Patents

Literature

37results about How to "Guaranteed to be consistent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

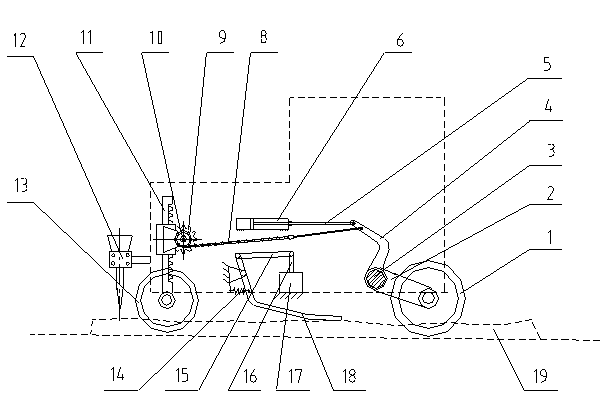

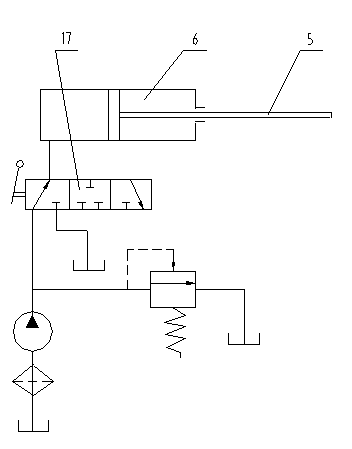

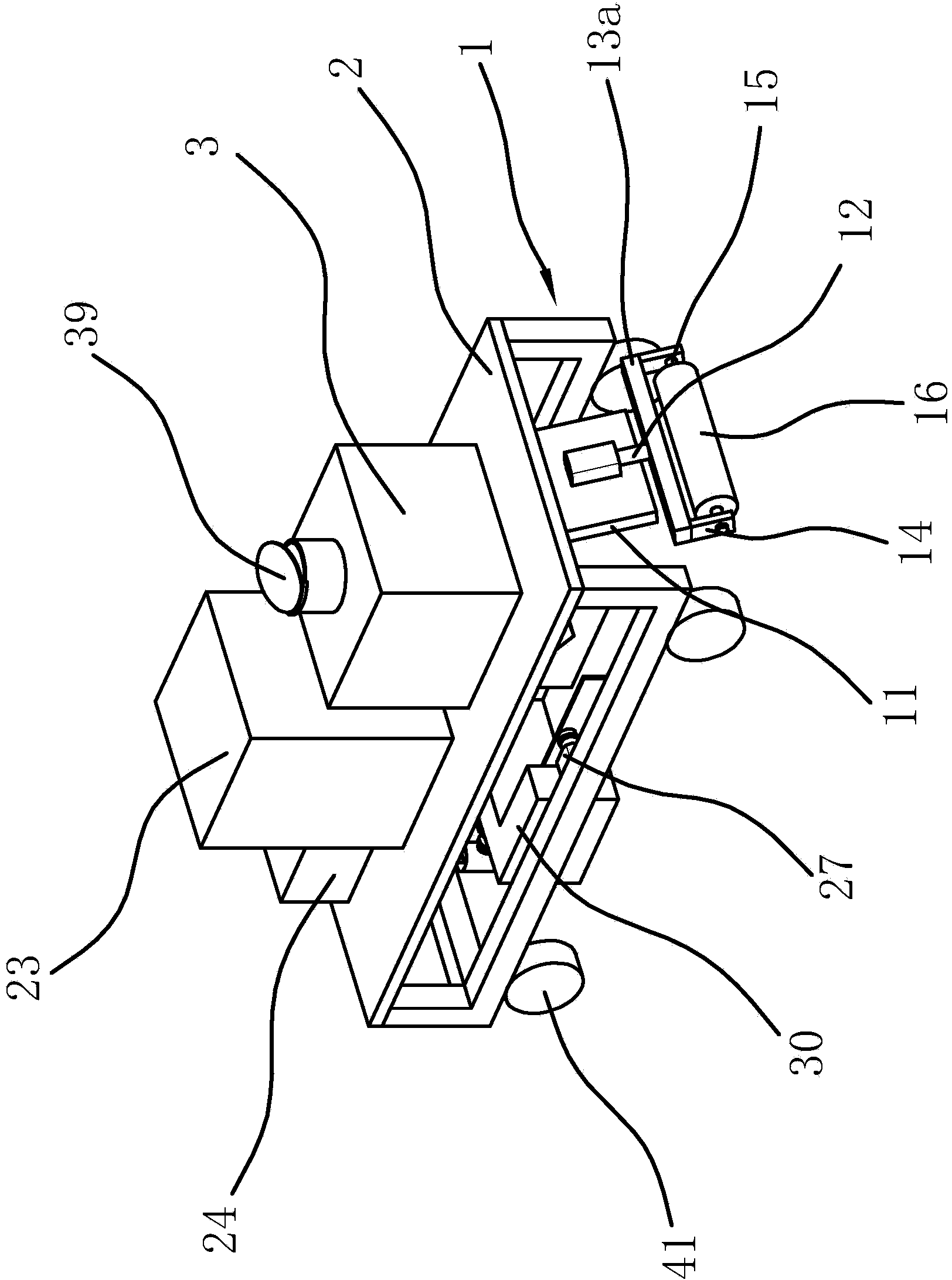

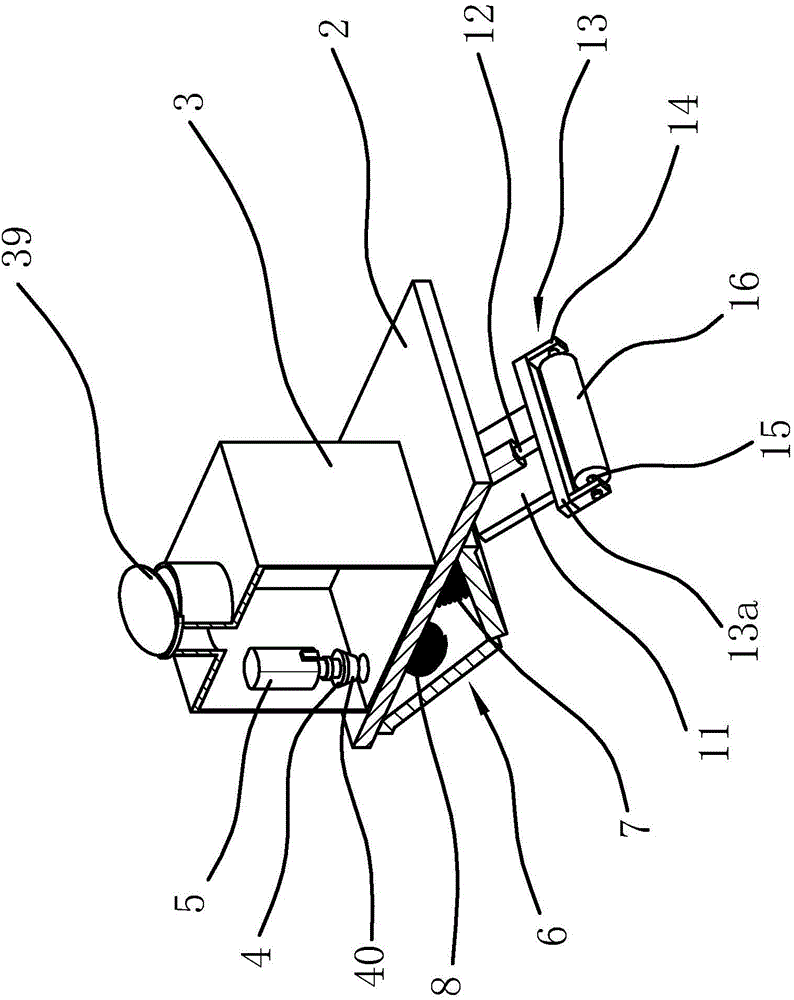

Four-wheel synchronous automatic lifting regulating mechanism

InactiveCN104025787AOvercoming the defects of the lifting methodEasy to makeTransplantingGear wheelEngineering

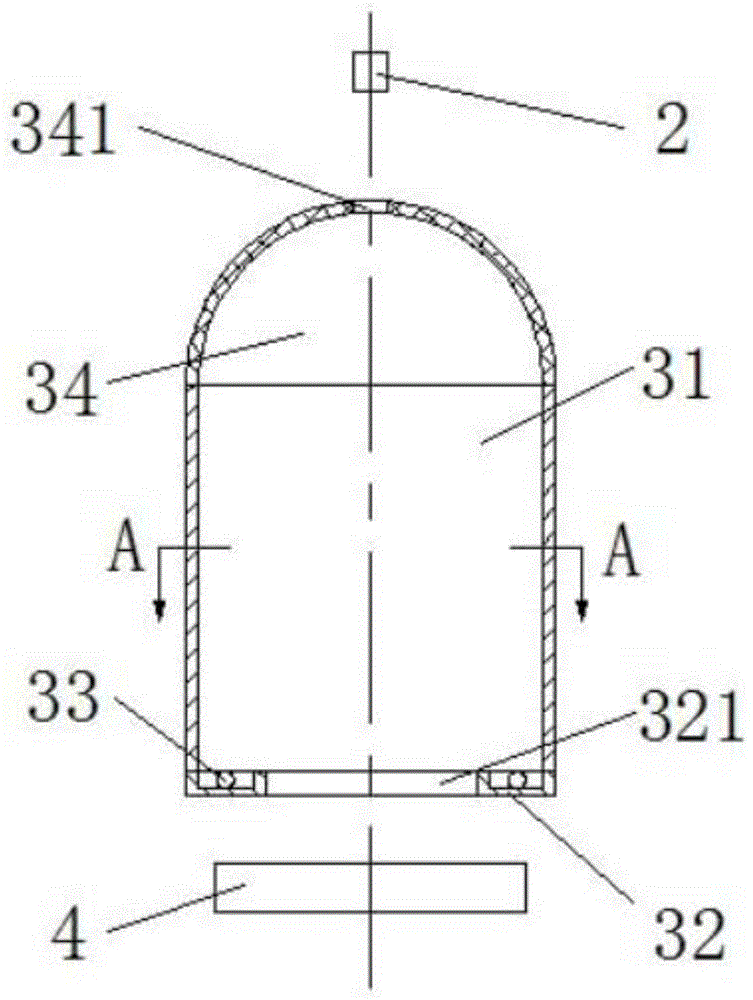

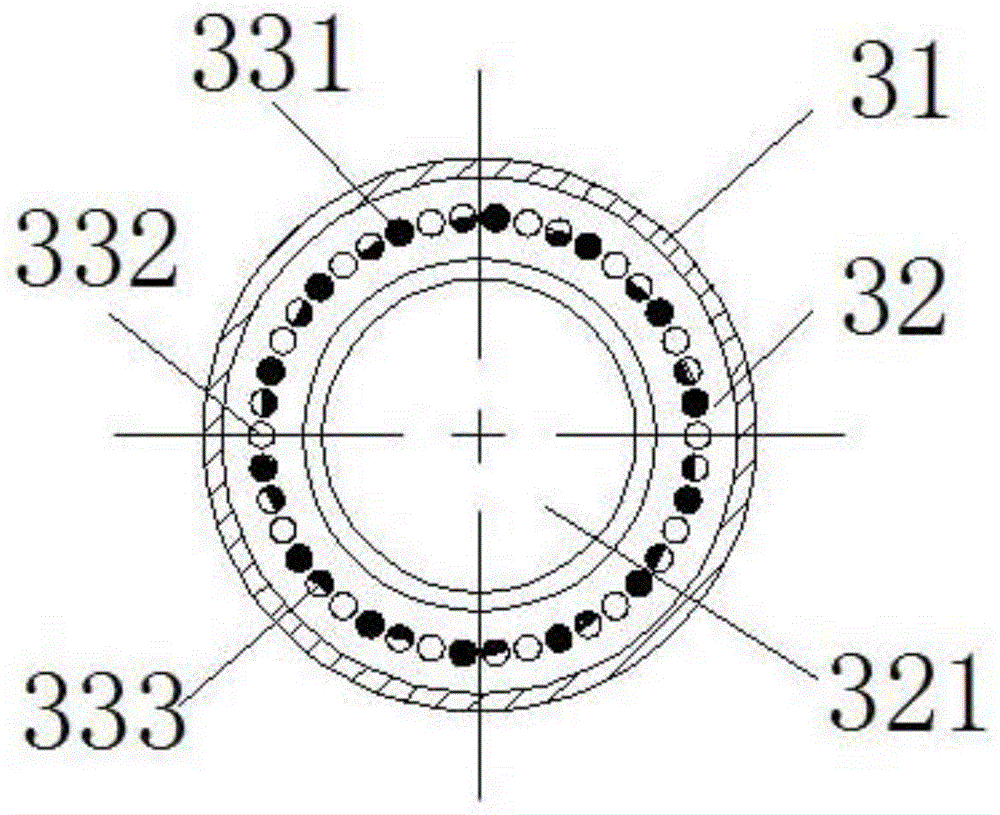

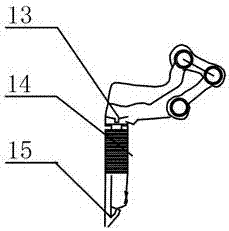

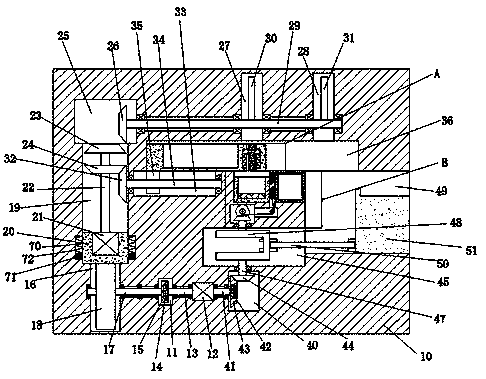

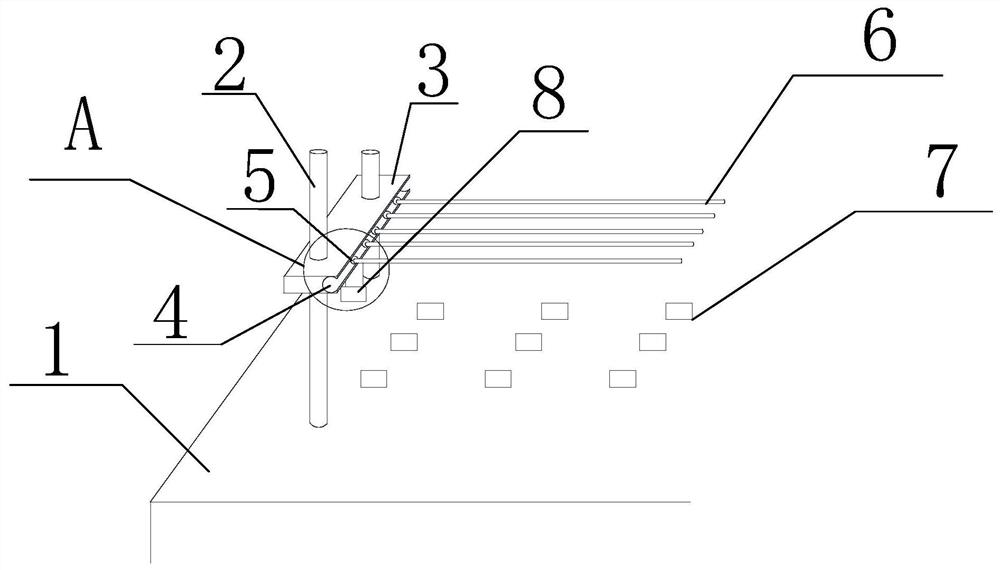

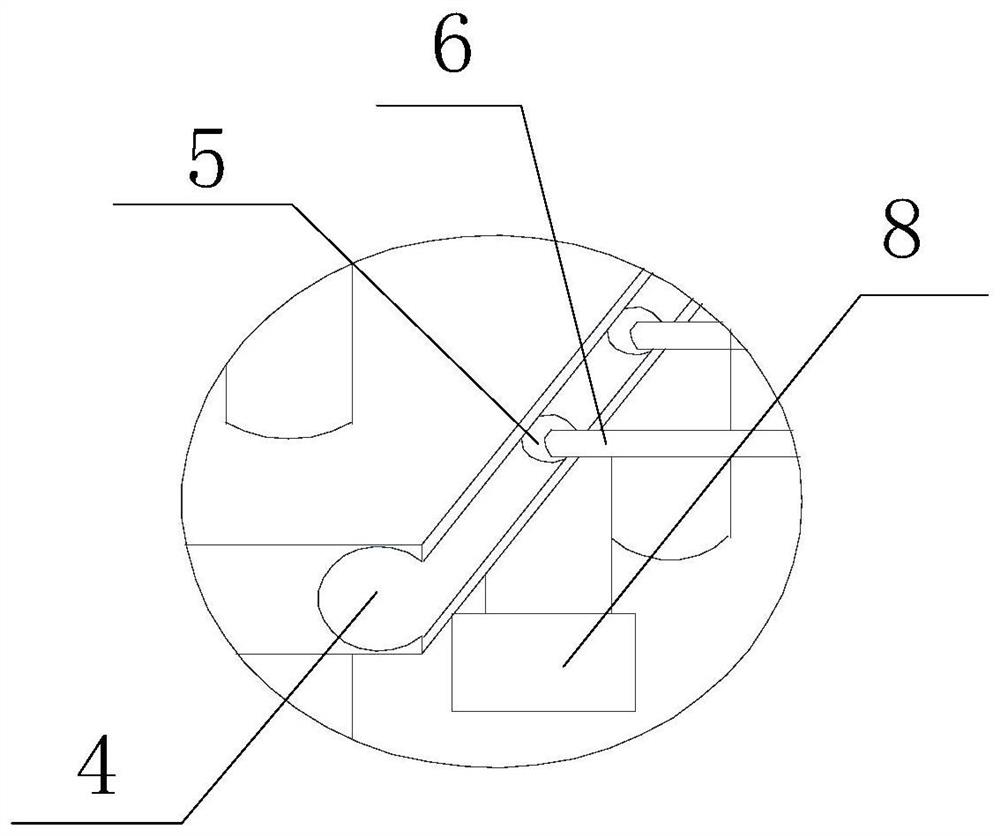

The invention relates to a four-wheel synchronous automatic lifting regulating mechanism. The mechanism comprises a sensing assembly, a hydraulic power assembly and a lifting performing mechanism, wherein the lifting performing mechanism comprises a front lifting device and a rear lifting device; a rear wheel driven chain box is driven by a hydraulic cantilever to rotate around a rear axle so as to lift a rear machine body; a chain and chain wheel drive assembly and a toothed wheel and toothed column drive assembly are driven by the hydraulic cantilever so as to lift a front machine body; during work, the height variation of a furrow is changed into shift motion by the sensing assembly and a hydraulic control valve of an oil cylinder is controlled to ensure that the oil cylinder respectively works in three states of oil feeding, oil discharging and pressure maintaining; a piston rod extends or retracts according to the different working states, the front body and the rear body of a transplanter are controlled through the performing mechanism to be lifted simultaneously so as to drive a pair of planting pincers to be lifted at the same time and realize the automatic regulation of planting depth; through the lifting control of a hydraulic automatic lifting mechanism, the uniform planting depth of seedlings is guaranteed in the transplanting process.

Owner:ZAOYANG CITY ZHENGTIAN TRANSPLANTER

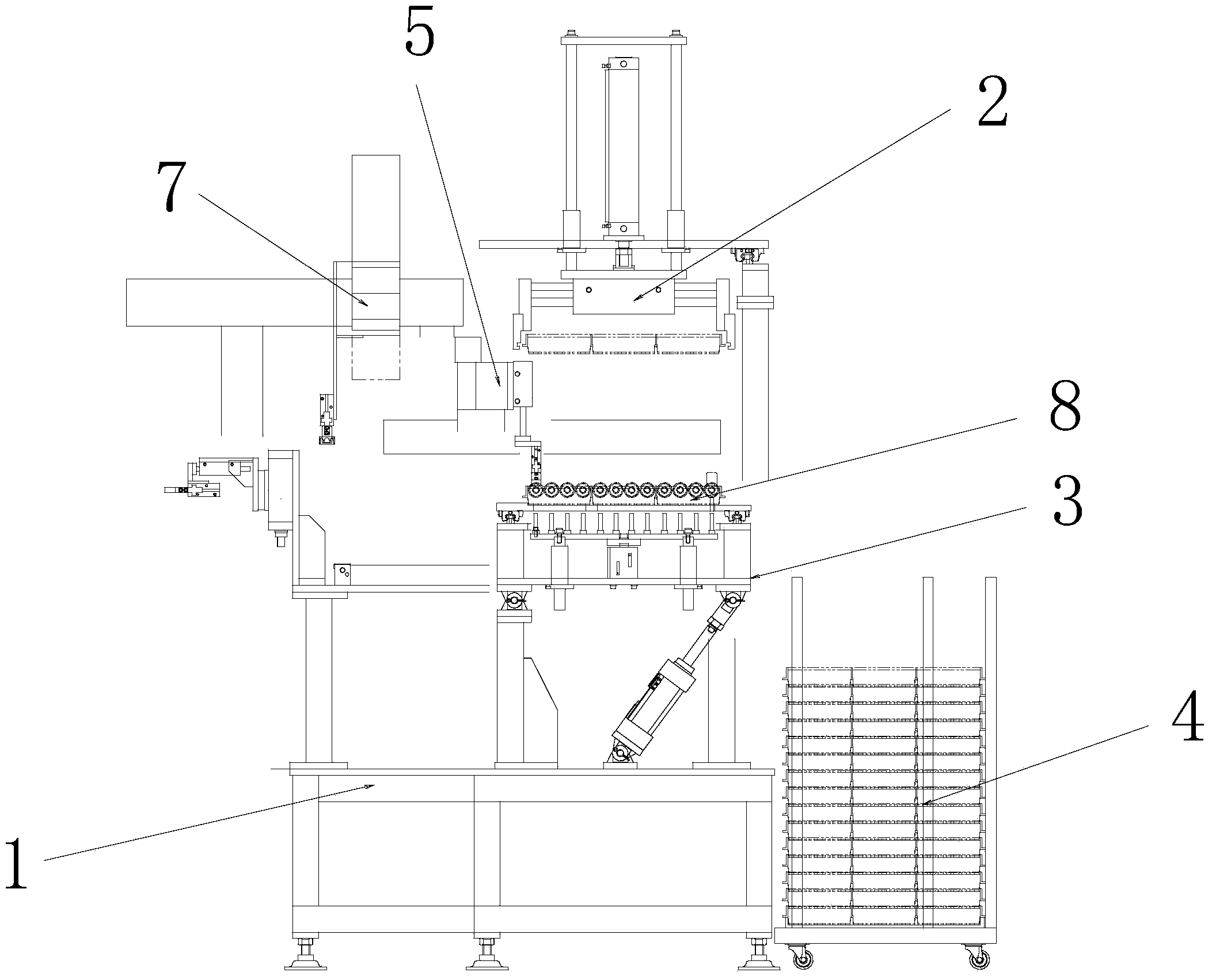

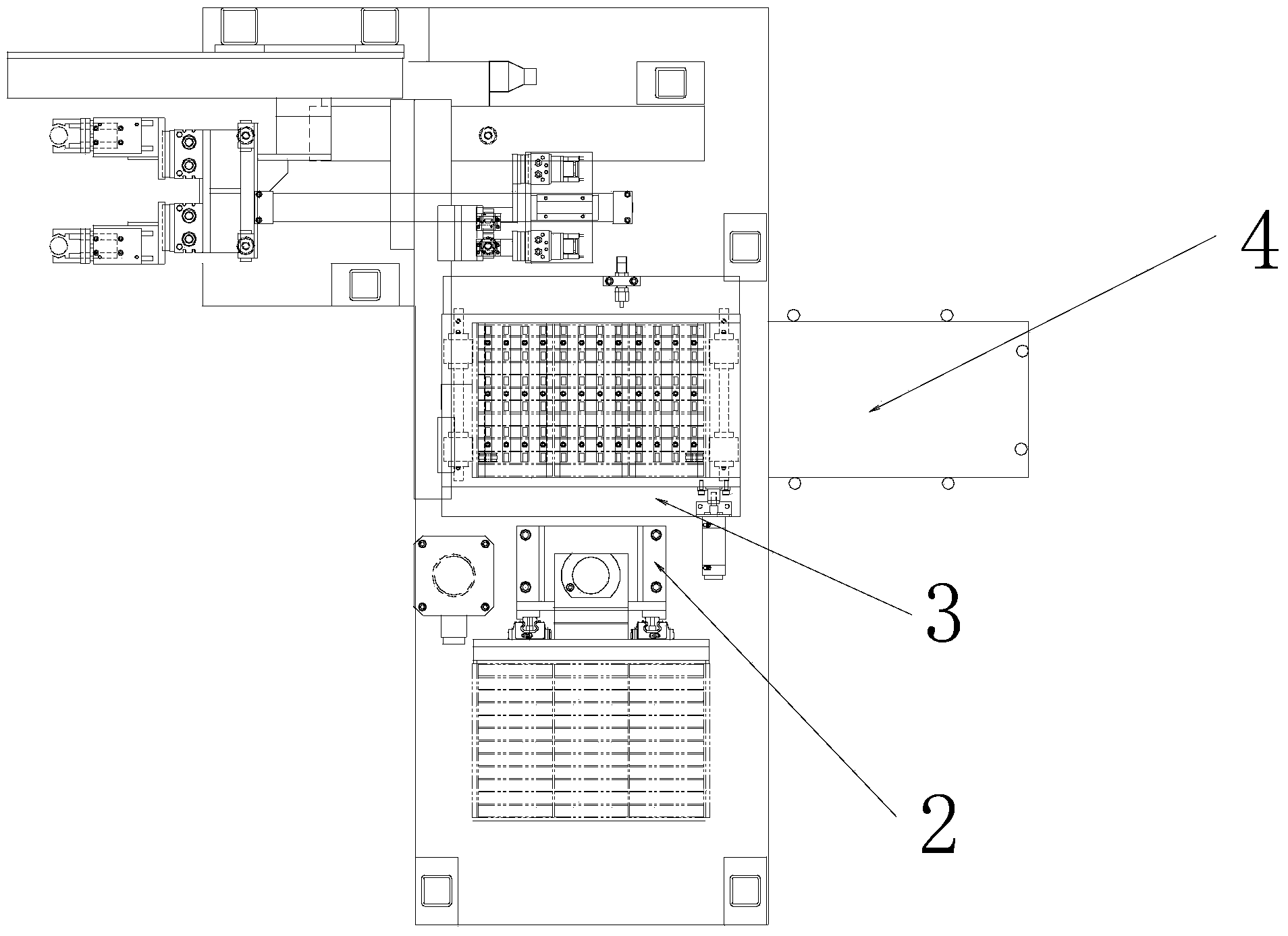

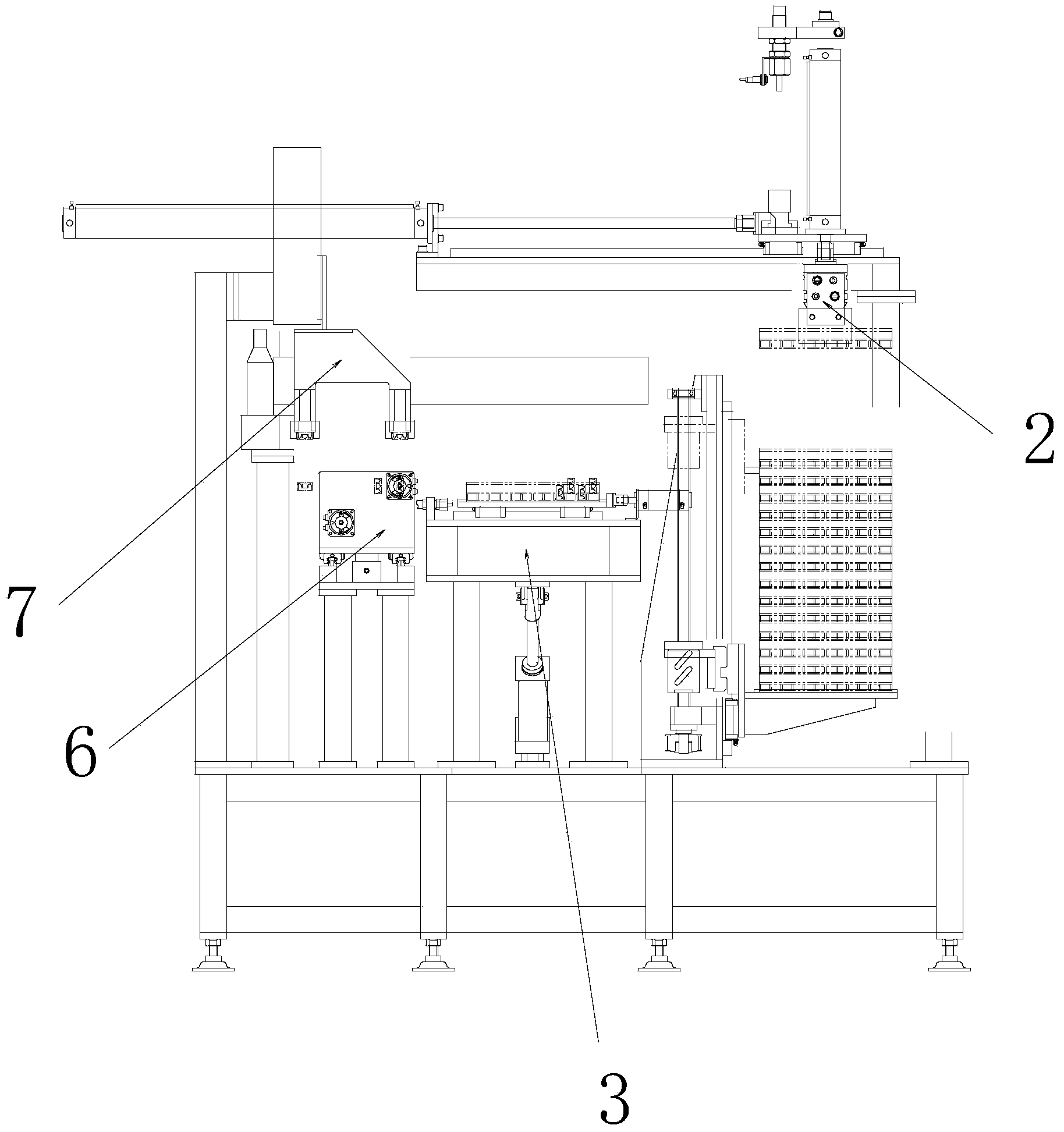

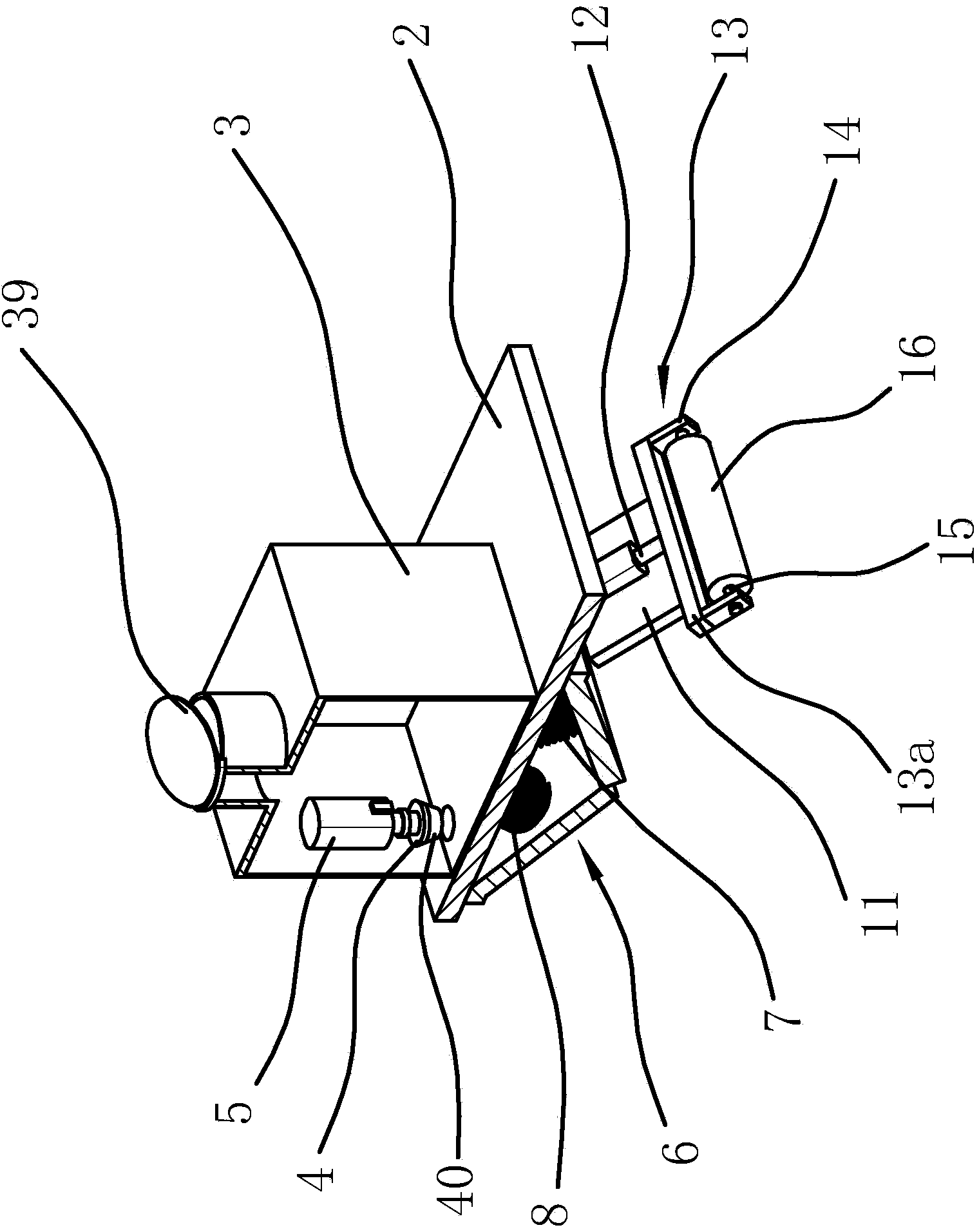

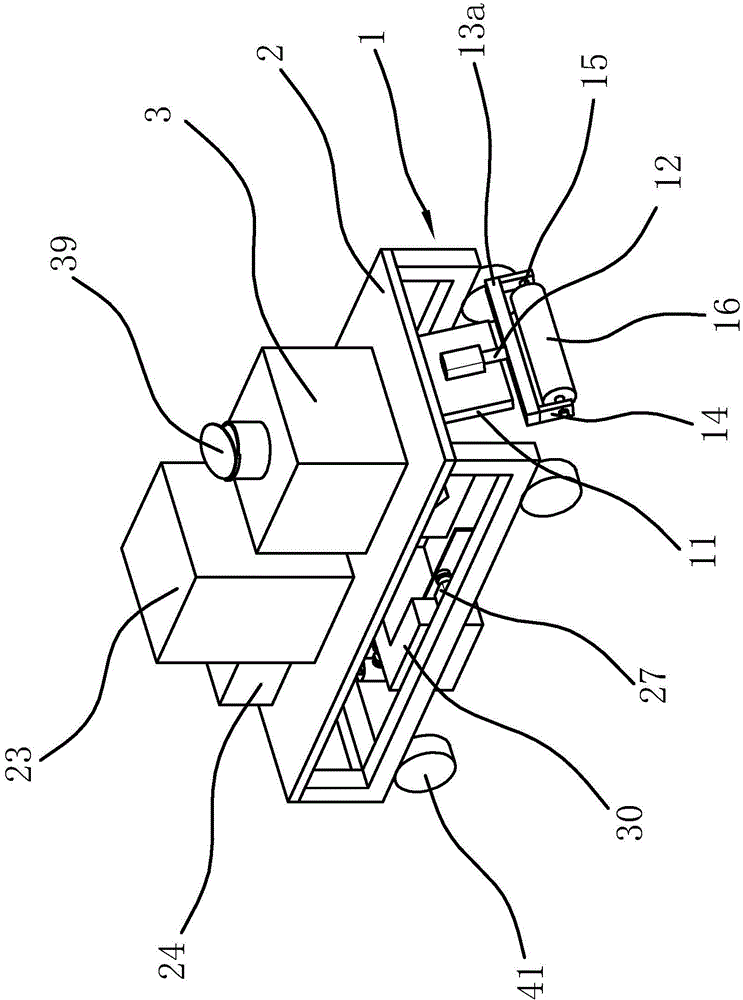

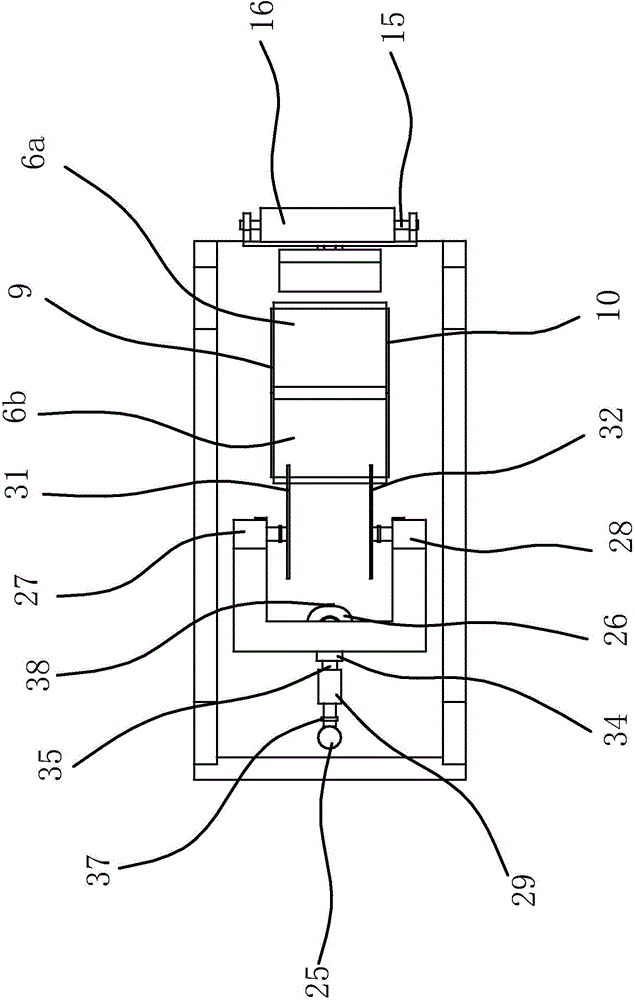

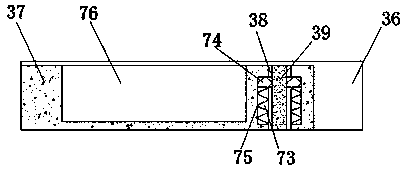

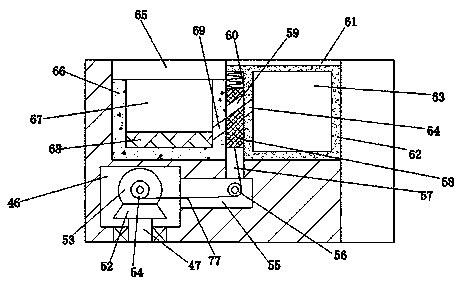

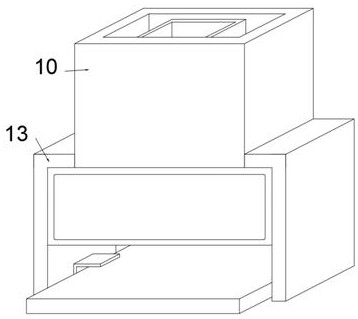

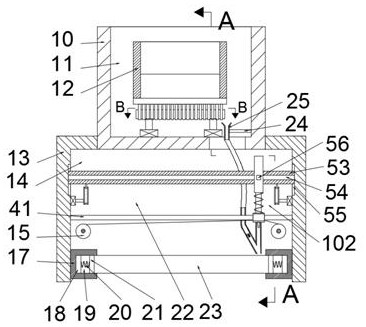

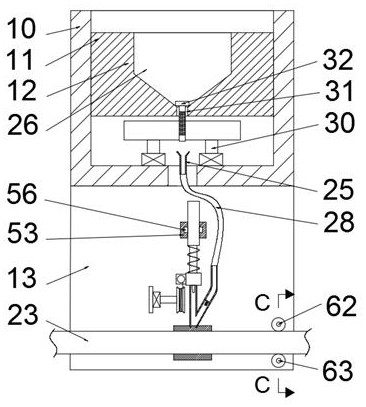

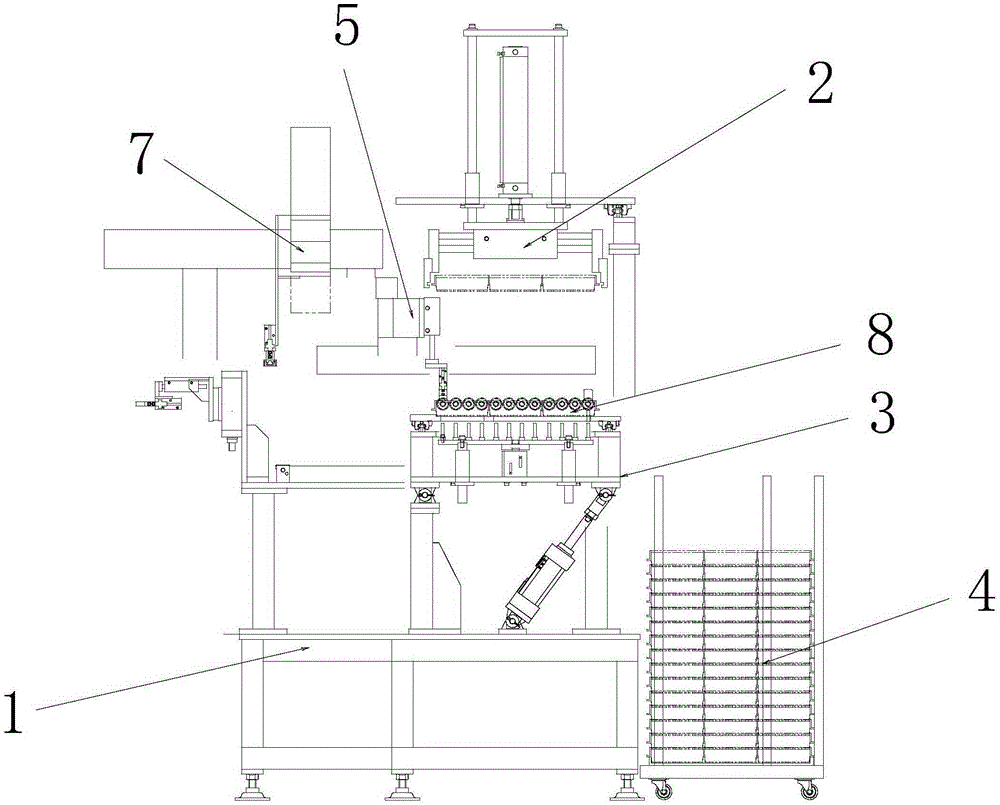

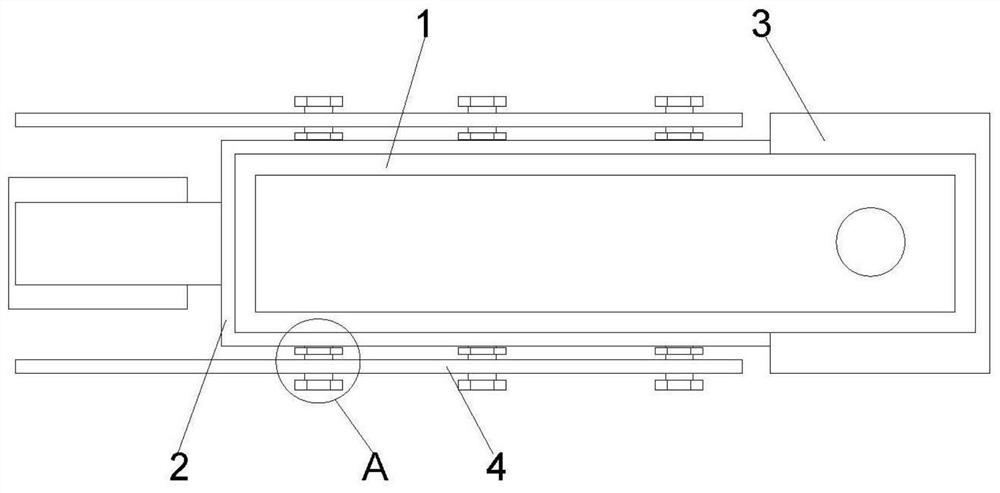

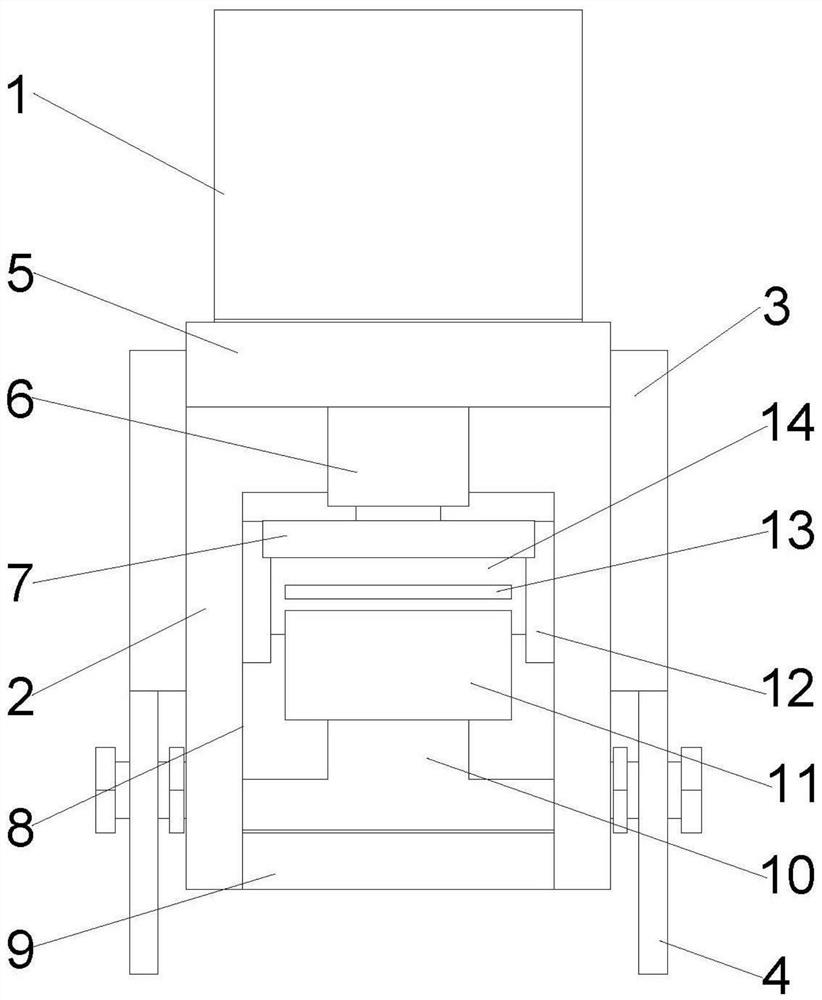

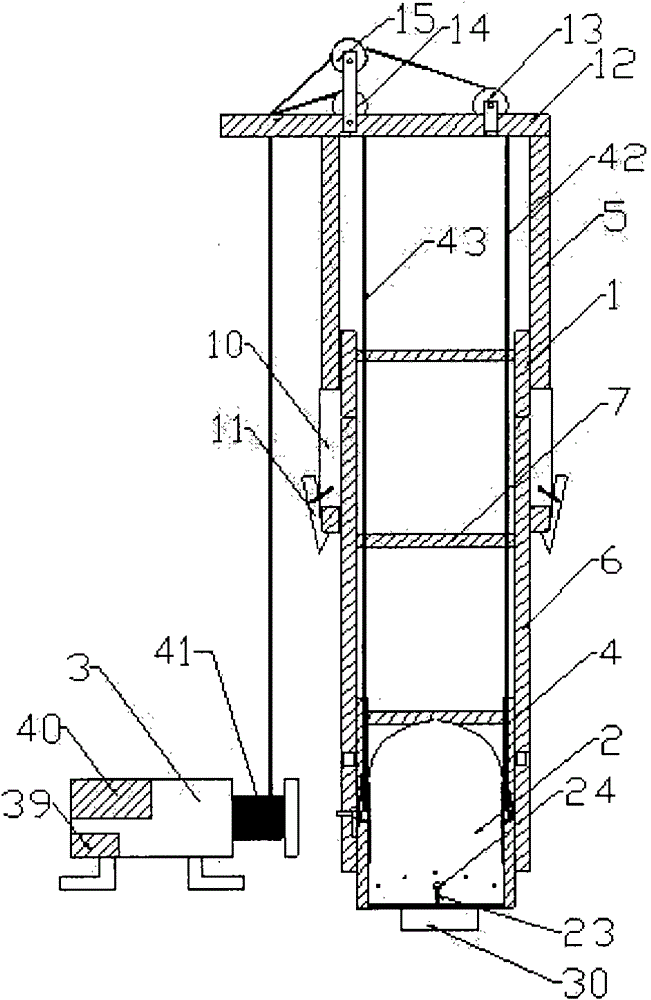

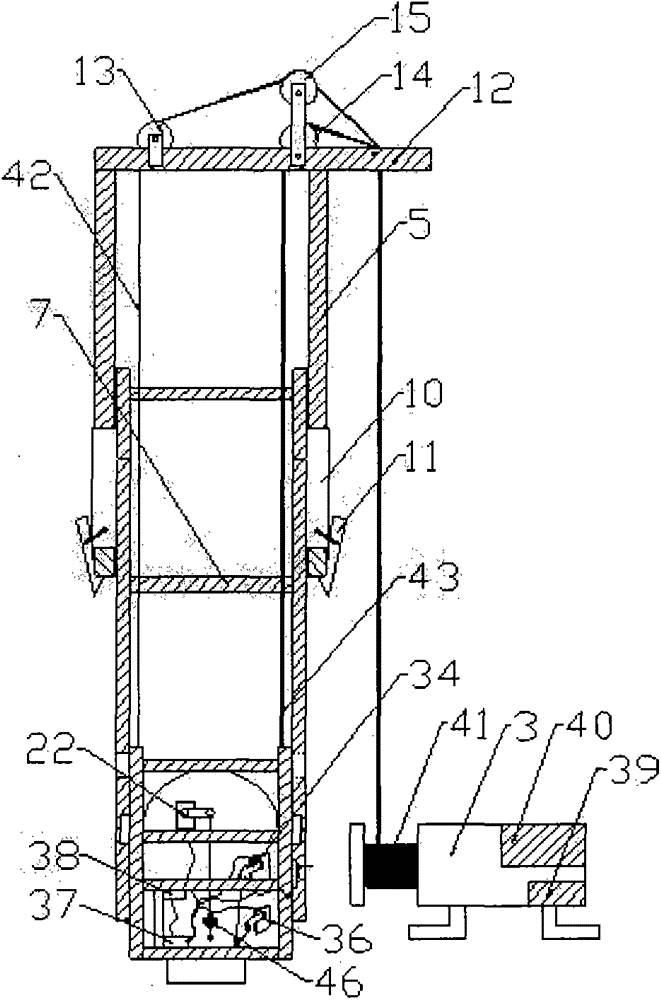

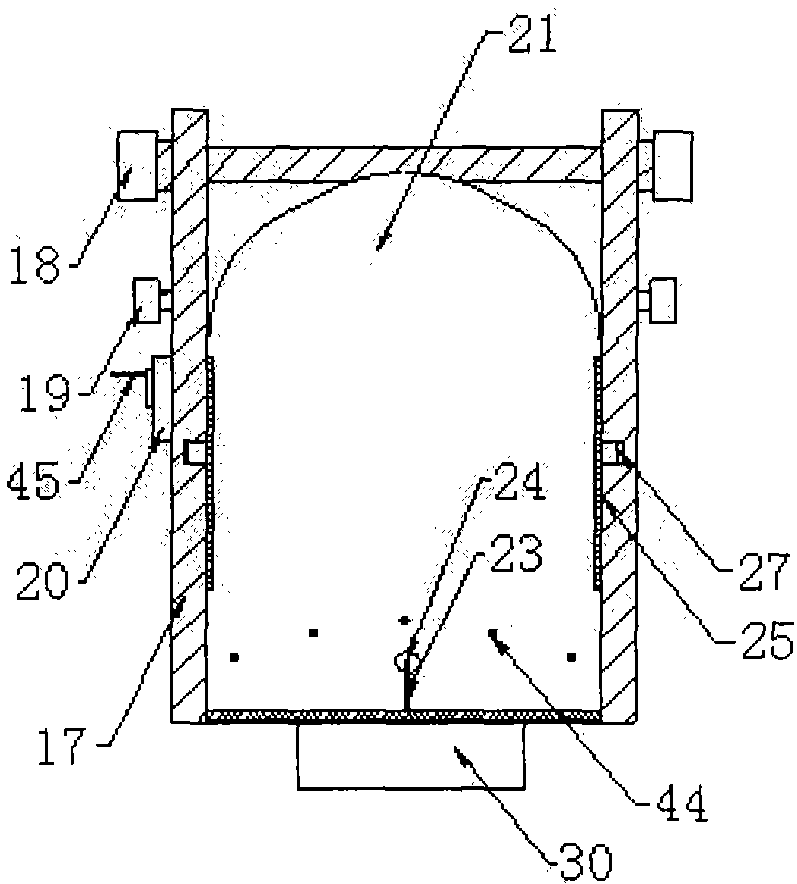

Automatic piston feeding machine for variable displacement compressor

ActiveCN103587947AGuaranteed piston placement speedImprove work efficiencyConveyor partsPistonExecute in place

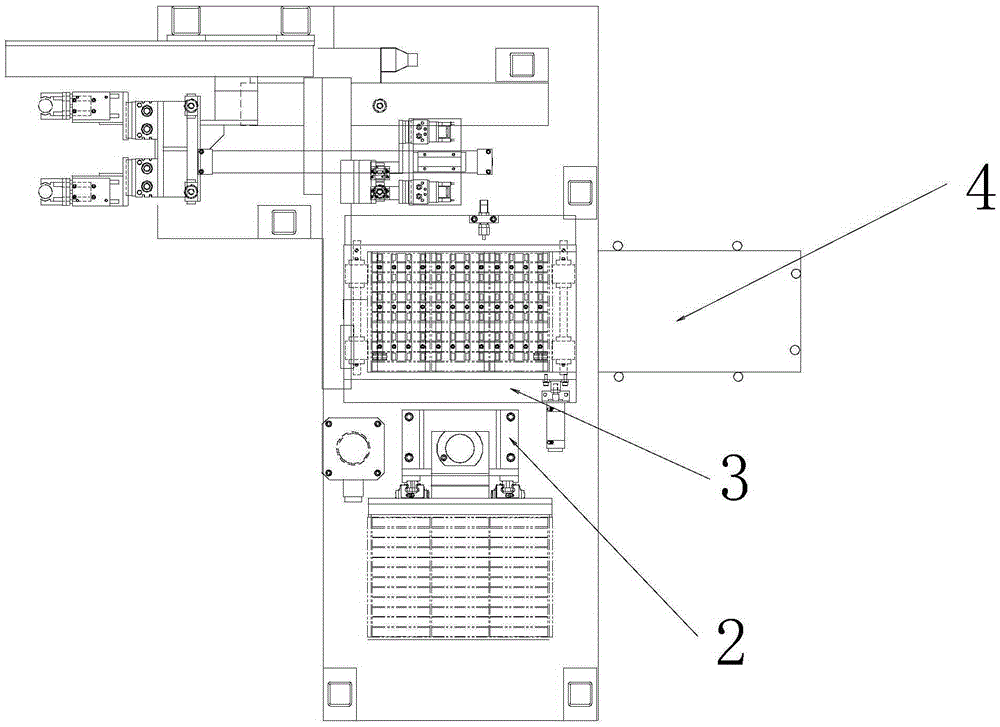

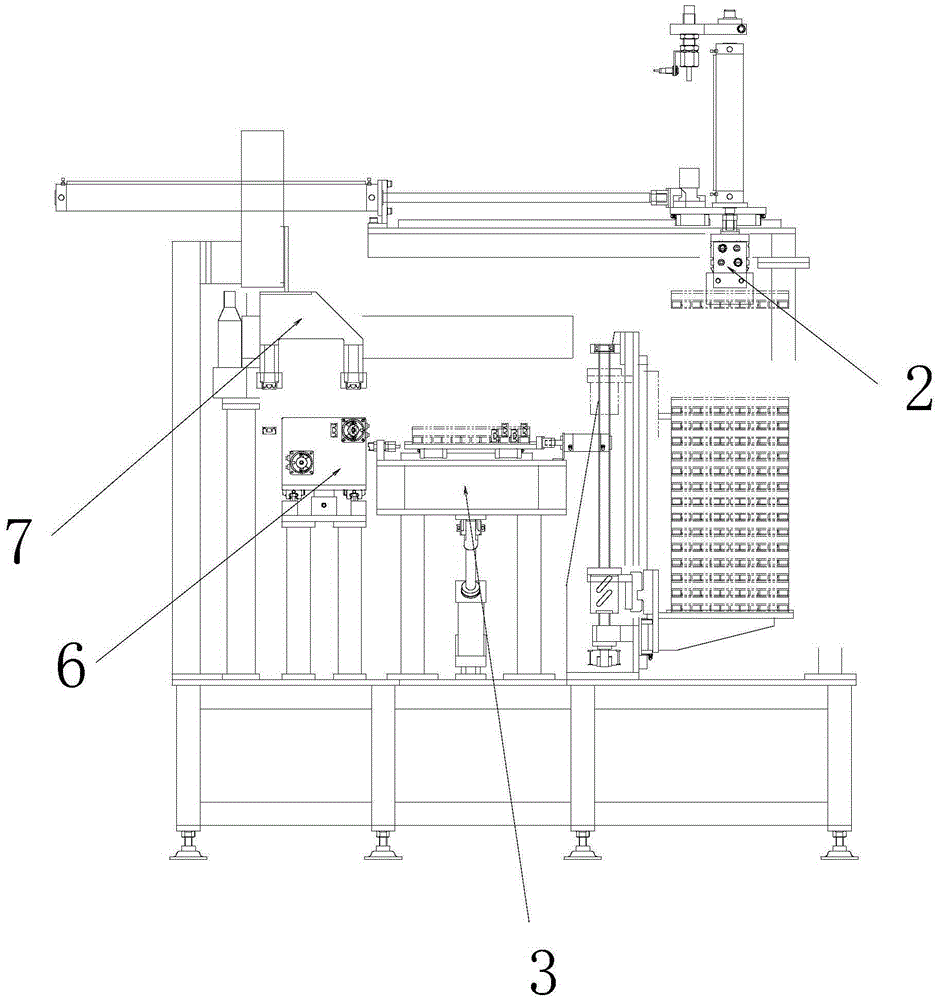

The invention relates to the technical field of machinery, in particular to an automatic piston feeding machine for a variable displacement compressor. The automatic piston feeding machine for the variable displacement compressor comprises a machine frame, a charging tray moving mechanism, a piston jacking mechanism, a charging tray trolley, a piston discharging mechanism, a piston overturning mechanism, and a piston front side and back side inspecting mechanism. The automatic piston feeding machine for the variable displacement compressor is characterized in that the charging tray moving mechanism is arranged in front of the machine frame, the piston overturning mechanism is arranged on the machine frame and is located behind the piston jacking mechanism, the piston discharging mechanism is arranged on the machine frame and is located above the piston overturning mechanism, and the piston front side and back side inspecting mechanism is arranged on the machine frame and is located on the left side of the piston discharging mechanism. Compared with the prior art, the provided automatic piston feeding machine has the advantages that the automatic piston feeding machine is controlled by a PLC in the whole production process, and actions in each process are calculated accurately and executed in place; meanwhile, due to the fact that the piston front side and back side inspecting mechanism is arranged, the piston placing speed is guaranteed, placement faces of pistons are kept consistent, working efficiency is greatly improved, and labor cost is reduced.

Owner:SHANGHAI SANDEN AUTO AIR CONDITIONING

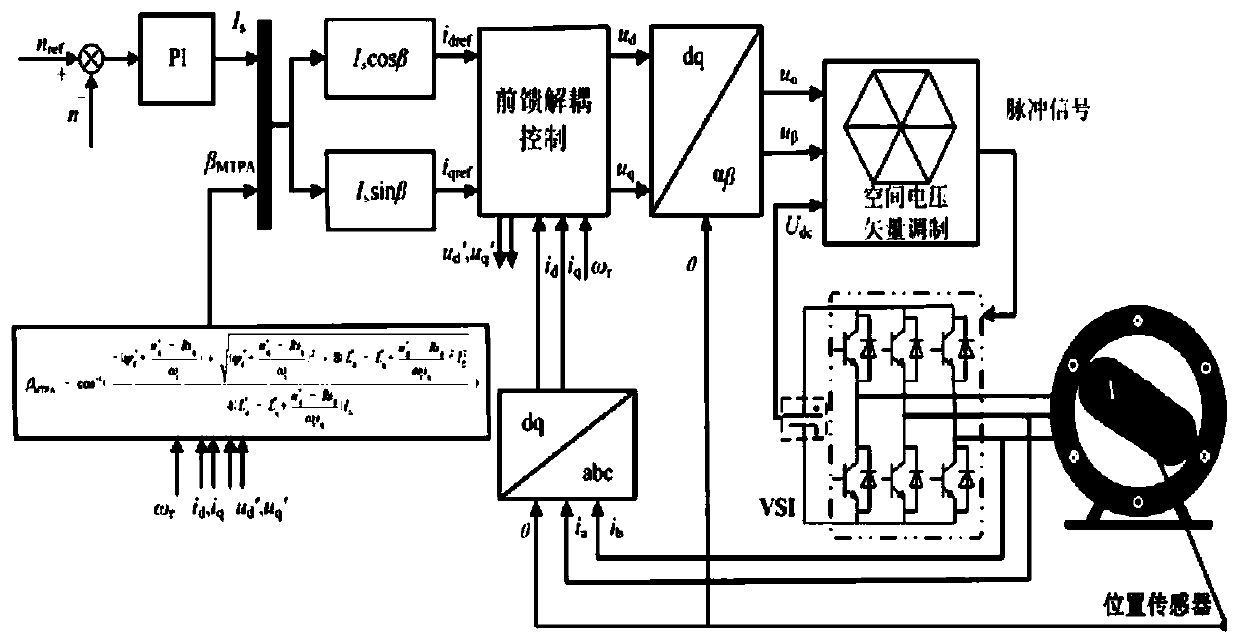

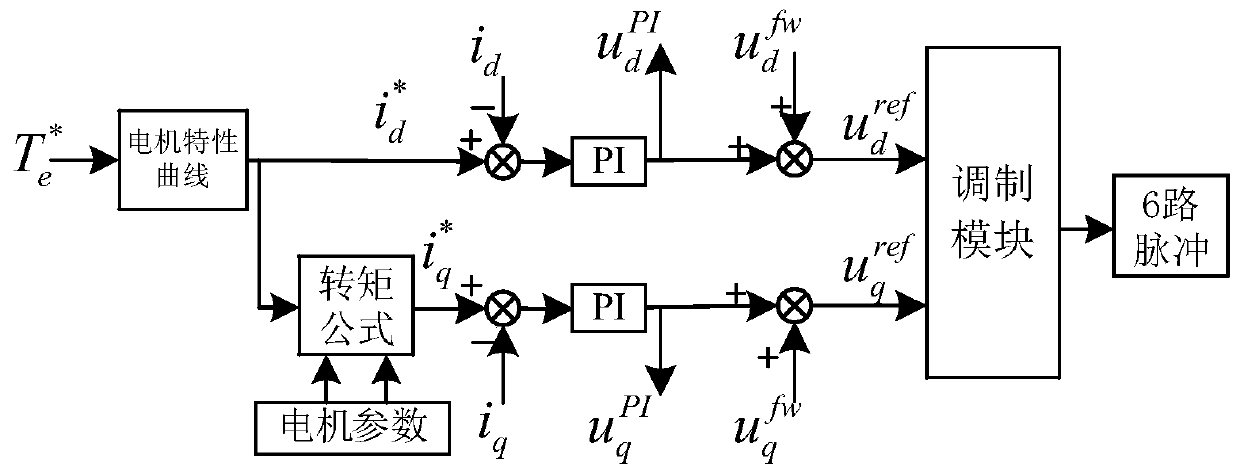

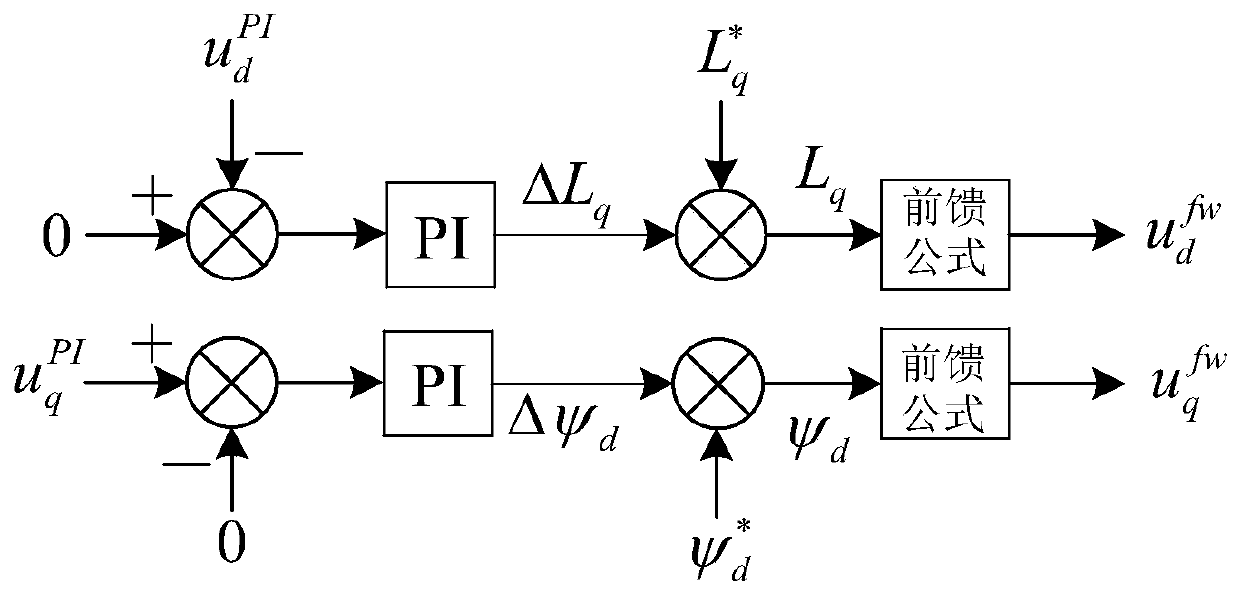

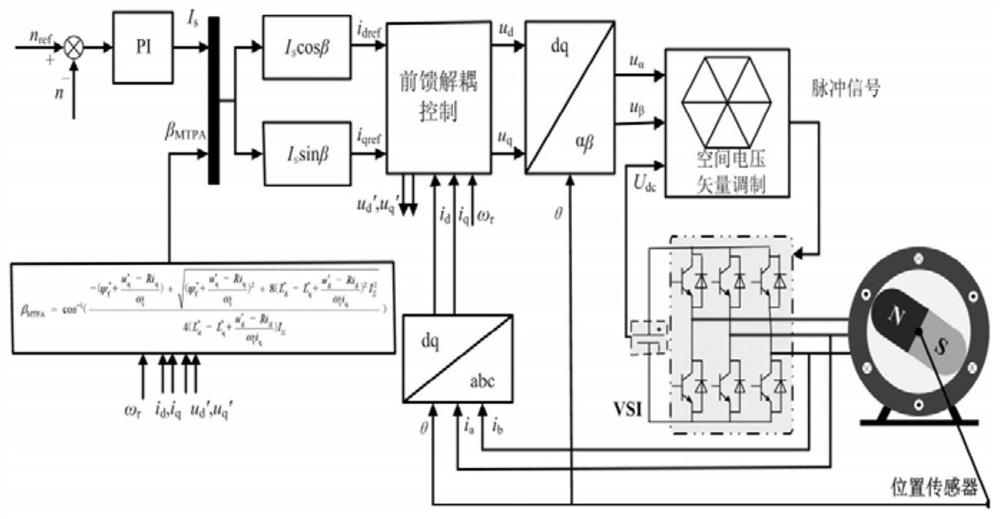

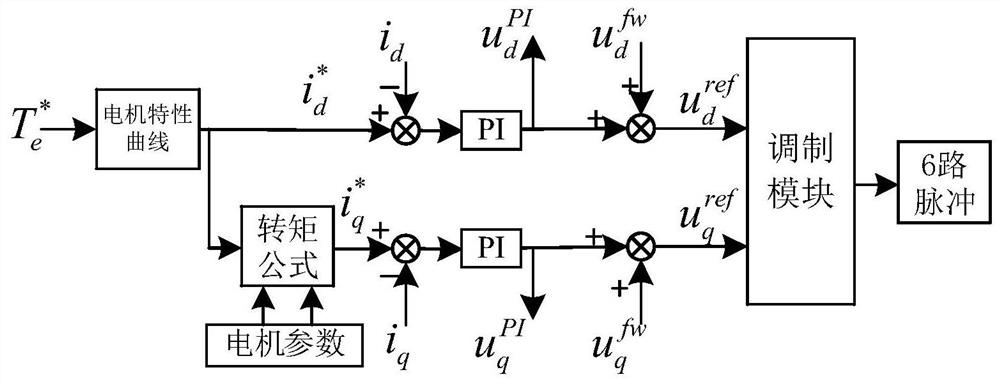

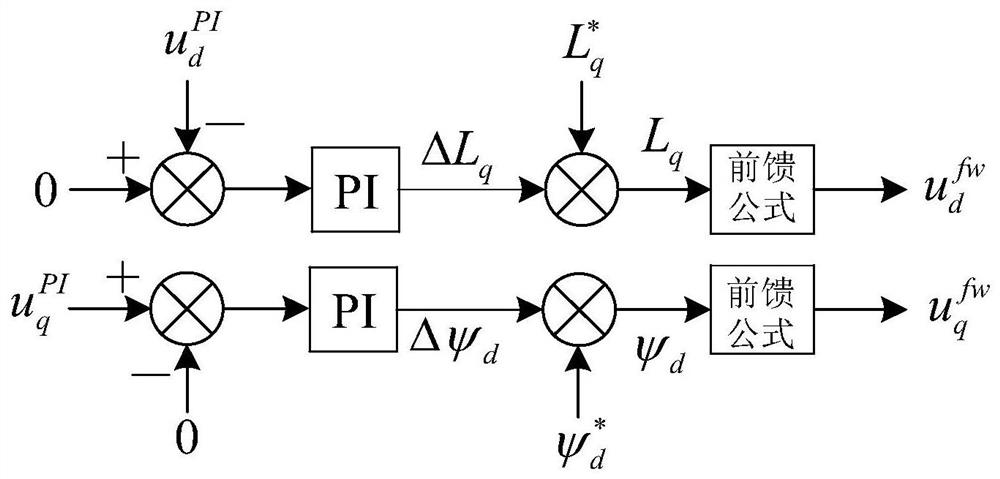

Compensation method for parameters (below base speed) of permanent magnet synchronous motor based on feedforward voltage compensation

ActiveCN110545057AIssued accuratelyGuaranteed to be consistentElectronic commutation motor controlVector control systemsPower inverterElectric machine

The invention relates to a compensation method for parameters (below base speed) of a permanent magnet synchronous motor based on feedforward voltage compensation. The method comprises the following steps: S1, performing calculation to obtain a d-axis current and a q-axis current; S2, obtaining a d-axis current instruction through the calculation of a torque instruction; S3, obtaining two values shown in the description through a current loop PI regulator; S4, calculating two values shown in the description, and respectively calculating the sums of the two values with the two values in step S3to obtain two new values; S5, inputting the two new values in step S4 into a space vector modulation module to obtain six paths of pulses which act on a voltage type inverter control motor; S6, compensating for the q-axis inductor and the d-axis flux linkage, wherein the compensated q-axis inductance and d-axis flux linkage are used for calculation in step S2 and the step S4 in the next calculation period; and the steps S1-S6 are circulated in a reciprocating manner, that is, the output torque of the motor is accurately controlled through the compensation of motor parameters.

Owner:BEIJING JIAOTONG UNIV

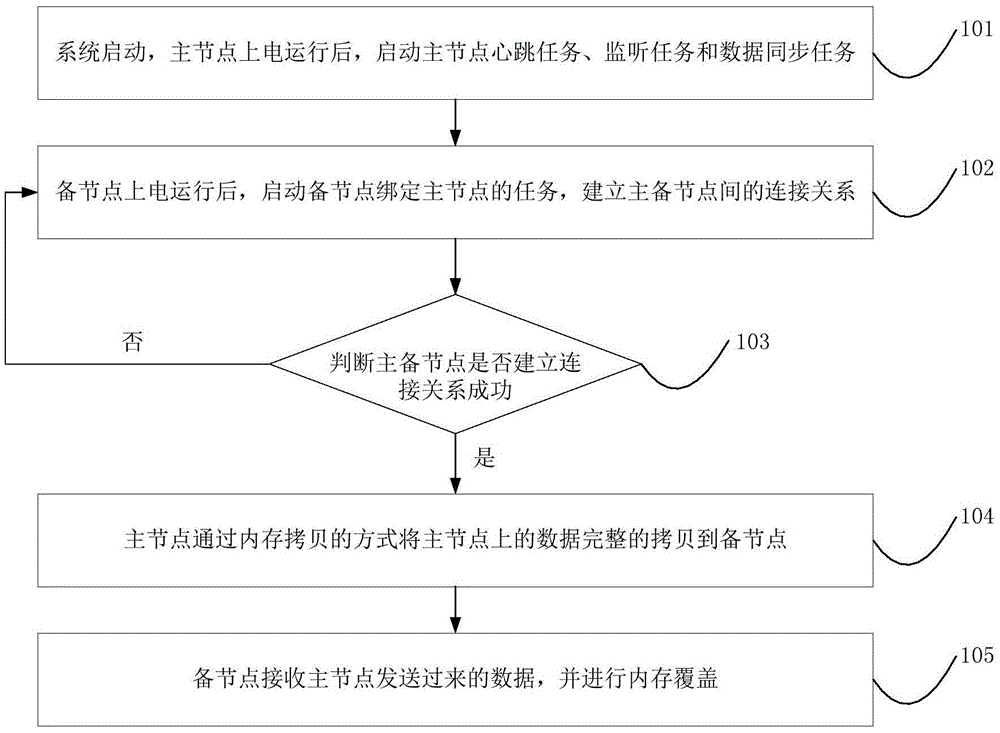

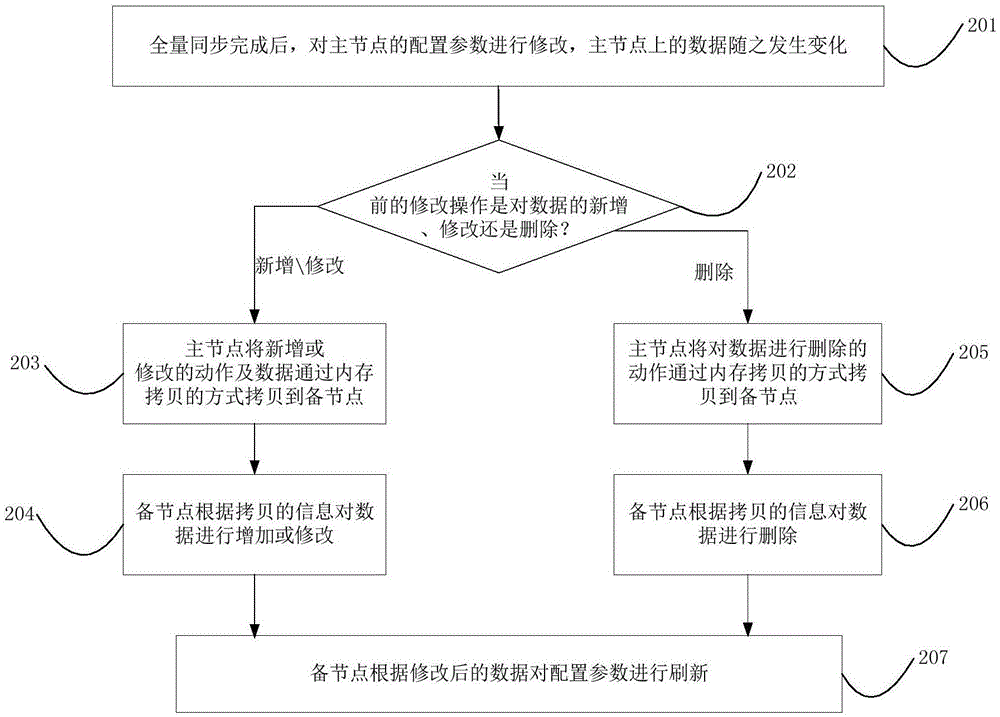

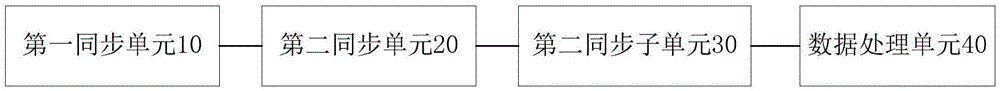

Real-time data synchronization method and system between main and standby nodes

InactiveCN105610566AImprove real-time performanceGuaranteed to be consistentSynchronising arrangementHandoverDistributed computing

The invention discloses a real-time data synchronization method and system between main and standby nodes. The method comprises the following steps: starting the system, realizing the data synchronization from a main node to a standby node in a total synchronization mode; after the total synchronization, modifying the configuration parameter of the main node, and realizing the data synchronization from the main node to the standby node in an incremental synchronization mode; during the incremental synchronization, synchronizing the data to the standby node in an internal memory copy mode; and modifying the data by the standby node according to the copied information, and refreshing the configuration parameter according to the modified data. By adopting the real-time data synchronization method and system disclosed by the invention, the instantaneity of data synchronization is obviously improved, and the consistency of the service operation state and the configuration parameter and other information of the device before and after the handover of the main and standby nodes is guaranteed.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

Garden fertilization device

InactiveCN104380894AGuaranteed depthGuaranteed to be consistentPlantingWatering devicesLand levelingFertilizer

The invention provides a garden fertilization device and belongs to the technical field of machinery. The problem in the prior art that garden vegetation can not be fertilized at high efficiency and high utilization rate is solved. The garden fertilization device comprises a rack and a bottom plate, wherein a fertilization mechanism is fixed on the bottom plate and comprises a chemical fertilizer box; the lower end of the bottom plate is hinged to a sealed door; a ditching structure is further fixed on the bottom plate; a land leveling and irrigation mechanism is fixed on the bottom plate and comprises a water tank, a water pump and a nozzle; the land leveling and irrigation mechanism further comprises a vertical air cylinder, a longitudinal air cylinder I, a longitudinal air cylinder II, a transverse air cylinder and a mounting plate; a pushing plate I is fixed at the end part of a piston rod of the longitudinal air cylinder I; a pushing plate II is fixed at the end part of a piston rod of the longitudinal air cylinder II; and the transverse air cylinder is arranged at the other side of the mounting plate in a sliding manner. The garden fertilization device has the advantages that ditching and fertilization can be carried out automatically and fertilized ditches are filled up and irrigated so that the working efficiency and the utilization rate of chemical fertilizers are improved.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

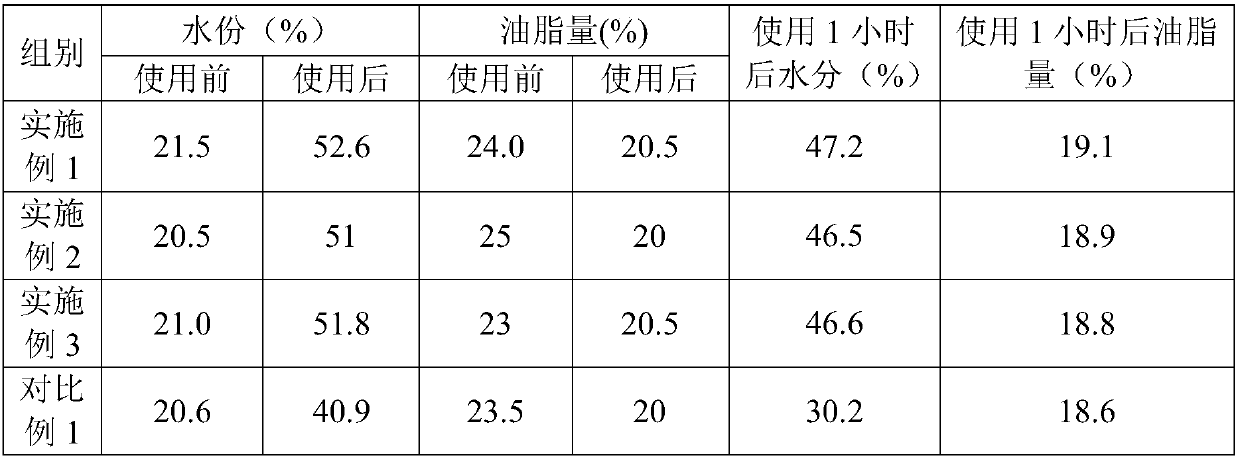

Hyaluronic acid stock solution and preparation method thereof

InactiveCN109620752ASynthesis speedRefreshing and non-sticky textureCosmetic preparationsToilet preparationsSodium hyaluronateChemistry

The invention discloses a hyaluronic acid stock solution, which comprises, by weight, 4-10% of butanediol, 2-7% of glycerol, 0.05-0.5% of sodium hyaluronate, 0.2-0.8% of hydroxyethyl cellulose, 0.5-2%of betaine, 1-5% of hydrolyzed chitin, 0.3-1.2% of p-hydroxyacetophenone, 0.5-2% of oat-beta-glucan, 0.1-0.8% of a mixture of sclerotium and phenoxyethanol,0.2-1% of 1, 2-hexanediol, water and the balance; the sum of the weight percentages of the above components is 100%. According to the hyaluronic acid stock solution, a hyaluronic acid precursor with small molecular weight is permeated into skin, so that the synthesis speed of the hyaluronic acid in the skin is promoted; and moreover, the hyaluronic acid stock solution is fresh and non-greasy in texture, and is water-supplementing and moisture-preserving. The invention also discloses a preparation method of the hyaluronic acid stock solution, which has simple operation and lower cost and is suitable for most production equipment on themarket.

Owner:深圳市琉璃光生物科技有限公司

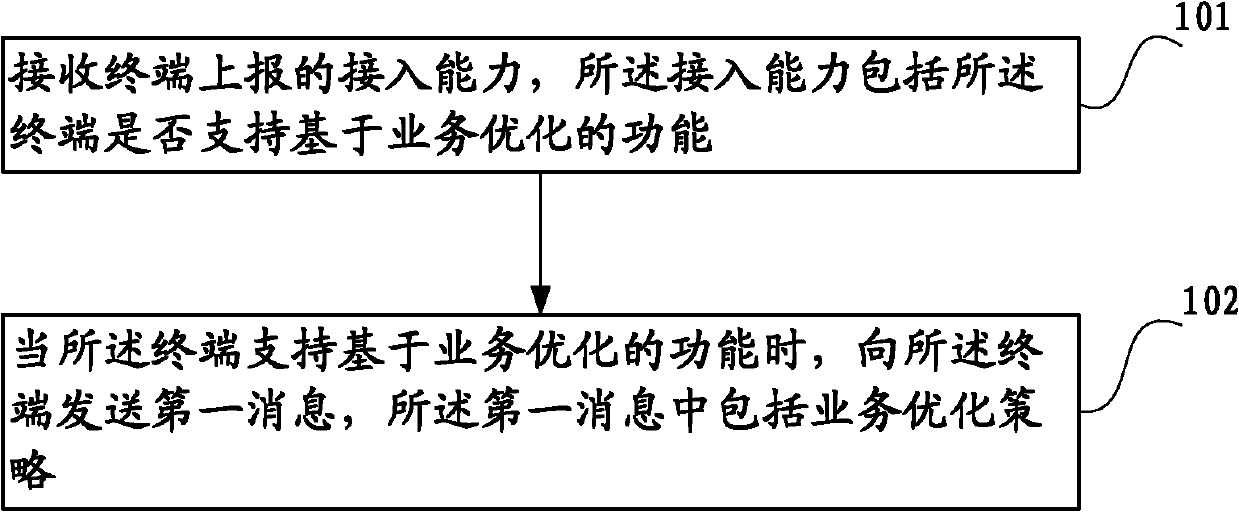

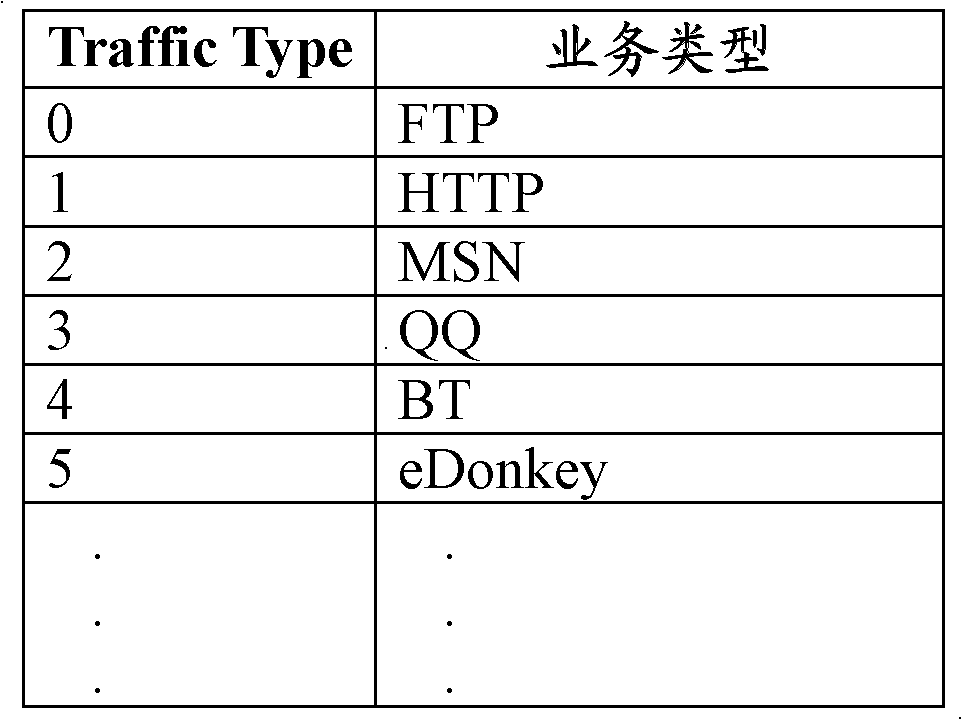

Method for notifying service optimization strategies, network side equipment and terminal

InactiveCN101951628AGuaranteed to be consistentImprove business optimization effectWireless communicationComputer engineeringService optimization

The invention discloses a method for notifying service optimization strategies and a corresponding device. The method for notifying the service optimization strategies comprises the following steps: receiving access capacity reported by a terminal, wherein the access capacity comprises whether the terminal supports a function based on service optimization; and when the terminal supports the function based on the service optimization, sending a first message to the terminal, wherein the first message comprises the service optimization strategies. The method for notifying the service optimization provided by the invention can send the service optimization strategies to the terminal in accordance with the access capacity of the terminal, thereby ensuring consistency of the terminal and the network side optimization strategies and improving service optimization effects.

Owner:HUAWEI TECH CO LTD

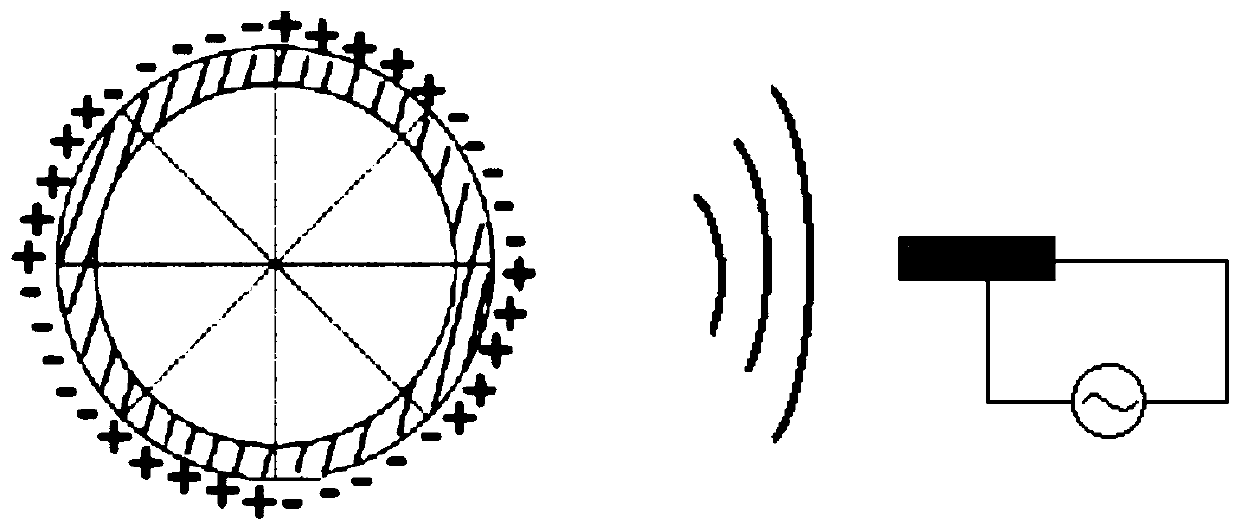

Electret mechanical antenna charging effect evaluating method

InactiveCN110146752AGuaranteed to be consistentRealize measurementAntenna radiation diagramsPlasma technologyElectret

The invention relates to the technical field of low frequency communication and plasma and provides a method of evaluating charging of an electret-based mechanical antenna. The evaluating system comprises two parts of a charging effect measurement module and a remaining power measurement module for measuring and evaluating the charge amount of the electret in the case of charging and in a using process with charging already completed. The charging effect measurement module adopts a method of combining multiple probes and a moving probe, the charge density graphical distribution is acquired byscanning the electret, a charging device is thus controlled with the graphical distribution as feedback, and thus, the electret obtained by charging at each time can reach a consistent index. The remaining power measurement module adopts a method of fixing the position of a receiving antenna and fixing the operation mode of the mechanical antenna, the remaining charge amount of the electret is calculated through signal intensity, and when the charge amount is low, a user is reminded to supplement charges for the electret.

Owner:BEIHANG UNIV

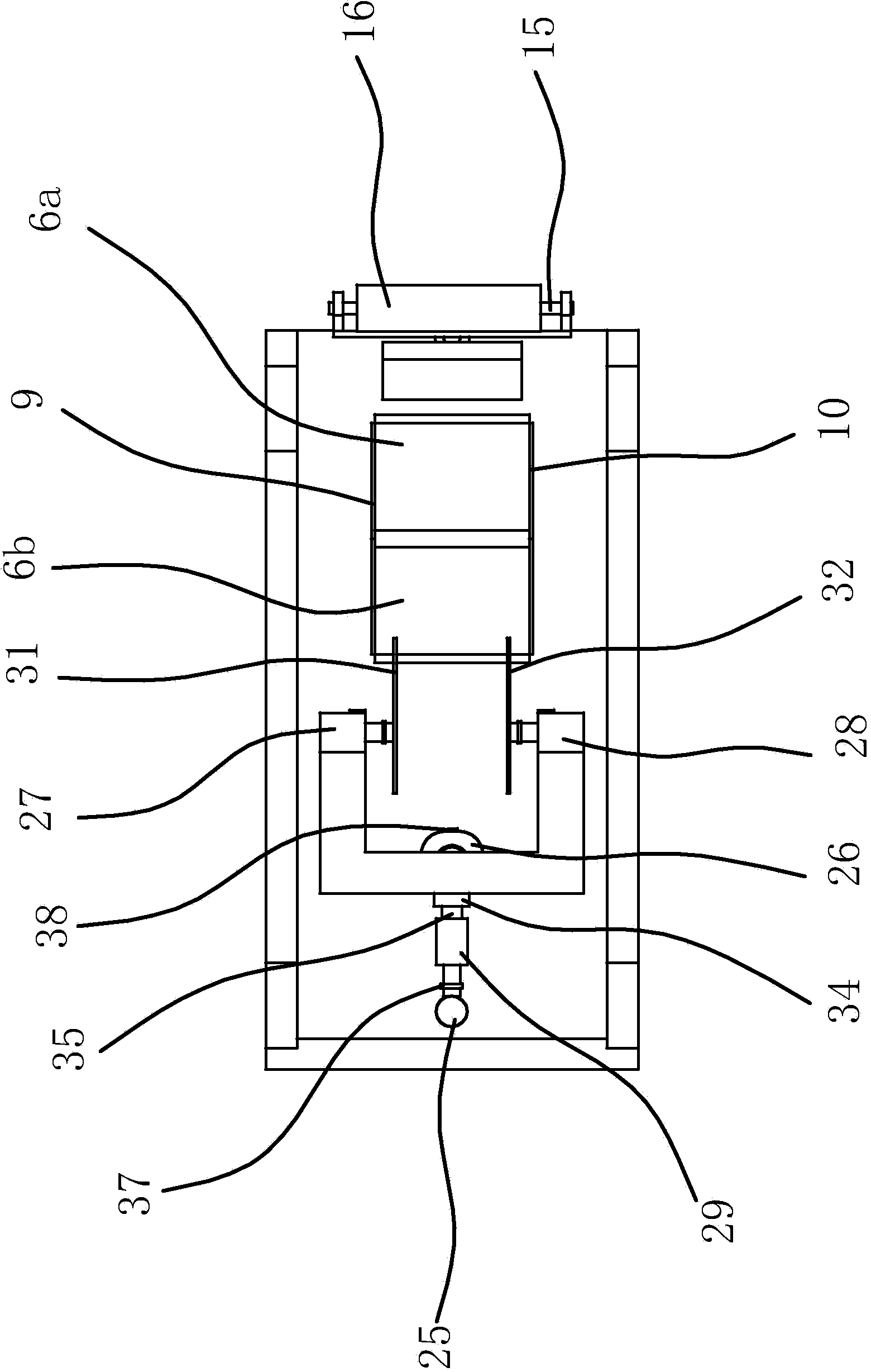

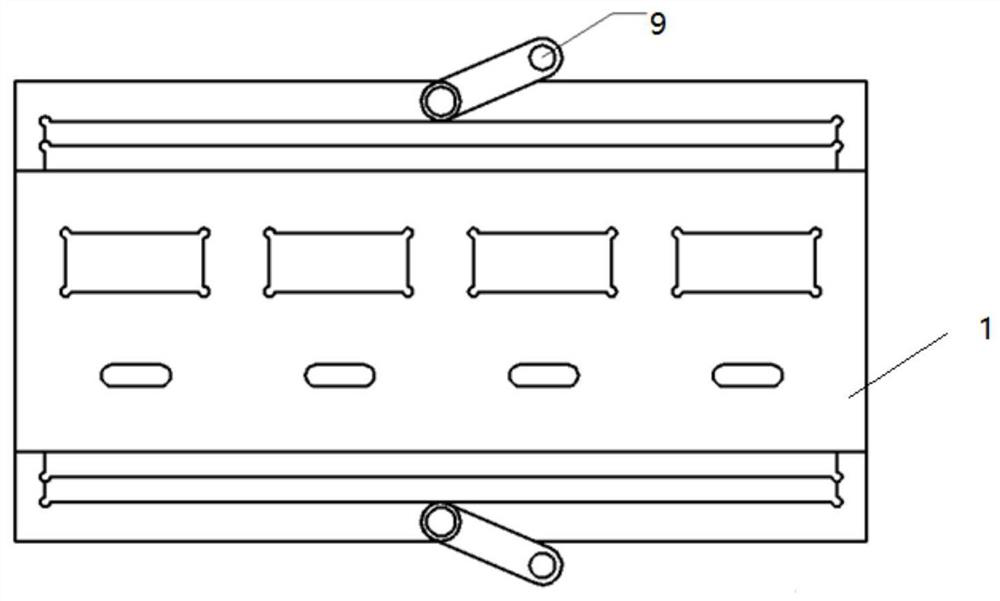

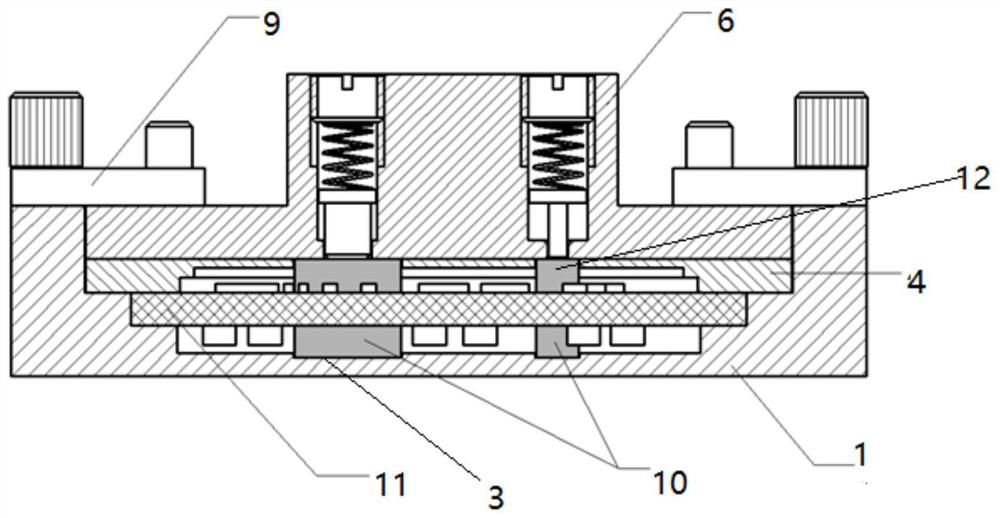

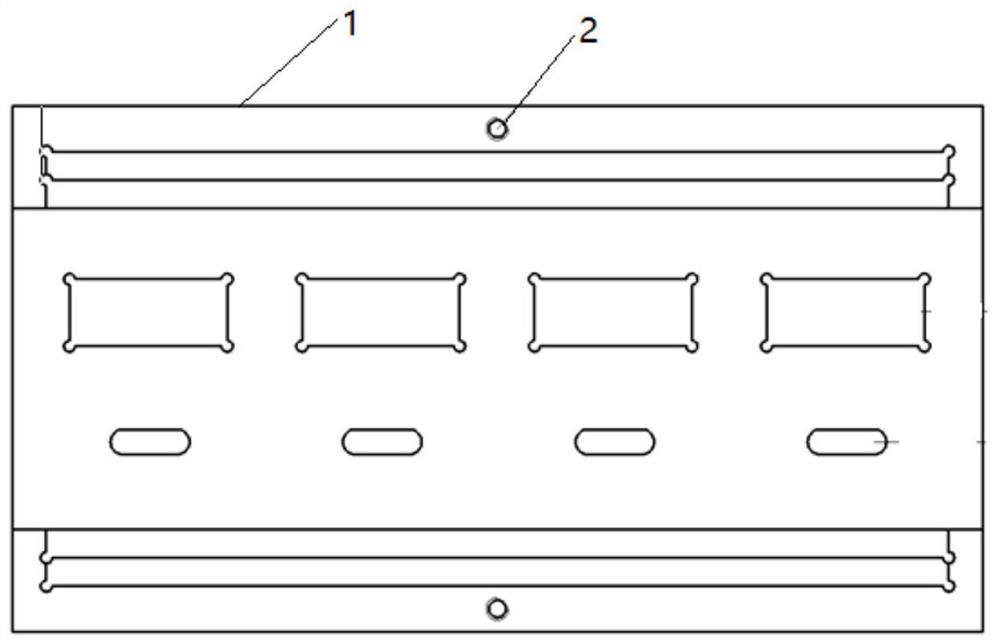

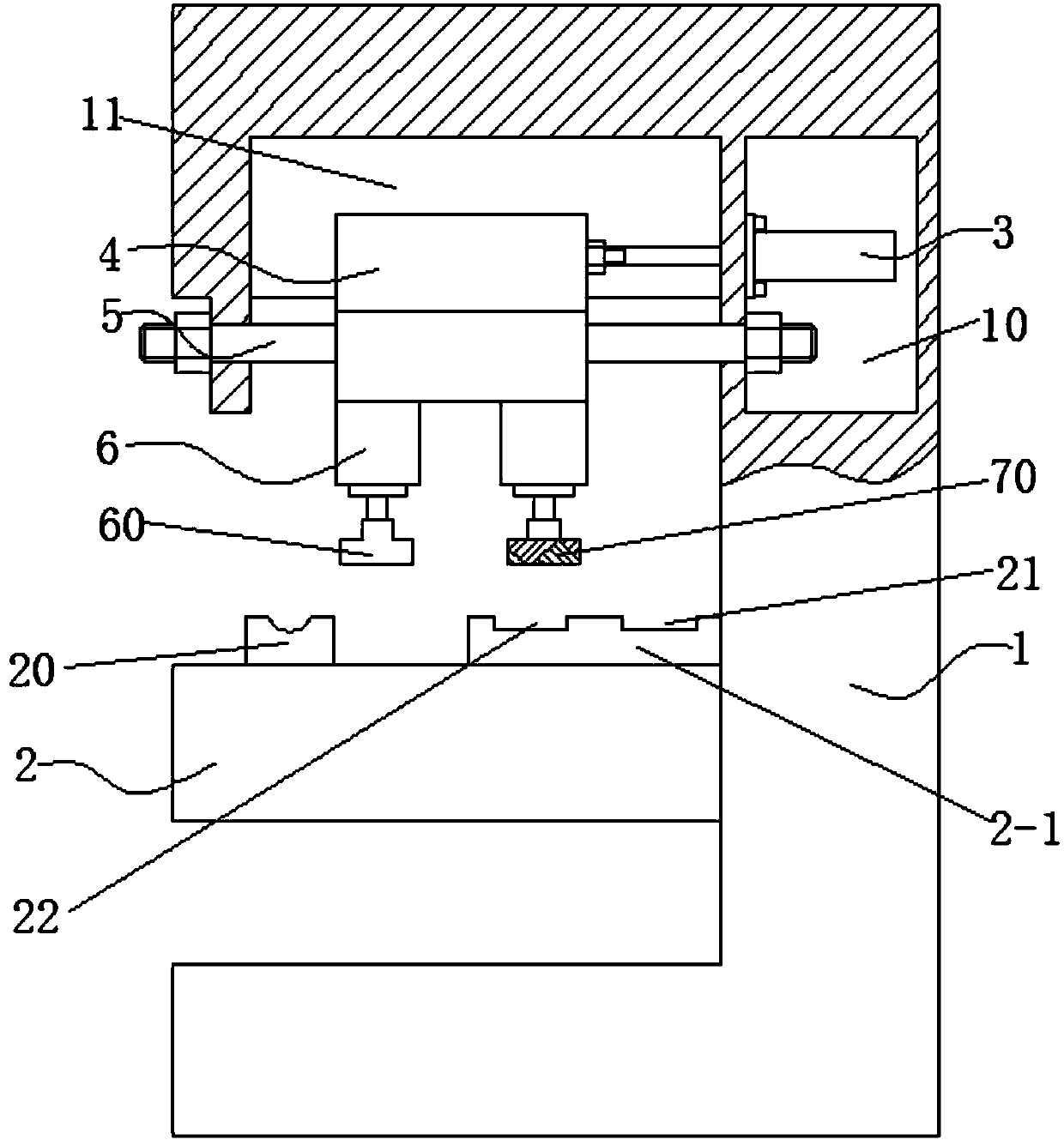

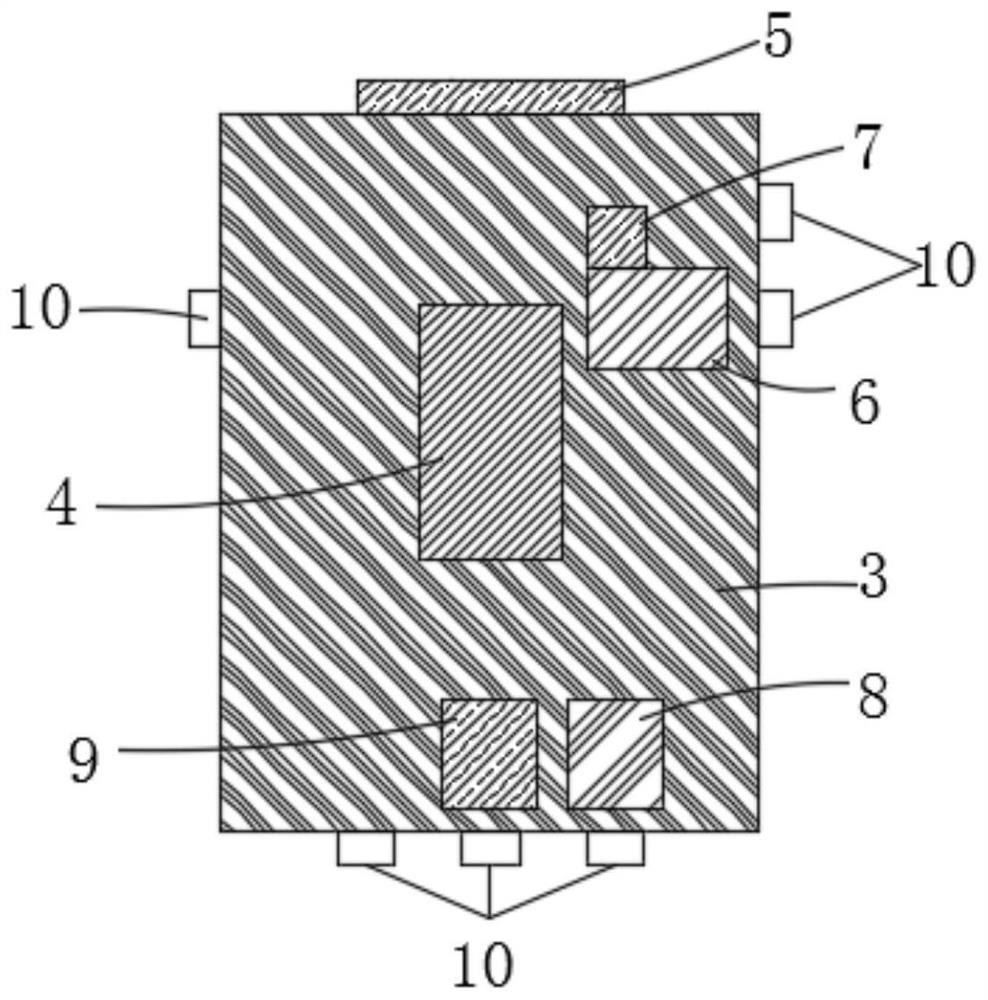

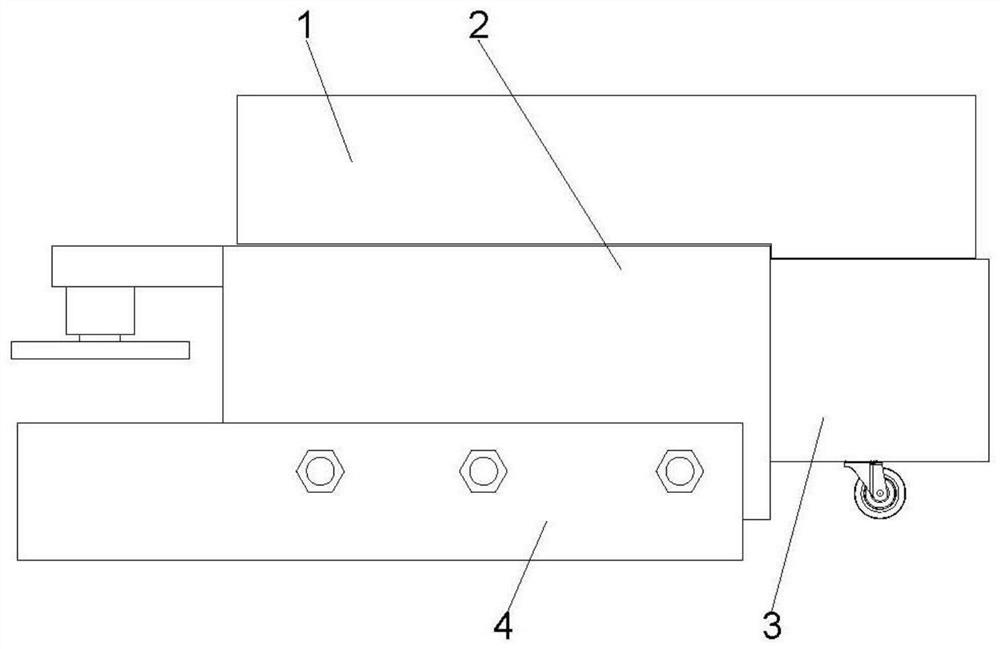

Pressure-adjustable magnetic core bonding tool

ActiveCN113262955AEnsure consistencyIncrease productivityLiquid surface applicatorsMaterial gluingMagnetic coreStructural engineering

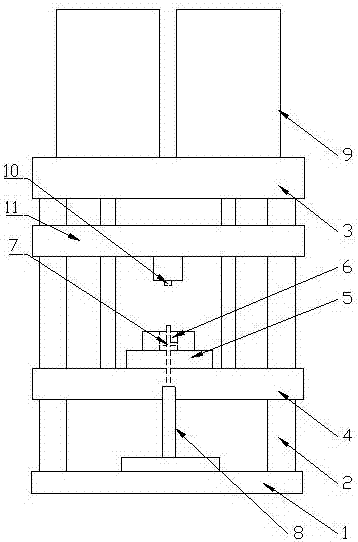

The invention relates to a pressure-adjustable magnetic core bonding tool, and belongs to the technical field of magnetic core bonding. The pressure-adjustable magnetic core bonding tool comprises a base, a lower magnetic core groove used for placing a lower magnetic core, a circuit board groove used for placing a circuit board and an upper magnetic core groove used for placing an upper magnetic core plate are sequentially formed in the base from bottom to top, and a positioning window facilitating the placing of the upper magnetic core is formed in the upper magnetic core plate. The upper magnetic core and the lower magnetic core are fixedly arranged on the upper surface and the lower surface of the circuit board in an aligned mode, and a pressing device used for pressing the upper magnetic core and the lower magnetic core is arranged vertically above the upper magnetic core plate. The tool has the beneficial effects that the tool has the functions of positioning upper magnetic core and the lower magnetic core, adjusting the pressure and maintaining the pressure; the positioning of the upper magnetic core and the lower magnetic core can realize that the magnetic cores are aligned and bonded without deviation, the pressure can be adjusted to determine proper pressure in a module test stage, the pressure maintaining function ensures that the pressure is consistent and unchanged in a magnetic core adhesive curing process, the consistency of output parameters of a power supply module can be ensured, and the production efficiency can be improved.

Owner:BEIJING INST OF RADIO MEASUREMENT

Fertilization mechanism in garden fertilization device

InactiveCN104429256AGuaranteed Ditch DepthGuaranteed to be consistentPlantingWatering devicesFertilizerAgricultural engineering

The invention provides a fertilization mechanism in a garden fertilization device, belonging to the technical field of machinery and aiming at solving the problems that ditches can not be automatically dug in soil, and fertilization can not be carried out in the prior art. According to the fertilization mechanism in the garden fertilization device, the garden fertilization device comprises a rack and a bottom plate; the fertilization mechanism comprises a chemical fertilizer box fixed on the bottom plate; a discharging opening is formed in the bottom of the chemical fertilizer box and a piston plate is arranged in the discharging opening; a telescopic air cylinder I is fixed on the inner wall of the chemical fertilizer box; the end part of a piston rod of the telescopic air cylinder I is fixed on the piston plate; a through hole is formed in the bottom plate and the lower end of the bottom plate is hinged to a closed door; and a ditching structure is further fixed on the bottom plate. The fertilization mechanism in the garden fertilization device has the advantages that the ditches with the consistent depth can be automatically dug and the uniform fertilization is carried out.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

LED bulb code spraying device

InactiveCN108099383ARealize automatic printing operationImprove operational efficiencyRotary pressesLED lampMechanical engineering

The invention discloses an LED bulb code spraying device comprising a base, a workbench, a main push air cylinder, a sliding block, a guide rail, a printing air cylinder and an ink smearing air cylinder. The workbench is fixedly connected with the lateral surface of the base, the upper end of the base is provided with an installing cavity and a machine head cavity, the main push air cylinder is installed in the installing cavity, and the front end of a piston rod of the main push air cylinder is connected with the sliding block. The sliding block is in sliding connection with the guide rail, the printing air cylinder is connected with the front side of the lower end of the sliding block, the ink smearing air cylinder is connected with the rear side of the lower end of the sliding block, aprinting head is arranged at the lower end of the printing air cylinder, and smearing cotton is arranged at the lower end of a piston rod of the ink smearing air cylinder. Automatic printing operationof parameters on LED bulbs is achieved, operation efficiency is high, and printing force is uniform.

Owner:马鞍山市鑫龙特钢有限公司

AOI (automatic optic inspection) device

InactiveCN104568980ASimple structureGuaranteed to be consistentOptically investigating flaws/contaminationCamera lensEngineering

The invention discloses an AOI (automatic optic inspection) device. The AOI device comprises a support, a camera mounted at the upper part of the support and a front light generation mechanism mounted below the camera, wherein the front light generation mechanism comprises a hollow barrel, a hollow bracket fixed at the lower part of the barrel, light sources arranged on the bracket and a dome arranged above the barrel, and a through hole corresponding to a lens of the camera is arranged in the center of the upper part of the dome. The AOI device is simple in structure, the dome scatters colored light generated by the lower light sources, compound light uniform in all directions is formed through repeated reflection in the barrel, so that light irradiating on a battery piece located below the barrel is consistent in all directions, the camera captures a clear picture, and the detection result is more accurate.

Owner:SUZHOU JUNENG IMAGE INSPECTION TECH

Programmable intelligent remote controlled walking rice transplanter

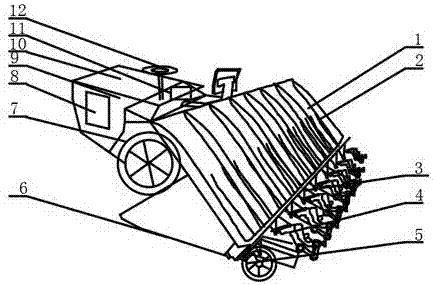

InactiveCN106982580AGuaranteed to be consistentGuaranteed survival rateTransplantingRemote controlAgricultural engineering

The invention discloses a programmable intelligent remote controlled walking rice transplanter, wherein the rice transplanter comprises a driving mechanism, a rice transplanting mechanism and a control mechanism; the control mechanism comprises an engine, a stepping motor clutch, a walking driving case, a steering operation disk, and a seedling boat; the rice transplanting mechanism comprises a seedling case, a seedling pressing rod, a seedling pusher and a planting arm; the control mechanism comprises a remote controller and a controller. Through manual remote control or programming remote control of the remote controller, the automatic walking of the rice transplanter is controlled, the rice transplanting depth is consistent, thereby avoiding people following the machine operation and also avoiding the solarization from scorching sun and mud immersion, and reducing labor intensity.

Owner:山东双菱内燃机制造有限公司

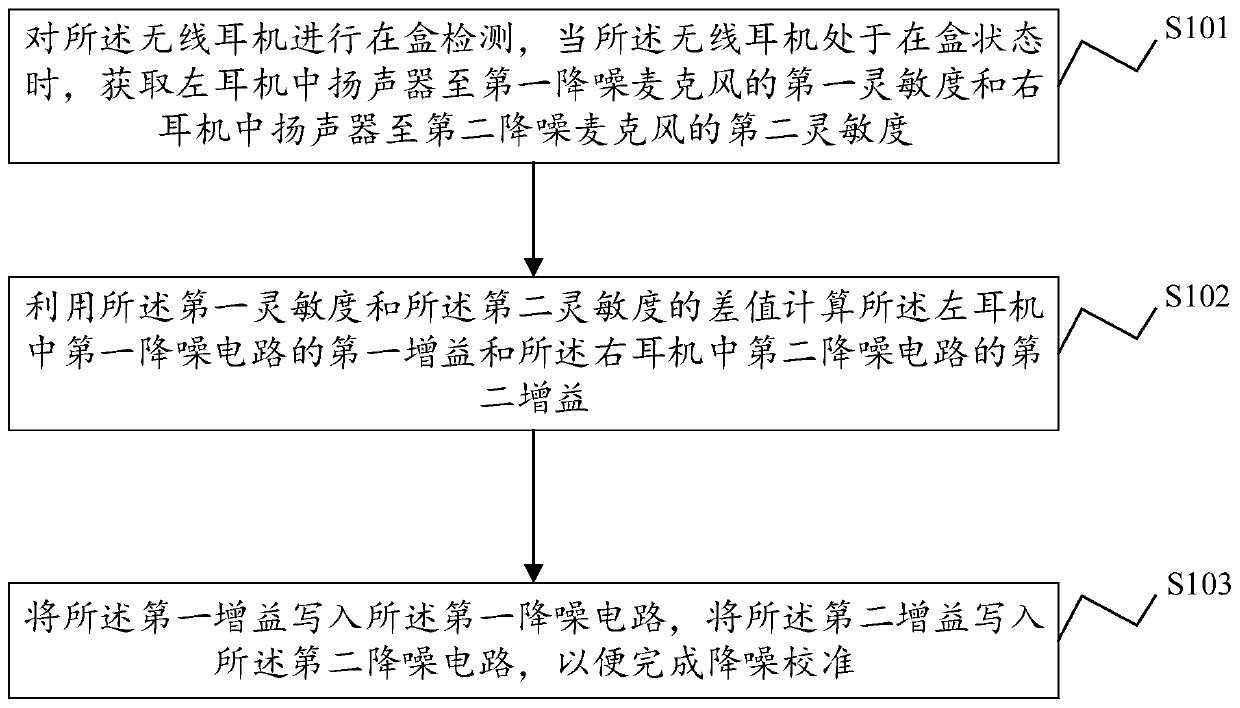

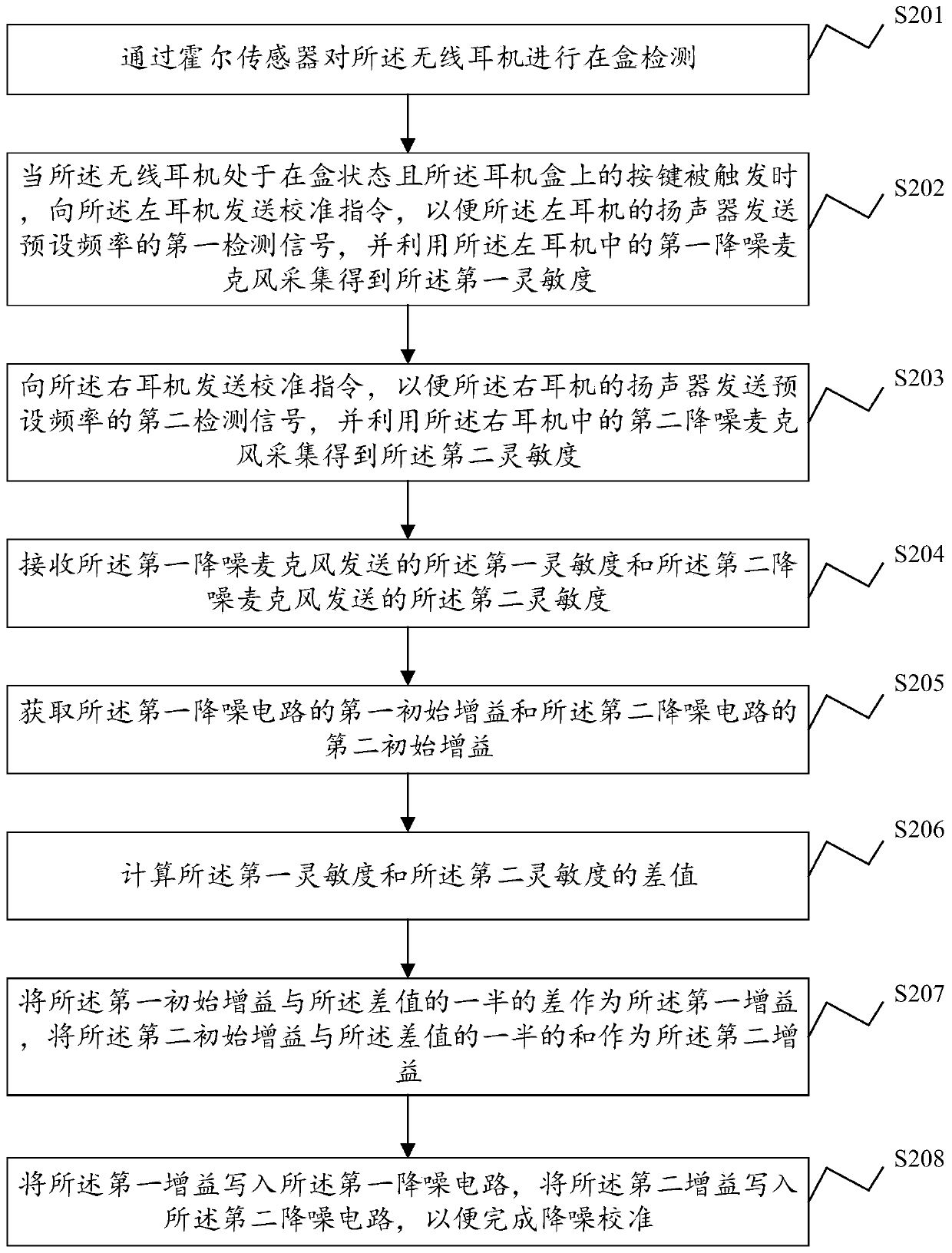

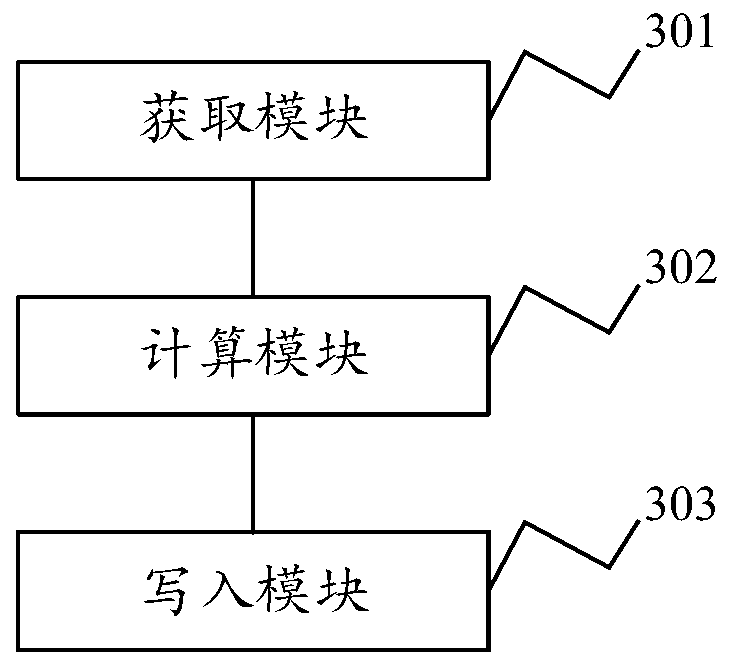

Wireless earphone noise reduction calibration method and device, earphone box and storage medium

ActiveCN110784804AEnsure the amount of noise reductionGuaranteed to be consistentMeasurement devicesFrequency response correctionLoudspeakerMicrophone

The invention discloses a wireless earphone noise reduction calibration method and device, an earphone box and a computer readable storage medium. The method comprises the following steps: carrying out on-box detection on the wireless earphone, and when the wireless earphone is in an on-box state, obtaining a first sensitivity from a loudspeaker in a left earphone to a first noise reduction microphone and a second sensitivity from a loudspeaker in a right earphone to a second noise reduction microphone; calculating a first gain of a first noise reduction circuit in the left earphone and a second gain of a second noise reduction circuit in the right earphone by using a difference value between the first sensitivity and the second sensitivity; writing the first gain into the first noise reduction circuit, and writing the second gain into the second noise reduction circuit so as to complete noise reduction calibration. According to the wireless earphone noise reduction calibration methodprovided by the invention, the gain values of the left and right earphone noise reduction circuits are recalculated by using the sensitivity difference between the left and right earphone loudspeakersand the noise reduction microphone, and the calibration of the noise reduction amount of the left and right earphones is realized by adjusting the difference of the gain value balance sensitivity.

Owner:GEER TECH CO LTD

Injection-molding mold lateral parting forced demoulding mechanism scheme

The invention discloses an injection-molding mold lateral parting forced demoulding mechanism scheme. The injection-molding mold lateral parting forced demoulding mechanism scheme comprises a device main body, a seal stamping device arranged inside the device main body and a moving device arranged inside the device main body, and the seal stamping device comprises a first rotating cavity arrangedinside the device main body. According to the injection-molding mold lateral parting forced demoulding mechanism scheme, at present, indispensable mold stamping and stamping of some mold stamping seals and official seals in the daily office are needed, use staff generally all adopt manual stamping to be prone to causing inconsistent stamping depth, attractiveness is affected, furthermore, the efficiency is low, and the invention aims to design the injection-molding mold lateral parting forced demoulding mechanism scheme that automatic seal stamping performed on molded plastic needing the moldstamping can be finished, and needed stamping ink can be replenished appropriately before the seal stamping every time, sufficient absorption is finished through a sponge foam block, a mold stamping block is guaranteed to be capable of being fully stained with the stamping ink, and meanwhile, coincident mold stamping depth and the clear mold stamping in the mold stamping every time can further beguaranteed.

Owner:嘉兴喜格丽服装有限公司

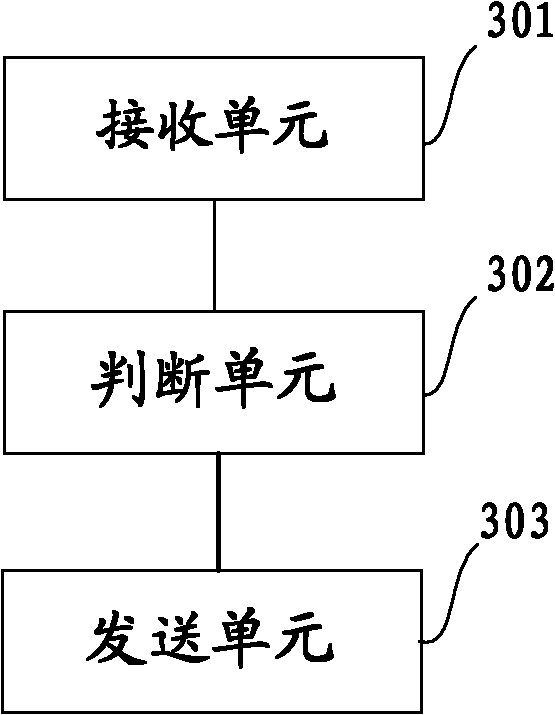

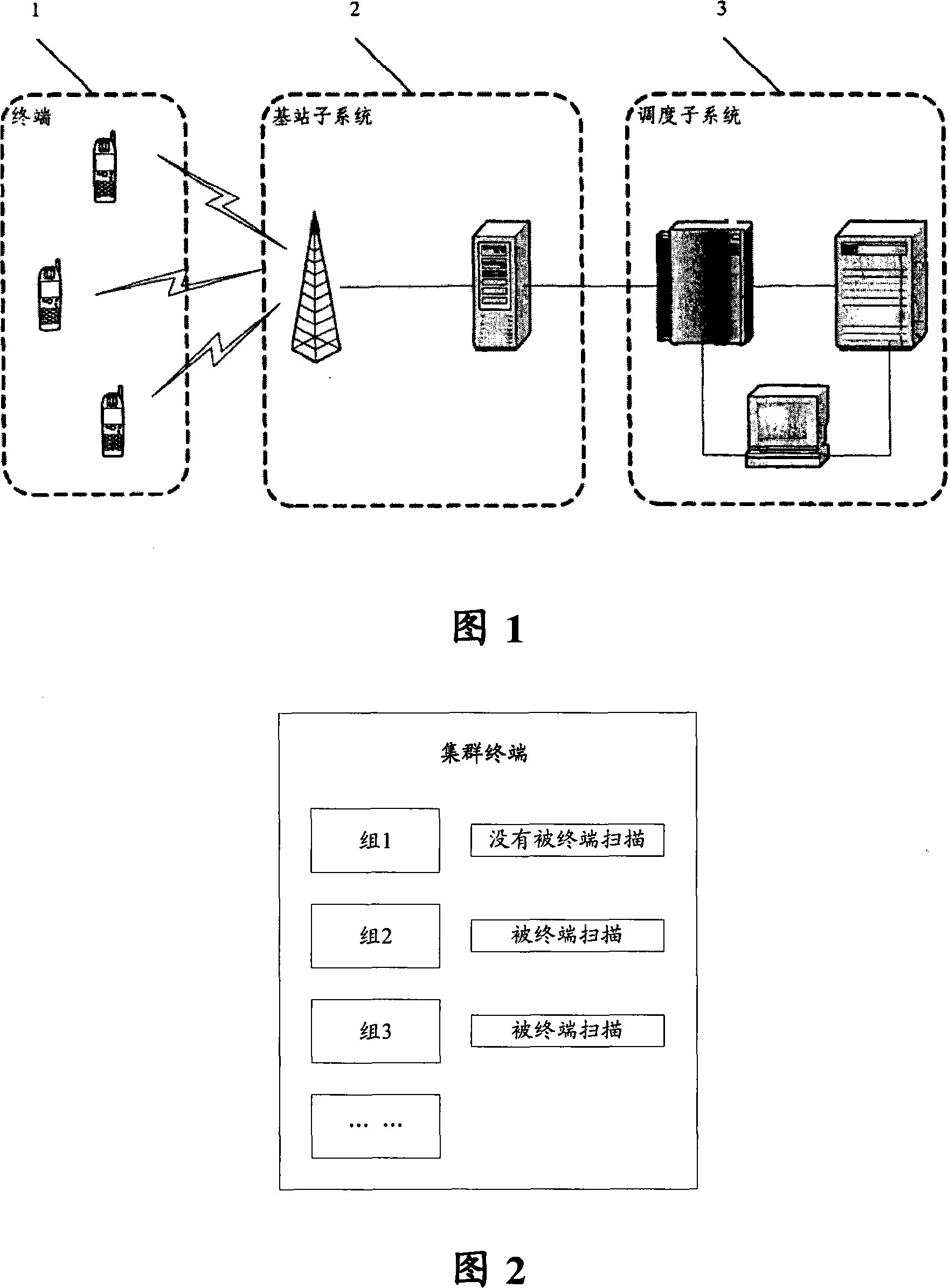

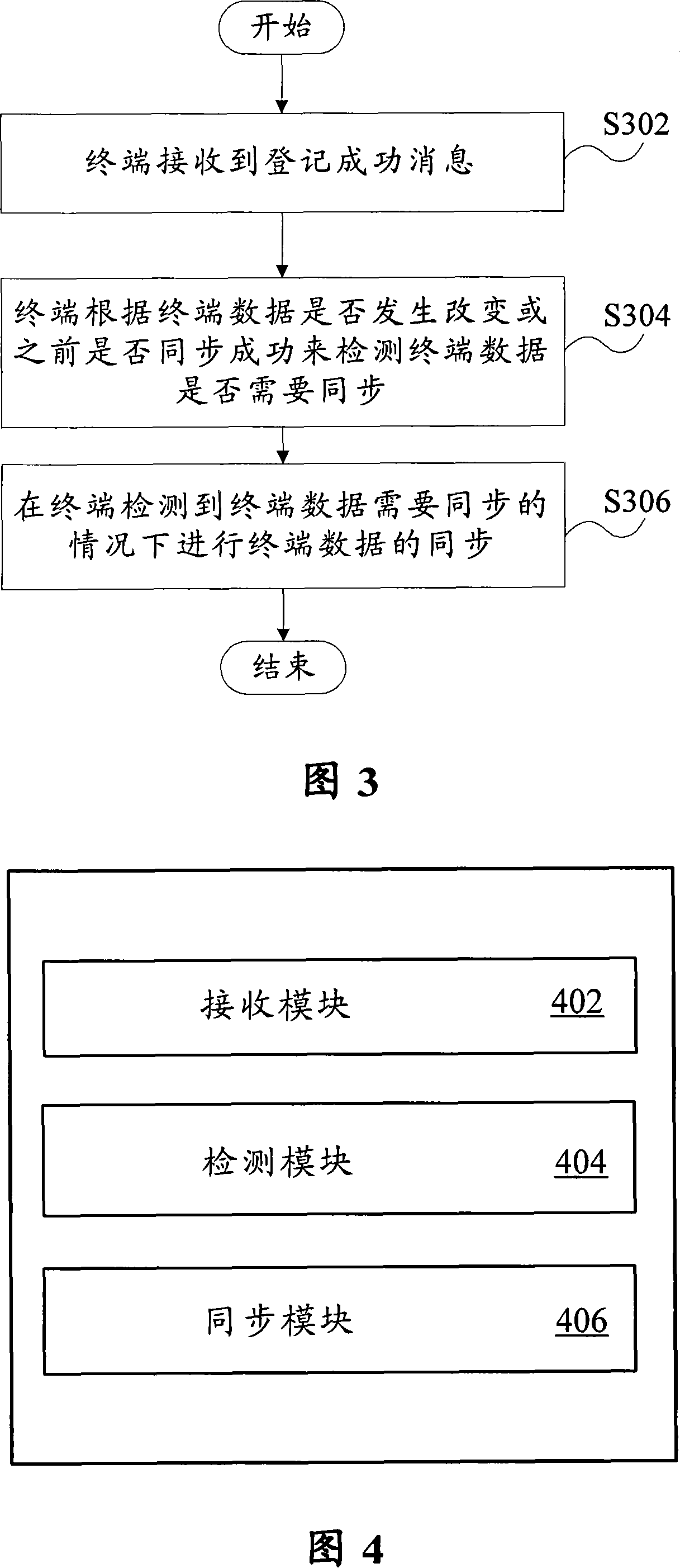

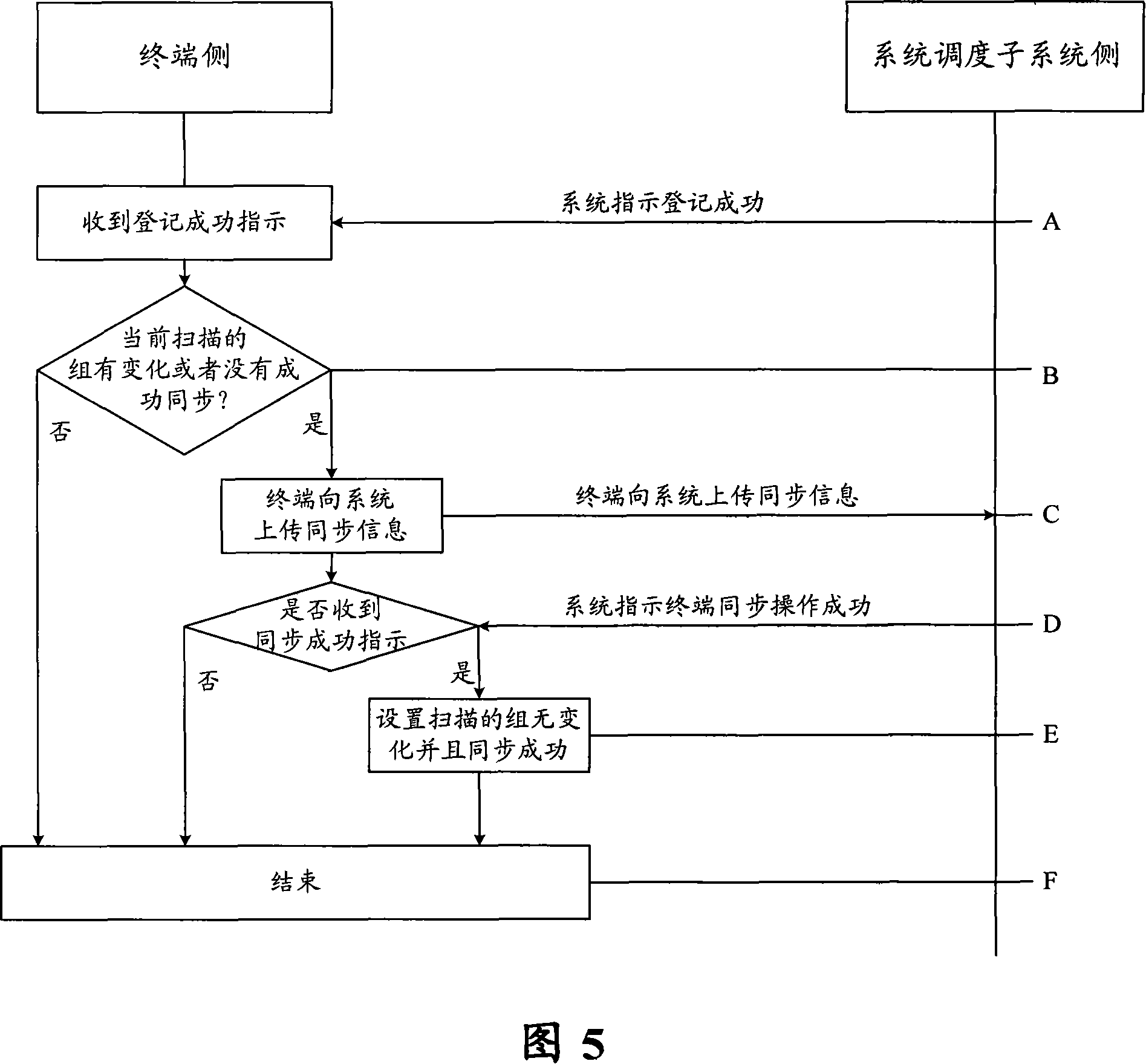

Method and device for cluster terminal to synchronize data of system

ActiveCN101115243AGuaranteed to be consistentEnsure consistencyRadio/inductive link selection arrangementsData needsReal-time computing

The invention provides a cluster terminal direction system synchrodata method. The method comprises following steps: step S302, the terminal receives successful register message (the message refers to that the CDMA is registered successfully or the GOTAPTT is registered successfully); step S304, the terminal detects whether terminal data is synchronous according to whether the terminal data are changed or synchronous before; and step S306, a synchronization of the terminal data is carried out when the terminal is detected that the terminal data need synchronization. By adopting the technic proposal of the invention, information saved by the terminal can be consistent with that saved by the system.

Owner:SHENZHEN ZTE TRUNKING TECH CORP

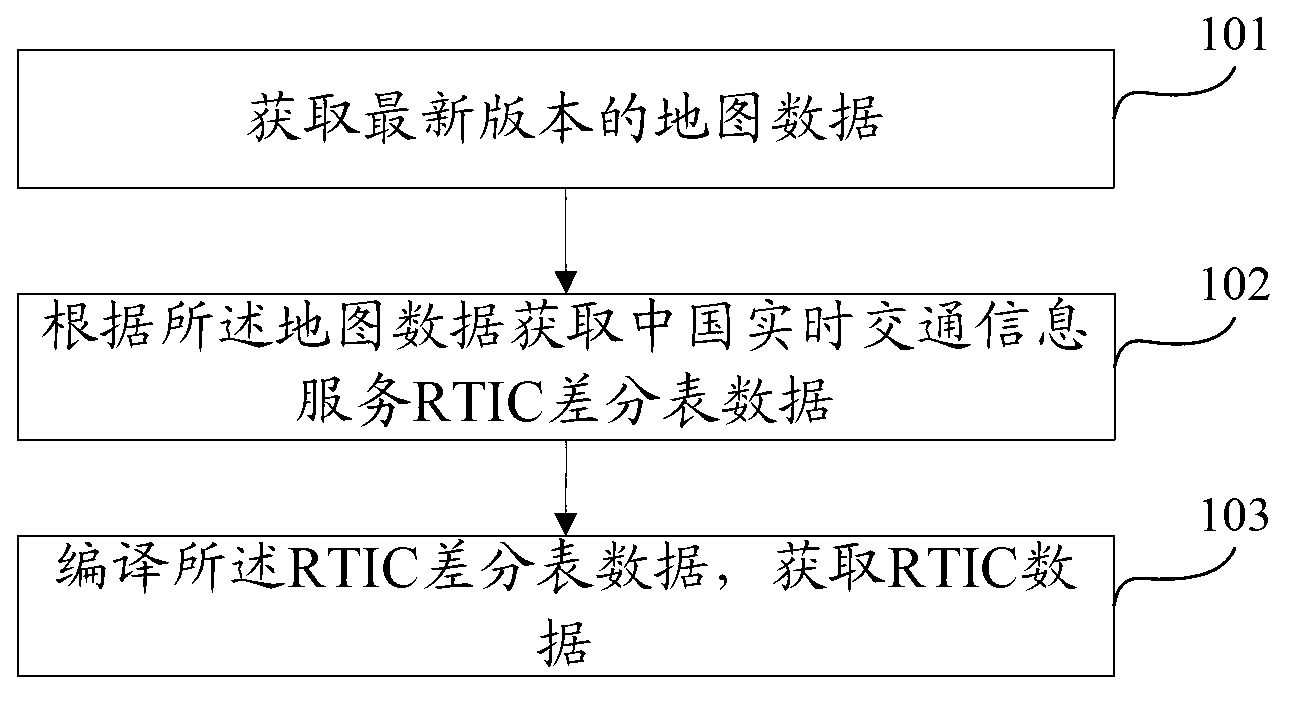

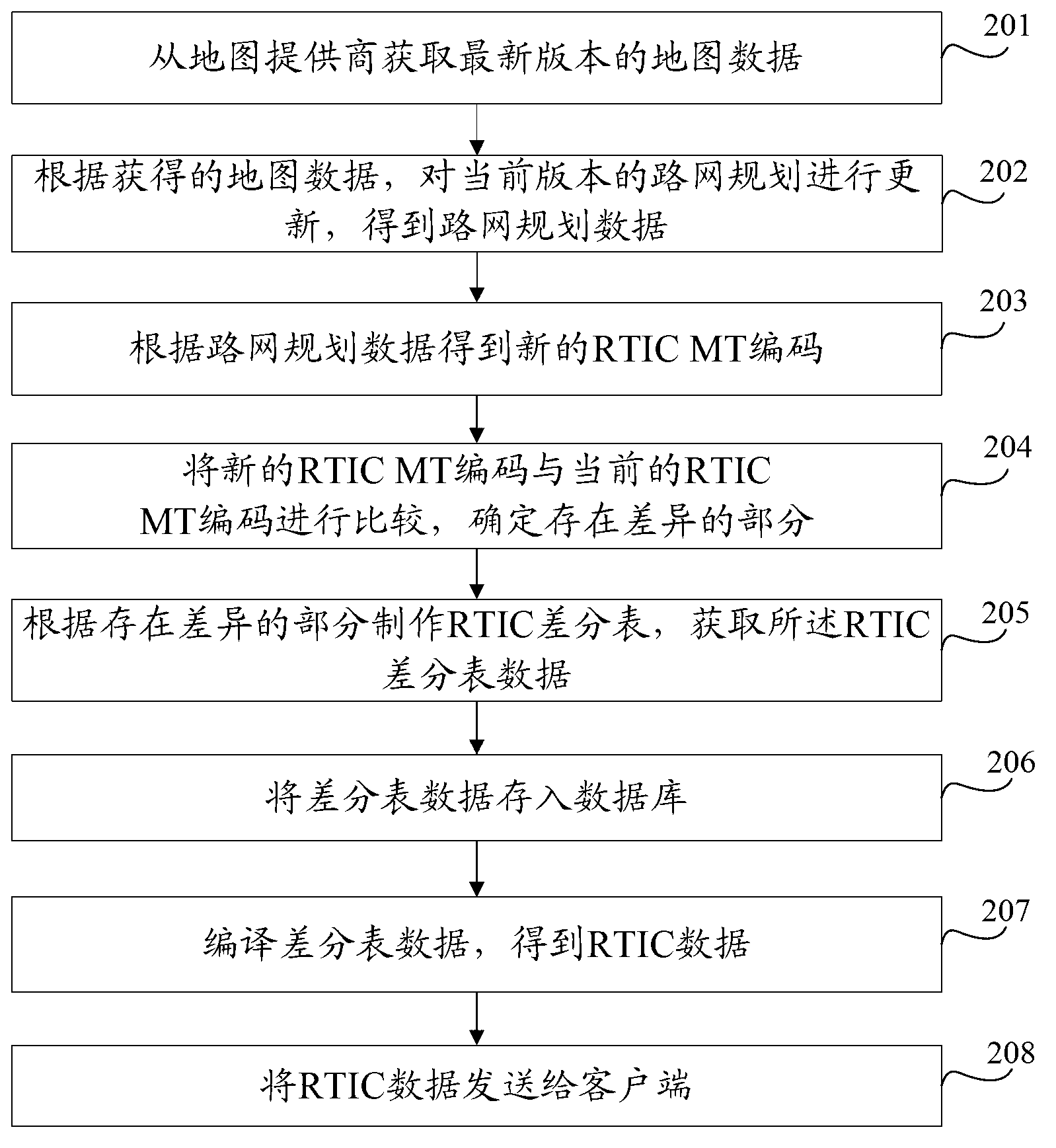

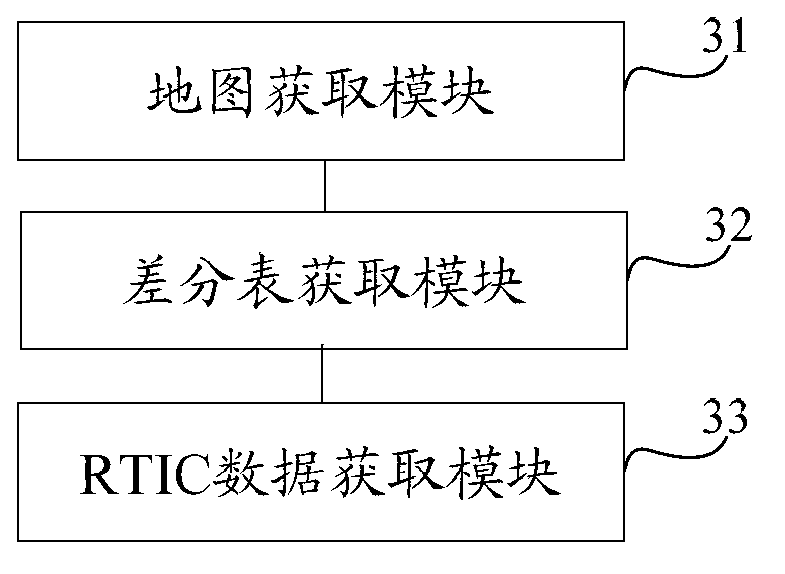

Updating method and device for real-time traffic information

ActiveCN102800208AGuaranteed to be consistentImprove user experienceRoad vehicles traffic controlTime information

The embodiment of the invention discloses an updating method and a device for real-time traffic information, and relates to the technical field of intelligent traffic information service. The method can solve the problem of poor real time of RTIC (Real-Time Information of China) data and improve user experience. The method comprises the following steps: obtaining map data of the newest version; obtaining difference table data of real-time information of China (RTIC) according to the map data; and compiling the difference table data of RTIC and obtaining RTIC data, wherein the RTIC data are used for updating the different parts of the current RTIC data from the map data. The method and the device are suitable for updating RTIC data in traffic information service.

Owner:CENNAVI TECH

Automatic screw locking machine system

InactiveCN113500381AGuaranteed to be consistentRealize automatic integrationMetal working apparatusScrew positionEngineering

The invention discloses an automatic screw locking machine system. The automatic screw locking machine system comprises a base, a smooth cavity penetrating front and back is formed in the base, first mounting blocks symmetrical in position are fixedly arranged on the left wall and the right wall of the smooth cavity, first sliding grooves with openings facing the symmetry center are formed in the first mounting blocks, and the first sliding grooves are slidably connected to first sliding blocks. According to the system, a controllable screw locking position adjusting device is arranged, the required screw locking position can be independently selected according to the requirement, a positioning device capable of conducting left-right positioning is arranged, the requirement for locking screws on different workpieces through the screw locking machine can be met, a screw locking depth of the screw locking machine can be achieved through a moving device, it is ensured that depths of locked screws are consistent, a conveying device is arranged to achieve automatic integration of the screw locking machine, labor intensity of workers is reduced, production quality and production efficiency are improved, universality is high, and the screw locking machine can be matched with industrial line operation.

Owner:厦门蕉承贸易有限公司

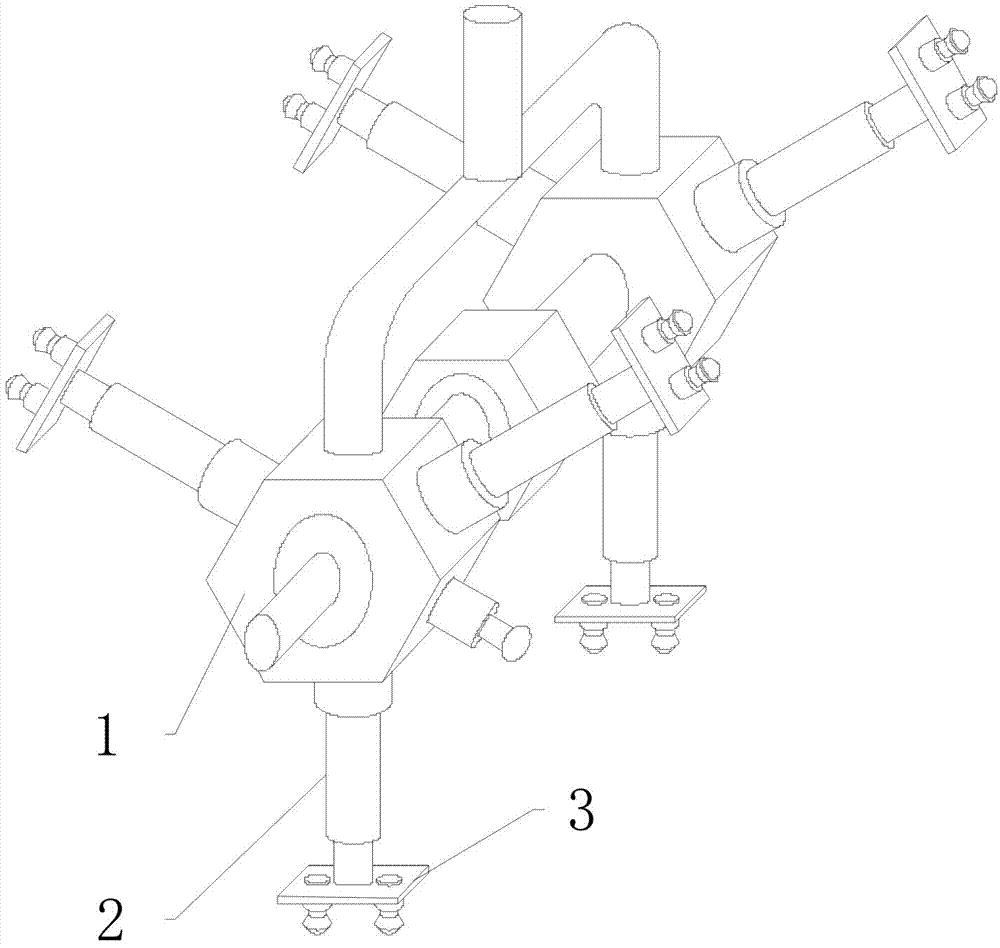

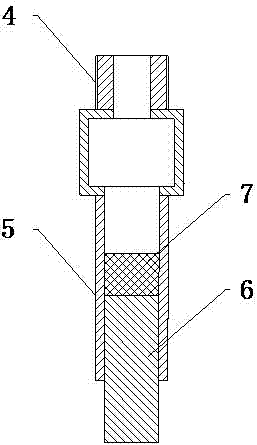

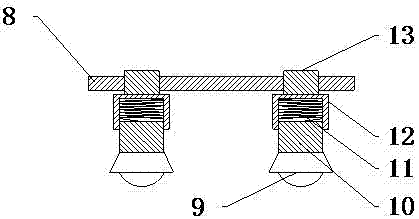

Travelling support arm used for flaw detecting and positioning of welded joint of petroleum pipeline

InactiveCN107387942AGuaranteed to be consistentEasy to assemble and disassembleYielding couplingPigs/molesEngineeringPetroleum

The invention provides a travelling support arm used for flaw detecting and positioning of a welded joint of a petroleum pipeline. The travelling support arm comprises hollow bolts, hollow rods, sliding rods, pistons, mounting plates, universal ball wheels, movable rods, springs, shells and studs. The hollow rods are arranged at the outer ends of the hollow bolts, the sliding rods are arranged at the outer ends of the hollow rods, the pistons are mounted at the inner ends of the sliding rods and inside the hollow rods, and according to the design, travelling mechanism can be extended or shortened conveniently, and the travelling support arm is enabled to be used for flaw detection in different diameters of pipelines. The movable rods are arranged at the inner ends of the universal ball wheels, the springs are arranged at the inner ends of the movable rods and inside the shells, the studs are arranged at the inner ends of the shells and on the mounting plates, and according to the design, convenience in replacement is realized. The travelling support arm is further provided with an automatic popping mechanism, and thereby being ensured to cross a weld joint or a barrier in case of coming across the weld joint or the barrier. The travelling support arm is convenient to use, large in application range, high in working efficiency and high in reliability.

Owner:洛阳高昌机电科技有限公司

An automatic piston feeder for variable displacement compressors

InactiveCN103587947BGuaranteed placement speedGuaranteed to be consistentConveyor partsEngineeringAutomatic variable

The invention relates to the technical field of machinery, in particular to an automatic piston feeding machine for a variable displacement compressor. The automatic piston feeding machine for the variable displacement compressor comprises a machine frame, a charging tray moving mechanism, a piston jacking mechanism, a charging tray trolley, a piston discharging mechanism, a piston overturning mechanism, and a piston front side and back side inspecting mechanism. The automatic piston feeding machine for the variable displacement compressor is characterized in that the charging tray moving mechanism is arranged in front of the machine frame, the piston overturning mechanism is arranged on the machine frame and is located behind the piston jacking mechanism, the piston discharging mechanism is arranged on the machine frame and is located above the piston overturning mechanism, and the piston front side and back side inspecting mechanism is arranged on the machine frame and is located on the left side of the piston discharging mechanism. Compared with the prior art, the provided automatic piston feeding machine has the advantages that the automatic piston feeding machine is controlled by a PLC in the whole production process, and actions in each process are calculated accurately and executed in place; meanwhile, due to the fact that the piston front side and back side inspecting mechanism is arranged, the piston placing speed is guaranteed, placement faces of pistons are kept consistent, working efficiency is greatly improved, and labor cost is reduced.

Owner:SHANGHAI SANDEN AUTO AIR CONDITIONING

Image acquisition method and device for synchronous trigger control of high-speed linear array camera and high-intensity light source

InactiveCN114339011AGuaranteed clarityGuaranteed uniformityTelevision system detailsColor television detailsComputer hardwareMachine vision

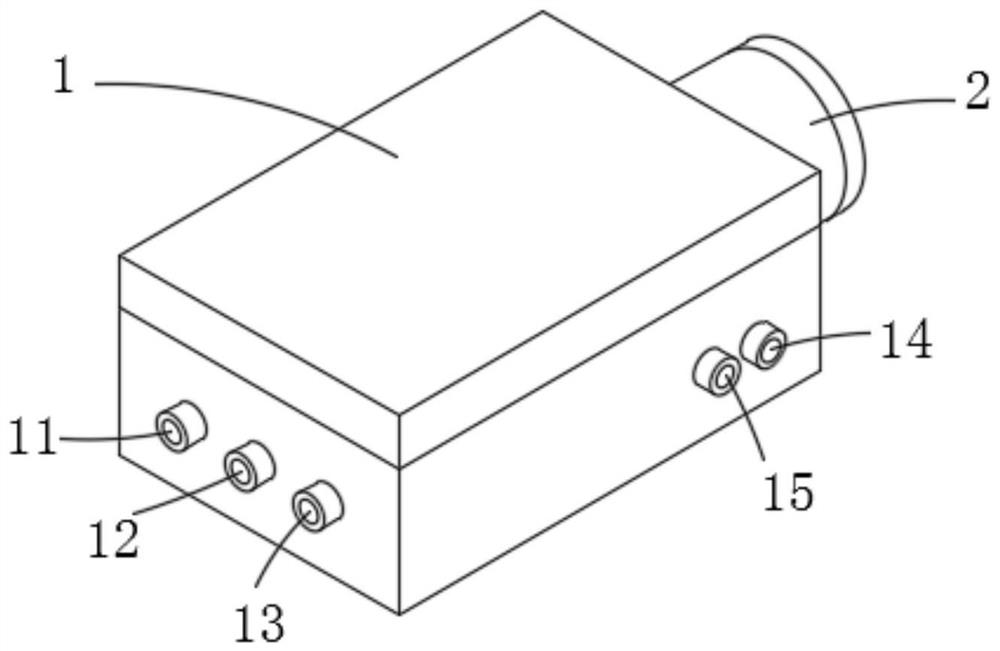

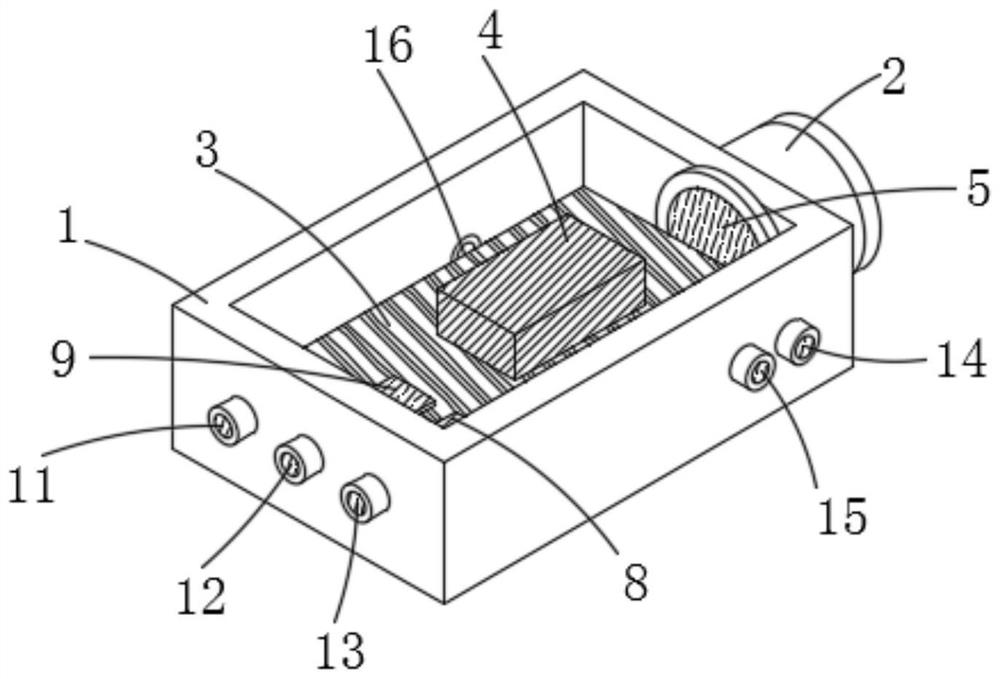

The invention discloses an image acquisition method and device for synchronous trigger control of a high-speed linear array camera and a high-intensity light source, and belongs to the technical field of machine vision, the image acquisition device comprises a shell, and is characterized in that a lens barrel is arranged at one end of the shell, and a mainboard is arranged in the shell; the mainboard is sequentially connected with a linear array camera, a lens, a high-intensity light source generator, a linear light source transmitting module, a self-adaptive pulse signal synchronous generation module, a power supply conversion module and six groups of interfaces. The exterior of the shell is connected with an external trigger sensor, a pulse adjustable generator, a light source power adjusting module and a linear parameter adjusting module through wires. According to the invention, the function of instantaneously synchronizing shutter exposure and light source and camera imaging in high-speed linear array camera acquisition can be realized, and the definition of acquired images and the balance and consistency of histogram distribution can be ensured in high-frame-rate image acquisition.

Owner:苏州博格泰新能源科技有限公司

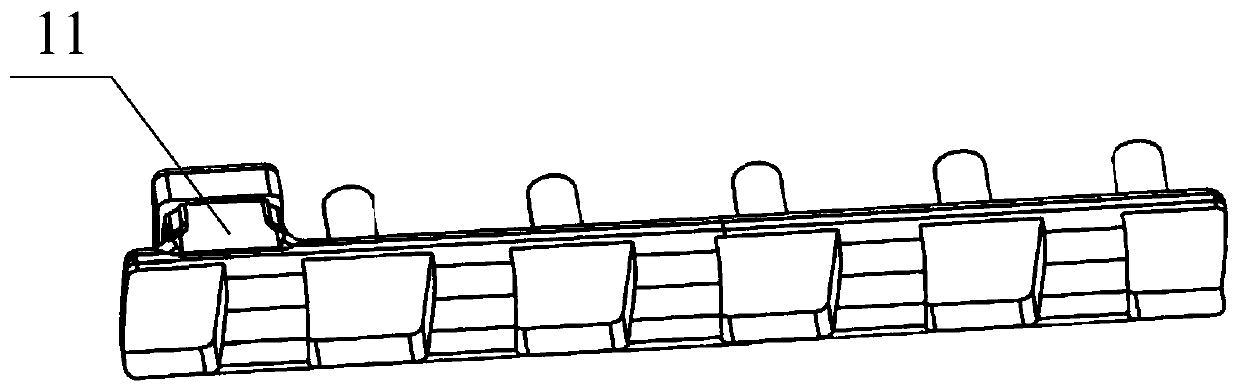

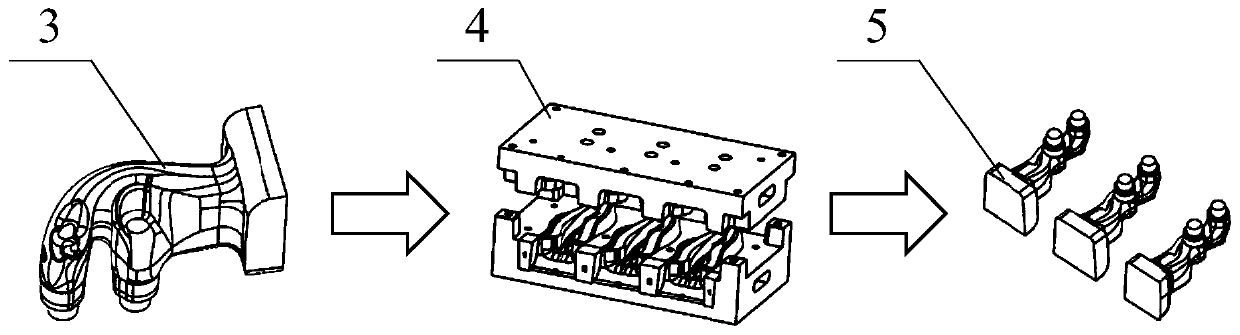

Air inflow way sand core structure and core manufacturing method

InactiveCN111299517AGuaranteed shapeGuaranteed to be consistentFoundry mouldsFoundry coresProcess engineering3D printing

The invention discloses an air inflow way sand core structure and a core manufacturing method. According to the core manufacturing method of the air inflow way sand core structure, an integral sand core is formed by effectively combining an air inflow pipe sand core manufactured in a 3D printing manner and multiple air inflow way sand cores manufactured with the same core manufacturing die. The core manufacturing method includes the following steps that the air inflow pipe sand core is mounted on a reference sand core and fixed; the multiple air inflow way sand cores are mounted on the reference sand core and the air inflow pipe sand core; the multiple air inflow way sand cores and the air inflow pipe sand core are smoothened and fixed through viscose and mud strips; and after the air inflow pipe sand core and the multiple air inflow way sand cores are firmly pasted, the integral sand core is taken out. By means of the core manufacturing method, the strength of the integral sand core can be guaranteed, and the requirement of the air way consistency can be met.

Owner:GUANGXI YUCHAI MASCH CO LTD

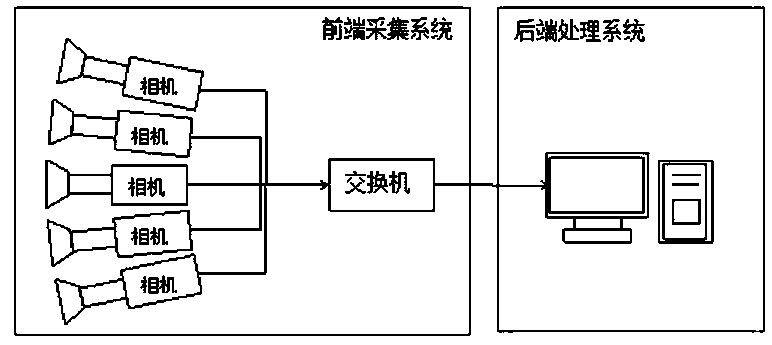

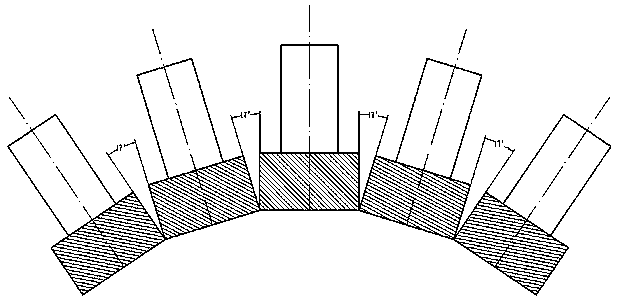

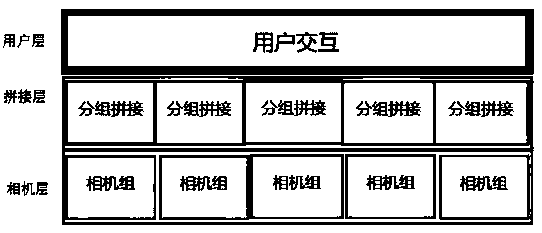

Image stitching system and image stitching method

PendingCN110544206ASmall distortionReduce parallaxGeometric image transformationShortest distanceData acquisition

The invention relates to an image splicing system and an image splicing method, the image splicing system comprises a front-end acquisition system and a rear-end processing system, the front-end processing system comprises five industrial cameras which are located on the same horizontal plane and are distributed in a fan shape, and the industrial cameras are connected with a gigabit network switch; and the rear-end processing system is composed of a computer provided with splicing system software, and the splicing system software comprises a camera layer, a splicing layer and a user layer. Through front-end acquisition system, reasonable placement positions and image overlapping ranges of the industrial cameras are obtained through calculation according to an image splicing method; and consistency of optical centers, the shooting problem of a shot object with the depth of field in a short distance is solved, the overlapped part between the two cameras can be smoothly spliced, the imagedistortion at the edge is small, then the rear-end processing system is connected through the gigabit switch, the calculated image overlapping range is input to carry out multi-thread parallel splicing operation, and a high-resolution image is output.

Owner:JINAN SHENBO INFORMATION TECH

Device and method for building walls

ActiveCN112252521BReduce labor intensityImprove flatnessWallsBuilding material handlingBrick masonryStructural engineering

The invention discloses a device and method for building walls. It includes a box body, which is provided with a box cavity inside the box body, and a slurry assembly is slidably connected to the box cavity, and a scraper assembly is fixed on the left side of the slurry assembly. The through-hole slot matched with the slurry assembly, the through-hole slot is located directly below the pulp outlet assembly, the bottom of the left side of the box body is provided with an opening communicating with the through-hole slot, the top of the box body is equipped with a slurry storage tank, and the slurry storage tank It is connected with the pulp assembly pipe, and the front and rear sides of the box are equipped with limiting plates, which are slidingly connected with the box. There is a pressing component between the two limiting plates, and the pressing component is installed on the left side of the box. face. The beneficial effects of the present invention are: the labor intensity of workers is reduced, and the efficiency of wall-building is improved; the flatness of the bricks to be built is greatly improved; stability of the wall.

Owner:邱亦钊

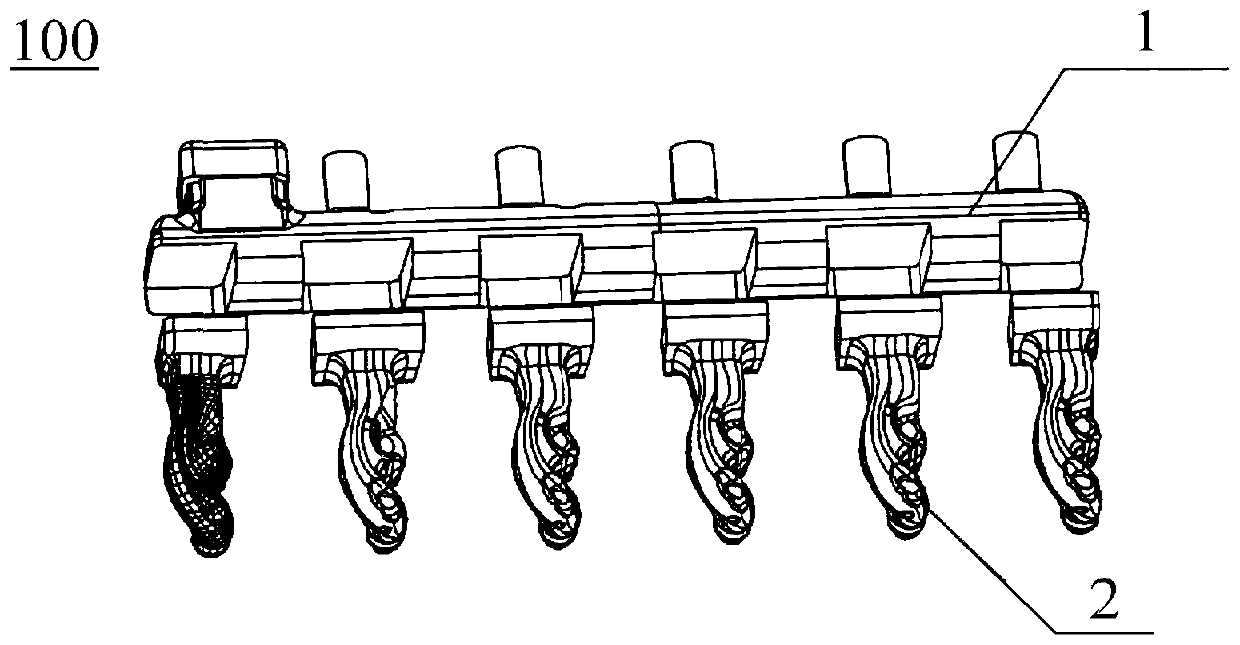

Green onion machine

ActiveCN104429252BReduce labor intensityGuaranteed to be consistentTransplantingEngineeringTransplanting

The invention relates to a green onion transplanting machine. The green onion transplanting machine comprises a rack, an engine, a speed changing box, a driving chain wheel, a driven chain wheel, a chain, a green onion storing box, a bent axle, a green onion taking clip, a green onion dividing device, a green onion transferring clip control board, a green onion transplanting board, a green onion transplanting device and a moving wheel. In a working process, the green onion transplanting machine is moved to a green onion transplanting part and green onion seedlings are divided into large, middle and small types; the green onion taking clip on the chain is driven by the chain wheels to the green onion storing box; the green onion taking clip is used for clamping the green onion seedlings from bottom to top and lifting the green onion seedlings along the chain to convey the green onion seedlings to a green onion fixing groove of a green onion dividing plate to be fixed; then green onion roots are put into the green onion fixing groove along the front-back and rotary movement of a green onion transplanting rod; the green onion seedlings are transferred to a green onion distance control groove in a green onion distance control board by a green onion transferring clip under the driving of the bent axle and a connection rod, and then are horizontally pushed to the green onion transplanting board; the green onion transplanting device in front of the green onion transplanting board is connected with the bent axle by the connection rod; and after the green onion roots are fixed by the green onion transplanting device, the green onion roots are clamped by the green onion transplanting device and the green onion transplanting device moves downwards so that the green onion seedlings are transplanted into soil. The process is repeated along the frontward movement of the green onion transplanting machine.

Owner:全椒县全动机械有限公司

Compensation Method for Parameters Below Base Speed of Permanent Magnet Synchronous Motor Based on Feedforward Voltage Compensation

ActiveCN110545057BIssued accuratelyGuaranteed to be consistentElectronic commutation motor controlAC motor controlElectric machinePermanent magnet synchronous motor

The invention relates to a method for compensating parameters below the base speed of a permanent magnet synchronous motor based on feedforward voltage compensation, comprising: S1. calculating d-axis current and q-axis current; S2. calculating d-axis current command through torque command; S3 .Through the current loop PI regulator to obtain and S4 respectively. Calculate and and respectively and sum to obtain and S5. And input to the space vector modulation module to obtain 6 pulses, which act on the voltage type inverter to control the motor; S6. The q-axis inductance and d-axis flux linkage are compensated; the compensated q-axis inductance and d-axis flux linkage are used for the calculation of step S2 and step S4 in the next calculation cycle; the reciprocating cycle of step S1-S6 is through the compensation of the motor parameters Achieve precise control of motor output torque.

Owner:BEIJING JIAOTONG UNIV

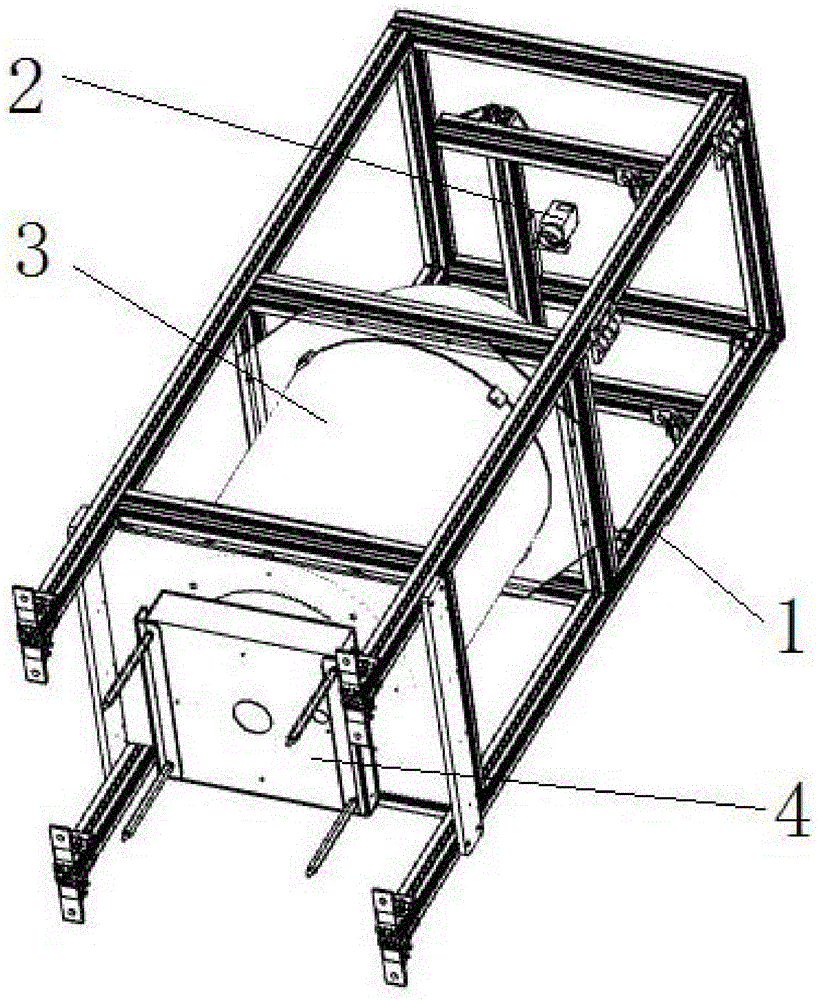

a lift device

The invention relates to an elevator device, comprising a bracket main body, a tray and a motor. The bracket main body is composed of a guide rail bracket and a pulley bracket. A guide rail is arranged on the guide rail bracket, and an inner pulley is arranged on the tray, and the inner pulley is fastened and connected to the guide rail. , the bottom of the tray is provided with a lift plate, the lift plate is connected to the ground of the pallet through a rotating shaft, and the rotating shaft is also provided with a traction column A and a traction column B respectively towing a stop forming switch and a standby travel switch, and the tray is provided with an inclined placement switch. There is a start travel switch on the rear side of the load board, a start trigger line is connected to the start formation switch, a return travel switch is arranged on the left side of the tray, a wireless signal transmitter and a battery pack are also arranged on the tray, and the tray The steel rope A and the steel rope B are hoisted, and the motor plays a driving role, and the motor drives the reel to realize retracting and unwinding of the steel rope A and the steel rope B. The invention has the advantages of simple structure, low manufacturing cost and high work efficiency.

Owner:高威

A rice transplanter and rice transplanting method for paddy rice pot cultivation

ActiveCN110506474BIntegrity guaranteedEasy to grabTransplantingAgricultural engineeringMechanical engineering

The present application discloses a rice transplanter and a rice transplanting method for paddy rice pot cultivation, including a rice transplanter body, a workbench arranged on the ricetransplanter, and a seedling raising tray located on the workbench. The workbench is provided with A pressing mechanism, the pressing mechanism acts on the seedling tray, the pressing mechanism includes a pole perpendicular to the workbench, the pole is covered with a lifting seat, and a chute is arranged on the side of the lifting seat where it is located. There are balls arranged in the chute, and the balls are fixedly connected with pressing rods outwardly. The pressing rods are arranged horizontally. The raised block is located below the seedling tray and corresponds to the seedling groove of the seedling tray. In this application, a pressing mechanism acting on the seedling tray is provided on the workbench of the existing rice transplanter, and the raised block under the seedling tray can completely eject the seedlings and the seedling soil together, which greatly reduces the weight of the seedlings. The root-cutting rate can increase the survival rate after transplanting.

Owner:宁夏广银米业有限公司

Belt pulley outer wall deburring device

The invention relates to a belt pulley outer wall deburring device. The belt pulley outer wall deburring device comprises a machining support, a belt pulley fixing unit, a compression unit and a driving unit. The belt pulley fixing unit comprises a belt pulley fixing platform; the two ends of the belt pulley fixing platform are mounted on stand columns in a sleeving manner correspondingly; a beltpulley fixing seat is mounted in the center of the belt pulley fixing platform; a groove allowing a belt pulley to be embedded therein is formed in the upper end of the belt pulley fixing seat; and the inner wall of the groove is provided with a tooth-shaped structure corresponding to the outer wall of the belt pulley. The compression unit comprises a compression block, wherein the compression block is mounted at the lower end of a cross beam. The driving unit comprises a pair of driving cylinders which are mounted at the upper end of the cross beam. The belt pulley outer wall deburring devicehas the beneficial effects that burrs on the outer wall can be well removed only through one time of machining; great convenience is achieved; machining consistency is guaranteed; in addition, manualwork is reduced; and work efficiency is improved.

Owner:南通冠达粉末冶金有限公司

Green onion transplanting machine

ActiveCN104429252AReduce labor intensityGuaranteed to be consistentTransplantingEngineeringTransplanting

The invention relates to a green onion transplanting machine. The green onion transplanting machine comprises a rack, an engine, a speed changing box, a driving chain wheel, a driven chain wheel, a chain, a green onion storing box, a bent axle, a green onion taking clip, a green onion dividing device, a green onion transferring clip control board, a green onion transplanting board, a green onion transplanting device and a moving wheel. In a working process, the green onion transplanting machine is moved to a green onion transplanting part and green onion seedlings are divided into large, middle and small types; the green onion taking clip on the chain is driven by the chain wheels to the green onion storing box; the green onion taking clip is used for clamping the green onion seedlings from bottom to top and lifting the green onion seedlings along the chain to convey the green onion seedlings to a green onion fixing groove of a green onion dividing plate to be fixed; then green onion roots are put into the green onion fixing groove along the front-back and rotary movement of a green onion transplanting rod; the green onion seedlings are transferred to a green onion distance control groove in a green onion distance control board by a green onion transferring clip under the driving of the bent axle and a connection rod, and then are horizontally pushed to the green onion transplanting board; the green onion transplanting device in front of the green onion transplanting board is connected with the bent axle by the connection rod; and after the green onion roots are fixed by the green onion transplanting device, the green onion roots are clamped by the green onion transplanting device and the green onion transplanting device moves downwards so that the green onion seedlings are transplanted into soil. The process is repeated along the frontward movement of the green onion transplanting machine.

Owner:全椒县全动机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com