the fork disc; a coupling device is installed at the upper center of the car body. The invention can realize the adjustment of the distance between the blade and the ground through the cooperation of the supporting legs and the height adjustment telescopic rod, and facilitate the adjustment of the depth of cutting grass; The grass on the ground can also be cut together with normal grass, ensuring the overall effect of cutting.

Owner:徐州屠氏生态科技开发有限公司

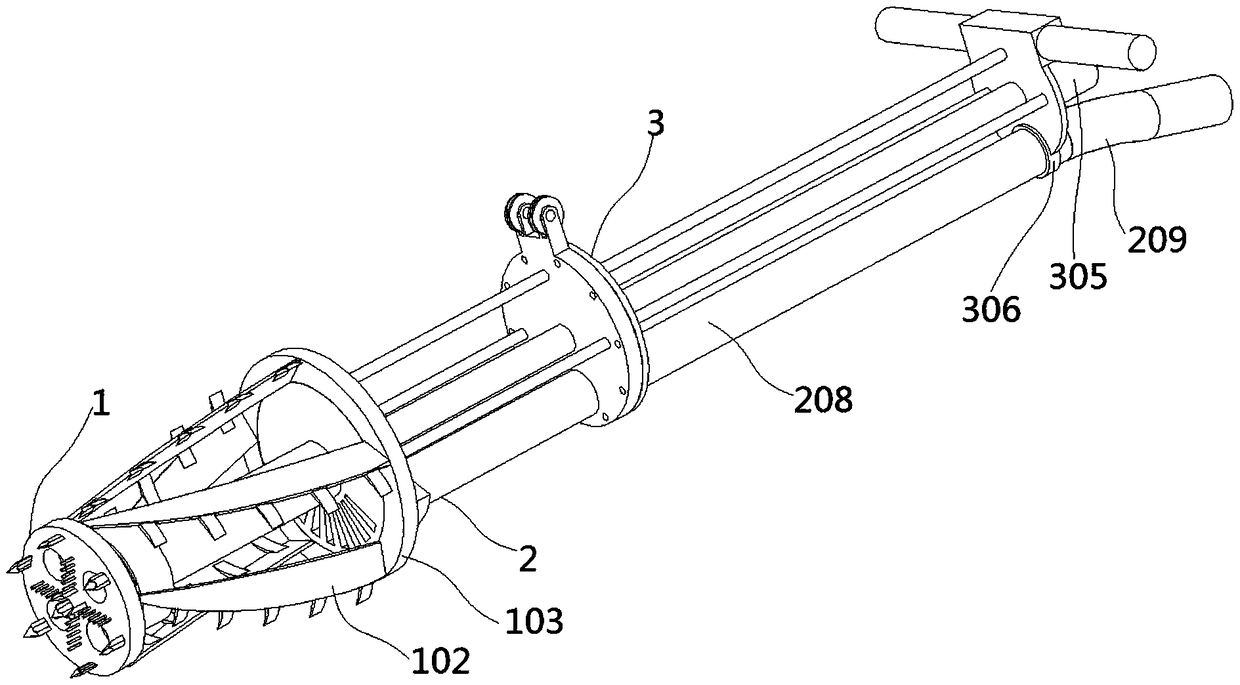

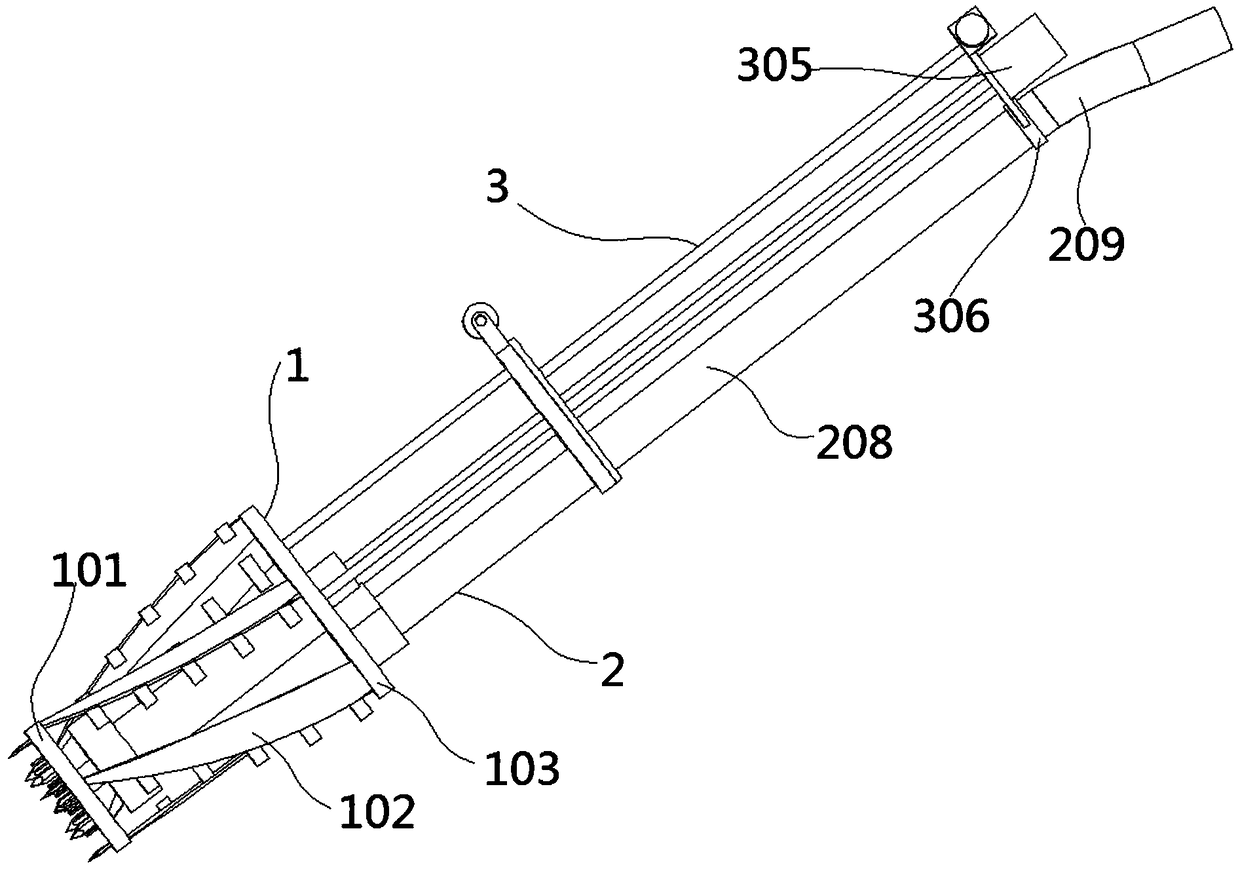

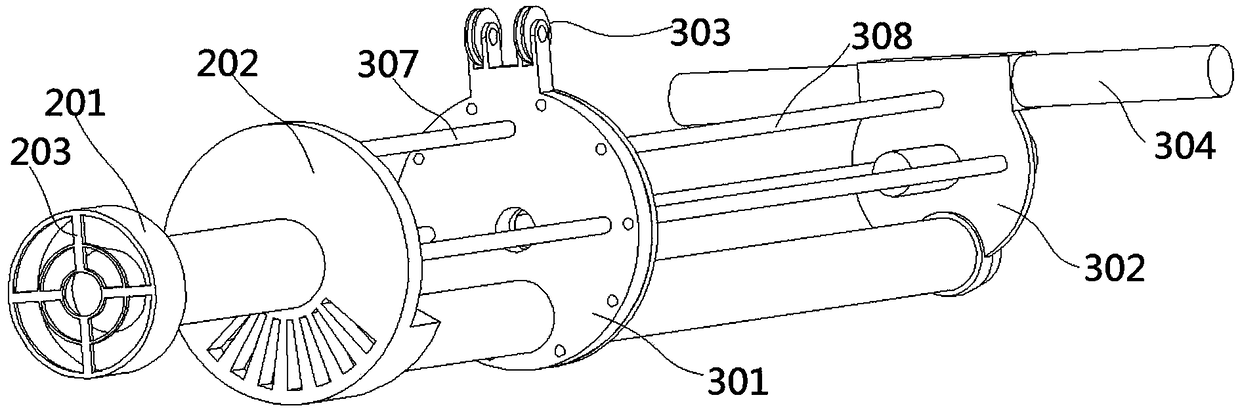

Efficient mud suction rake head of river course sediment rake suction boat

ActiveCN108797670AGood ground breaking effectIncrease productivityMechanical machines/dredgersEngineeringSediment

The invention discloses an efficient mud suction rake head of a river course sediment rake suction boat, and relates to the technical field of dredge boats. The efficient mud suction rake head comprises a rake head device and a rake suction device, wherein the rake head device comprises a front rake head, a side rake head and an outer ring; a mud guide pipe is arranged on the rear mud suction device, and rectangular hole are formed in the peripheral side face of the mud guide pipe; and mud suction holes B are formed in the surface of the rear mud suction device; a mud collecting cavity is formed inside the rear mud suction device and communicates with the mud suction pipeline; a rotary shaft is matched with the front mud suction device; the peripheral side surface of the rotary shaft is matched with the inner surface of the mud guide pipe; and the inner surface of the outer ring is matched with the peripheral side surface of the rear mud suction device; and the mud suction pipeline isfixedly connected with the mud suction pump through a corrugated pipe. The device has the advantages that through the action of rake head device and the rake suction device, the mud is efficiently absorbed, the raking depth is adjusted, the mud raking depth is large, the soil breaking effect is better, and the improvement on the production efficiency and the construction progress of a drag-suctiondredger are achieved.

Owner:ANHUI JIAMING ENVIRONMENTAL PROTECTION TECHCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com