Patents

Literature

55results about How to "No skewing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

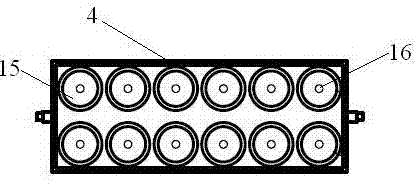

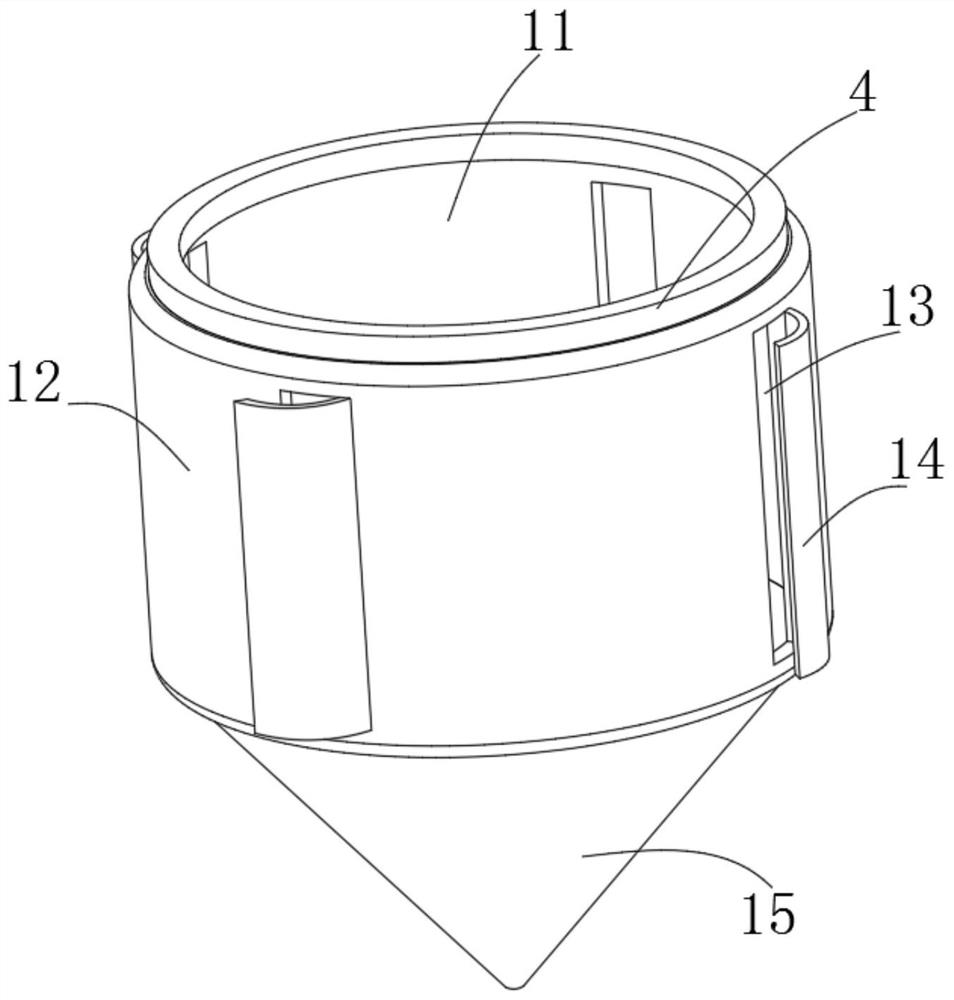

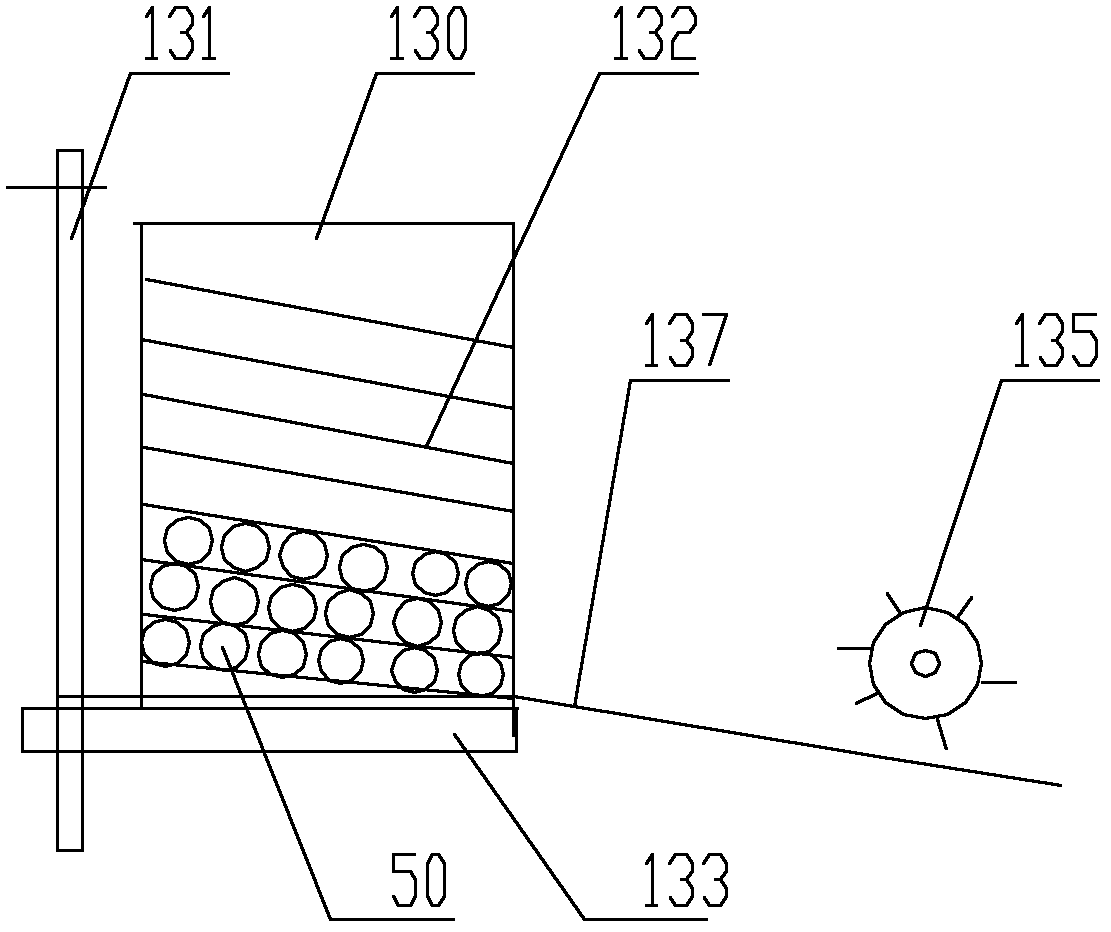

Clamp for battery charge-discharge test

InactiveCN104849514ANo skewingIncrease temperatureMeasurement instrument housingBattery chargeStructural engineering

The invention provides a clamp for a battery charge-discharge test. The clamp is provided with a pedestal and an upper cover. A plurality of positioning grooves are arranged in the pedestal. Negative pole connecting sheets are arranged at the bottom ends of the positioning grooves. A plurality of positive pole contacts are arranged on the lower surface of the upper cover. When using, batteries are inserted into the positioning grooves vertically and the negative poles of the batteries press against the negative pole connecting sheets. Then the upper cover is arranged above the positioning grooves and the positive pole contacts press against the positive poles of the batteries inserted in the positioning grooves. In this way, performance parameters such as voltage characteristics and the like of the batteries can be tested. Since the batteries are inserted in the positioning grooves when the clamp provided by the invention is in use, battery inclination is avoided during the testing process, so that problems of battery inclination and pole short circuit due to insecure clamping of the batteries in the prior art are avoided.

Owner:BEIQI FOTON MOTOR CO LTD

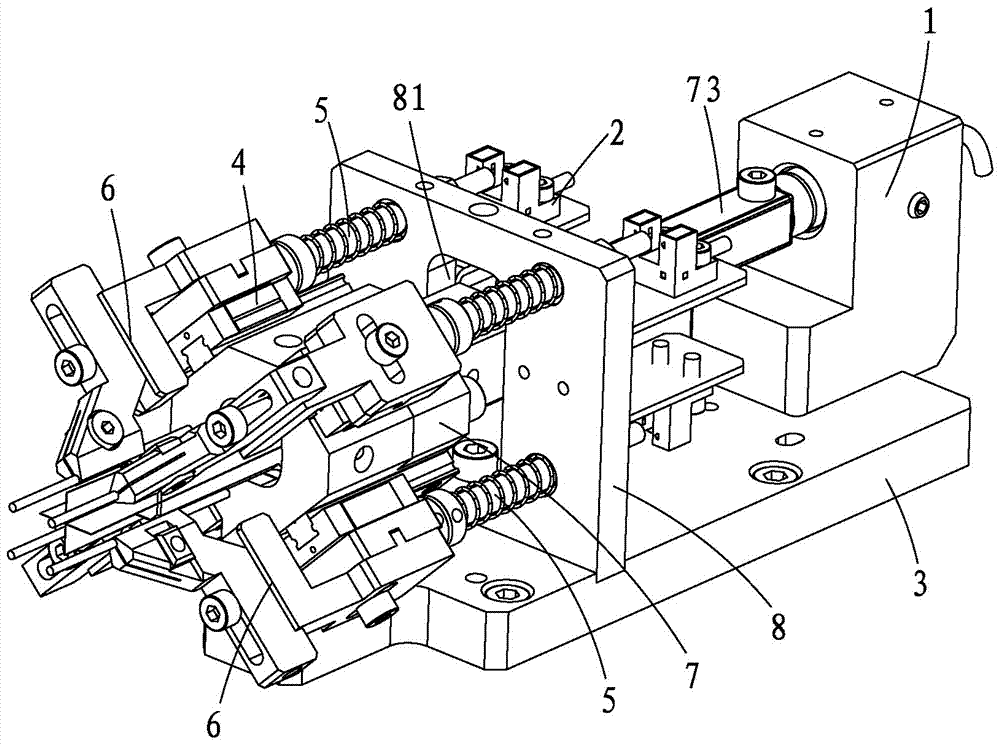

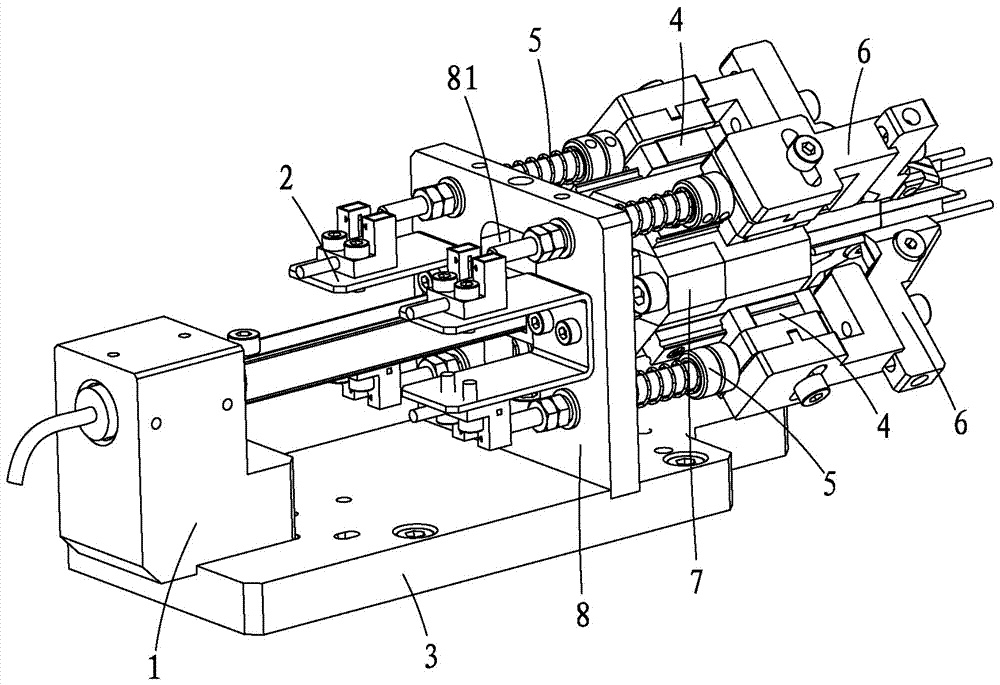

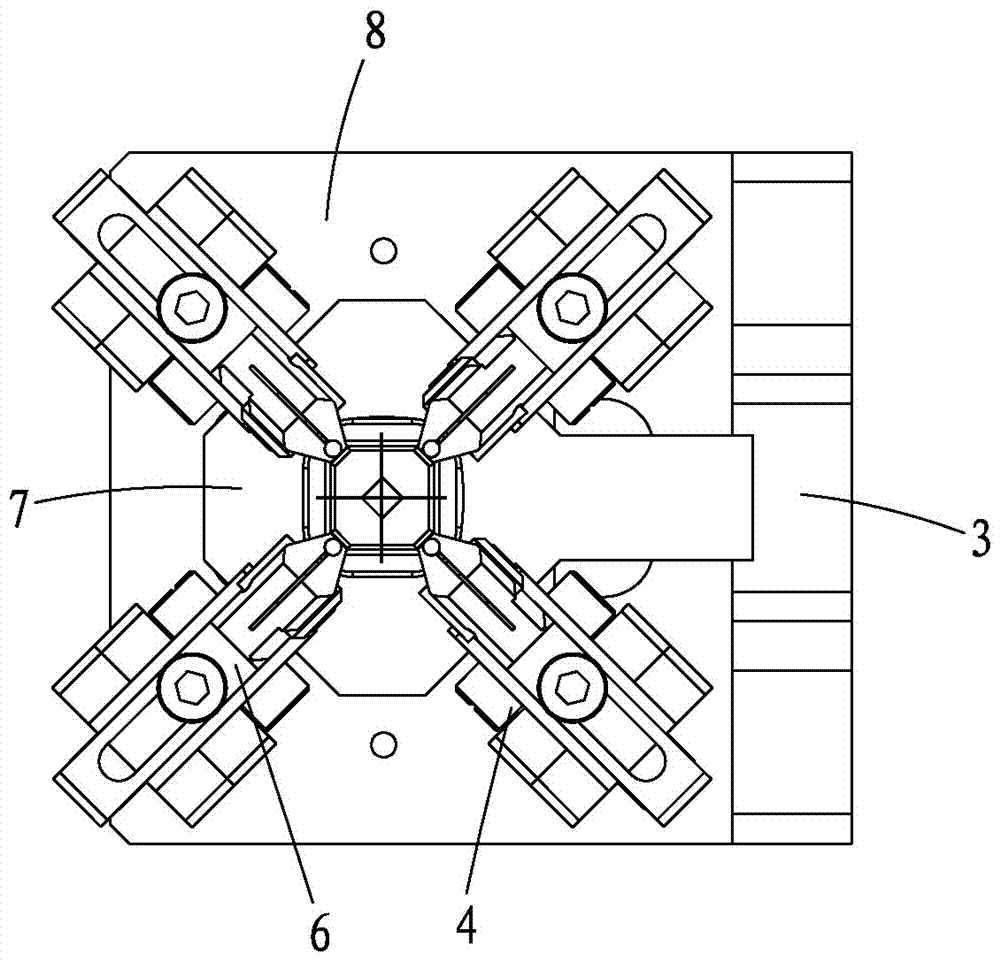

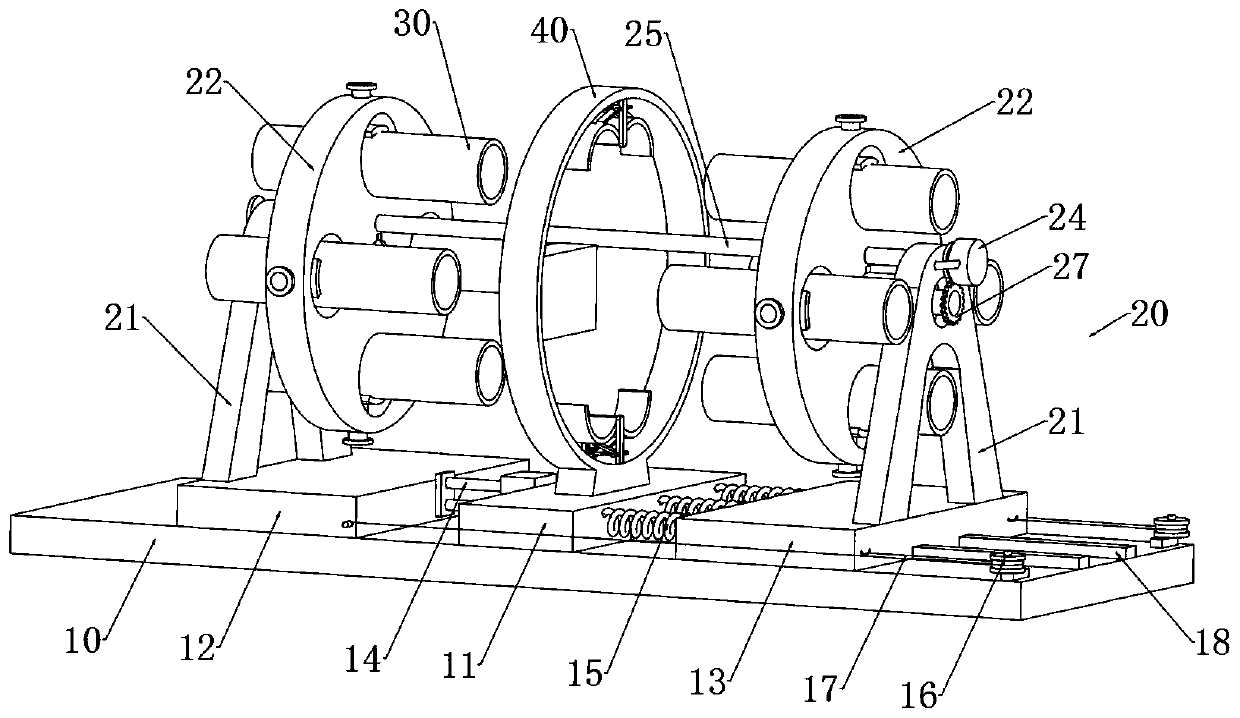

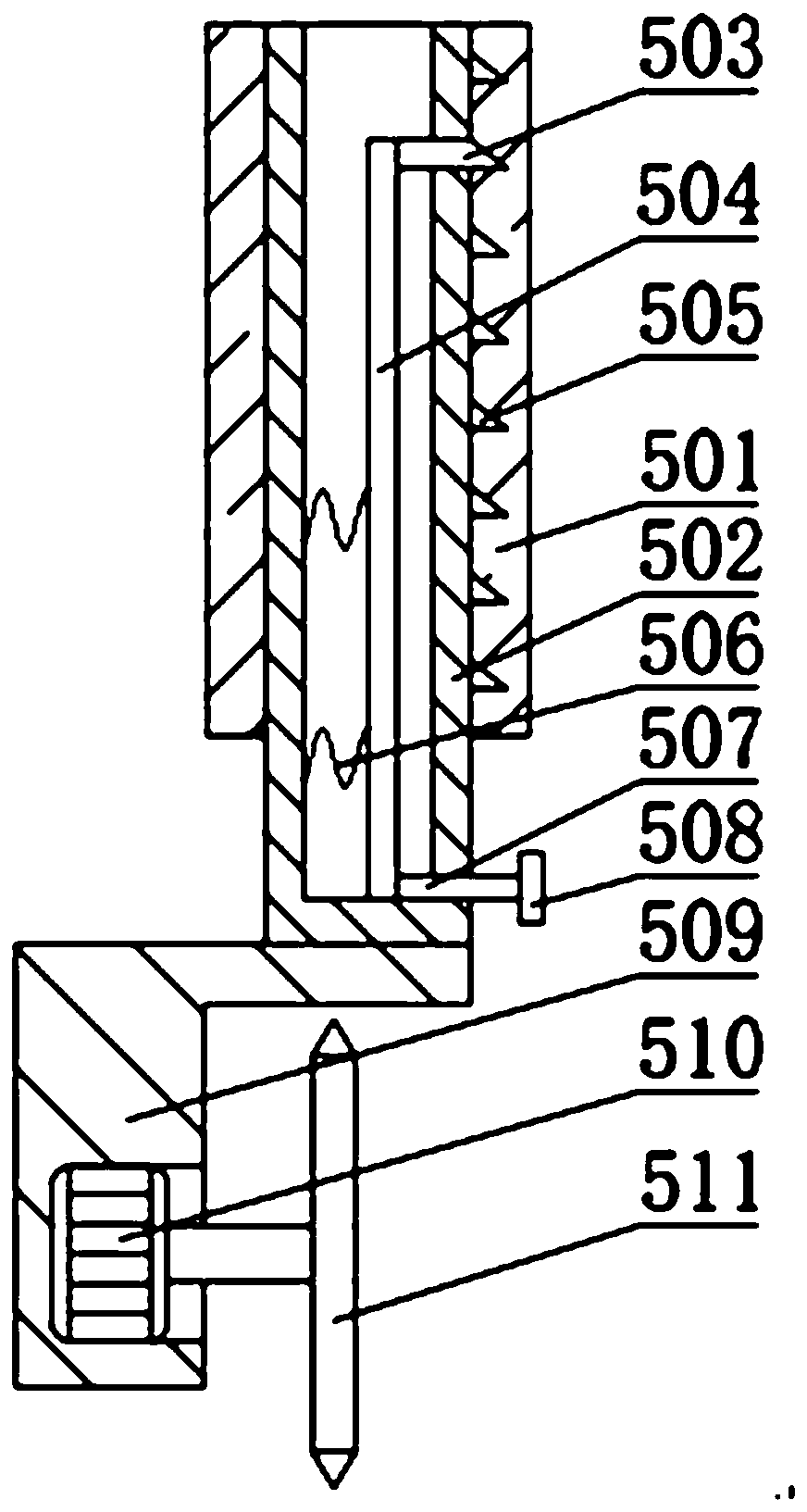

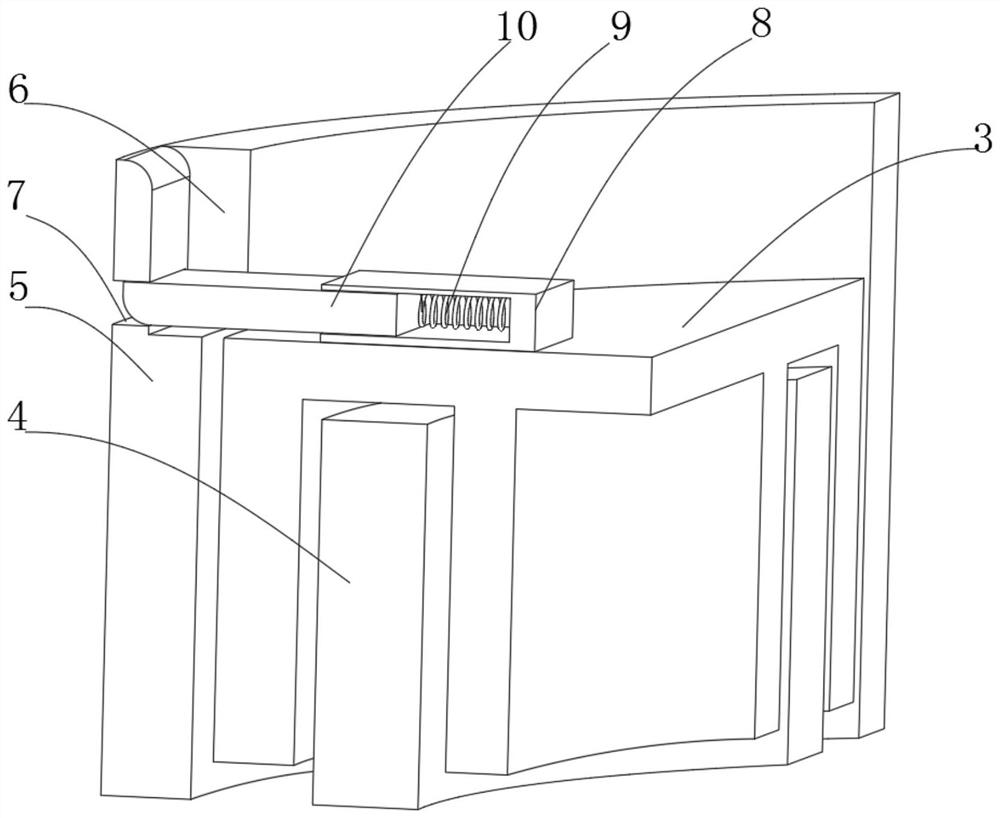

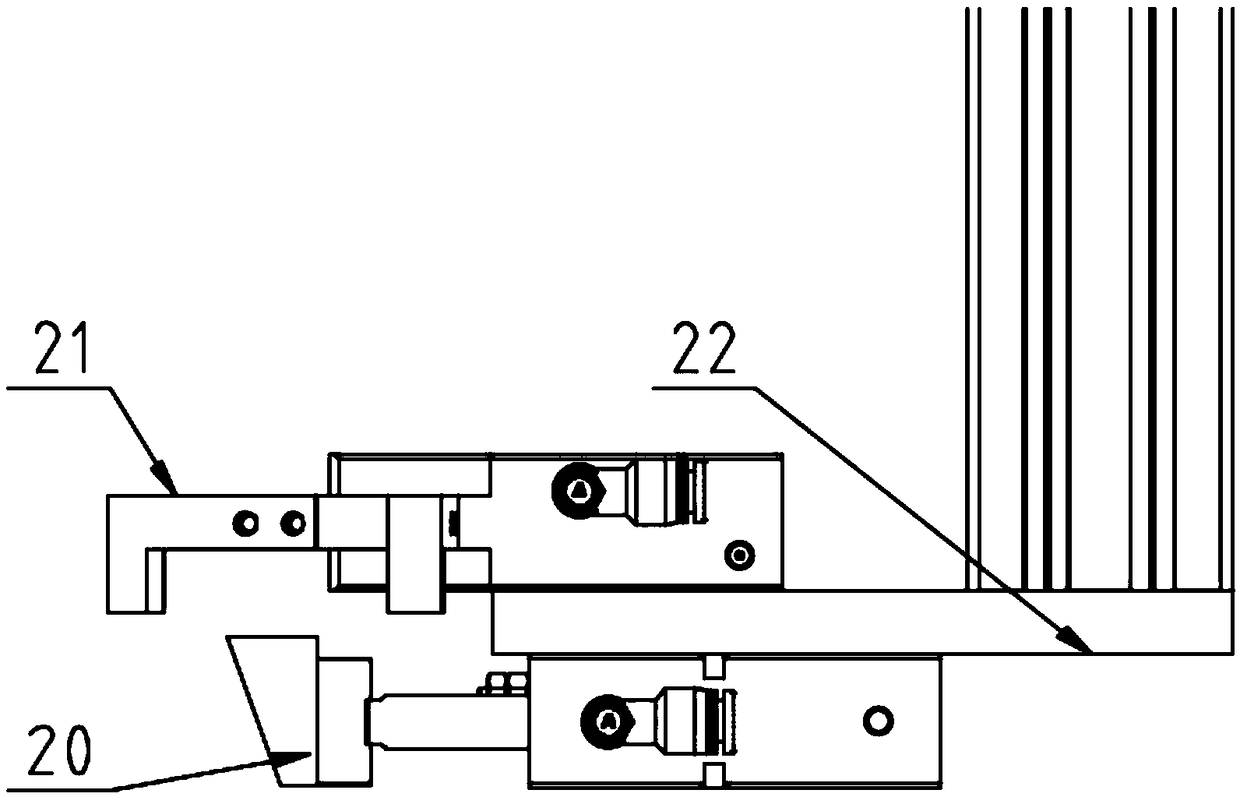

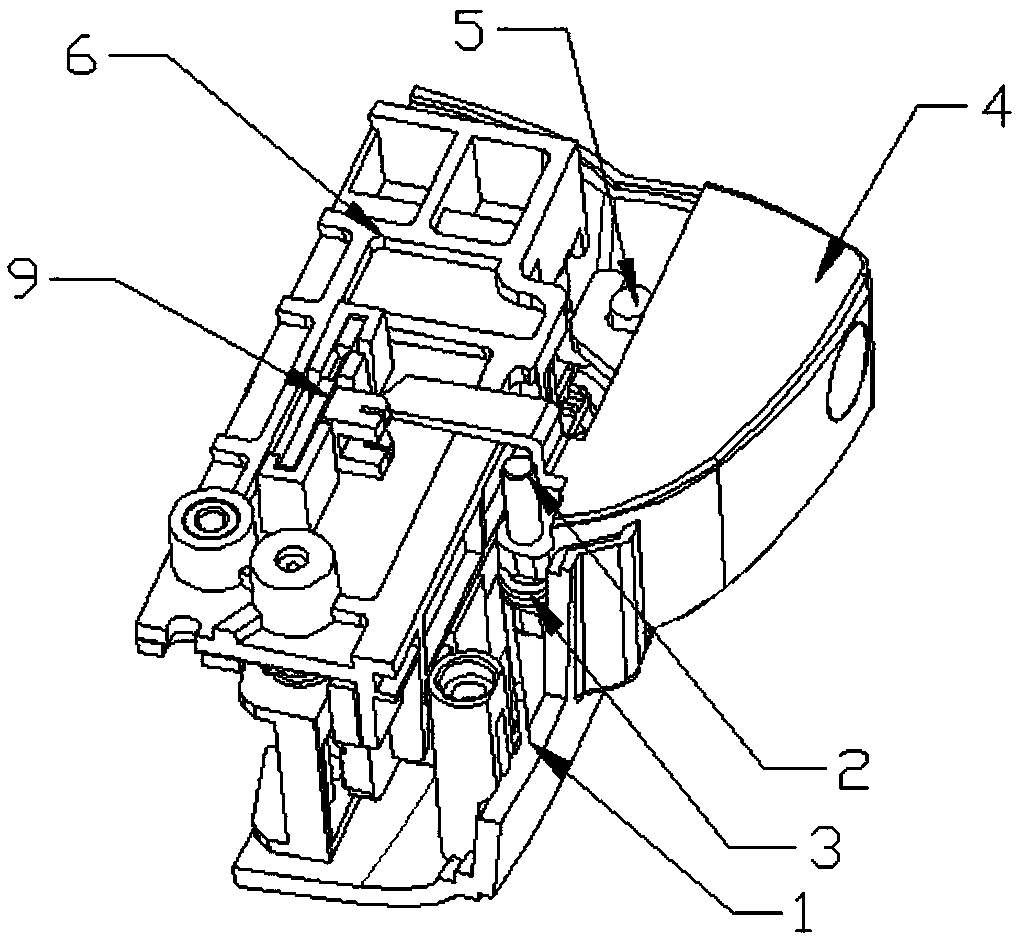

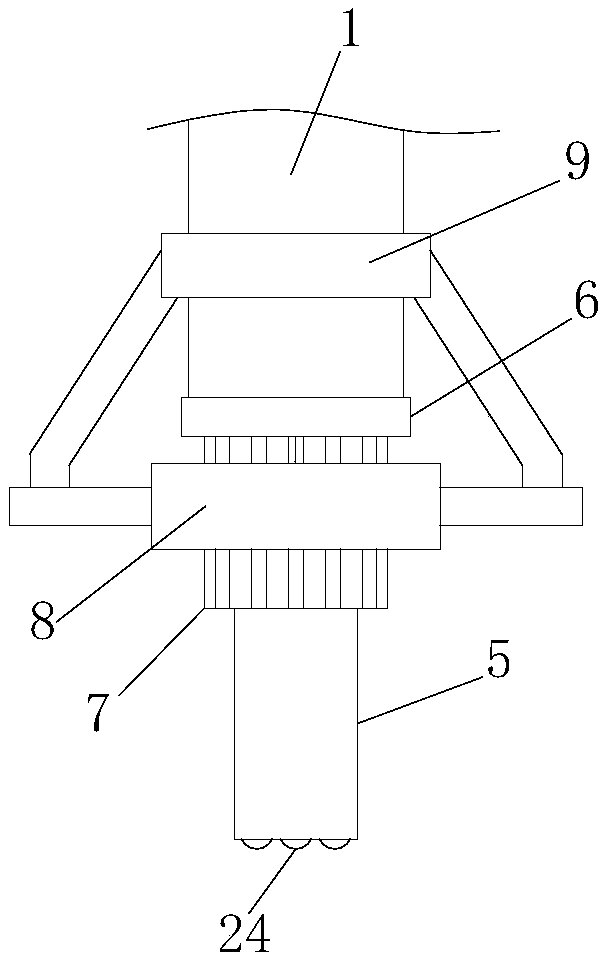

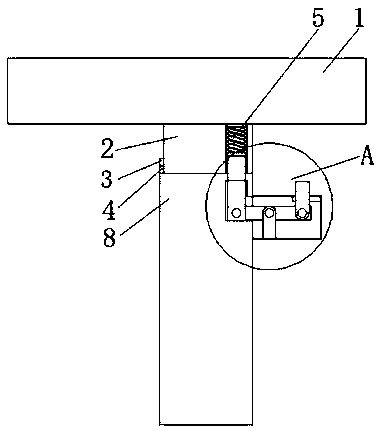

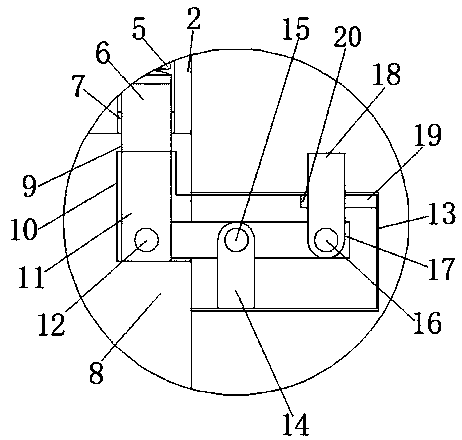

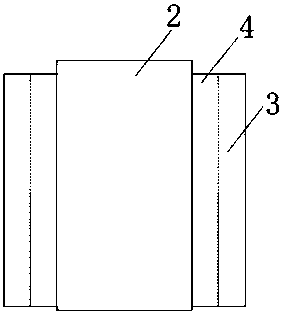

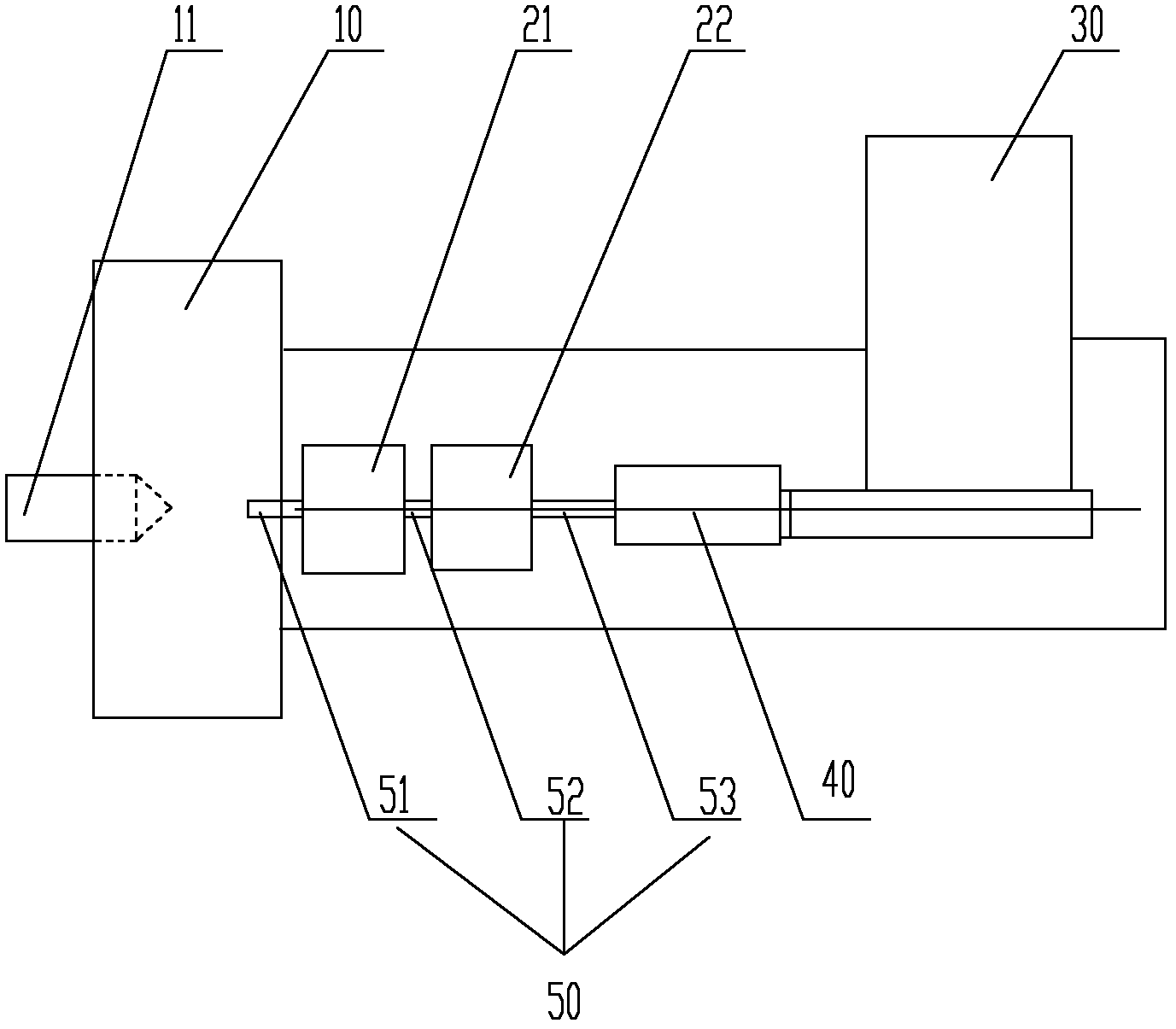

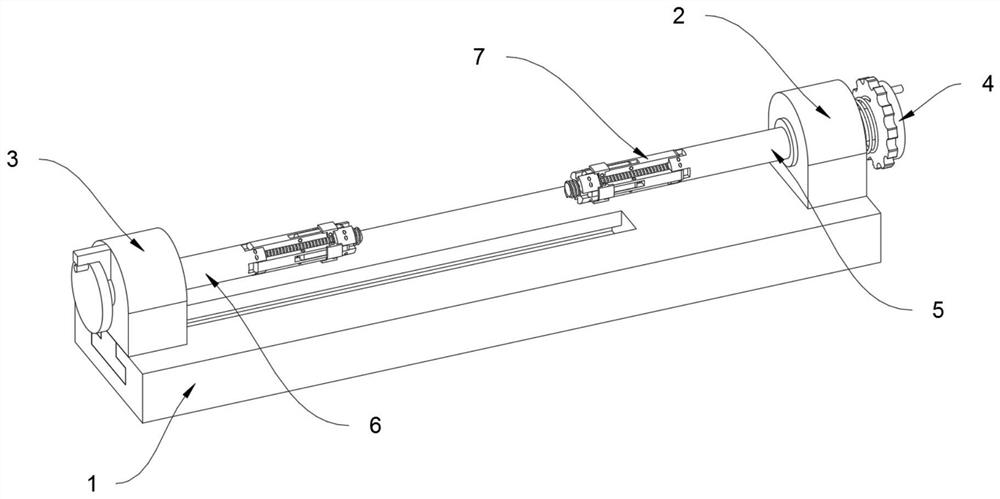

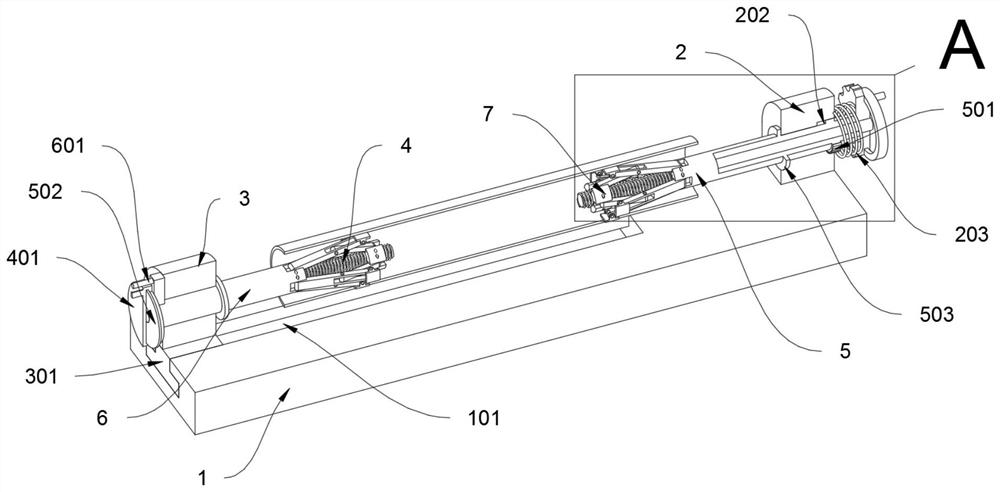

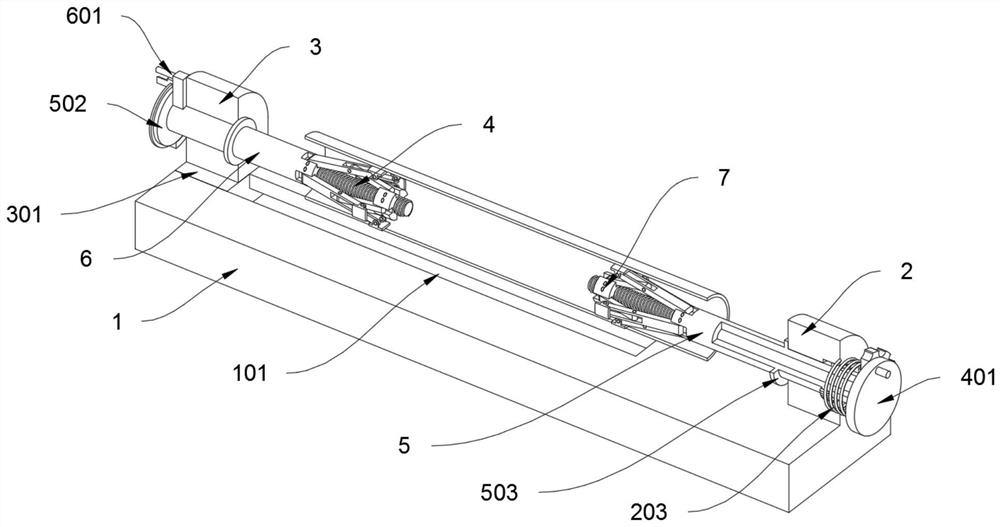

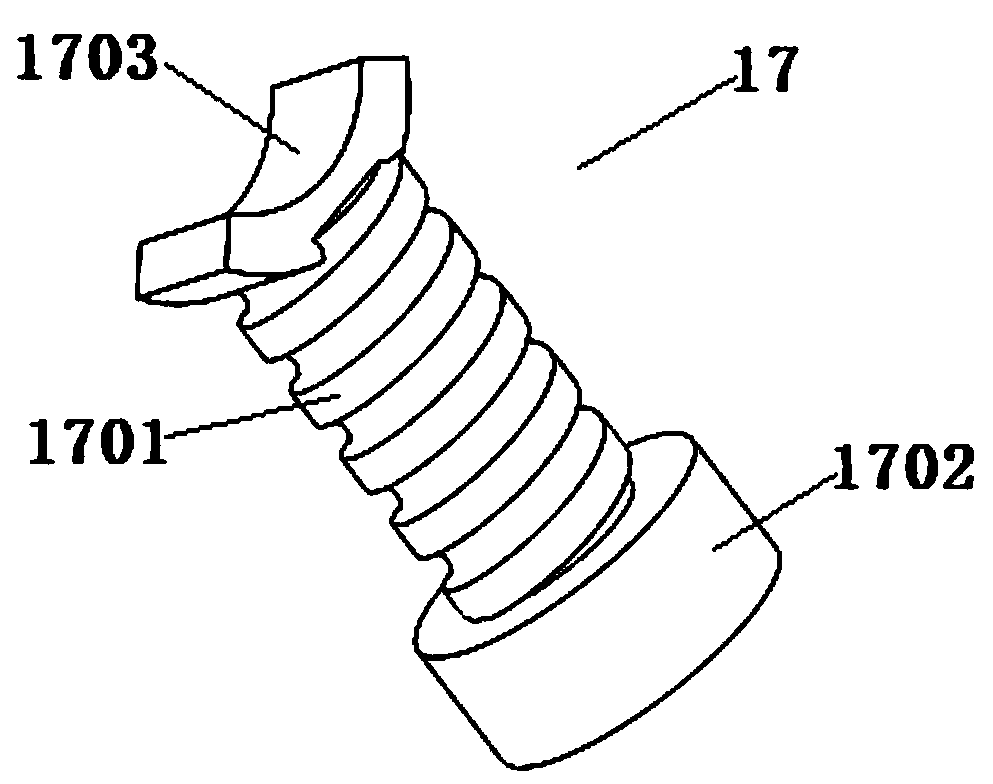

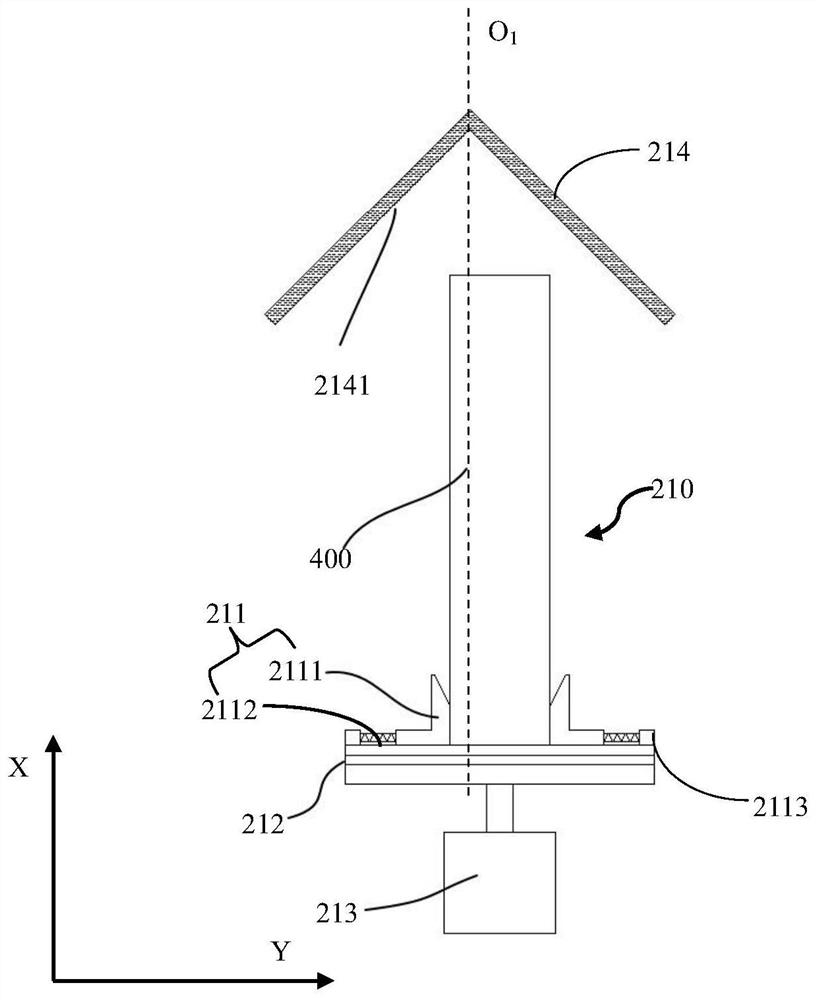

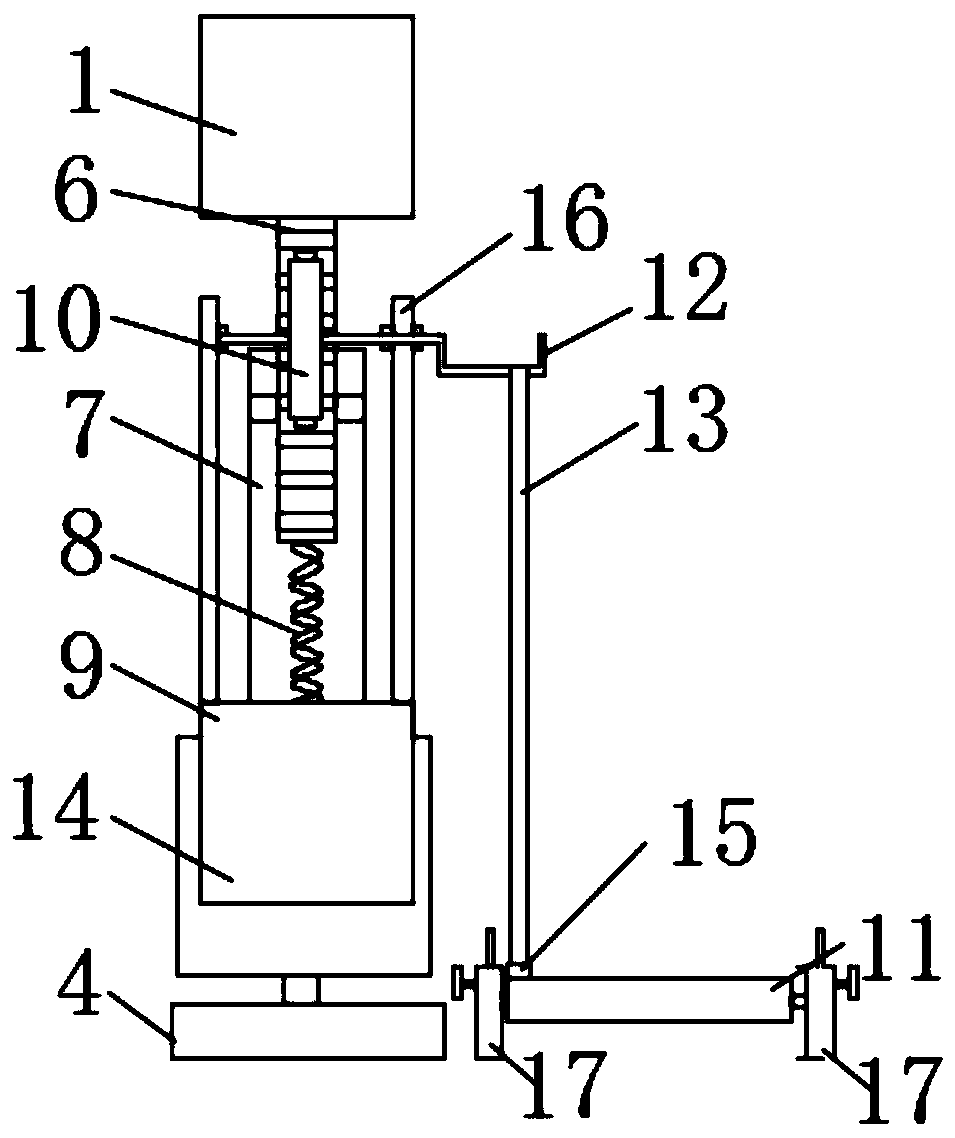

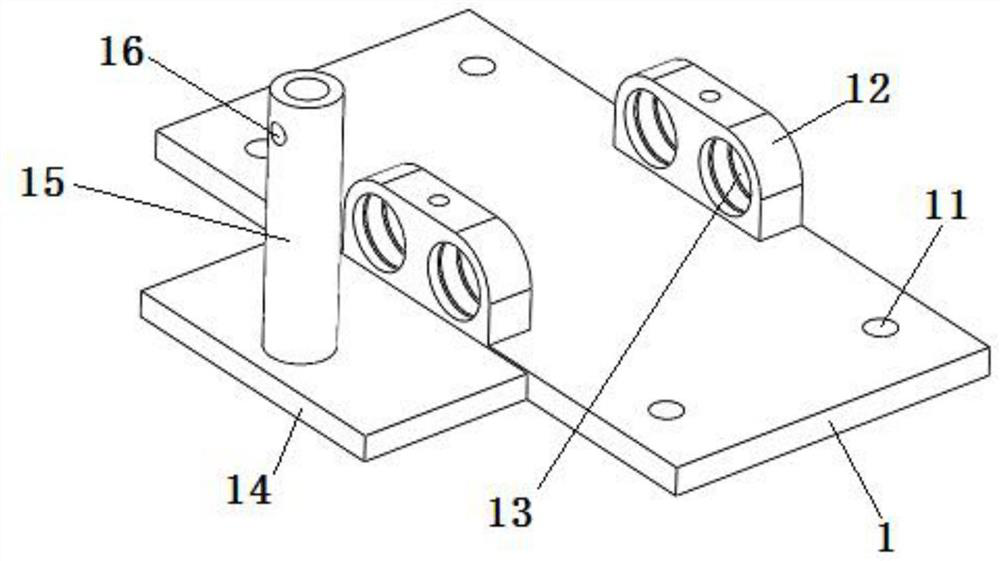

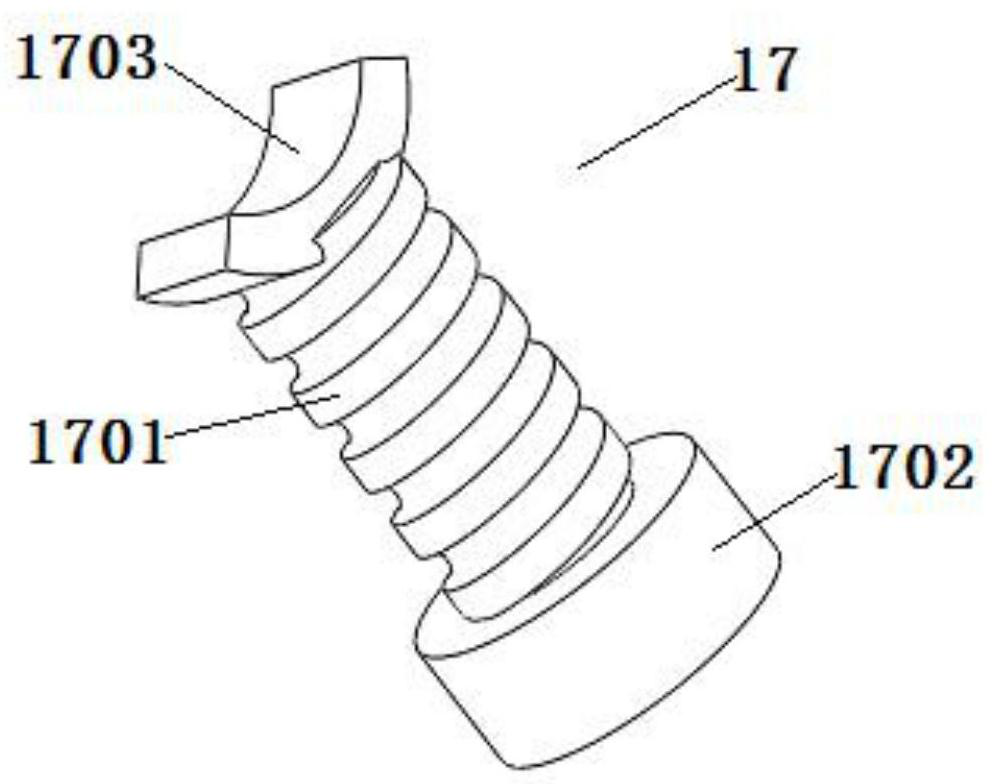

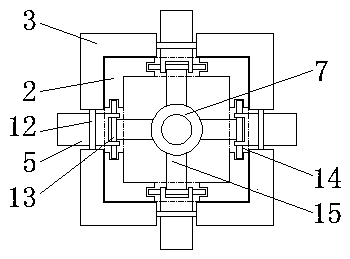

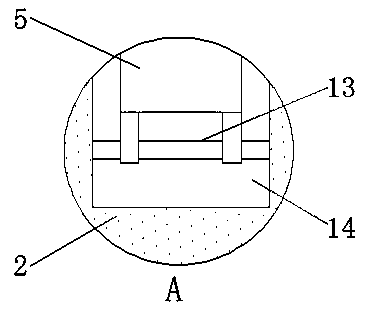

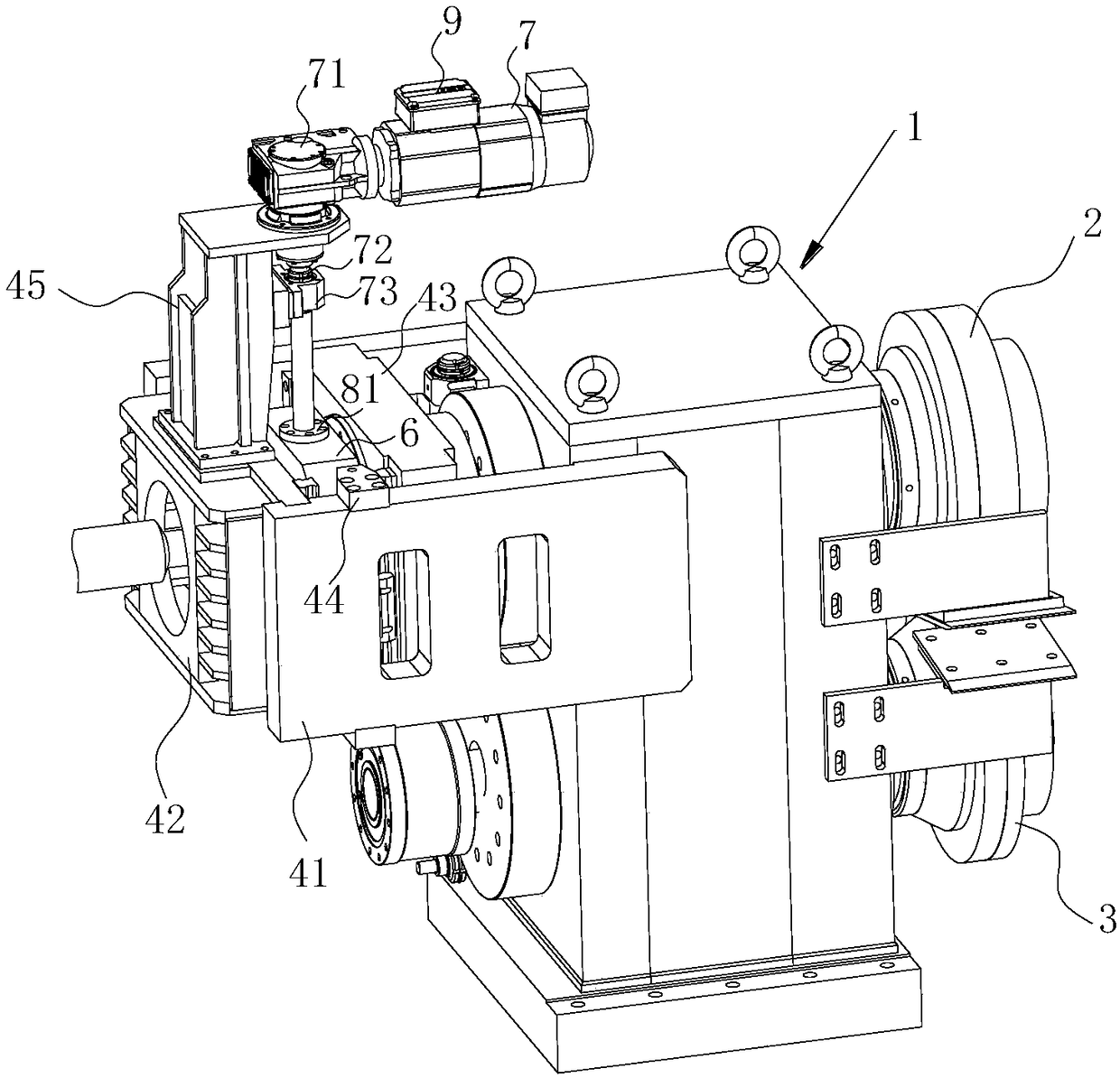

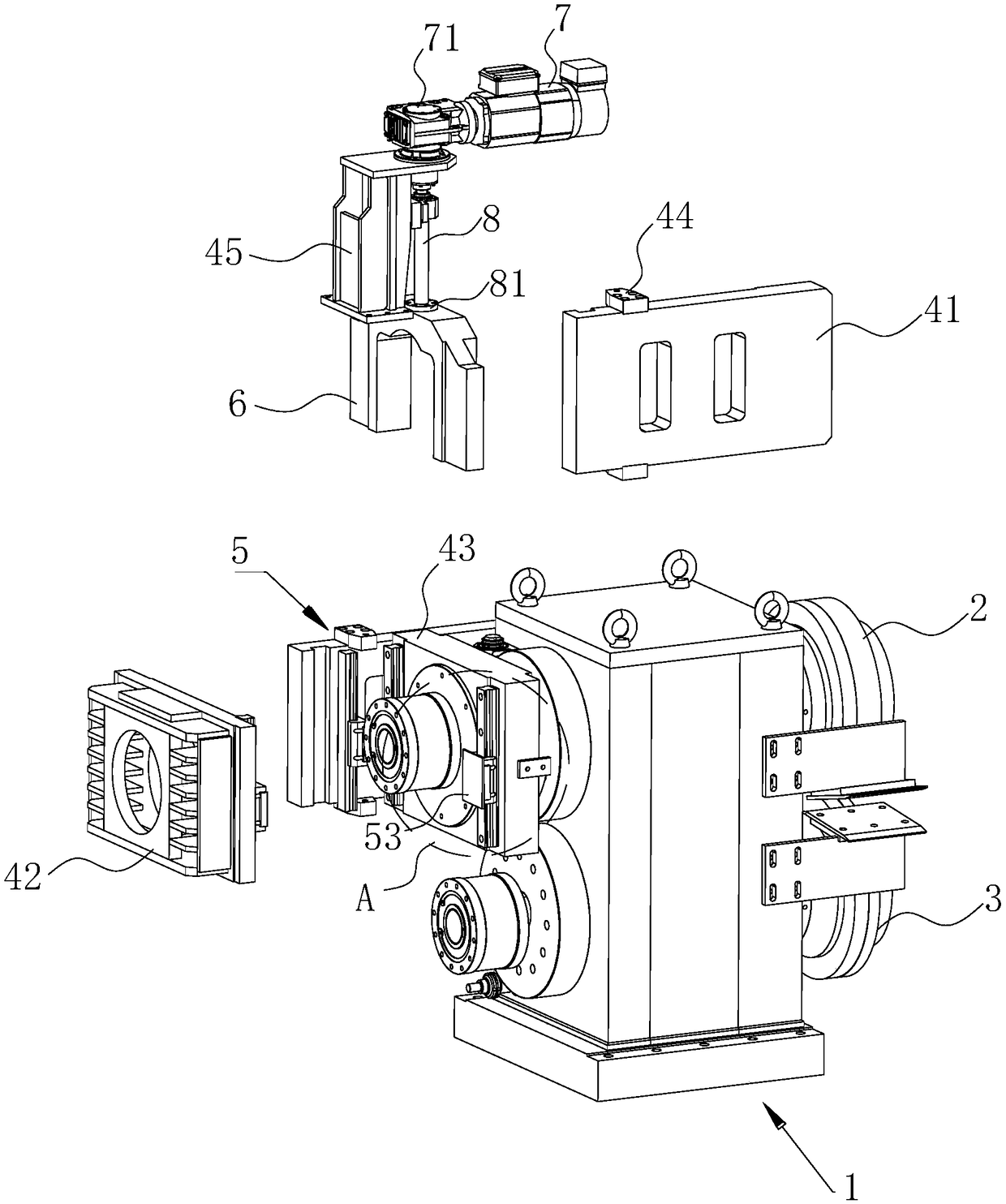

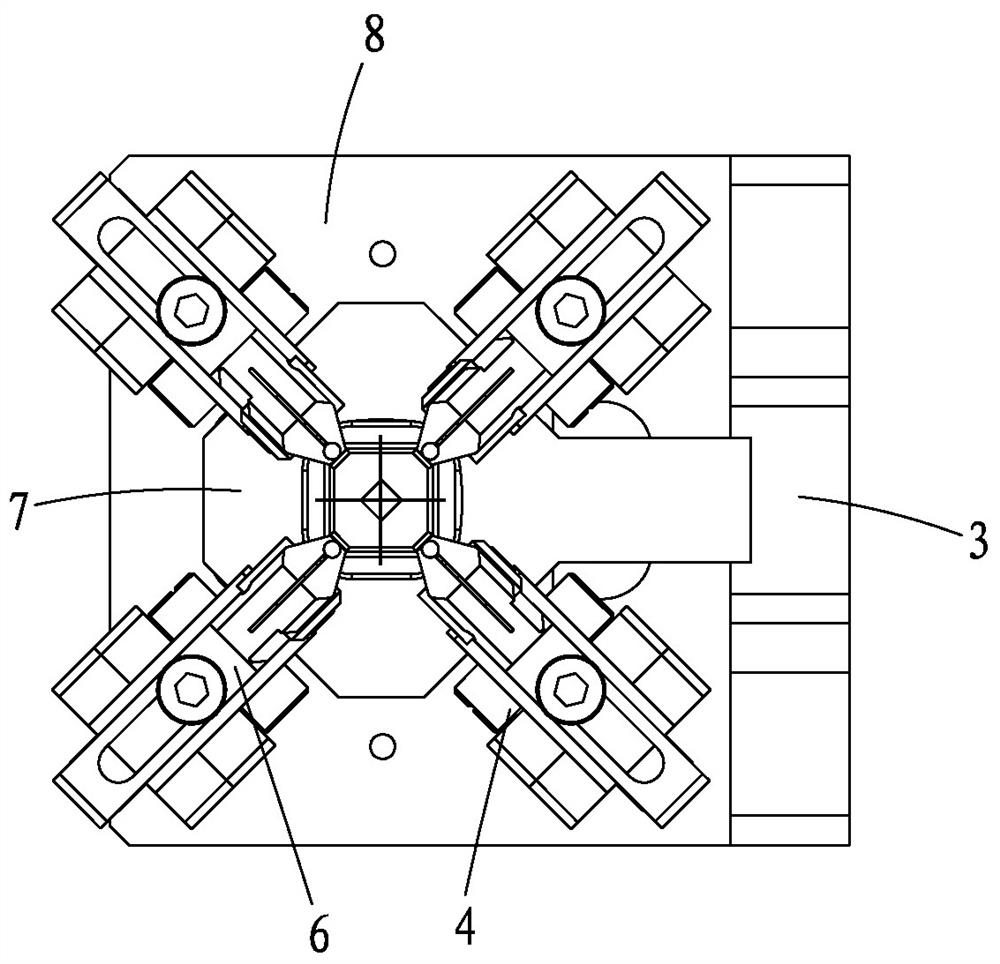

Four-needle point welding head device

ActiveCN107150182AImprove spot welding precision and spot welding qualityIncrease the speed of needle adjustmentWelding/soldering/cutting articlesMetal working apparatusNeedle guideEngineering

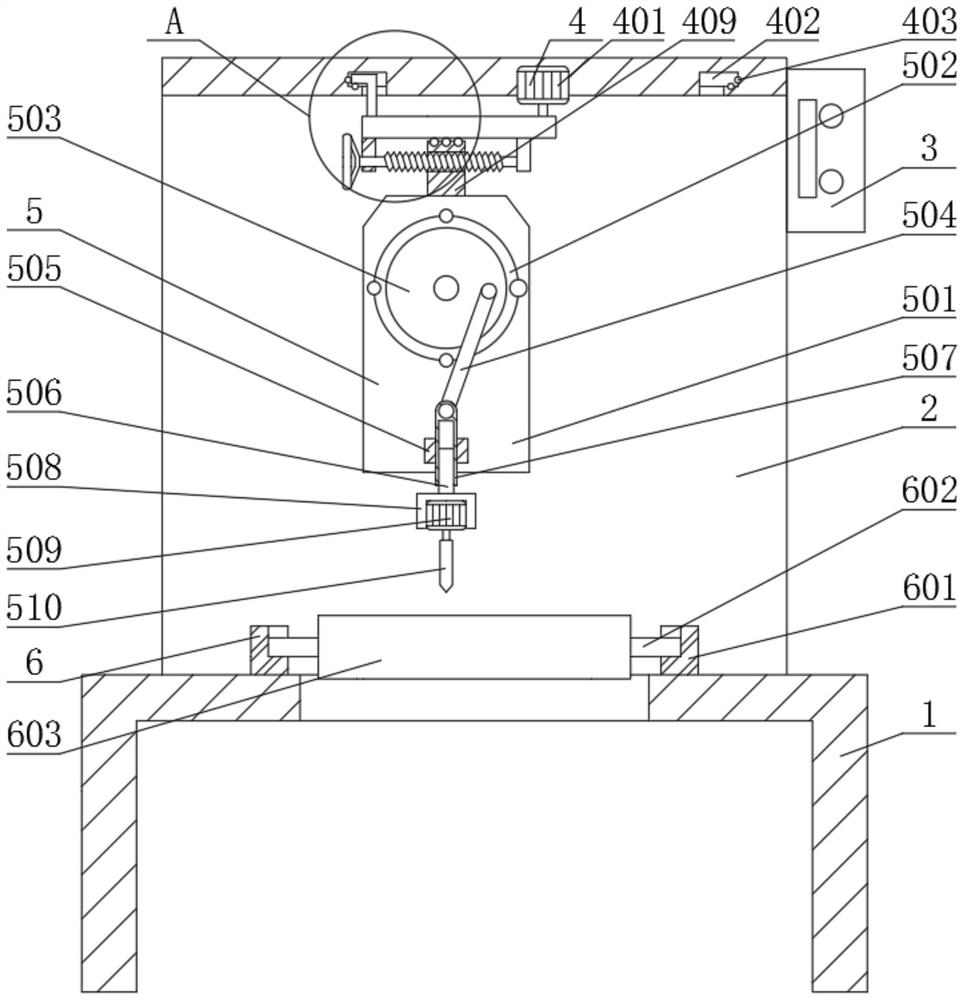

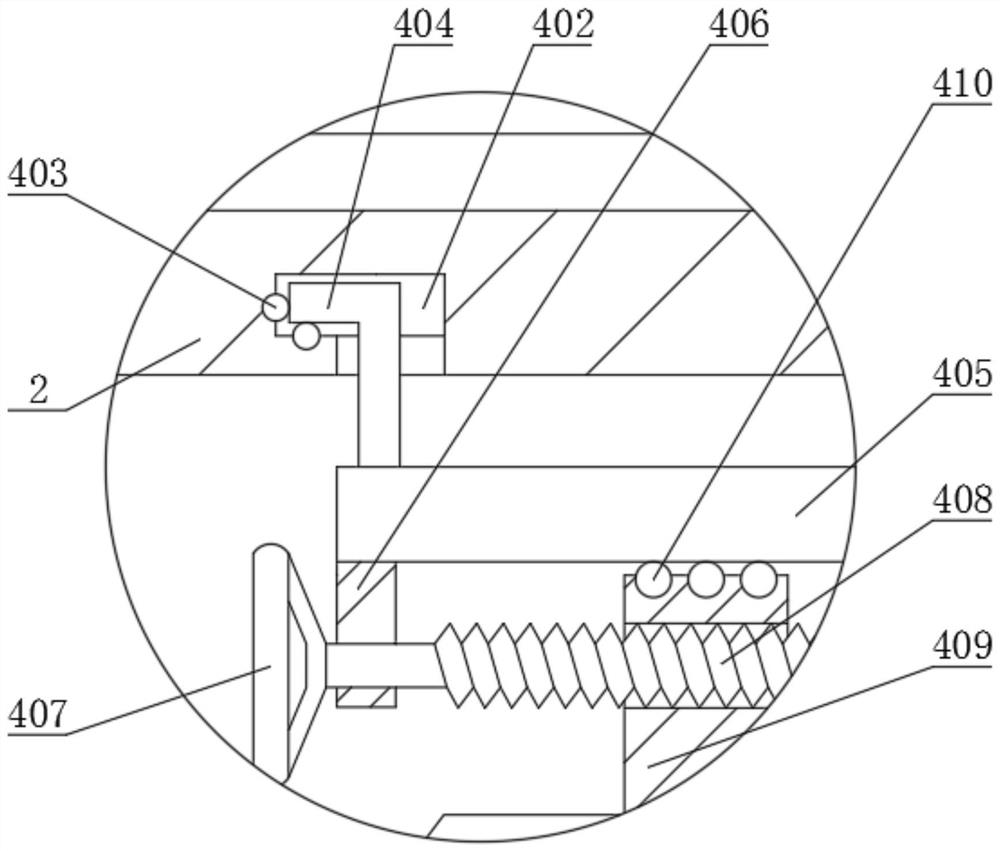

The invention provides a four-needle point welding head device. The four-needle point welding head device comprises a laser alignment mechanism, a position induction mechanism, a fixed base, a welding needle guide mechanism, a pressure adjusting mechanism, a welding needle position adjusting mechanism and a rapid welding needle adjusting mechanism. The fixed base is provided with a point welding head vertical plate with an open hole. The rapid welding needle adjusting mechanism is arranged at the front end of the point welding head vertical plate and provided with a guide through hole. The position induction mechanism is arranged at the back end of the point welding head vertical plate. The laser alignment mechanism is arranged on the fixed base. The welding needle position adjusting mechanism is movably connected with the welding needle guide mechanism. The welding needle guide mechanism is slidably arranged on the rapid welding needle adjusting mechanism. The front end of the pressure adjusting mechanism is fixed to the welding needle guide mechanism, and the tail end of the pressure adjusting mechanism extends to the front end of the position induction mechanism. The four-needle point welding head device has the advantages that the welding efficiency of a welding point can be improved through the point welding head device; the welding quality of the welding point is ensured; and meanwhile, the needle adjusting speed can be greatly increased.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

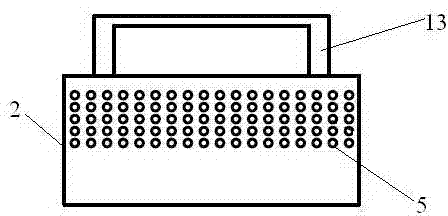

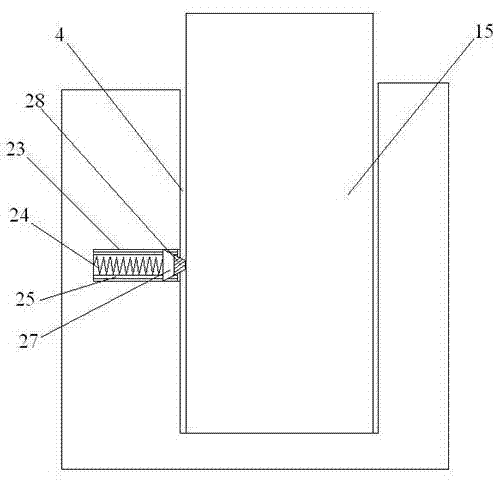

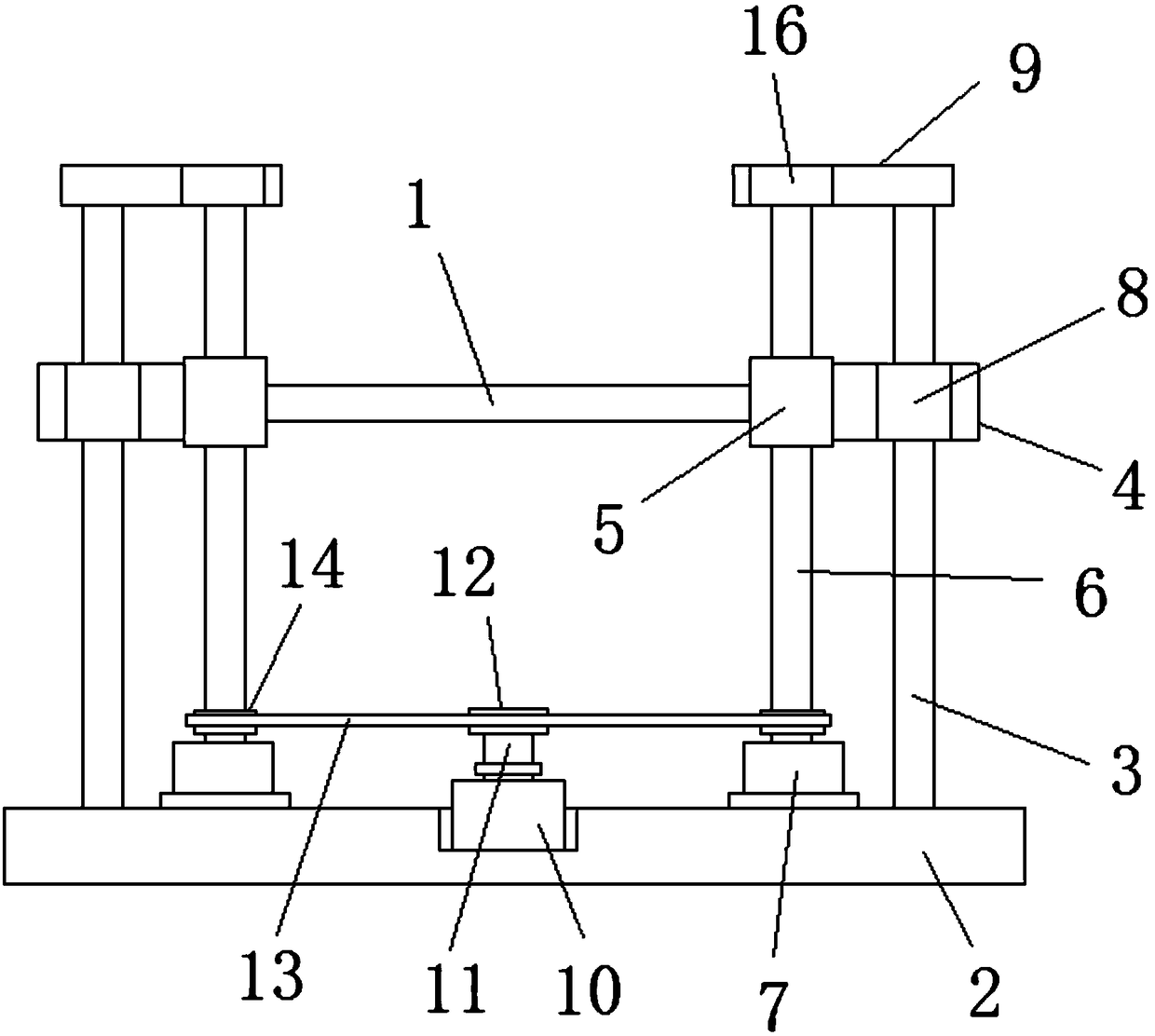

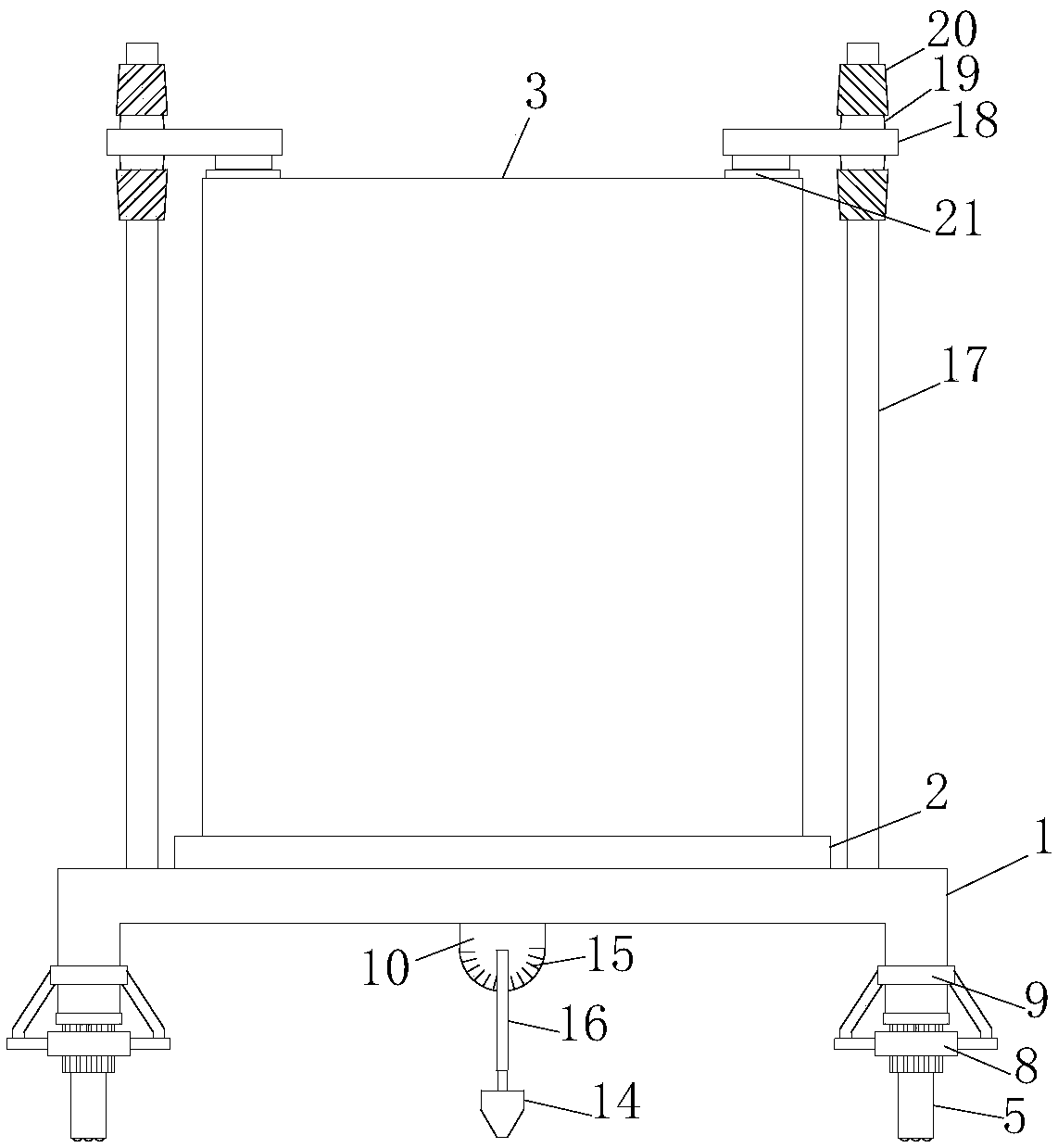

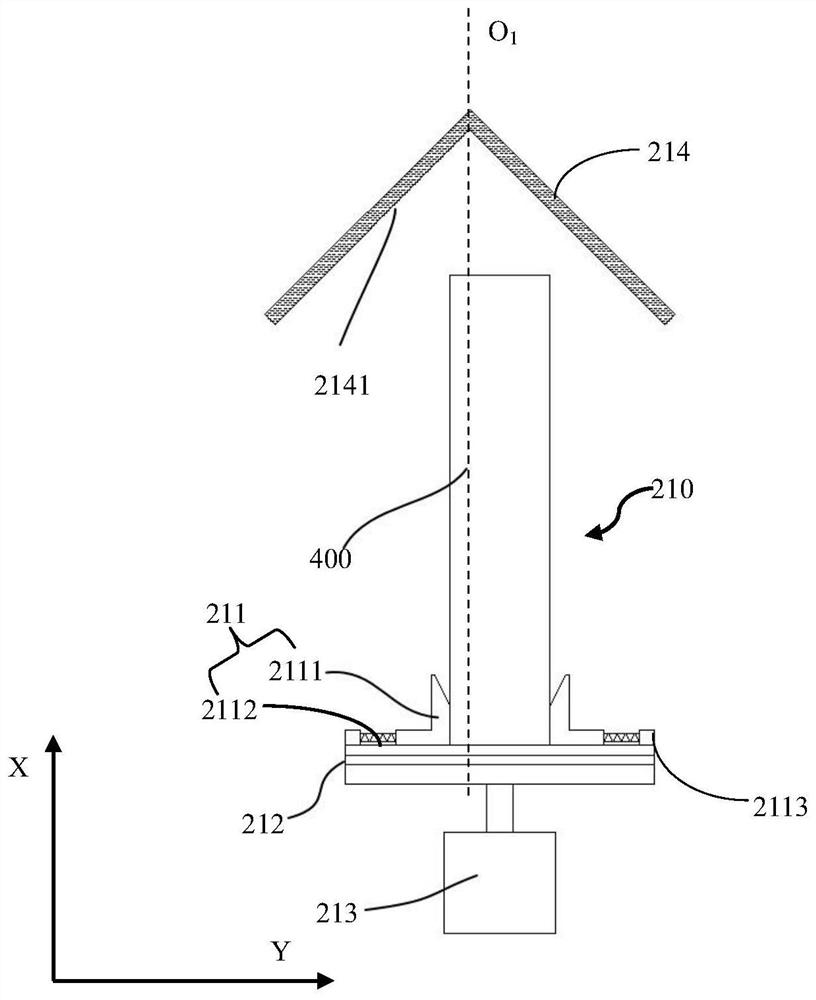

Balance adjusting device for 3D printer

InactiveCN108099199ANo skewingAct as a brakeManufacturing platforms/substrates3d printerMechanization

The invention discloses a balance adjusting device for a 3D printer. The balance adjusting device comprises a printing tray and a supporting platform located below the printing tray, and the two sidesof the printing tray are provided with guiding rods fixedly mounted on the top of the supporting platform; the two guiding rods are vertically arranged, movable seats are slidably mounted on the twoguiding rods, and screw rod sleeves are fixedly welded to the sides, close to each other, of the two movable seats; and the sides, close to each other, of the two screw rod sleeves are fixed and welded to the two sides of the printing tray correspondingly, the position below the printing tray is provided with a mounting groove formed in the top of the supporting platform, and a stepper motor is fixedly mounted in the mounting groove. The balance adjusting device for the 3D printer is simple in structure and high in practicability and mechanization degree, the trouble of manual adjusting of theprinting tray by people is avoided, the situation that people adjust and use the printing tray according to the actual needs is facilitated, the stability of the printing tray after being adjusted isgood, the situation of inclining does not occur, and use demands of people are met.

Owner:金智丽

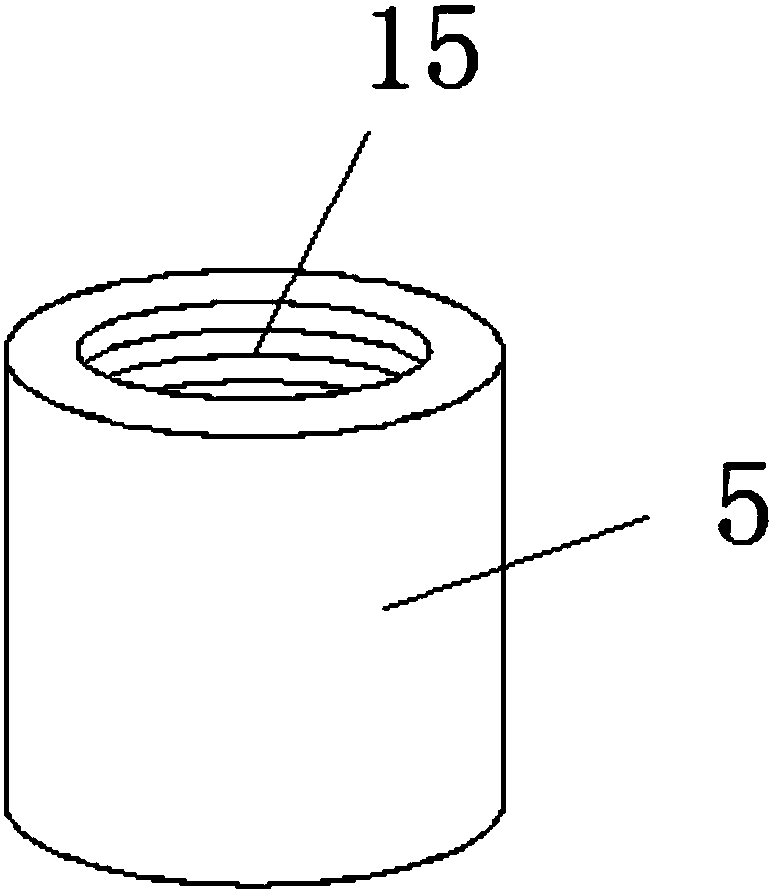

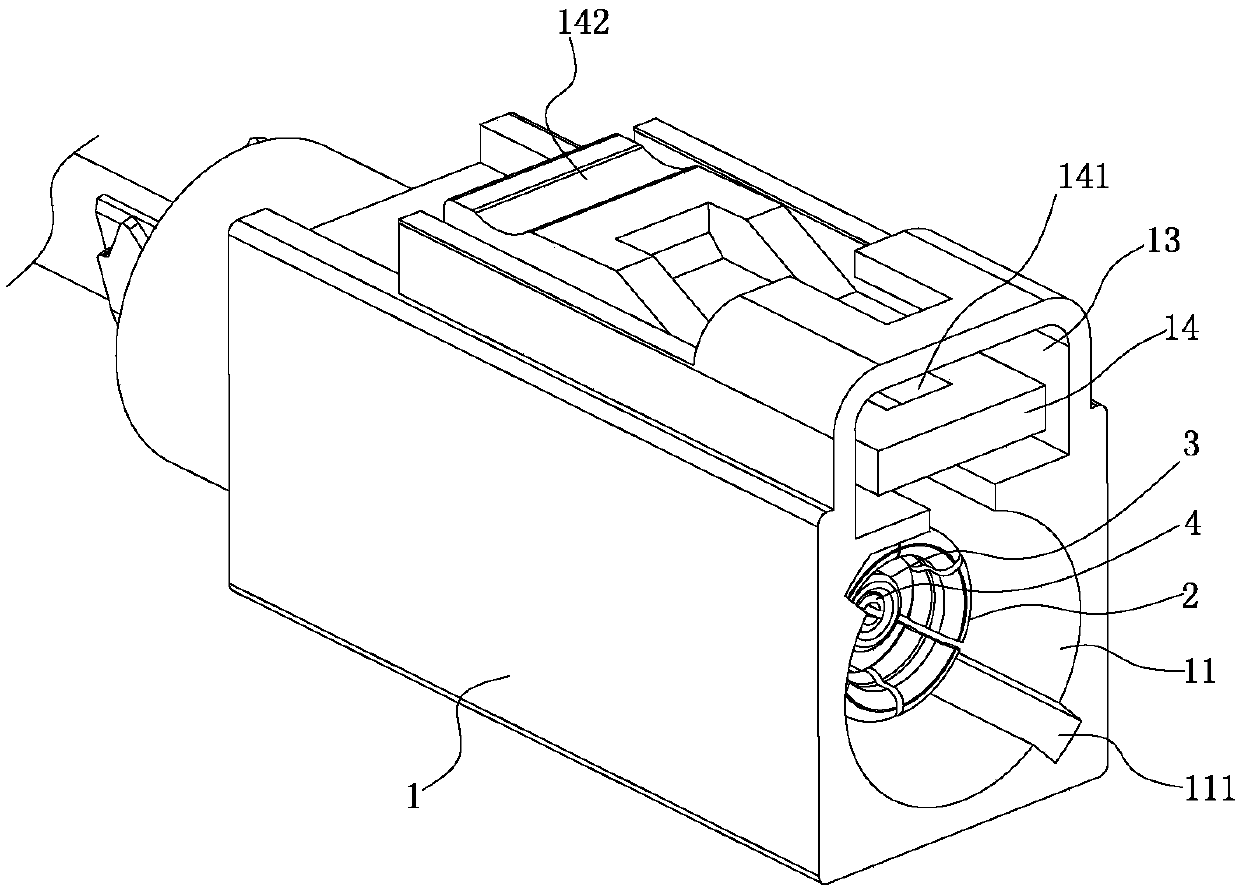

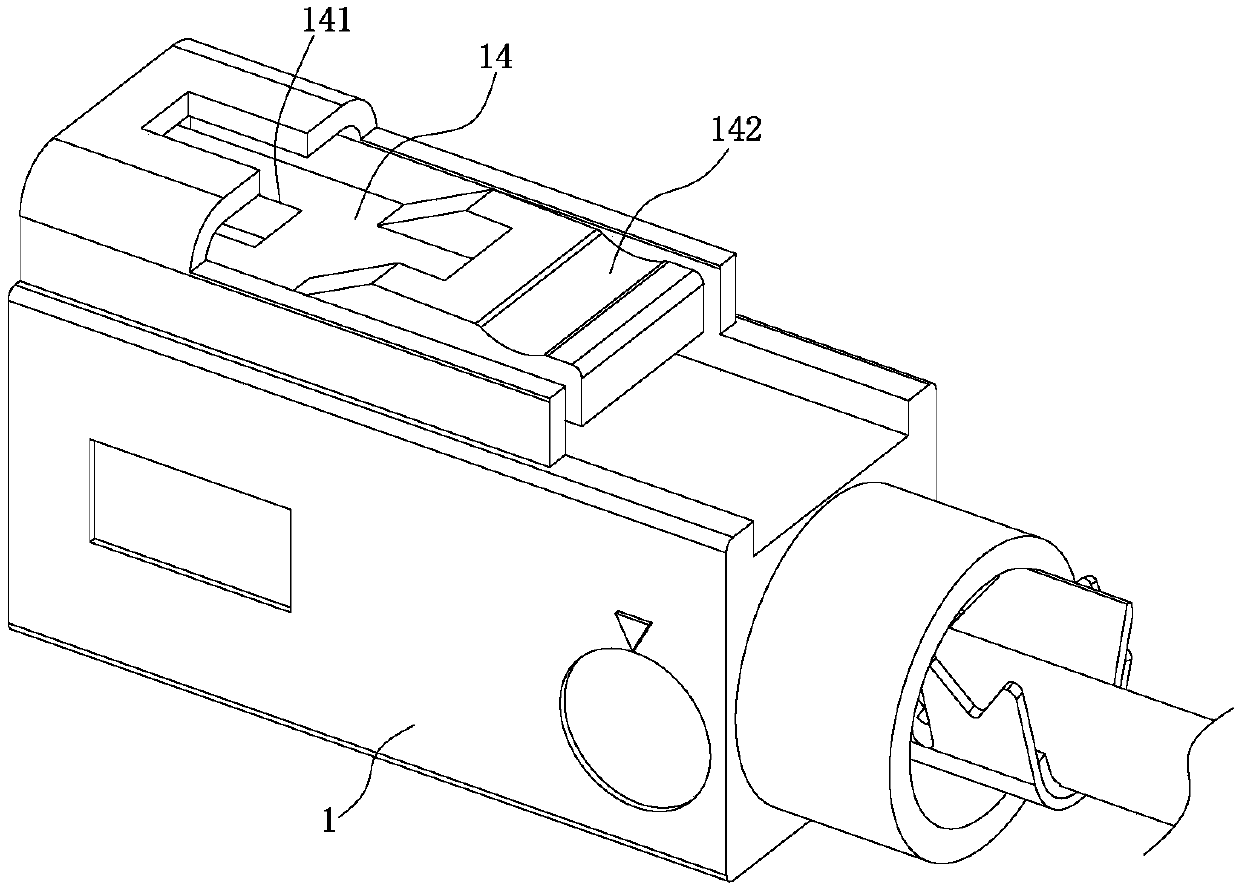

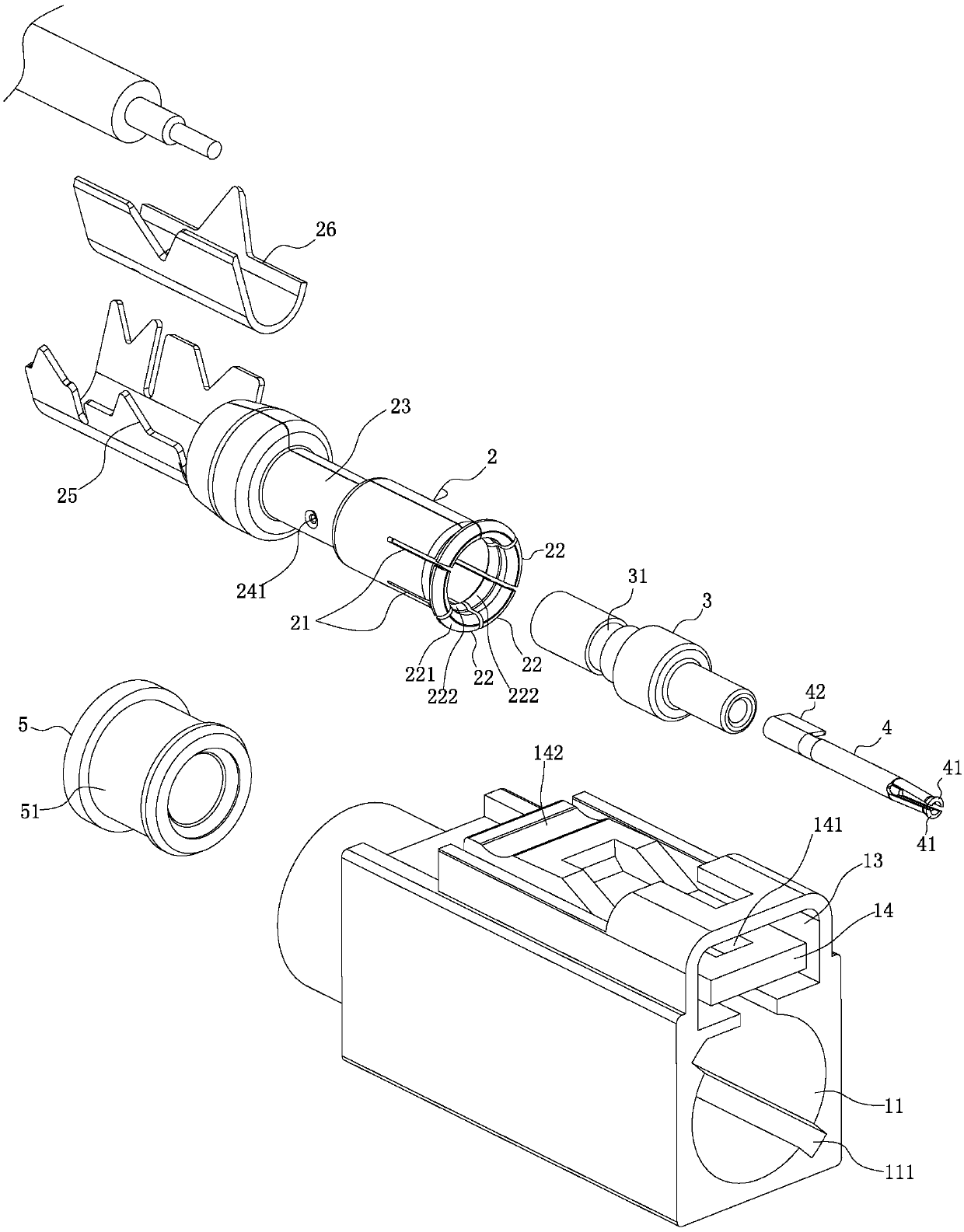

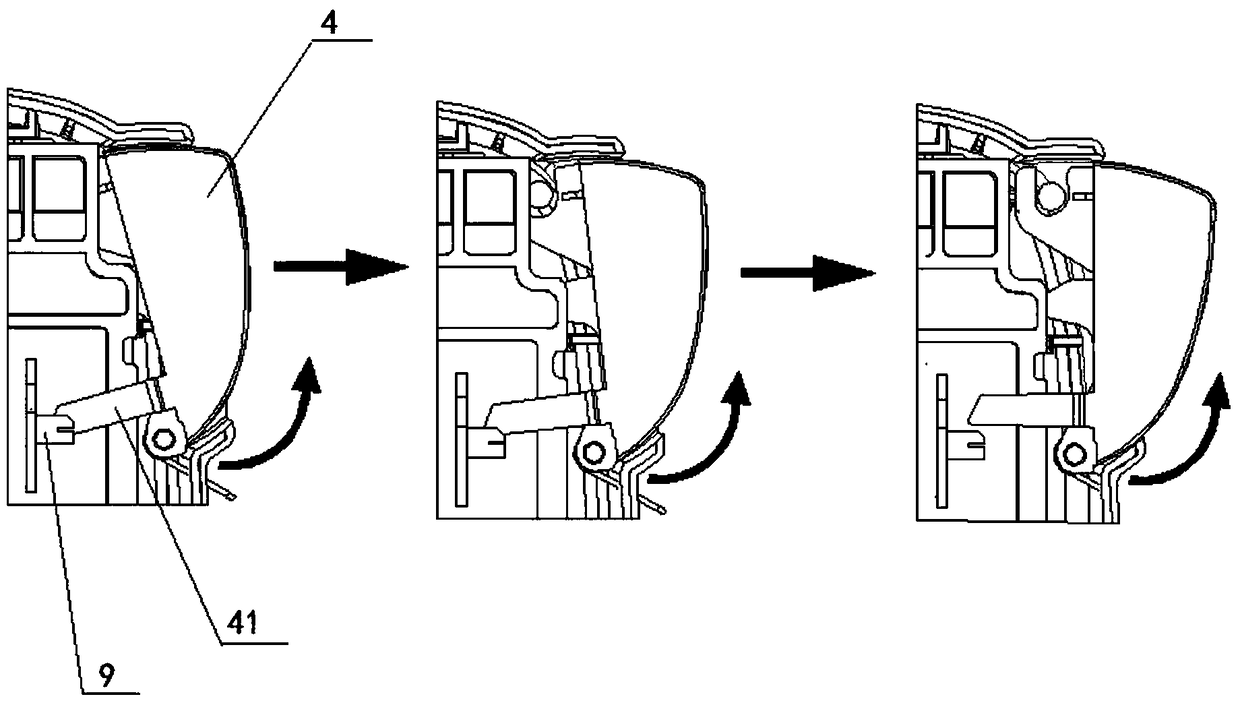

FAKRA connector and manufacturing method thereof

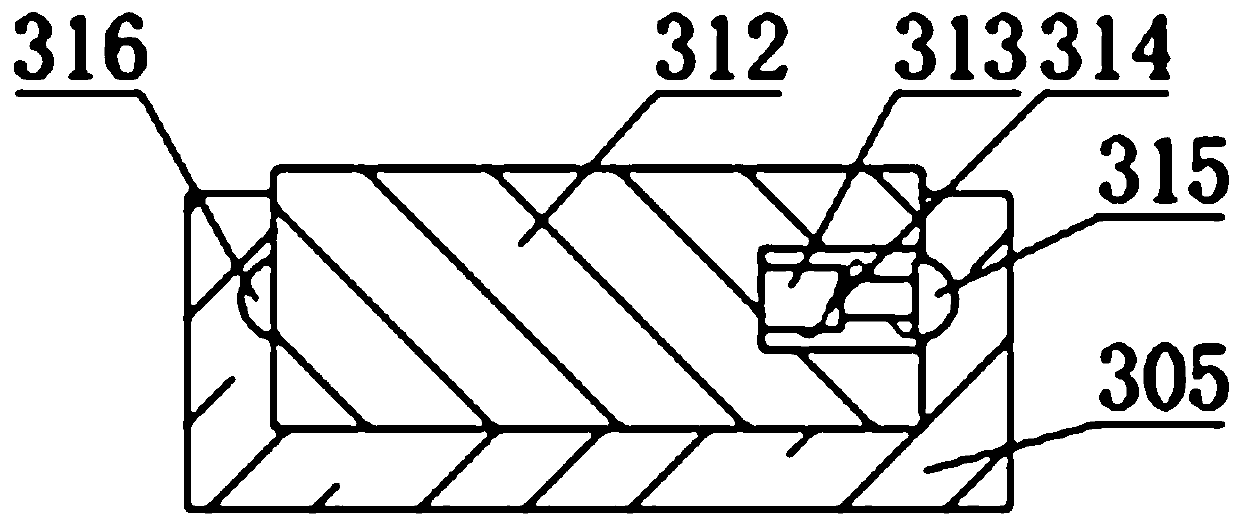

PendingCN109687238ANo skewingImprove stabilityContact member manufacturingContact member cases/bases manufactureEngineeringMechanical engineering

The invention discloses an FAKRA connector and a manufacturing method thereof. The FAKRA connector comprises a plastic seat, a metal shell inserted in the plastic seat, an insulating seat arranged inthe metal shell and a metal terminal arranged in the insulating seat, wherein the metal shell, the insulating seat and the metal terminal are coaxially arranged, and the front ends of the metal shell,the insulating seat and the metal terminal are all exposed in butt holes of the plastic seat; an elastic buckle is formed in the plastic seat, and the elastic buckle comprises a base integrally formed in the plastic seat and an elastic buckle body extending forward along the base and in an inclined state; a positioning ring seat fixedly sleeves the periphery of the metal shell; a first annular positioning groove is formed in the periphery of the positioning ring seat; the elastic buckle is clamped and positioned with the first annular positioning groove, so that the metal shell is fixed in the plastic seat; and the rear end surface of the base and the front end surface of the elastic buckle body are separately in contact with the two inner walls of the first annular positioning groove ina butting mode. The elastic buckle is in contact with the whole annular surface of the positioning ring seat for positioning, so that the structural stability is high, and the metal shell cannot be skewed during use.

Owner:东莞宇典铭通讯科技有限公司

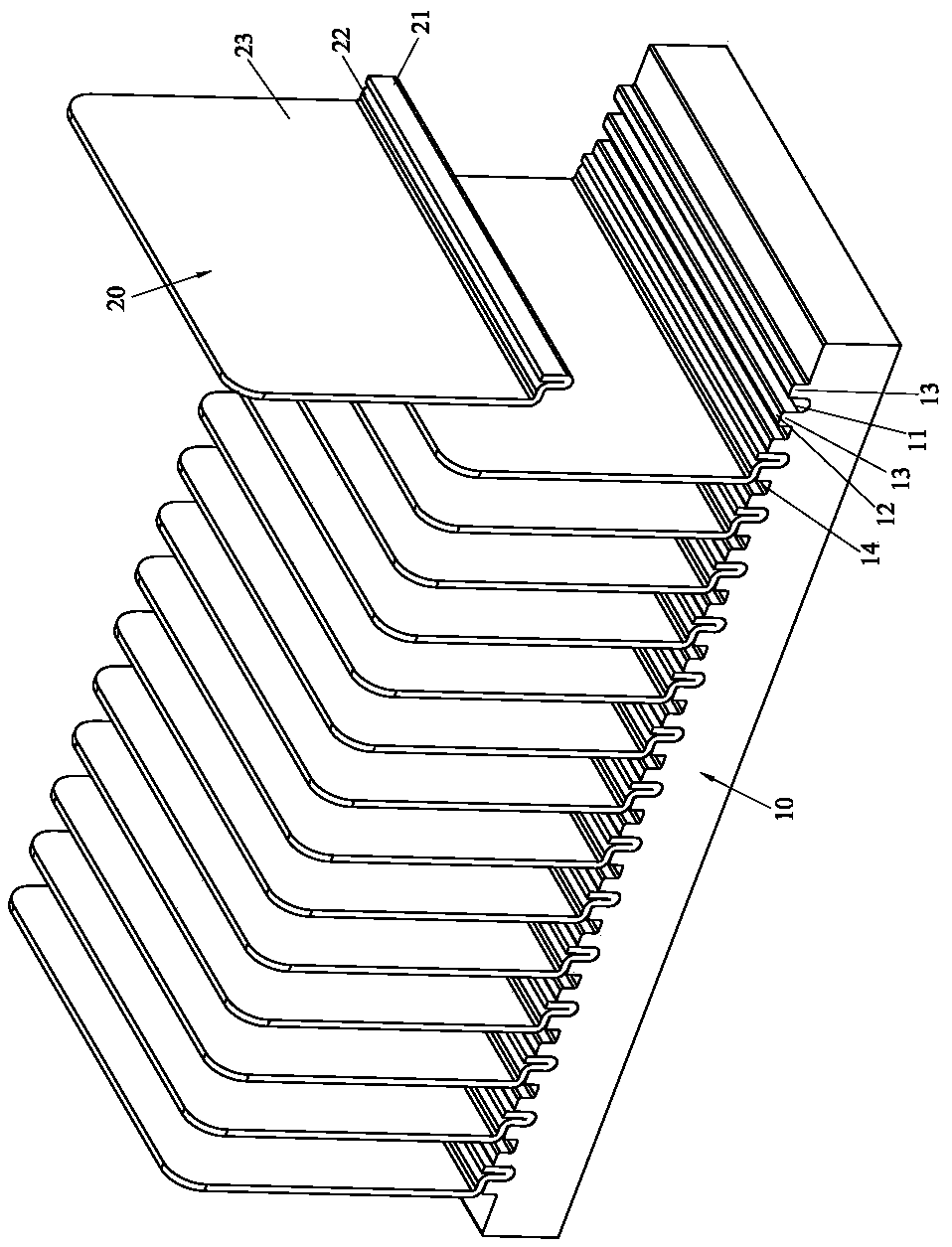

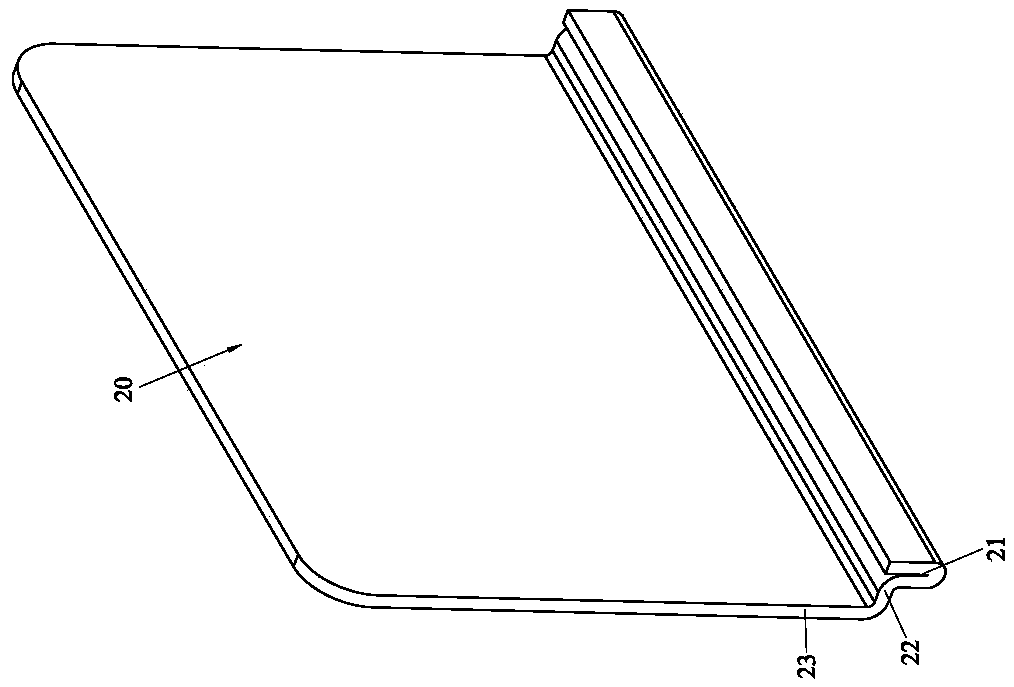

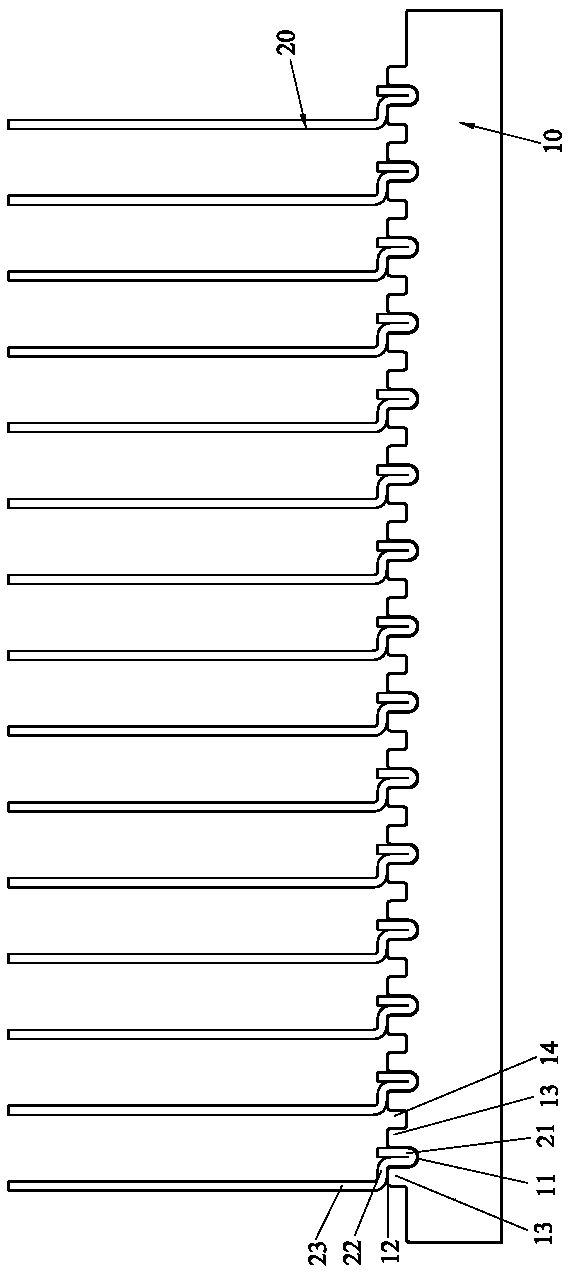

Cooling fin stamping and riveting structure

PendingCN110388845AImprove bindingLower the altitudeHeat exchanger casingsEngineeringMechanical engineering

The invention discloses a cooling fin stamping and riveting structure. The structure comprises a base and cooling fins. Grooves are formed in the surface of the base. At least one sides of openings ofthe grooves are provided with contact surfaces correspondingly. Each cooling fin comprises an implanting portion, a connecting portion and a body portion which are connected together, wherein the implanting portion is of a reflexed structure and embedded into the corresponding groove, and the connecting portion extends to one side relative to the implanting portion and abuts against the corresponding contact surface. By forming the connecting portions on the cooling fins correspondingly and making the connecting portions make contact with the contact surfaces on the base, on the one hand, onesides of the cooling fins can be stably supported, the implanting portions of the reflexed structures are better stressed when being stamped by a stamping punch, the cooling fins are more reliably bonded to the base, the height of the cooling fins is further decreased, bending deformation is not prone to occurring, deflection is avoided, and it is ensured that cooling flow channels formed betweenthe cooling fins are straight; and on the other hand, heat on the base can be directly transmitted to the connecting portions, and the cooling efficiency is effectively improved.

Owner:HUANG TSUNG HSIEN YUAN SHAN HSIANG

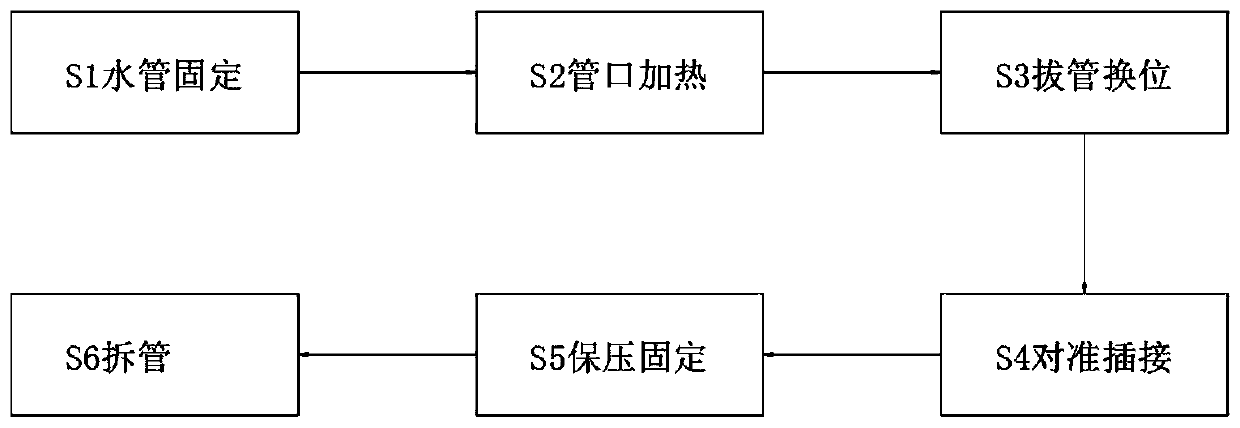

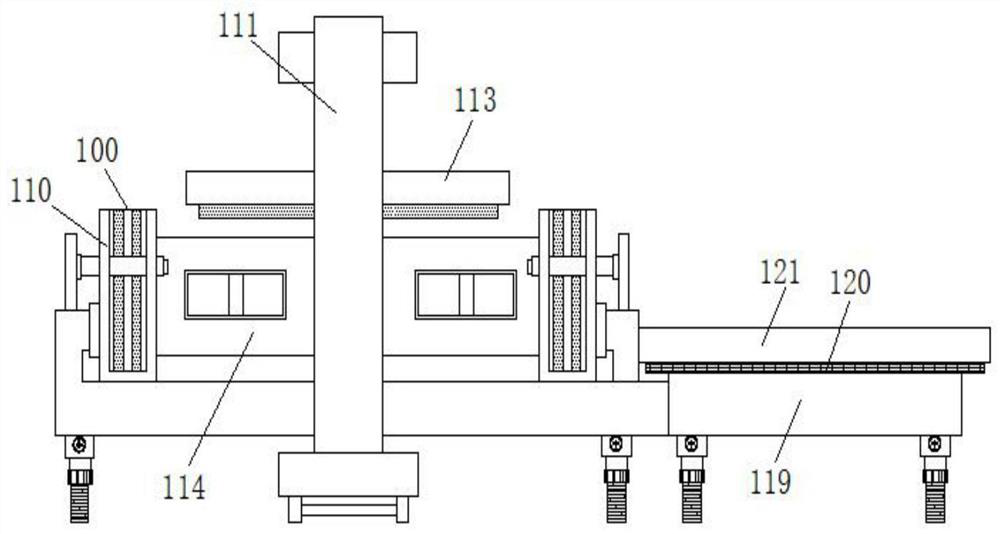

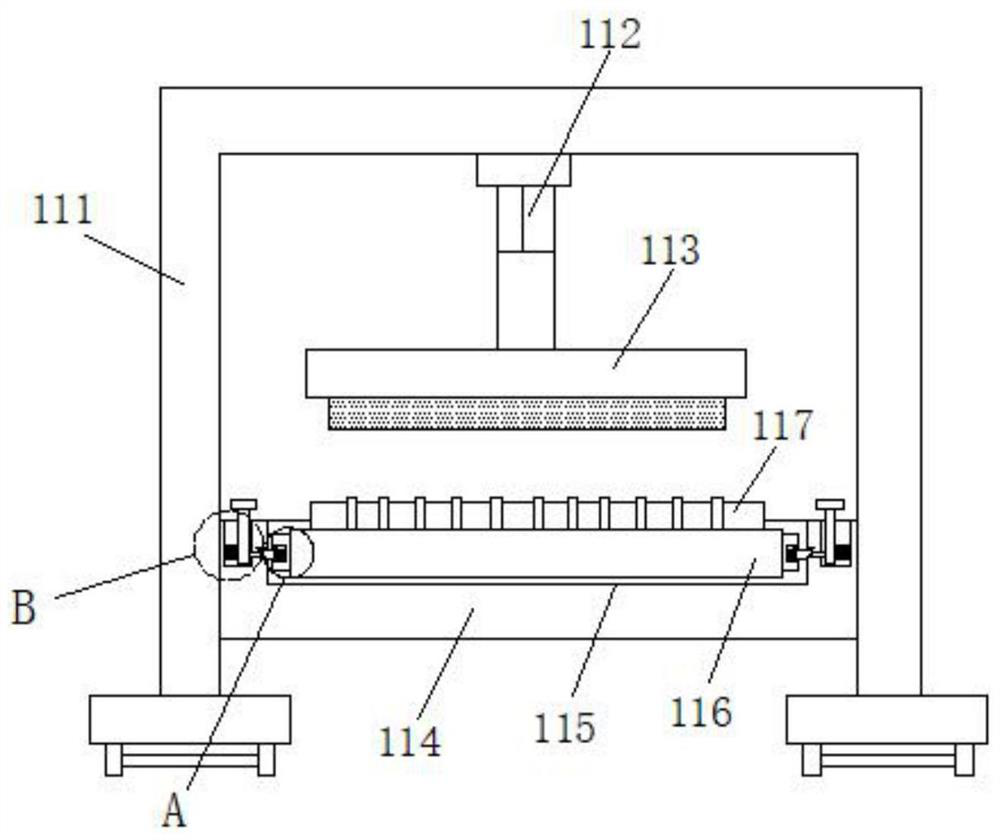

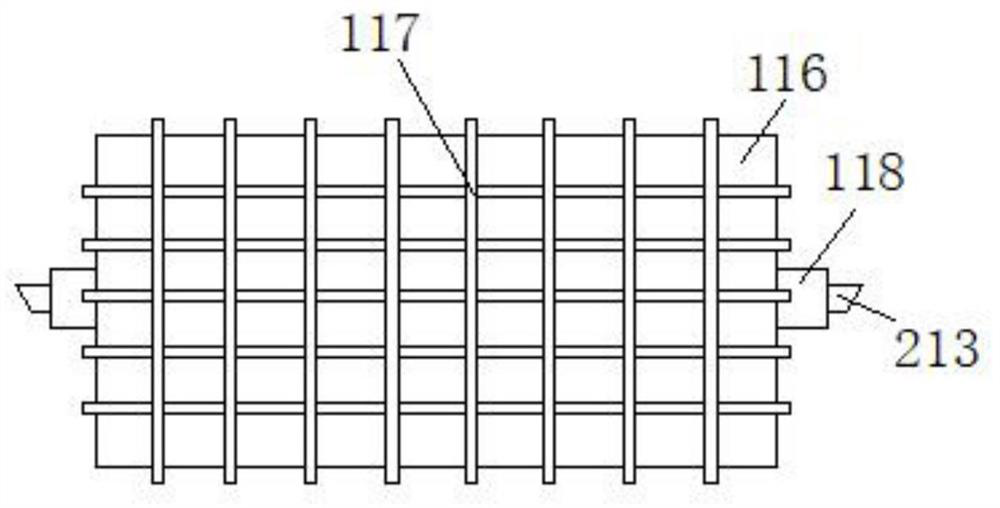

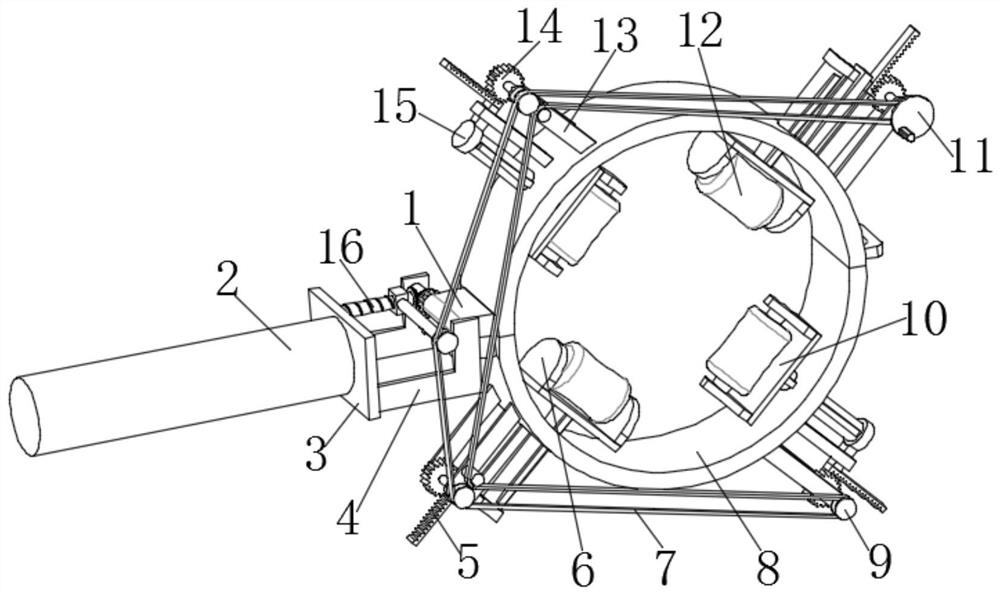

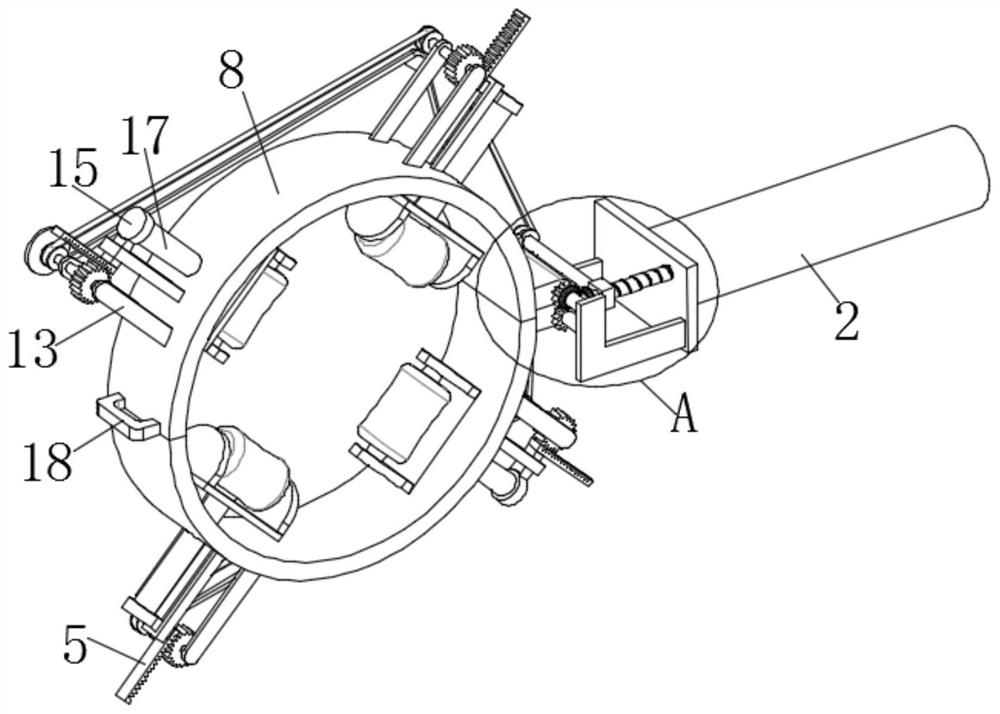

Hot melting connection processing technology for PPR water pipes

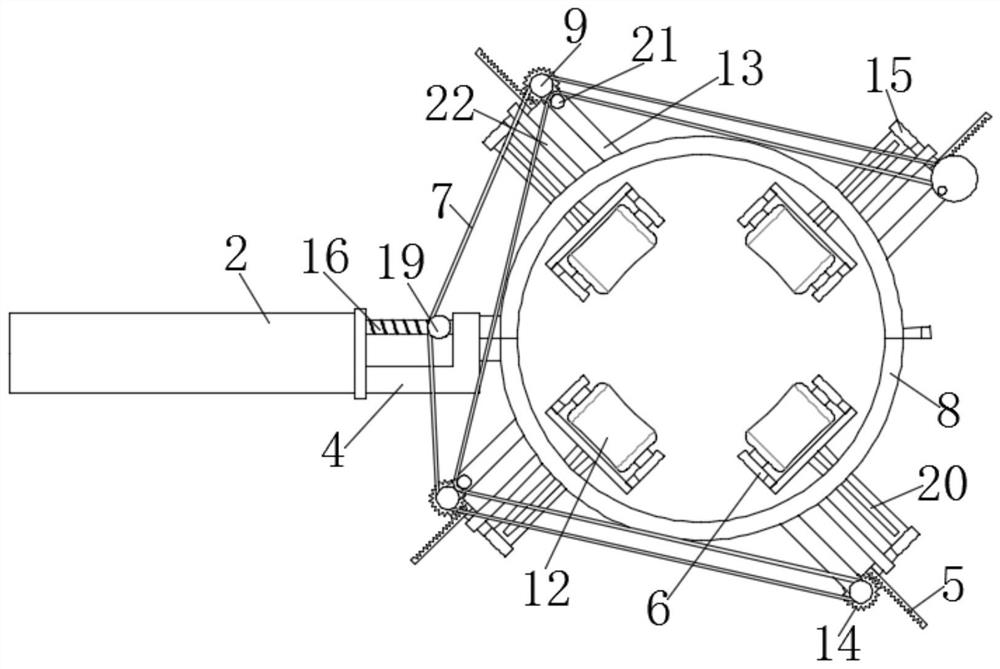

The invention relates to a hot melting connection processing technology for PPR water pipes. The hot melting connection processing technology for the PPR water pipes adopts a following hot melting connection machine, the hot melting connection machine comprises a bottom plate and fixing devices arranged at the top of the bottom plate, wherein the PPR water pipes are fixed to the fixing devices, and a melting connection device is arranged in the middle of the top of the bottom plate. By cooperation of an air cylinder and fixed pulleys, the air cylinder drives two rotating discs to be synchronously close to each other or away from each other, the pipes are fixed in the rotating discs and can move with the same distance simultaneously, a rotating shaft is utilized for driving two incomplete gears to rotate, so that the two rotating discs simultaneously rotate for the same angle, the skewed condition of the pipes during aligned inserting connection is avoided, and the error is smaller as compared with that of manual operation; and the joints of the pipes are subjected to pressure-maintaining fixation by arc-shaped plates, cooling shaping of the pipes are accelerated, furthermore, the shaking or moving condition of the pipes is avoided, and the two pipes can be subjected to hot melting and pressure-maintaining fixation simultaneously respectively by arrangement of multiple stations.

Owner:台州蓝锐机电科技有限公司

LED advertising lamp spliced back plate adjusting mechanism and application method thereof

ActiveCN111438732AThere will be no shakingImprove practicalityMetal working apparatusStructural engineeringCutting tool

The invention relates to the technical field of LED advertising lamps, in particular to an LED advertising lamp spliced back plate adjusting mechanism and an application method thereof. The adjustingmechanism comprises a base and a controller; the controller is fixedly connected with the left end of the base; a fixing adjusting device is fixedly connected with the bottom end of the base; an adjusting device is fixedly connected with the front end of the base; a cutting device is fixedly connected with the bottom end of the adjusting device; and a back plate is arranged on the inner side of the fixing adjusting device. Via the arrangement of a fixed cylinder, a moving cylinder, a clamping rod, a connecting rod, clamping grooves, a push rod, a protecting rack and a cutting tool, operators can adjust the position of the cutting tool in the vertical direction based on actual situation of use, so complete cutting of the back plate by the cutting tool is guaranteed and dimension adjustmentof the back plate is thereby completed; and furthermore, via mutual buckling of the clamping rod and the fixed cylinder, operators can conveniently adjust the position of the cutting tool in the vertical direction, and use of the mechanism is convenient.

Owner:漳州市蓝威网络科技有限公司

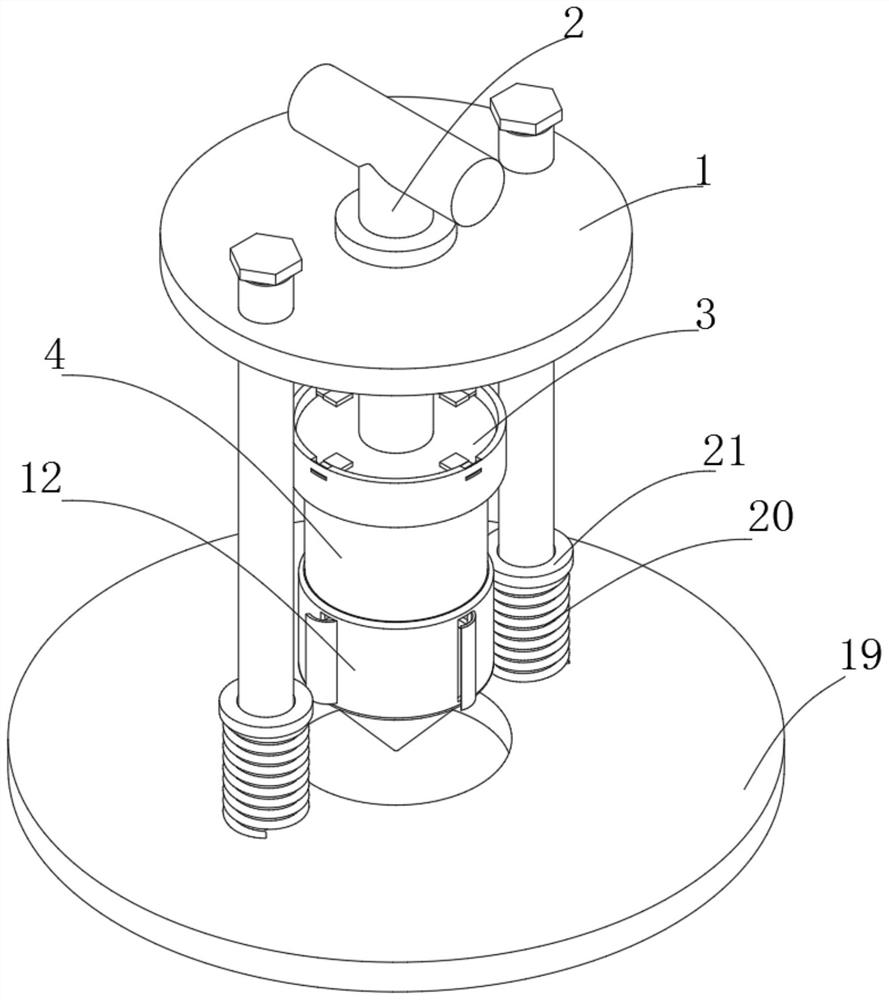

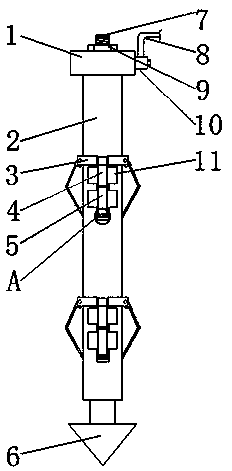

Soil sampling device for roadbed compactness detection based on engineering supervision

InactiveCN112557086AEasy to fixNo skewingWithdrawing sample devicesEarth material testingAgricultural engineeringStructural engineering

The invention discloses a soil sampling device for roadbed compactness detection based on engineering supervision. A rotating rod is rotatably connected to the top end of a supporting plate, a clamping block is fixedly connected to the bottom end of the rotating rod, a fixed cylinder is clamped to the bottom end of the clamping block, and a connecting plate is fixedly connected to the top of the outer end of the fixed cylinder; sliding grooves are formed in the inner wall of the connecting plate at equal intervals, embedding holes are formed in the bottoms of the inner walls of the sliding grooves, and storage blocks are fixedly connected to the top end of the clamping block at equal intervals; the structure is provided with the clamping blocks, the sliding grooves, the embedding holes, telescopic springs and sliding blocks; through cooperation of the sliding grooves and the telescopic springs, the sliding blocks are shrunk in the storage blocks under the action of the telescopic springs; and when the clamping block is clamped at the top end of the fixed cylinder, the sliding blocks are clamped in the embedding holes through the acting force of the telescopic springs again, so thatthe fixed cylinder is convenient to install and fix, and the phenomenon of inclination does not occur in the soil sampling process.

Owner:安徽家思特涂料有限责任公司

Automobile cylinder cover feeding and discharging device

InactiveCN108974917ARealize automatic feeding processNo manual operationConveyor partsEngineeringAssembly line

The invention discloses an automobile cylinder cover feeding and discharging device and belongs to the field of machine manufacturing. The automobile cylinder cover feeding and discharging device comprises a mounting frame, a rodless air cylinder, a connecting rod and a conveying gripper, wherein the conveying gripper comprises a push rod and a discharging rod, the discharging rod is arranged at the top of a mounting plate, and the push rod is arranged under the mounting plate. The automobile cylinder cover feeding and discharging device can be matched with an assembly line to achieve automatic feeding and discharging, save manual operation and achieve high safety.

Owner:北京宏远鑫瑞科技有限公司

Manual label making machine with continuous printing function

PendingCN109227703AControlled start and stopRealize no blank printingTypewritersMetal working apparatusPulp and paper industryPaper sheet

The invention discloses a manual label making machine with a continuous printing function. The manual label making machine comprises a housing, a full cutting button is installed on the housing, the full cutting button is connected with a full cutting knife assembly, an extension arm is connected to the full cutting button, and a photoelectric detection switch area is arranged in the housing; whenthe full cutting button is pressed to start label paper cutting, the extension arm enters the photoelectric detection switch area under the driving of the full cutting button; when the full cutting button resets after label paper cutting, the extension arm leaves the photoelectric detection switch area under the driving of the full cutting button. In the manual label making machine, through the cooperation of the extension arm arranged on the full cutting button and the photoelectric detection switch area, start and stop of a paper feeding mechanism and a printing head of the label marking machine can be controlled according to signals sent when the extension arm enters and exits from the photoelectric detection switch area, then, the label marking machine can perform printing without blanks, and the waste of the label paper can be reduced. Besides, through structural improvement on the full cutting knife assembly, cutting is facilitated, the phenomena of skew, deckle edges and the like of cuts of the label paper do not occur easily, and the manual label making machine is suitable for application and popularization.

Owner:BEIJING SUPVAN ELECTRONIC TECH CO LTD

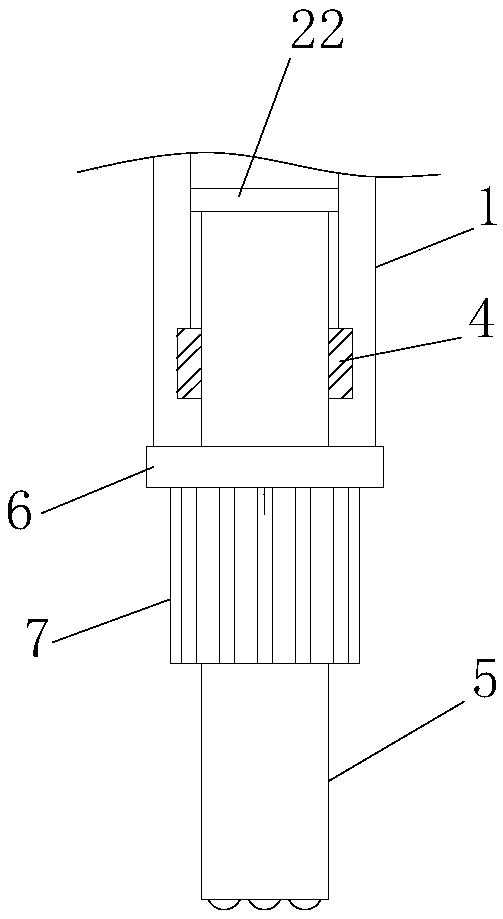

Fixing installation device of village and town river channel water processing equipment

The invention discloses a fixing installation device of village and town river channel water processing equipment. The fixing installation device of the village and town river channel water processingequipment comprises a base. A clamping seat is welded to the top of the base, a water processing equipment body is connected to the top of the clamping seat in a clamping mode, first gear sleeves aremounted on the left and right sides of an inner cavity of the base, and adjusting columns are mounted in the first gear sleeves in a threaded mode. A gear ring is mounted at the bottom of the base, athreaded sleeve with an external thread is movably mounted at the bottom of the gear ring, an inner side of the threaded sleeve is connected to the outer walls of the adjusting columns in a threadedmode, a bearing end cover is connected to the outside of the threaded sleeve in a sleeving mode, a fixing frame is connected to the outside of the bearing end cover in a welding mode, and the top of the fixing frame is connected to the outside of the base in a sleeving mode. According to the fixing installation device of the village and town river channel water processing equipment, a height adjusting mechanism is arranged to properly install the water processing equipment body on the steep and rough river channel, so that a skewing phenomenon of the water processing equipment body cannot occur, and thus the later normal operation of the water processing equipment body is guaranteed.

Owner:绍兴嘉越纺织机械有限公司

Electric bicycle cushion convenient to disassemble

InactiveCN108146547AEasy to disassembleImprove structural stabilityCycle saddlesMechanical engineeringStructural stability

The invention discloses an electric bicycle cushion convenient to disassemble, and relates to the technical field of bicycle accessories. The electric bicycle cushion convenient to disassemble comprises a cushion body. The bottom portion of the cushion body is fixedly connected with a fixing block. Sliding grooves are formed in the bottom portions of both sides of the fixing block. A spring is arranged in the fixing block. One end of the spring is fixedly connected with a clamping block. Both sides of the clamping block are provided with fixing pieces. The clamping block penetrates through thebottom portion of the fixing block and extends to the outside of the fixing block. The bottom portion of the fixing block is fixedly connected with a vehicle rod. Sliding blocks are connected with the sliding grooves in a sleeved mode, and the clamping block is arranged in a through hole in a clamping mode, so that the structure stability of the whole electric bicycle is effectively improved. A first stable block and a second stable block are arranged at the right angle position of a press block and an inner wall of a control box, it is effectively guaranteed that the press block cannot appear skew in the process of being pressed into the control box.

Owner:无锡永锋科技有限公司

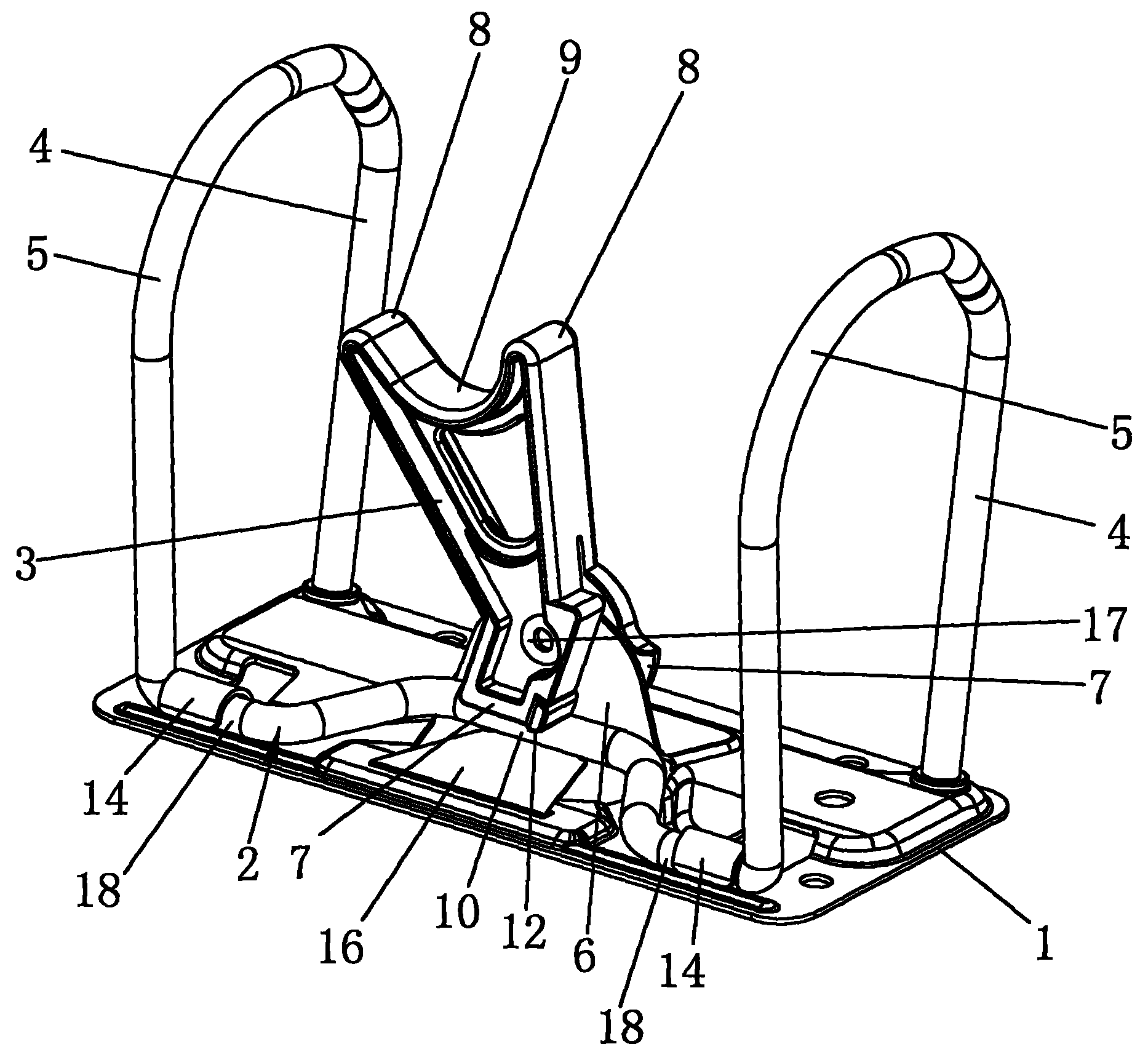

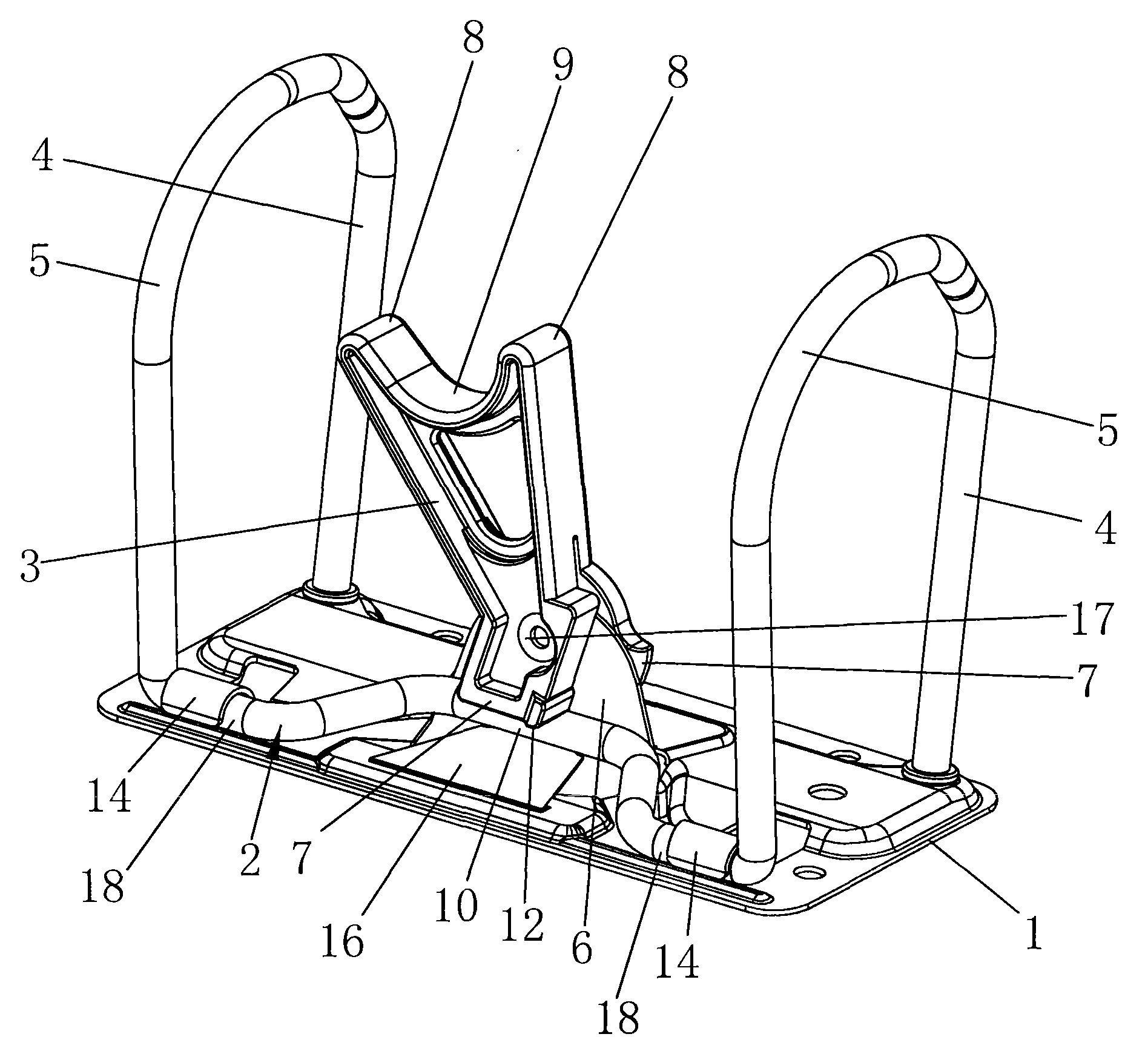

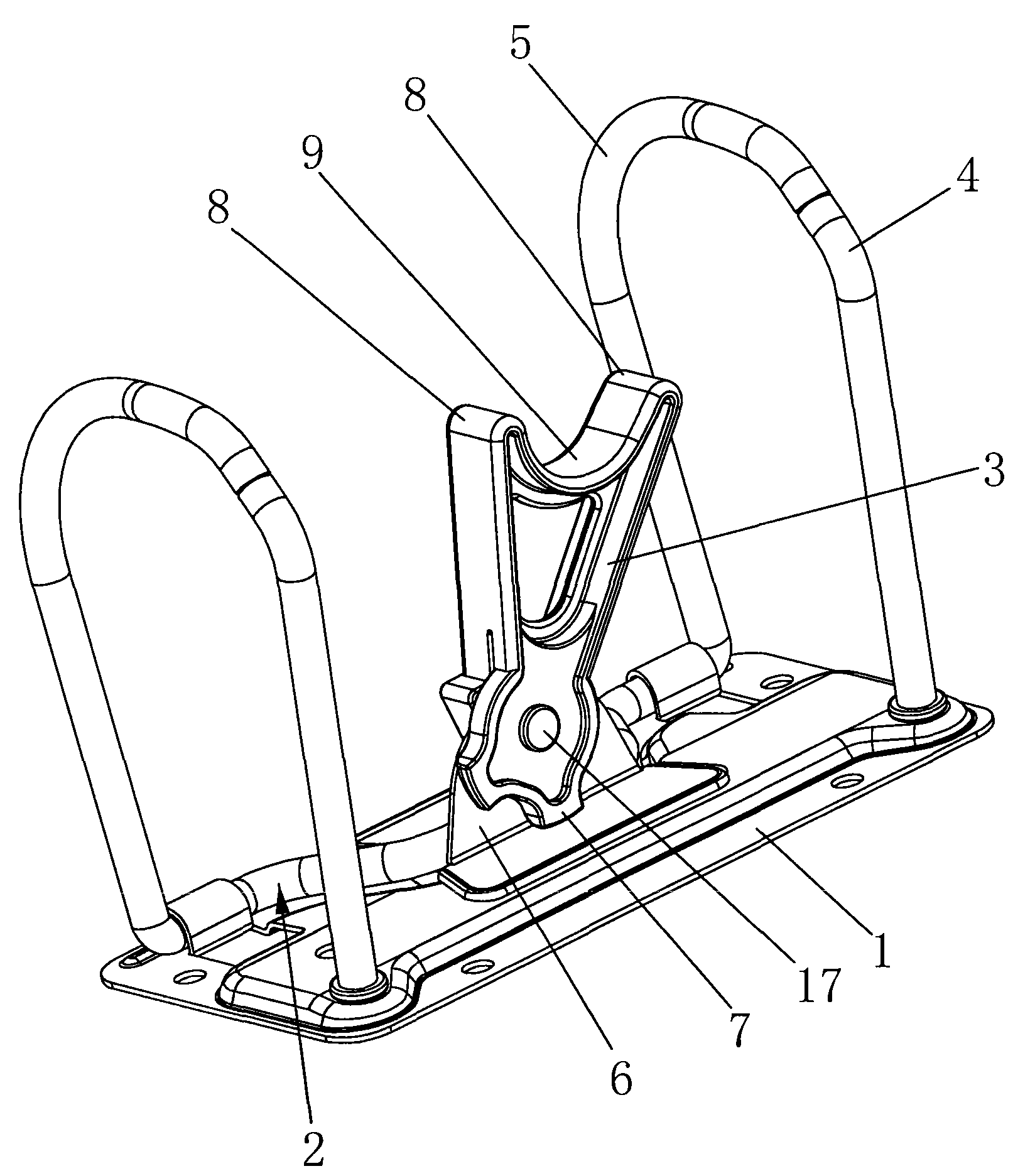

File folder with Y-fork handle

The invention relates to the technical field of file folders, in particular to a file folder with a Y-fork handle. The upper end of the handle is an operating end; the lower end of the handle is provided with two supporting legs which are used for butting against a hook bracket and a bottom plate; the two supporting legs are respectively clamped at the outer side of a middle ear; the two supporting legs of the handle are hinged on the middle ear of the bottom plate by a same hinge hole; as the operating end of the handle is arranged at the upper end, the handle is limited to move in the range of a sector above the hinge hole; the finger of a user does not press the bottom plate and components above the bottom plate so as to be safer and more reliable when opening and closing the folder and be more convenient for operation; besides, in the processing of opening and closing the folding, the handle and the two sides of the middle ear are stressed equally; the handle and the middle ear do not incline; the file folder can still obtain enough locking and clamping force under the condition that the material used for the bottom plate is thinner; and the file folder is not easy to damage, thus the purposes for saving materials and reducing production cost and prolonging the service life of the file folder are achieved.

Owner:林春海

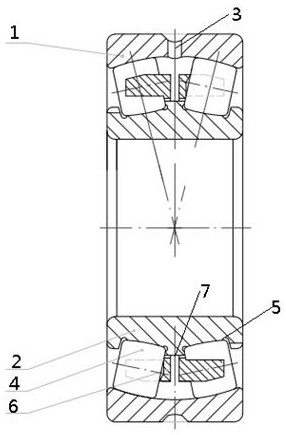

Vibrating screen self-aligning roller bearing

InactiveCN111911528AEnsure adequate lubricationNo high temperatureRoller bearingsBearing componentsClassical mechanicsEngineering

The invention discloses a vibrating screen self-aligning roller bearing and belongs to the field of mechanical equipment. The vibrating screen self-aligning roller bearing comprises an outer ring andan inner ring positioned inside the outer ring. A double-row rolling device is arranged between the outer ring and the inner ring, double-row roller ways are arranged on the inner ring, and a bulge, between the double-row roller ways, on the inner ring is a high guide pitch diameter. The double-row rolling device comprises a double-row rolling body and a double-row retainer used for supporting thedouble-row rolling body, and the double-row rolling body is placed on the double-row roller ways and moves on the double-row roller ways. The double-row roller ways and the roller double-guide retainer are adopted, the double-row roller ways are adopted for guiding, locking sintering damage to the bearing due to the fact that the retainer and the rolling body are clamped under the impact load isgreatly reduced, due to the fact that the double-row retainer is adopted, mutual interference of the retainer is avoided in the rotating process, and the rolling body and the retainer cannot be clamped due to part of dust. The service life of the bearing is prolonged, and the production efficiency is improved.

Owner:山东华工轴承有限公司

Baking production line with cutting mechanism and for biscuit production

InactiveCN111955505AEasy to install and disassembleEasy to replaceDough shaping and cutting apparatusDough processingManufacturing lineIndustrial engineering

The invention relates to the technical field of biscuits, in particular to a baking production line used for biscuit production and provided with a cutting mechanism, the baking production line comprises a production line body, the production line body comprises a first bearing table, a first placement groove is formed in the top end of the first bearing table, and a cutter base is installed at the top end of the first placement groove; a cross cutter is fixedly installed at the top end of the cutter base, connecting blocks are fixedly installed on the two sides of the cutter base, a fixing mechanism is installed on one sides of the connecting blocks and comprises a first groove, the first groove is formed in one sides of the connecting blocks, a first spring is fixedly connected into thefirst groove, and a second spring is fixedly connected into the second groove. A limiting block is fixedly installed at one end of each first spring, and limiting grooves are formed in the two sides of the interior of each first containing groove. Through the arrangement of the fixing mechanism, workers can conveniently replace cross cutters in different shapes, the production line body can produce biscuits in different shapes, and the use limitation is reduced.

Owner:湖南嘉士利食品有限公司

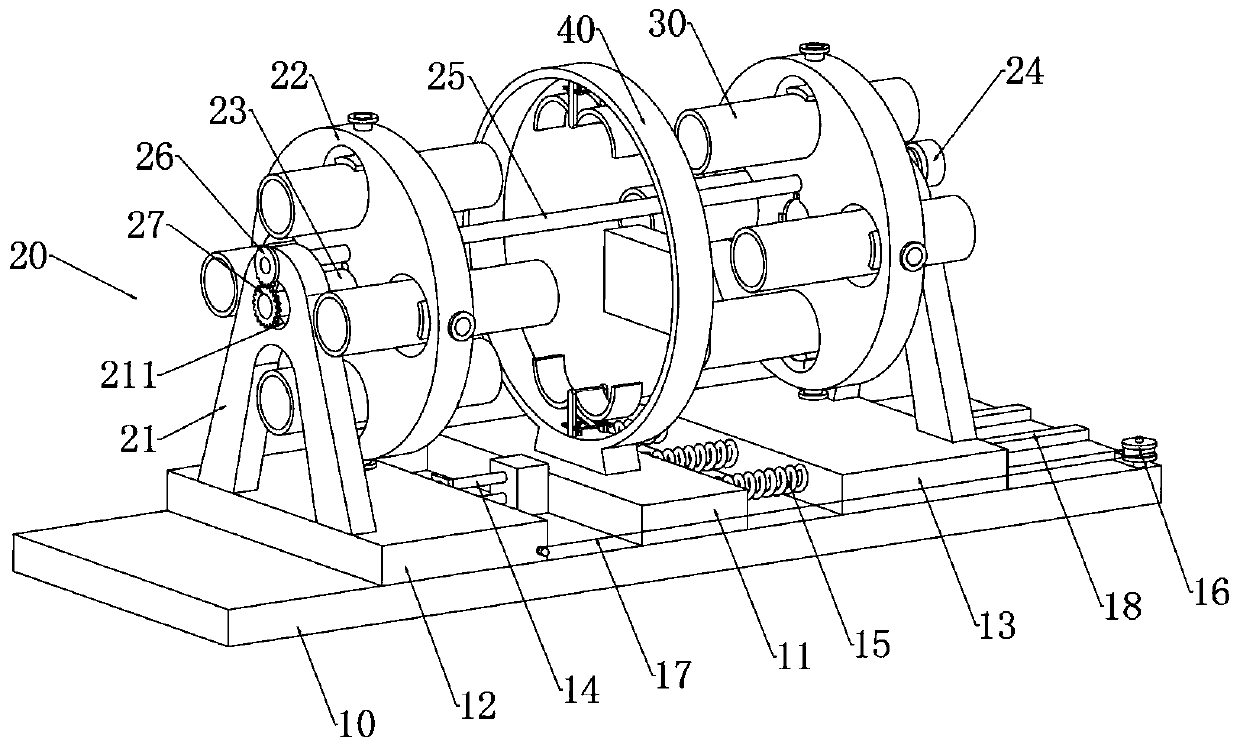

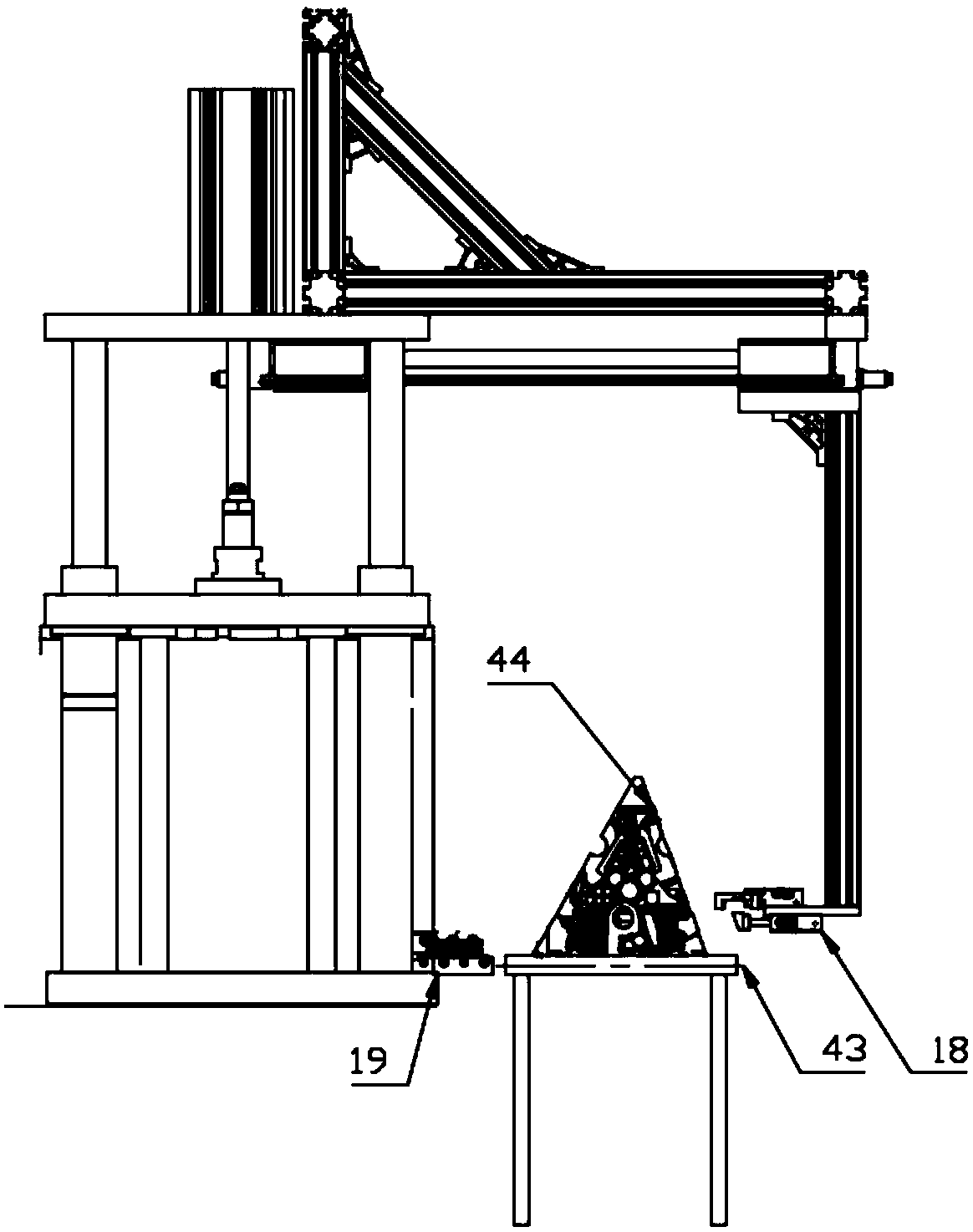

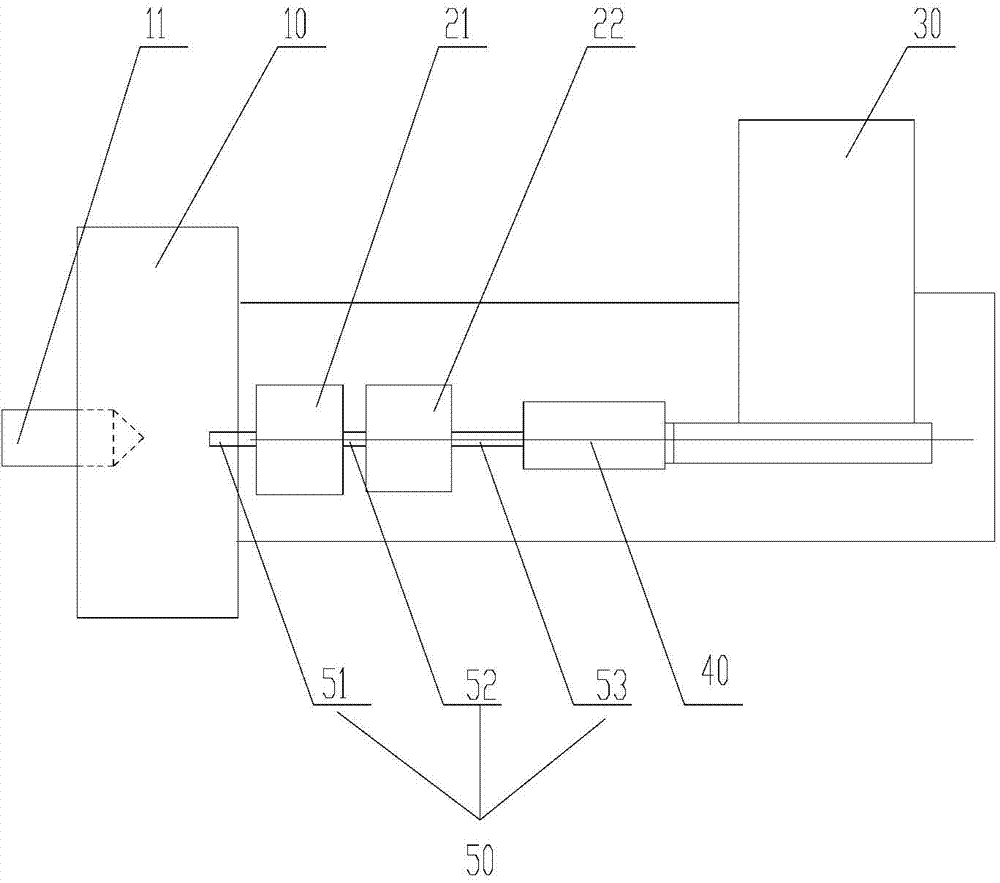

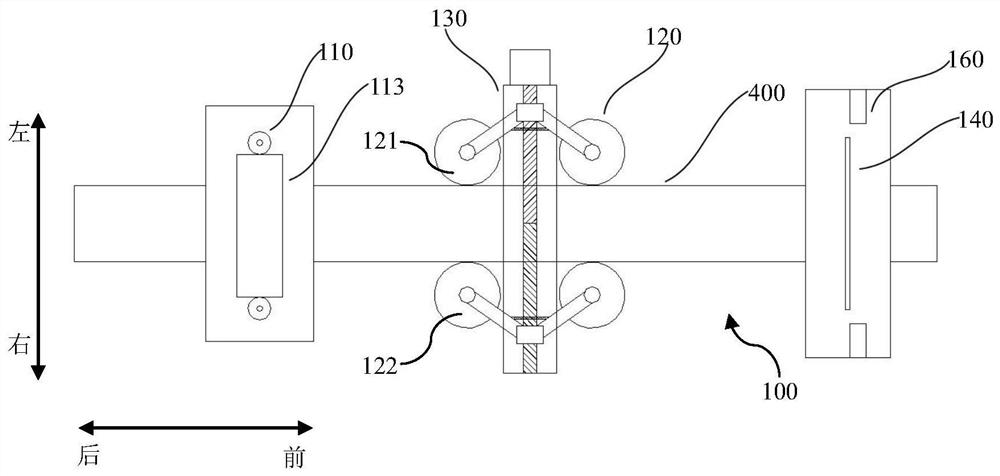

Equipment and technology for preparing metal powder

InactiveCN102528064ASolve the problem of low yieldSolve the problem of low powder yieldMetal powderMechanical engineering

The invention provides equipment and technology for preparing metal powder, which are used for atomizing a raw material rod into metal powder. The equipment for preparing metal powder comprises a driving mechanism for driving the raw material rod to rotate, wherein the driving mechanism comprises a motor of the driving mechanism, a driving roll of the driving mechanism and a driven roll of the driving mechanism; the driving roll of the driving mechanism is connected to the motor of the driving mechanism; the driven roll of the driving mechanism is used for pressing the raw material rod; a clamping space for clamping the raw material rod is arranged between the driving roll of the driving mechanism and the driven roll of the driving mechanism; the driving roll of the driving mechanism and the driven roll of the driving mechanism clamp the raw material rod to rotate; and the diameter of the driving roll of the driving mechanism is more than 2 times that of the raw material rod. According to the technology, the driving roll of the driving mechanism and the driven roll of the driving mechanism clamp the raw material rods to rotate so that the rotating speed of the raw material rod is higher than 30 thousand turns / minute. The equipment can be used for preparing powder of which the particle size is below 1mm, and the yield of the fine powder with particle size below 50mu m is very high.

Owner:姚振梅

File folder with Y-fork handle

The invention relates to the technical field of file folders, in particular to a file folder with a Y-fork handle. The upper end of the handle is an operating end; the lower end of the handle is provided with two supporting legs which are used for butting against a hook bracket and a bottom plate; the two supporting legs are respectively clamped at the outer side of a middle ear; the two supporting legs of the handle are hinged on the middle ear of the bottom plate by a same hinge hole; as the operating end of the handle is arranged at the upper end, the handle is limited to move in the rangeof a sector above the hinge hole; the finger of a user does not press the bottom plate and components above the bottom plate so as to be safer and more reliable when opening and closing the folder and be more convenient for operation; besides, in the processing of opening and closing the folding, the handle and the two sides of the middle ear are stressed equally; the handle and the middle ear donot incline; the file folder can still obtain enough locking and clamping force under the condition that the material used for the bottom plate is thinner; and the file folder is not easy to damage, thus the purposes for saving materials and reducing production cost and prolonging the service life of the file folder are achieved.

Owner:林春海

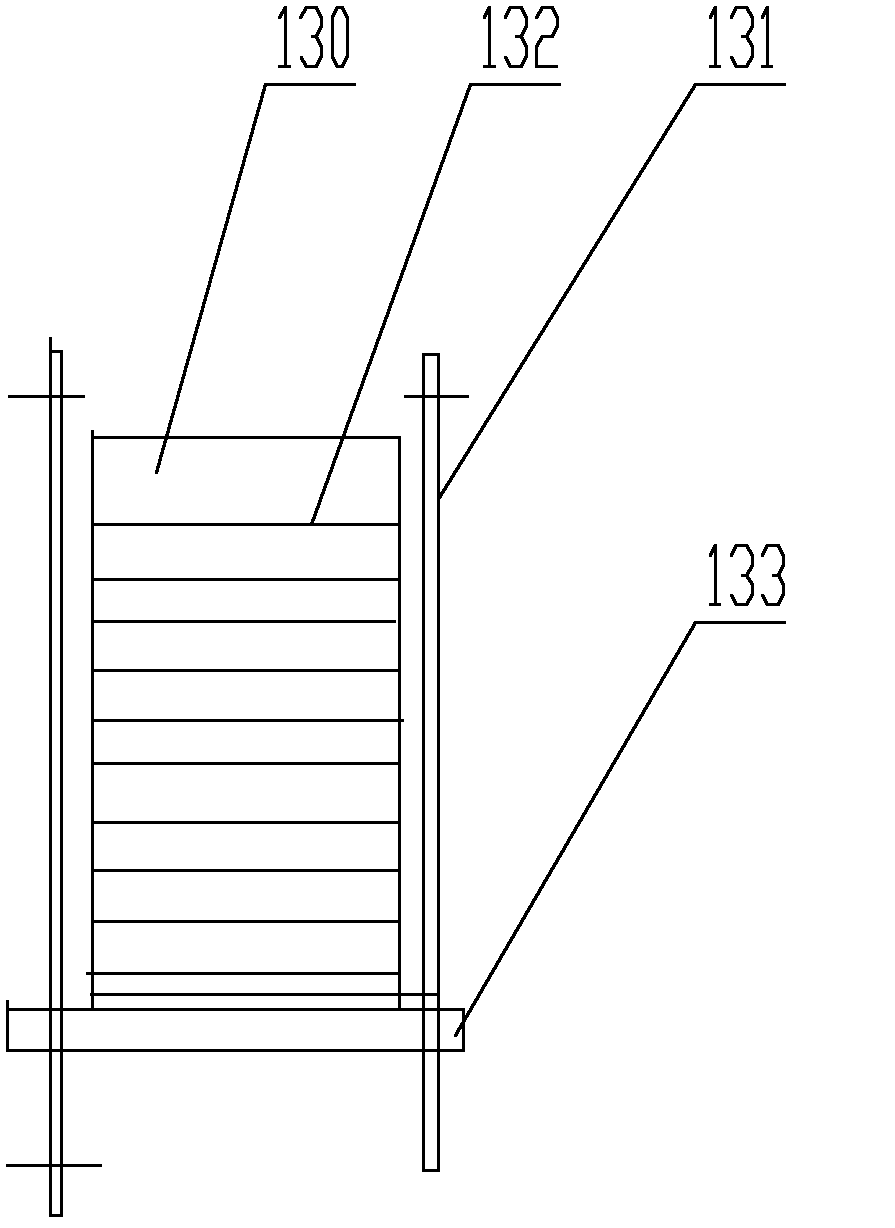

A fast positioning and grinding device for energy-saving building stairs

ActiveCN111546169BEasy to fixNo skewingEdge grinding machinesGrinding carriagesSS - Stainless steelSteel tube

The invention discloses an energy-saving fast positioning and grinding device for building stairs, which relates to the technical field of grinding and fixing devices, and solves the problem that the stainless steel tube is easily squeezed when the steel tube of the existing stair railing is fixed by using a bench vise when it is polished, and the stainless steel tube is not fixed after being fixed. Ability to rotate the question to sand different parts. An energy-saving building stair fast positioning and polishing device includes a strut mechanism; the strut mechanism is composed of a support rod, a power rod and an adjustment block. The device fixes the stainless steel tube by extending the strut mechanism into the inside of the stainless steel tube to expand the stainless steel tube, avoiding the phenomenon that the traditional bench vise clamps the stainless steel tube from the outside, causing the stainless steel tube to be squeezed and affecting the use. , during the grinding process, the fixed stainless steel tube can be rotated by pressing the rotating rod, which is convenient for the quick positioning and grinding of the stainless steel tube, so that the finished product rate of the stainless steel tube is higher after grinding.

Owner:嘉兴鼎尚信息科技有限公司

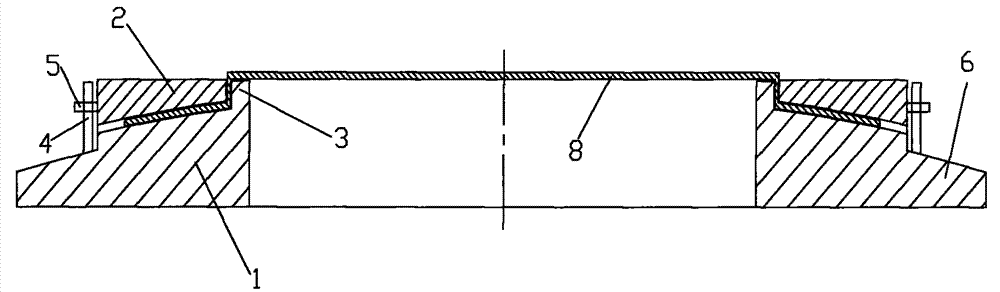

Semitrailer carriage and vehicle head joint bottom supporting structure and using method thereof

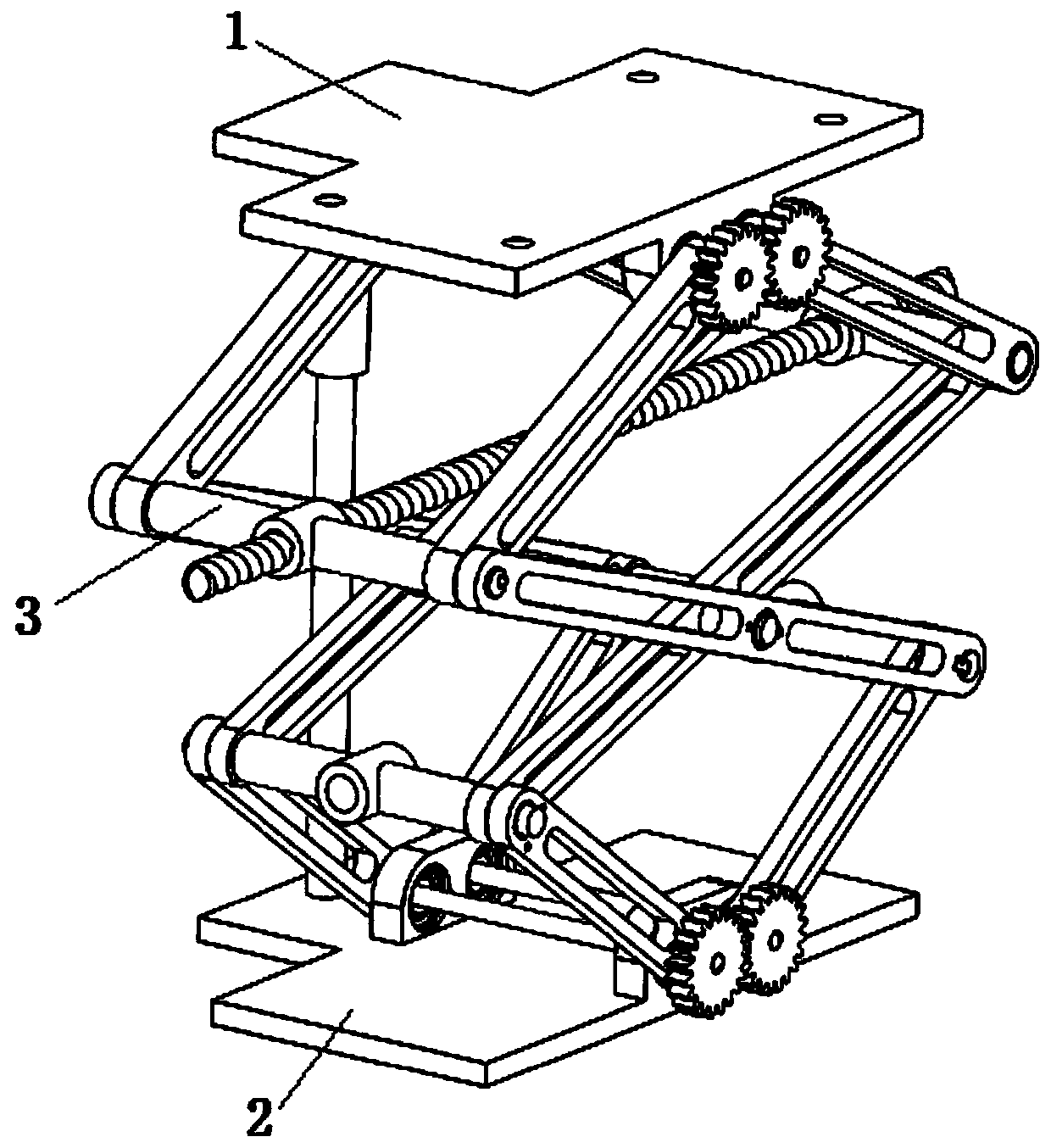

ActiveCN110979268AImprove stabilityPrevent fallingVehicle fittings for liftingTractor-trailer combinationsGear wheelEngineering

The invention discloses a semitrailer carriage and vehicle head joint bottom supporting structure. The supporting structure comprises a connecting plate, a support and a lifting mechanism, and the lifting mechanism is installed between the connecting plate and a supporting plate; two first vertical plates which are oppositely arranged are fixed to the upper surface of the connecting plate, and twosecond circular through holes are formed in the surface of each first vertical plate; a first shaft rod, a first connecting rod, a third connecting rod, a fourth connecting rod and a fifth shaft rodof the lifting mechanism form a rhombus structure; and a connecting cylinder is fixed to the second shaft rod in a penetrating mode, thread is formed in the inner wall of the connecting cylinder, anda threaded shaft is installed in the connecting cylinder. The fit design of the connecting rod and the threaded shaft makes the lifting movement of the supporting plate achieved by rotating a handle connected to the threaded shaft, so a speed-changing gear box is not used, the whole structure is compact, occupies no space, and can achieve the stable supporting effect; and the structure is compact,is easy to operate, and is suitable for supporting the bottom of the joint of the semitrailer carriage and the semitrailer head.

Owner:ANHUI LONGJIA TRAFFIC EQUIP

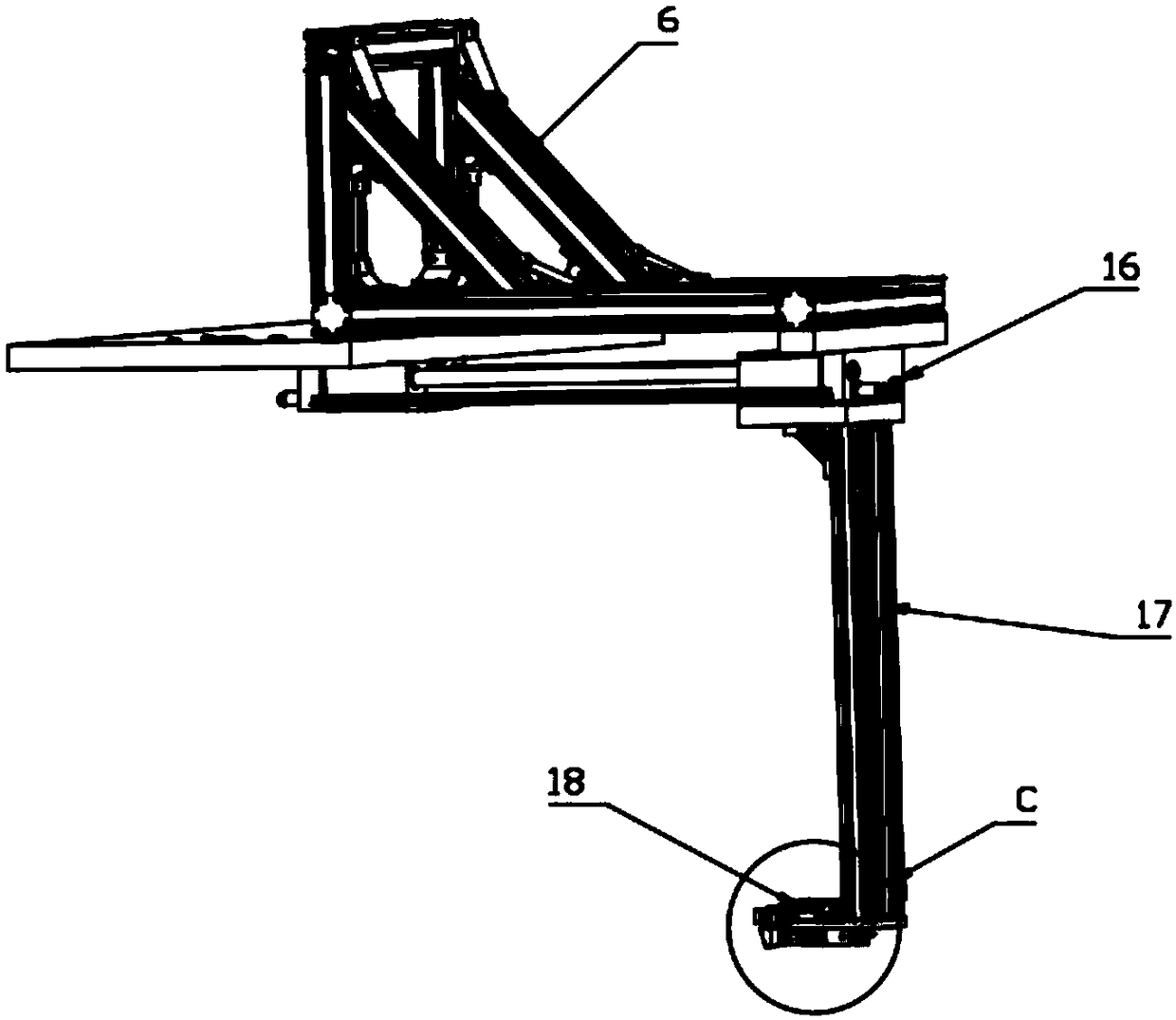

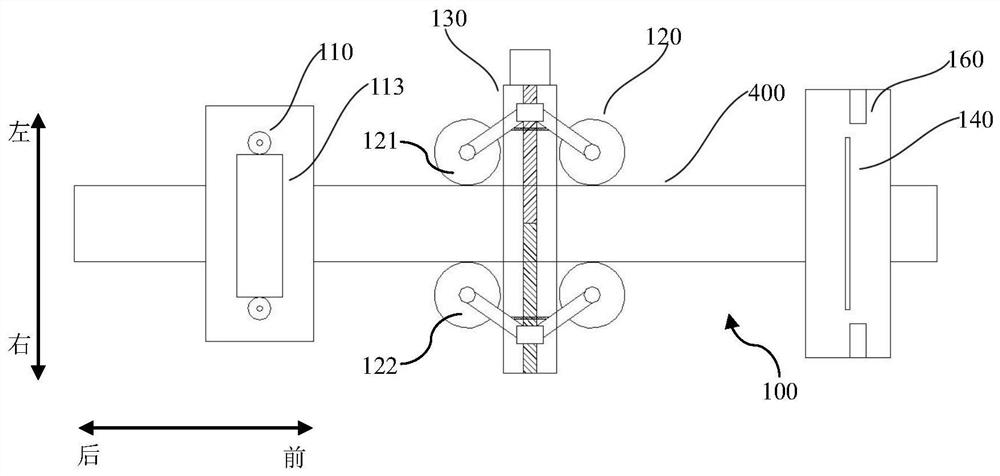

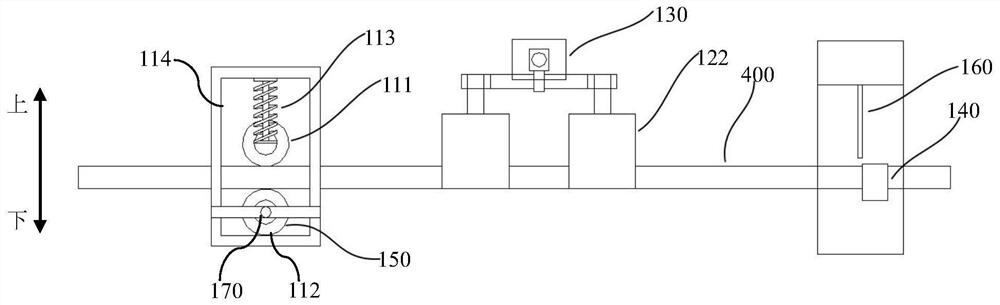

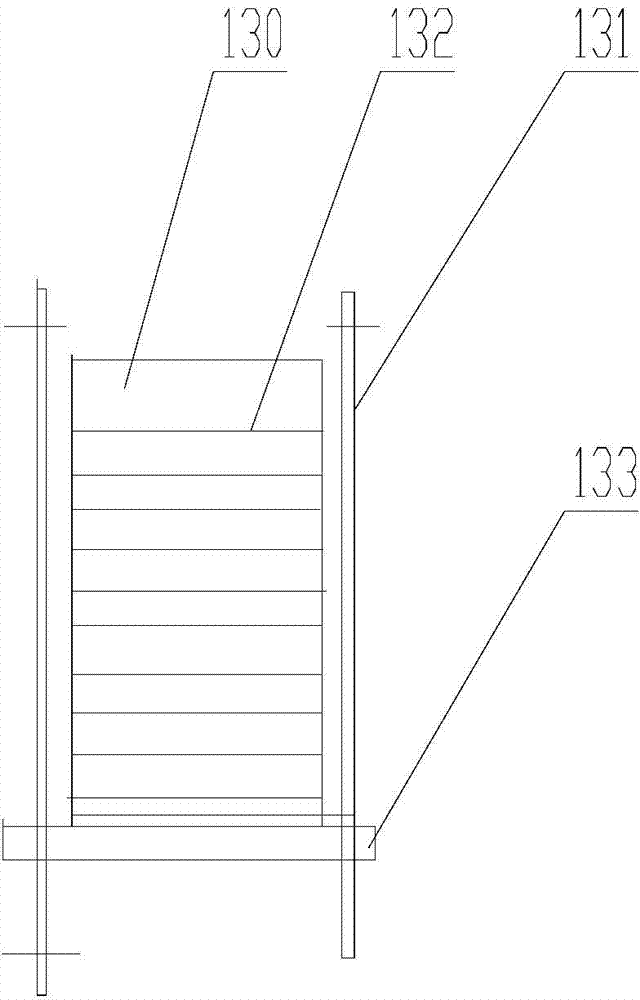

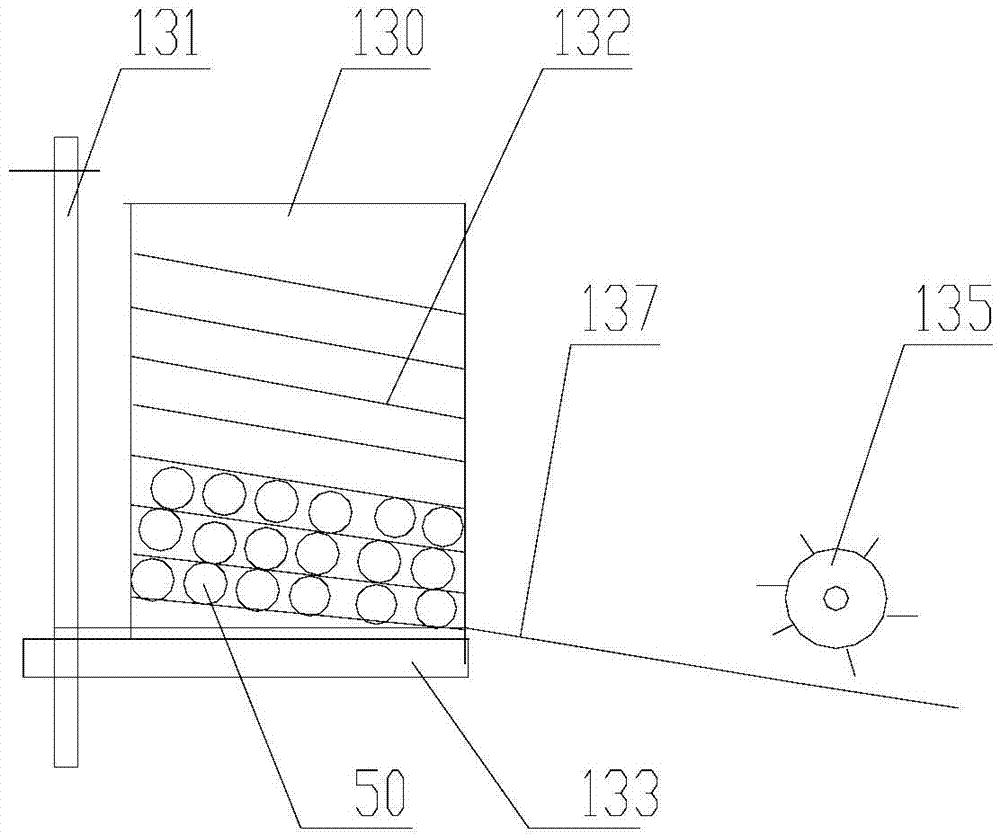

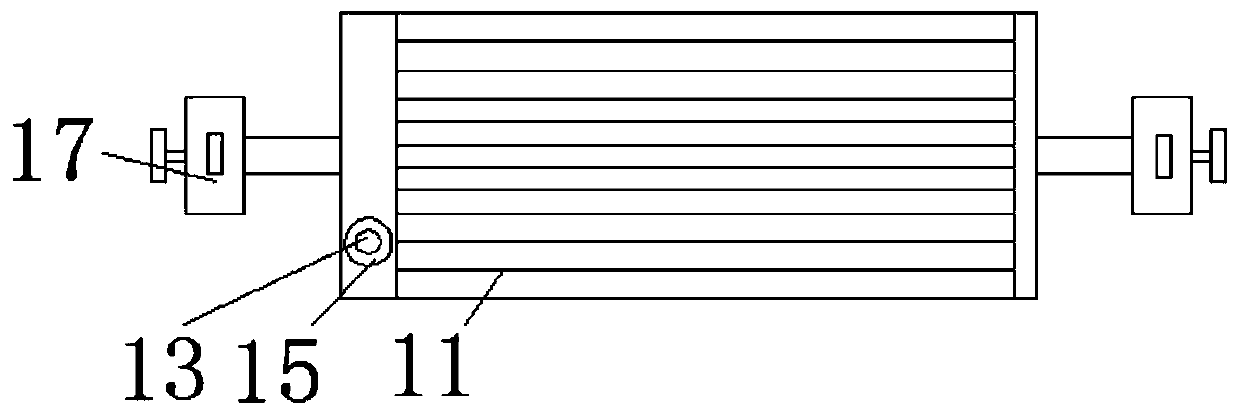

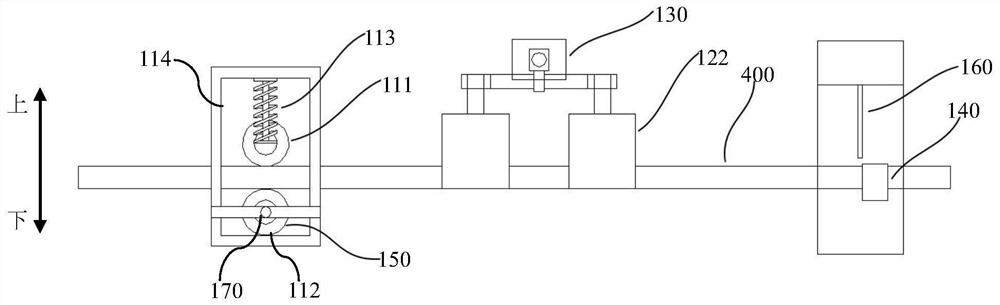

Copper bar processing system and processing method

ActiveCN113579742BUnhindered movementNo skewingOther manufacturing equipments/toolsPunchingStructural engineering

The invention discloses a copper bar processing system and a processing method. The present invention includes a shearing system, a punching system and a bending system; the shearing system includes a first clamping mechanism for clamping copper bars up and down, a second clamping mechanism for clamping copper bars left and right mechanism, the first control mechanism for controlling the clamping state of the second clamping mechanism, the first identification mechanism for identifying the origin position of the copper bar, the first driving mechanism for driving the copper bar to move, and the first driving mechanism for copper bar shearing A shearing mechanism and a second identification mechanism for detecting the rotation angle of the second clamping mechanism; the punching system includes a positioning device for copper bar alignment and punching equipment for copper bar punching; The bending system includes a bending mold and bending equipment for bending copper bars. The invention can realize precise cutting, punching and bending of copper bars.

Owner:南京恒标斯瑞冷冻机械制造有限公司

Equipment and technology for preparing metal powder

InactiveCN102528064BSolve the problem of low yieldSolve the problem of low powder yieldMetal powderMechanical engineering

The invention provides equipment and technology for preparing metal powder, which are used for atomizing a raw material rod into metal powder. The equipment for preparing metal powder comprises a driving mechanism for driving the raw material rod to rotate, wherein the driving mechanism comprises a motor of the driving mechanism, a driving roll of the driving mechanism and a driven roll of the driving mechanism; the driving roll of the driving mechanism is connected to the motor of the driving mechanism; the driven roll of the driving mechanism is used for pressing the raw material rod; a clamping space for clamping the raw material rod is arranged between the driving roll of the driving mechanism and the driven roll of the driving mechanism; the driving roll of the driving mechanism and the driven roll of the driving mechanism clamp the raw material rod to rotate; and the diameter of the driving roll of the driving mechanism is more than 2 times that of the raw material rod. According to the technology, the driving roll of the driving mechanism and the driven roll of the driving mechanism clamp the raw material rods to rotate so that the rotating speed of the raw material rod is higher than 30 thousand turns / minute. The equipment can be used for preparing powder of which the particle size is below 1mm, and the yield of the fine powder with particle size below 50mu m is very high.

Owner:姚振梅

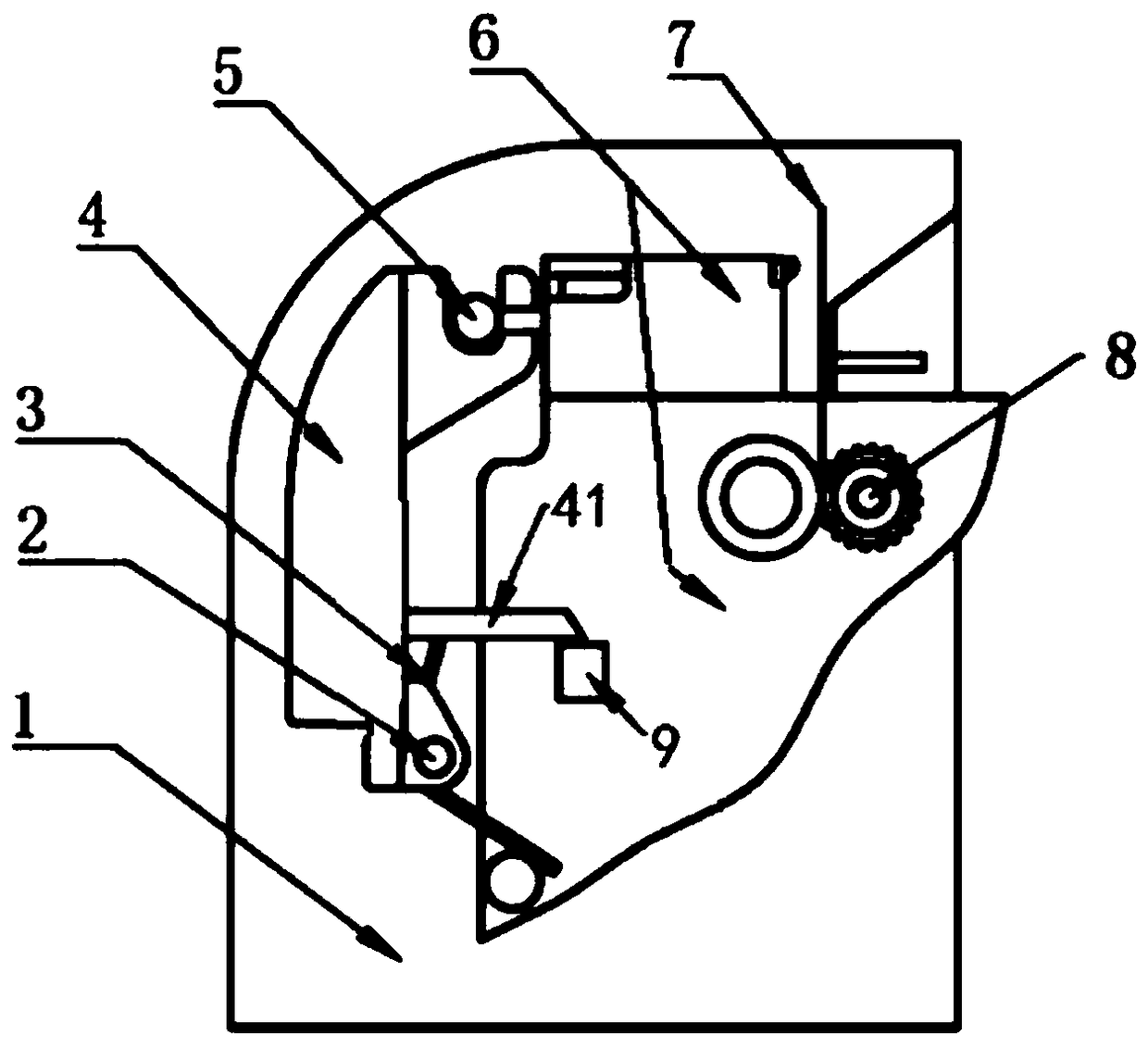

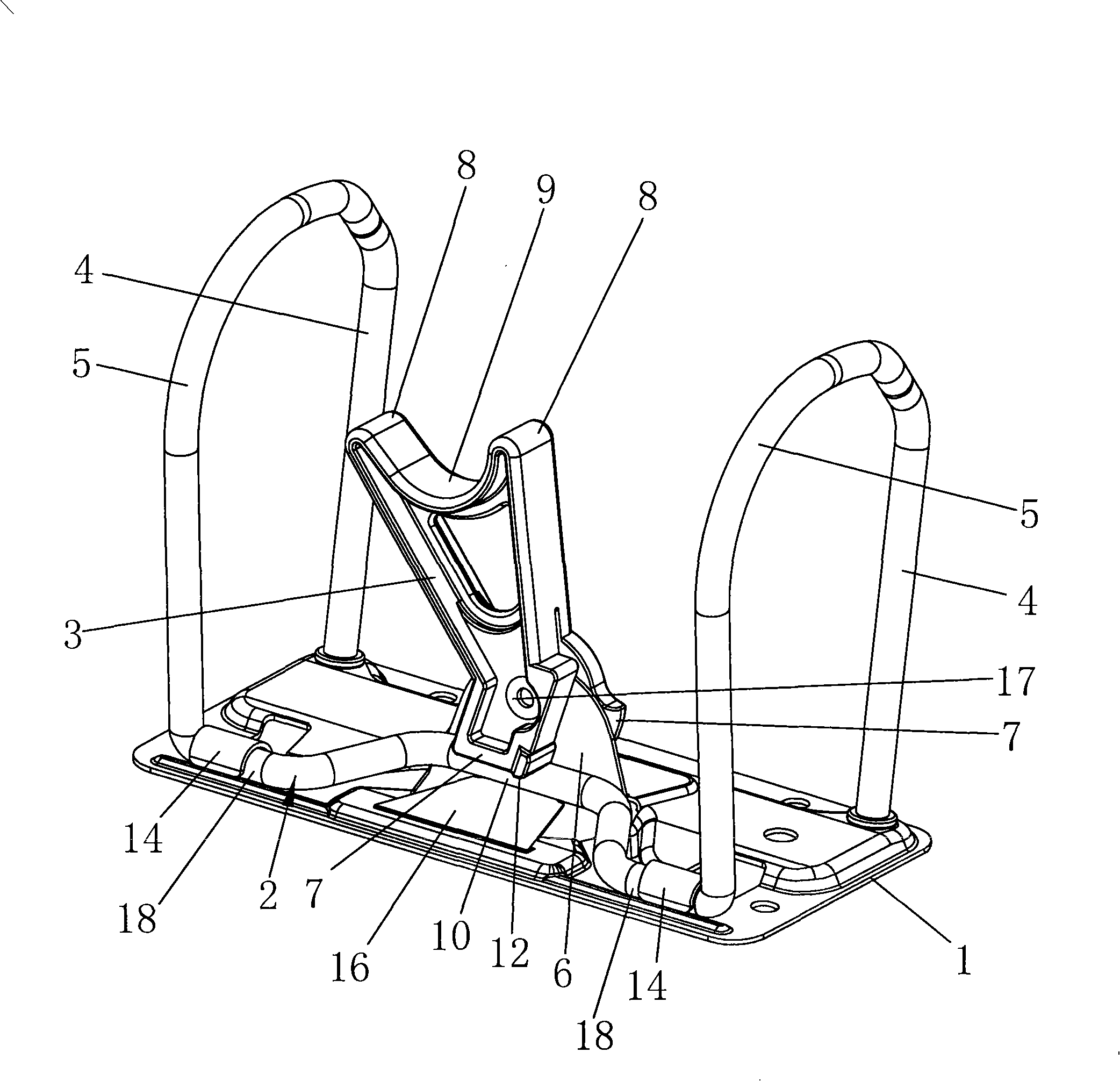

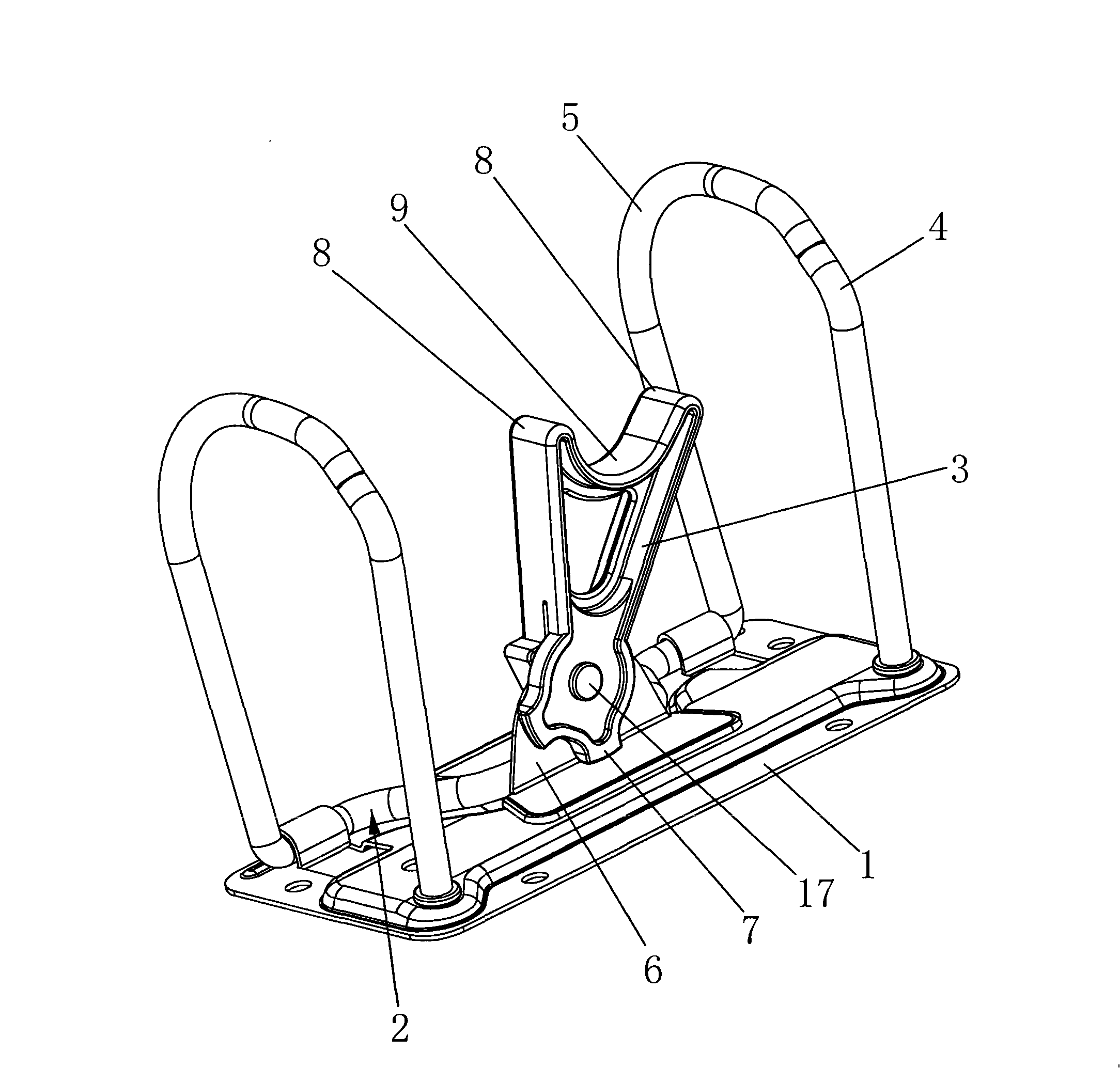

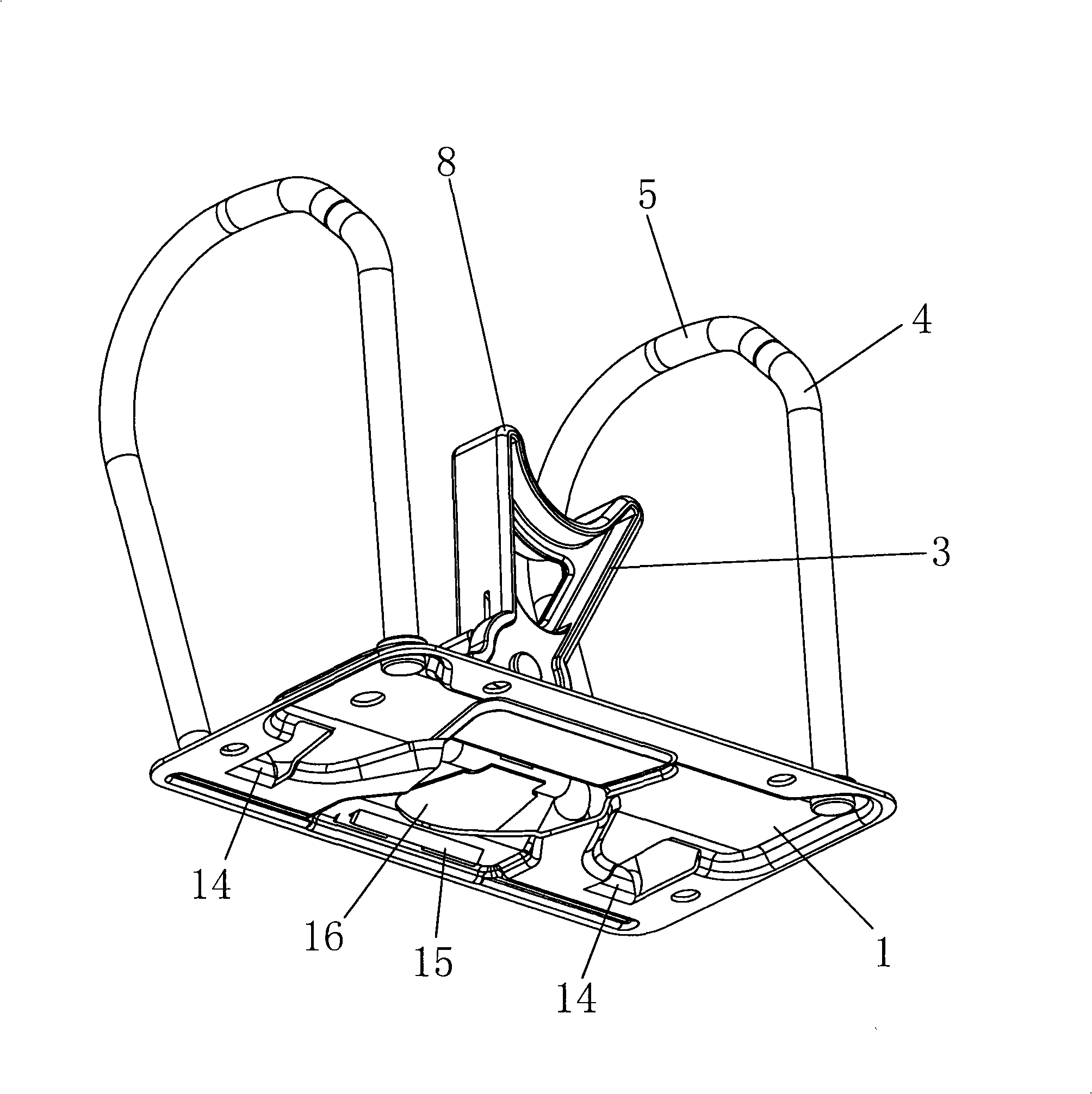

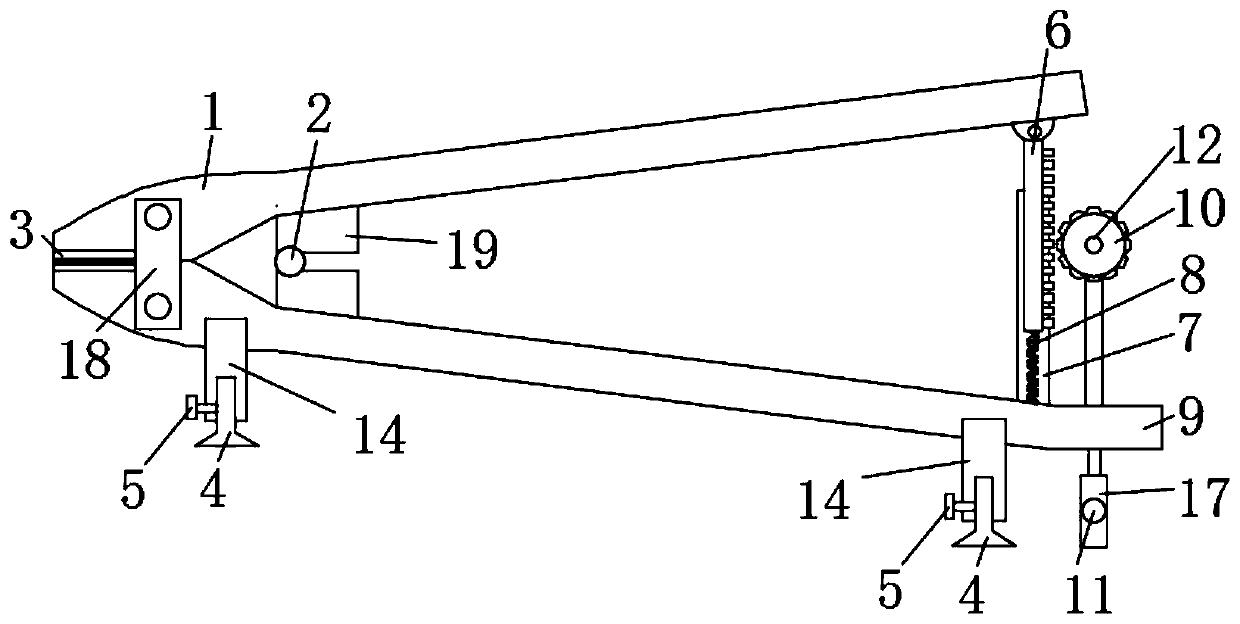

Pedal type steel bar plier

The invention provides a pedal type steel bar plier, and belongs to the technical field of steel bar construction. The pedal type steel bar plier comprises an upper shear block (1), a first rotating shaft (2), a support leg (4), a tightening bolt (5), a transmission strip (6), a lower shear block (9), a gear (10), a pedal (11), a rotating shaft (12), a vertical rod (13), a fixing block (14), a second rotating shaft (15), a fixing rod (16), a fixing support (17), a connecting block (18) and a limiting block (19). The pedal type steel bar plier has the advantages that the efficiency is higher than that of a manual handheld plier, and the operation is more convenient and fast; and construction personnel cut off steel bars with less effort, and the working efficiency is greatly improved.

Owner:BEIJING SHOUGANG CONSTR GROUP

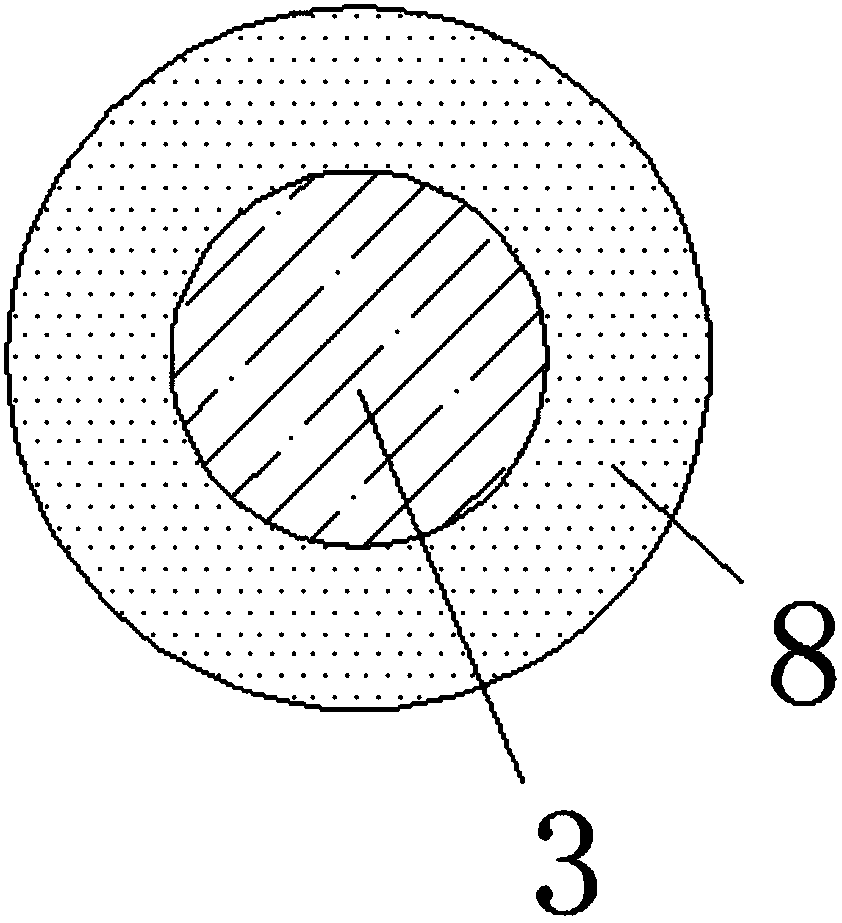

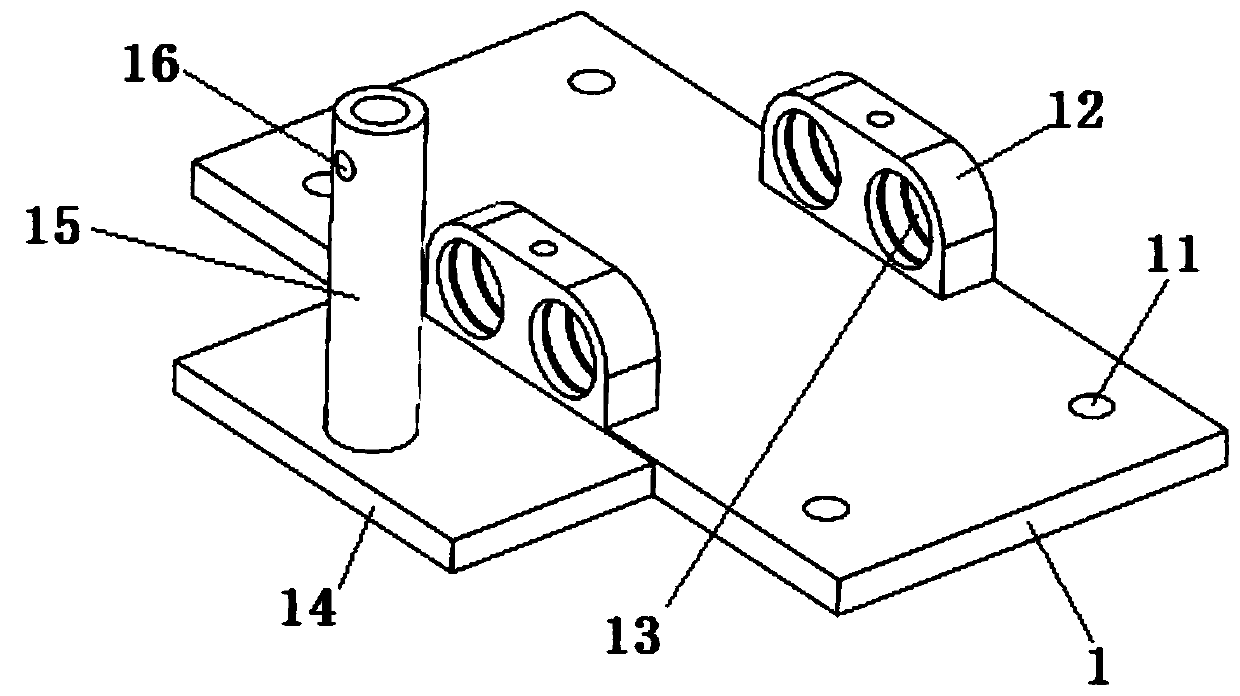

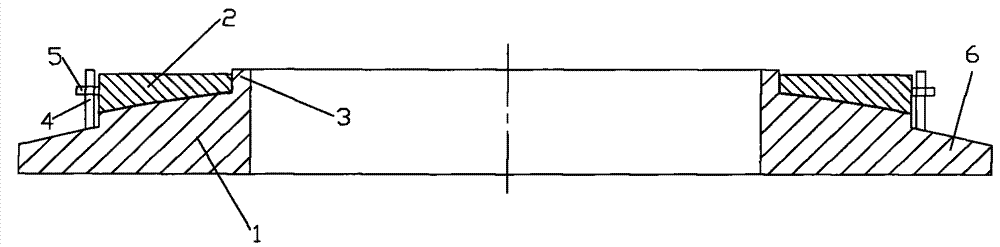

Wafer tensioning device for semiconductor packaging

InactiveCN103617959AEasy to operateSimple structureSemiconductor/solid-state device manufacturingSemiconductor packageEngineering

The invention relates to a wafer tensioning device for semiconductor packaging. The wafer tensioning device for semiconductor packaging comprises a wafer tensioning base and a downward-pressing cover plate, wherein a first cavity is formed inside the wafer tensioning base, a wafer tensioning bearing protruding ring is arranged on the wafer tensioning base, a second cavity is formed inside the wafer tensioning bearing protruding ring, the diameter of the second cavity is equal to that of the first cavity, the outer diameter of the wafer tensioning bearing protruding ring is smaller than that of the wafer tensioning base, the downward-pressing cover plate is connected with the wafer tensioning base through a hinge, and is used in cooperation with the wafer tensioning base, a third cavity is formed inside the downward-pressing cover plate, the diameter of the third cavity is larger than the outer diameter of the wafer tensioning bearing protruding ring, and the downward-pressing cover plate is arranged on the wafer tensioning bearing protruding ring in a sleeved mode through the third cavity. The wafer tensioning device for semiconductor packaging has the advantages of being simple in structure, safe, reliable, high in working efficiency and wide in range of wafer tensioning.

Owner:NANTONG HUALONG MICROELECTRONICS

A bottom support structure at the junction between a semi-trailer compartment and a vehicle front and its application method

ActiveCN110979268BImprove stabilityPrevent fallingVehicle fittings for liftingTractor-trailer combinationsGear wheelEngineering

The invention discloses a semitrailer carriage and vehicle head joint bottom supporting structure. The supporting structure comprises a connecting plate, a support and a lifting mechanism, and the lifting mechanism is installed between the connecting plate and a supporting plate; two first vertical plates which are oppositely arranged are fixed to the upper surface of the connecting plate, and twosecond circular through holes are formed in the surface of each first vertical plate; a first shaft rod, a first connecting rod, a third connecting rod, a fourth connecting rod and a fifth shaft rodof the lifting mechanism form a rhombus structure; and a connecting cylinder is fixed to the second shaft rod in a penetrating mode, thread is formed in the inner wall of the connecting cylinder, anda threaded shaft is installed in the connecting cylinder. The fit design of the connecting rod and the threaded shaft makes the lifting movement of the supporting plate achieved by rotating a handle connected to the threaded shaft, so a speed-changing gear box is not used, the whole structure is compact, occupies no space, and can achieve the stable supporting effect; and the structure is compact,is easy to operate, and is suitable for supporting the bottom of the joint of the semitrailer carriage and the semitrailer head.

Owner:ANHUI LONGJIA TRAFFIC EQUIP

Wire arranging mechanism for communication device and wire arranging method thereof

The invention discloses a wire arranging mechanism for a communication device and a wire arranging method thereof, and relates to the technical field of wire arranging mechanisms for communication devices. The wire arranging mechanism comprises two symmetrically arranged mounting blocks, rotating rods are fixedly mounted on the side walls of the two mounting blocks, and second gears are fixedly connected to the two rotating rods in a sleeving manner. The invention further discloses a wire arranging method of the wire arranging mechanism for the communication device. According to the wire arranging mechanism for the communication device and the wire arranging method thereof, by arranging a wire arranging size adjusting part, the distance between a plurality of extrusion rollers can be adjusted, then wires are fixed, the wire arranging mechanism can arrange the wires of different thicknesses, wire arranging mechanisms of different sizes do not need to be prepared, the application range of the wire arranging mechanism is wider, the multiple extrusion rollers can roll on the surfaces of the wires by moving the wire arranging mechanism, the wires are stably arranged, and the wire arranging mechanism is more practical.

Owner:陈正刚

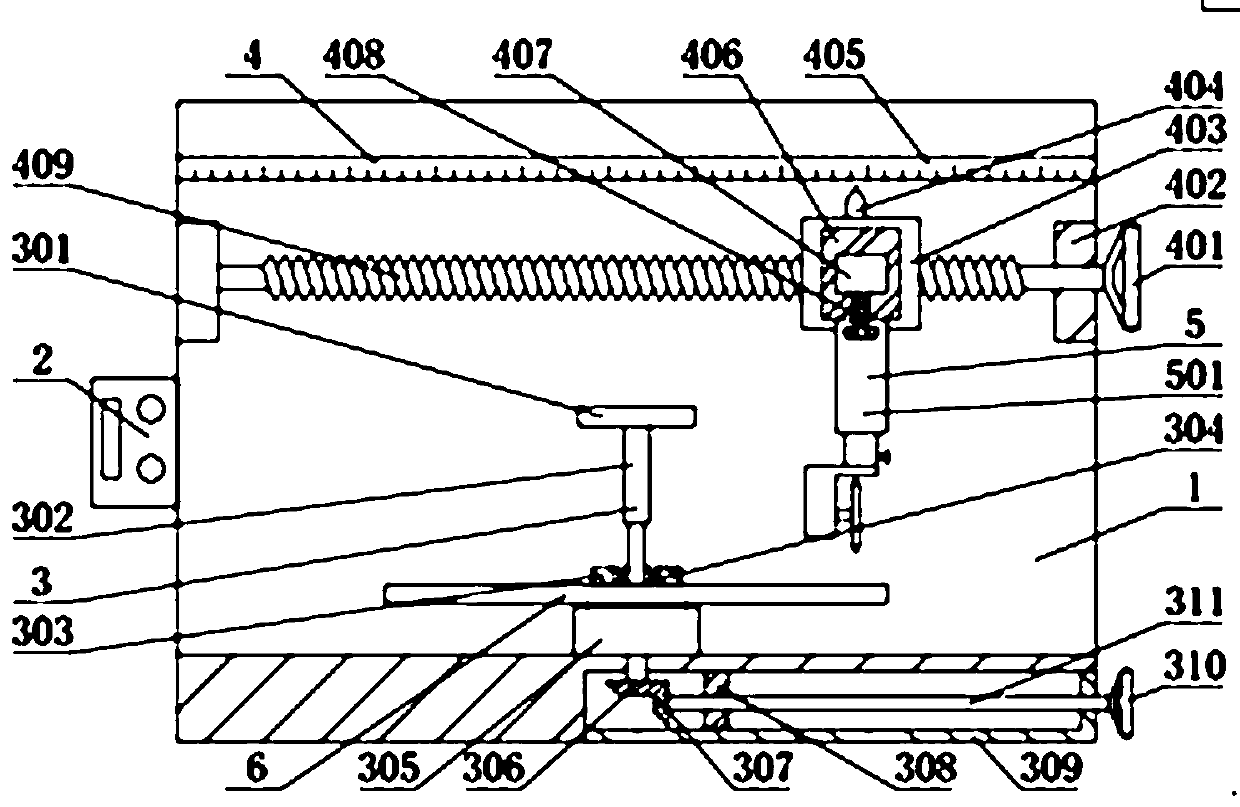

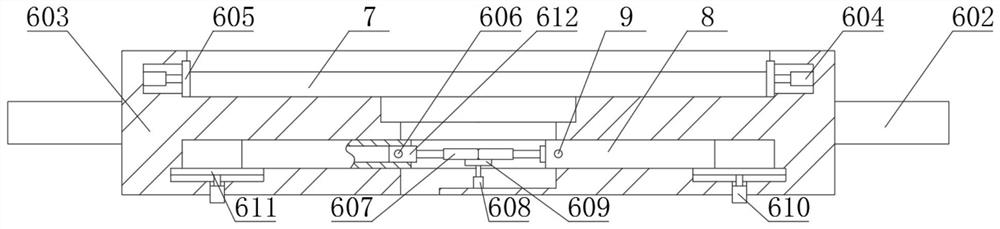

A kind of drilling device for antenna vibrator processing

ActiveCN112139543BEasy to drillEasy to operateAutomatic control devicesFeeding apparatusEngineeringAntenna element

The invention relates to the technical field of antenna vibrator processing, in particular to a drilling device for antenna vibrator processing, including a base and a fixing frame, the top of the base is fixedly connected with a fixing frame, and the right end of the fixing frame is fixedly connected with a controller. The inner side of the top end of the fixed frame is fixedly connected with a position adjustment device, the bottom end of the position adjustment device is fixedly connected with a drilling device, and the top end of the base is fixedly connected with a clamping device. , clamping rod, and connecting block, the clamping and fixing of the circular antenna vibrator can be realized through the first clamping plate, so as to ensure that the circular antenna vibrator will not shake when drilling, and ensure that there will be no vibration during the drilling process. In case of skewing, the loop antenna vibrator can be clamped and fixed by the second clamping plate, and at the same time, the ring antenna vibrator can be supported by the support column to prevent the inner wall of the loop antenna vibrator from being sunken during the drilling process.

Owner:SHENZHEN FRD SCI & TECH

Grounding device for TN-C-S power supply system

InactiveCN109524804AStable structurePrevent disengagementClamped/spring connectionsMulticonductor cable end piecesPrismEngineering

The invention relates to a grounding device for a TN-C-S power supply system. The grounding device comprises a main body in a hollow quadrangular prism shape, wherein four groups of fixing rings are fixed to the upper end of the main body; a tapered fixing block is fixed to the lower end of the main body; a square connecting wire fixing block is welded on the right side of each fixing ring; a lifting rod is inserted into the top of each fixing ring; a fixing nut is nested outside the lifting rod; L-shaped fixing rings are engaged with the four corners of the main body; strip-shaped sliding slots are formed in the four sides of the main body; a second fixing rod is engaged with the inner sides of the sliding slots; the four groups of fixing rings are connected through the first fixing rod and are annularly nested outside the main body; and a first connecting rod is nested outside the first fixing rod. The grounding device for the TN-C-S power supply system is firm and stable in structure, cannot be inclined when fixed in the soil, is greatly improved in fixing effect, and is provided with an anti-separation structure on the outer side so as to be prevented from being detached from the soil layer under a non-human operation.

Owner:POWER MANAGEMENT CORP OF SHENGLI PETROLEUM ADMINISTATION BUREAU OF CHINA PETROCHEM CORP

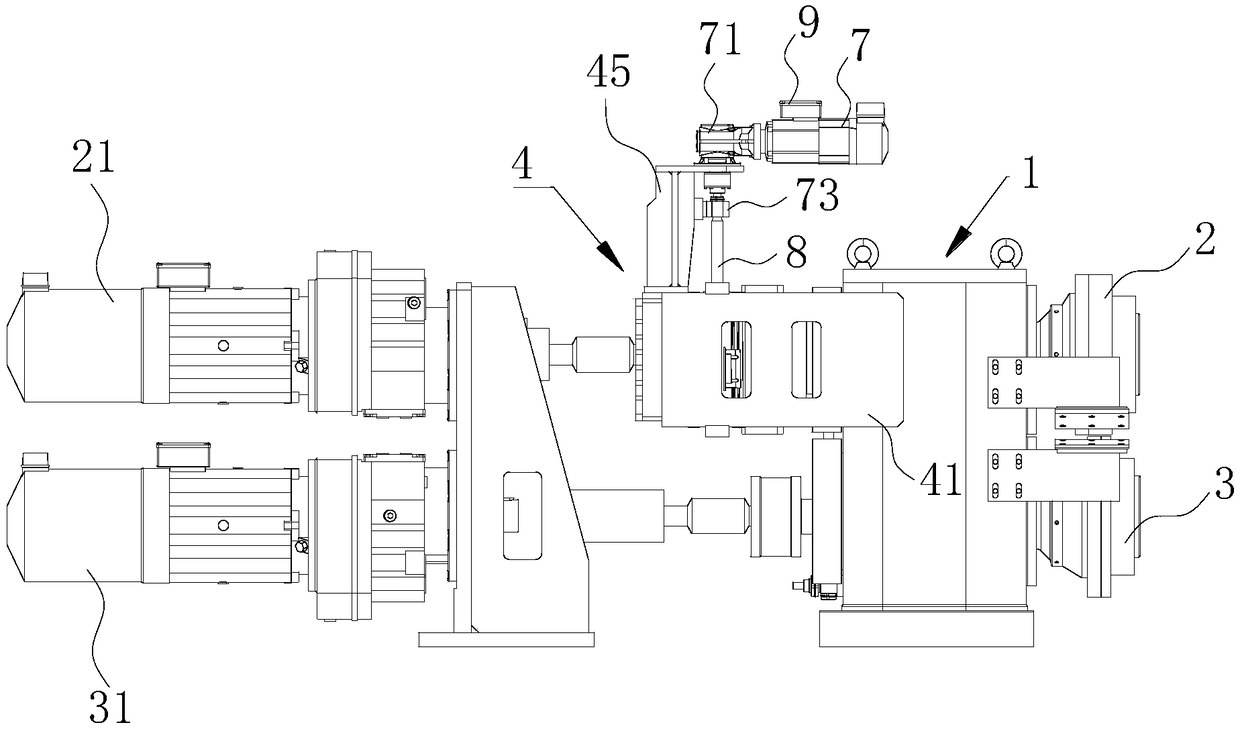

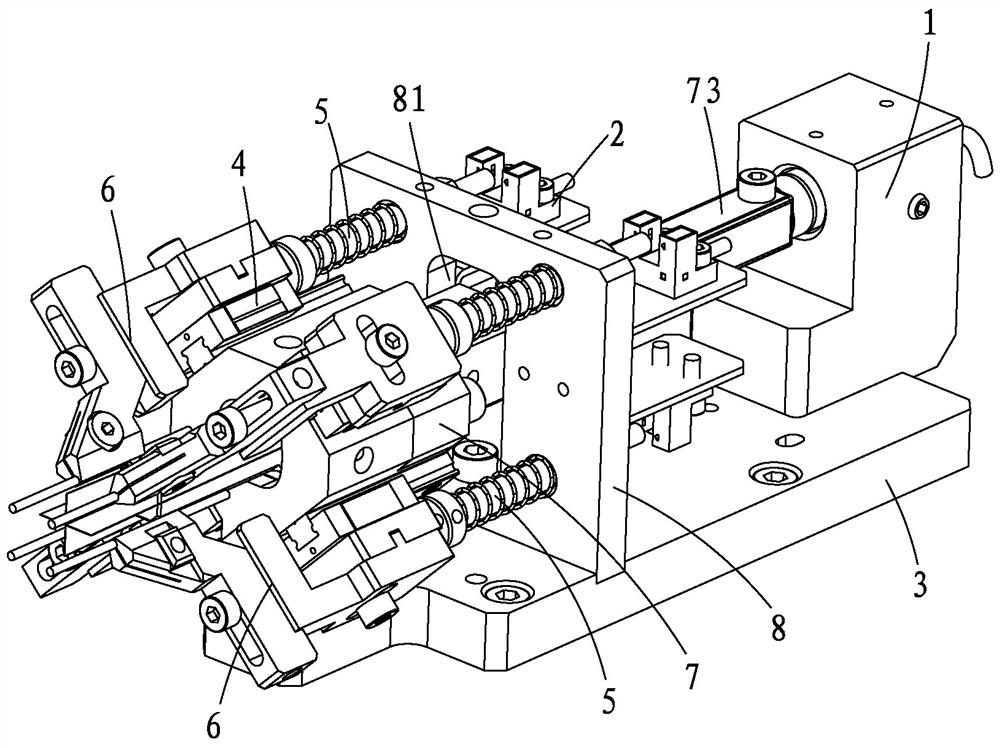

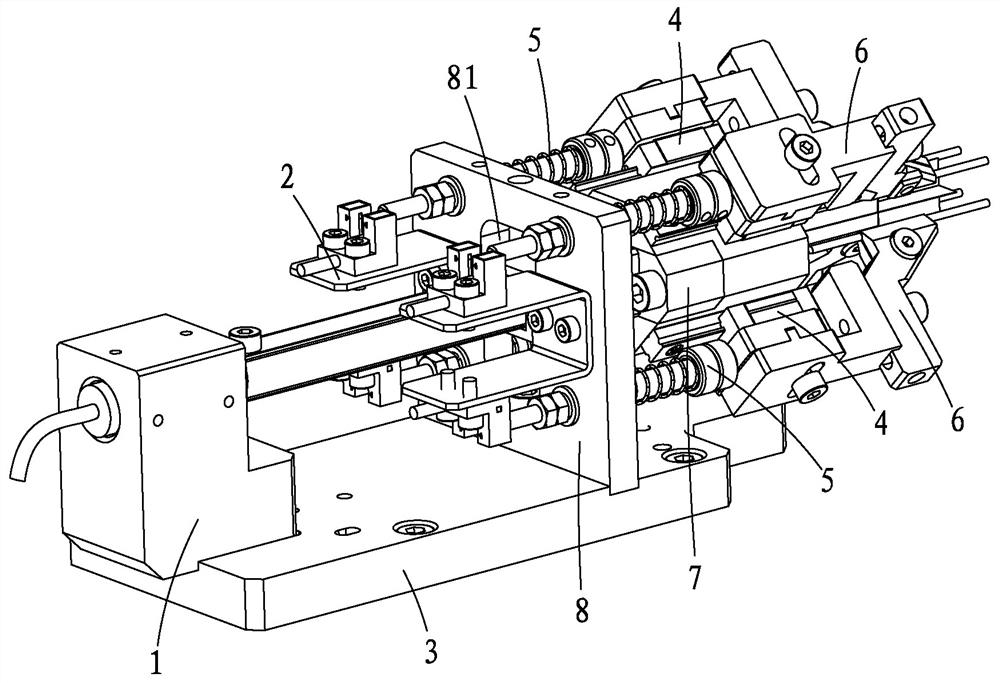

Disk shear

PendingCN108907319AImprove strip shear qualityImprove cut qualityShearing machinesDriving apparatusMotor driveLow transmission

The invention relates to the technical field of metallurgy manufacturing, in particular to a disk shear. The backlash adjusting function is achieved, meanwhile, active rotating of an upper tool shaftassembly can be achieved, and the upper tool shaft assembly and a lower tool shaft assembly each have drive power so as to improve the shear quality of a plate and strip. The disk shear is technicallycharacterized in that the disk shear comprises a disk shear box, the upper tool shaft assembly, the lower tool shaft assembly, a lower transmission motor in transmission connection with the lower tool shaft assembly and an upper transmission motor which is located above the lower transmission motor and is in transmission connection with the upper tool shaft assembly, wherein the upper tool shaftassembly and the lower tool shaft assembly penetrate through the disk shear box; a backlash adjusting device is arranged on the side, close to the upper transmission motor, of the upper tool shaft assembly and mainly comprises a U-shaped nut sleeve mounting plate and a backlash adjusting motor driving the U-shaped nut sleeve mounting plate to move; and wedge blocks, a C-shaped sliding block and alinear guide rail are arranged on the side wall of the U-shaped nut sleeve mounting plate, the C-shaped sliding block and the linear guide rail can relatively slide, and backlash adjustment is achieved through movement of the C-shaped sliding block and cooperation of the wedge blocks.

Owner:XIANGYANG YUQING TRANSMISSION TECH

A four-pin spot welding head device

ActiveCN107150182BQuick clampingMeet the needs of useWelding/soldering/cutting articlesMetal working apparatusEngineeringSpot welding

The present invention provides a four -needle welding header, including laser -to -pairing mechanism, location sensing mechanism, fixed base, welding needle -oriented mechanism, pressure adjustment mechanism, welding needle position adjustment mechanism, and rapid welding needle adjustment mechanism;There is a point welding head plate with an open hole, and the rapid welding needle adjustment mechanism is set on the front end of the point welding head stand, and the fast welding needle adjustment mechanism has a guidance pores;In the back end, the laser -to -level mechanism is located on a fixed base; the welding needle position adjustment mechanism and the welding needle -oriented mechanism can be moved, and the welding needle -oriented mechanism slides on the rapid welding needle adjustment mechanism; the front end of the pressure adjustment mechanism is fixed on the weldingOn the needle -oriented mechanism, the end is extended to the front end of the position sensing mechanism.Advantages of the present invention: The welding header device of the present invention can improve the welding efficiency of the welding joint and ensure the welding quality of the welding joint, and at the same time, it can greatly increase the rate of needle adjustment.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

Copper bar processing system and processing method

ActiveCN113579742AUnhindered movementNo skewingOther manufacturing equipments/toolsPunchingStructural engineering

The invention discloses a copper bar processing system and a copper bar processing method. The copper bar processing system comprises a shearing system, a punching system and a bending system, wherein the shearing system comprises a first clamping mechanism used for clamping a copper bar up and down, a second clamping mechanism used for clamping the copper bar left and right, a first control mechanism used for controlling the clamping state of the second clamping mechanism, a first recognition mechanism used for recognizing the original position of the copper bar, a first driving mechanism used for driving the copper bar to move, a shearing mechanism used for shearing the copper bar, and a second recognition mechanism used for detecting the rotation angle of the second clamping mechanism; the punching system comprises a positioning device used for copper bar centering and punching equipment used for copper bar punching. The bending system comprises a bending die and bending equipment used for bending the copper bar. Precise shearing, punching and bending of the copper bar can be achieved.

Owner:南京恒标斯瑞冷冻机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com