A kind of drilling device for antenna vibrator processing

A drilling device and antenna vibrator technology, applied in metal processing, feeding devices, positioning devices, etc., can solve the problems of drilling skew, arc antenna vibrator processing depression, and inability to adjust the drilling depth, etc., to achieve simple operation and prevent The effect of the inner wall depression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

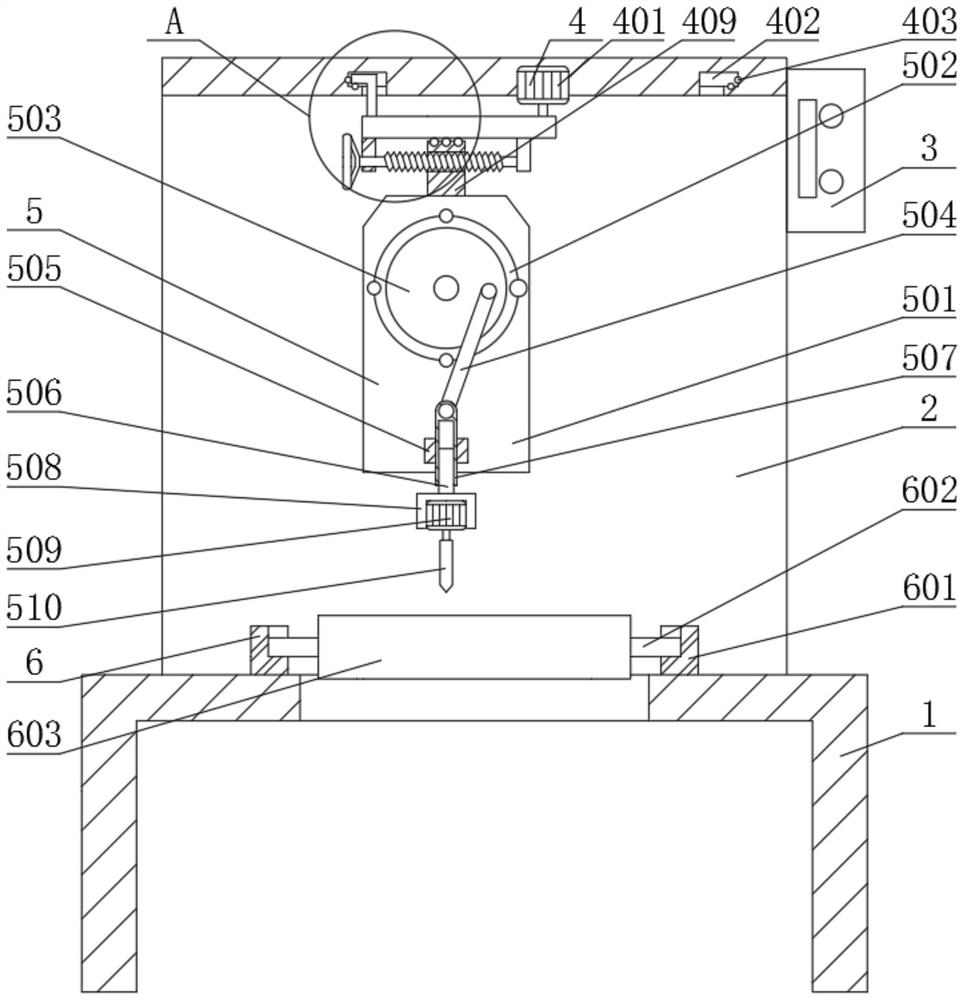

[0027] see Figure 1-6 , the present invention provides a technical solution:

[0028] A drilling device for antenna oscillator processing, comprising a base 1 and a fixed frame 2, the top of the base 1 is fixedly connected with a fixed frame 2, the right end of the fixed frame 2 is fixedly connected with a controller 3, and the inner side of the top of the fixed frame 2 is fixedly connected with The position adjustment device 4, the bottom end of the position adjustment device 4 is fixedly connected with the drilling device 5, the top end of the base 1 is fixedly connected with the clamping device 6, the top of the clamping device 6 is provided with a circular antenna vibrator 7, the clamping device 6 A loop antenna vibrator 8 is provided inside the bottom end of the circular antenna vibrator 7 , a second mounting hole 10 is opened inside the circular antenna vibrator 7 , and a first mounting hole 9 is opened inside the loop antenna vibrator 8 .

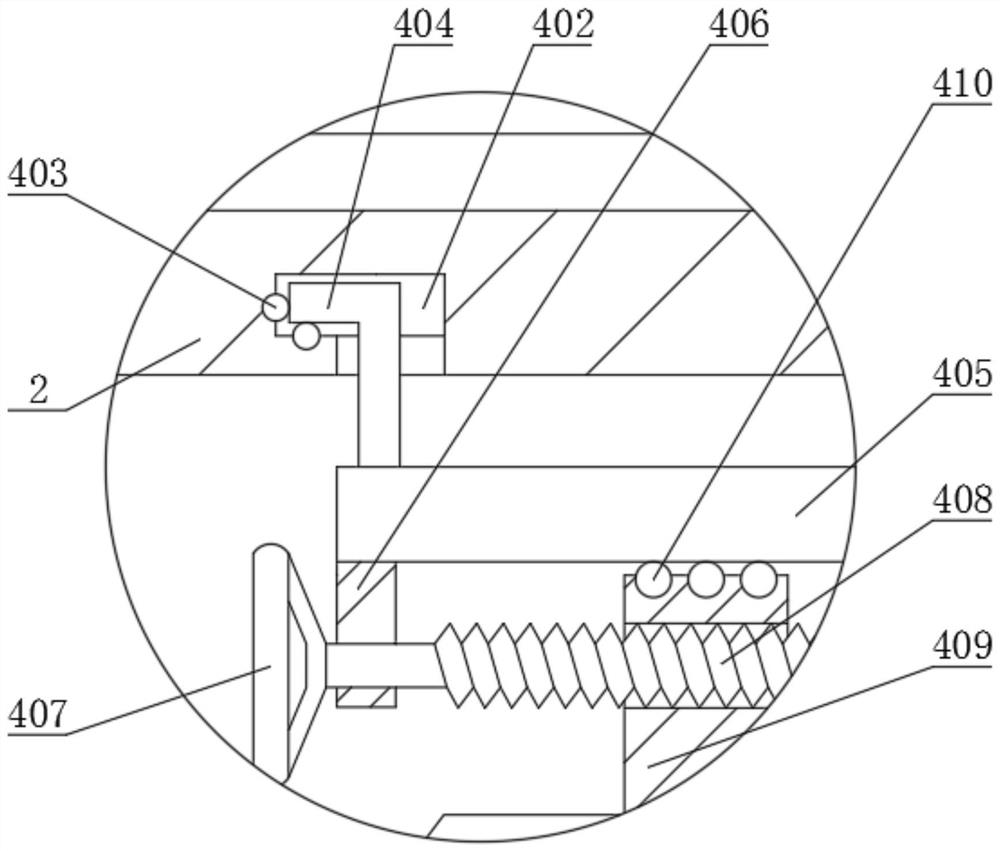

[0029]The position adjustme...

Embodiment 2

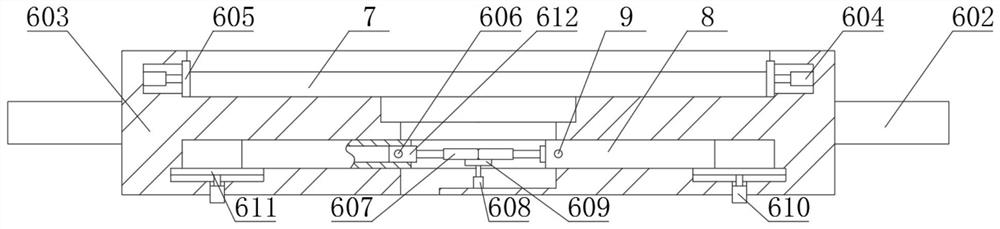

[0031] Embodiment 2 and Embodiment 1 will not repeat the same parts. The difference is that if the loop antenna vibrator 8 is drilled, the staff first adjusts the position of the clamping seat 603 so that the first clamping plate 605 is on the rear side, The second clamping plate 611 is on the front side, and the clamping seat 603 is placed on the card seat 601 through the clamping rod 602 at the same time, and then the staff places the loop antenna vibrator 8 in the placement groove inside the clamping seat 603, and then works The personnel control the fourth electric telescopic rod 610 on the left and right sides through the controller 3 to drive the second clamping plate 611 to clamp the loop antenna vibrator 8 to realize the limit and fixation of the loop antenna vibrator 8, and then the staff controls through the controller 3 The third electric telescopic rod 608 drives the connecting block 609 to move to the rear side, so that the connecting block 609 drives the support c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com