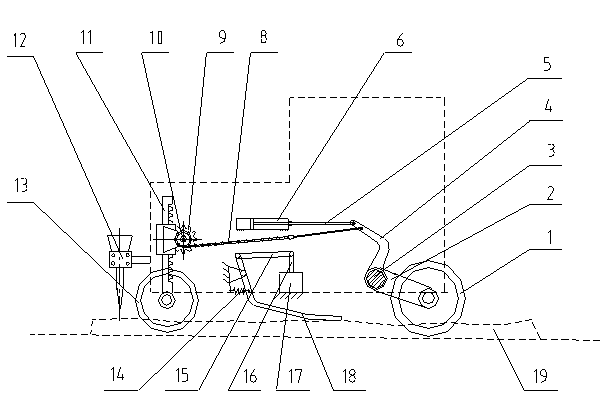

Four-wheel synchronous automatic lifting regulating mechanism

A technology of synchronous automatic and lifting mechanism, which is applied in the direction of transplanting machinery, application, agriculture, etc. It can solve the problems of tilting transplanted seedlings, affecting the planting effect, and large forward and backward movement of the center of gravity, and achieves the effect of low cost and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] specific implementation plan

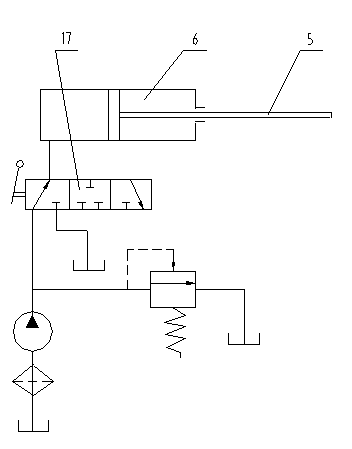

[0007] Below in conjunction with the accompanying drawings, the working principle and process of the four-wheel synchronous automatic lifting adjustment mechanism will be described in detail. Under normal circumstances, the planting depth of the transplanter is adjusted to a reasonable depth according to the needs of the seedlings. Under the condition that the height of the ridge remains constant and the sinking depth of the wheels remains unchanged, it can ensure that the planting depth of each seedling remains constant and remains at the standard planting depth. However, in the actual planting process, the height of the ridge and the sinking depth of the wheels change at any time. The higher the ridge or the deeper the sinking of the wheels, the deeper the planting depth will be. The lower the ridge or the smaller the sinking of the wheel, the shallower the planting depth will be. In order to correct the change of planting depth at any...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com