Patents

Literature

34results about How to "Constant depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

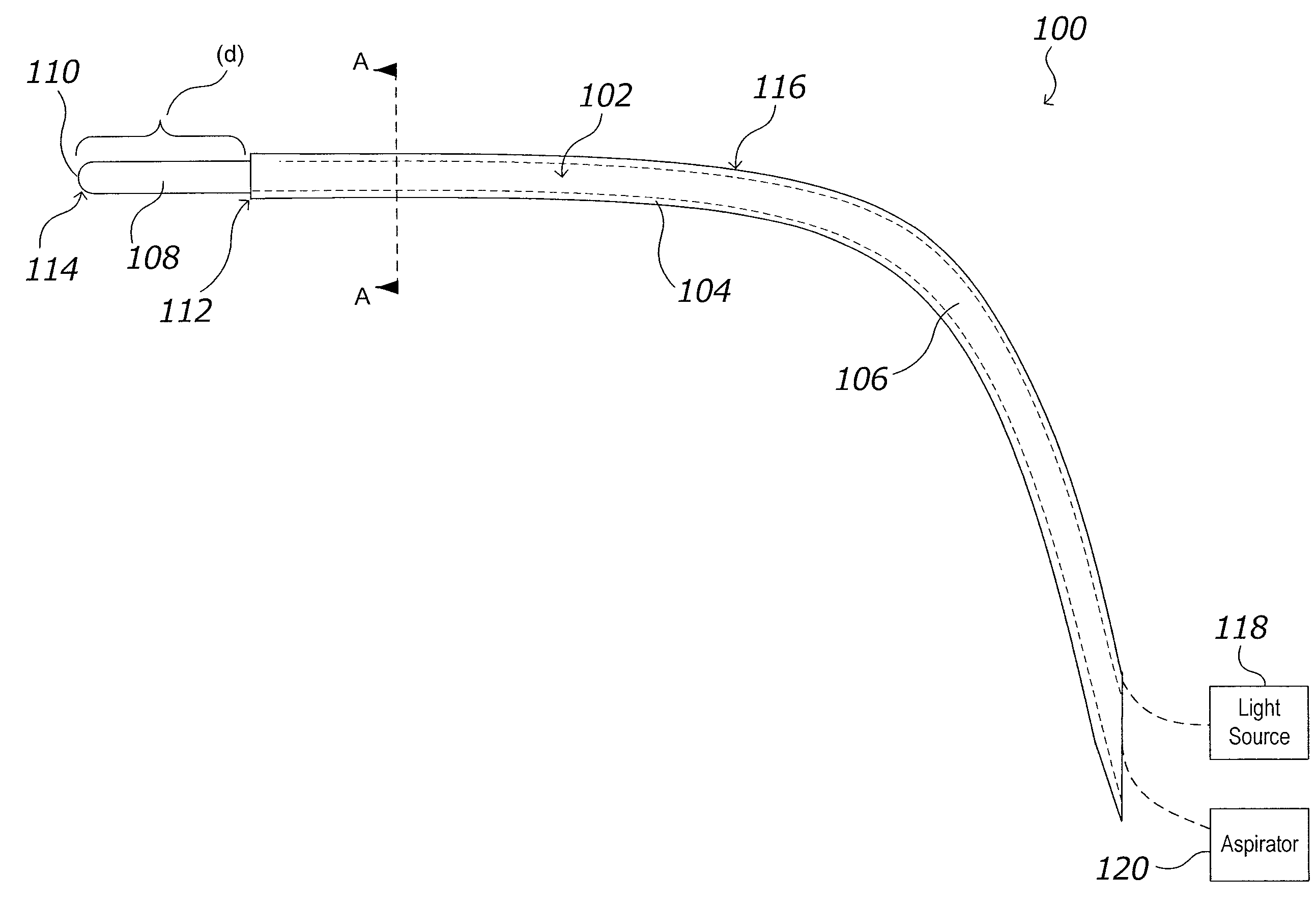

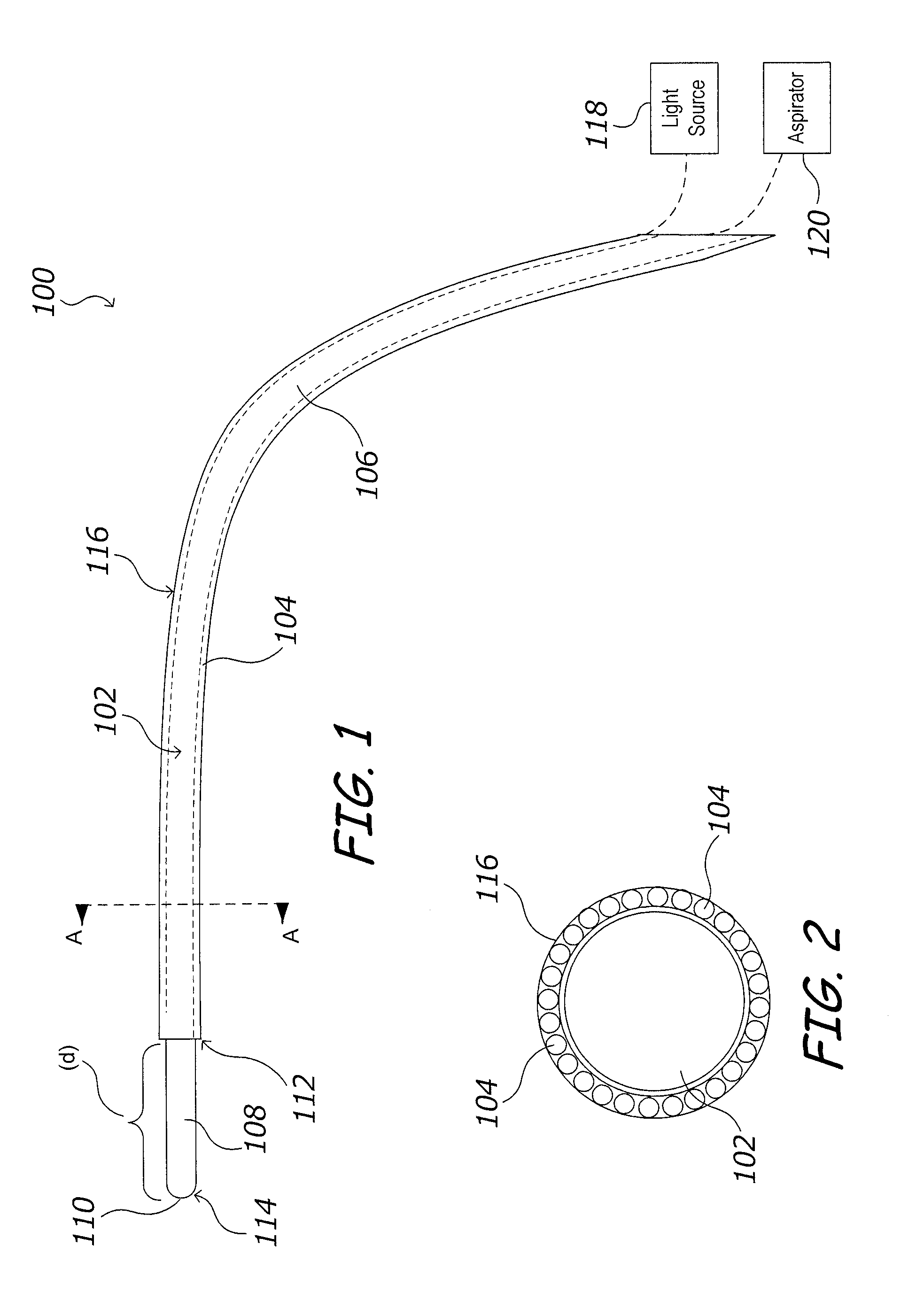

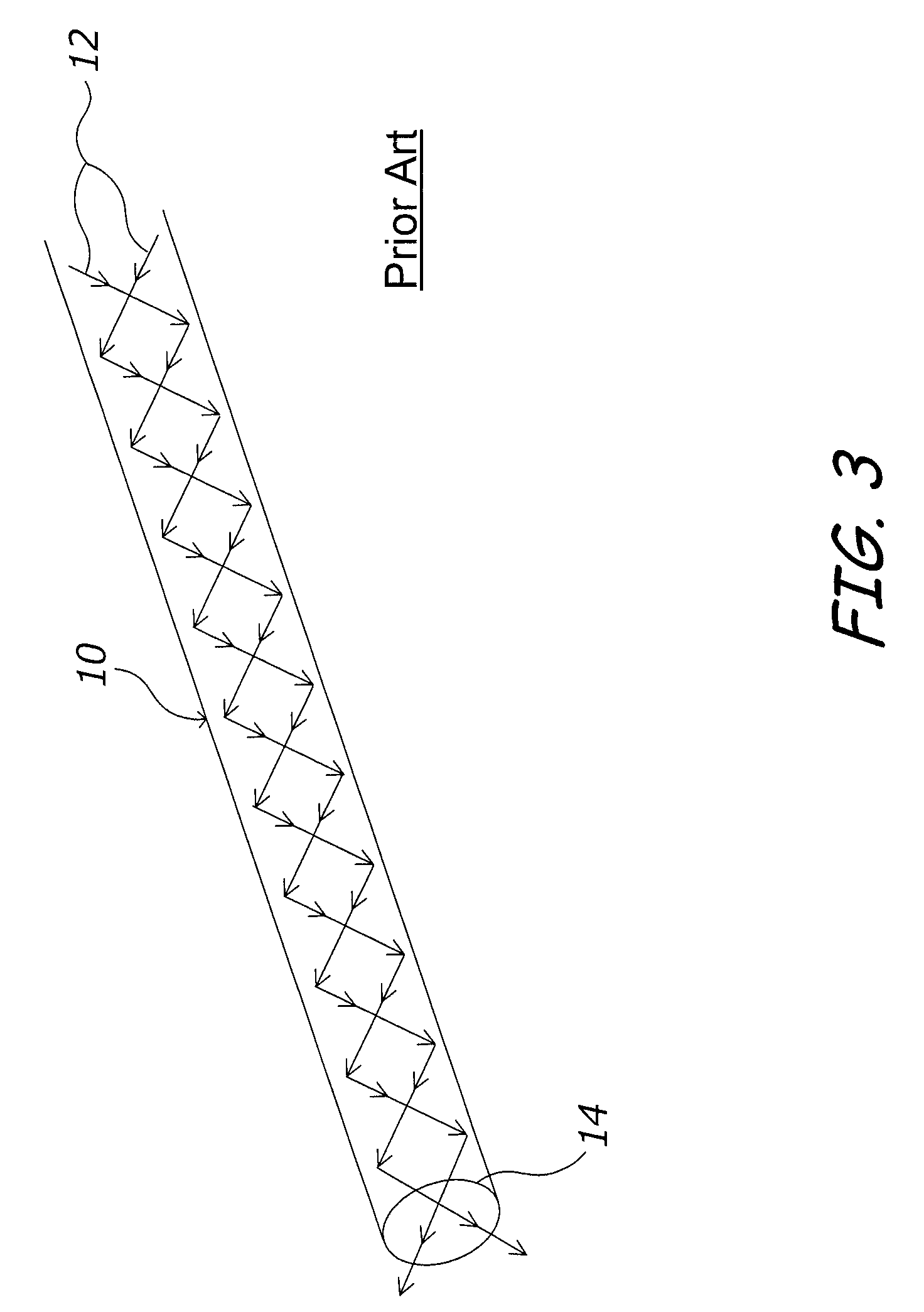

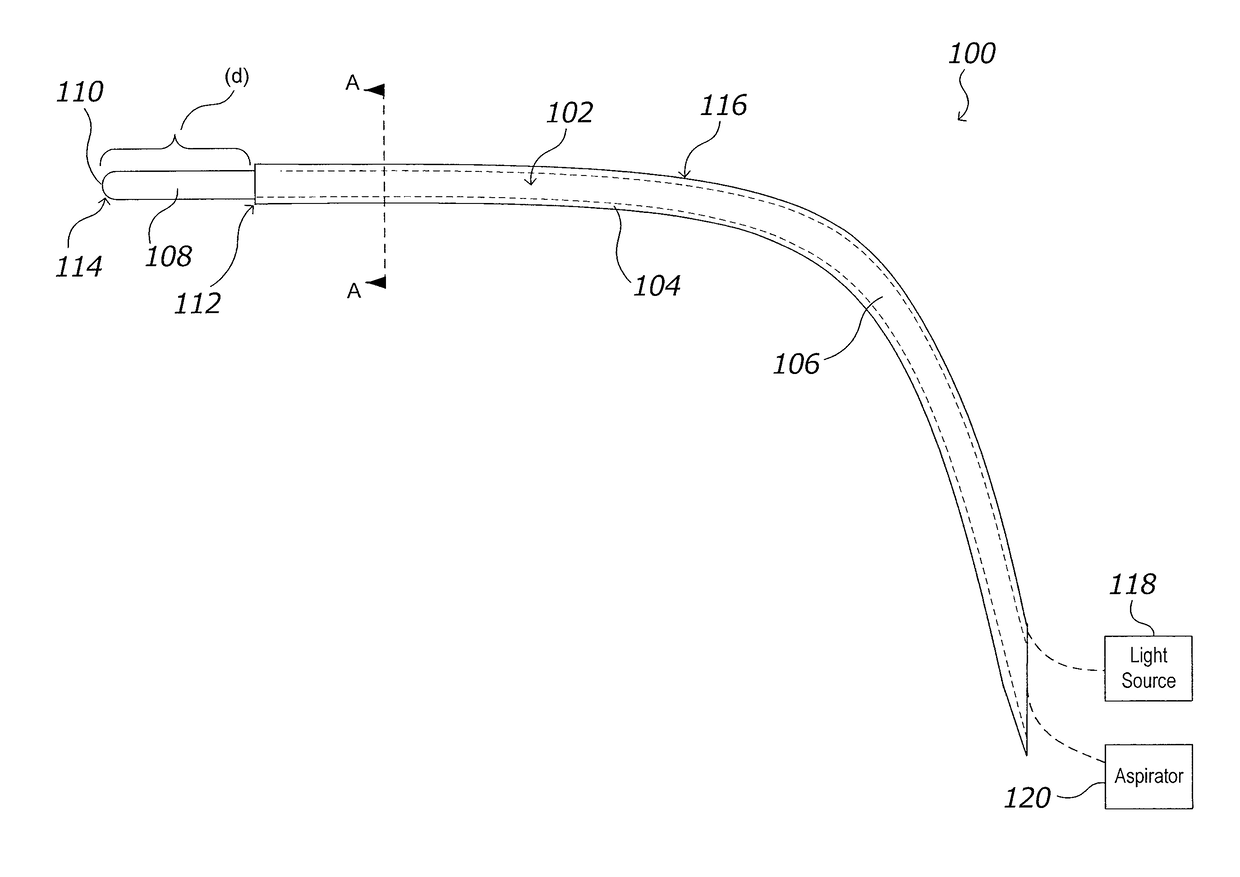

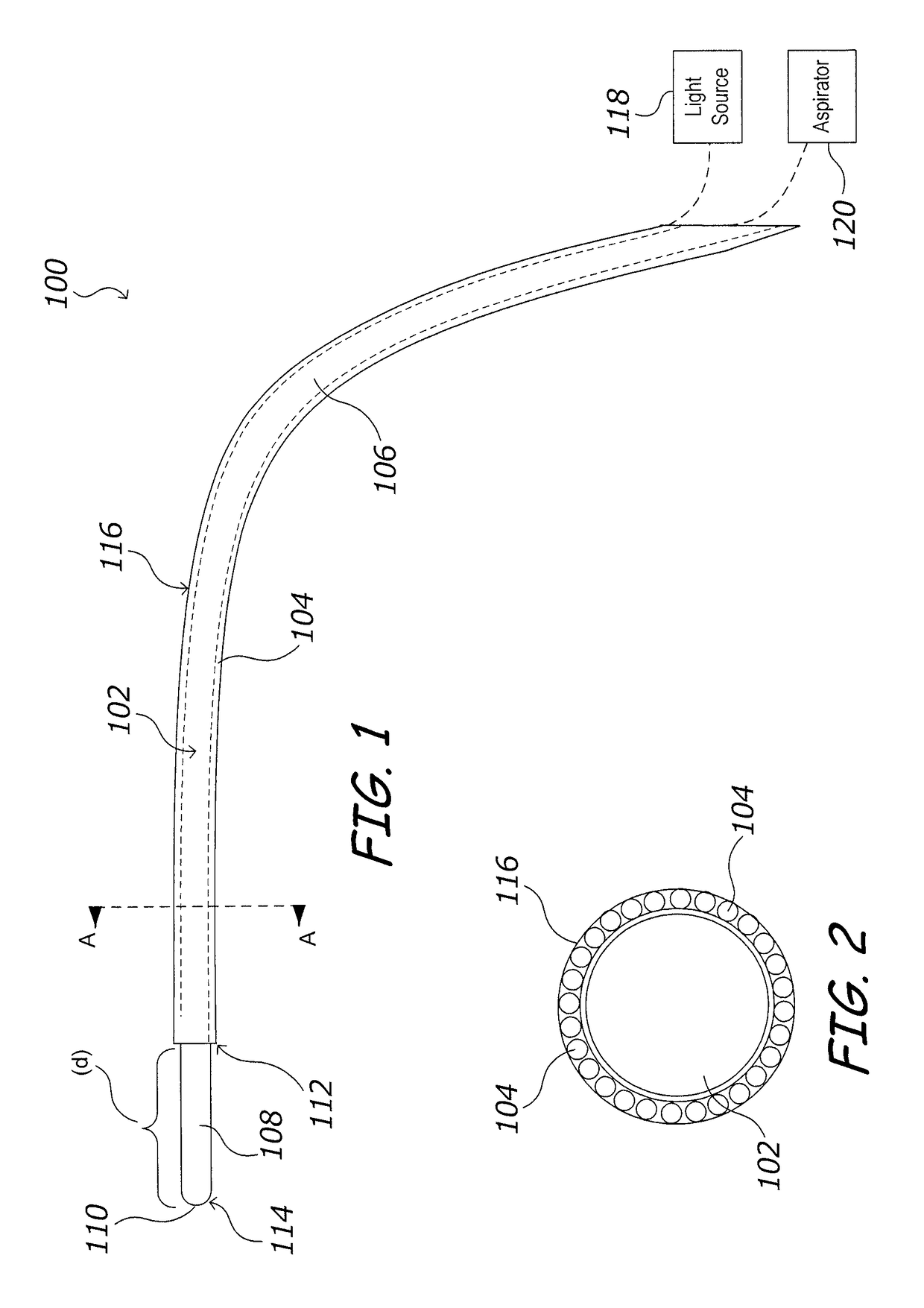

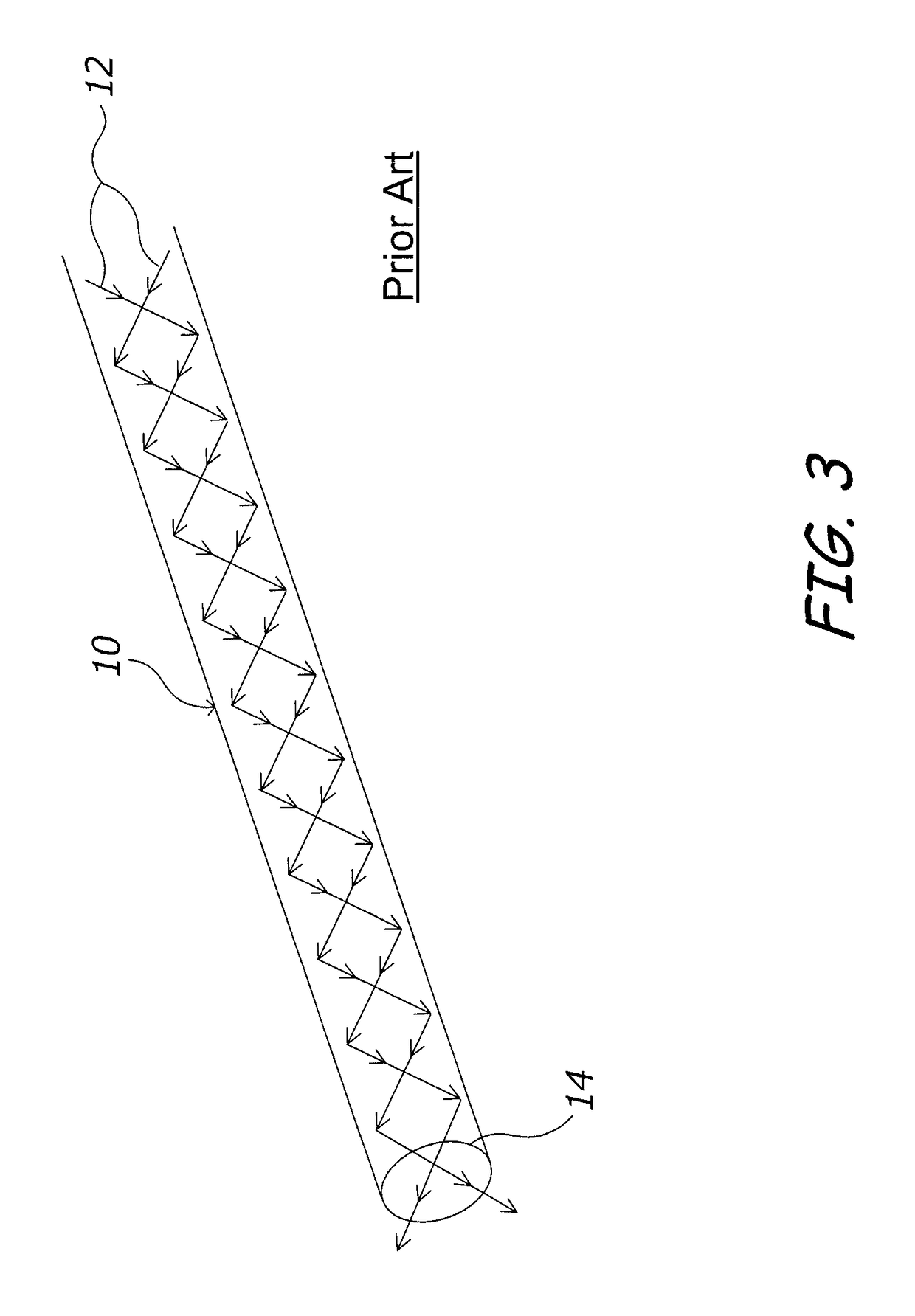

Multi-Purpose Surgical Instrument With Removable Component

A combination aspiration / irrigation and illumination device using optical fibers circumferentially disposed around the aspiration conduit for transmitting illuminating light to a cavity to be aspirated. The aspiration conduit having a tip that is detachably affixed to and end of the aspiration conduit. The optical fibers terminated at a distance (d) from a distal end of the tip. Also provided is an image fiber(s) for transmitting image data from the distal end of the device.

Owner:LIEPONIS JONAS V

Multi-purpose surgical instrument with removable component

A combination aspiration / irrigation and illumination device using optical fibers circumferentially disposed around the aspiration conduit for transmitting illuminating light to a cavity to be aspirated. The aspiration conduit having a tip that is detachably affixed to and end of the aspiration conduit. The optical fibers terminated at a distance (d) from a distal end of the tip. Also provided is an image fiber(s) for transmitting image data from the distal end of the device.

Owner:LIEPONIS JONAS V

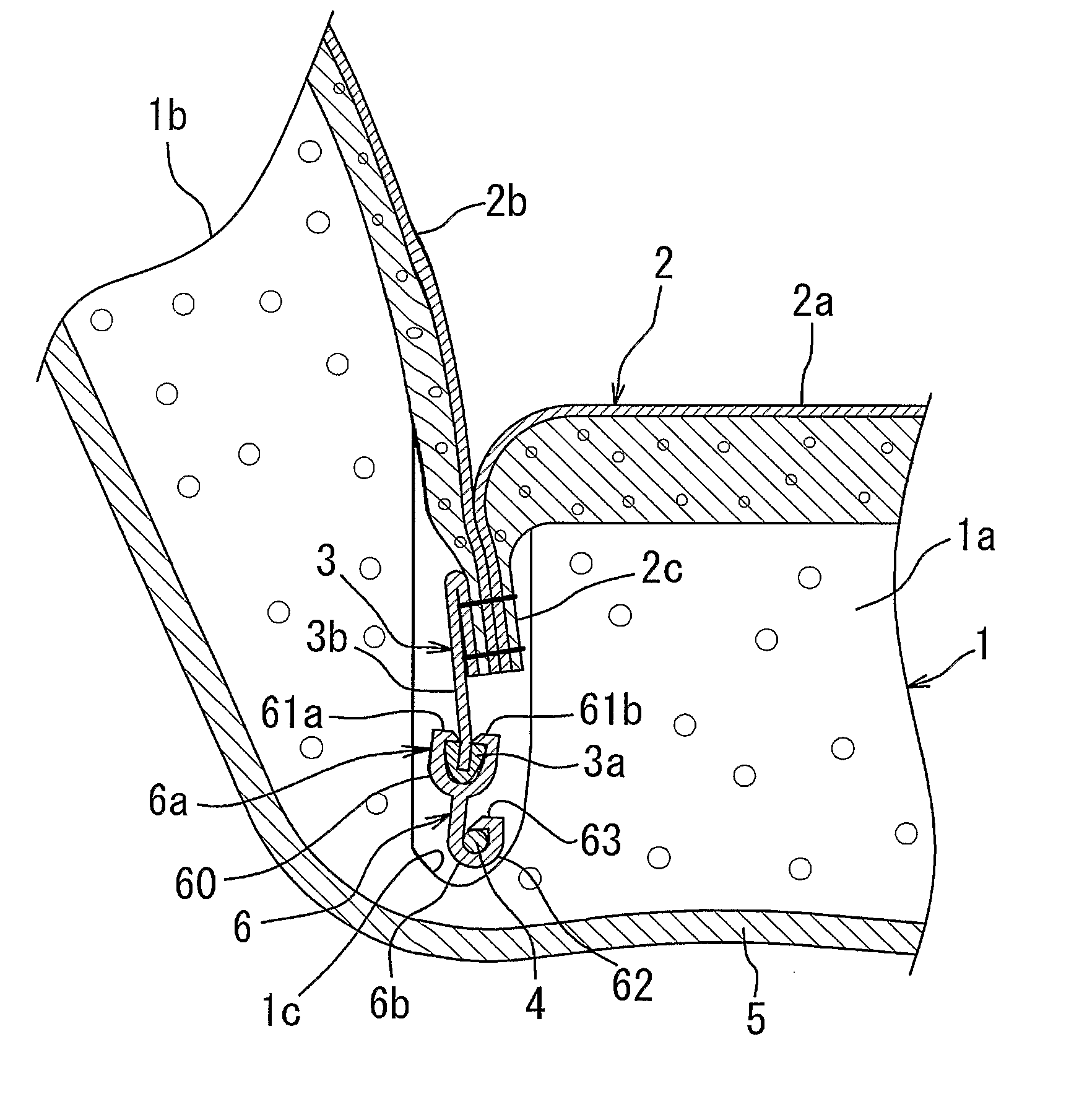

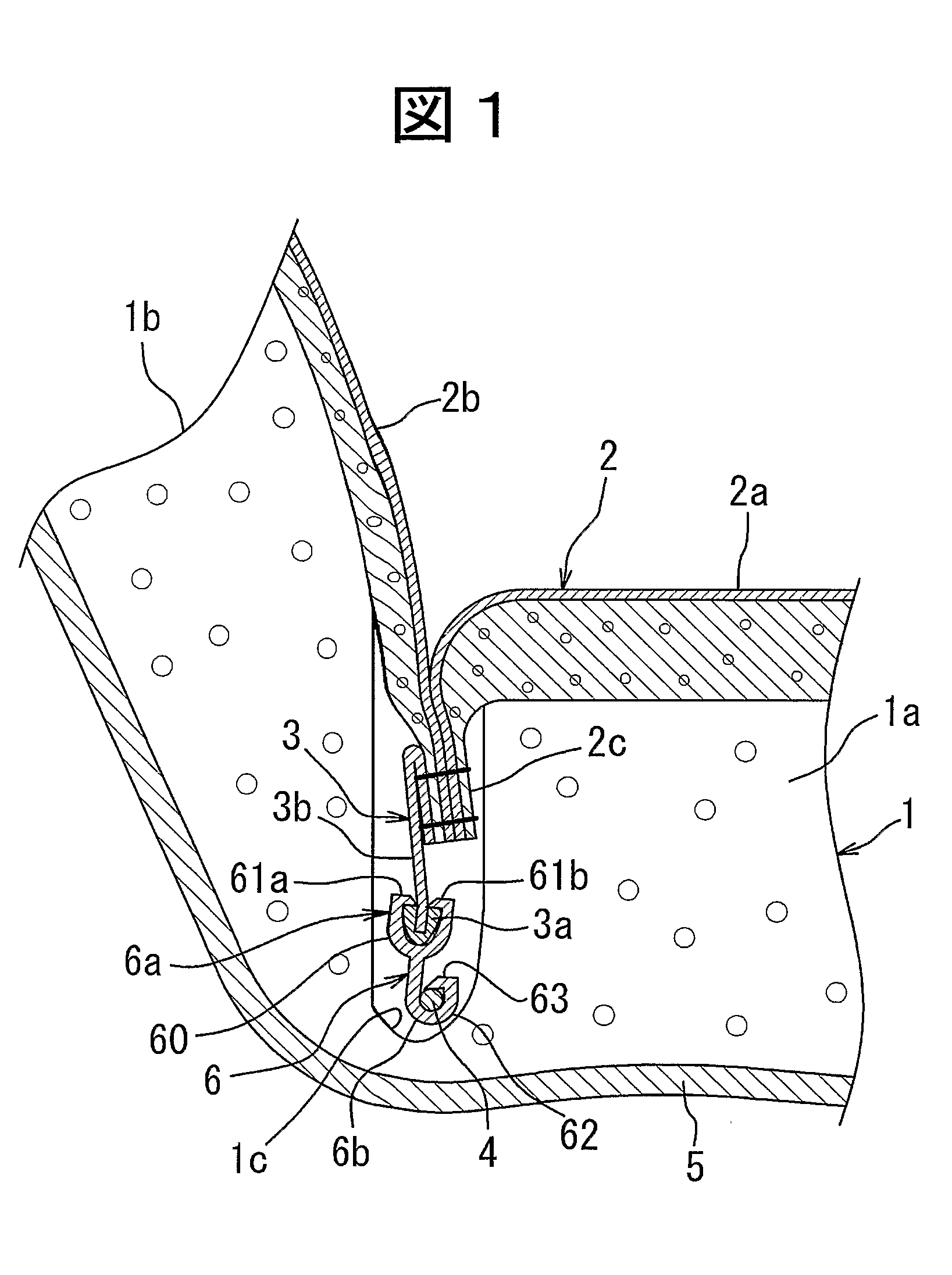

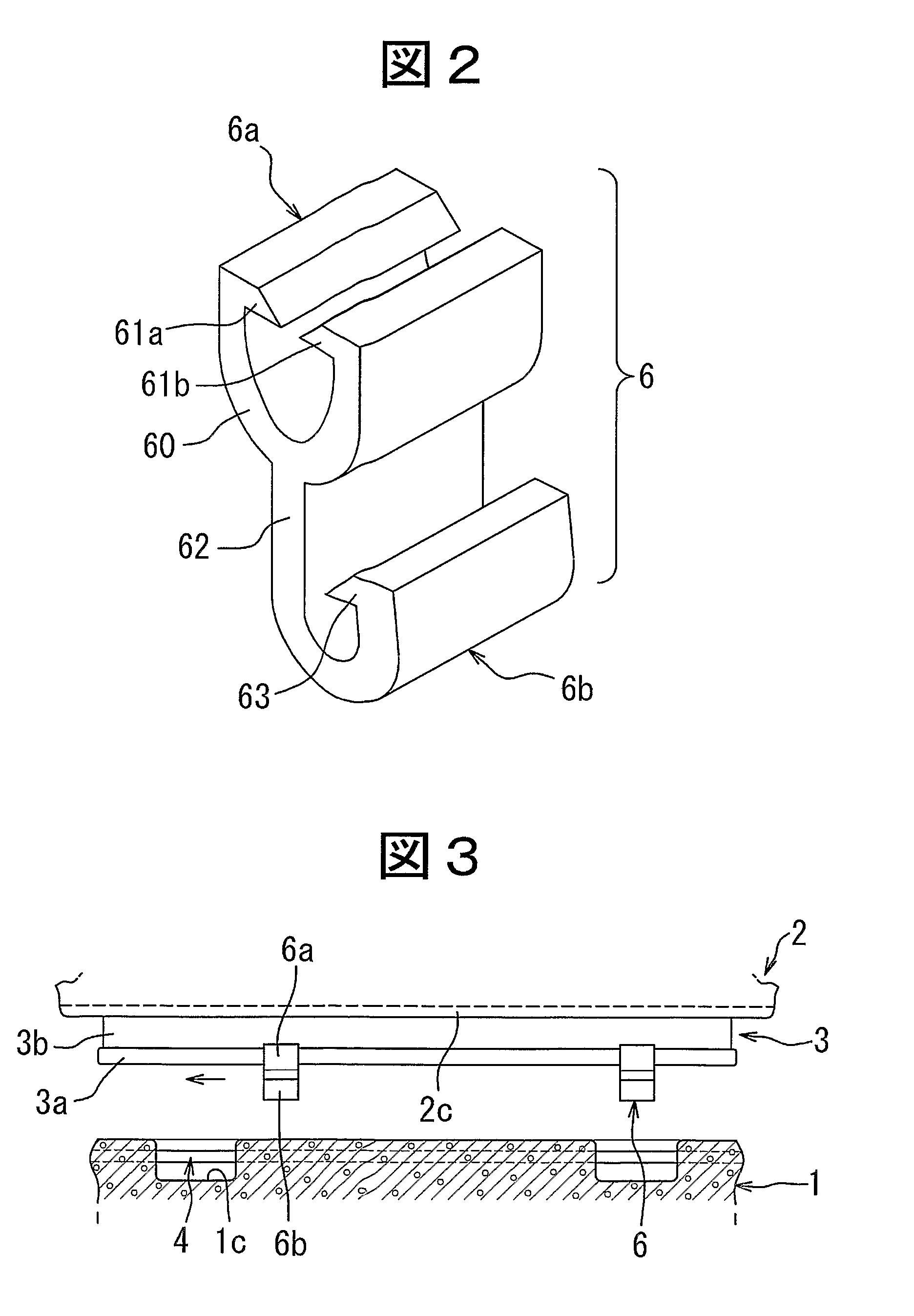

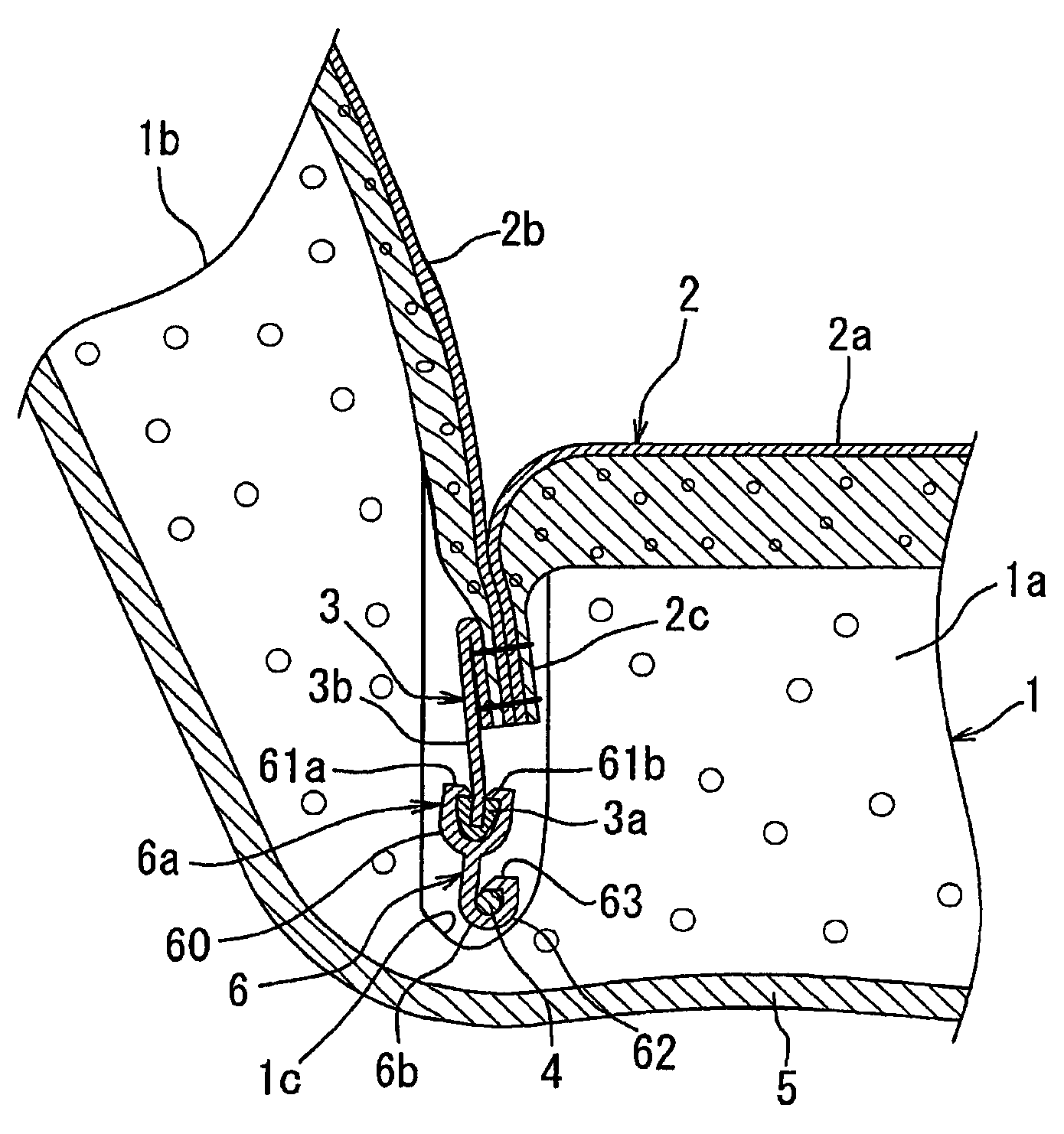

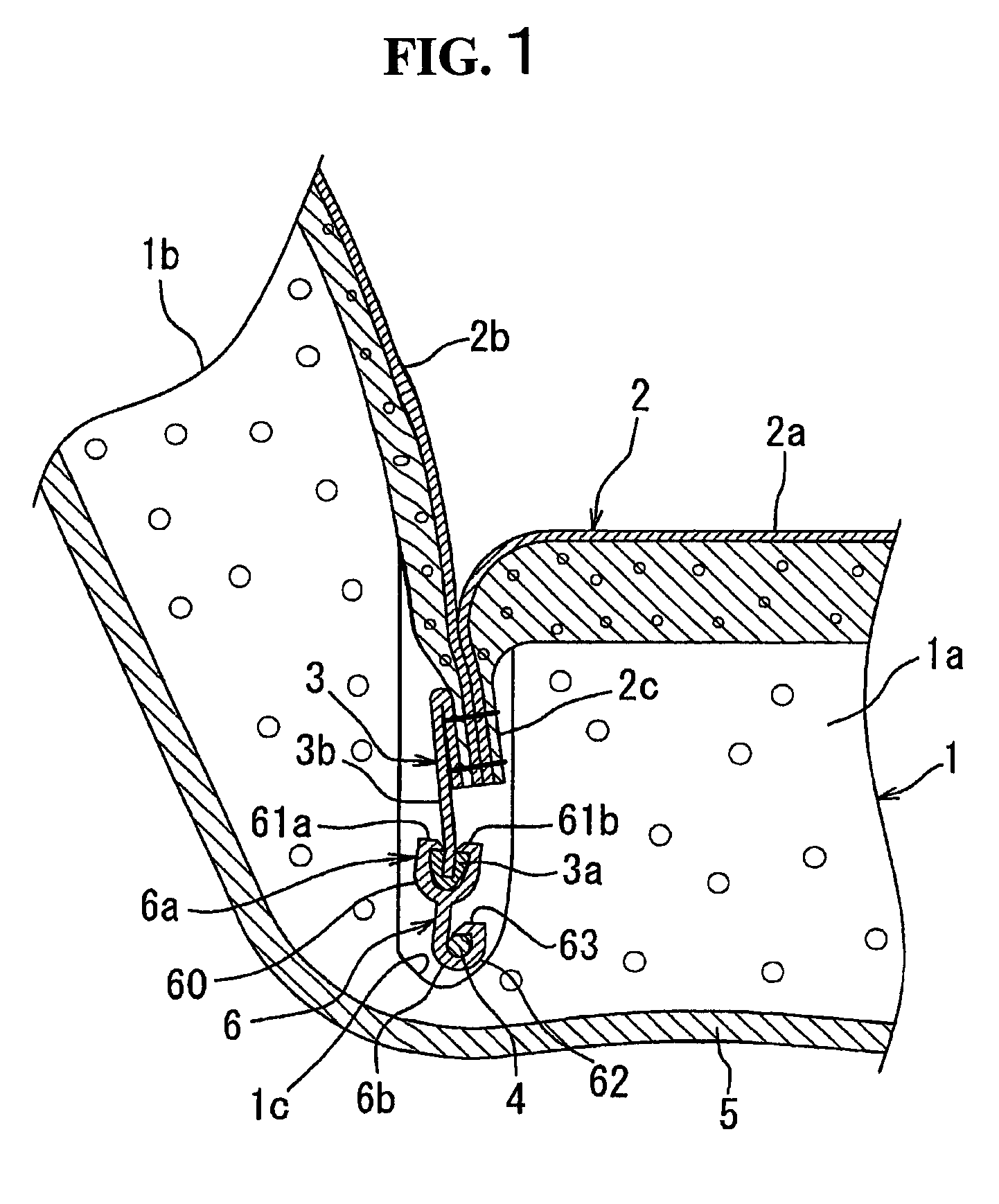

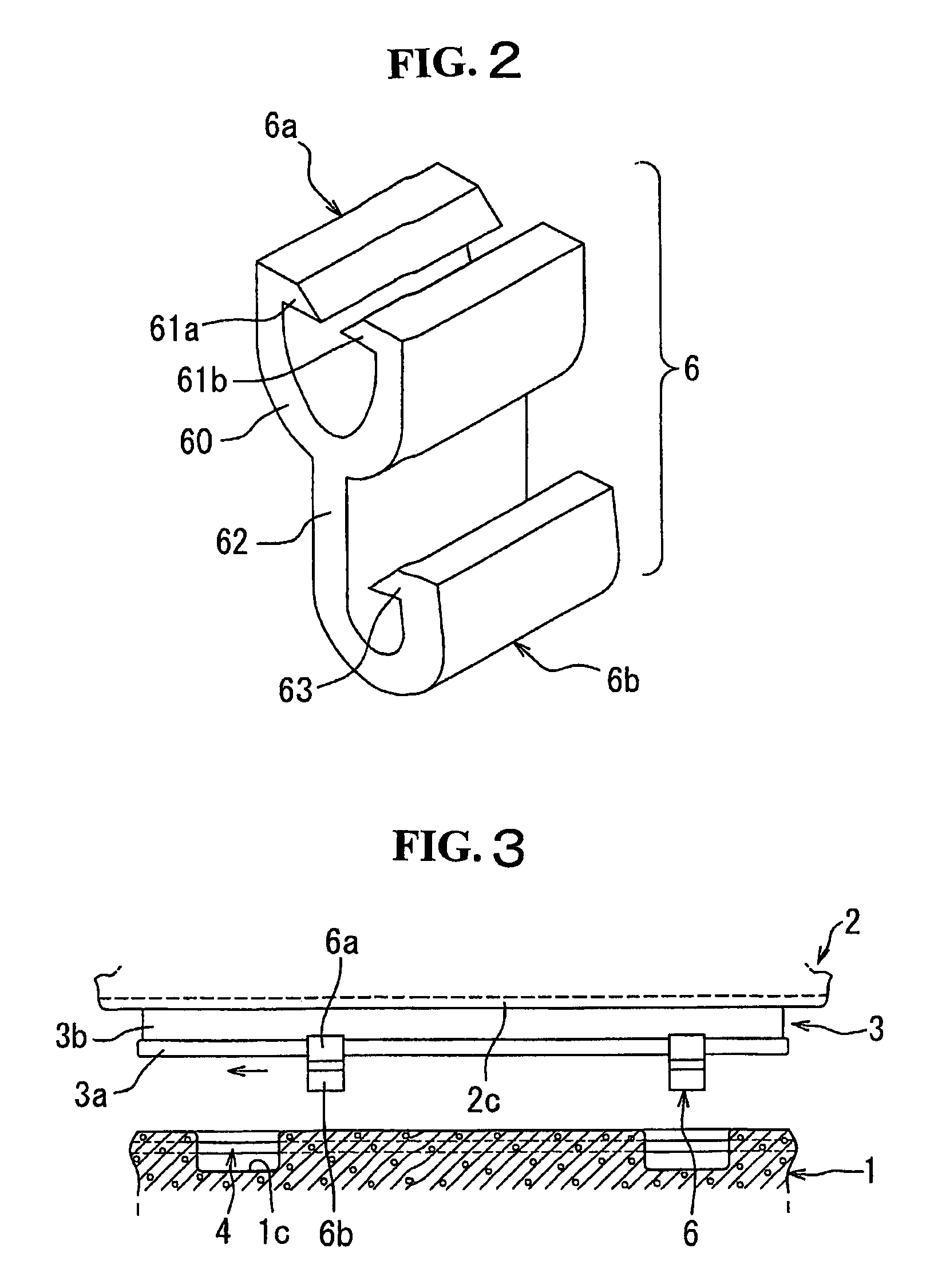

Clip for Hanging and Fixing Trim Cover

InactiveUS20070257531A1Easily and securely coupleEasily shiftUpholstery manufactureVehicle seatsEngineeringMechanical engineering

Owner:TS TECH CO LTD

Clip for hanging and fixing trim cover

InactiveUS7568761B2Precise positioningEasily and securely coupledUpholstery manufactureVehicle seatsMechanical engineering

Owner:TS TECH CO LTD

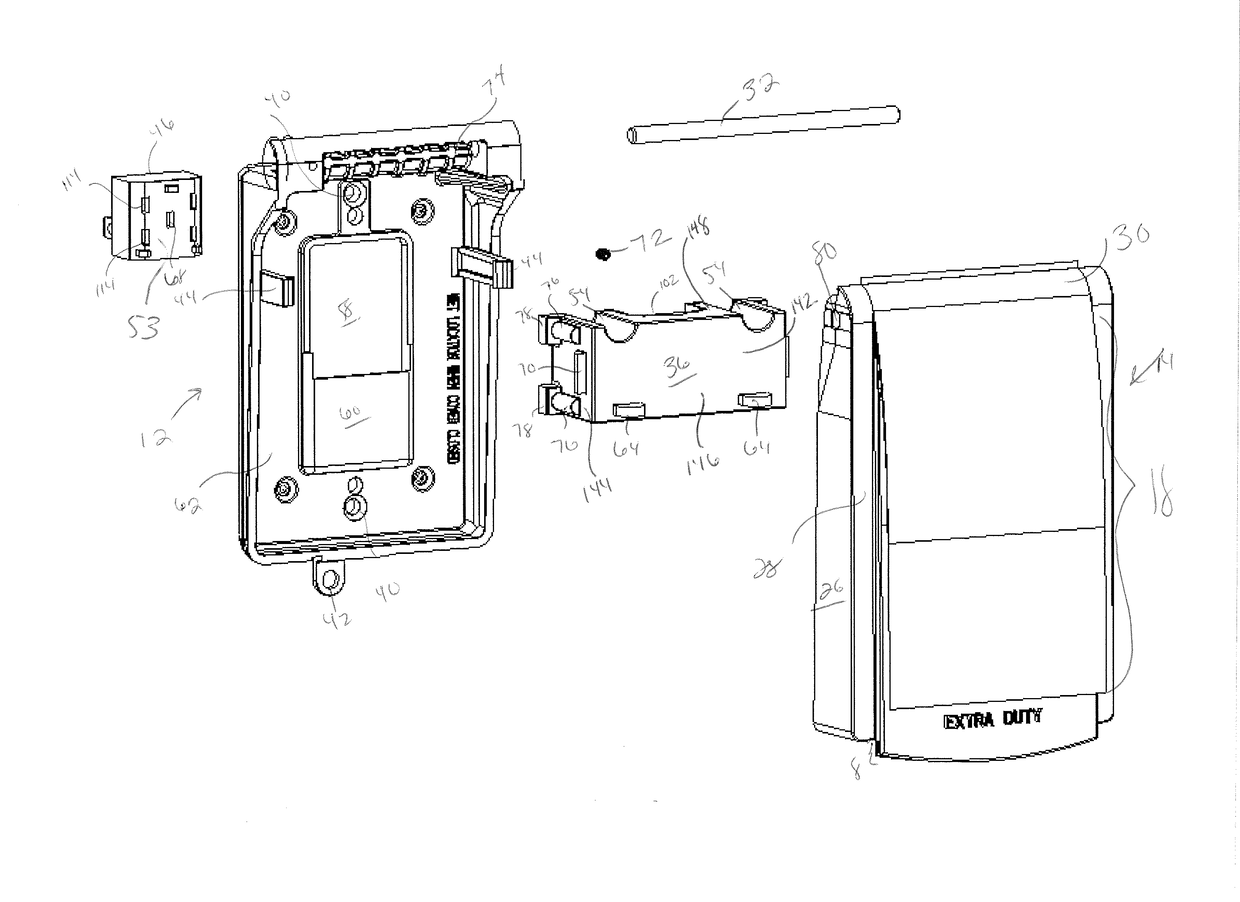

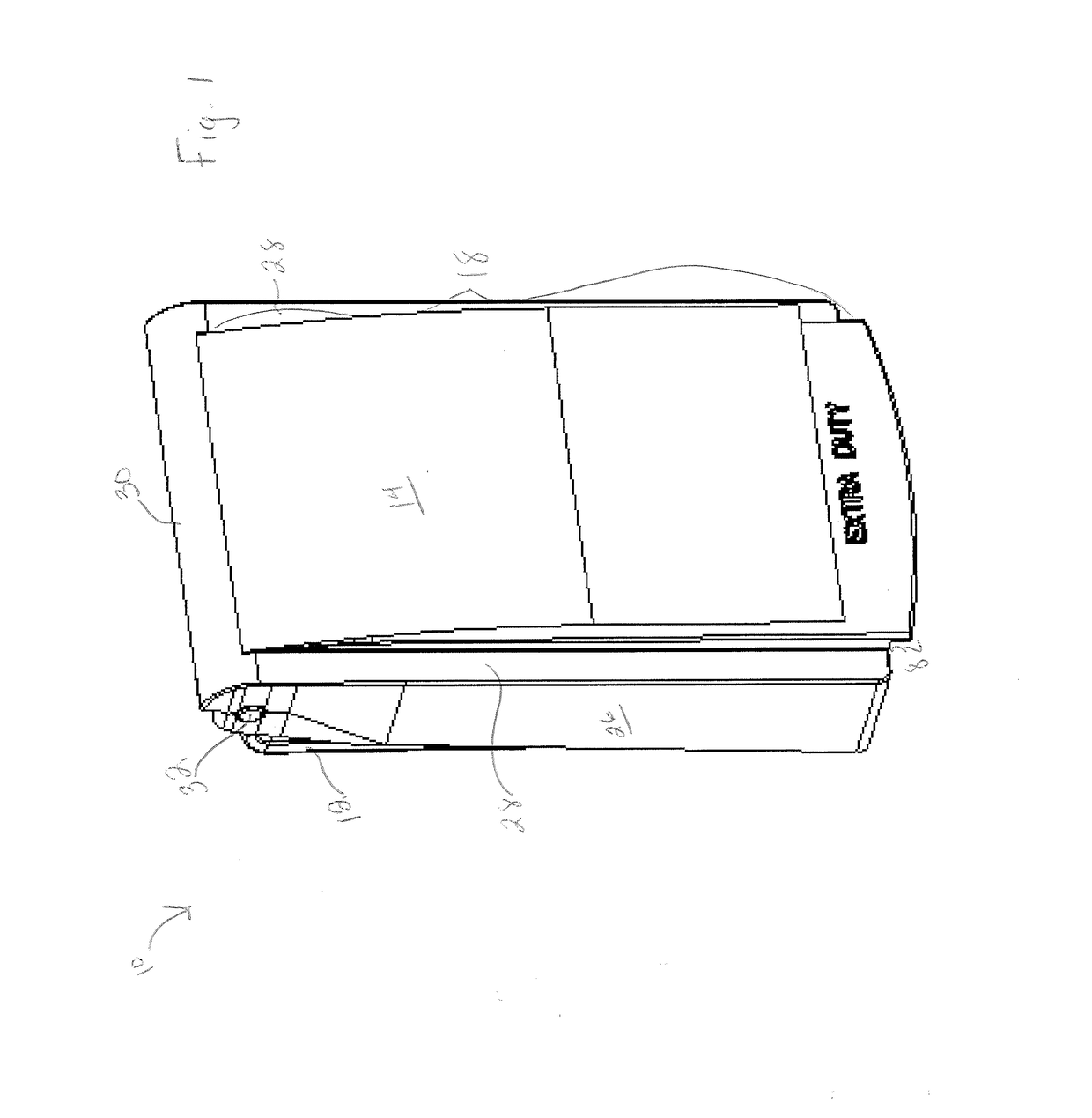

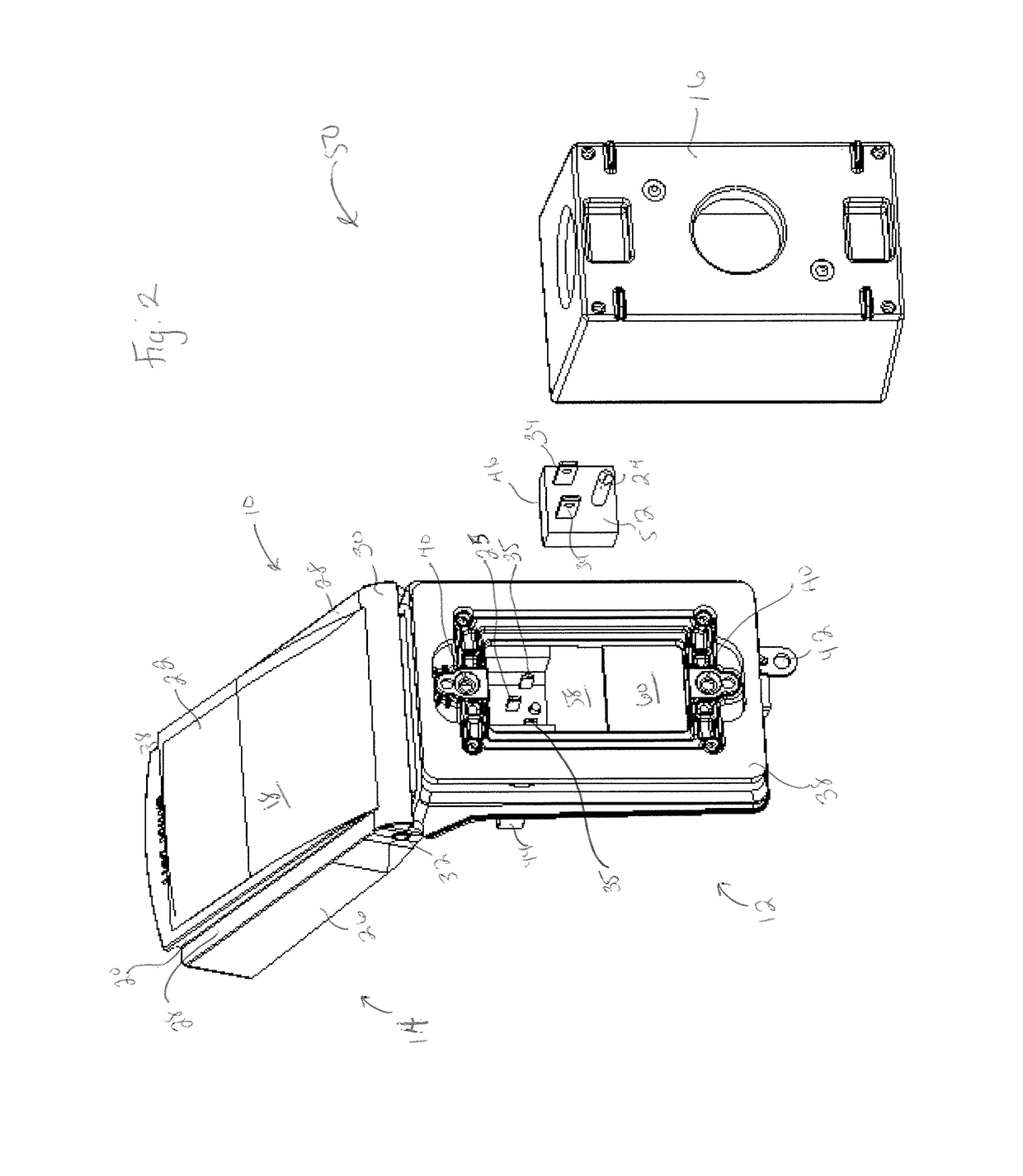

Slim line while in use cover and methods for making and using the same

ActiveUS20170237198A1Constant depthCoupling device engaging/disengagingCouplings bases/casesEngineeringPower cord

A while in use cover assembly includes a lid hingedly attached to a base having a back wall; a current member attached to the base, wherein the current member comprises a face with blade apertures configured to receive a power cord plug; and a orientable adaptor attached to the current member, wherein the orientable adaptor is symmetrical about a center line and wherein the orientable adaptor allows the current member to have a constant orientation within the base; and wherein the while in use cover assembly is configured to be attached to an outlet socket.

Owner:SIGMA ELECTRIC MFG

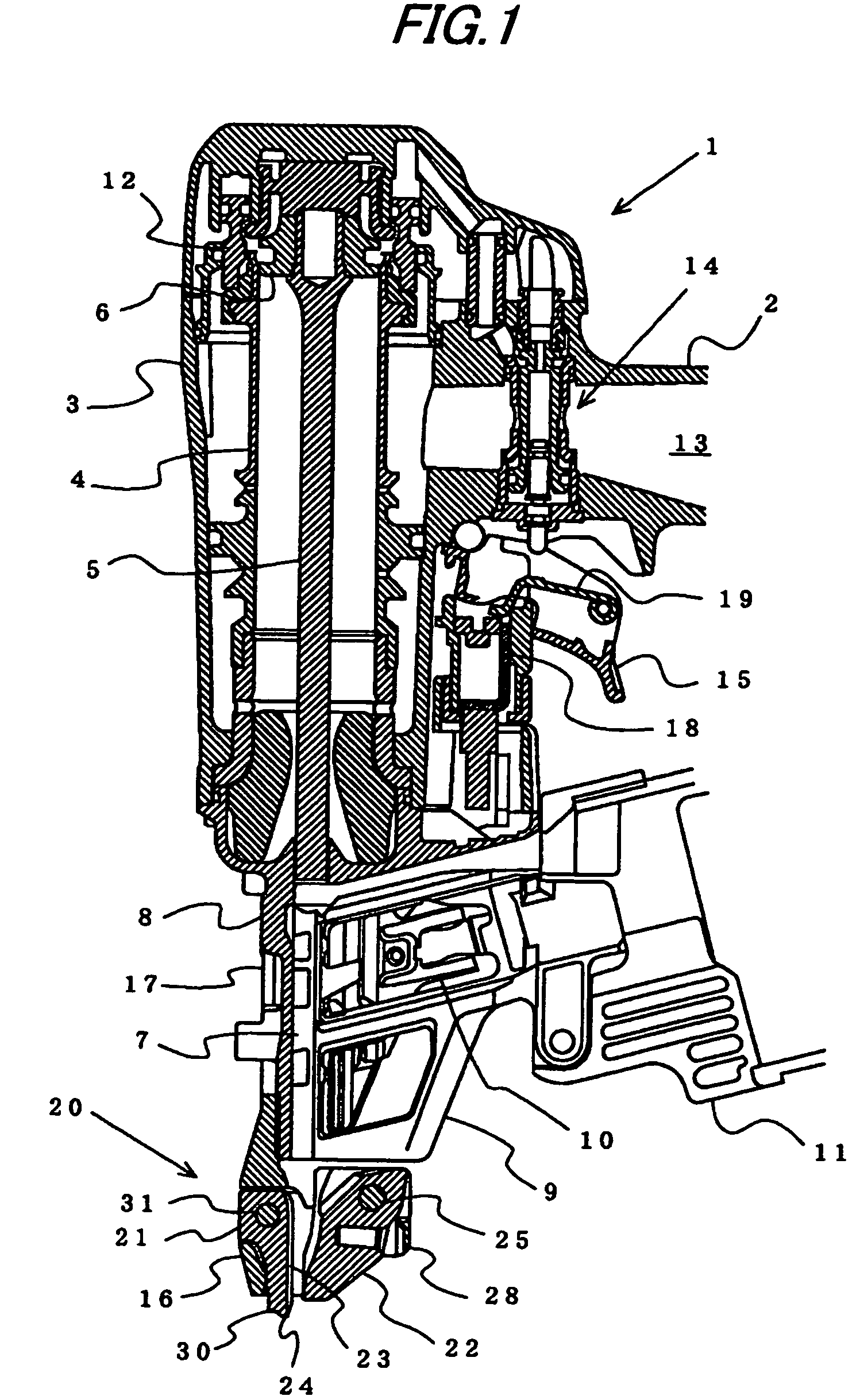

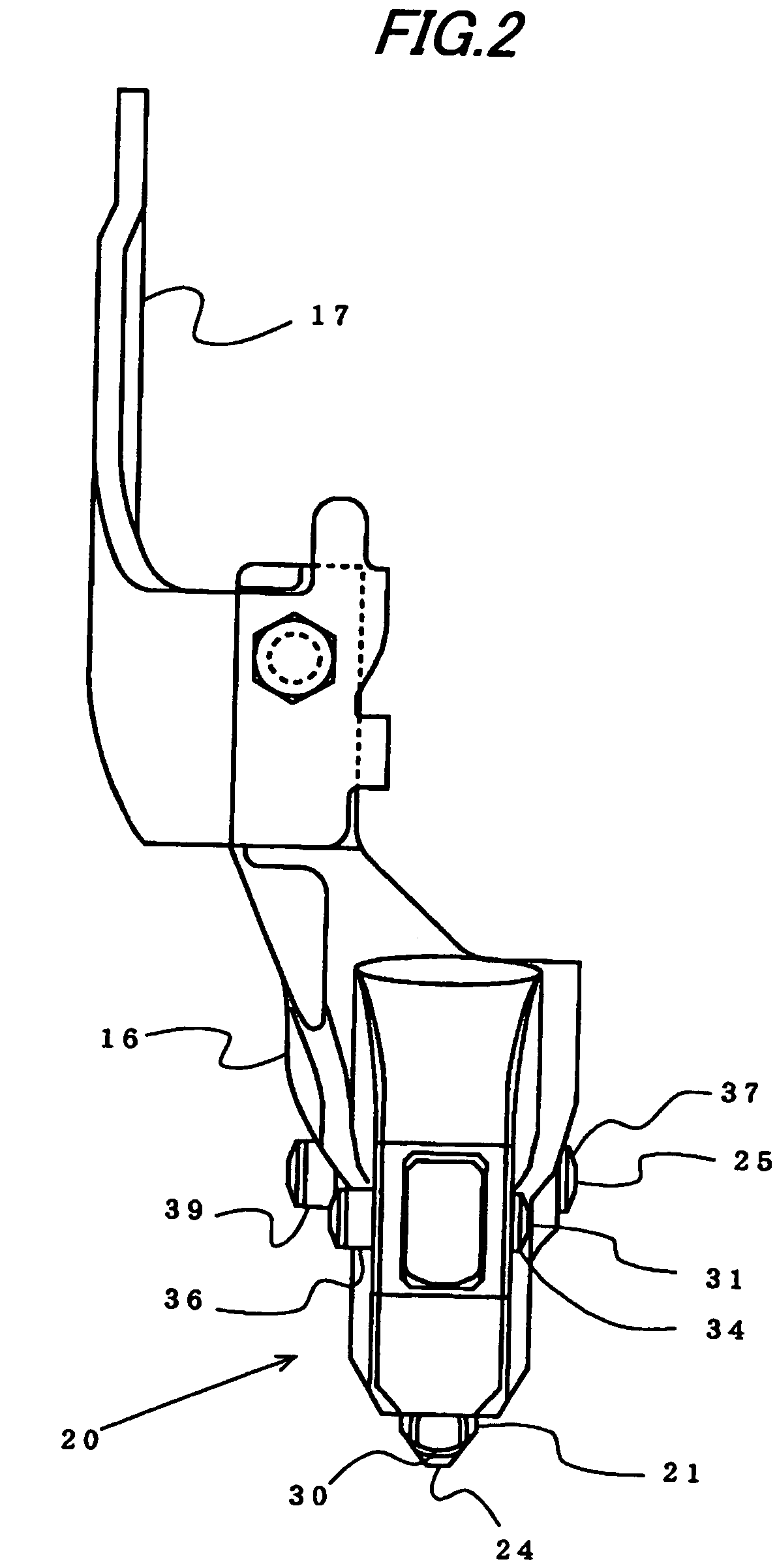

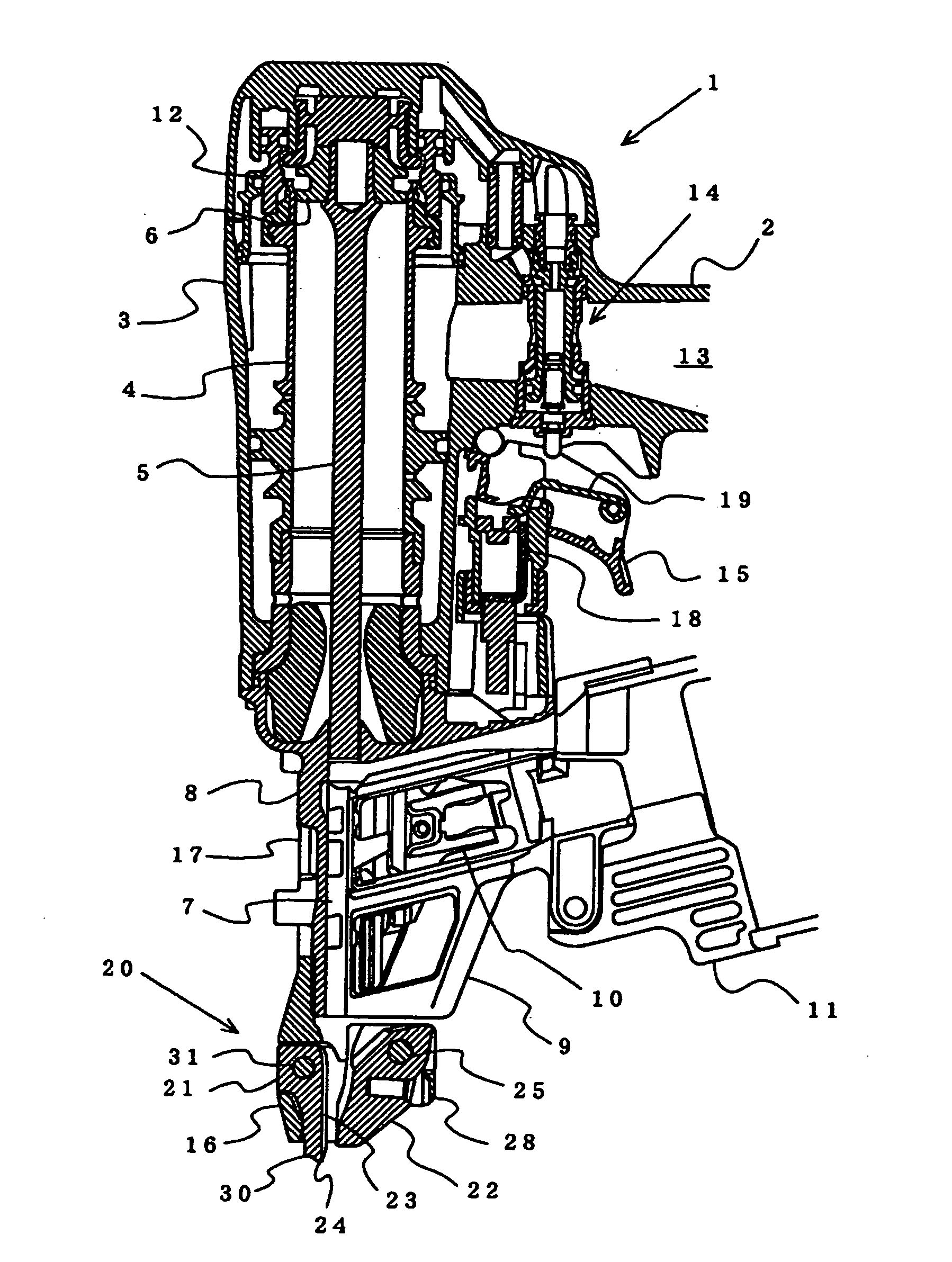

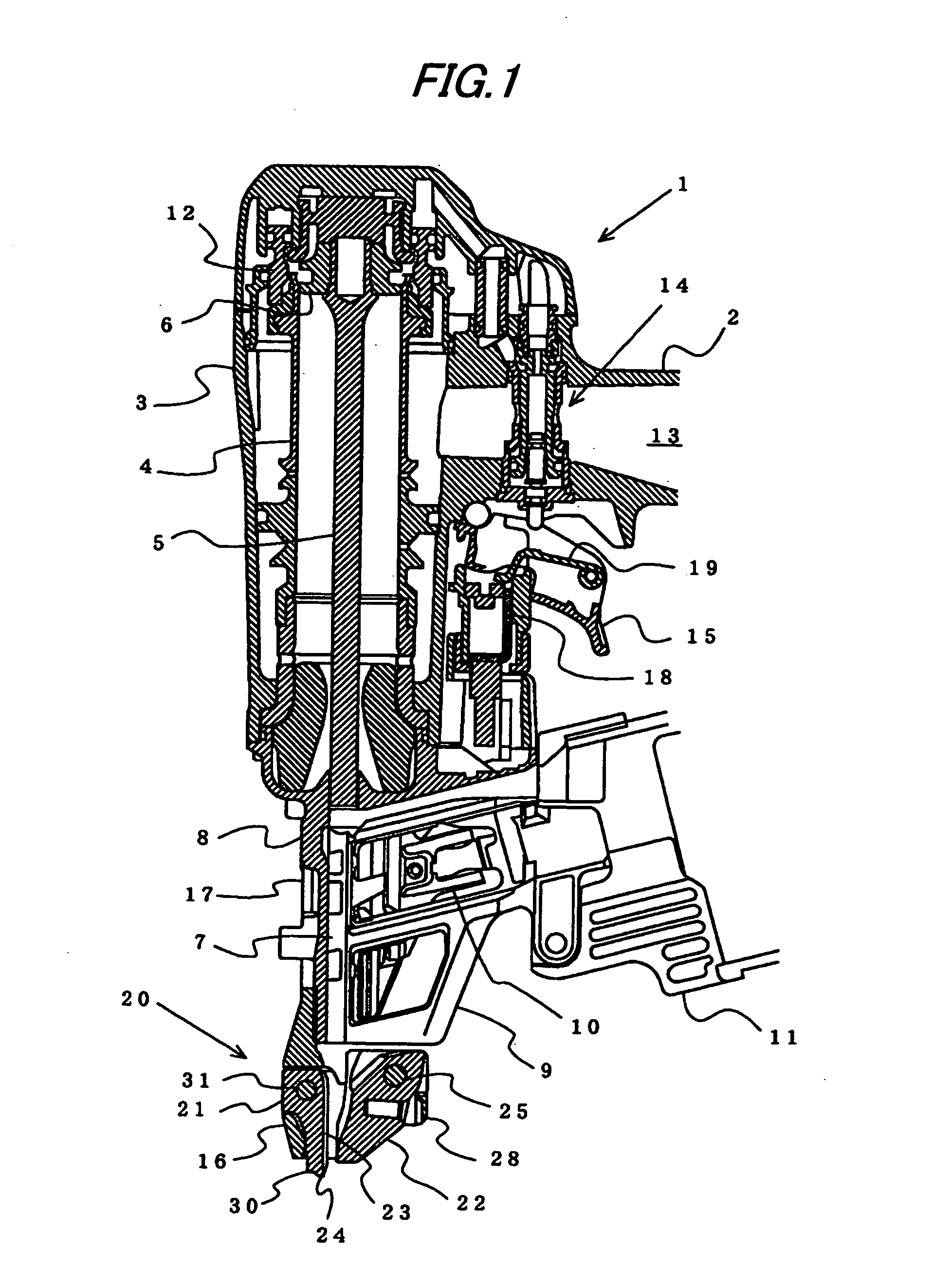

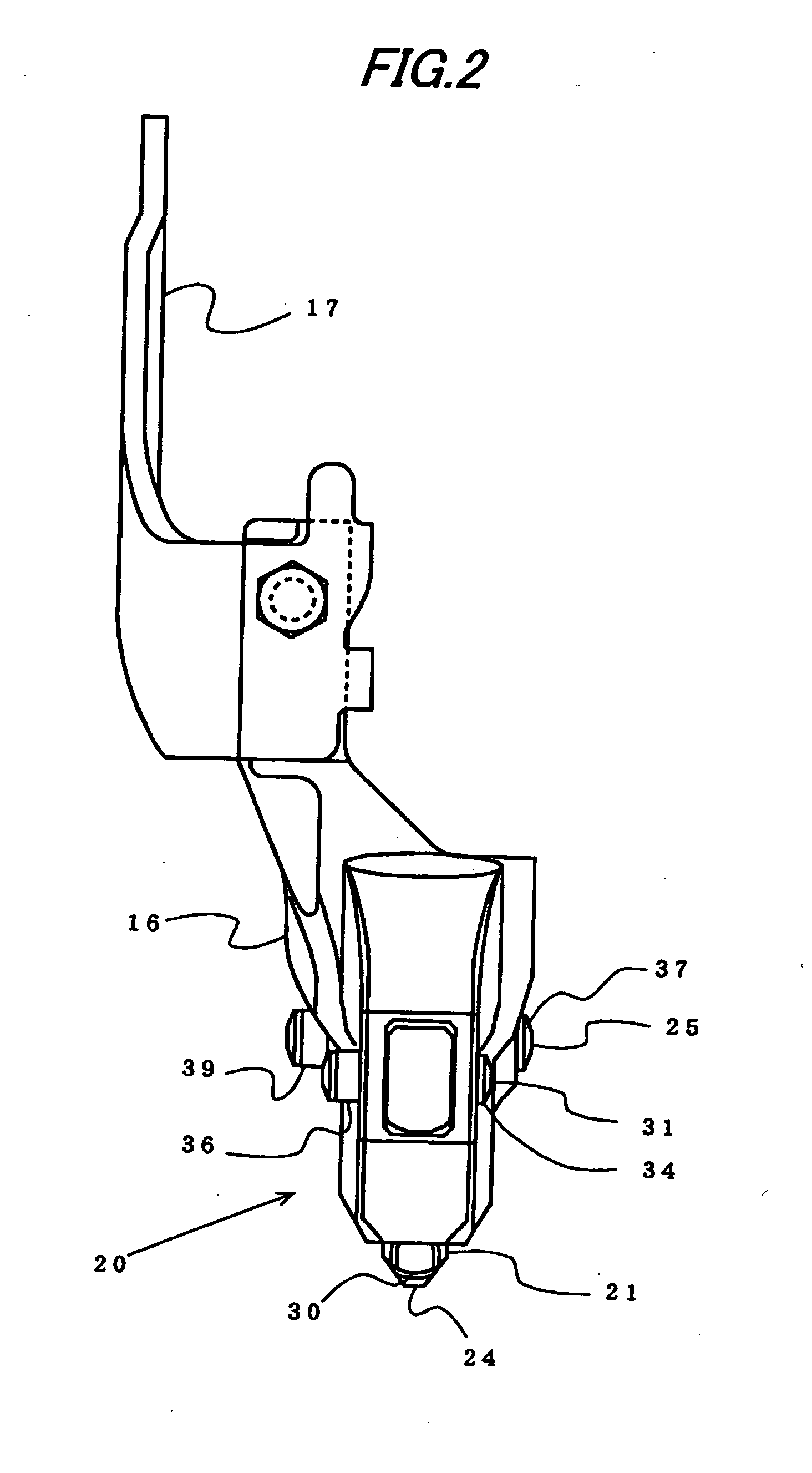

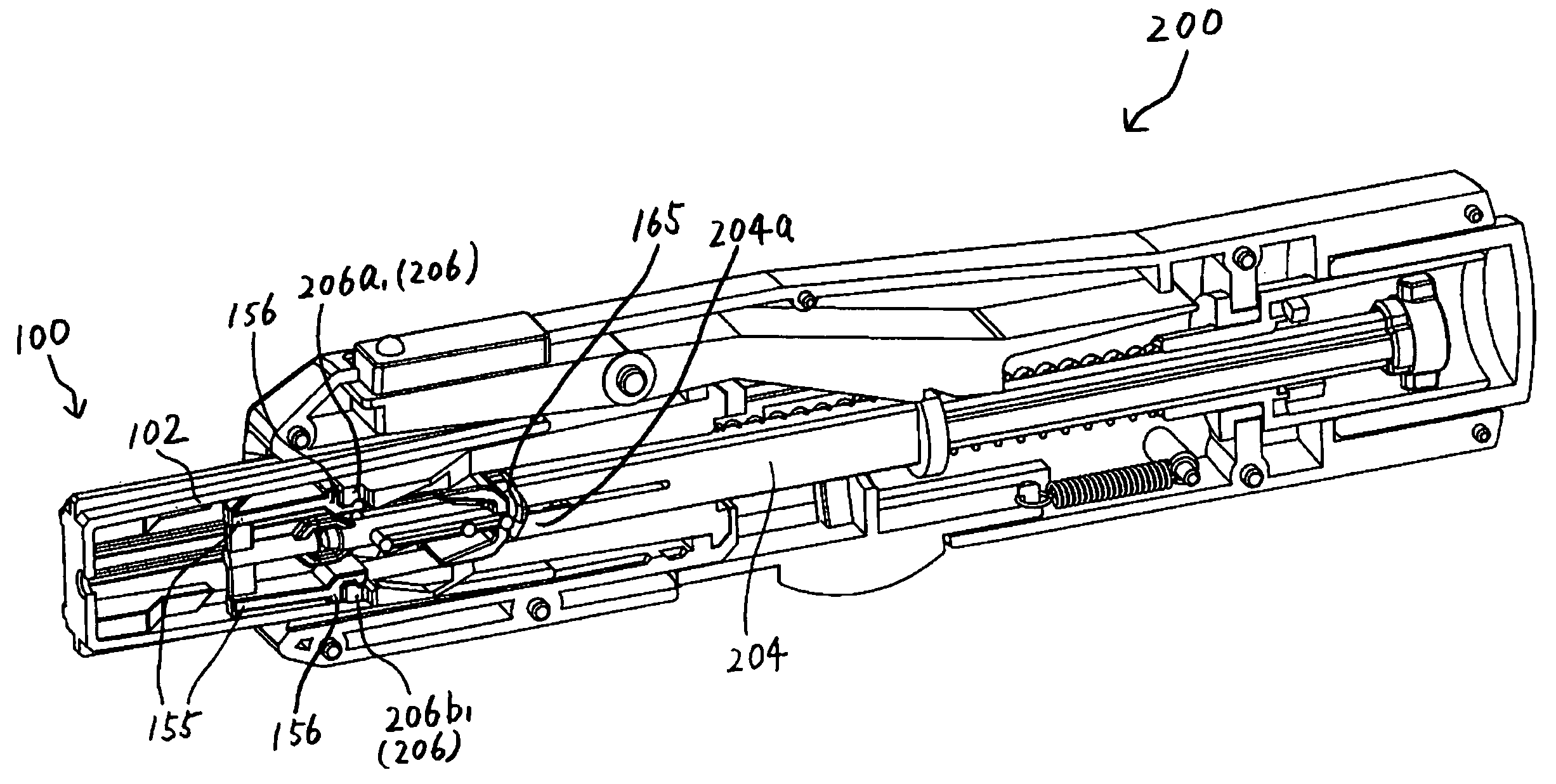

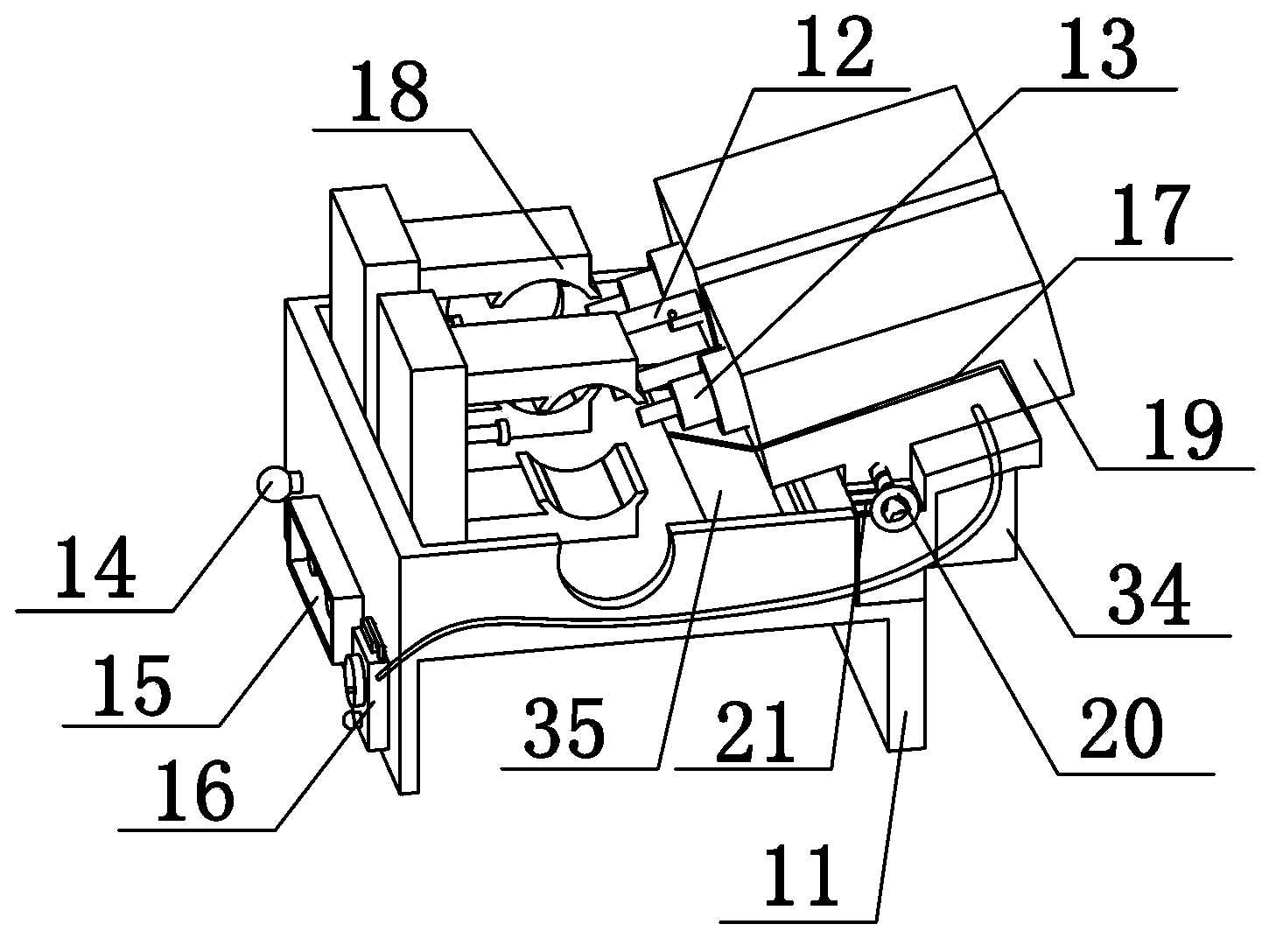

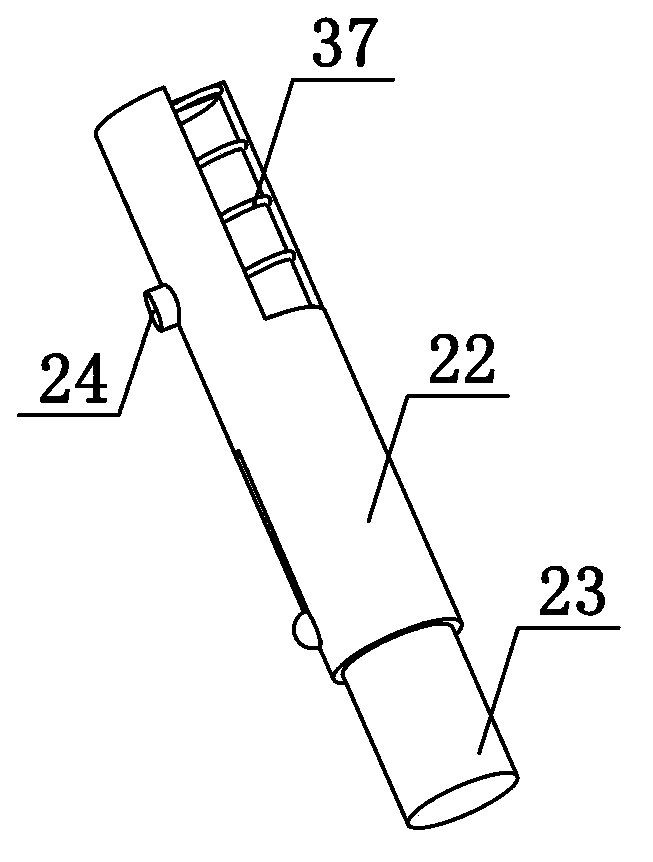

Nail guiding apparatus of nailing machine

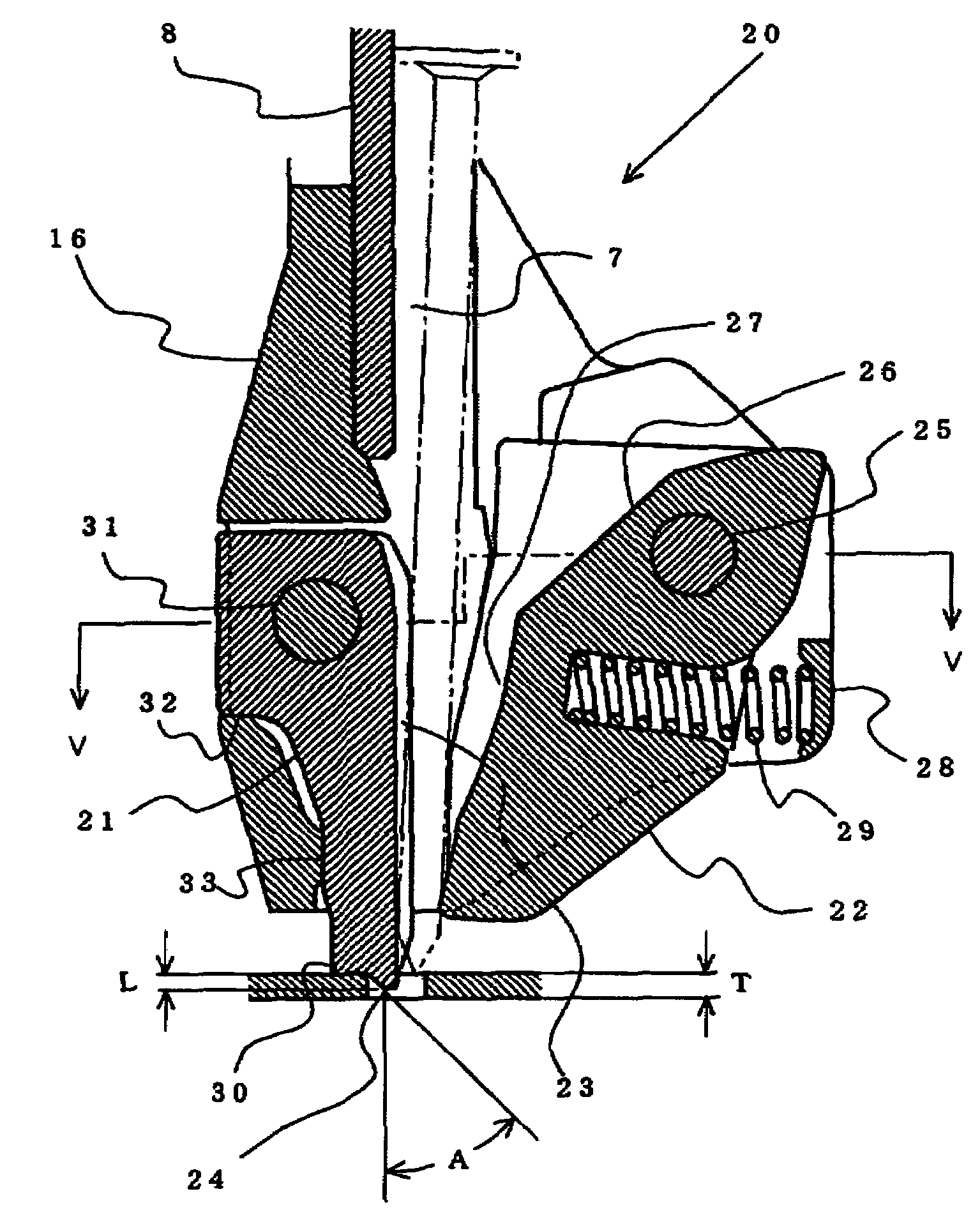

ActiveUS7628304B2Constant depthEasy to separateStapling toolsNailing toolsInjection portMechanical engineering

A nailing machine for striking a nail supplied into an injection port formed at a nose portion by a driver to strike out from inside of the injection port is provided with a nail guide member on a front side of the injection port. The nail guide member is provided with a guiding guide groove for guiding a front end portion of the nail struck out from inside of the injection port at an inner side face thereof, provided with a projected portion an outer diameter shape of which is formed in a half cut converging taper shape, and provided with a bulged portion brought into contact with a surface of a construction metal piece on an upper side of the projected portion. The nailing machine is positioned by inserting the projected portion into a nail hole formed at a construction metal piece. The bulged portion constitutes a fulcrum of rotation by which the nailing machine is inclined when the nailing machine is inclined to a front side.

Owner:MAX CO LTD

Nail Guiding Apparatus of Nailing Machine

ActiveUS20080277446A1Constant depthEasy to separateStapling toolsNailing toolsInjection portMechanical engineering

A nailing machine for striking a nail supplied into an injection port formed at a nose portion by a driver to strike out from inside of the injection port is provided with a nail guide member on a front side of the injection port. The nail guide member is provided with a guiding guide groove for guiding a front end portion of the nail struck out from inside of the injection port at an inner side face thereof, provided with a projected portion an outer diameter shape of which is formed in a half cut converging taper shape, and provided with a bulged portion brought into contact with a surface of a construction metal piece on an upper side of the projected portion. The nailing machine is positioned by inserting the projected portion into a nail hole formed at a construction metal piece. The bulged portion constitutes a fulcrum of rotation by which the nailing machine is inclined when the nailing machine is inclined to a front side.

Owner:MAX CO LTD

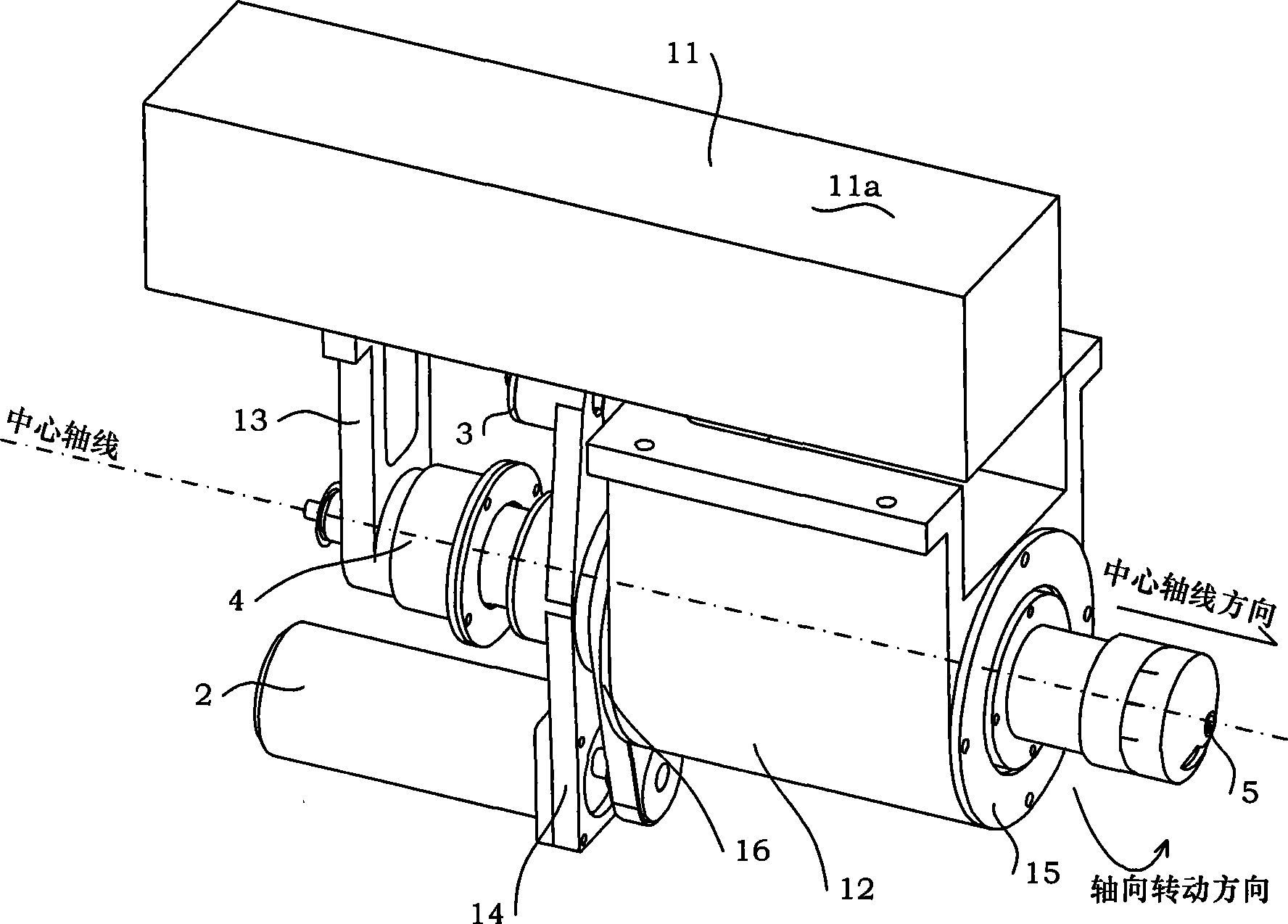

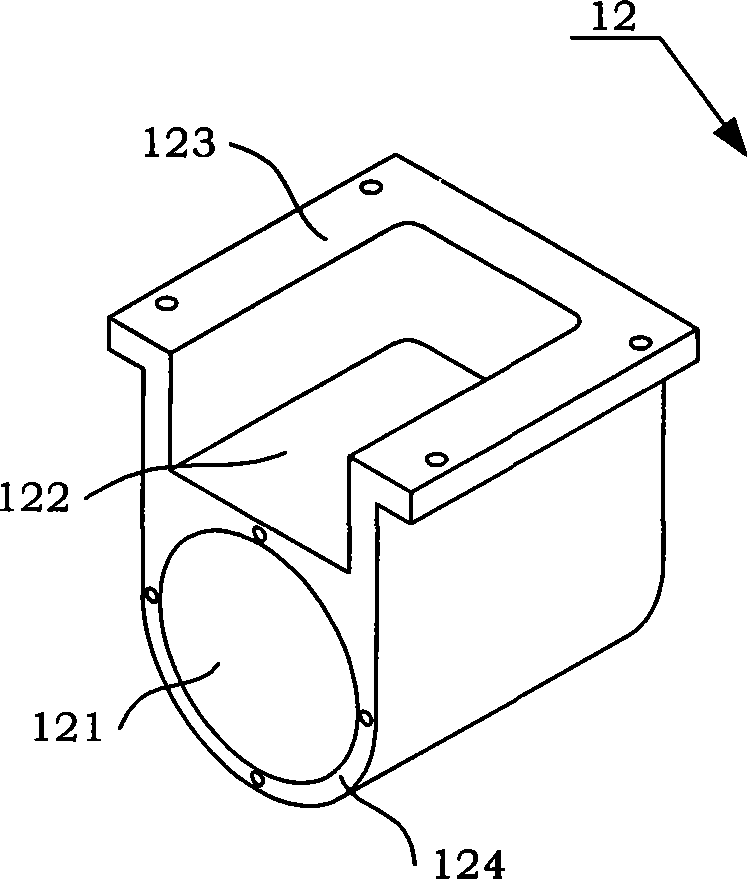

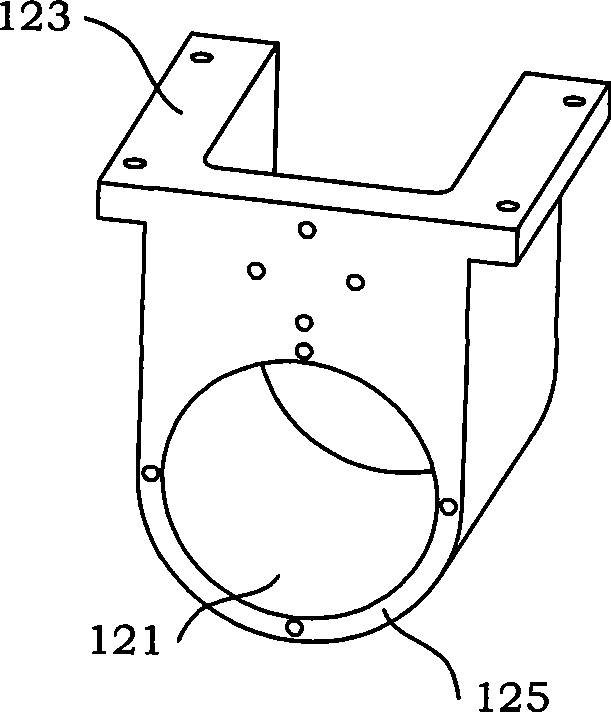

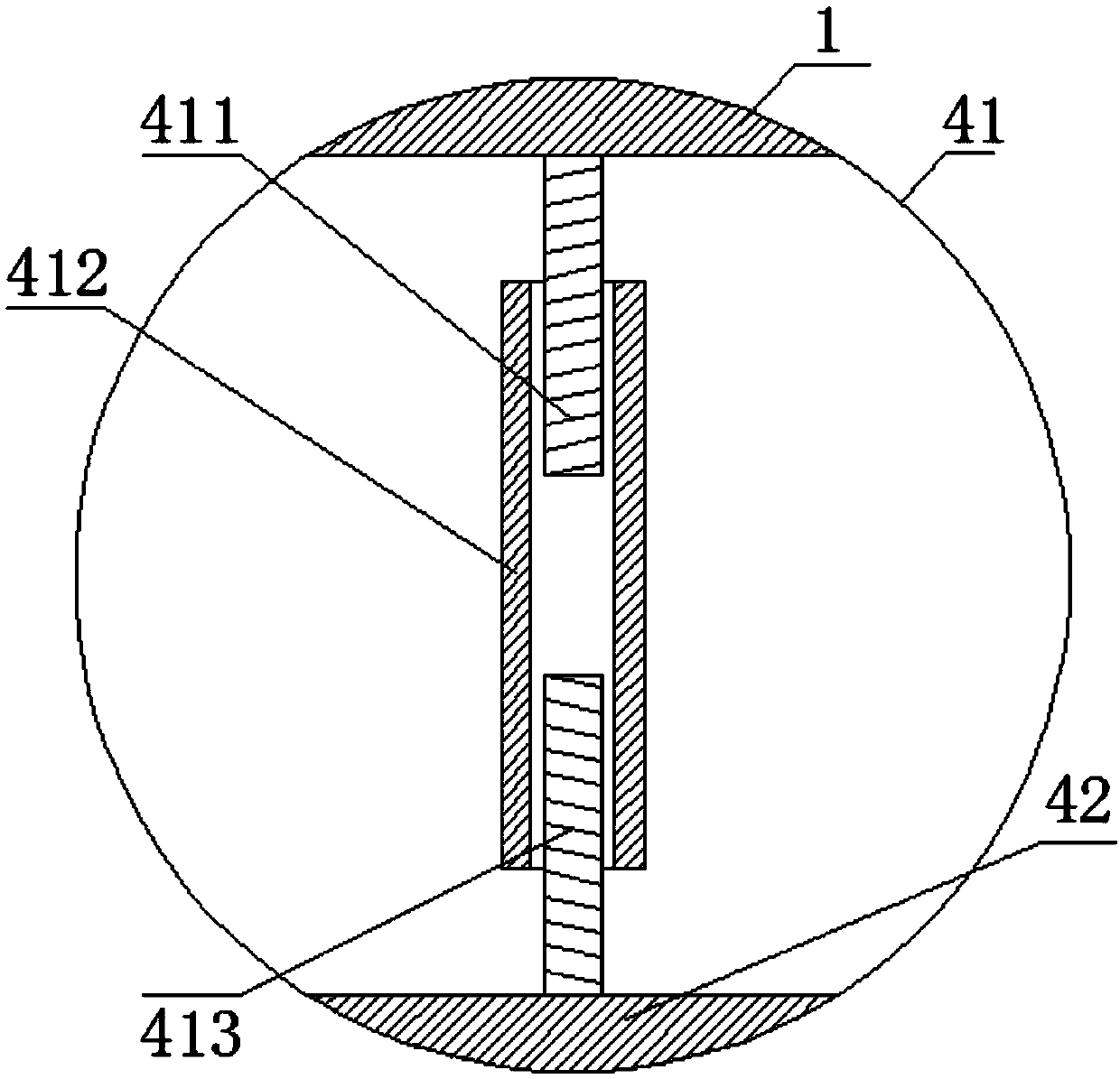

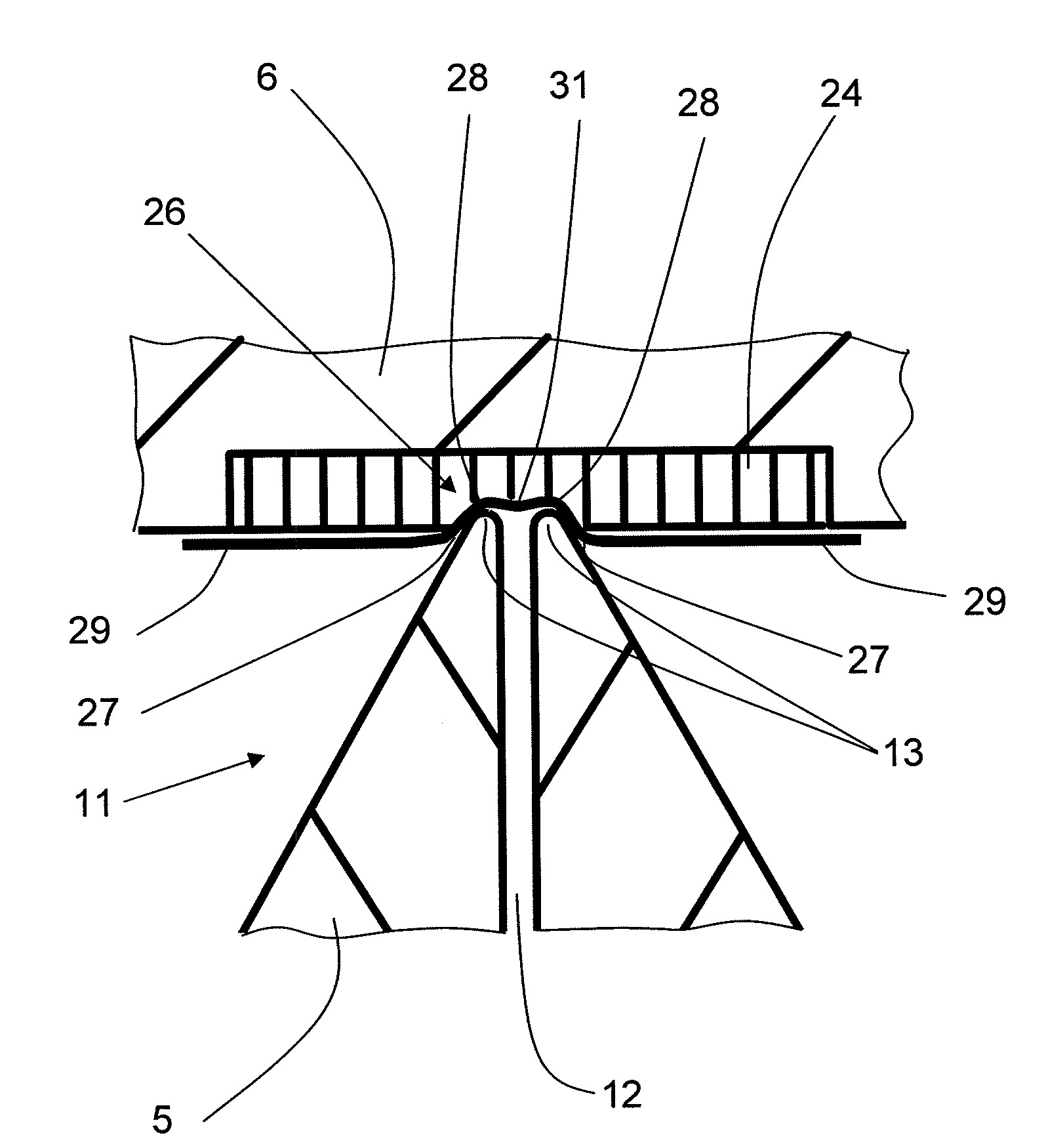

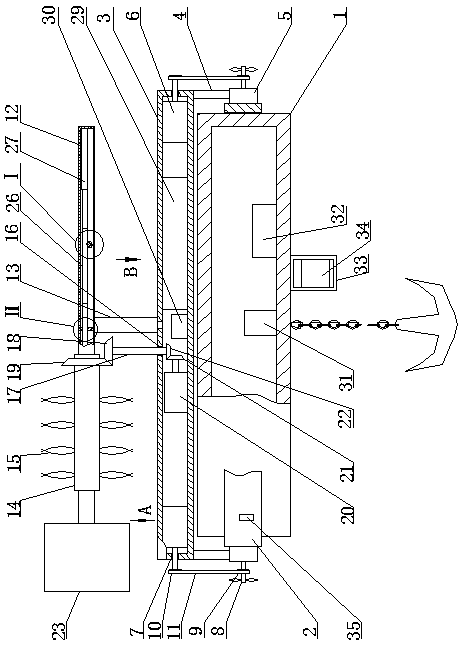

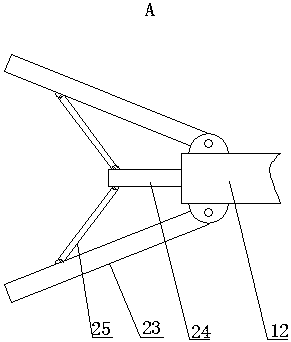

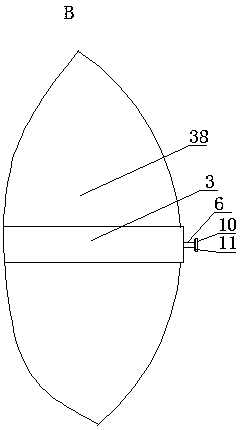

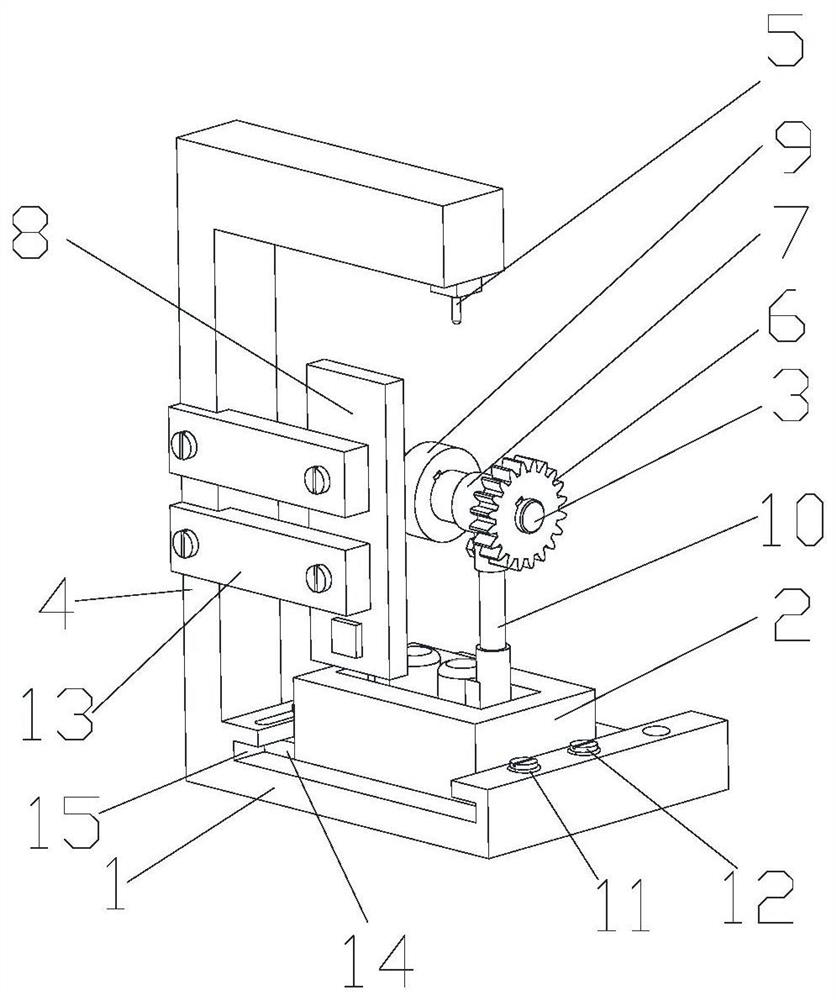

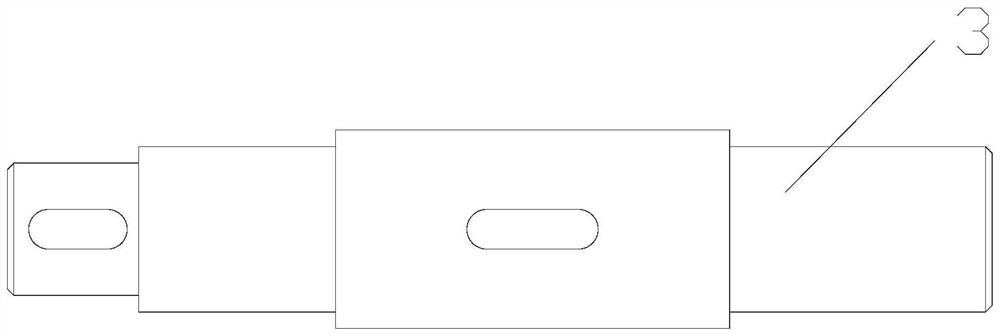

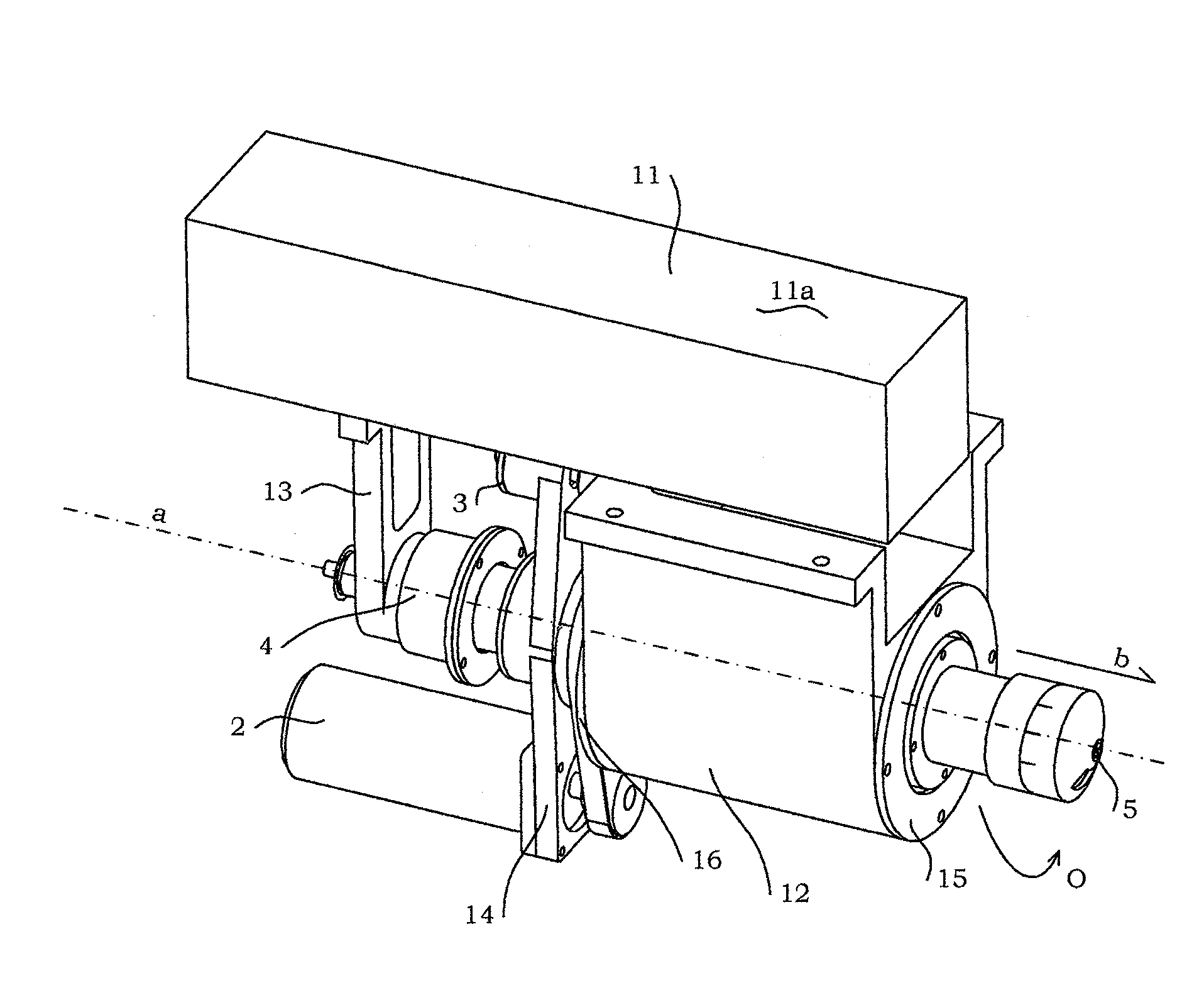

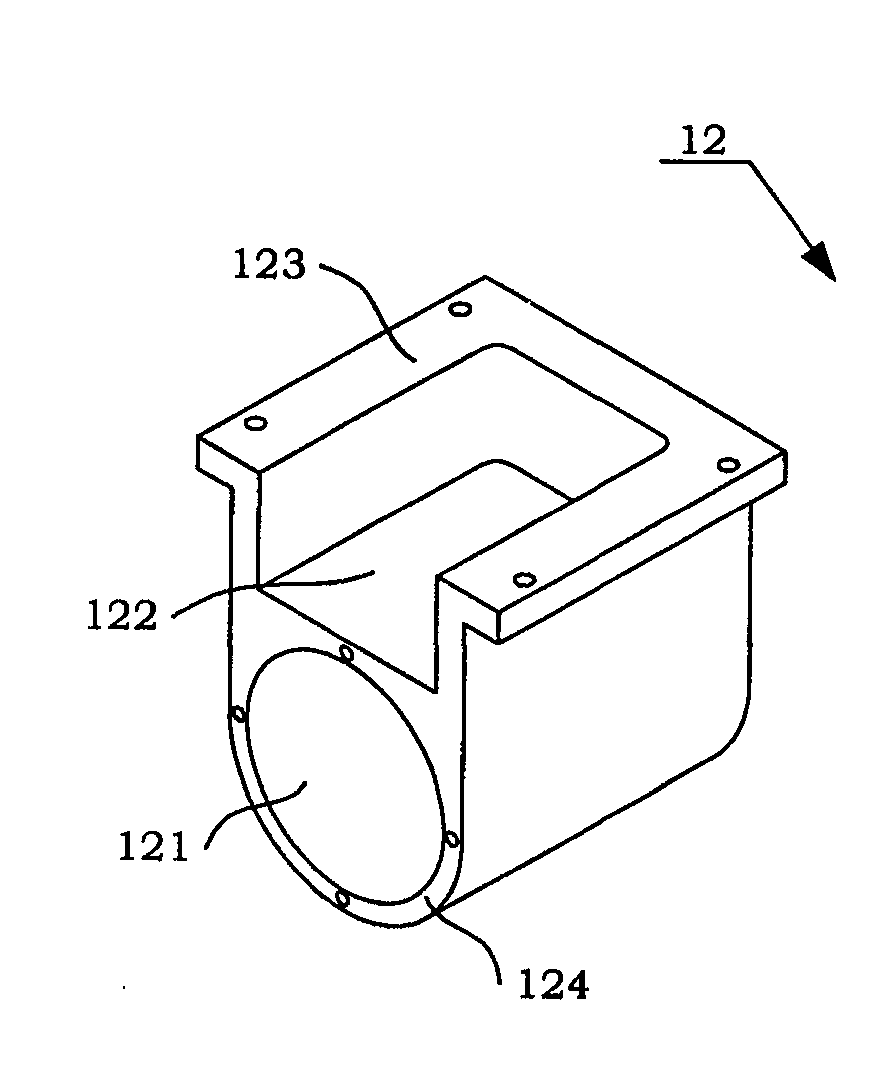

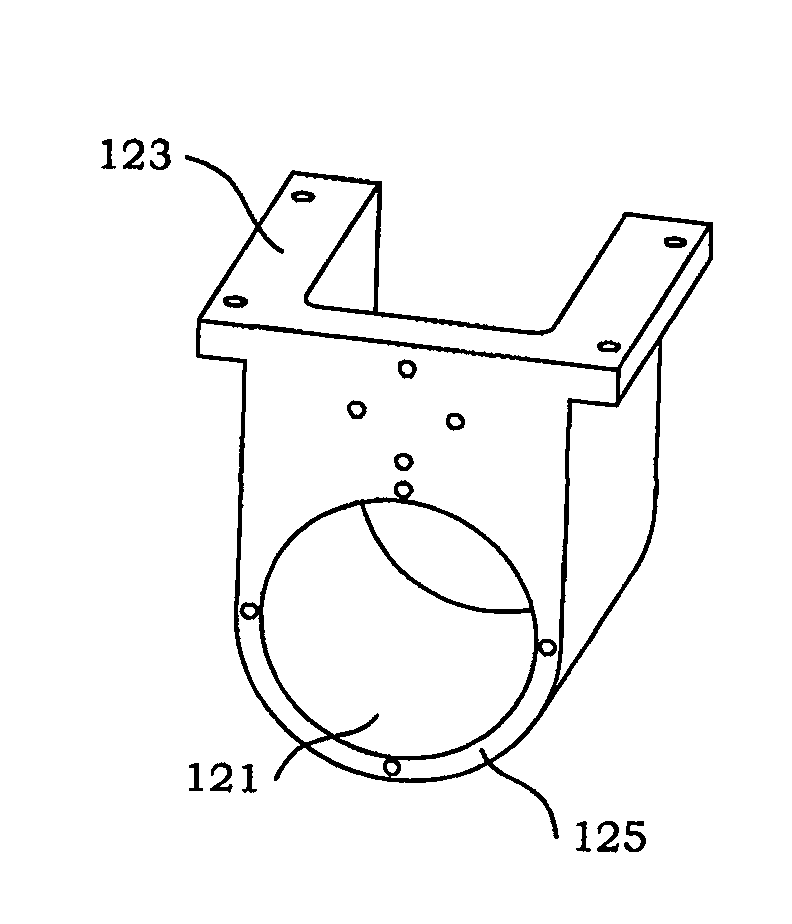

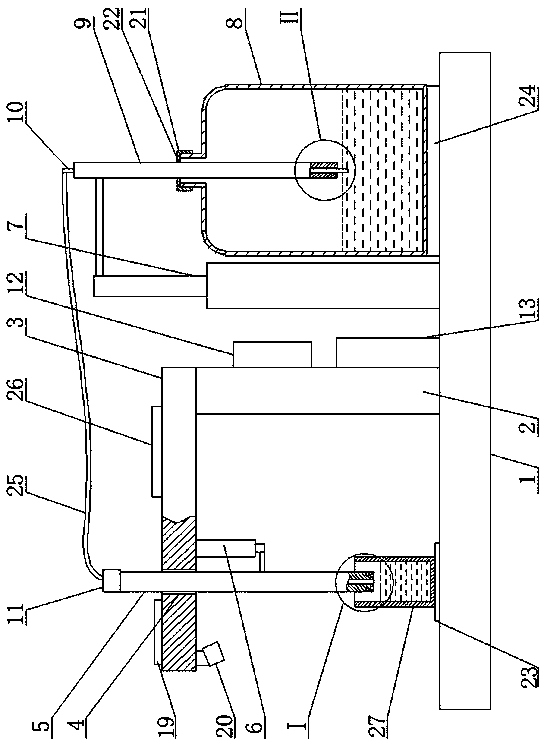

Floating type oval-shaped supersonic vibration micro-engraving device

InactiveCN101376179AMake up for the defect of not being able to rotateDepth remains constantMechanical vibrations separationLarge fixed membersNumerical controlTransducer

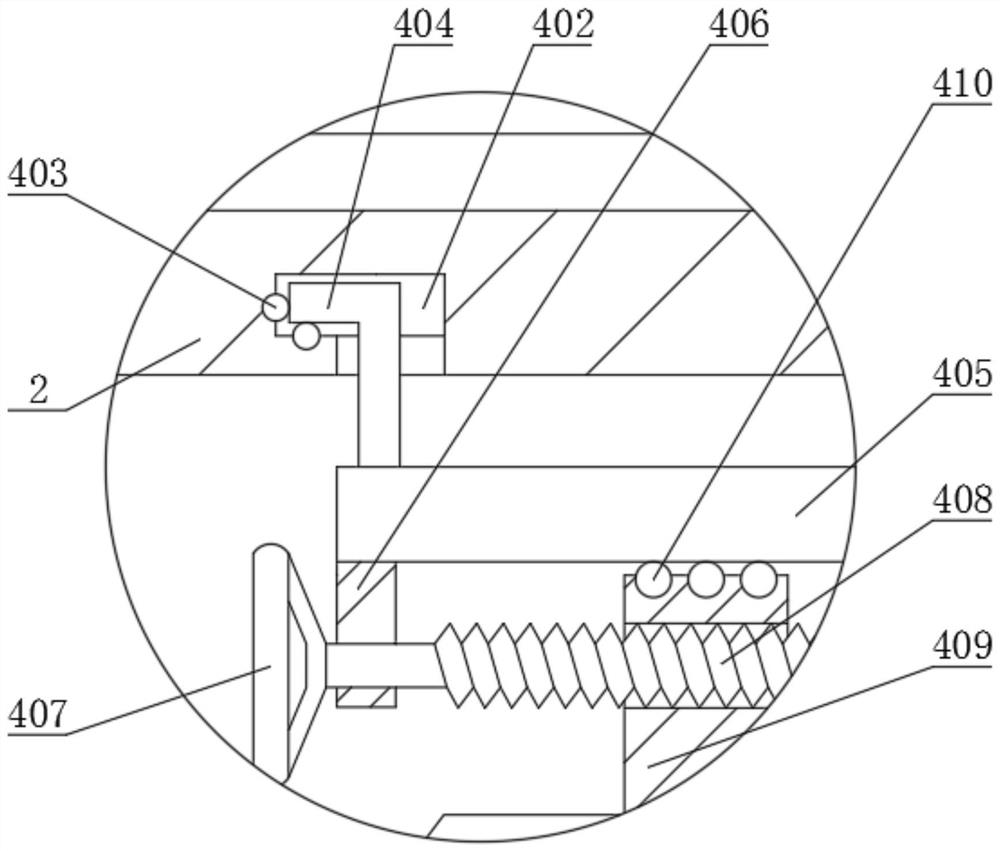

The invention discloses a floating elliptical ultrasonic vibration micro-sculpture device, which comprises an installation table (11), a support unit, a driving unit (2), a sliding unit (3), a floating transduction component (4) and a longitudinal bending transducer (1); the support unit is composed of a support base (12), an A bracket (13) and a B bracket (14); the lower installing surface of the installation table (11) is respectively connected with the support base (12) and the A bracket (13); and the upper installing surface (11a) of the installation table (11) is connected with a numerical control table. The cutter of the sculpture device can produce elliptical ultrasonic vibration to realize micro-sculpturing under the drive of an ultrasonic transducer. The micro-sculpture device can ensure that the depth of a processed groove maintains constant through the floating transduction component; then the longitudinal bending transducer causes the cutter to produce ultrasonic elliptical vibration; the characteristics of ultrasonic elliptical vibration which can reduce the cutting force to improve the machining accuracy and reduce the surface roughness are utilized to ensure that the groove on the processed part surface has high geometric accuracy and surface quality without burrs on the edge thereof; and the unitized design of the longitudinal bending transducer and the driving unit remedies the defect that the cutter cannot rotate in the traditional planing process, thereby realizing free-adjusting sculpture process with multiple cutting directions.

Owner:BEIHANG UNIV

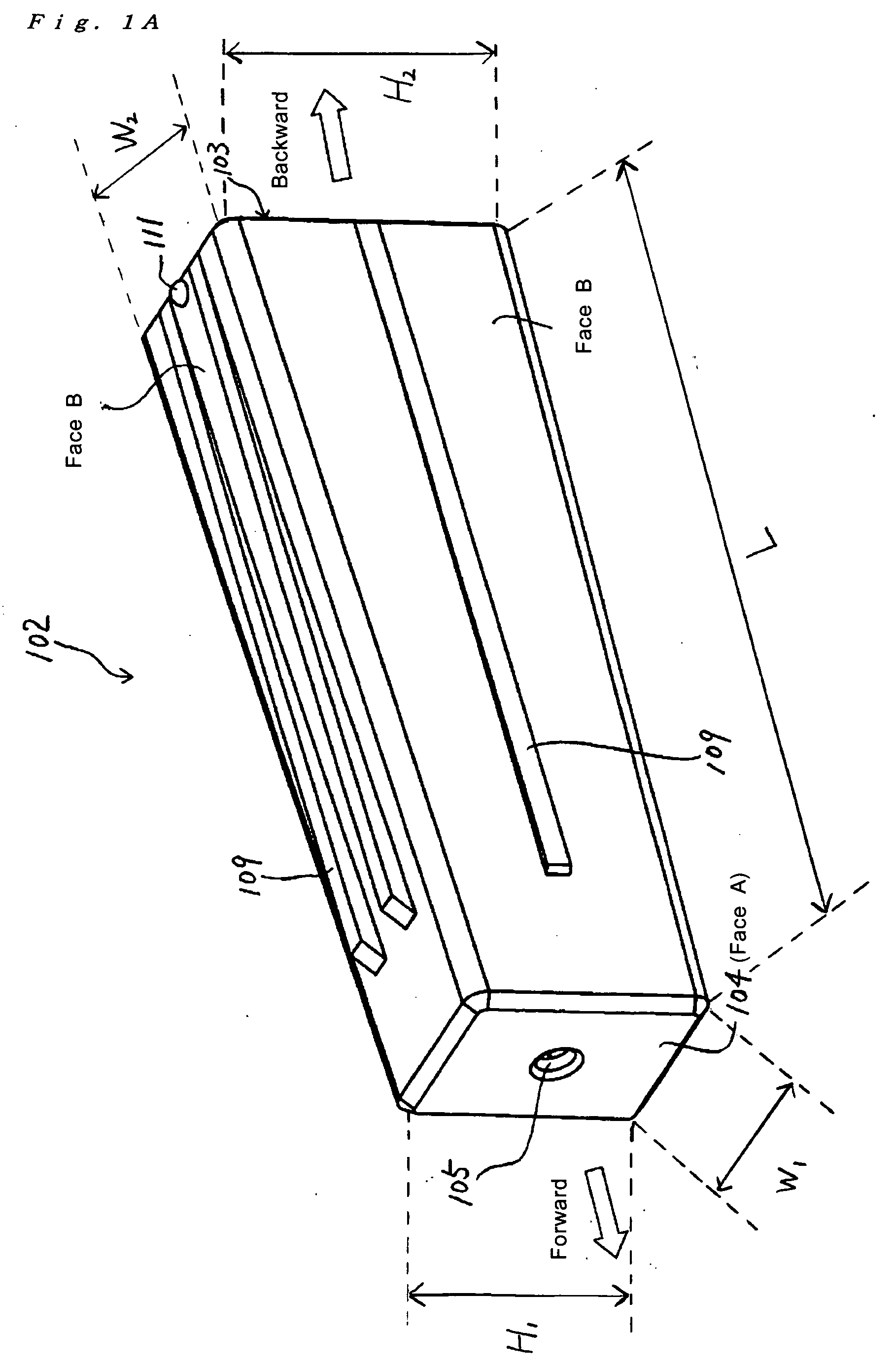

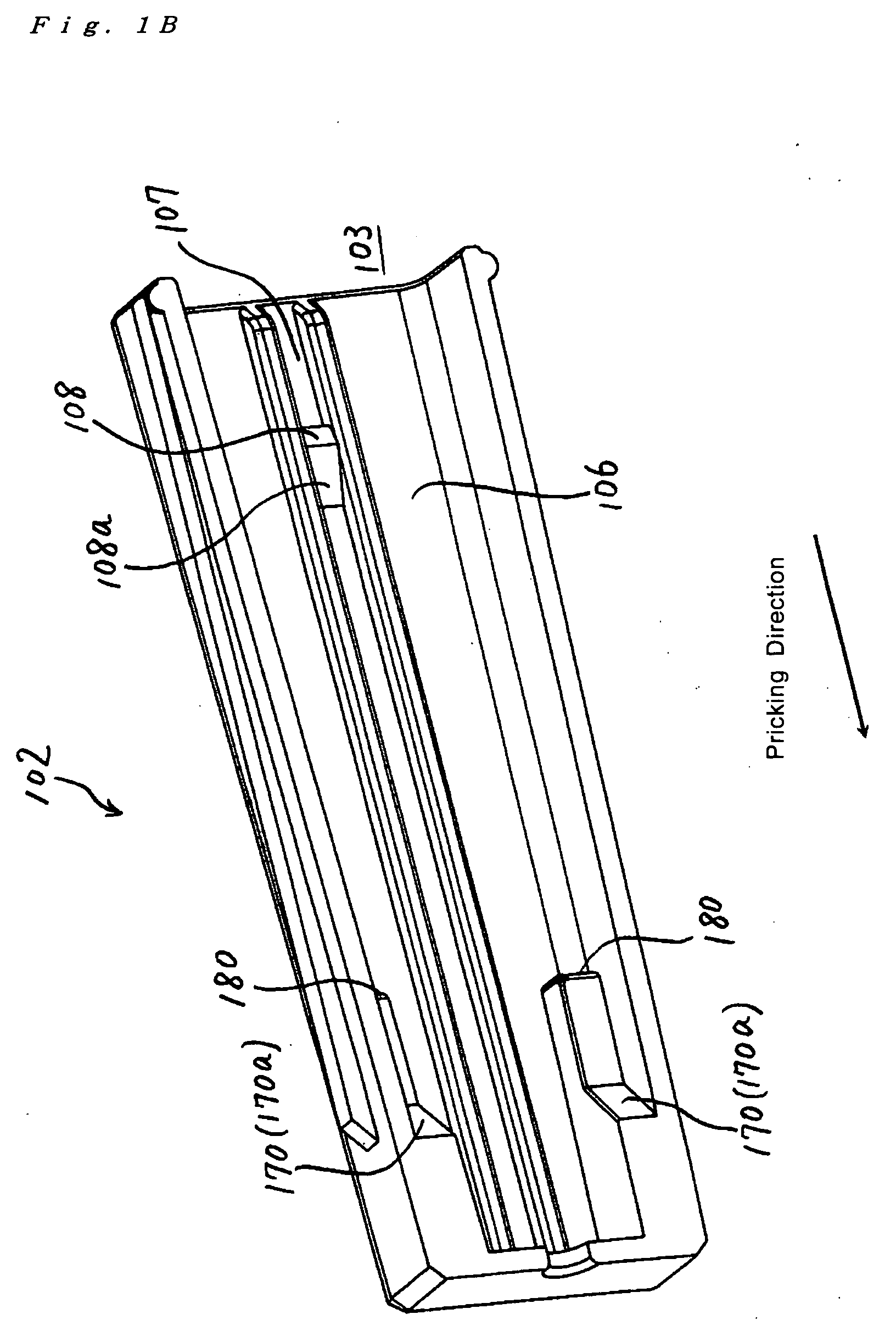

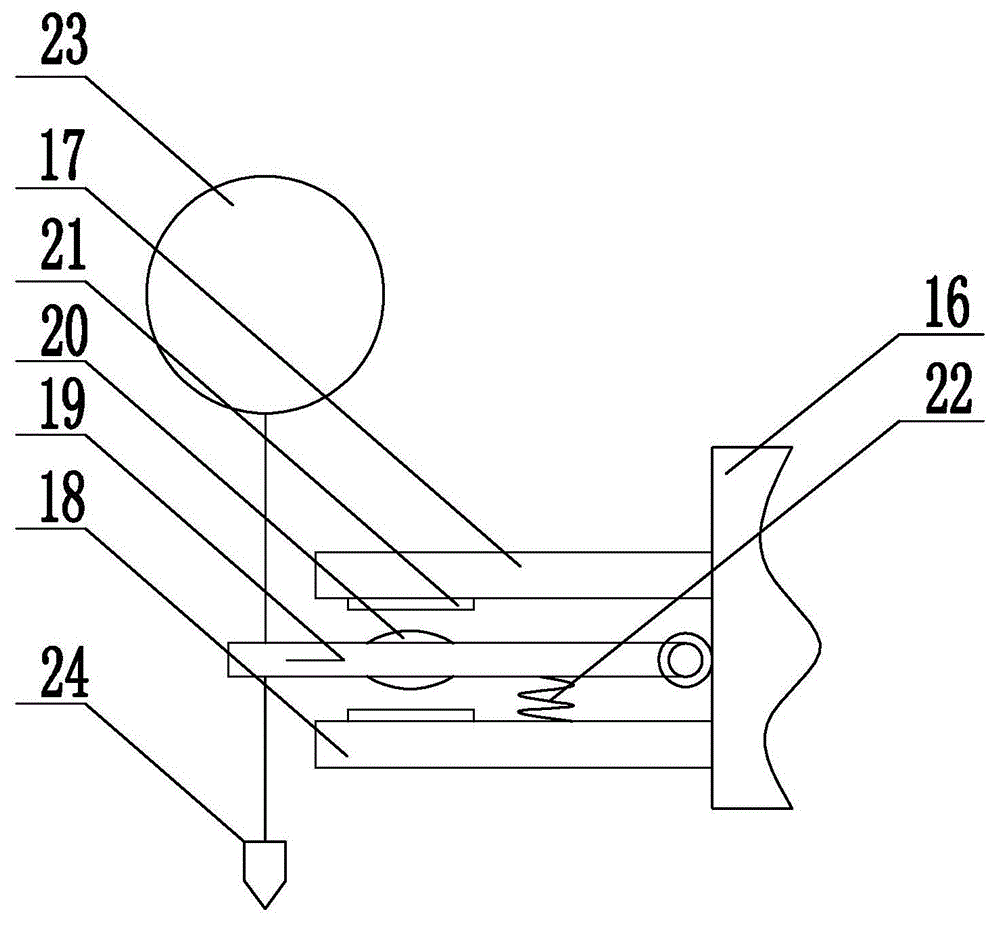

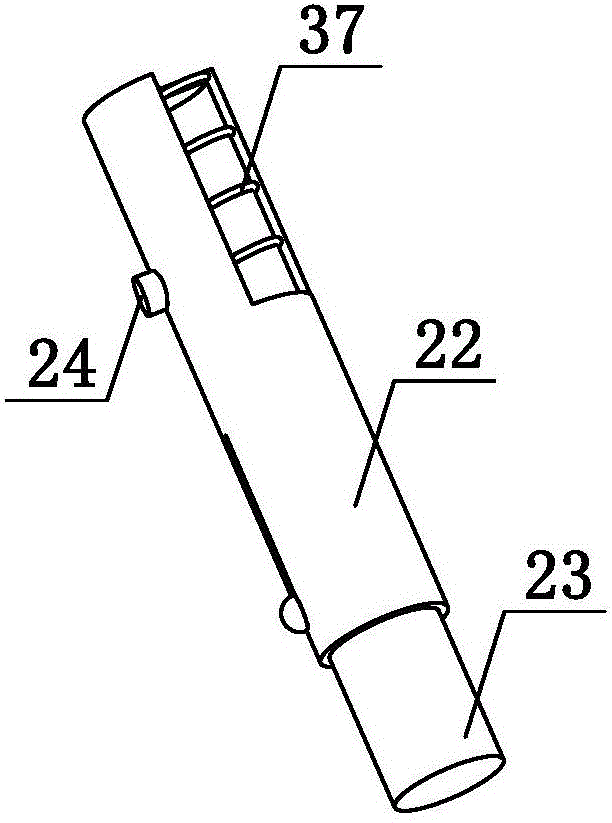

Lancet Assembly and Pricking Device

InactiveUS20090143810A1Safely dischargeConstant depthSurgical needlesDiagnostic recording/measuringGeneral surgery

A lancet assembly that enables it to prick with smaller number of steps and be disposed safely. The lancet assembly comprising a lancet and a lancet holder that houses the lancet, whereinthe lancet comprises a lancet body, a lancet cap and a pricking component, the pricking component is situated in both of the lancet body and the lancet cap, the tip of the pricking component is covered with the lancet cap, and the lancet cap and the lancet body are integrally connected together by a bridging component;when the lancet cap is pressed in the pricking direction with the lancet body attached to the lancet holder, the bridging component is broken so that the lancet cap is separated from the lancet body; and thereafterwhen the separated lancet cap is pressed further in the pricking direction, the separated lancet cap moves to a position that is off the pricking pathway of the pricking component.

Owner:IZUMI COSMO CO

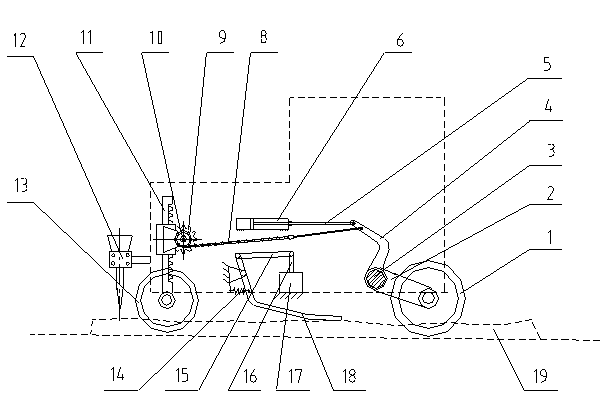

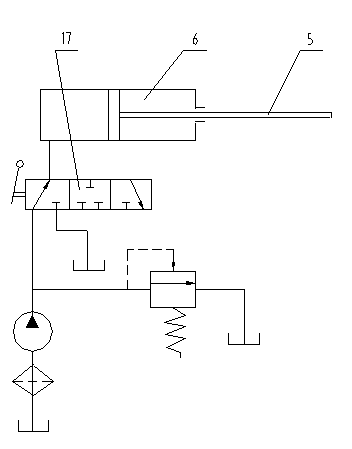

Four-wheel synchronous automatic lifting regulating mechanism

InactiveCN104025787AOvercoming the defects of the lifting methodEasy to makeTransplantingGear wheelEngineering

The invention relates to a four-wheel synchronous automatic lifting regulating mechanism. The mechanism comprises a sensing assembly, a hydraulic power assembly and a lifting performing mechanism, wherein the lifting performing mechanism comprises a front lifting device and a rear lifting device; a rear wheel driven chain box is driven by a hydraulic cantilever to rotate around a rear axle so as to lift a rear machine body; a chain and chain wheel drive assembly and a toothed wheel and toothed column drive assembly are driven by the hydraulic cantilever so as to lift a front machine body; during work, the height variation of a furrow is changed into shift motion by the sensing assembly and a hydraulic control valve of an oil cylinder is controlled to ensure that the oil cylinder respectively works in three states of oil feeding, oil discharging and pressure maintaining; a piston rod extends or retracts according to the different working states, the front body and the rear body of a transplanter are controlled through the performing mechanism to be lifted simultaneously so as to drive a pair of planting pincers to be lifted at the same time and realize the automatic regulation of planting depth; through the lifting control of a hydraulic automatic lifting mechanism, the uniform planting depth of seedlings is guaranteed in the transplanting process.

Owner:ZAOYANG CITY ZHENGTIAN TRANSPLANTER

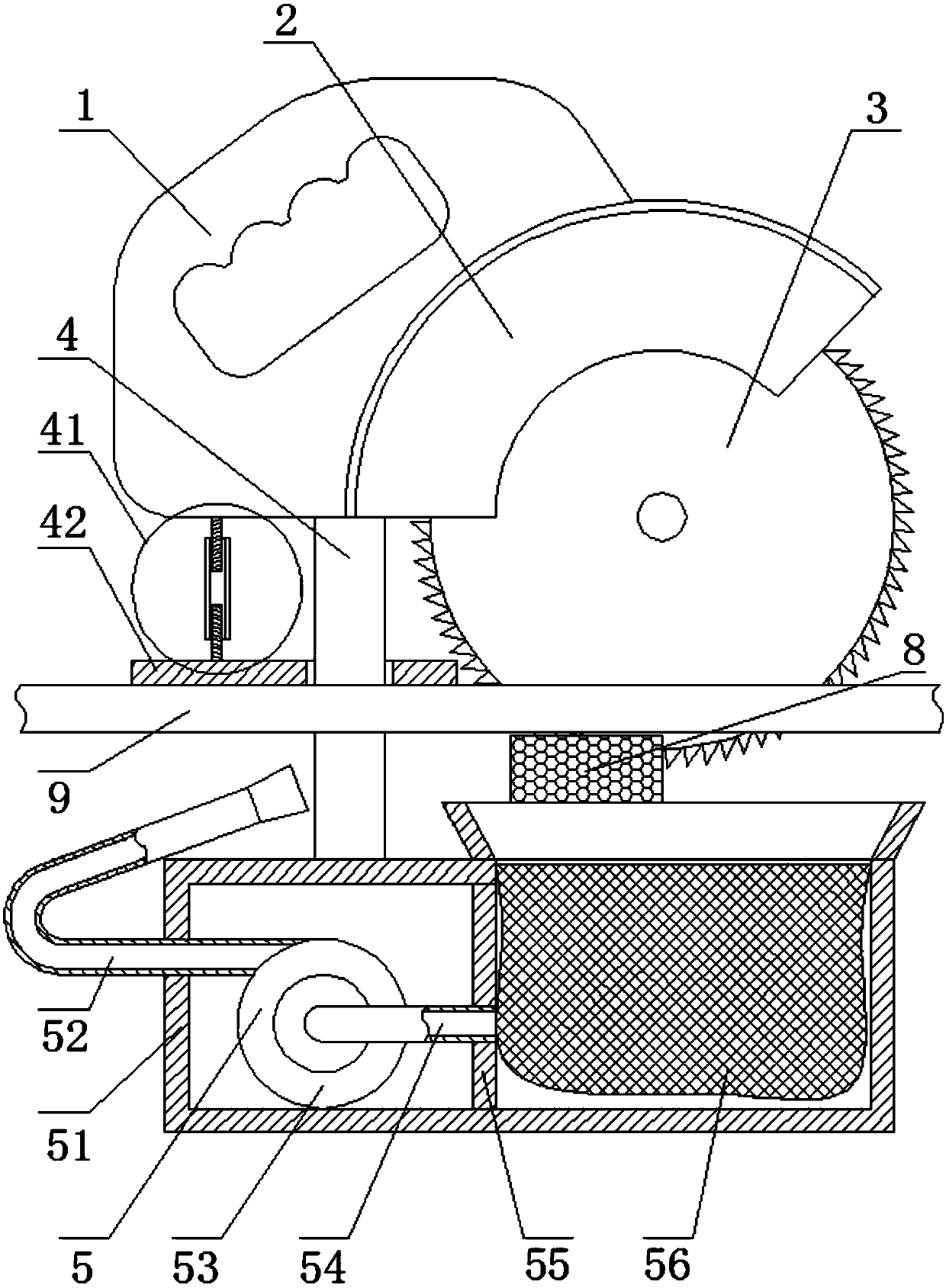

PC sunlight plate cutting equipment

InactiveCN109531656APreventing Cut-off Wheel Damage ProblemsConstant depthMetal working apparatusScrapEngineering

The invention discloses PC sunlight plate cutting equipment. The PC sunlight plate cutting equipment comprises a main body connecting block, a protective cover, a cutting wheel, an adjusting device, adust collecting and cooling device, a water cooling and cooling device, a power motor and a chip removing block, wherein the front side wall of the main body connecting block is fixedly connected with the protective cover, the main body connecting block is fixedly connected with a power motor, the output end of the power motor is fixedly connected with the cutting wheel, the lower end surface ofthe main body connecting block is connected with the adjusting device, and an upper threaded rod, a threaded sleeve, a lower threaded rod and the like are added, so that the cutting depth can be adjusted; after adjustment is completed, the cutting depth can be kept unchanged; the dust collecting and cooling device and the water cooling and cooling device are added, so that the cutting wheel can beeffectively cooled, and the problem that the cutting wheel is damaged due to high temperature is solved; and the structures such as the chip removing block, a gauze cloth bag and an air inlet pipe are added, so that cut scraps can be collected in the gauze cloth bag, and the pollution of debris to the environment cannot be caused.

Owner:GUANGDONG GUOWEIXING PLASTIC SCI & TECHCO LTD

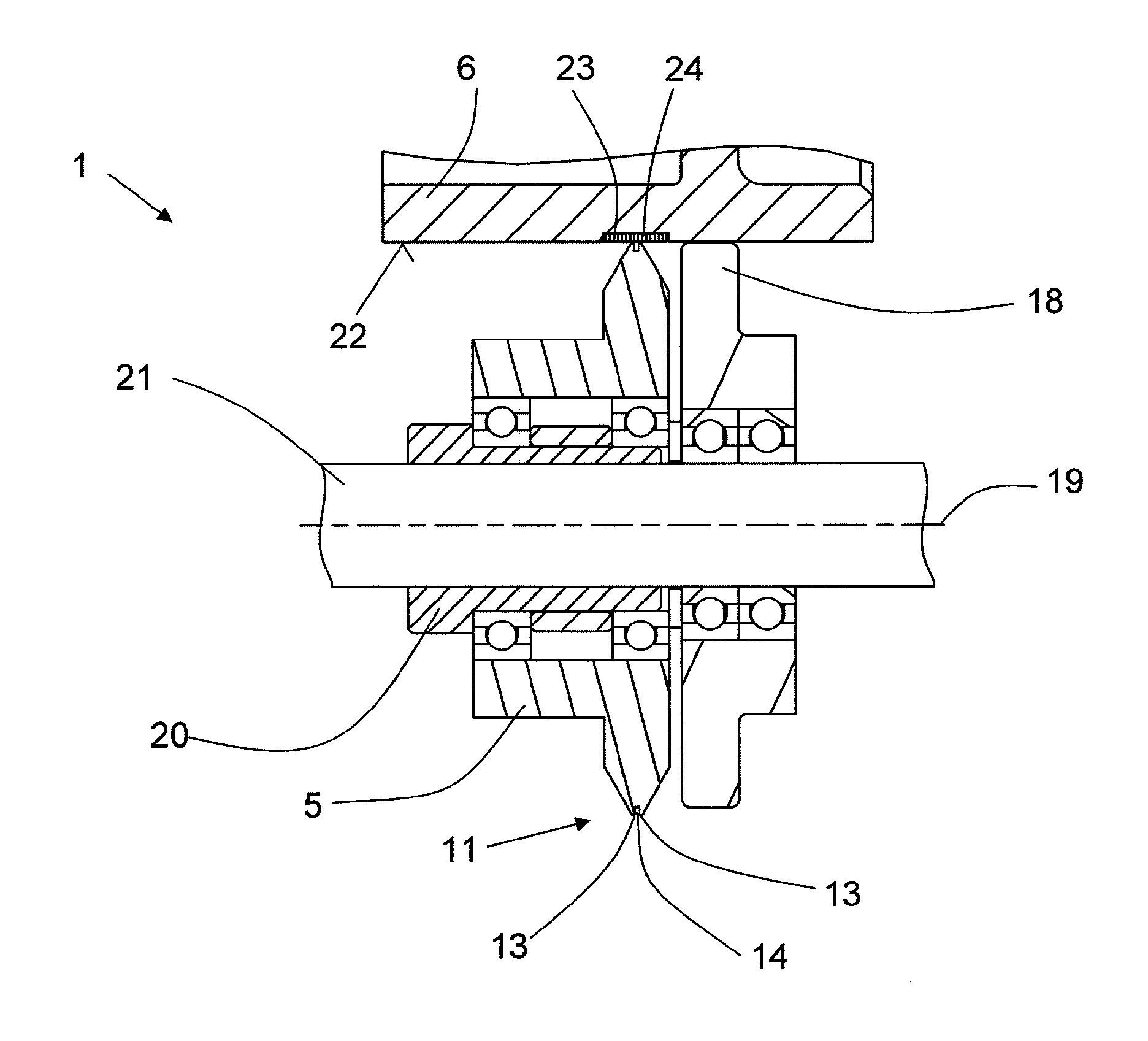

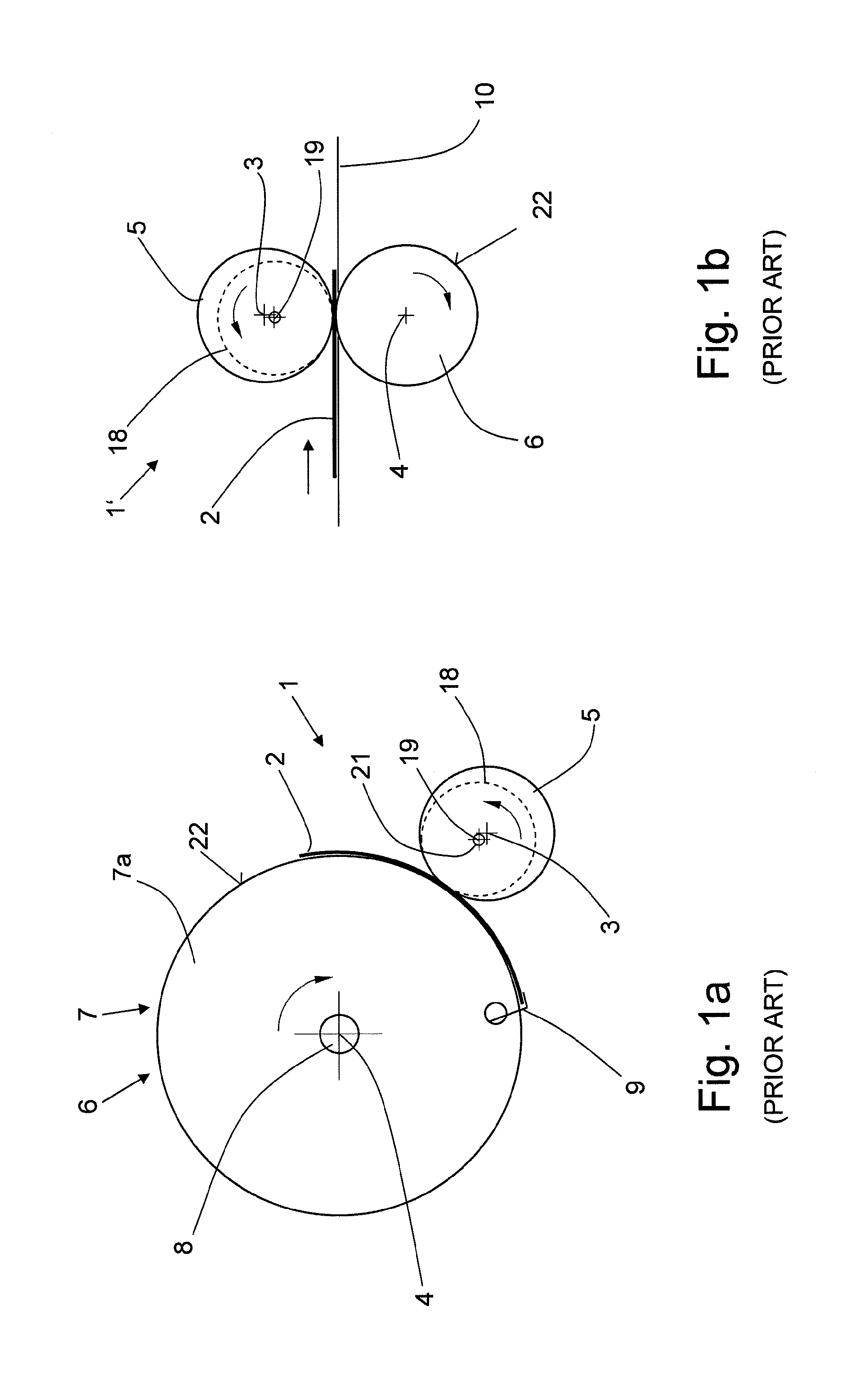

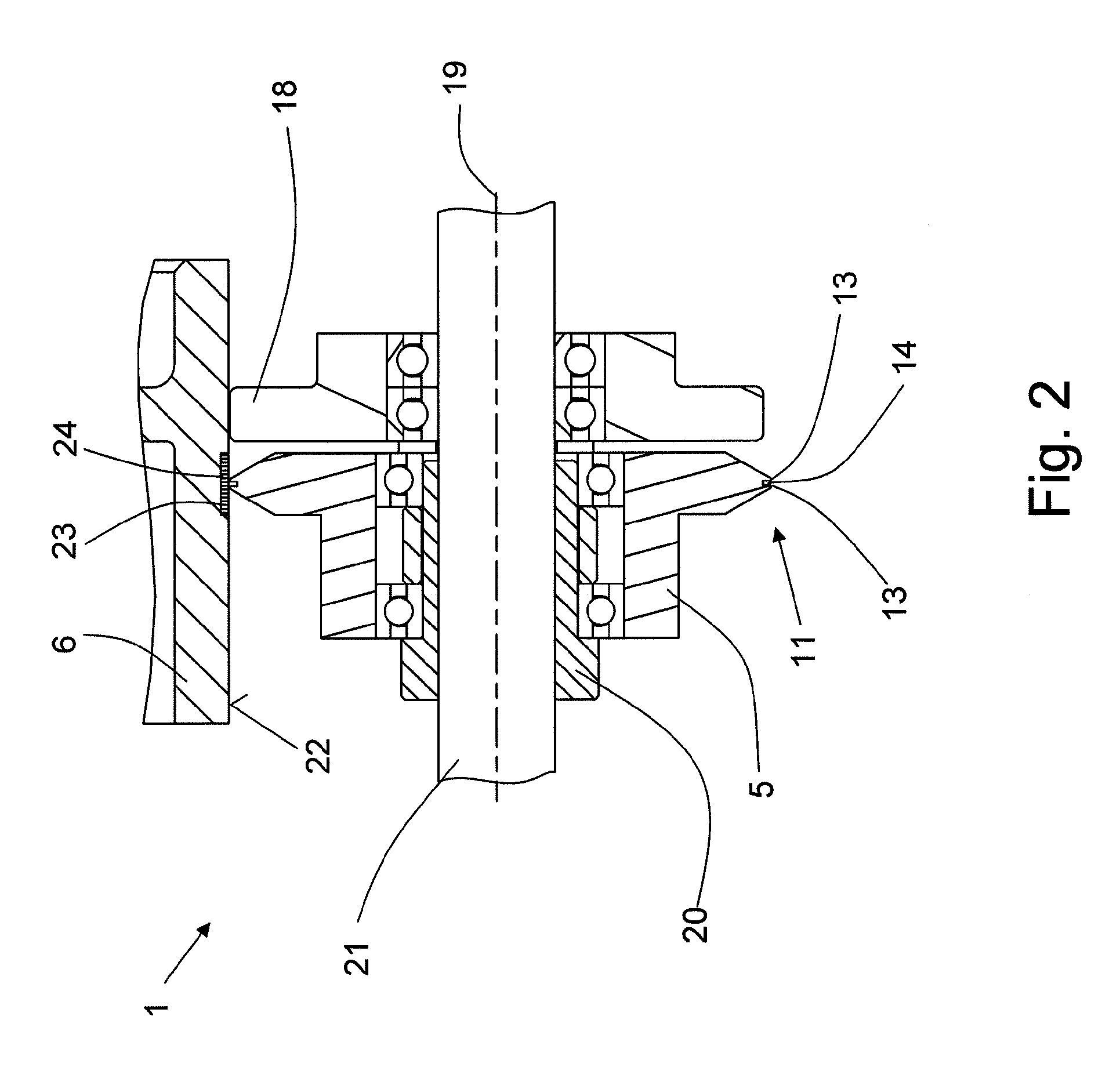

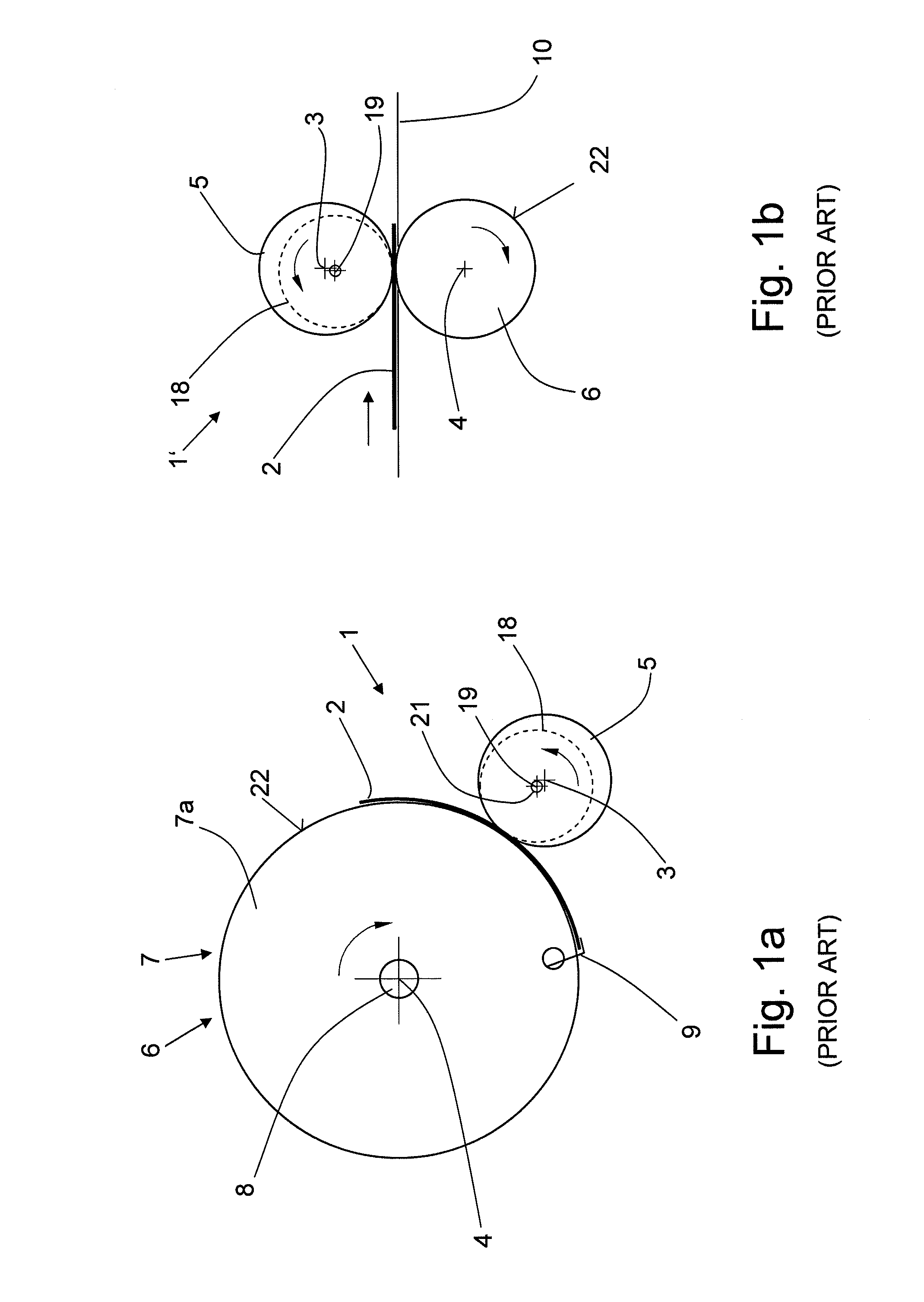

Device for forming a groove

InactiveUS20130291703A1Easy and careful scoringCareful compressing and displacementMechanical working/deformationBox making operationsMechanical engineeringIntermediate space

A device for forming a groove in a cover, the device including a circular score anvil having a first axis and being rotatable in a first direction and a circular scoring knife having a second axis positioned parallel to the first axis and arranged radially opposite the circular score anvil to define a gap between the score anvil and the scoring knife. The scoring knife is rotatable in a second direction opposite to the first direction and comprises a scoring element having an edge region that is tapered to form a ridge toward a periphery of the element. The edge region includes an intermediate space that divides the edge region into two spaced apart knife edges. A groove is formed in the cover while moving through the gap by operative cooperation of the scoring knife and score anvil.

Owner:MULLER MARTINI HLDG

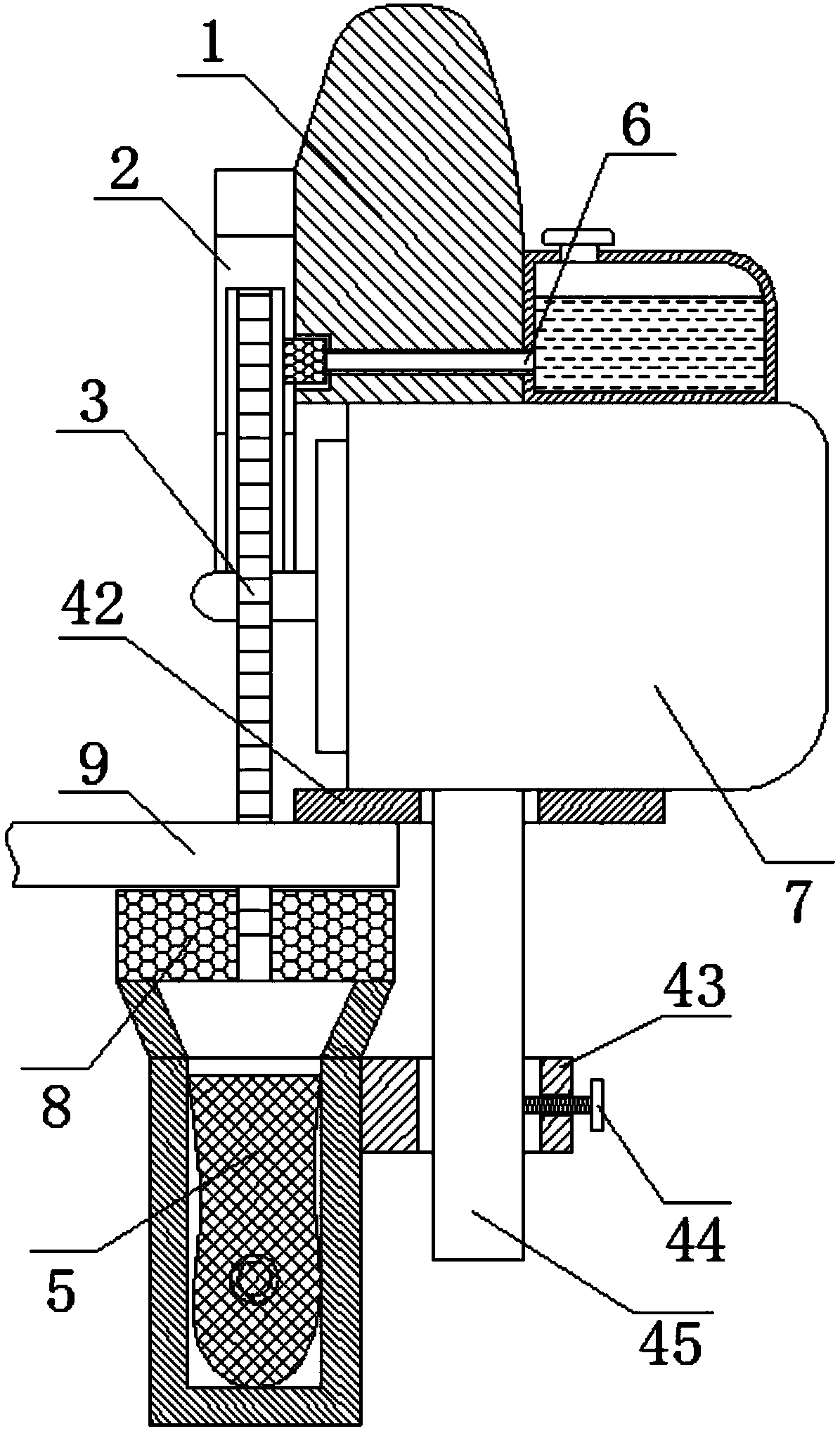

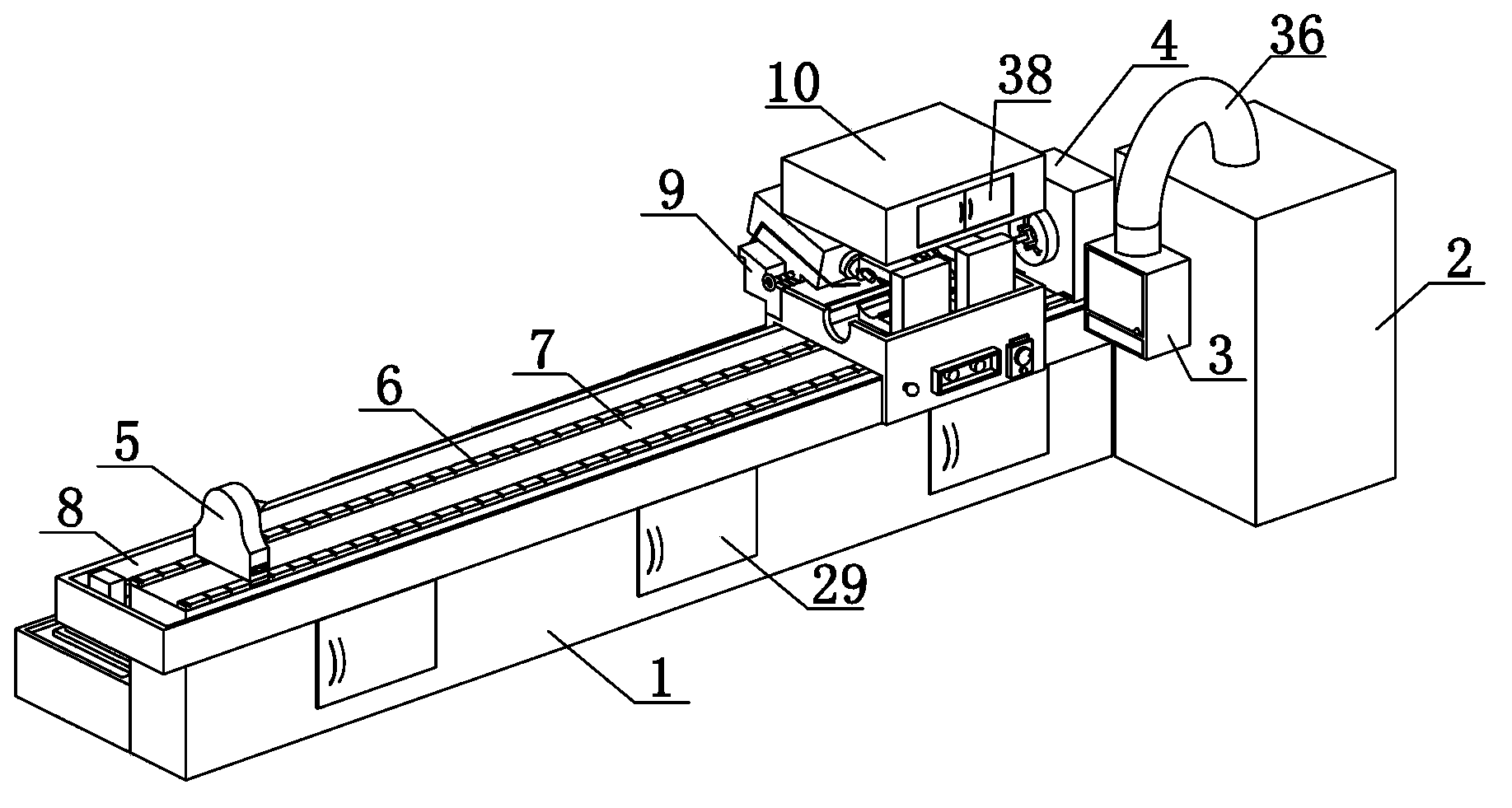

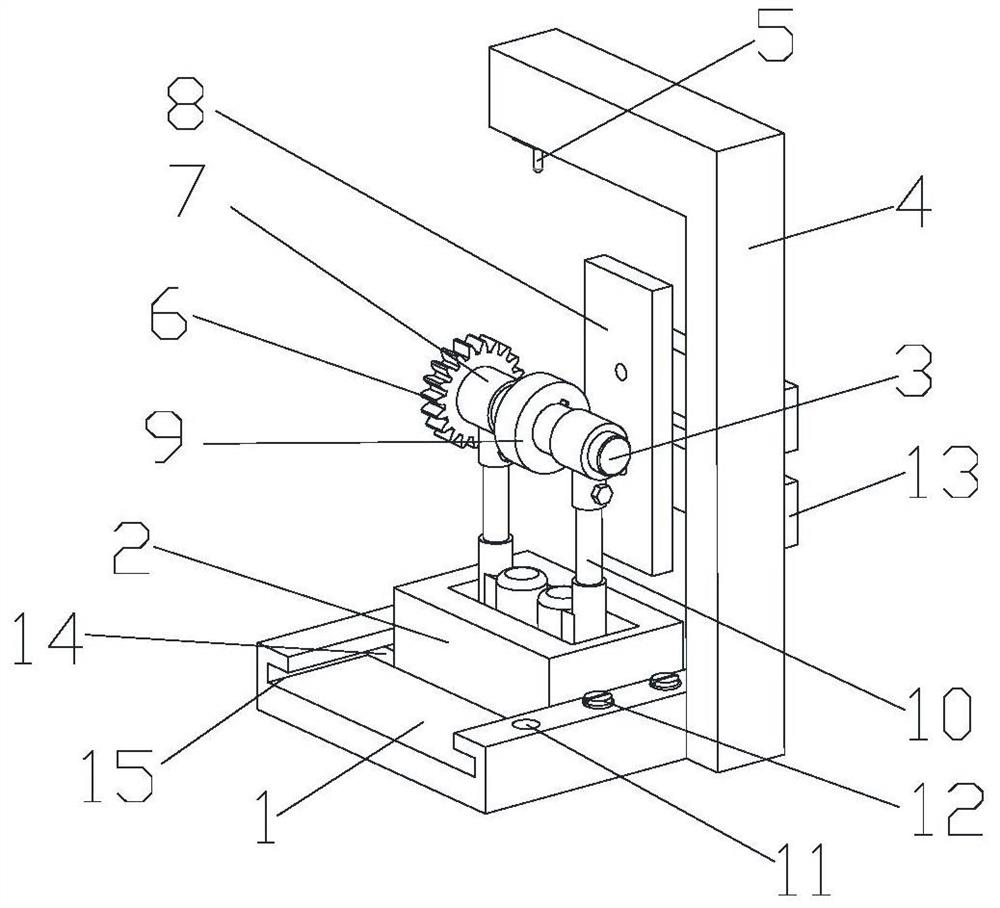

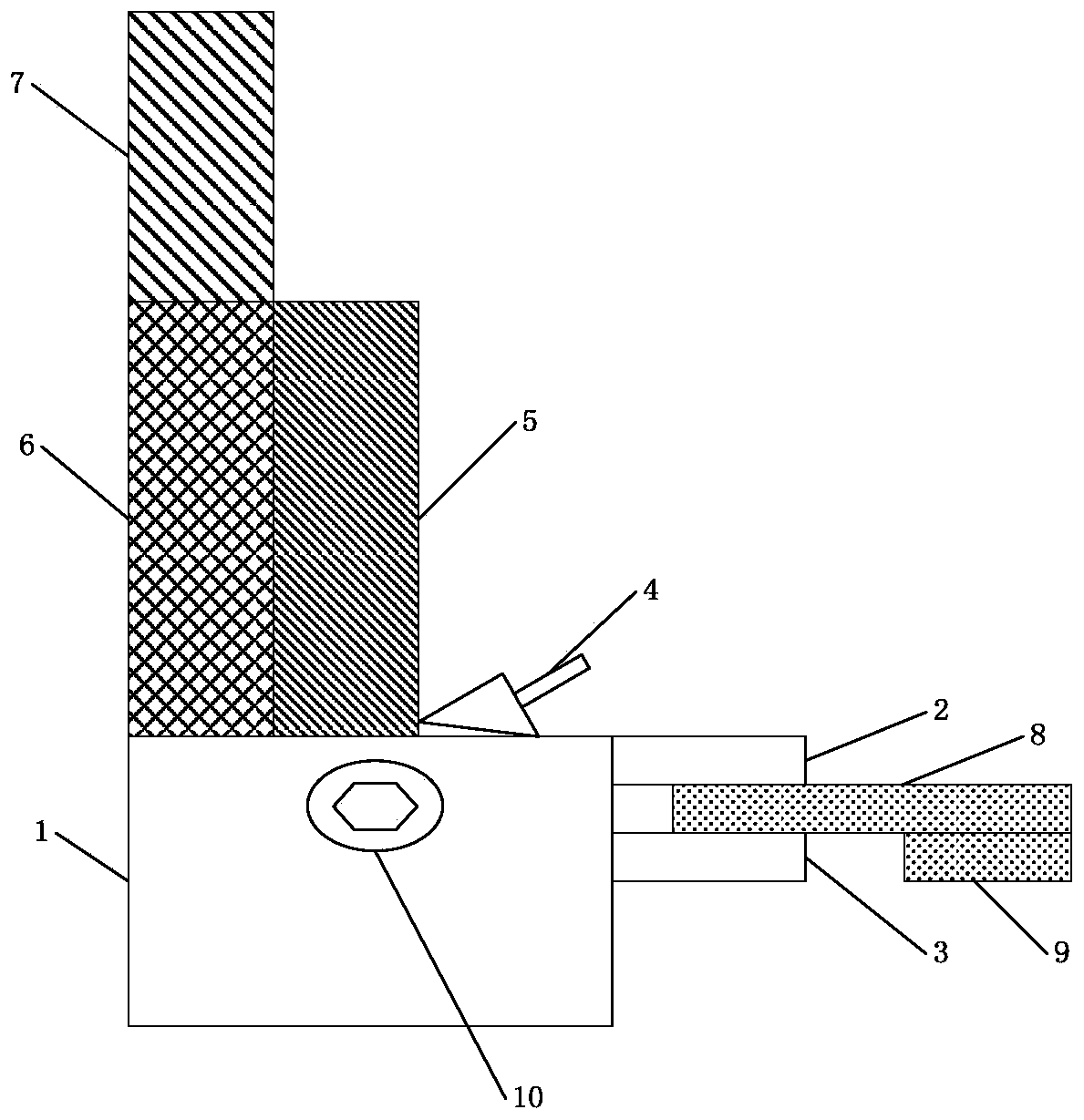

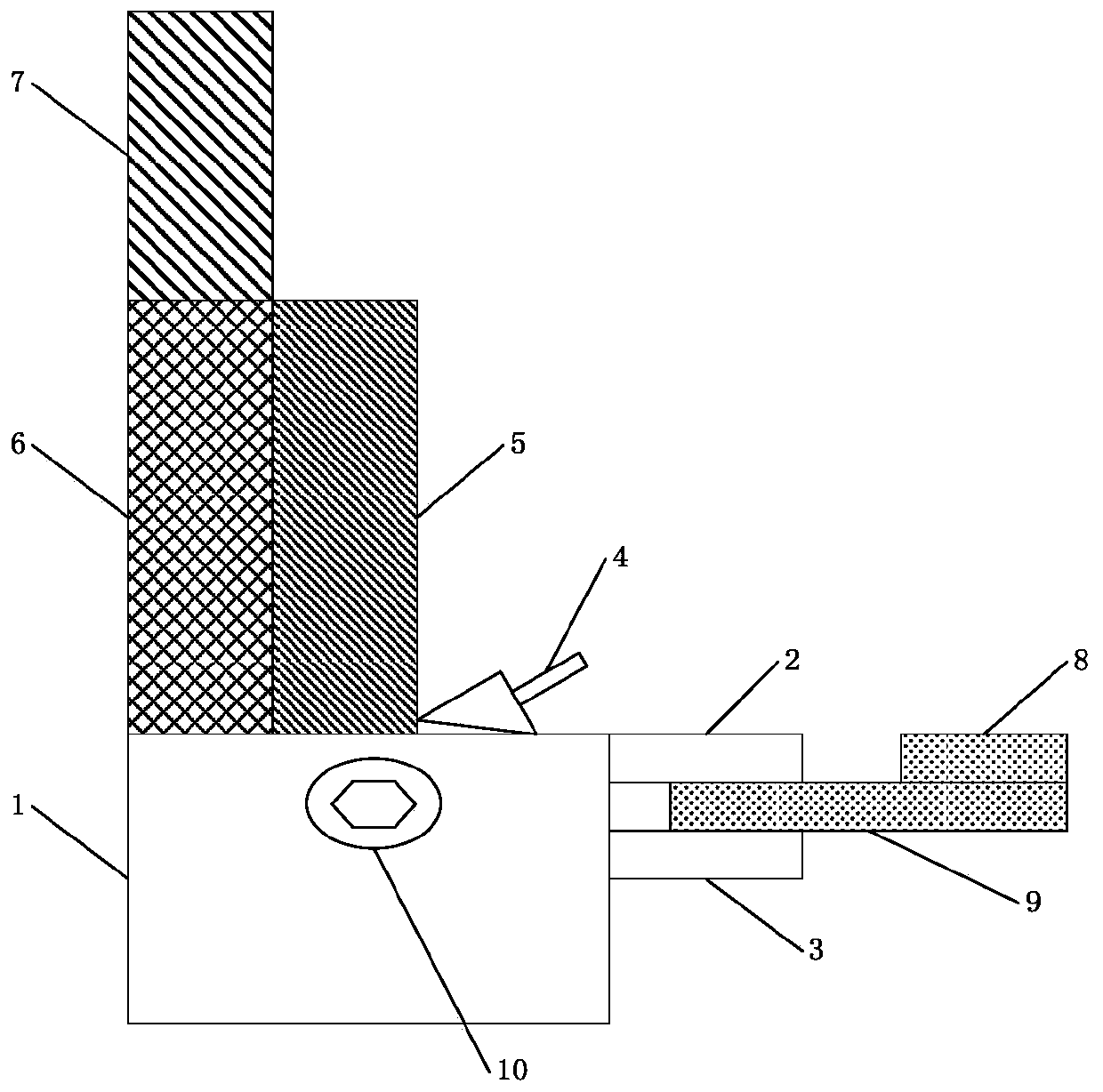

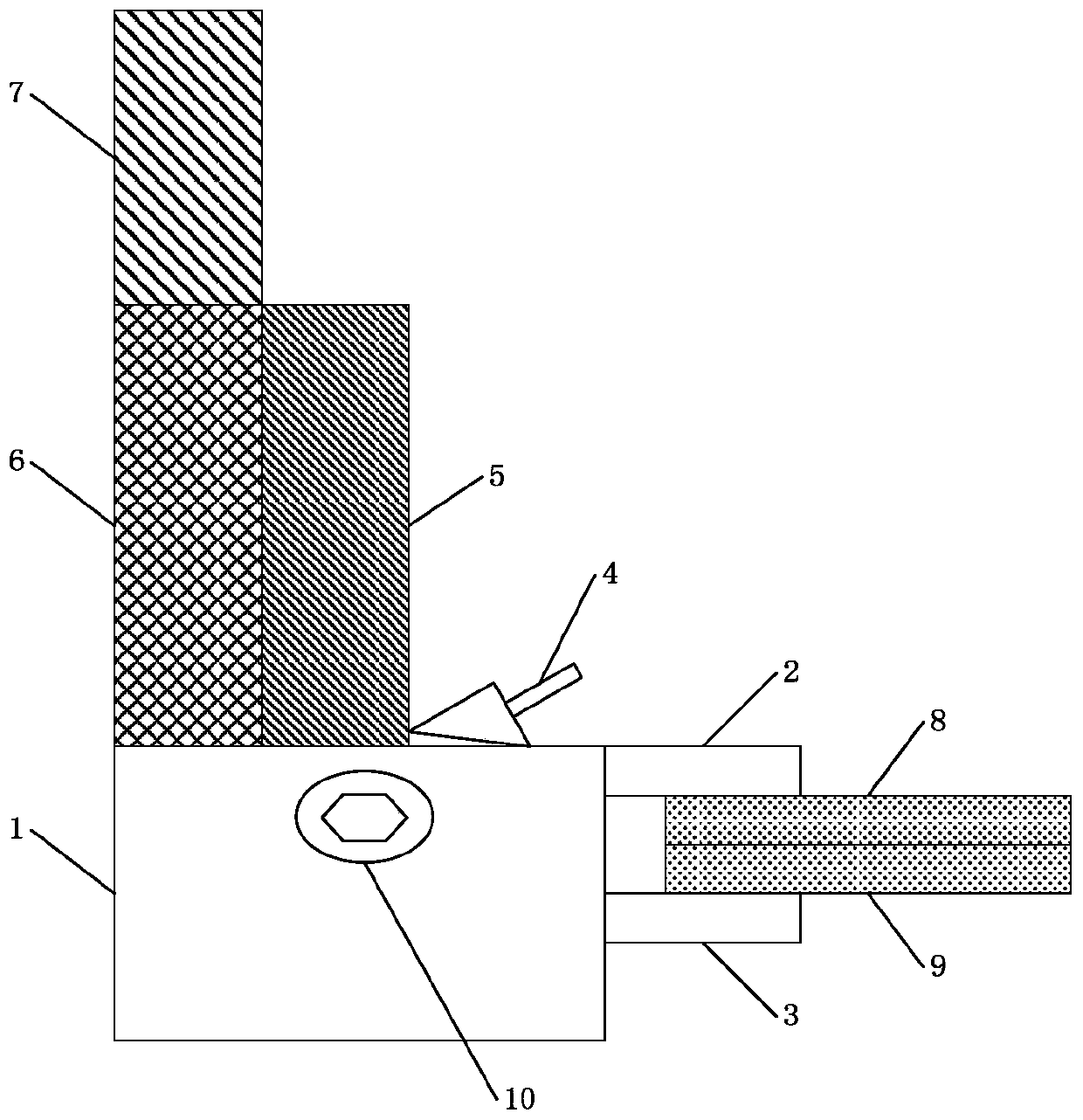

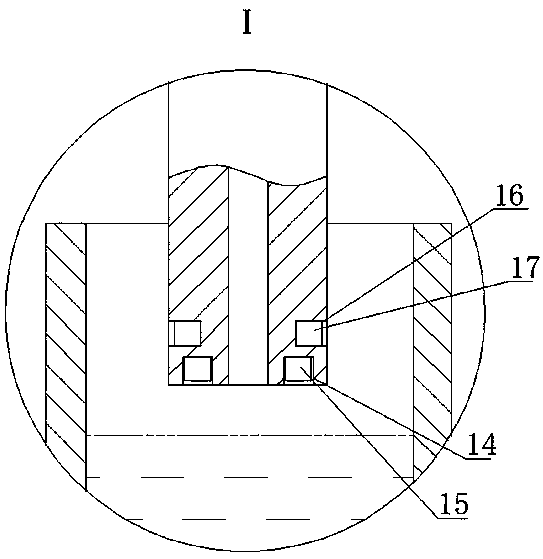

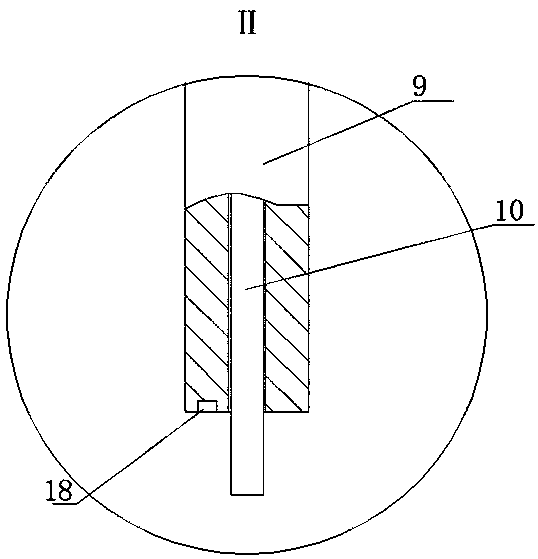

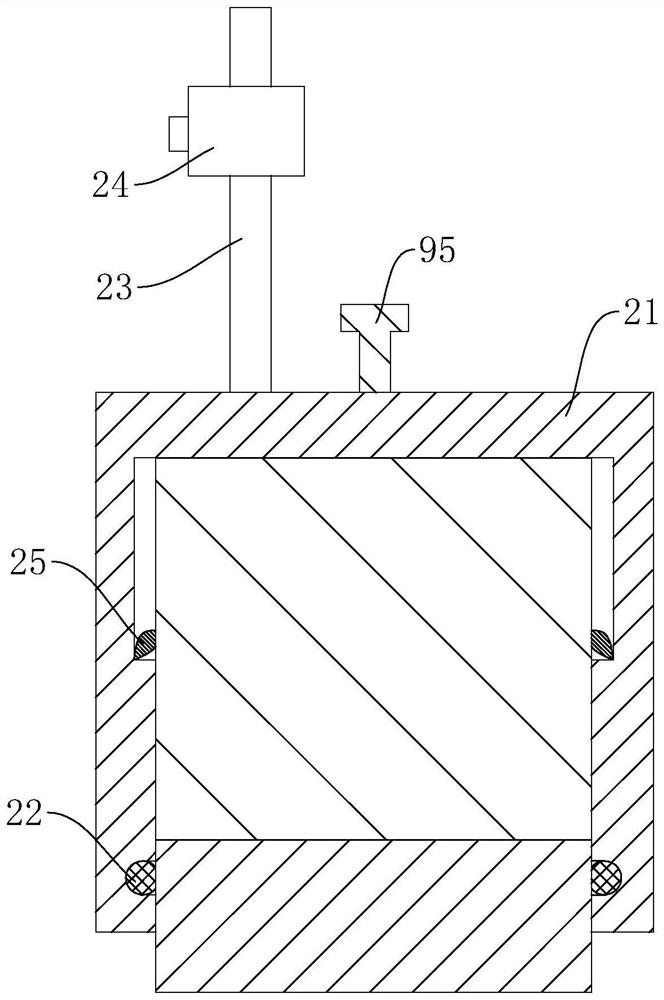

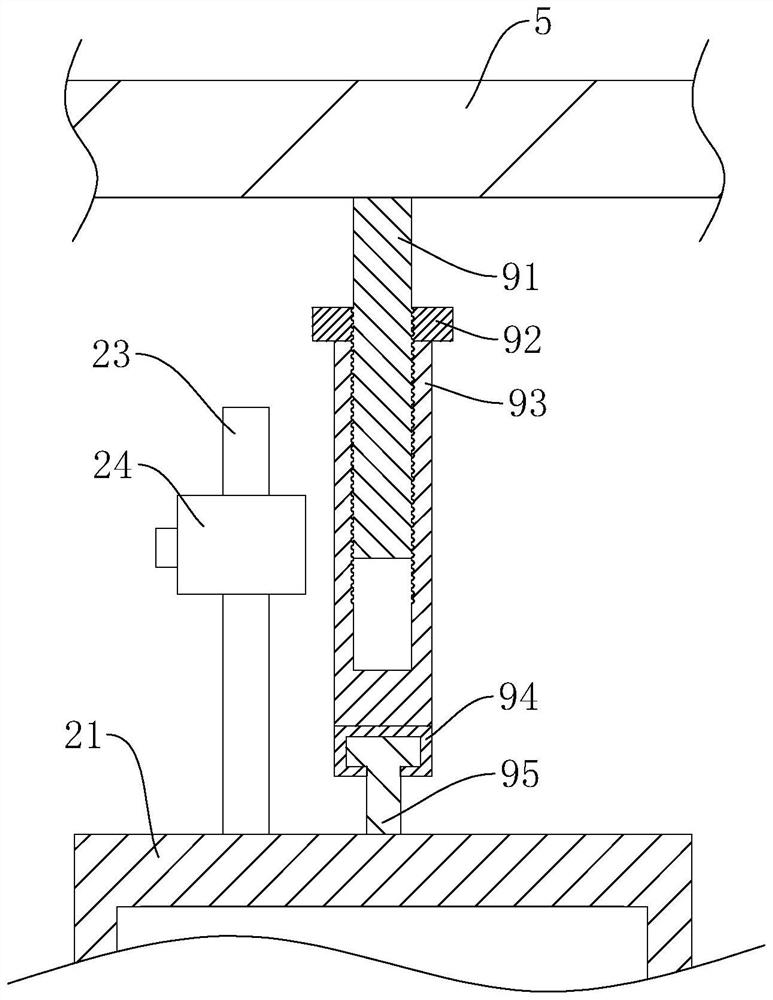

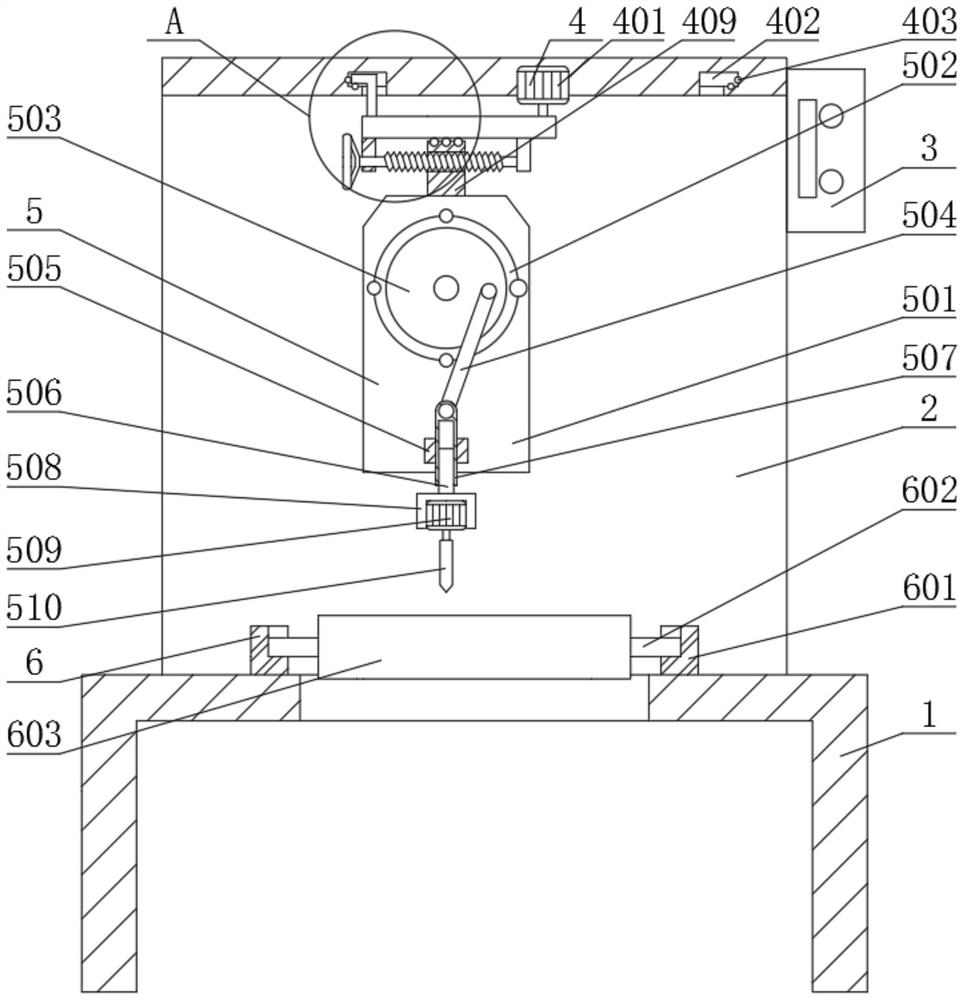

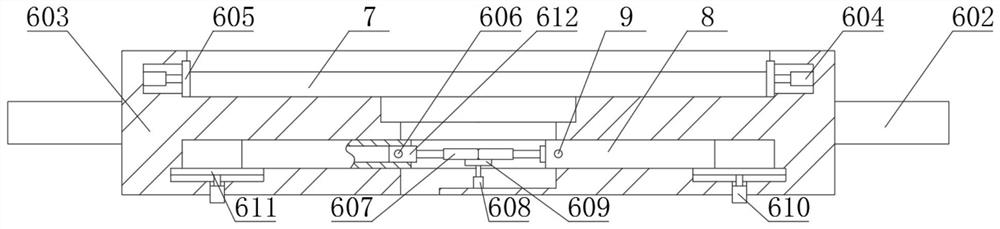

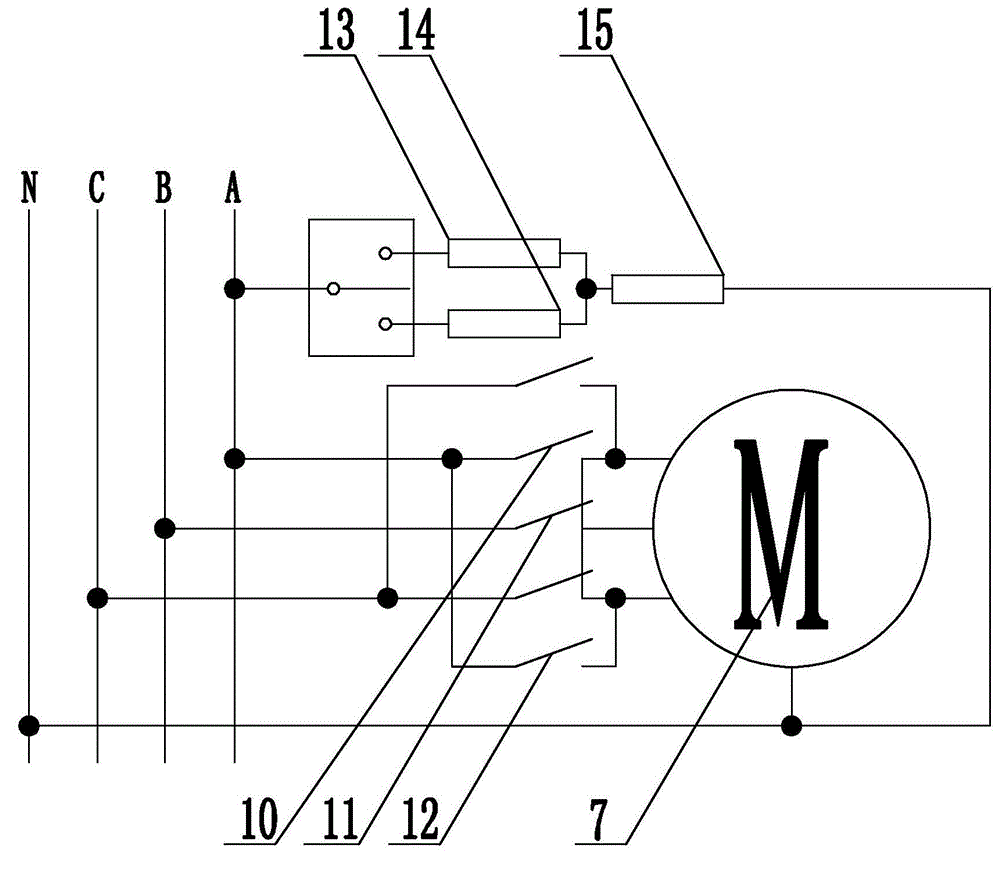

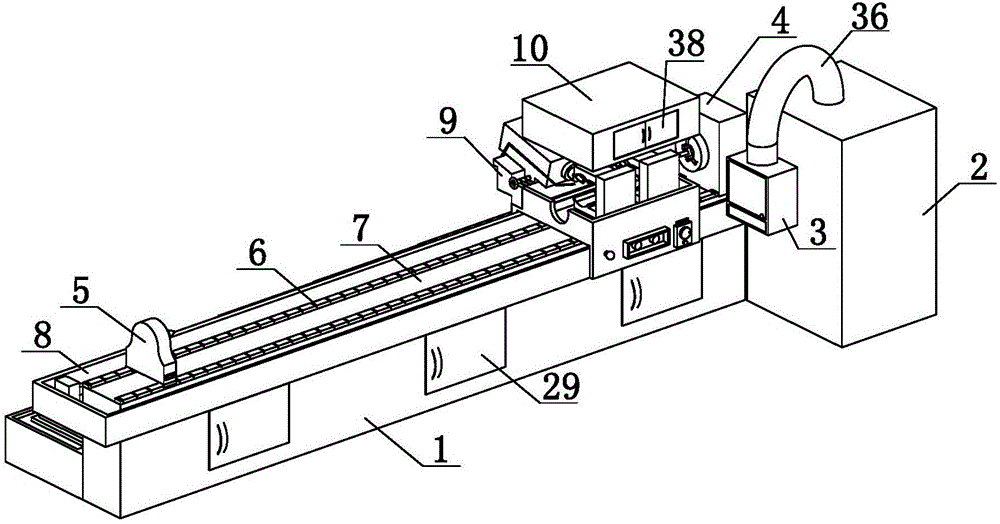

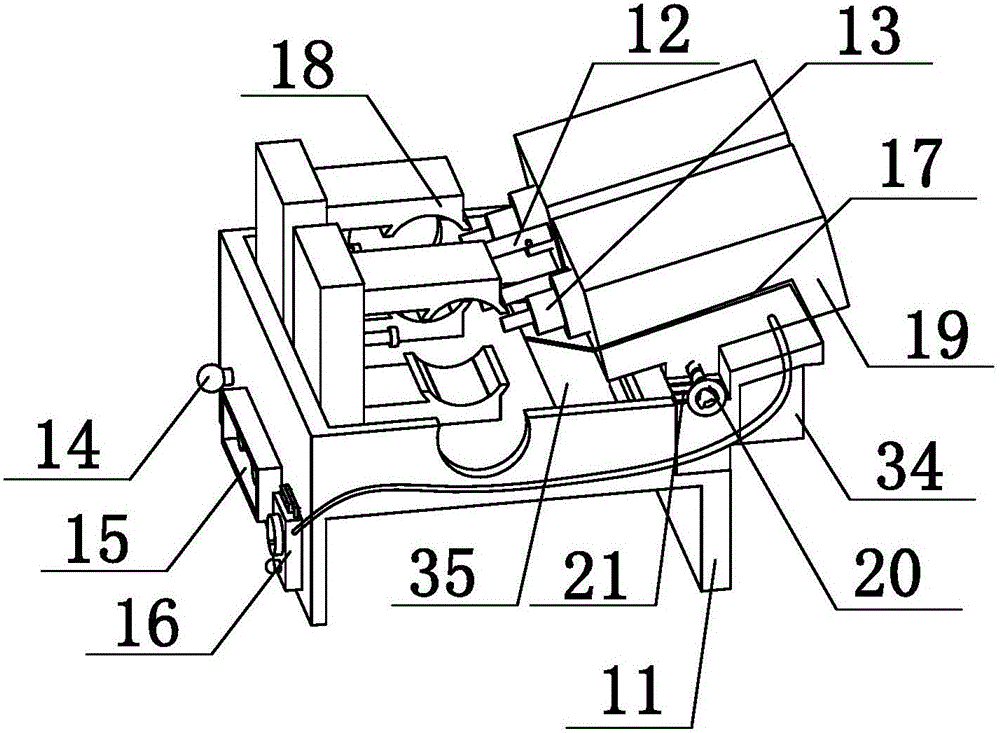

Numerical control machine tool for dual-blade blind hole fixed depth machining

InactiveCN103658731AGuaranteed depthImprove machining accuracyAutomatic control devicesDrilling/boring measurement devicesNumerical controlGun barrel

The invention discloses a numerical control machine tool for dual-blade blind hole fixed depth machining. The numerical control machine tool comprises a machine tool body (1), a machine tool electrical cabinet (2), a numerical control panel (3), a clamping table top (4), a tailstock (5) and a dual-blade fixed depth machining device (9). The machine tool electrical cabinet (2) is arranged on one side of the machine tool body (1), the machine tool electrical cabinet (2) and the numerical control panel (3) are connected through a rotating rod (36), and the clamping table top (4) is arranged at the upper end of the machine tool body (1). The machine tool body (1) is provided with a rail table top (7), the rail table top (7) is provided with a rail (6), the tailstock (5) and the dual-blade fixed depth machining device (9) are arranged on the rail (6), and the tailstock (5) is locked through a bolt. According to the numerical control machine tool for dual-blade blind hole fixed depth machining, the blind hole depth can be guaranteed in the bending process of a gun barrel, machining precision is improved, machining and transporting difficulty is reduced, the machining efficiency is approximately doubled at the same time, the demand for large consumption is met, and meanwhile the numerical control machine tool has the advantages of being simple in structure and low in cost.

Owner:WENZHOU UNIVERSITY

Device for forming a groove

InactiveUS20090293699A1Easy and careful scoringCareful compressing and displacementMechanical working/deformationBox making operationsEdge regionIntermediate space

A device for forming a groove in a cover, the device including a circular score anvil having a first axis and being rotatable in a first direction and a circular scoring knife having a second axis positioned parallel to the first axis and arranged radially opposite the circular score anvil to define a gap between the score anvil and the scoring knife. The scoring knife is rotatable in a second direction opposite to the first direction and comprises a scoring element having an edge region that is tapered to form a ridge toward a periphery of the element. The edge region includes an intermediate space that divides the edge region into two spaced apart knife edges. A groove is formed in the cover while moving through the gap by operative cooperation of the scoring knife and score anvil.

Owner:MULLER MARTINI HLDG

An ecohydrological monitoring device

ActiveCN108444456BGuaranteed accuracyConstant depthBatteries circuit arrangementsTransmission systemsSlider bearingElectric machine

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

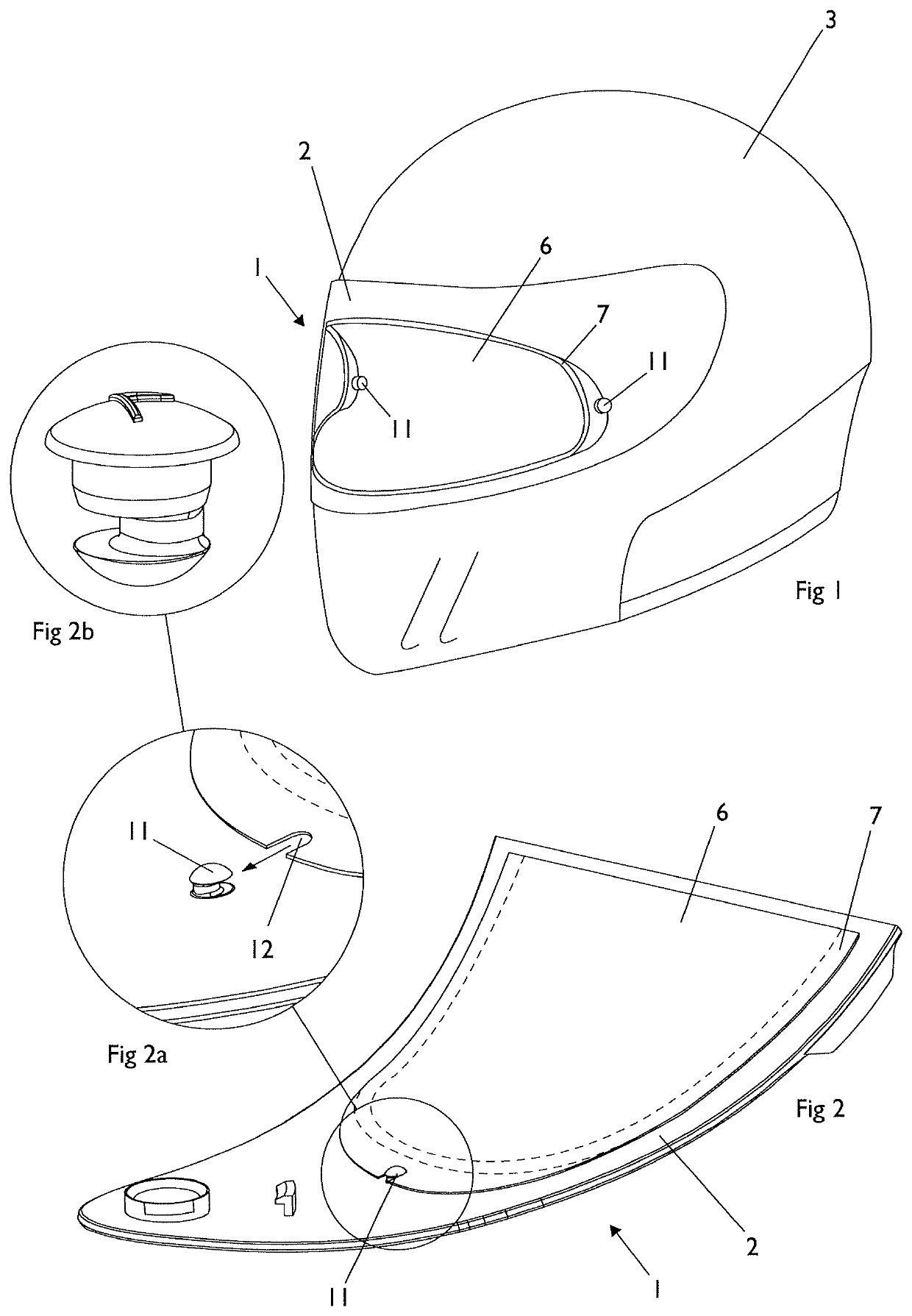

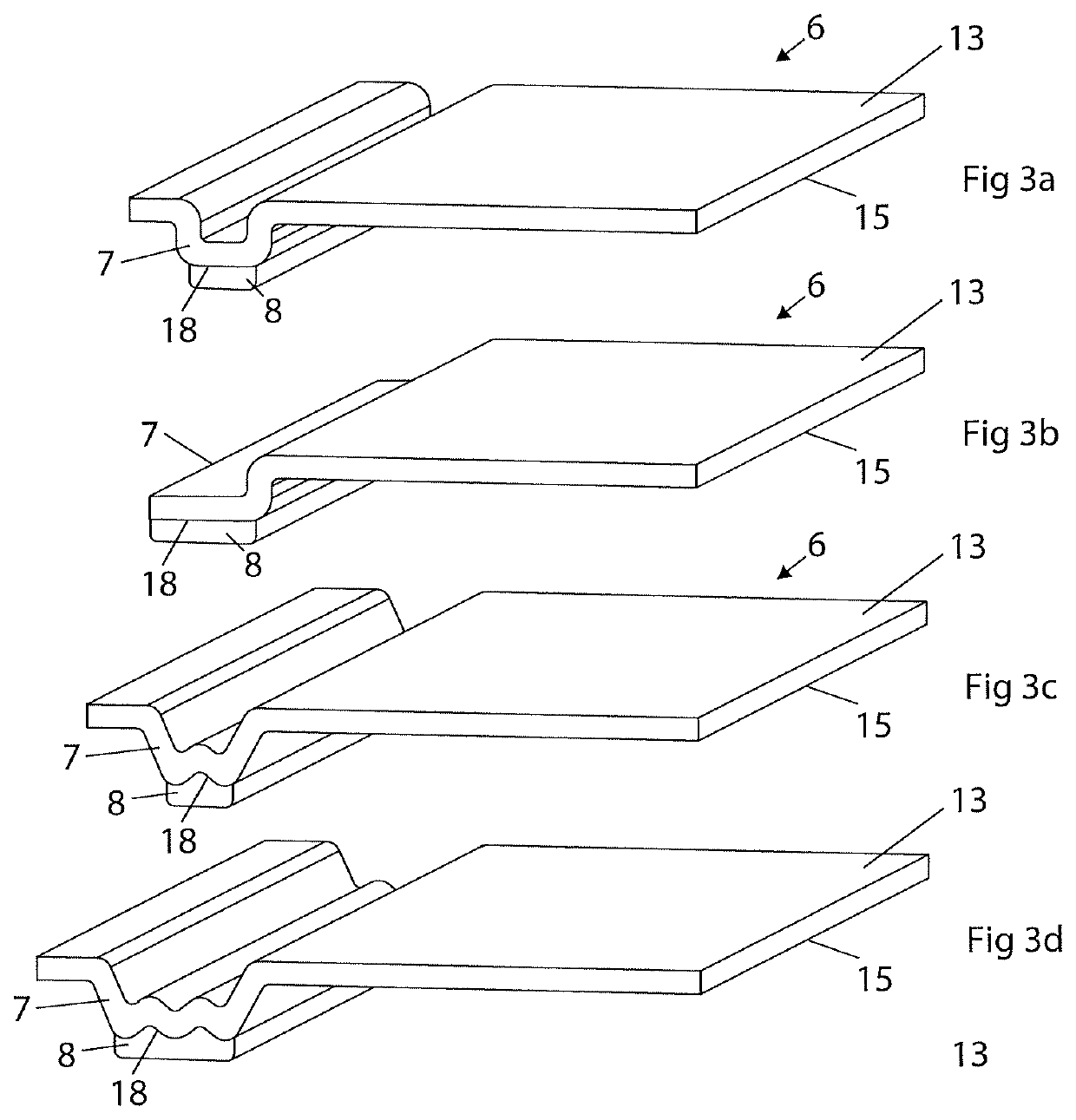

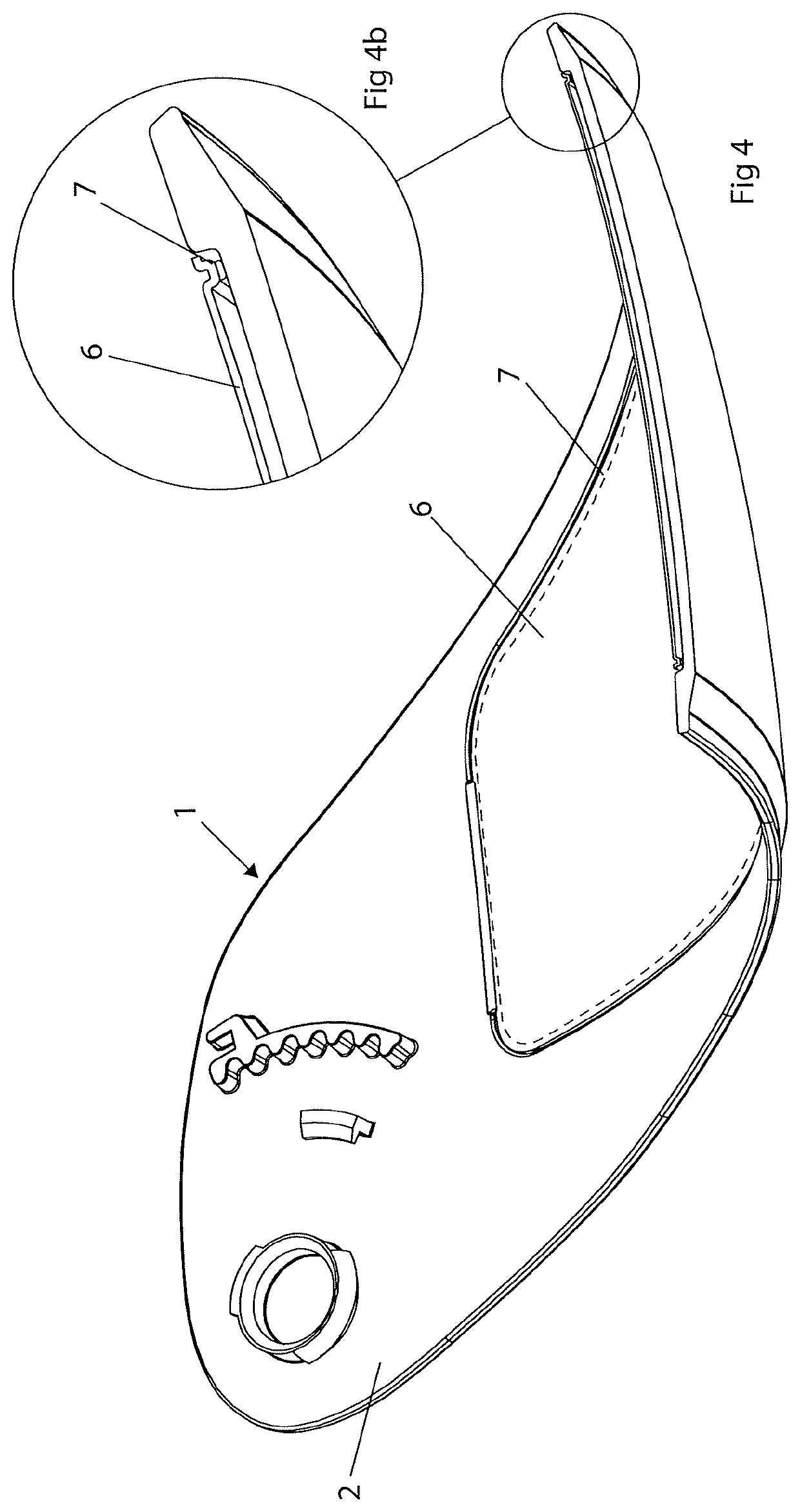

Visor assembly

PendingUS20200329803A1Constant depthImprove performanceHelmetsHelmet coversMotor cycling helmetVisor

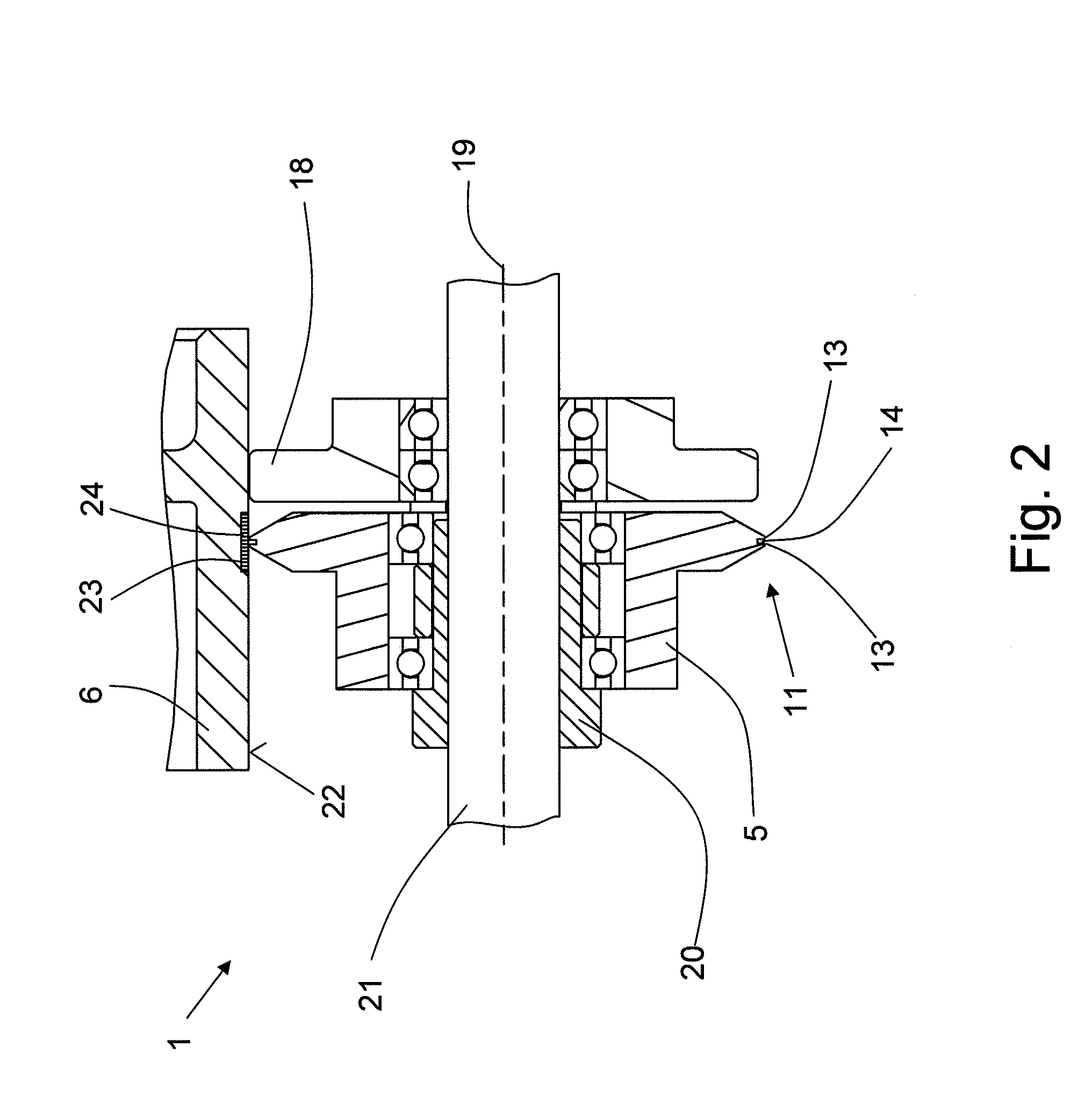

There is provided a visor assembly (1), preferably for the motorcycle helment, comprising a shield-visor (2) having a surface, an overlay-visor (6) adapted to be releasably attached to the shield-visor, the overlay-visor comprising a viewing area, an integrally formed spacer (7) extending along at least a portion of a periphery of the viewing area, and a gasket (8) upon a distal surface of the spacer; and a mechanical fastening (11) releasably attaching the overlay-visor to the surface of the shield-visor.

Owner:PINLOCK PATENT

Device for achieving laser processing on surface of involute cylindrical gear

ActiveCN111730211ATo achieve the requirement that the tangents are perpendicular to each otherConstant depthLaser beam welding apparatusLaser processingGear wheel

The invention discloses a device for achieving laser processing on the surface of an involute cylindrical gear. The device comprises a base, a sliding table arranged on the base in a sliding manner, amounting shaft rotationally arranged on the sliding table, a gear fixed to the mounting shaft, a laser marking device fixedly arranged on one side of the base and an electromagnetic chuck fixedly arranged on one side of the base. A lantern ring is fixed to the mounting shaft, and the outer diameter of the lantern ring is basically consistent with the basic circle diameter of the gear. A drive mechanism used for driving the lantern ring to roll on the electromagnetic chuck is further fixed to the sliding table. Light emitted by the laser marking device is located on the normal line of the involute of the gear. According to the device, the lantern ring is controlled by an electric push rod to roll on the electromagnetic chuck, according to the character that the normal line of the basic ring involute of the gear is tangential to the basic ring of the gear, the requirement that a laser beam is perpendicular to the tangent line of the outline of the involute cylindrical gear all the timeis achieved, shapes and depths of machined grooves can keep unchanged, and the precision of the gear face microstructure of the involute cylindrical gear of laser machining is improved.

Owner:JIANGSU UNIV OF TECH

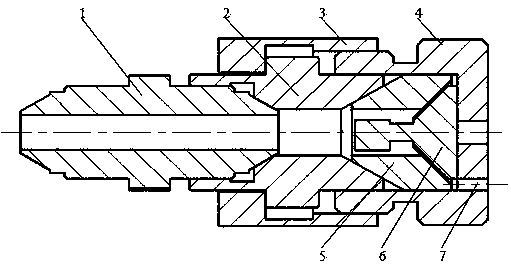

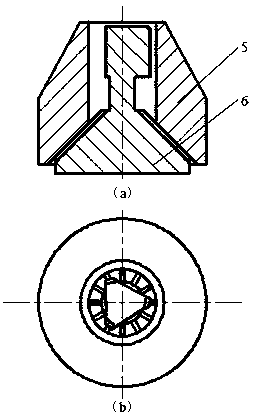

Conically sealed microjet homogenizing valve

The invention discloses a homogenizing device applying a conically sealed structure. The key parts of the device are a conical valve element (6) and a conical-hole-shaped valve pedestal (5). Micro-fine groove structures are engraved on a conical surface of the valve element, a plurality of radial micro-fine runners are formed when a valve body works. The conical end face of the valve element is fitted with a conical hole of the valve pedestal and is pressed by external force to form conical seal, and the conical seal is linear seal, so that the independence of a plurality of micropore runners and the micro-fine effect of homogenizing are guaranteed. The valve element and the valve pedestal are separated after a valve hole is blocked, so as to clear up the micro runners, and after grooves are worn out, the conical surface of the valve element is processed again and the grooves are engraved again.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

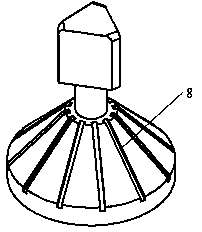

Floating type oval-shaped supersonic vibration micro-engraving device

InactiveCN100566898CMake up for the defect of not being able to rotateDepth remains constantMechanical vibrations separationLarge fixed membersUltrasonic sensorInsertion stent

The invention discloses a floating elliptical ultrasonic vibration micro-engraving device, which comprises a mounting table (11), a support unit, a drive unit (2), a sliding unit (3), a floating transducing component (4), a longitudinal bending transducing device (1); support base (12), A support (13), B support (14) constitute a support unit; the lower mounting surface of the mounting table (11) is connected with support base (12), A support (13) respectively, The upper mounting surface (11a) of the mounting table (11) is connected with the numerical control workbench. Driven by the ultrasonic transducer, the cutting tool of the engraving device of the present invention can generate elliptical ultrasonic vibrations to realize micro-engraving. The micro-engraving device of the present invention uses the floating transducer assembly to ensure that the depth of the processed groove remains constant; and then uses the longitudinal bending transducer to make the tool generate ultrasonic elliptical vibration, and cutting with the help of ultrasonic elliptical vibration can reduce cutting force, improve processing accuracy and reduce The characteristics of surface roughness to ensure that the groove on the surface of the machined part has high geometric accuracy and surface quality and the edge is free of burrs; the combined design of the longitudinal bending transducer and the drive unit makes up for the inability of the tool in traditional planing The defect of rotation realizes freely adjustable engraving in multiple cutting directions.

Owner:BEIHANG UNIV

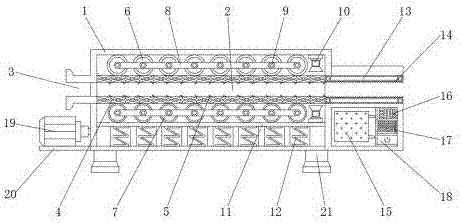

Conveying mechanism

InactiveCN110329783AConstant depthAvoid wastingCharge manipulationConveyor partsEngineeringSurface plate

The invention relates to a conveying mechanism, wherein an upper gasket is arranged on the surface, facing a lower clamping plate, of an upper clamping plate, and the upper gasket comprises a first upper gasket and a second upper gasket. Therefore, the conveying mechanism can be adapted to different modes of clamping a single panel and clamping double panels, so that the manual adjustment of the distance between the upper clamping plate and the lower clamping plate is avoided, the problems that the productivity is wasted, the management is not easy, the process is complicated, and the yield islost are avoided, and finally the effects of saving the production cost and improving the production efficiency are achieved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Intelligent identification liquid supply device

InactiveCN110806763AConstant depthWon't overflowLevel controlEnvironmental engineeringWater security

The invention discloses an intelligent identification liquid supply device which includes a base. A vertical plate is fixedly mounted in the middle of the top of the base, the right end of a horizontal plate is fixedly connected to the vertical plate, a first through hole is formed in the top surface of the horizontal plate, and a first vertical pipe can slide up and down along the first through hole. A first vertical electric telescopic rod is fixedly installed at the bottom of the horizontal plate, a control button group, a first distance sensor, a second distance sensor, a third distance sensor, a first electric telescopic rod and a second electric telescopic rod are all connected to a controller, the control button group includes a manual liquid outlet button and a manual stop button,and a water suction pipe has a certain deformation ability. According to the design, water cups of different sizes can be automatically added with water to ensure that the water does not overflow whenbeing added, the occurrence of water splashes during adding water is reduced, water can be prevented from splashing to the outside due to falling from a high place when the water cups are added withwater, water spreading and leaking are reduced, the waste of water resources is reduced, the risk of scalding users from boiled water splashing and overflowing when hot water is held is reduced, and the safety of adding water to the water cups is improved.

Owner:王炜程

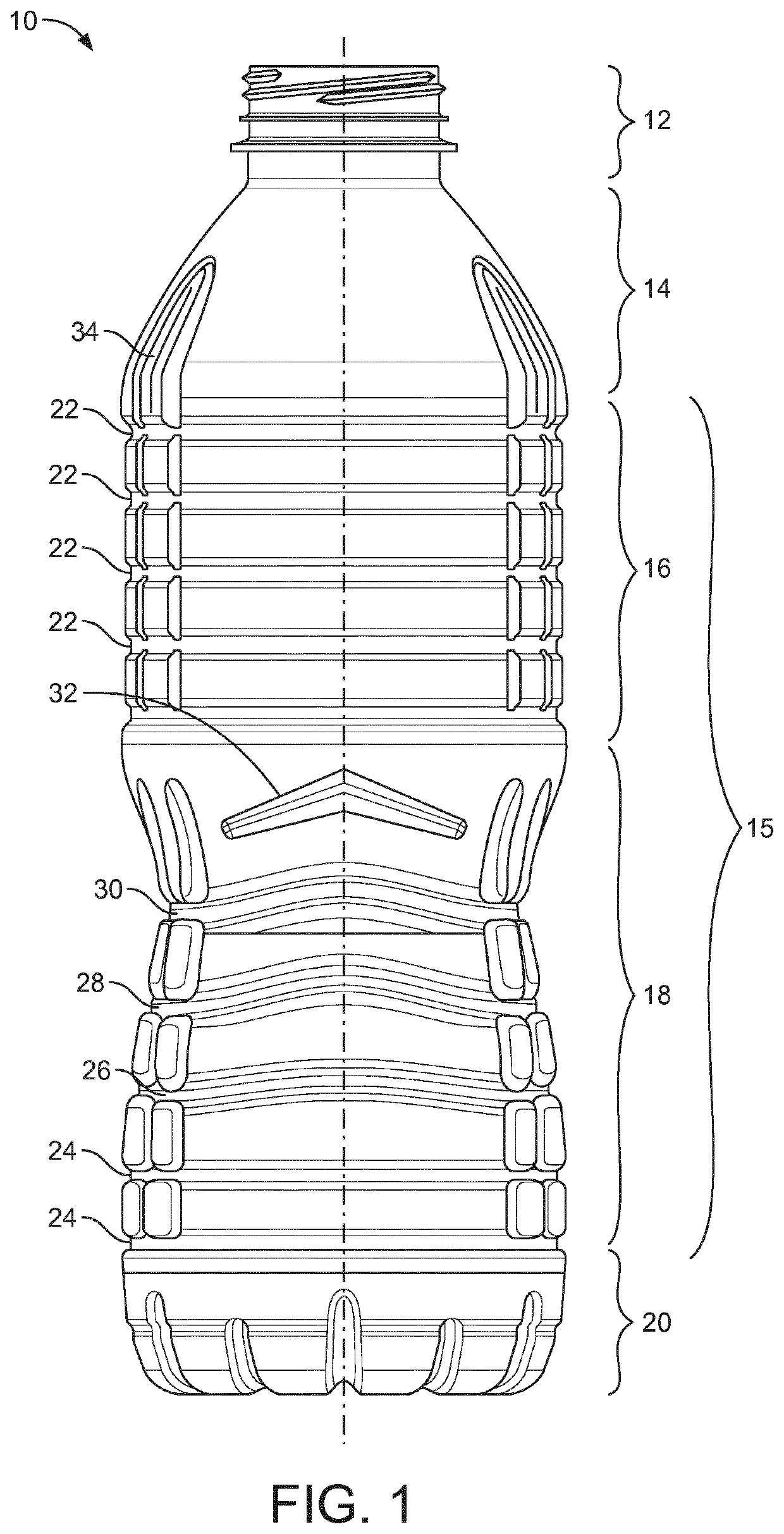

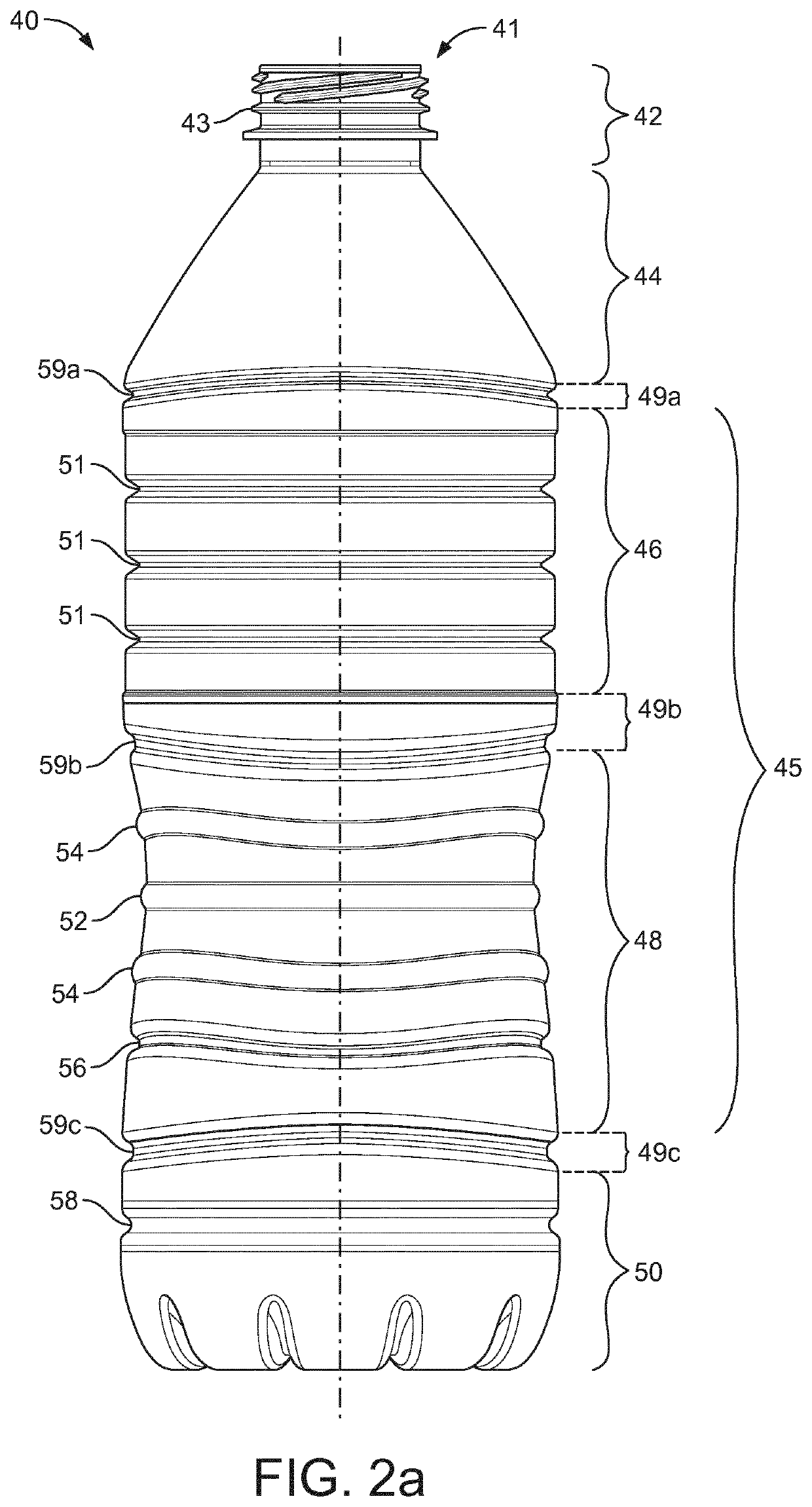

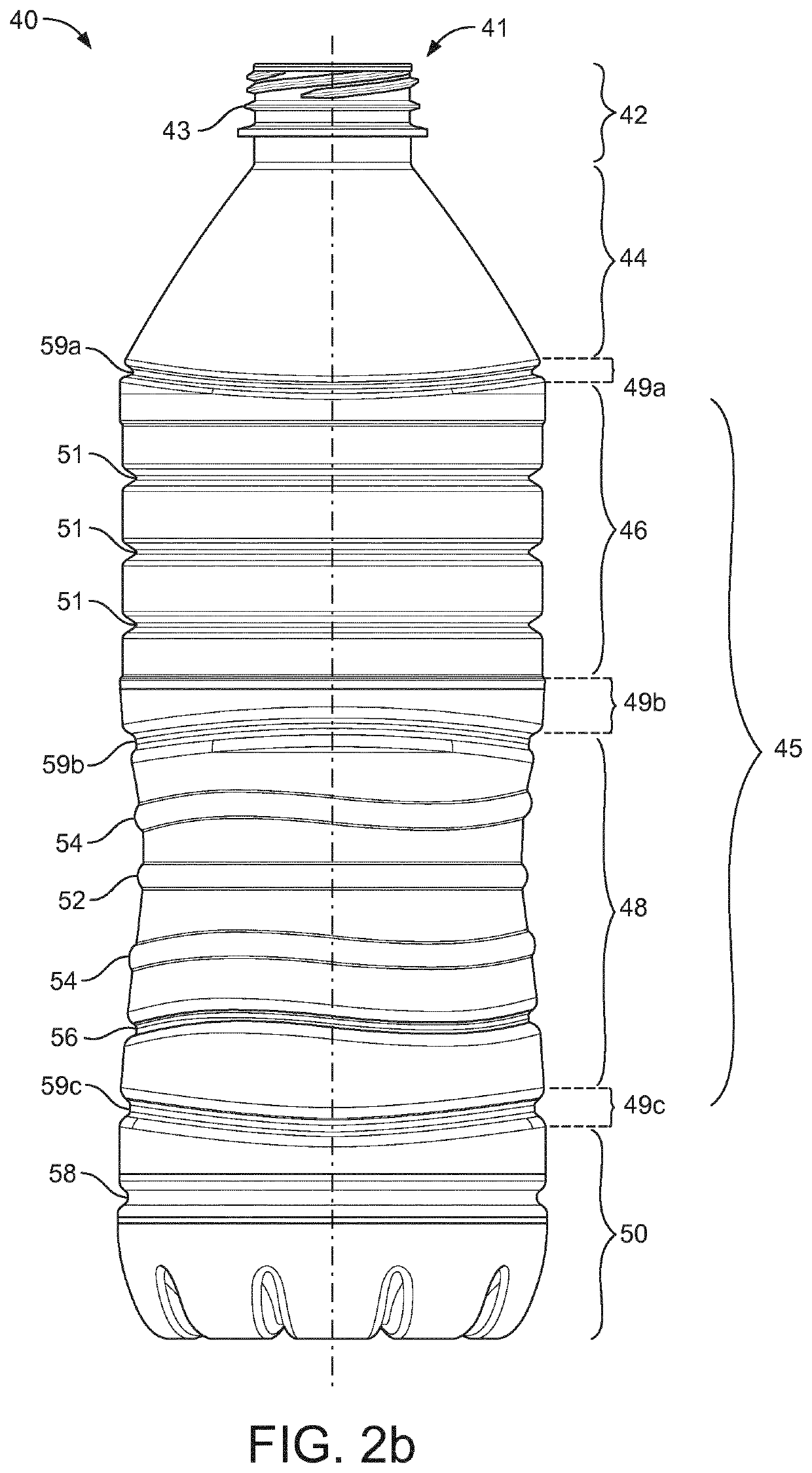

Bottle with grip portion

PendingUS20210214114A1Improve the immunityImproved deformation repartitionBottlesContainer handlesAnatomyBottle

The invention concerns a container (40), preferably a bottle, presenting a longitudinal axis comprising—a neck portion (42),—a shoulder portion (44) connected to the neck portion (42),—a bod portion (45) comprising a label portion (46) and a grip portion (48) and connected to the shoulder portion (44) via a first connecting portion (49a), the label portion (46) and the grip portion (48) being connected together via a second connection portion (49b), and—a base portion (50) forming the bottom of the container (40) connected to the bod portion via a third connecting portion (49c), wherein the grip portion (48) comprises at least one undulating bead (54).

Owner:SOC DES PROD NESTLE SA

Bed batten trimming tool

InactiveCN107972133ASmooth outer surfaceImprove trimming qualityMulti-purpose machinesProgrammable logic controllerEngineering

The invention discloses a bed batten trimming tool. The bed batten trimming tool comprises a synchronous cutter toothed belt, a levelling roller, a level detector, a pressure reducing plate, finishingcutter teeth and a programmable logic controller (PLC), wherein the levelling roller is arranged above the synchronous cutter toothed belt, the pressure reducing plate is arranged below the level detector, and the PLC is arranged below the finishing cutter teeth. The bed batten trimming tool has the advantages of scientific and reasonable structure and safety and convenience in use; the synchronous cutter toothed belt is arranged, so that the speed and the cutting depth can be kept constant when a bed batten is trimmed and cut; the levelling roller is arranged, so that the outer surface of the bed batten is flat during trimming; the level detector is arranged and is used for detecting the flatness of the bed batten after trimming, so that the trimming quality is increased; the pressure reducing plate is arranged, so that the pressure at the bottom of a tool body is reduced during trimming; the finishing cutter teeth are arranged, so that the trimming quality of the bed batten is further increased; and the PLC is arranged, so that the tool body does not need to be looked by specially-assigned persons during operation, and the cost is reduced.

Owner:青岛宝泓家具有限公司

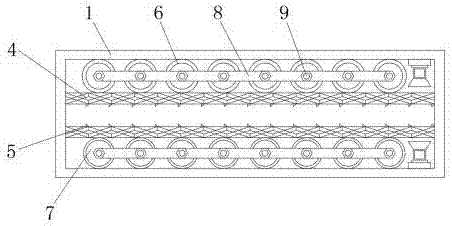

Cobalt removal device for polycrystalline diamond compact and cobalt removal method applying cobalt removal device

The invention relates to the field of diamond compact processing, and particularly discloses a polycrystalline diamond compact cobalt removal device and a cobalt removal method applying the device.The device comprises a solution tank and a cobalt removal mold, heating equipment and oscillation equipment are arranged in the solution tank, a clamping base is erected on the solution tank, and the cobalt removal mold is arranged on the clamping base. The cobalt removal mold is installed on the clamping seat, a polycrystalline layer of a polycrystalline diamond compact in the cobalt removal mold is immersed in cobalt removal liquid in the solution tank, and a wave suppression plate flush with the liquid level in the solution tank is arranged in the solution tank. The wave suppression plate is made of a corrosion-resistant material, and a through hole for a polycrystalline layer of the polycrystalline diamond compact to penetrate through is formed in the wave suppression plate in a penetrating manner. The method has the effects of being short in cobalt removal time, high in cobalt removal efficiency and accurate and controllable in cobalt removal depth.

Owner:武汉锐特金刚石有限公司

A kind of drilling device for antenna vibrator processing

ActiveCN112139543BEasy to drillEasy to operateAutomatic control devicesFeeding apparatusEngineeringAntenna element

The invention relates to the technical field of antenna vibrator processing, in particular to a drilling device for antenna vibrator processing, including a base and a fixing frame, the top of the base is fixedly connected with a fixing frame, and the right end of the fixing frame is fixedly connected with a controller. The inner side of the top end of the fixed frame is fixedly connected with a position adjustment device, the bottom end of the position adjustment device is fixedly connected with a drilling device, and the top end of the base is fixedly connected with a clamping device. , clamping rod, and connecting block, the clamping and fixing of the circular antenna vibrator can be realized through the first clamping plate, so as to ensure that the circular antenna vibrator will not shake when drilling, and ensure that there will be no vibration during the drilling process. In case of skewing, the loop antenna vibrator can be clamped and fixed by the second clamping plate, and at the same time, the ring antenna vibrator can be supported by the support column to prevent the inner wall of the loop antenna vibrator from being sunken during the drilling process.

Owner:SHENZHEN FRD SCI & TECH

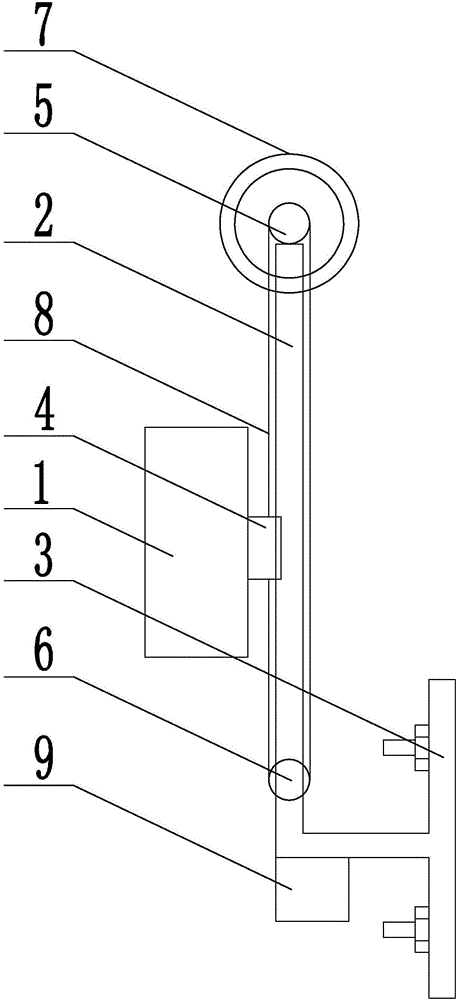

Submerged pump capable of achieving automatic adjusting according to water level

InactiveCN104154018AConstant depthConstant water pressurePump componentsPump controlCouplingWater level

The invention provides a submerged pump capable of achieving automatic adjusting according to water level and belongs to the field of automatic-adjusting submerged pumps. The submerged pump comprises a submerged pump body. The submerged pump is provided with a rail which is fixed on the lateral wall of a pond through a support. The submerged pump body is mounted on the rail through a slider. A drive gear and a driven gear are respectively disposed at the top end and the lower end of the rail. The rotary shaft of the drive gear is connected to the rotor of a reduction motor through a coupler. A chain winds around the drive gear and the driven gear to be fixed at two ends of the slider. The reduction motor is connected to a power supply through a control device. The submerged pump has the advantages that that the positions of the submerged pump can be automatically adjusted according to the water level, demounting is not needed, and the submerged pump is long in service life and labor saving.

Owner:SHANDONG HUALIAN MINING

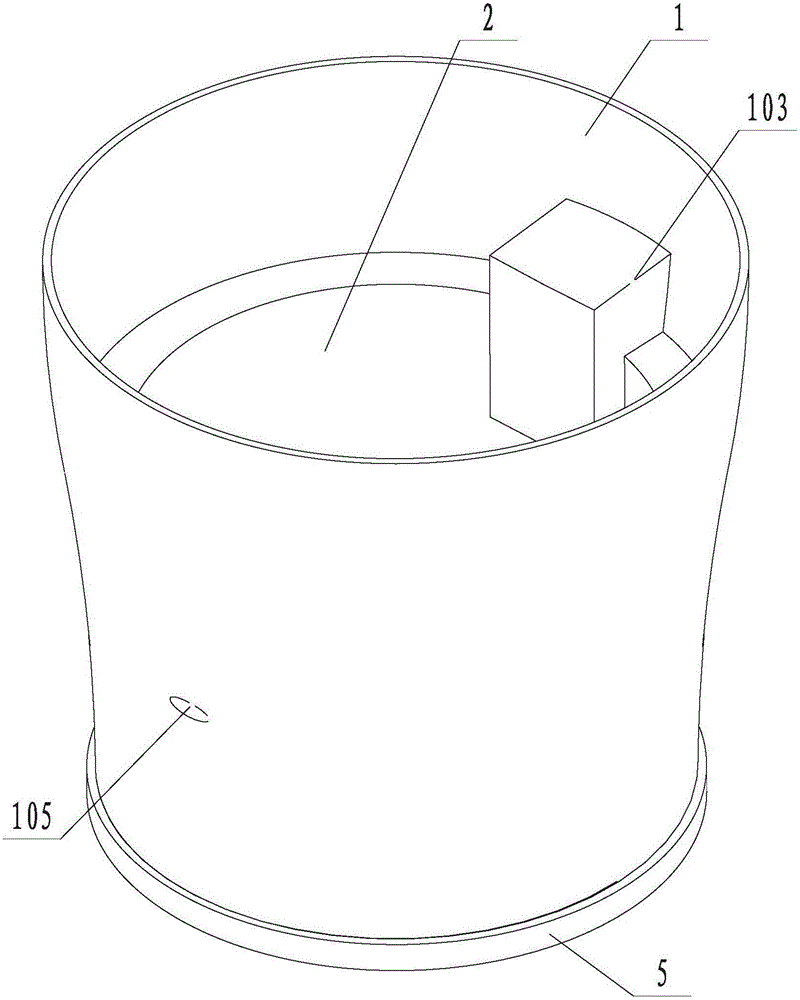

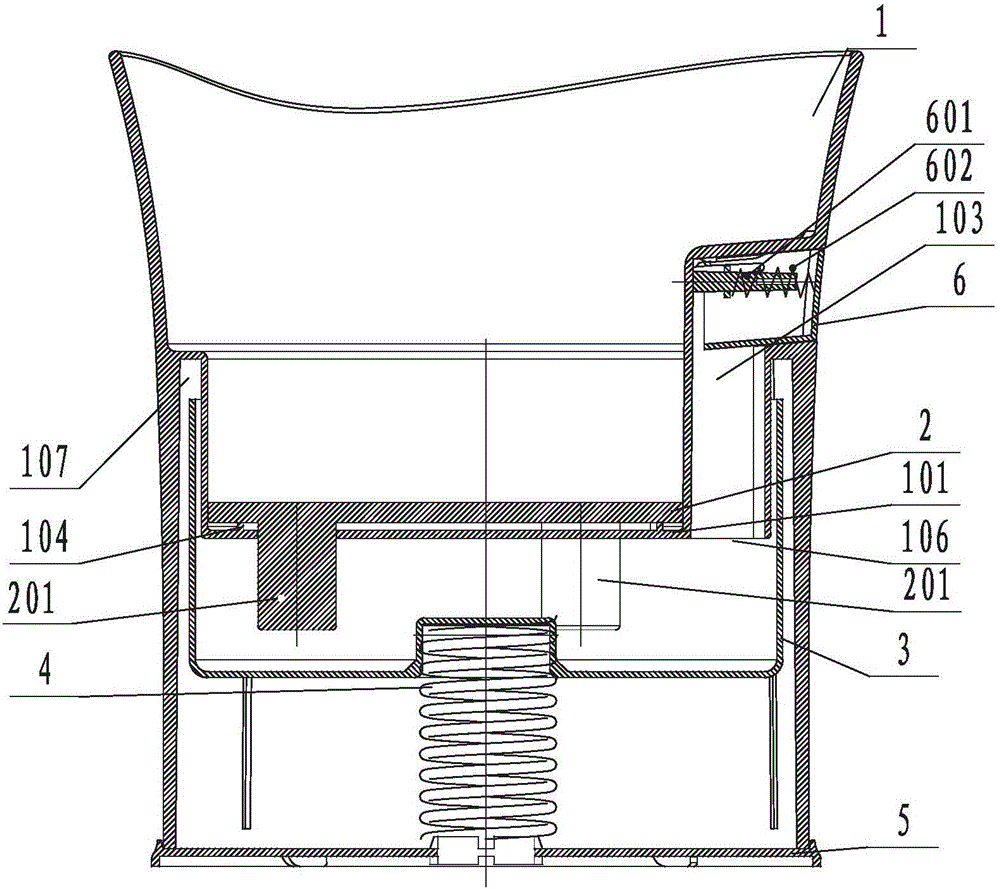

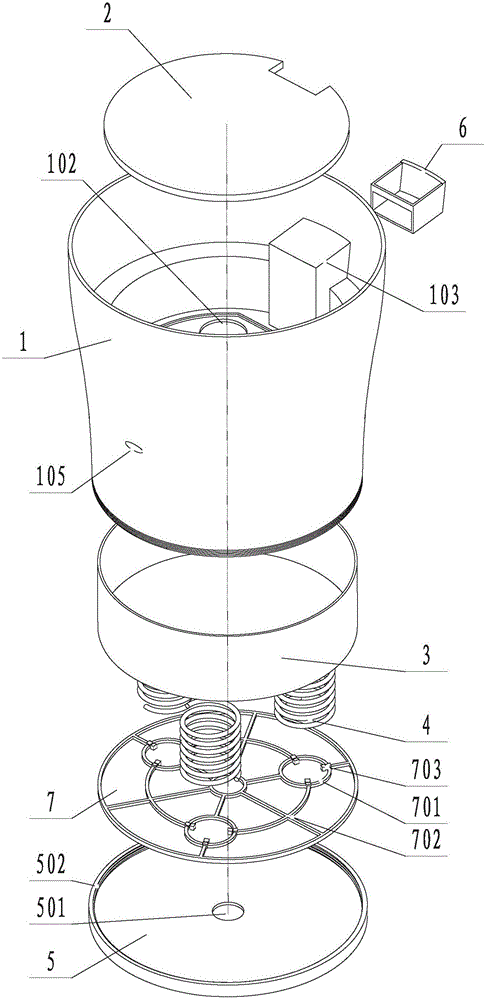

A flower growing device with an automatic lifting water absorption device

InactiveCN104396611BSame water absorptionHealthy growthSelf-acting watering devicesReceptacle cultivationWater storageEngineering

The invention discloses a flower growing device with an automatic lifting water absorption apparatus and relates to a flowerpot. Ordinary flowerpots do not have a water storage function, flowers are needed to be watered every day, and dryness can be easily caused without day's watering. The flower growing device comprises a flowerpot body and an automatic lifting water absorption unit arranged in the flowerpot body. A partition layer is arranged in the flowerpot body and divides the flowerpot body into an upper layer and a lower layer. The automatic lifting water suction unit comprises a water suction disc, a water storage disc below the water suction disc and an elastic element below the water storage disc. The elastic element supports the water storage disc, and the compression amount of the elastic element is changed along with the water amount of the water storage disc. The water suction disc is disposed on the partition layer, a water suction hole is formed in the partition layer, a water suction column matched with the water suction hole is arranged on the water suction disc, and the height of the water suction column is larger than the thickness of the partition layer, so that the lower end of the water suction column can stretch out of the lower surface of the partition layer. A water injection hole is formed in the flowerpot body. By means of the device, the water storage disc is changed up and down along with the amount of storage water, and the water suction amount of the water suction disc is identical; plants can grow healthily by the fixed water suction amount.

Owner:胡越强

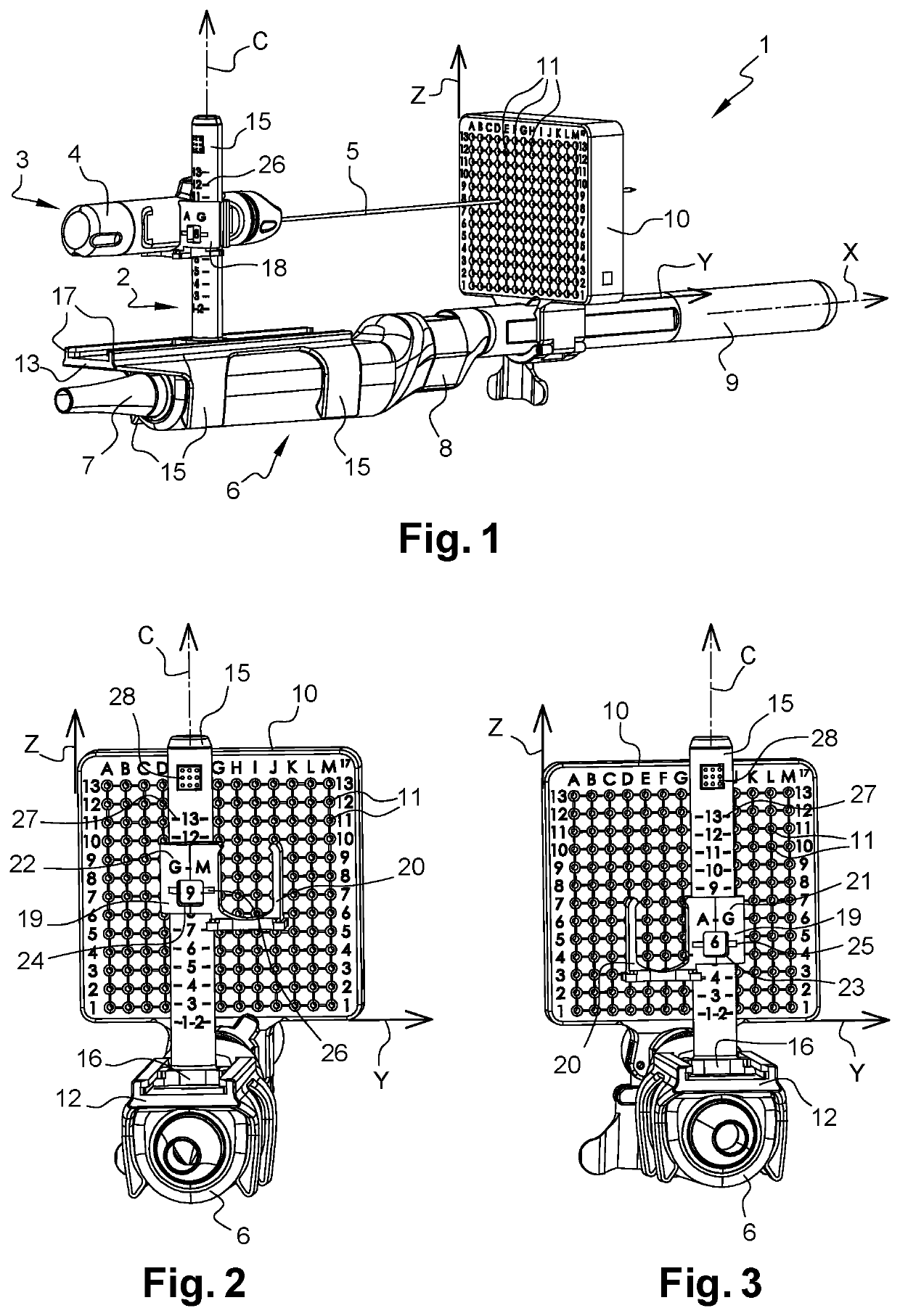

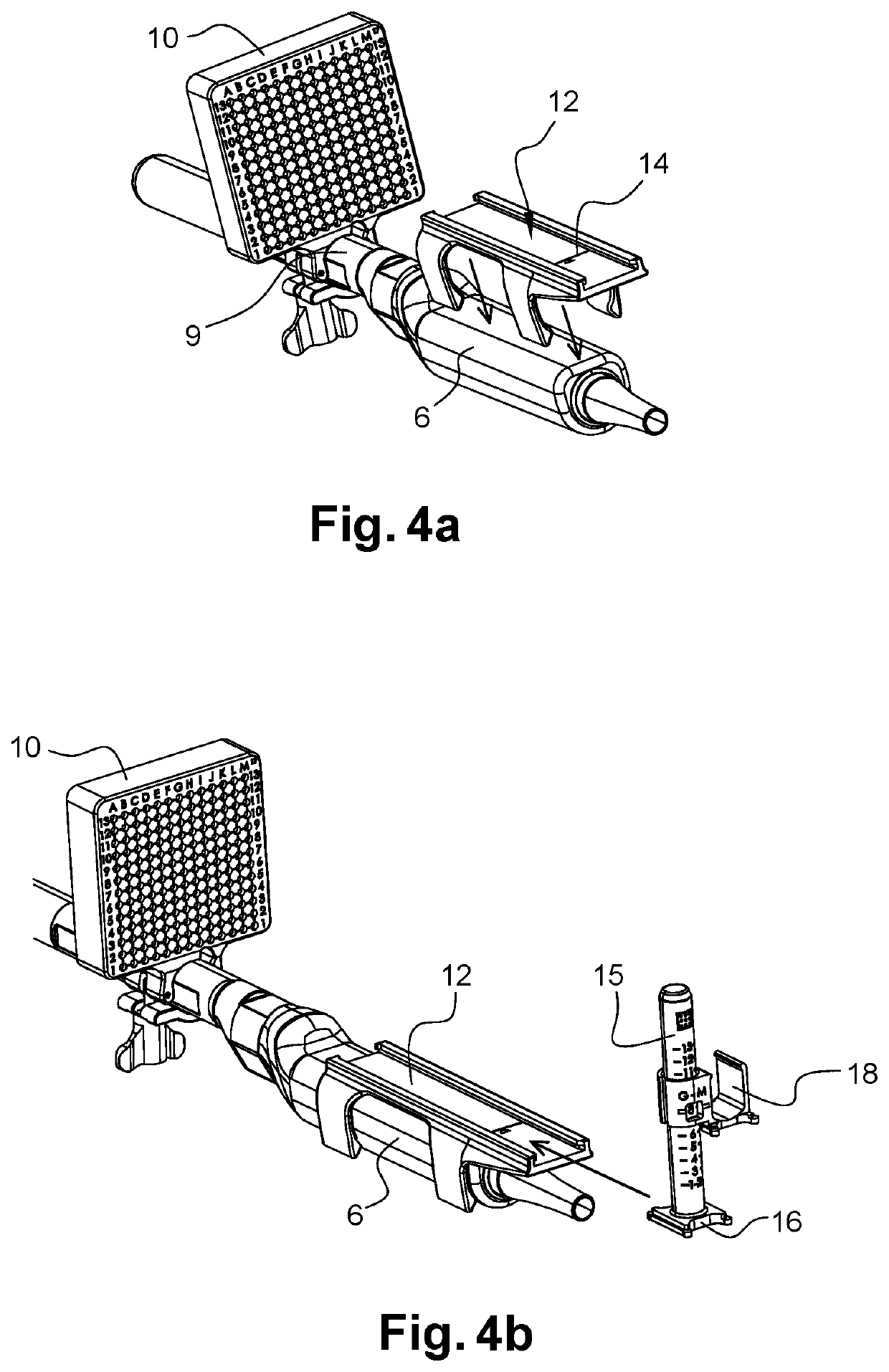

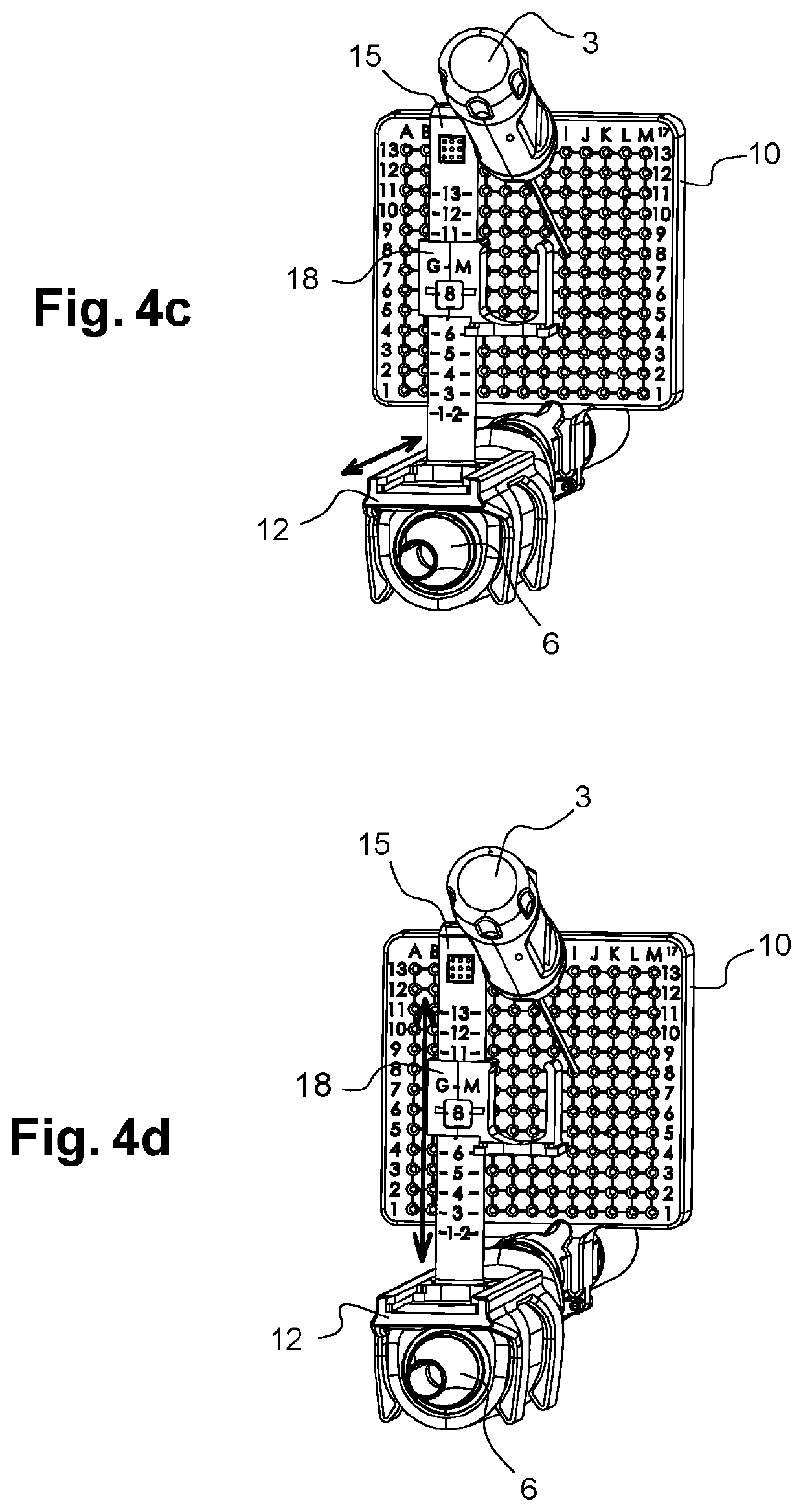

Device for holding a medical instrument and apparatus comprising such a device

PendingUS20220354455A1Controlling the riskConstant depthUltrasonic/sonic/infrasonic diagnosticsGuide needlesMedical imagingApparatus instruments

The invention relates to a holder device for holding a medical instrument, the device comprising:a base that is to be carried by an apparatus comprising a medical imaging probe associated with the medical instrument; anda carrier structure for carrying the medical instrument and movably mounted on the base so as to be capable of moving on the base between a first position and a second position.The invention also relates to an installation including both such a device and a needle-guide.

Owner:KOELIS

A double-knife blind hole fixed-depth machining CNC machine tool

InactiveCN103658731BAdjustable distanceEasy to processAutomatic control devicesDrilling/boring measurement devicesNumerical controlEngineering

The invention discloses a numerical control machine tool for dual-blade blind hole fixed depth machining. The numerical control machine tool comprises a machine tool body (1), a machine tool electrical cabinet (2), a numerical control panel (3), a clamping table top (4), a tailstock (5) and a dual-blade fixed depth machining device (9). The machine tool electrical cabinet (2) is arranged on one side of the machine tool body (1), the machine tool electrical cabinet (2) and the numerical control panel (3) are connected through a rotating rod (36), and the clamping table top (4) is arranged at the upper end of the machine tool body (1). The machine tool body (1) is provided with a rail table top (7), the rail table top (7) is provided with a rail (6), the tailstock (5) and the dual-blade fixed depth machining device (9) are arranged on the rail (6), and the tailstock (5) is locked through a bolt. According to the numerical control machine tool for dual-blade blind hole fixed depth machining, the blind hole depth can be guaranteed in the bending process of a gun barrel, machining precision is improved, machining and transporting difficulty is reduced, the machining efficiency is approximately doubled at the same time, the demand for large consumption is met, and meanwhile the numerical control machine tool has the advantages of being simple in structure and low in cost.

Owner:WENZHOU UNIV

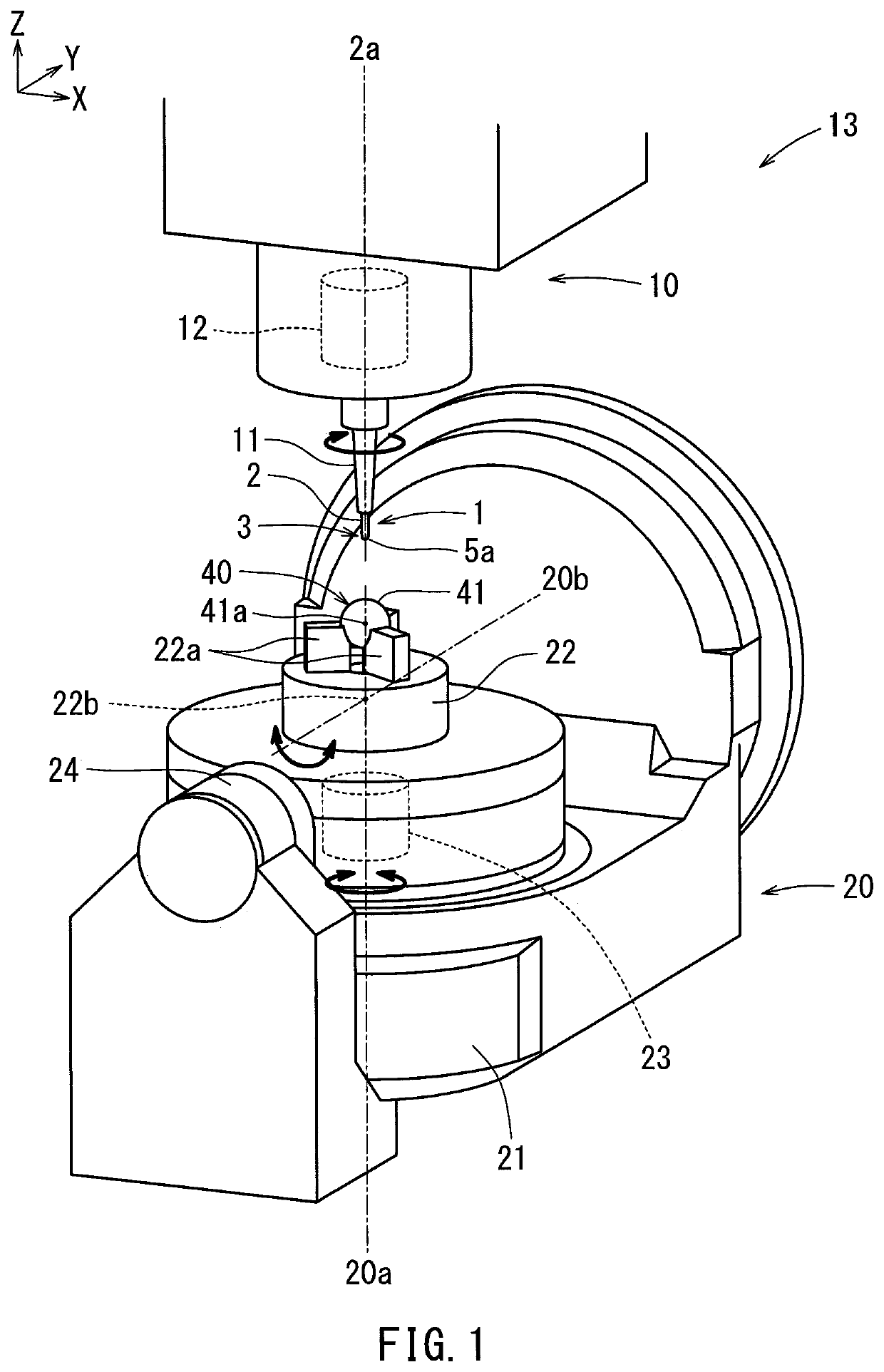

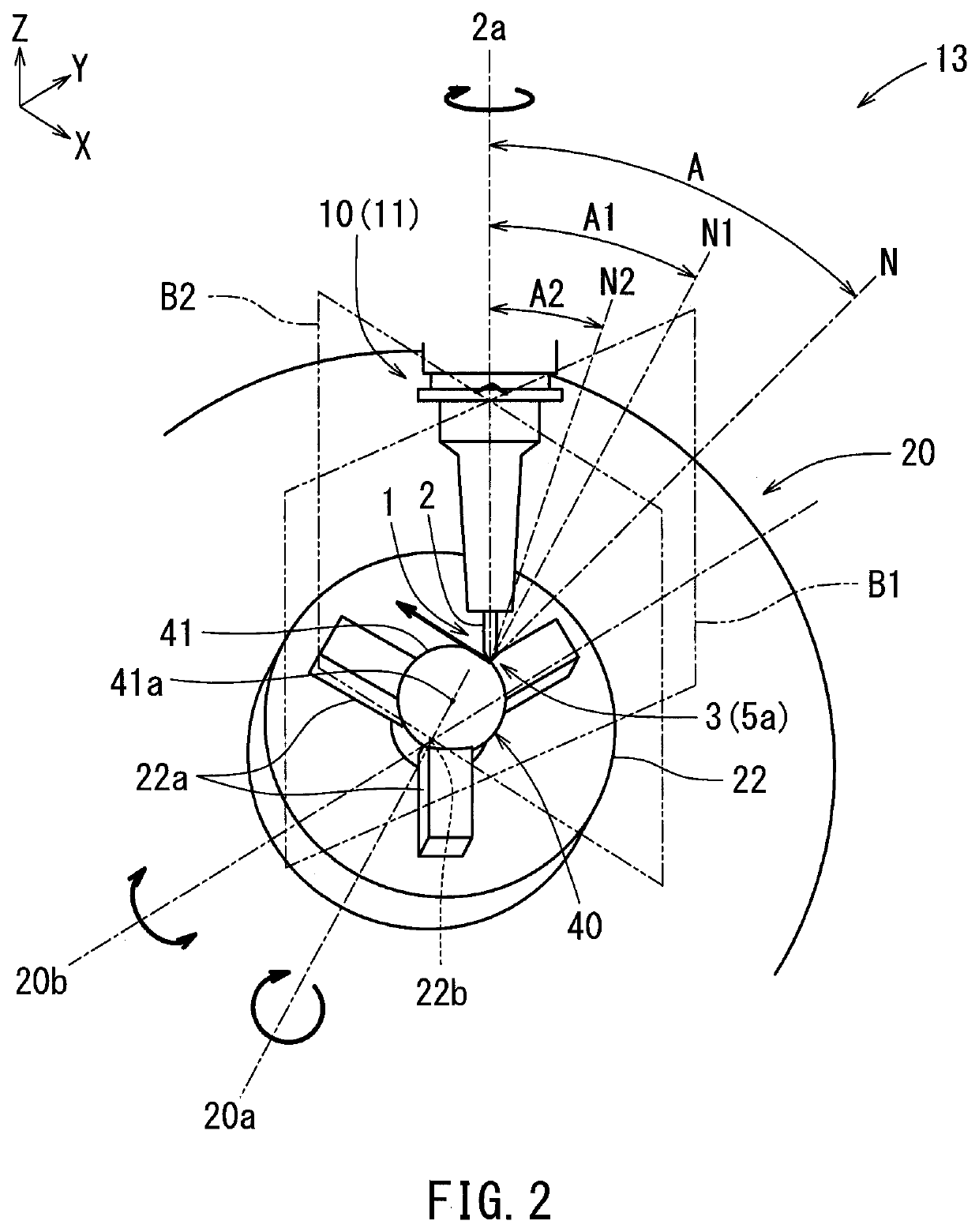

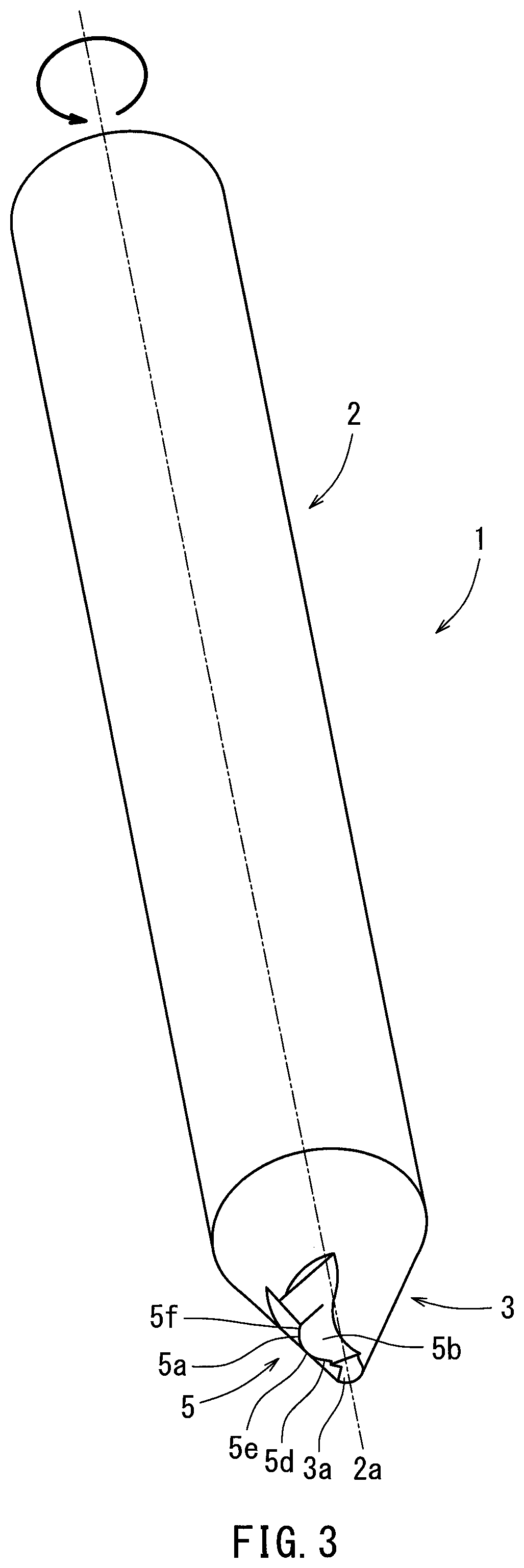

Dimple Processing Method

PendingUS20220324036A1Reducing approach angleShort timeProgramme controlMilling cuttersEngineeringPhysics

In a dimple processing method for forming dimples on a curved surface of a workpiece, a cutting tool having a cutting edge on a rod-shaped body is rotated about a central axis of the cutting tool. The workpiece is rotated about a first axis. The cutting tool or the workpiece moves on a virtual plane through which the first axis passes or on a plane parallel to the virtual plane. The cutting tool or the workpiece moves such that the tip end of the cutting tool follows the curved surface of the workpiece. The cutting edge forms one or more dimple on the curved surface each time the cutting tool rotates.

Owner:KANEFUSA HAMONO KOUGIYOU KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com